height MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 525 of 1500

Page 531 of 1500

Page 567 of 1500

FLOOR, SEAT AND ROOF

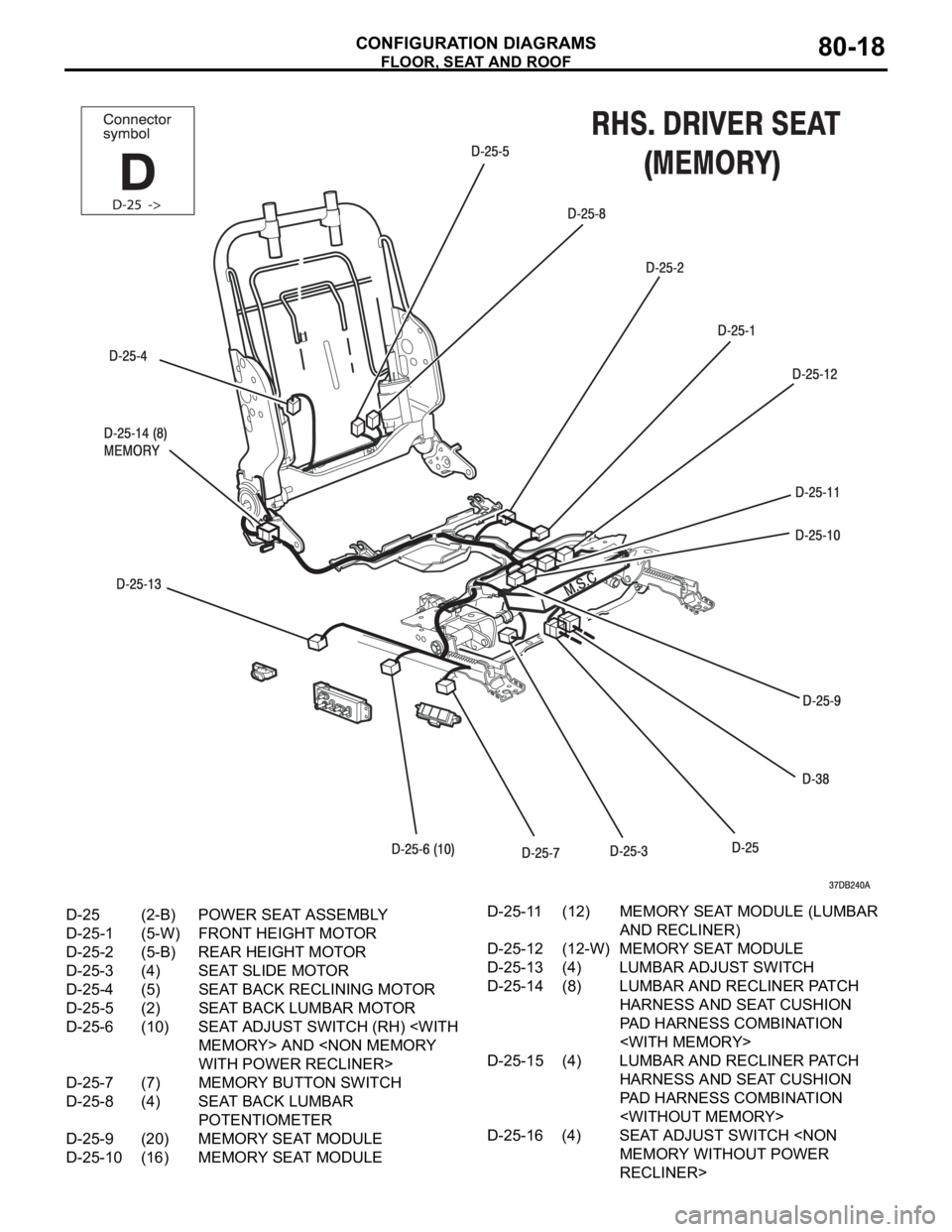

CONFIGURATION DIAGRAMS80-18

D-25 (2-B) POWER SEAT ASSEMBLY

D-25-1 (5-W) FRONT HEIGHT MOTOR

D-25-2 (5-B) REAR HEIGHT MOTOR

D-25-3 (4) SEAT SLIDE MOTOR

D-25-4 (5) SEAT BACK RECLINING MOTOR

D-25-5 (2) SEAT BACK LUMBAR MOTOR

D-25-6 (10) SEAT ADJUST SWITCH (RH)

D-25-7 (7) MEMORY BUTTON SWITCH

D-25-8 (4) SEAT BACK LUMBAR

POTENTIOMETER

D-25-9 (20) MEMORY SEAT MODULE

D-25-10 (16) MEMORY SEAT MODULED-25-11 (12) MEMORY SEAT MODULE (LUMBAR

AND RECLINER)

D-25-12 (12-W) MEMORY SEAT MODULE

D-25-13 (4) LUMBAR ADJUST SWITCH

D-25-14 (8) LUMBAR AND RECLINER PATCH

HARNESS AND SEAT CUSHION

PAD HARNESS COMBINATION

D-25-15 (4) LUMBAR AND RECLINER PATCH

HARNESS AND SEAT CUSHION

PAD HARNESS COMBINATION

D-25-16 (4) SEAT ADJUST SWITCH

RECLINER>

Page 571 of 1500

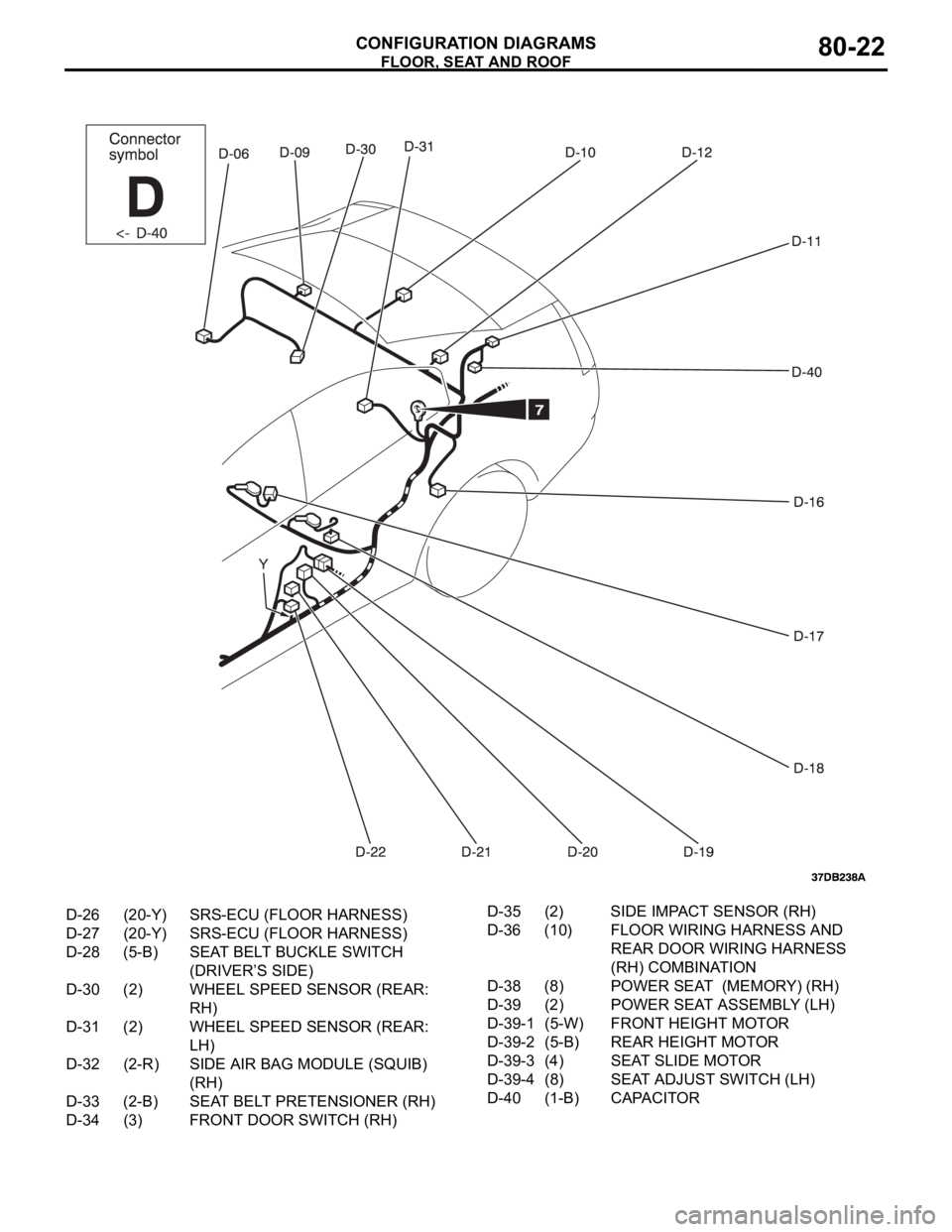

FLOOR, SEAT AND ROOF

CONFIGURATION DIAGRAMS80-22

D-26 (20-Y) SRS-ECU (FLOOR HARNESS)

D-27 (20-Y) SRS-ECU (FLOOR HARNESS)

D-28 (5-B) SEAT BELT BUCKLE SWITCH

(DRIVER’S SIDE)

D-30 (2) WHEEL SPEED SENSOR (REAR:

RH)

D-31 (2) WHEEL SPEED SENSOR (REAR:

LH)

D-32 (2-R) SIDE AIR BAG MODULE (SQUIB)

(RH)

D-33 (2-B) SEAT BELT PRETENSIONER (RH)

D-34 (3) FRONT DOOR SWITCH (RH)D-35 (2) SIDE IMPACT SENSOR (RH)

D-36 (10) FLOOR WIRING HARNESS AND

REAR DOOR WIRING HARNESS

(RH) COMBINATION

D-38 (8) POWER SEAT (MEMORY) (RH)

D-39 (2) POWER SEAT ASSEMBLY (LH)

D-39-1 (5-W) FRONT HEIGHT MOTOR

D-39-2 (5-B) REAR HEIGHT MOTOR

D-39-3 (4) SEAT SLIDE MOTOR

D-39-4 (8) SEAT ADJUST SWITCH (LH)

D-40 (1-B) CAPACITOR

Page 953 of 1500

THERMOSTAT

ENGINE COOLING14-38

INSPECTIONM1141002500450.

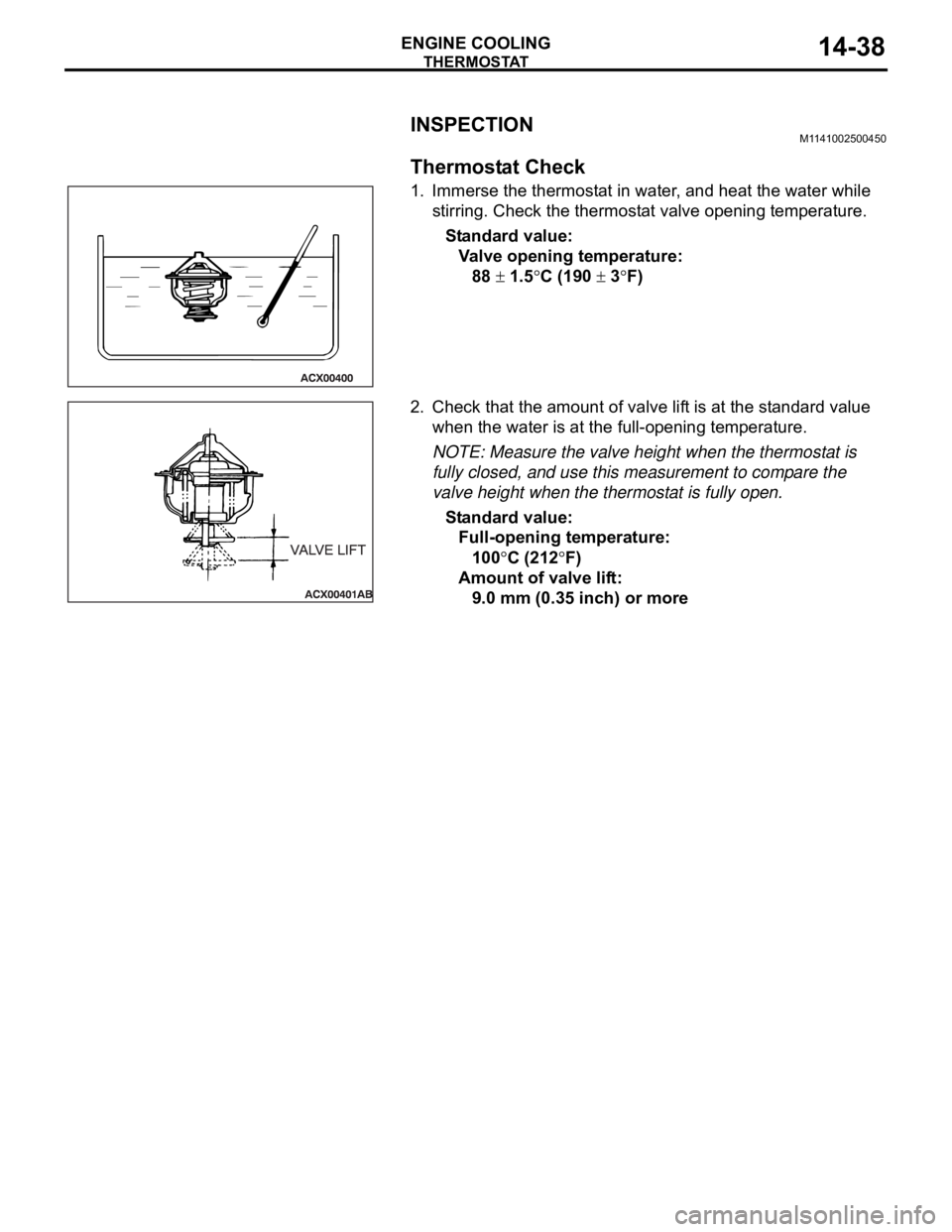

Thermostat Check

1. Immerse the thermostat in water, and heat the water while

stirring. Check the thermostat valve opening temperature.

Standard value:

Valve opening temperature:

88

1.5C (190 3F)

2. Check that the amount of valve lift is at the standard value

when the water is at the full-opening temperature.

NOTE: Measure the valve height when the thermostat is

fully closed, and use this measurement to compare the

valve height when the thermostat is fully open.

Standard value:

Full-opening temperature:

100

C (212F)

Amount of valve lift:

9.0 mm (0.35 inch) or more

Page 988 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-11

11.Increase the engine speed to 2,500 r/min.

12.Read the value displayed on the voltmeter when

the current output by the alternator becomes 10 A

or less.

13.If the voltage reading conforms to the value in the

voltage regulation table, then the voltage regulator

is operating normally.

If the voltage is outside the standard value, there

is a malfunction of the voltage regulator or the

alternator (Refer to the following table).14.After the test, lower the engine speed to idle.

15.Turn the ignition switch to the "LOCK" (OFF)

position.

16.Disconnect the engine tachometer or diagnostic

tool .

17.Disconnect the negative battery cable.

18.Disconnect the ammeter and voltmeter.

19.Connect the negative battery cable.

20.Run the engine for 10 minutes at an idle.

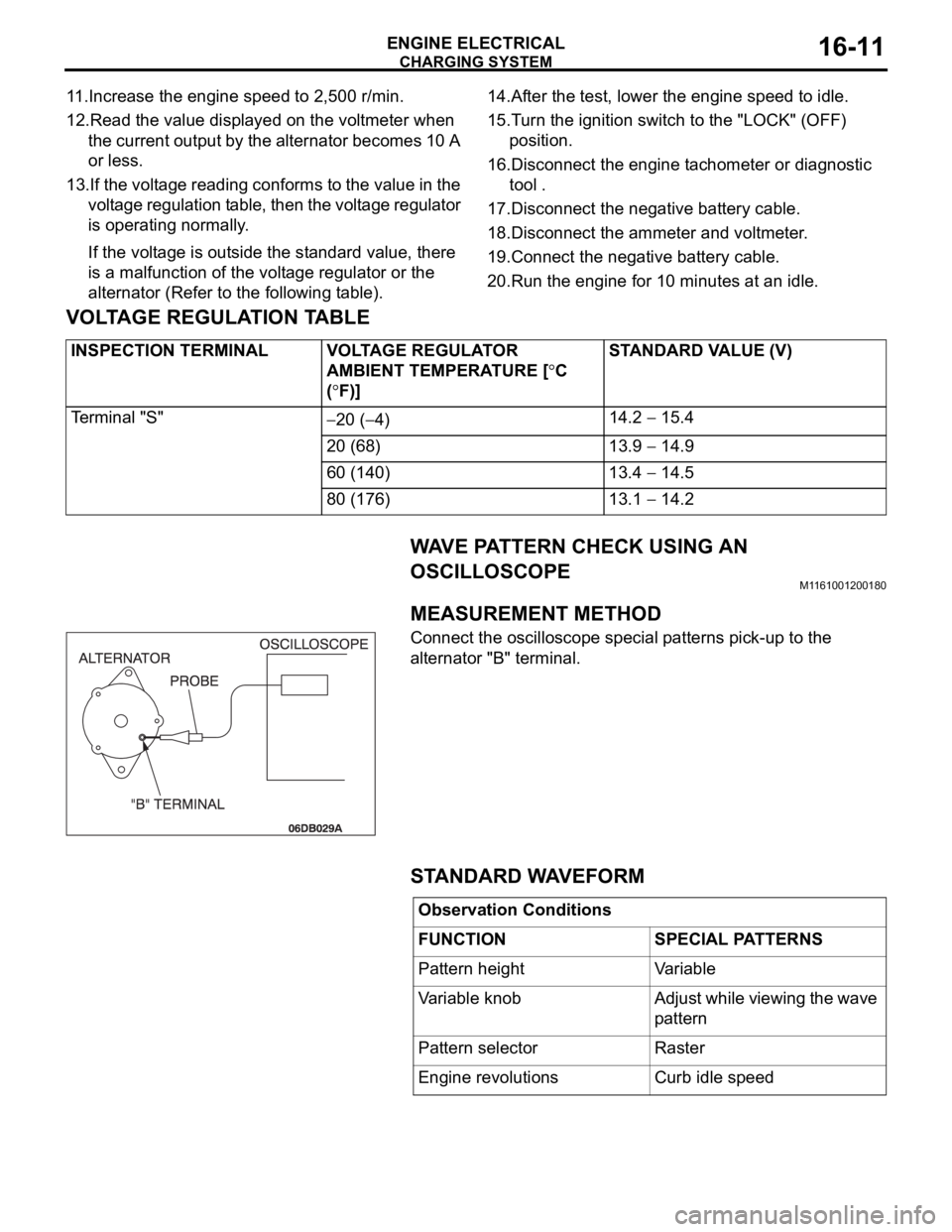

VOLTAGE REGULATION TABLE

WAVE PATTERN CHECK USING AN

OSCILLOSCOPE

M1161001200180.

MEASUREMENT METHOD

Connect the oscilloscope special patterns pick-up to the

alternator "B" terminal.

.

STANDARD WAVEFORM

INSPECTION TERMINAL VOLTAGE REGULATOR

AMBIENT TEMPERATURE [

C

(

F)]STANDARD VALUE (V)

Te r m i n a l " S "

20 (4)14.2 15.4

20 (68) 13.9

14.9

60 (140) 13.4

14.5

80 (176) 13.1

14.2

Observation Conditions

FUNCTION SPECIAL PATTERNS

Pattern height Variable

Variable knob Adjust while viewing the wave

pattern

Pattern selector Raster

Engine revolutions Curb idle speed

Page 989 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-12

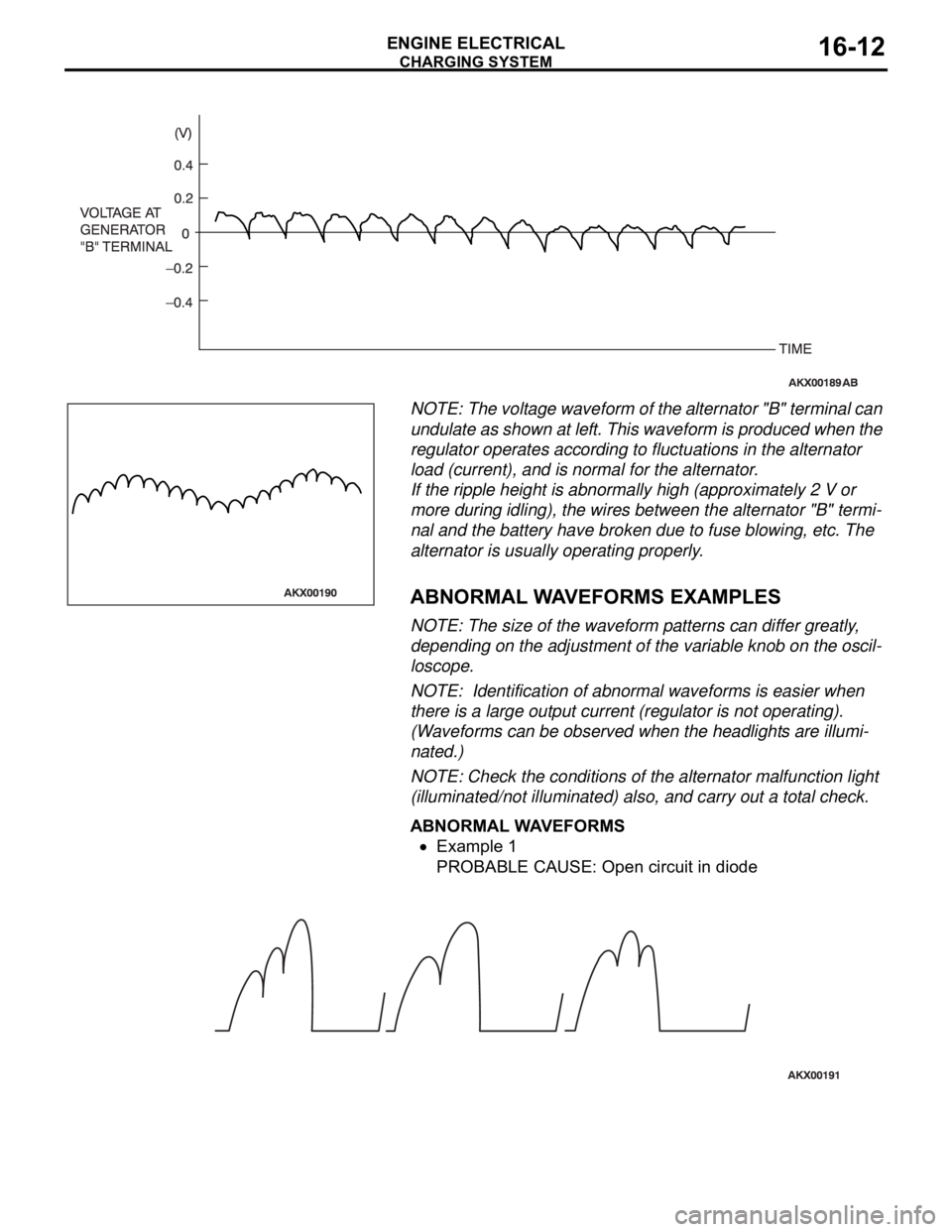

NOTE: The voltage waveform of the alternator "B" terminal can

undulate as shown at left. This waveform is produced when the

regulator operates according to fluctuations in the alternator

load (current), and is normal for the alternator.

If the ripple height is abnormally high (approximately 2 V or

more during idling), the wires between the alternator "B" termi-

nal and the battery have broken due to fuse blowing, etc. The

alternator is usually operating properly.

.

ABNORMAL WAVEFORMS EXAMPLES

NOTE: The size of the waveform patterns can differ greatly,

depending on the adjustment of the variable knob on the oscil-

loscope.

NOTE: Identification of abnormal waveforms is easier when

there is a large output current (regulator is not operating).

(Waveforms can be observed when the headlights are illumi-

nated.)

NOTE: Check the conditions of the alternator malfunction light

(illuminated/not illuminated) also, and carry out a total check.

ABNORMAL WAVEFORMS

Example 1

PROBABLE CAUSE: Open circuit in diode

Page 1068 of 1500

42-1

GROUP 42

BODY

CONTENTS

HOOD . . . . . . . . . . . . . . . . . . . . .

42-4

BODY DIAGNOSIS . . . . . . . . . . . .

42-4

INTRODUCTION TO HOOD DIAGNOSIS42-4

HOOD DIAGNOSTIC TROUBLESHOOTING

STRATEGY . . . . . . . . . . . . . . . . . . . . . . 42-4

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-4

SYMPTOM PROCEDURES . . . . . . . . . 42-4

ON-VEHICLE SERVICE. . . . . . . . .42-6

ADJUSTMENT OF CLEARANCE

AROUND HOOD . . . . . . . . . . . . . . . . . . 42-6

ALIGNMENT OF HOOD LATCH AND

STRIKER . . . . . . . . . . . . . . . . . . . . . . . . 42-6

ADJUSTMENT OF HOOD HEIGHT . . . 42-7

HOOD . . . . . . . . . . . . . . . . . . . . . . .42-8

REMOVAL AND INSTALLATION . . . . . 42-8

FENDER . . . . . . . . . . . . . . . . . . .42-10

REMOVAL AND INSTALLATION .

42-10

FUEL FILLER LID . . . . . . . . . . .42-11

REMOVAL AND INSTALLATION .

42-11

STRUT TOWER BAR . . . . . . . . 42-12

REMOVAL AND INSTALLATION .

42-12

WINDOW GLASS . . . . . . . . . . . 42-12

GENERAL . . . . . . . . . . . . . . . . . . . .

42-12

WINDOW GLASS DIAGNOSIS . . .42-14

INTRODUCTION TO WINDOW GLASS

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-14

WINDOW GLASS DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . 42-14

WINDOW GLASS DIAGNOSTIC TROUBLE

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-14

SYMPTOM PROCEDURES . . . . . . . . . . 42-14

SPECIAL TOOL . . . . . . . . . . . . . . .42-14

WINDSHIELD . . . . . . . . . . . . . . . . .42-15

REMOVAL AND INSTALLATION . . . . . . 42-15

REAR WINDOW GLASS . . . . . . . .42-20

REMOVAL AND INSTALLATION . . . . . . 42-20

Continued on next page

Page 1069 of 1500

BODY42-2

DOOR . . . . . . . . . . . . . . . . . . . . . . . . .42-23

GENERAL DESCRIPTION . . . . . .

42-23

CENTRAL DOOR LOCKING SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

POWER WINDOW DIAGNOSIS . . . . . . 42-23

DOOR DIAGNOSIS . . . . . . . . . . . . . . . . 42-23

INTRODUCTION TO GLASS AND DOOR

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-23

GLASS AND DOOR DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . 42-23

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-24

SYMPTOM PROCEDURES . . . . . . . . . 42-24

HOW TO LOCATE WIND NOISE . . . . . 42-27

SPECIAL TOOLS. . . . . . . . . . . . . .42-28

ON-VEHICLE SERVICE. . . . . . . . .42-30

DOOR FIT ADJUSTMENT. . . . . . . . . . . 42-30

DOOR WINDOW GLASS ADJUSTMENT42-31

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . 42-32

POWER WINDOW TIMER FUNCTION

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 42-32

POWER WINDOW OPERATING

CURRENT CHECK . . . . . . . . . . . . . . . . 42-33

POWER WINDOW RELAY CHECK . . . 42-33

CIRCUIT BREAKER (INCORPORATED IN

THE POWER WINDOW MOTOR)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

POWER WINDOW CHECK . . . . . . . . . . 42-34

CENTRAL DOOR LOCKING SYSTEM

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

DOOR OUTSIDE HANDLE PLAY CHECK42-35

DOOR INSIDE HANDLE PLAY CHECK 42-35

DOOR ASSEMBLY . . . . . . . . . . . .42-37

REMOVAL AND INSTALLATION . . . . . 42-37

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-38

DOOR GLASS AND REGULATOR42-39

REMOVAL AND INSTALLATION . . . . . 42-39

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-43

DOOR HANDLE AND LATCH . . . .42-46

REMOVAL AND INSTALLATION . . . . . 42-46

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-49

WINDOW GLASS RUNCHANNEL

AND DOOR OPENING

WEATHERSTRIP . . . . . . . . . . . . . .

42-52

REMOVAL AND INSTALLATION . . . . . . 42-52

TRUNK LID. . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSIS . . . . . . . .

42-60

INTRODUCTION TO TRUNK LID

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . 42-60

TRUNK LID DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . 42-60

SYMPTOM CHART . . . . . . . . . . . . . . . . 42-60

SYMPTOM PROCEDURES . . . . . . . . . . 42-60

ON-VEHICLE SERVICE . . . . . . . . .42-61

ADJUSTMENT OF CLEARANCE

AROUND TRUNK LID . . . . . . . . . . . . . . 42-61

TRUNK LID LATCH ADJUSTMENT. . . . 42-61

TRUNK LID HEIGHT ADJUSTMENT . . . 42-62

TRUNK LID . . . . . . . . . . . . . . . . . . .42-63

REMOVAL AND INSTALLATION . . . . . . 42-63

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-65

KEYLESS ENTRY SYSTEM 42-67

GENERAL DESCRIPTION . . . . . . .

42-67

KEYLESS ENTRY SYSTEM

DIAGNOSIS . . . . . . . . . . . . . . . . . .

42-68

SPECIAL TOOL . . . . . . . . . . . . . . .42-68

ON-VEHICLE SERVICE . . . . . . . . .42-69

TRANSMITTER BATTERY CHECK . . . . 42-69

HOW TO REPLACE THE TRANSMITTER

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . 42-70

KEYLESS ENTRY SYSTEM INSPECTION42-71

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION . . . . . . . . . . . 42-71

ENABLING/DISABLING THE

ANSWERBACK FUNCTION . . . . . . . . . 42-72

HOW TO REGISTER SECRET CODE . 42-73

Continued on next page

Page 1071 of 1500

HOOD

BODY42-4

HOOD

BODY DIAGNOSIS

INTRODUCTION TO HOOD DIAGNOSISM1421005800363

Wind noise at the hood may be caused by improper

hood adjustment.

HOOD DIAGNOSTIC TROUBLESHOOTING STRATEGYM1421005900337

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find a

hood fault.

1. Gather information from the customer.2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

SYMPTOM CHARTM1421006000371

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Difficult Locking and Unlocking

DIAGNOSIS

STEP 1. Check that the release cable is routed

correctly.

Q: Is the release cable routed correctly?

YES :

Go to Step 2.

NO : Re-route the release cable. Then go to Step

4.

STEP 2. Check the engagement of the hood latch

and hood striker.

Q: Are the hood latch and hood striker engaged

correctly?

YES :

Go to Step 3.

NO : Adjust the hood latch (Refer to P.42-6).

Then go to Step 4.

STEP 3. Check for proper lubrication of release

cable.

Q: Is the release cable properly lubricated?

YES :

Go to Step 4.

NO : Lubricate, then go to Step 4.

STEP 4. Retest the system.

Q: Does the hood lock operate easily?

YES :

The procedure is complete.

NO : Return to Step 1. SYMPTOM INSPECTION

PROCEDUREREFERENCE PAGE

Difficult locking and unlocking 1

P.42-4

Uneven body clearance 2

P.42-5

Uneven height 3

P.42-5