service MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1395 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-64

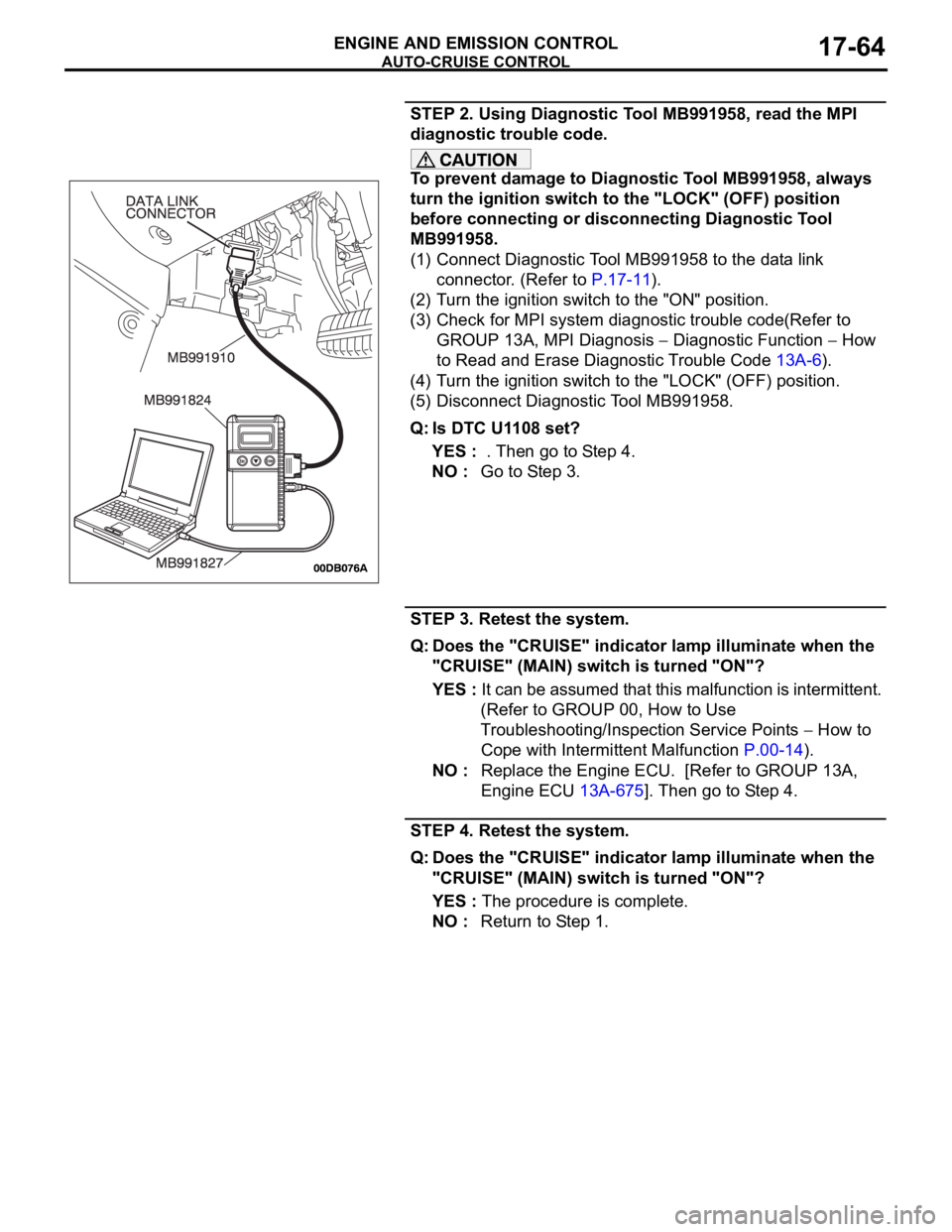

STEP 2. Using Diagnostic Tool MB991958, read the MPI

diagnostic trouble code.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

connector. (Refer to P.17-11).

(2) Turn the ignition switch to the "ON" position.

(3) Check for MPI system diagnostic trouble code(Refer to

GROUP 13A, MPI Diagnosis

Diagnostic Function How

to Read and Erase Diagnostic Trouble Code 13A-6).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is DTC U1108 set?

YES : . Then go to Step 4.

NO : Go to Step 3.

STEP 3. Retest the system.

Q: Does the "CRUISE" indicator lamp illuminate when the

"CRUISE" (MAIN) switch is turned "ON"?

YES : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14).

NO : Replace the Engine ECU. [Refer to GROUP 13A,

Engine ECU 13A-675]. Then go to Step 4.

STEP 4. Retest the system.

Q: Does the "CRUISE" indicator lamp illuminate when the

"CRUISE" (MAIN) switch is turned "ON"?

YES : The procedure is complete.

NO : Return to Step 1.

Page 1401 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-70

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222

Harness set

A: Inspection harness

B: LED harness

C: LED harness adapter

D: ProbeGeneral service tools Checking the continuity

and measuring the

voltage at the harness

connector

MB992044

Engine ECU check

harness

Measuring the terminal

voltage at the Engine

ECU

MB992045

Auto Trans. ECU check

harness

Measuring the terminal

voltage at the Auto Trans.

ECU TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

Page 1402 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-71

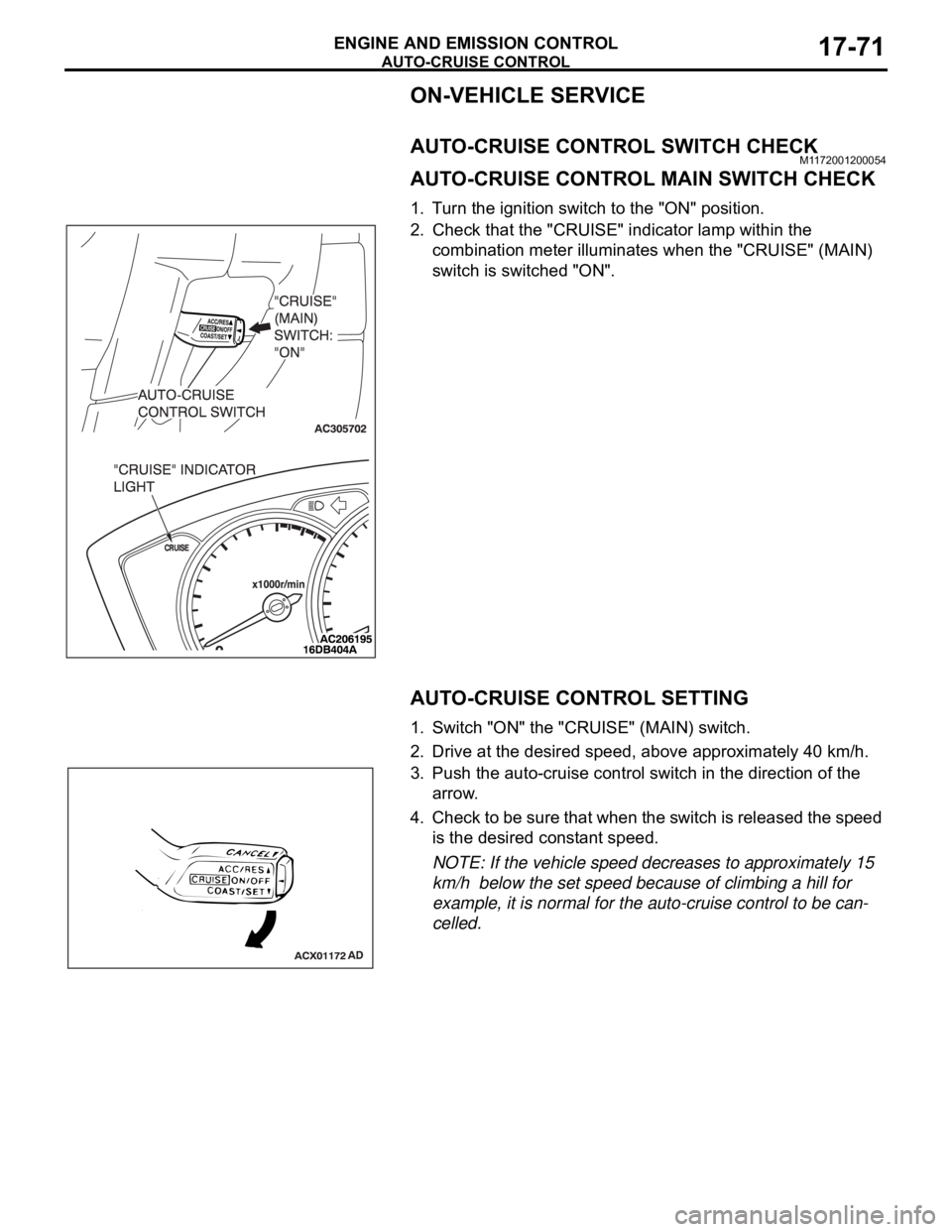

ON-VEHICLE SERVICE

AUTO-CRUISE CONTROL SWITCH CHECKM1172001200054

AUTO-CRUISE CONTROL MAIN SWITCH CHECK

1. Turn the ignition switch to the "ON" position.

2. Check that the "CRUISE" indicator lamp within the

combination meter illuminates when the "CRUISE" (MAIN)

switch is switched "ON".

AUTO-CRUISE CONTROL SETTING

1. Switch "ON" the "CRUISE" (MAIN) switch.

2. Drive at the desired speed, above approximately 40 km/h.

3. Push the auto-cruise control switch in the direction of the

arrow.

4. Check to be sure that when the switch is released the speed

is the desired constant speed.

NOTE: If the vehicle speed decreases to approximately 15

km/h below the set speed because of climbing a hill for

example, it is normal for the auto-cruise control to be can-

celled.

Page 1405 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-74

THROTTLE POSITION SENSOR

Refer to GROUP 13A, On-vehicle Service Throttle Actuator

Control Motor Check 13A-671 (3.8L engine).

If the air intake duct is removed from the throttle

body take great care to keep fingers away from the

throttle plate. The drive motor has very high torque

and is capable of random movement at any time. Do

not under any circumstance activate the throttle plate

by hand.

When removing the throttle body from the intake

manifold disconnect the wiring first.During replace-

ment connect the wiring last.

Do not activate the throttle body using a DC supply to

test the motor, as permanent damage to the throttle

body will result.

TRANSMISSION INHIBITOR SWITCH ("N"

POSITION)

Refer to GROUP 23A, On-vehicle Service Essential Service

P.23A-294.

Page 1406 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-75

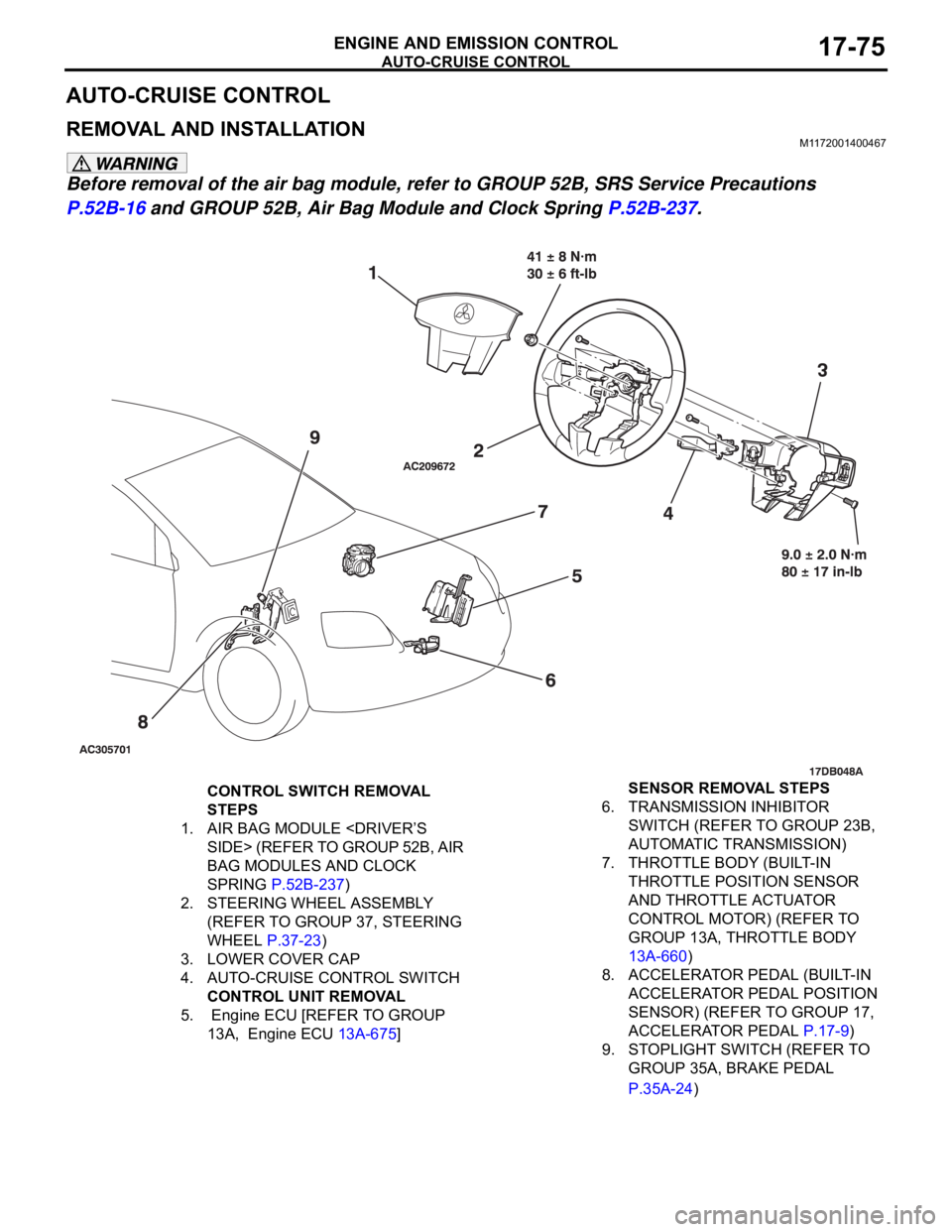

AUTO-CRUISE CONTROL

REMOVAL AND INSTALLATIONM1172001400467

Before removal of the air bag module, refer to GROUP 52B, SRS Service Precautions

P.52B-16 and GROUP 52B, Air Bag Module and Clock Spring P.52B-237.

CONTROL SWITCH REMOVAL

STEPS

1. AIR BAG MODULE

BAG MODULES AND CLOCK

SPRING P.52B-237)

2. STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37, STEERING

WHEEL P.37-23)

3. LOWER COVER CAP

4. AUTO-CRUISE CONTROL SWITCH

CONTROL UNIT REMOVAL

5. Engine ECU [REFER TO GROUP

13A, Engine ECU 13A-675] SENSOR REMOVAL STEPS

6. TRANSMISSION INHIBITOR

SWITCH (REFER TO GROUP 23B,

AUTOMATIC TRANSMISSION)

7. THROTTLE BODY (BUILT-IN

THROTTLE POSITION SENSOR

AND THROTTLE ACTUATOR

CONTROL MOTOR) (REFER TO

GROUP 13A, THROTTLE BODY

13A-660)

8. ACCELERATOR PEDAL (BUILT-IN

ACCELERATOR PEDAL POSITION

SENSOR) (REFER TO GROUP 17,

ACCELERATOR PEDAL P.17-9)

9. STOPLIGHT SWITCH (REFER TO

GROUP 35A, BRAKE PEDAL

P.35A-24)

Page 1407 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-76

EMISSION CONTROL

GENERAL DESCRIPTIONM1173000100314

The emission control system consists of the fol-

lowing subsystems:

Positive crankcase ventilation system

Evaporative emission system

Exhaust emission control system

DIAGNOSISM1173000700112

SPECIAL TOOLSM1173000600193

SYMPTOM PROBABLE CAUSE REMEDY

Engine will not start or hard

to startVacuum hose disconnected or damaged Repair or replace

Malfunction of the evaporative emission

purge solenoidRepair or replace

Rough idle or engine stalls

Vacuum hose disconnected or damaged. Repair or replace

Malfunction of the positive crankcase

ventilation valveReplace

Malfunction of the purge control system Check the system; If there is a

problem, check its component

parts.

Excessive oil consumption Positive crankcase ventilation line

cloggedCheck positive crankcase

ventilation system

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB995061

Purge flow indicatorMLR6890A

Part of MIT280220Inspection of purge

control system

MD998770

Oxygen sensor wrenchMD998770-01 or General

service toolRemoval/installation of

heated oxygen sensor

Page 1416 of 1500

SPECIFICATIONS

ENGINE AND EMISSION CONTROL17-85

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1173006400324

SERVICE SPECIFICATIONSM1173000300545

ITEM SPECIFICATION

Auto-cruise control system

Lower cover cap bolt 9.0

2.0 Nm (80 17 in-lb)

Steering wheel assembly nut 41

8 Nm (30 6 ft-lb)

Engine control system

Accelerator pedal assembly nut 13

2 Nm ( 111 22 in-lb)

ITEMSSTANDARD VALUE

Engine control system

Curb idle speed r/min 3.8L Engine 680

100

Emission control system

Purge flow cm

3/s (SCFH) [at 80 95C (176 205F) with sudden revving]20 (2.5)

Evaporative emission purge solenoid coil resistance [at 20

C)] 16

Page 1418 of 1500

26-1

GROUP 26

FRONT AXLE

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .26-2

FRONT AXLE DIAGNOSIS . . . . . . . .26-2

TROUBLESHOOTING STRATEGY . . . . . . 26-2

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 26-3

SYMPTOM PROCEDURES . . . . . . . . . . . . 26-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .26-4

ON-VEHICLE SERVICE . . . . . . . . . . .26-8

WHEEL BEARING END PLAY CHECK . . . 26-8

HUB BOLT REPLACEMENT . . . . . . . . . . . 26-8

FRONT AXLE HUB ASSEMBLY . . . .26-9

REMOVAL AND INSTALLATION . . . . . . . . 26-9

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-12

DRIVE SHAFT ASSEMBLY . . . . . . . .26-13

REMOVAL AND INSTALLATION . . . . . . . . 26-13

DISASSEMBLY AND ASSEMBLY . . . . . . . 26-18

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-25

BJ BOOT REPLACEMENT . . . . . . . . . . . . . 26-26

SPECIFICATIONS . . . . . . . . . . . . . . .26-29

FASTENER TIGHTENING SPECIFICATIONS26-29

GENERAL SPECIFICATIONS . . . . . . . . . . 26-29

SERVICE SPECIFICATIONS . . . . . . . . . . . 26-29

LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . 26-30

Page 1421 of 1500

SPECIAL TOOLS

FRONT AXLE26-4

STEP 5. Retest the system.

Q: Is the abnormal noise eliminated?

YES : The procedure is complete.

NO : Repeat from Step 1.

INSPECTION PROCEDURE 2: Noise Due to Excessive Play of Wheel in Turning Direction

DIAGNOSIS

STEP 1. Check for play in the inner shaft and side

gear serration, the drive shaft and side gear

serration, or the drive shaft and front hub

serration.

Q: Is the play found?

YES :

Replace the part. Then go to Step 2.

NO : The procedure is complete.

STEP 2. Retest the system.

Q: Is the abnormal noise eliminated?

YES :

The procedure is complete.

NO : Repeat from Step 1.

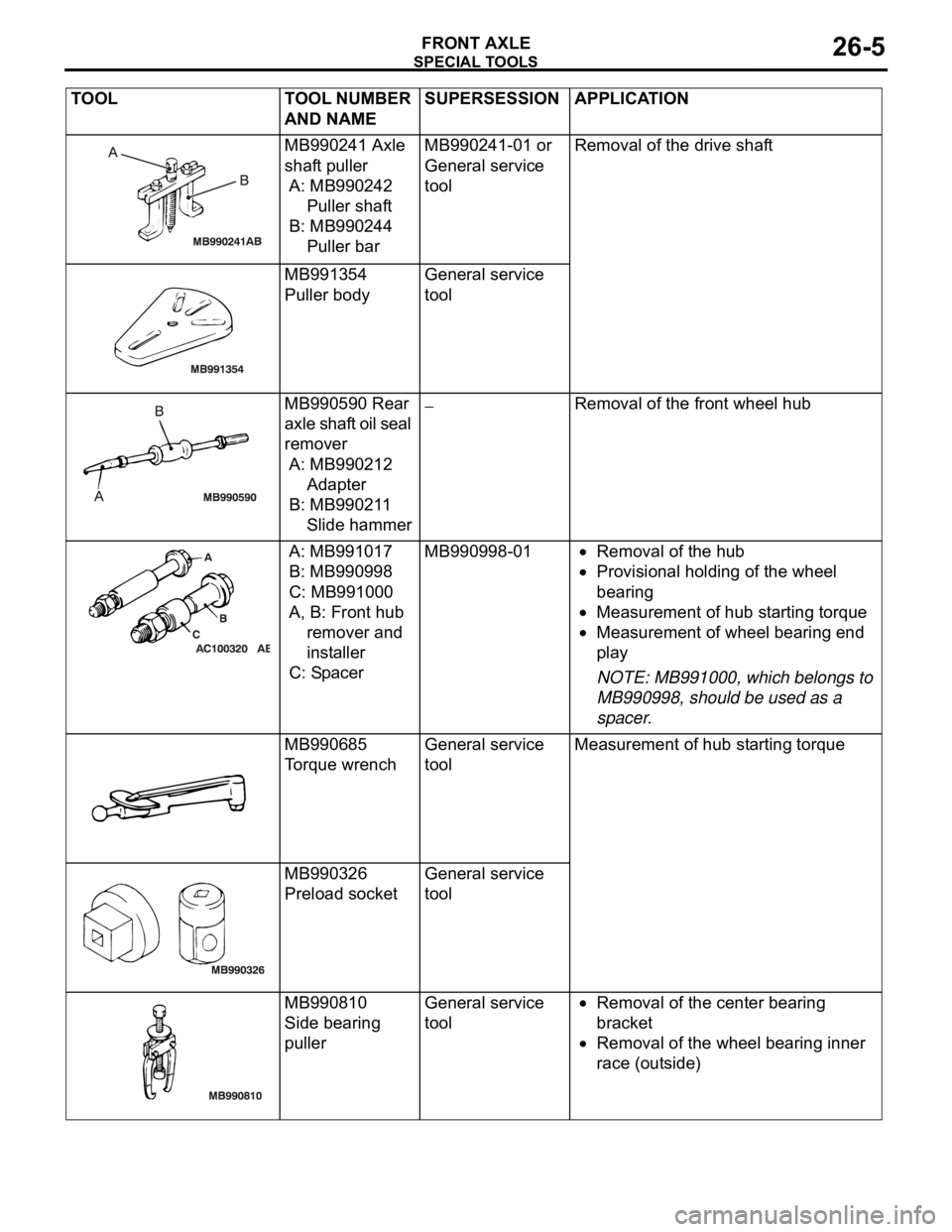

SPECIAL TOOLSM1261000600405

TOOL TOOL NUMBER

AND NAMESUPERSESSION APPLICATION

MB990767

Front hub and

flange yoke

holderMB990767-01 Fixing of the hub

MB991618

Hub bolt removerGeneral service

toolRemoval of the hub bolt

MB991897

Ball joint

removerMB991113-01,

MB990635-01 or

General service

tool Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113)is also used

to disconnect knuckle and tie rod end

ball joint.

Page 1422 of 1500

SPECIAL TOOLS

FRONT AXLE26-5

MB990241 Axle

shaft puller

A: MB990242

Puller shaft

B: MB990244

Puller barMB990241-01 or

General service

toolRemoval of the drive shaft

MB991354

Puller bodyGeneral service

tool

MB990590 Rear

axle shaft oil seal

remover

A: MB990212

Adapter

B: MB990211

Slide hammer

Removal of the front wheel hub

A: MB991017

B: MB990998

C: MB991000

A, B: Front hub

remover and

installer

C: SpacerMB990998-01

Removal of the hub

Provisional holding of the wheel

bearing

Measurement of hub starting torque

Measurement of wheel bearing end

play

NOTE: MB991000, which belongs to

MB990998, should be used as a

spacer.

MB990685

Torque wrenchGeneral service

toolMeasurement of hub starting torque

MB990326

Preload socketGeneral service

tool

MB990810

Side bearing

pullerGeneral service

tool

Removal of the center bearing

bracket

Removal of the wheel bearing inner

race (outside) TOOL TOOL NUMBER

AND NAMESUPERSESSION APPLICATION