ECU MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 287 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-287

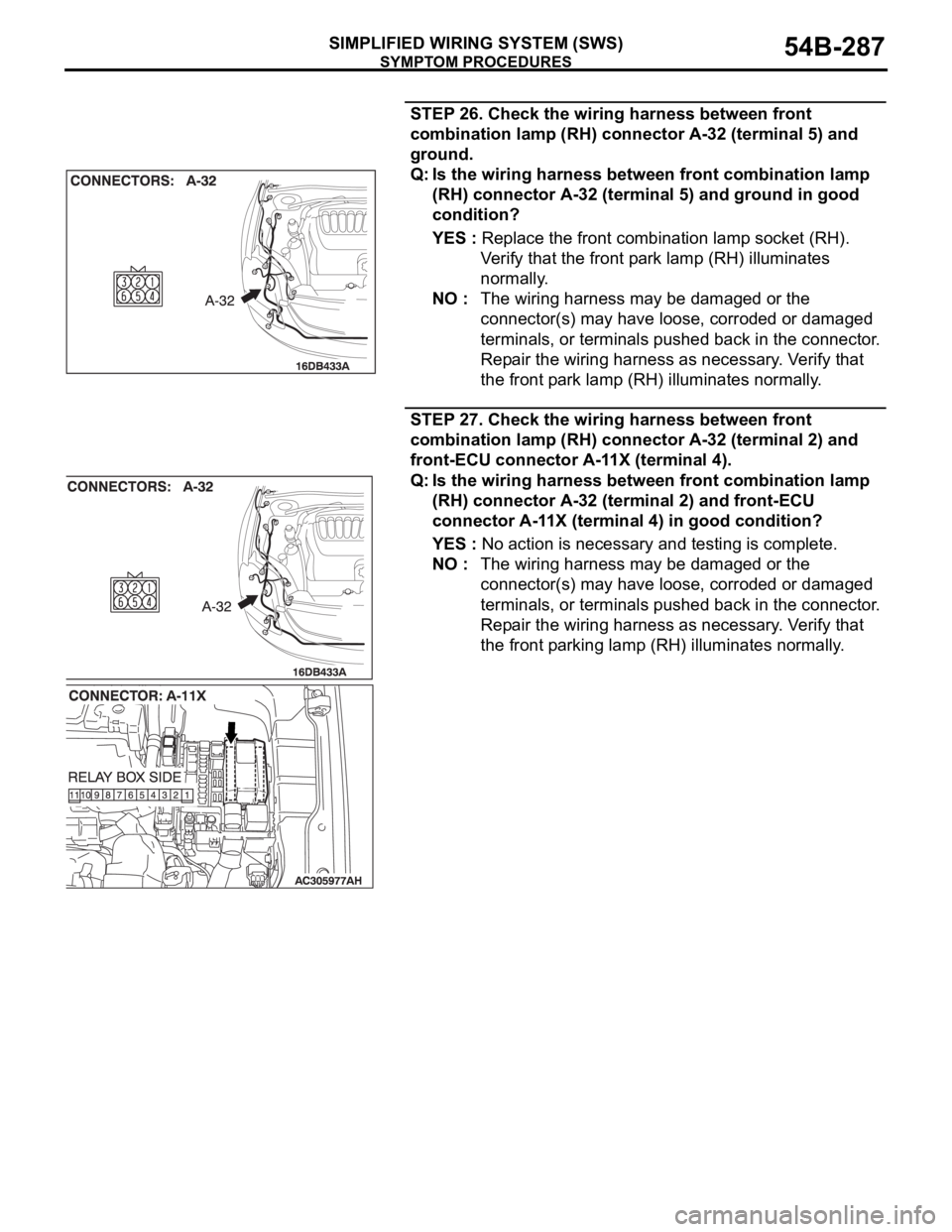

STEP 26. Check the wiring harness between front

combination lamp (RH) connector A-32 (terminal 5) and

ground.

Q: Is the wiring harness between front combination lamp

(RH) connector A-32 (terminal 5) and ground in good

condition?

YES : Replace the front combination lamp socket (RH).

Verify that the front park lamp (RH) illuminates

normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the front park lamp (RH) illuminates normally.

STEP 27. Check the wiring harness between front

combination lamp (RH) connector A-32 (terminal 2) and

front-ECU connector A-11X (terminal 4).

Q: Is the wiring harness between front combination lamp

(RH) connector A-32 (terminal 2) and front-ECU

connector A-11X (terminal 4) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the front parking lamp (RH) illuminates normally.

Page 294 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-294

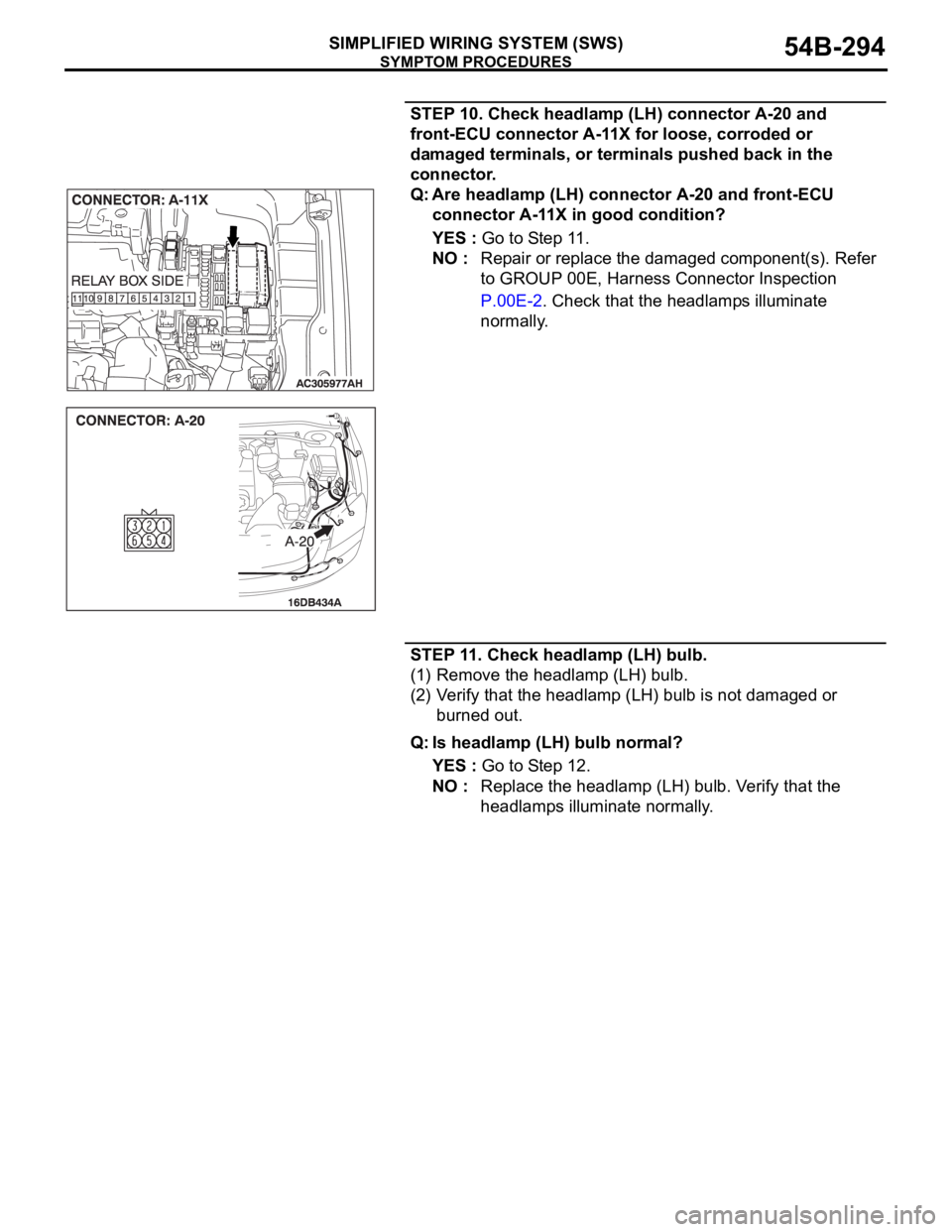

STEP 10. Check headlamp (LH) connector A-20 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (LH) connector A-20 and front-ECU

connector A-11X in good condition?

YES : Go to Step 11.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the headlamps illuminate

normally.

STEP 11. Check headlamp (LH) bulb.

(1) Remove the headlamp (LH) bulb.

(2) Verify that the headlamp (LH) bulb is not damaged or

burned out.

Q: Is headlamp (LH) bulb normal?

YES : Go to Step 12.

NO : Replace the headlamp (LH) bulb. Verify that the

headlamps illuminate normally.

Page 295 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-295

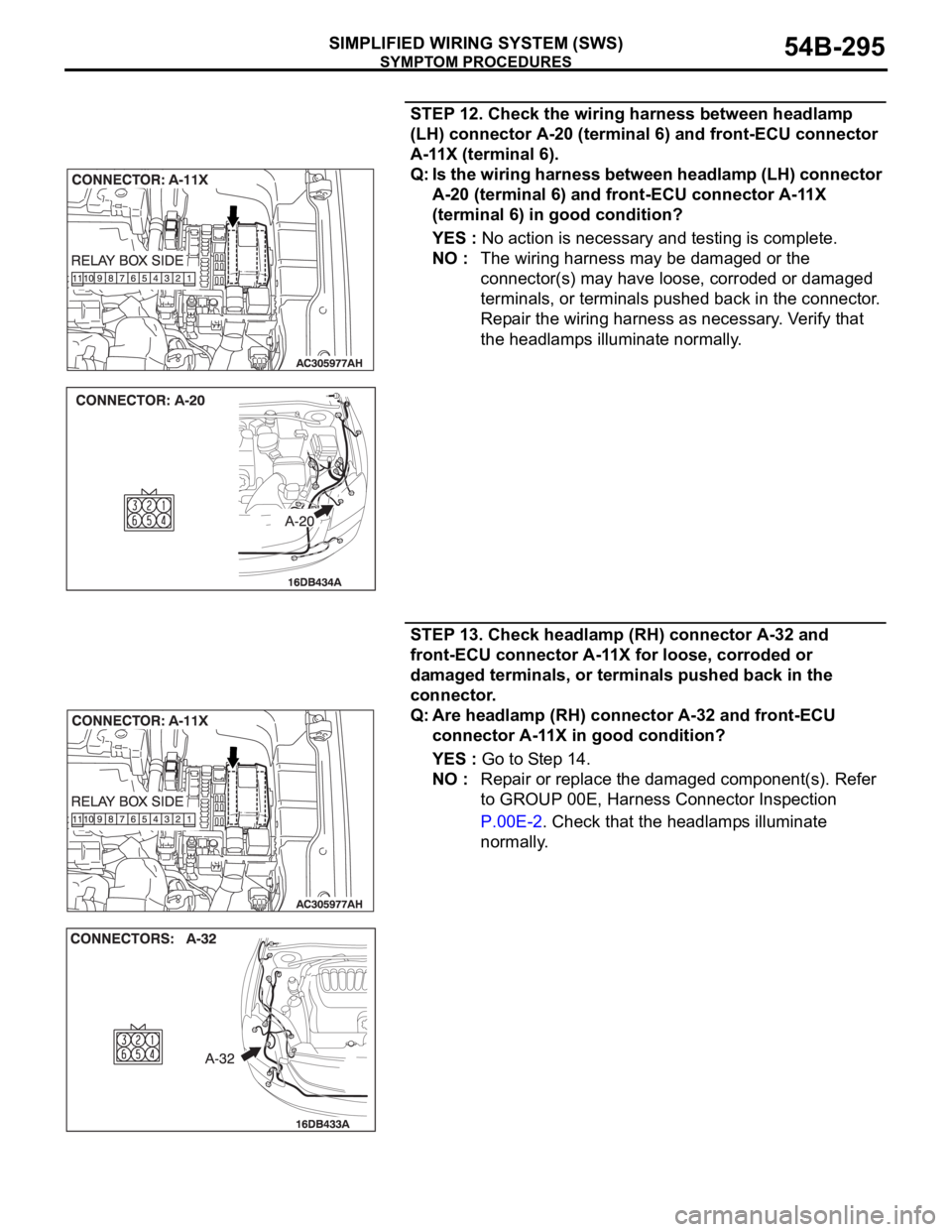

STEP 12. Check the wiring harness between headlamp

(LH) connector A-20 (terminal 6) and front-ECU connector

A-11X (terminal 6).

Q: Is the wiring harness between headlamp (LH) connector

A-20 (terminal 6) and front-ECU connector A-11X

(terminal 6) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

STEP 13. Check headlamp (RH) connector A-32 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (RH) connector A-32 and front-ECU

connector A-11X in good condition?

YES : Go to Step 14.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the headlamps illuminate

normally.

Page 296 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-296

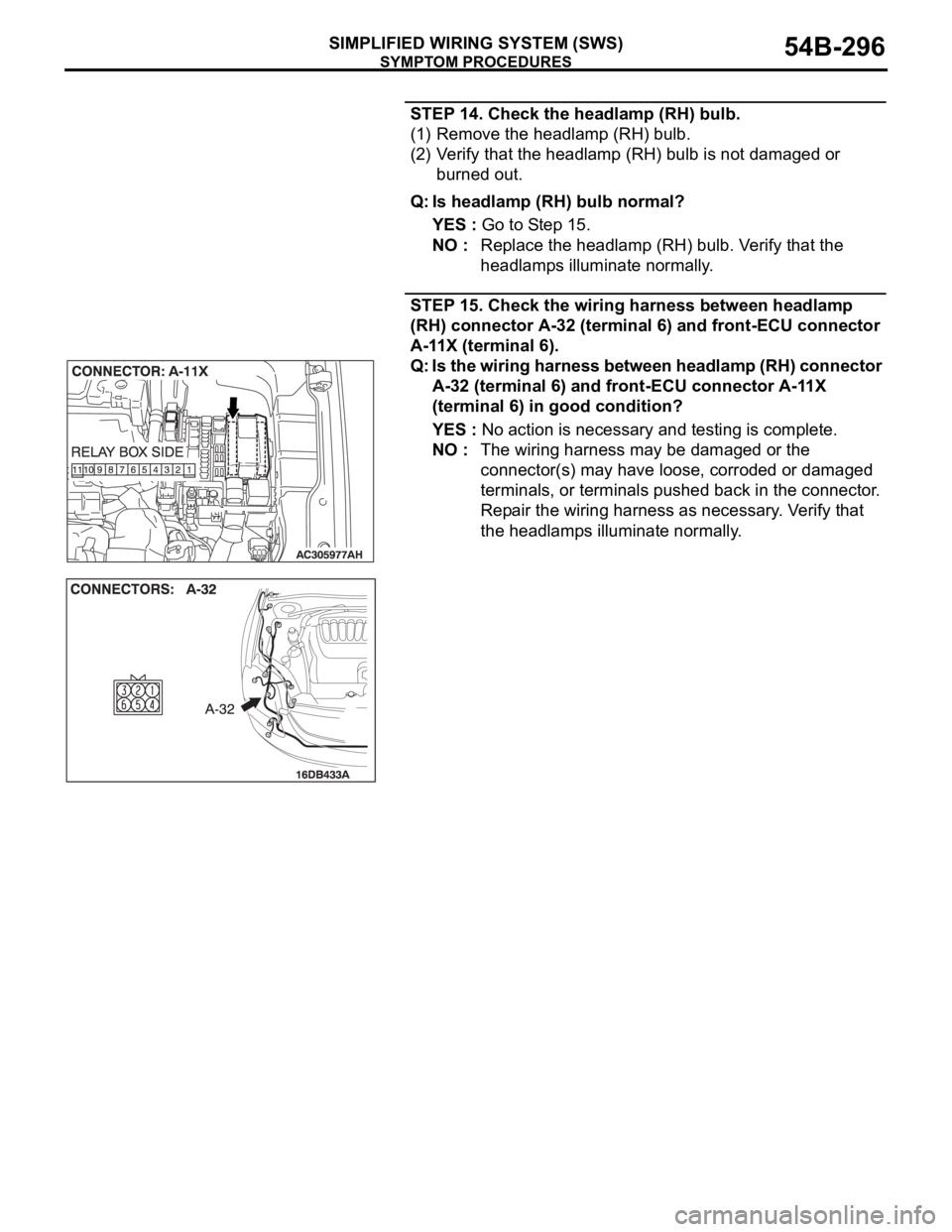

STEP 14. Check the headlamp (RH) bulb.

(1) Remove the headlamp (RH) bulb.

(2) Verify that the headlamp (RH) bulb is not damaged or

burned out.

Q: Is headlamp (RH) bulb normal?

YES : Go to Step 15.

NO : Replace the headlamp (RH) bulb. Verify that the

headlamps illuminate normally.

STEP 15. Check the wiring harness between headlamp

(RH) connector A-32 (terminal 6) and front-ECU connector

A-11X (terminal 6).

Q: Is the wiring harness between headlamp (RH) connector

A-32 (terminal 6) and front-ECU connector A-11X

(terminal 6) in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

Page 297 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-297

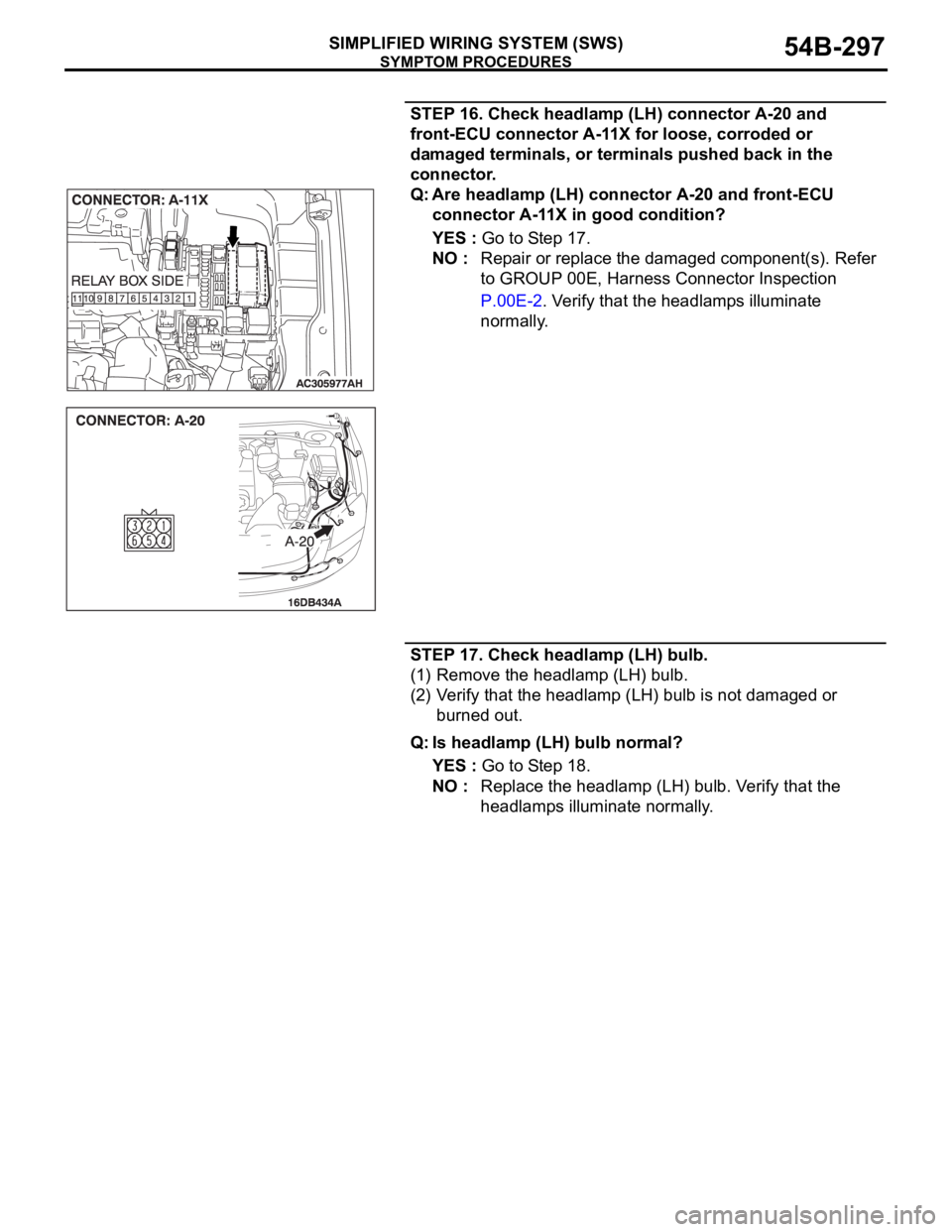

STEP 16. Check headlamp (LH) connector A-20 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (LH) connector A-20 and front-ECU

connector A-11X in good condition?

YES : Go to Step 17.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the headlamps illuminate

normally.

STEP 17. Check headlamp (LH) bulb.

(1) Remove the headlamp (LH) bulb.

(2) Verify that the headlamp (LH) bulb is not damaged or

burned out.

Q: Is headlamp (LH) bulb normal?

YES : Go to Step 18.

NO : Replace the headlamp (LH) bulb. Verify that the

headlamps illuminate normally.

Page 298 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-298

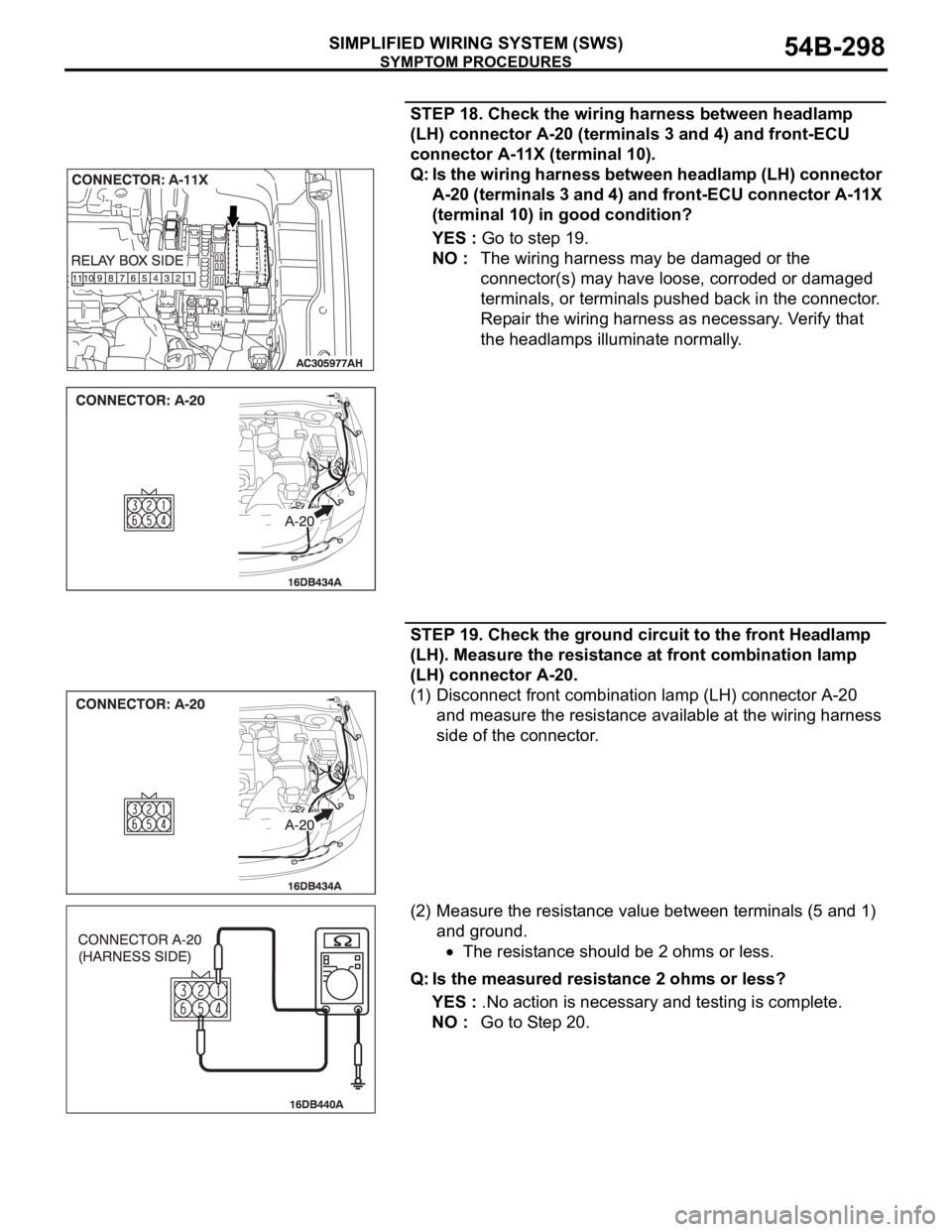

STEP 18. Check the wiring harness between headlamp

(LH) connector A-20 (terminals 3 and 4) and front-ECU

connector A-11X (terminal 10).

Q: Is the wiring harness between headlamp (LH) connector

A-20 (terminals 3 and 4) and front-ECU connector A-11X

(terminal 10) in good condition?

YES : Go to step 19.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

STEP 19. Check the ground circuit to the front Headlamp

(LH). Measure the resistance at front combination lamp

(LH) connector A-20.

(1) Disconnect front combination lamp (LH) connector A-20

and measure the resistance available at the wiring harness

side of the connector.

(2) Measure the resistance value between terminals (5 and 1)

and ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : .No action is necessary and testing is complete.

NO : Go to Step 20.

Page 299 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-299

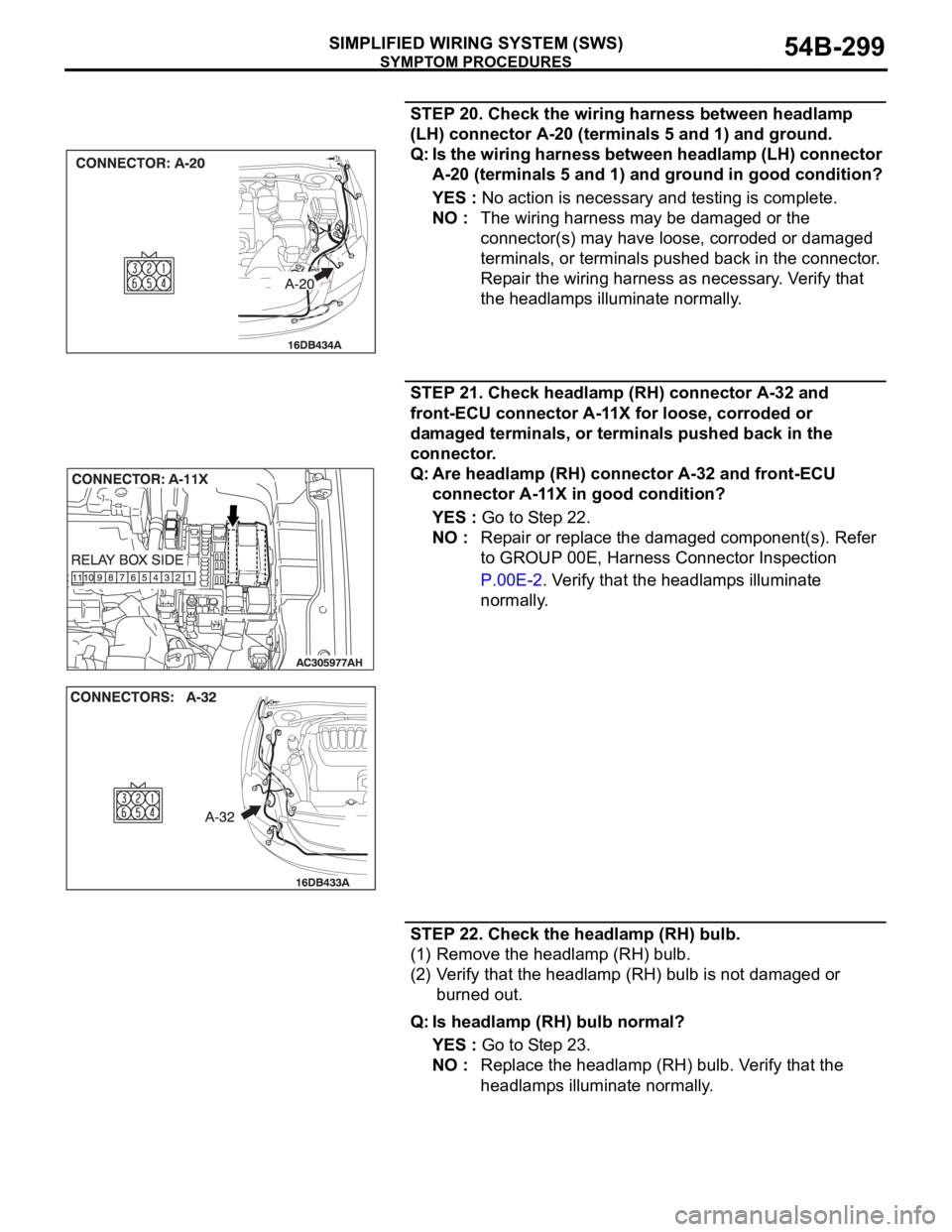

STEP 20. Check the wiring harness between headlamp

(LH) connector A-20 (terminals 5 and 1) and ground.

Q: Is the wiring harness between headlamp (LH) connector

A-20 (terminals 5 and 1) and ground in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

STEP 21. Check headlamp (RH) connector A-32 and

front-ECU connector A-11X for loose, corroded or

damaged terminals, or terminals pushed back in the

connector.

Q: Are headlamp (RH) connector A-32 and front-ECU

connector A-11X in good condition?

YES : Go to Step 22.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. Verify that the headlamps illuminate

normally.

STEP 22. Check the headlamp (RH) bulb.

(1) Remove the headlamp (RH) bulb.

(2) Verify that the headlamp (RH) bulb is not damaged or

burned out.

Q: Is headlamp (RH) bulb normal?

YES : Go to Step 23.

NO : Replace the headlamp (RH) bulb. Verify that the

headlamps illuminate normally.

Page 300 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-300

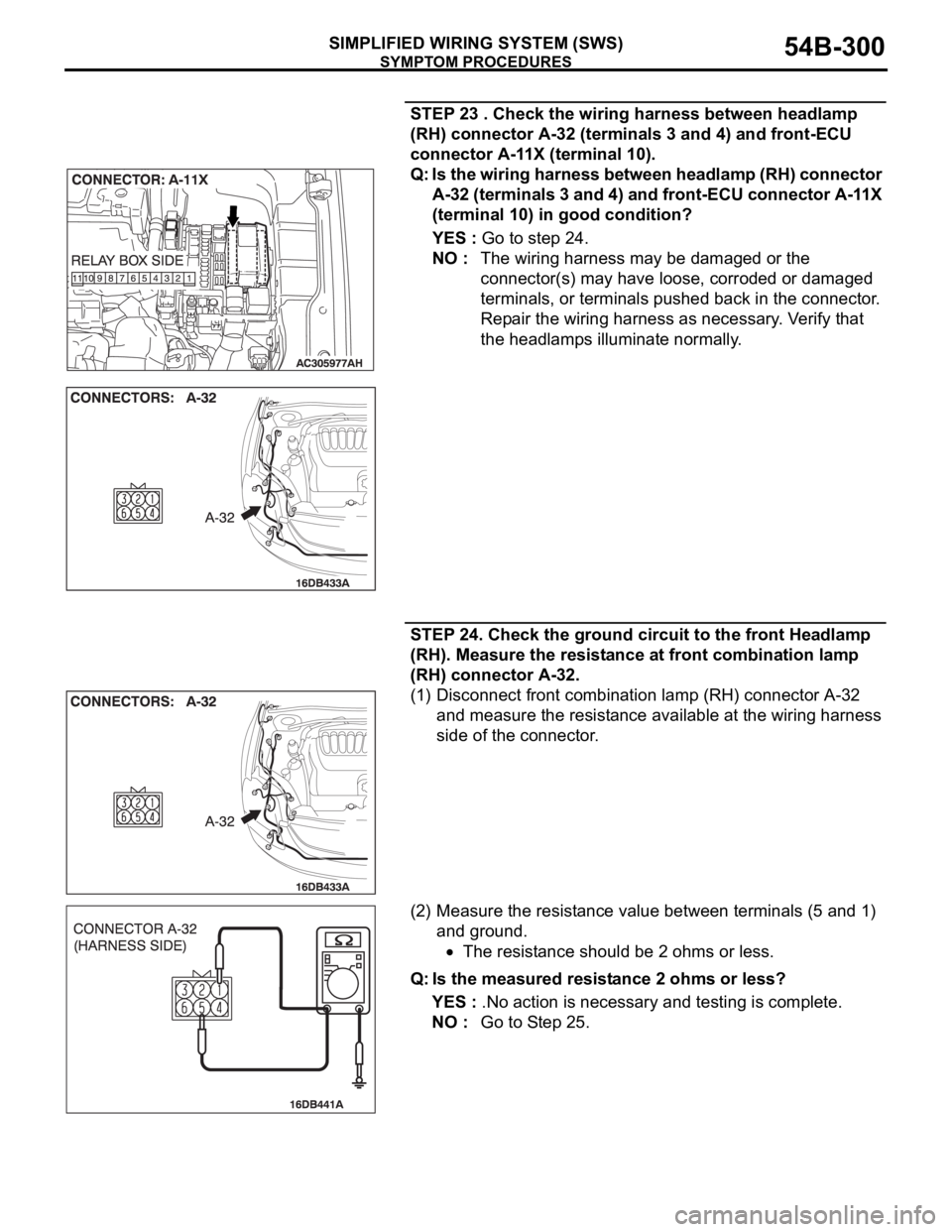

STEP 23 . Check the wiring harness between headlamp

(RH) connector A-32 (terminals 3 and 4) and front-ECU

connector A-11X (terminal 10).

Q: Is the wiring harness between headlamp (RH) connector

A-32 (terminals 3 and 4) and front-ECU connector A-11X

(terminal 10) in good condition?

YES : Go to step 24.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

STEP 24. Check the ground circuit to the front Headlamp

(RH). Measure the resistance at front combination lamp

(RH) connector A-32.

(1) Disconnect front combination lamp (RH) connector A-32

and measure the resistance available at the wiring harness

side of the connector.

(2) Measure the resistance value between terminals (5 and 1)

and ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : .No action is necessary and testing is complete.

NO : Go to Step 25.

Page 301 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-301

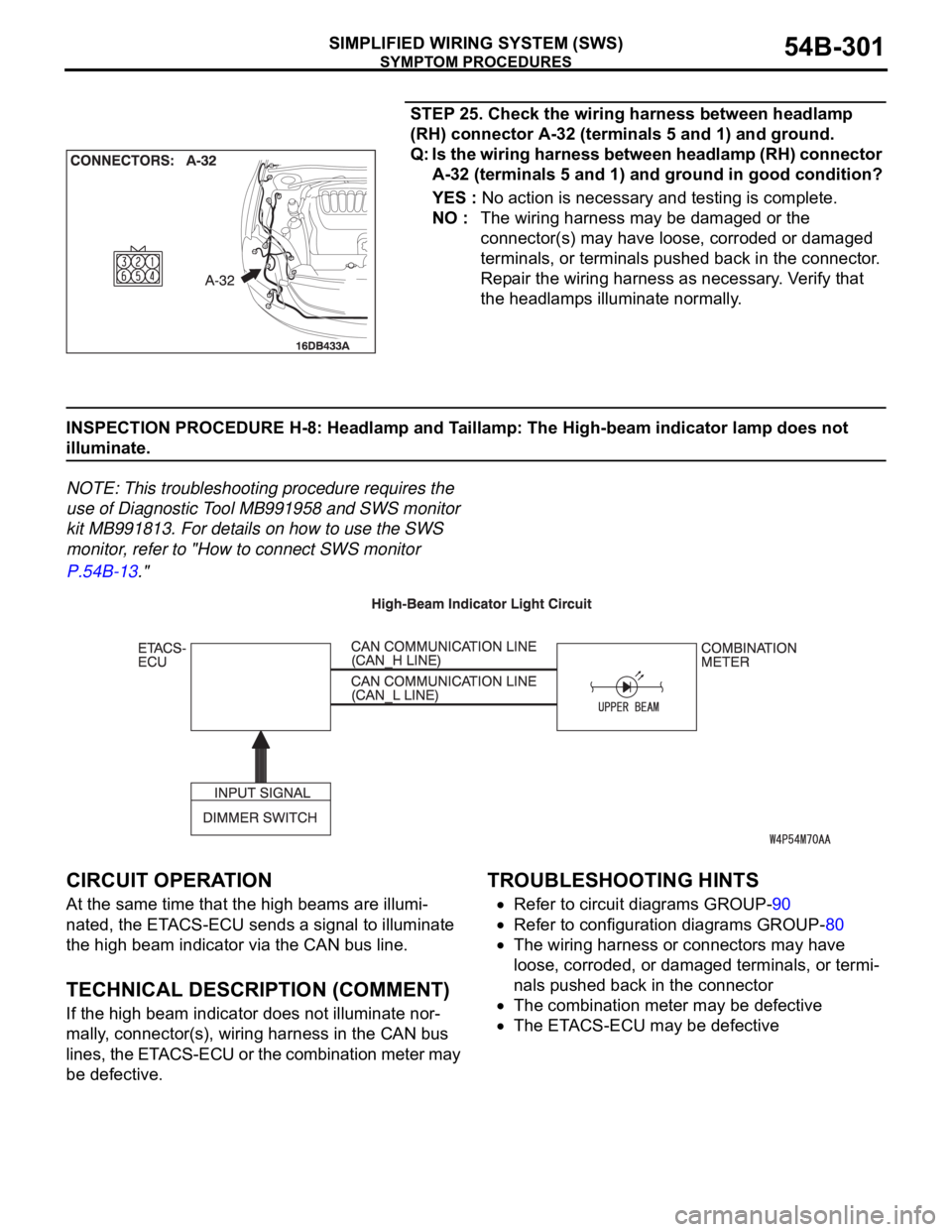

STEP 25. Check the wiring harness between headlamp

(RH) connector A-32 (terminals 5 and 1) and ground.

Q: Is the wiring harness between headlamp (RH) connector

A-32 (terminals 5 and 1) and ground in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the headlamps illuminate normally.

INSPECTION PROCEDURE H-8: Headlamp and Taillamp: The High-beam indicator lamp does not

illuminate.

NOTE: This troubleshooting procedure requires the

use of Diagnostic Tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

At the same time that the high beams are illumi-

nated, the ETACS-ECU sends a signal to illuminate

the high beam indicator via the CAN bus line.

.

TECHNICAL DESCRIPTION (COMMENT)

If the high beam indicator does not illuminate nor-

mally, connector(s), wiring harness in the CAN bus

lines, the ETACS-ECU or the combination meter may

be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The combination meter may be defective

The ETACS-ECU may be defective

.

Page 302 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-302

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB991813: SWS Monitor Kit

MB991806: SWS Monitor Cartridge

MB991812: SWS Monitor Harness (For Column-ECU)

MB991822: Test Probe Harness

STEP 1. Check the headlamps.

When the lighting switch is operated, check that the headlamps

illuminate/go off normally.

Q: Are the headlamps in good condition?

YES : Go to Step 2.

NO : First, repair the headlamps. Refer to Inspection

Procedure H-7 "One of the headlamps does not

illuminate P.54B-290."

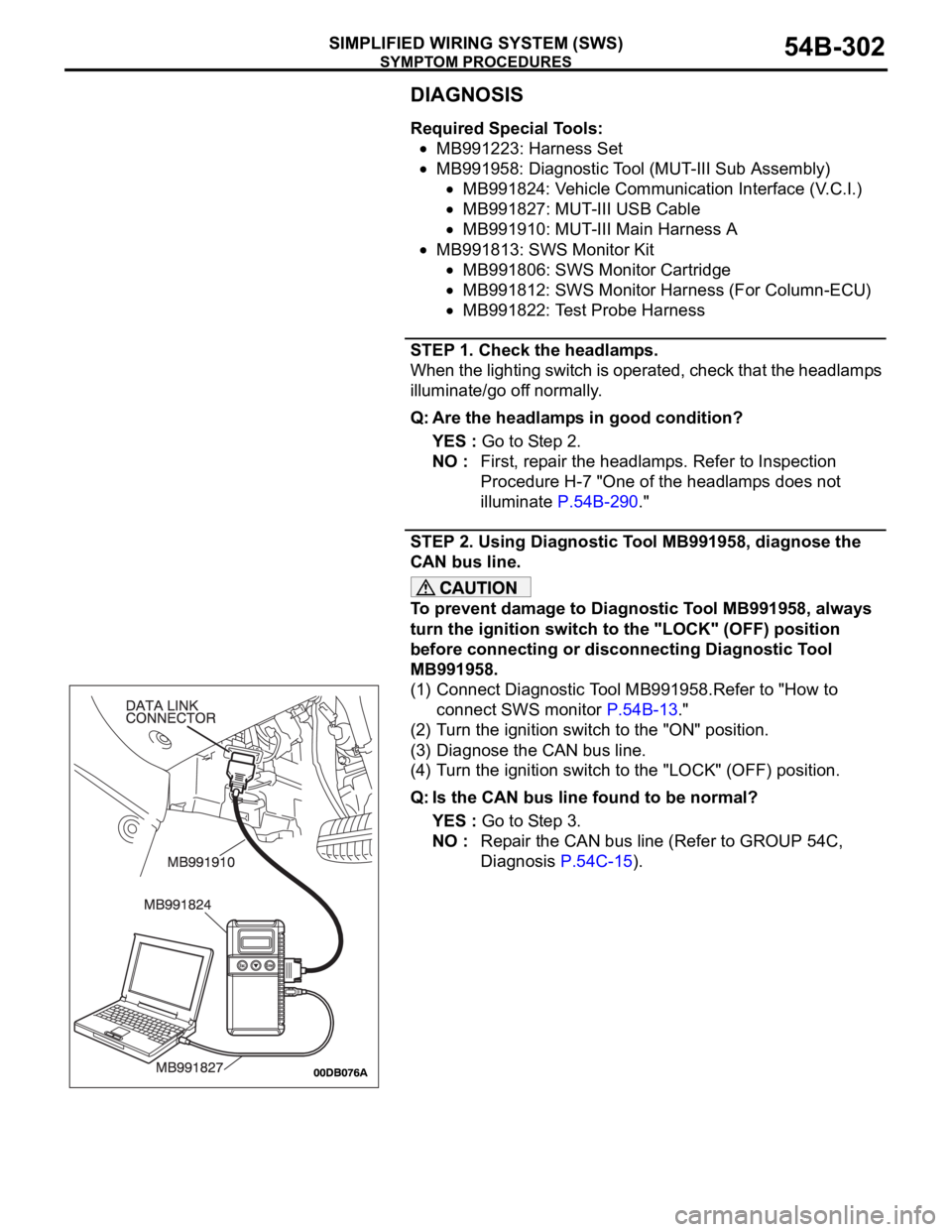

STEP 2. Using Diagnostic Tool MB991958, diagnose the

CAN bus line.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958.Refer to "How to

connect SWS monitor P.54B-13."

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose the CAN bus line.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 3.

NO : Repair the CAN bus line (Refer to GROUP 54C,

Diagnosis P.54C-15).