ECU MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 910 of 1500

HOW TO DIAGNOSE

GENERAL

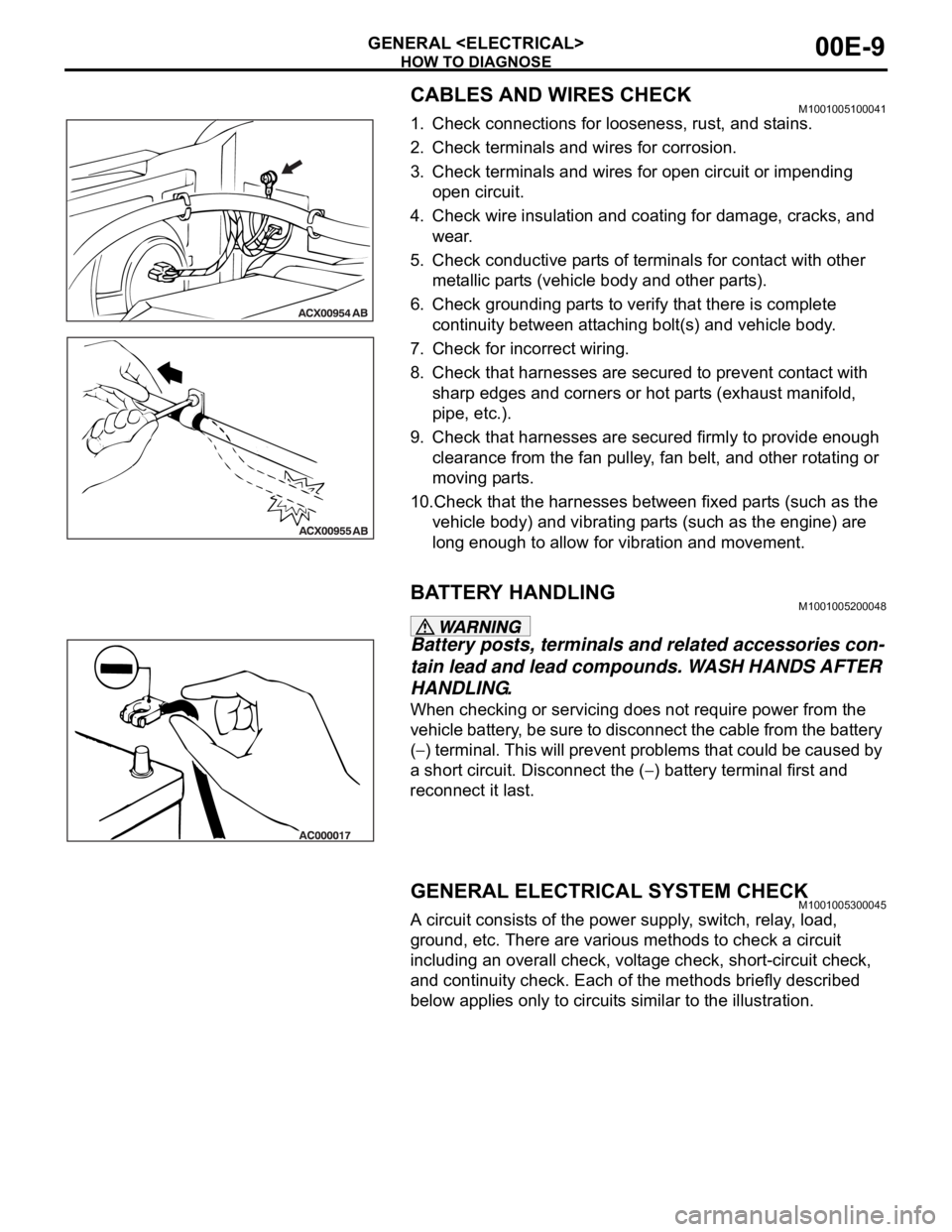

CABLES AND WIRES CHECKM1001005100041

1. Check connections for looseness, rust, and stains.

2. Check terminals and wires for corrosion.

3. Check terminals and wires for open circuit or impending

open circuit.

4. Check wire insulation and coating for damage, cracks, and

wear.

5. Check conductive parts of terminals for contact with other

metallic parts (vehicle body and other parts).

6. Check grounding parts to verify that there is complete

continuity between attaching bolt(s) and vehicle body.

7. Check for incorrect wiring.

8. Check that harnesses are secured to prevent contact with

sharp edges and corners or hot parts (exhaust manifold,

pipe, etc.).

9. Check that harnesses are secured firmly to provide enough

clearance from the fan pulley, fan belt, and other rotating or

moving parts.

10.Check that the harnesses between fixed parts (such as the

vehicle body) and vibrating parts (such as the engine) are

long enough to allow for vibration and movement.

BATTERY HANDLINGM1001005200048

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

When checking or servicing does not require power from the

vehicle battery, be sure to disconnect the cable from the battery

(

) terminal. This will prevent problems that could be caused by

a short circuit. Disconnect the (

) battery terminal first and

reconnect it last.

GENERAL ELECTRICAL SYSTEM CHECKM1001005300045

A circuit consists of the power supply, switch, relay, load,

ground, etc. There are various methods to check a circuit

including an overall check, voltage check, short-circuit check,

and continuity check. Each of the methods briefly described

below applies only to circuits similar to the illustration.

Page 920 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-5

INSPECTION PROCEDURE 3: Radiator Fan and Condenser Fan do not Operate

.

CIRCUIT OPERATION

The fan controller is powered from fusible link

No.2.

The engine-ECU uses input signals from the A/C

switch, the water temperature sensor unit and the

vehicle speed sensor

speed sensor to control the speed of the

radiator fan motor and the condenser fan motor.

The engine-ECU controls the fan controller to

activate the radiator fan motor and the condenser

fan motor.

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the fan con-

troller power supply or earth circuit.

If the communication line wiring harness between

the fan controller and the engine-ECU is

short-circuited to earth, the radiator fan motor

and the condenser fan motor will not rotate.

The cause could also be a malfunction of input

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU.

The cause could also be a malfunction of the fan

controller or the engine-ECU.

.

TROUBLESHOOTING HINTS

Malfunction of fusible link No.2

Malfunction of fan control relay

Malfunction of cooling fan motor and fan control-

ler

Malfunction of engine-ECU.

Damaged wiring harness or connector

Refer to component locations GROUP-1

Refer to configuration diagrams GROUP-1

Refer to circuit diagrams GROUP-1

Page 926 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-11

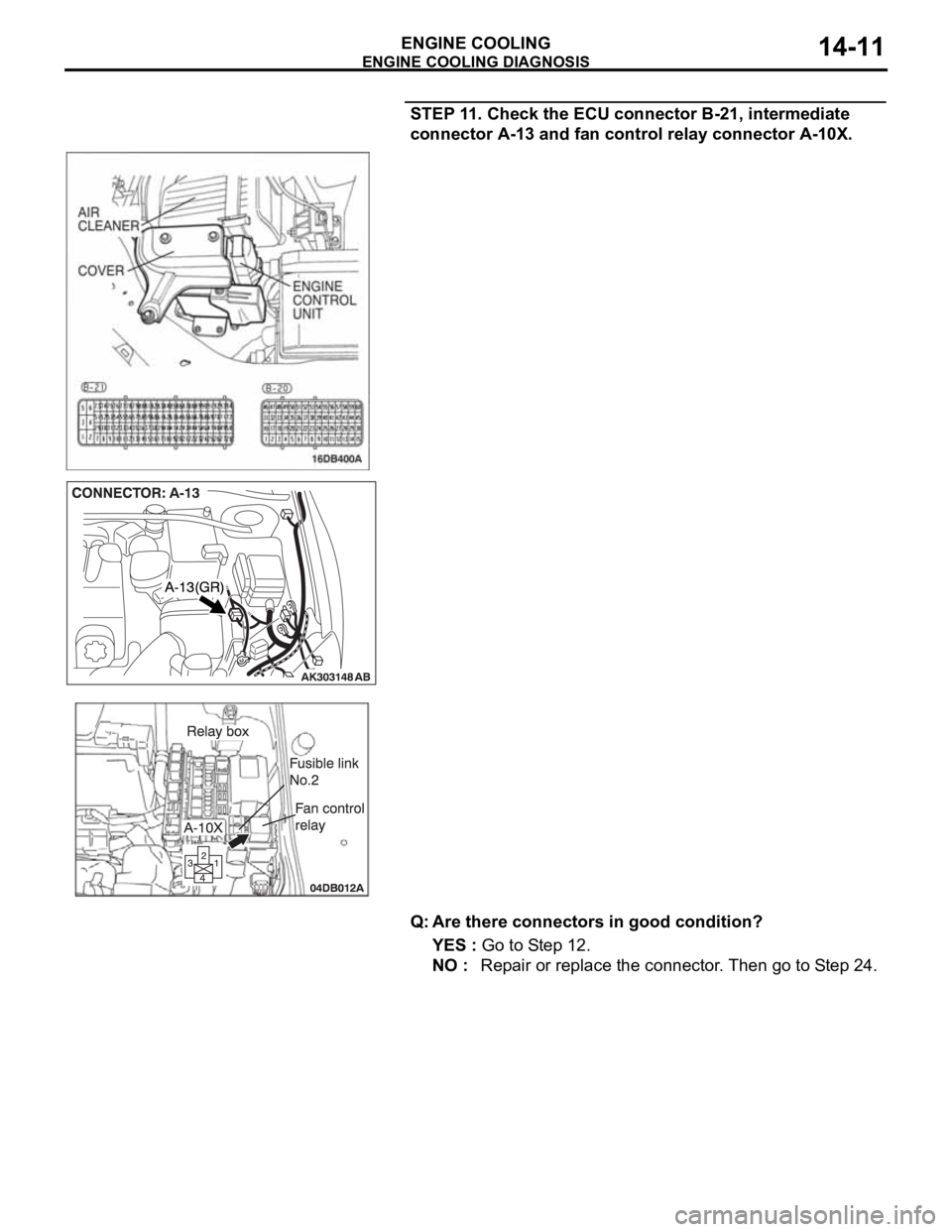

STEP 11. Check the ECU connector B-21, intermediate

connector A-13 and fan control relay connector A-10X.

Q: Are there connectors in good condition?

YES : Go to Step 12.

NO : Repair or replace the connector. Then go to Step 24.

Page 932 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-17

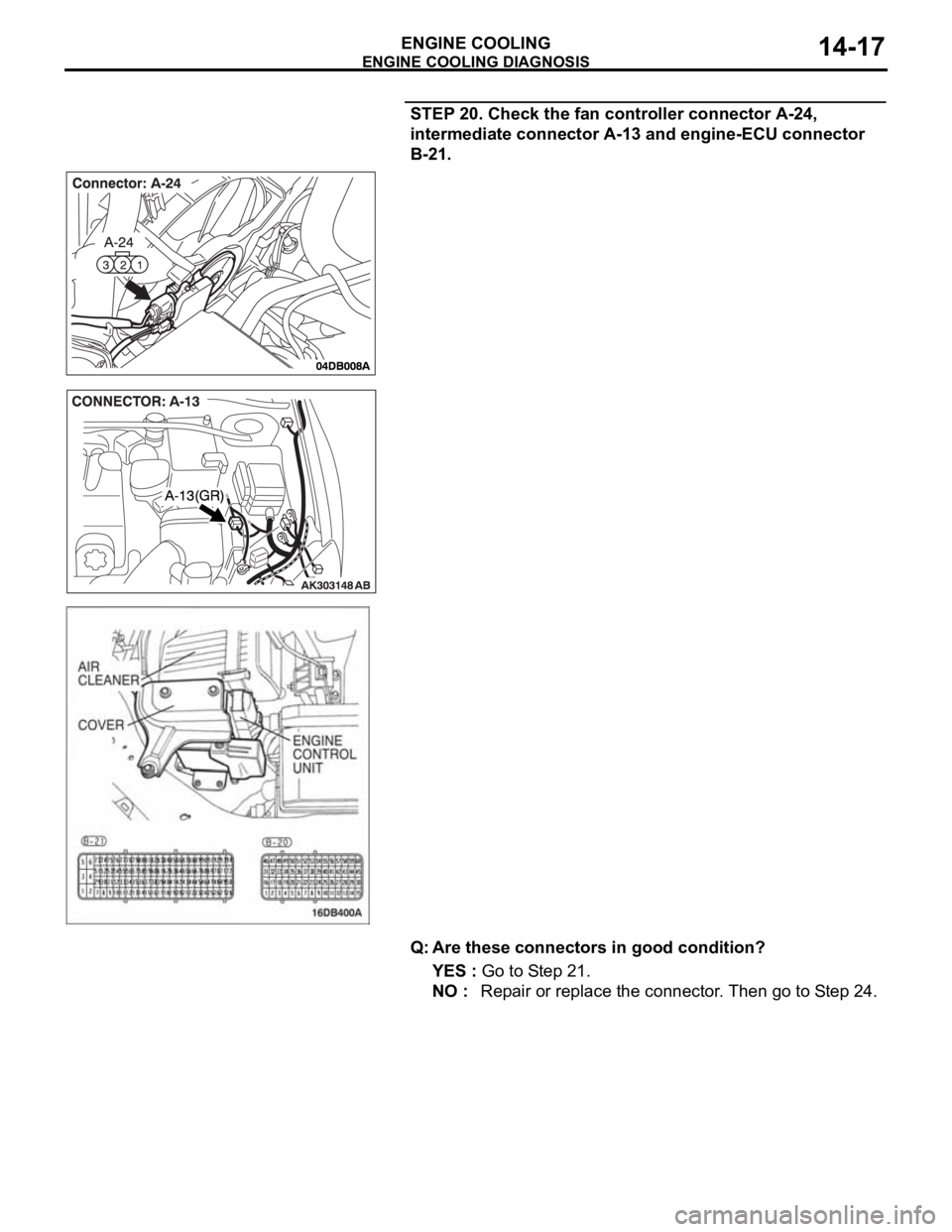

STEP 20. Check the fan controller connector A-24,

intermediate connector A-13 and engine-ECU connector

B-21.

Q: Are these connectors in good condition?

YES : Go to Step 21.

NO : Repair or replace the connector. Then go to Step 24.

Page 933 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-18

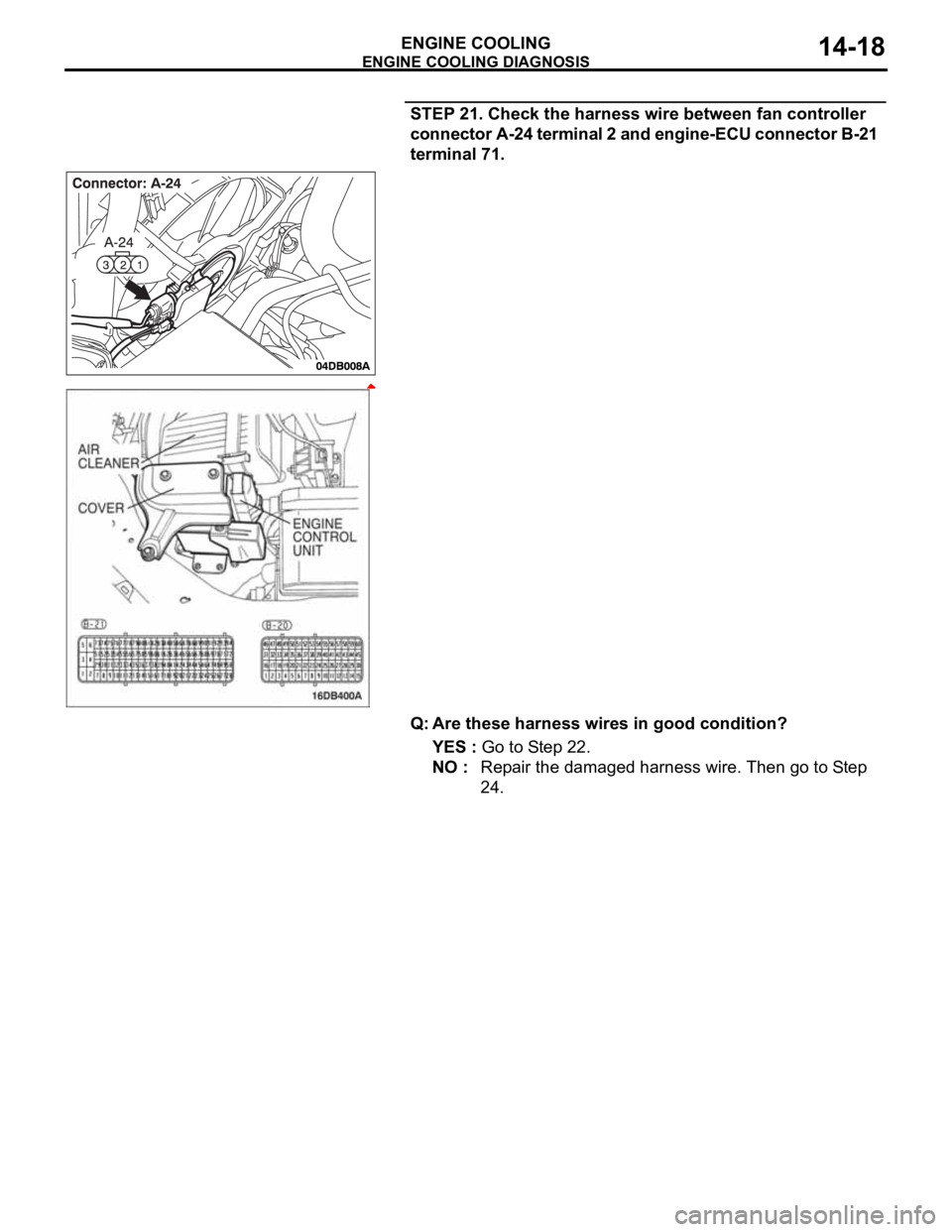

STEP 21. Check the harness wire between fan controller

connector A-24 terminal 2 and engine-ECU connector B-21

terminal 71.

Q: Are these harness wires in good condition?

YES : Go to Step 22.

NO : Repair the damaged harness wire. Then go to Step

24.

Page 935 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-20

STEP 23. MUT-III self-diag code

Check if an MPI system self-diag code is set. (Refer to GROUP

13A - Trouble shooting 13A-5).

Q: Diagnosis code set?

YES : Inspection chart for diagnosis code (Refer to GROUP

13A - Trouble shooting 13A-17)

NO : Replace the engine-ECU (Refer to GROUP 13A,

Engine-ECU 13A-675 ). Then go to Step 24.

STEP 24. Check the symptoms.

Q: Does the radiator fan motor and the condenser fan

motor operate correctly?

YES : This symptom is complete.

NO : Return to Step 1.

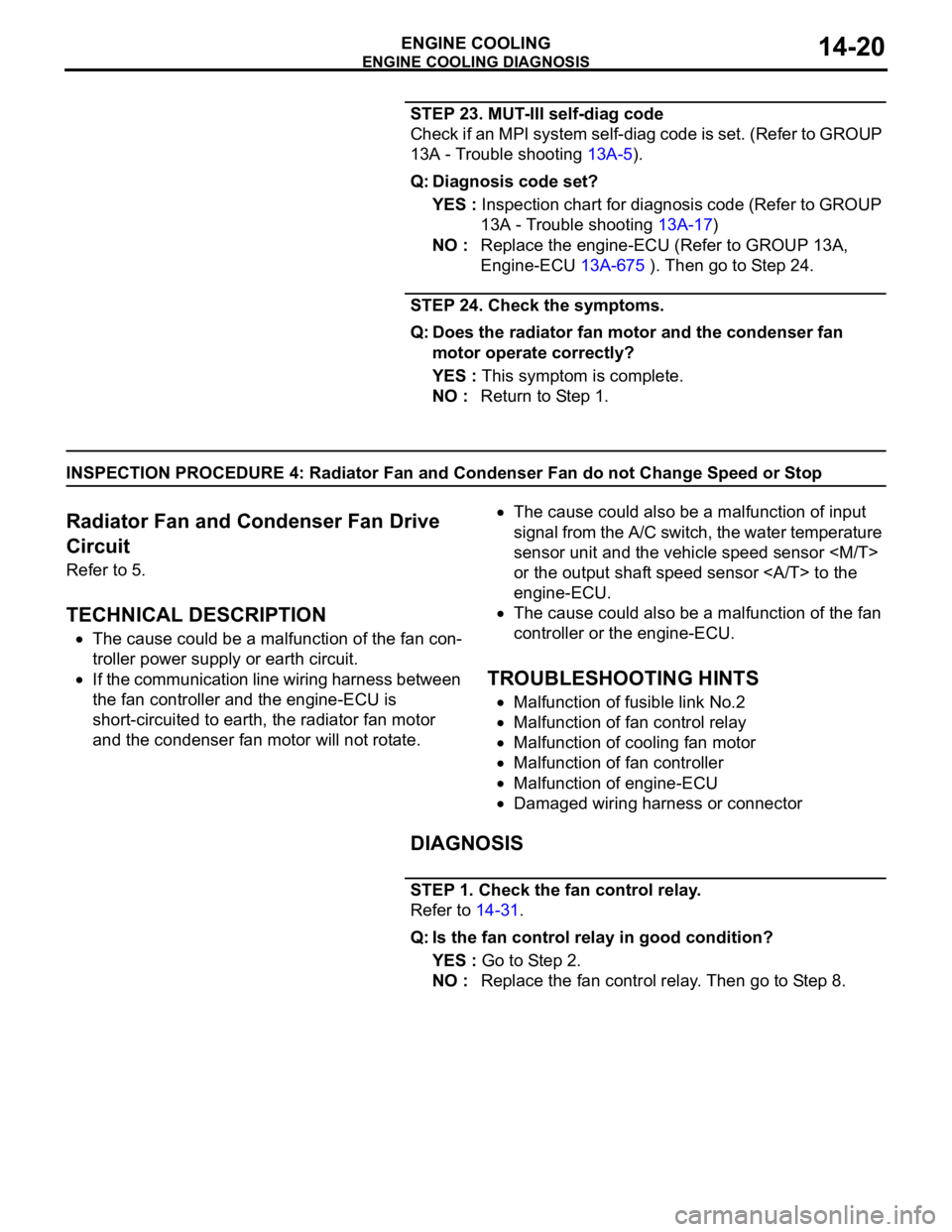

INSPECTION PROCEDURE 4: Radiator Fan and Condenser Fan do not Change Speed or Stop

.

Radiator Fan and Condenser Fan Drive

Circuit

Refer to 5.

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the fan con-

troller power supply or earth circuit.

If the communication line wiring harness between

the fan controller and the engine-ECU is

short-circuited to earth, the radiator fan motor

and the condenser fan motor will not rotate.

The cause could also be a malfunction of input

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU.

The cause could also be a malfunction of the fan

controller or the engine-ECU.

.

TROUBLESHOOTING HINTS

Malfunction of fusible link No.2

Malfunction of fan control relay

Malfunction of cooling fan motor

Malfunction of fan controller

Malfunction of engine-ECU

Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the fan control relay.

Refer to 14-31.

Q: Is the fan control relay in good condition?

YES : Go to Step 2.

NO : Replace the fan control relay. Then go to Step 8.

Page 937 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-22

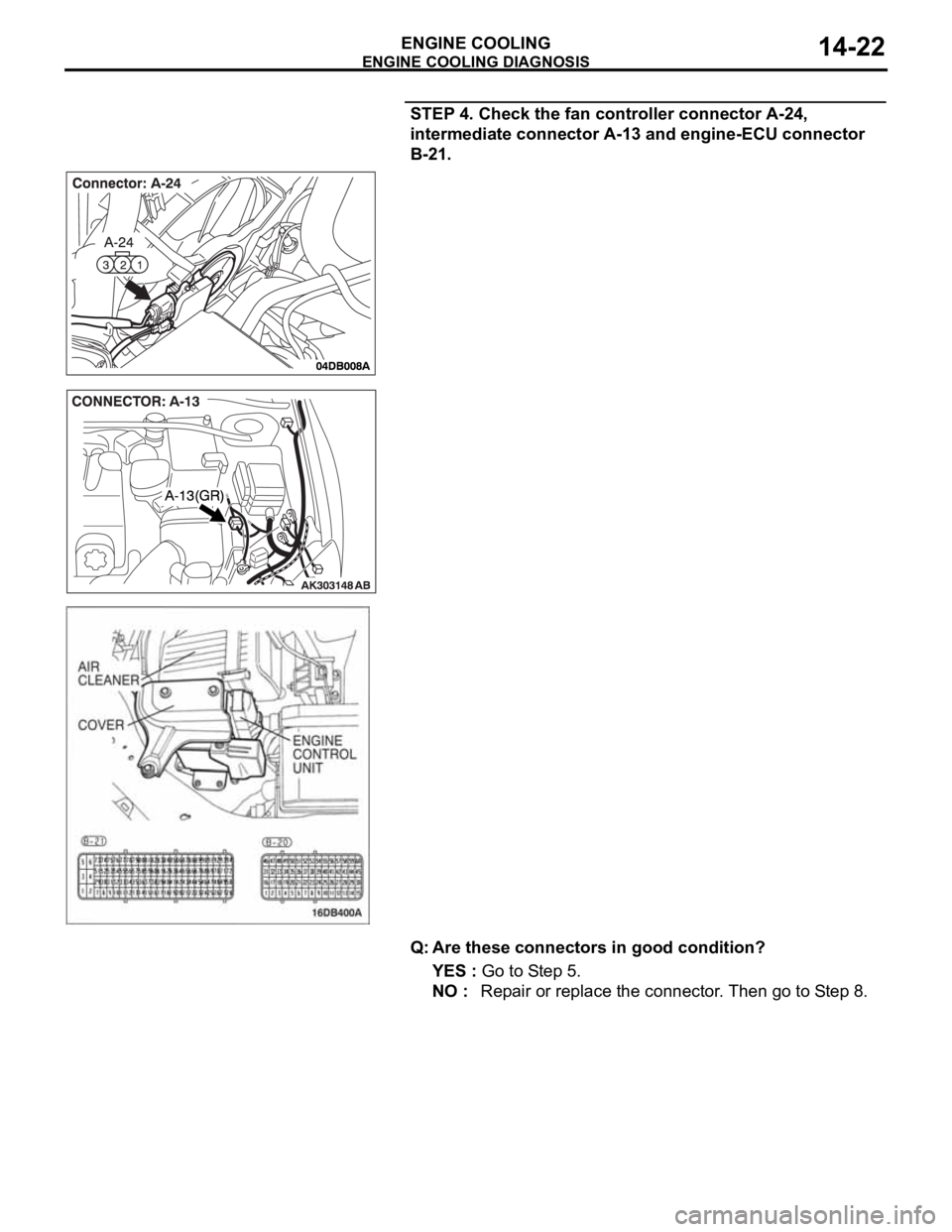

STEP 4. Check the fan controller connector A-24,

intermediate connector A-13 and engine-ECU connector

B-21.

Q: Are these connectors in good condition?

YES : Go to Step 5.

NO : Repair or replace the connector. Then go to Step 8.

Page 938 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-23

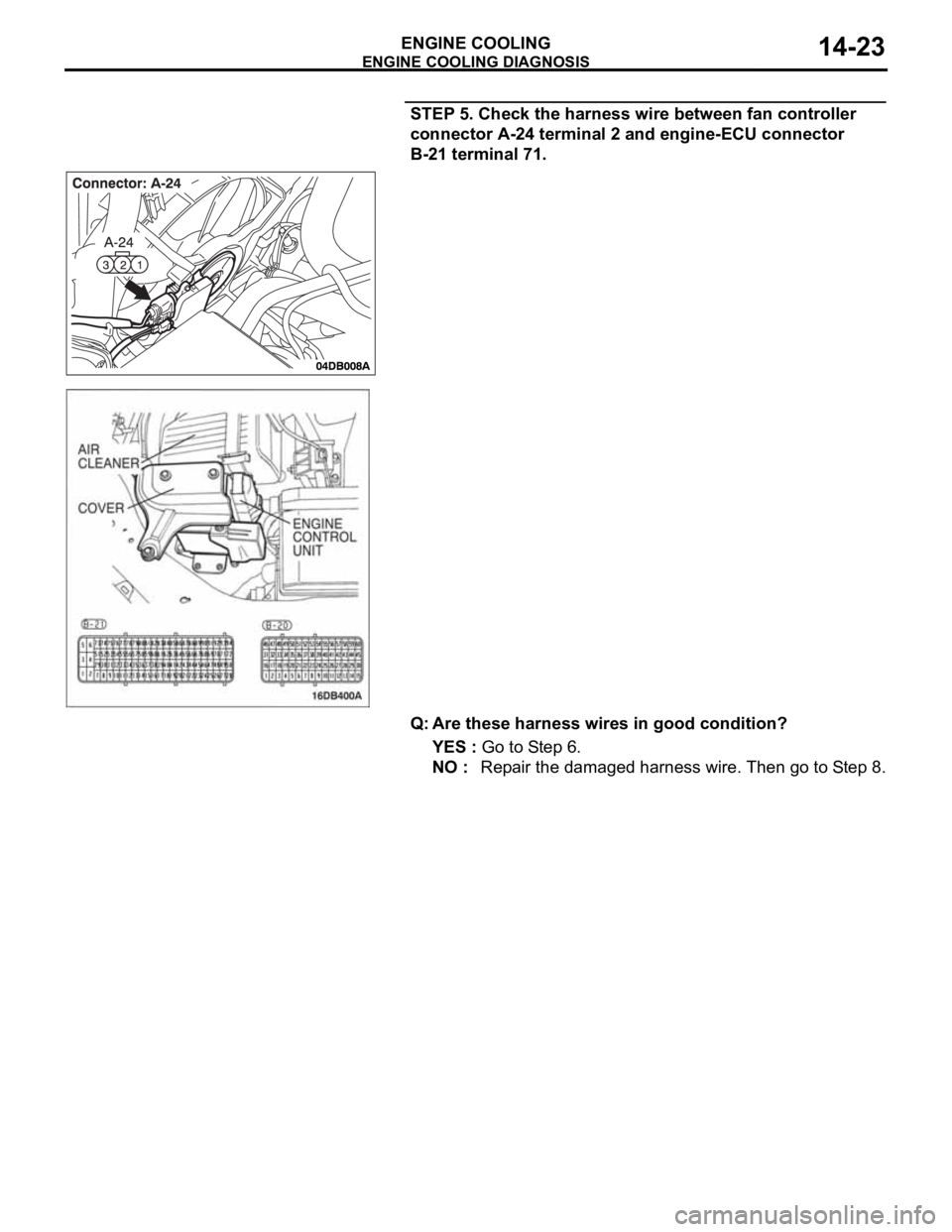

STEP 5. Check the harness wire between fan controller

connector A-24 terminal 2 and engine-ECU connector

B-21 terminal 71.

Q: Are these harness wires in good condition?

YES : Go to Step 6.

NO : Repair the damaged harness wire. Then go to Step 8.

Page 940 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-25

STEP 7. MUT-III self-diag code

Check if an MPI system self-diag code is set. (Refer to GROUP

13A - Trouble shooting 13A-5)

Q: Diagnosis code set?

YES : Inspection chart for diagnosis code (Refer to GROUP

13A - Trouble shooting 13A-5)

NO : Replace the engine-ECU (Refer to GROUP 13A,

Engine-ECU 13A-675 ) Then go to Step 8 .

STEP 8. Check the symptoms.

Q: Does the radiator fan motor and the condenser fan

motor operate correctly?

YES : This symptom is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 5: Radiator Fan does not Operate

.

Radiator Fan and Condenser Fan Drive

Circuit

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the radiator fan

motor or an open circuit between the fan controller

and the radiator fan motor.

.

TROUBLESHOOTING HINTS

Malfunction of radiator fan motor

Malfunction of fan controller

Refer to component locations GROUP-1

Refer to configuration diagrams GROUP-1

Refer to circuit diagrams GROUP-1

DIAGNOSIS

Replace the radiator fan motor and fan controller assembly.

Q: Does the radiator fan operate correctly?

YES : There is no action to be taken?

NO : Repair the wiring harness between the fan controller

and the radiator fan motor.

INSPECTION PROCEDURE 6: Condenser Fan does not Operate

.

Radiator Fan and Condenser Fan Drive

Circuit

.

TECHNICAL DESCRIPTION

The cause could be a malfunction of the condenser

fan motor or fan controller.

.

TROUBLESHOOTING HINTS

Malfunction of condenser fan motor

Malfunction of fan controller

Refer to component locations GROUP-1

Refer to configuration diagrams GROUP-1

Refer to circuit diagrams GROUP-1

Page 943 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-28

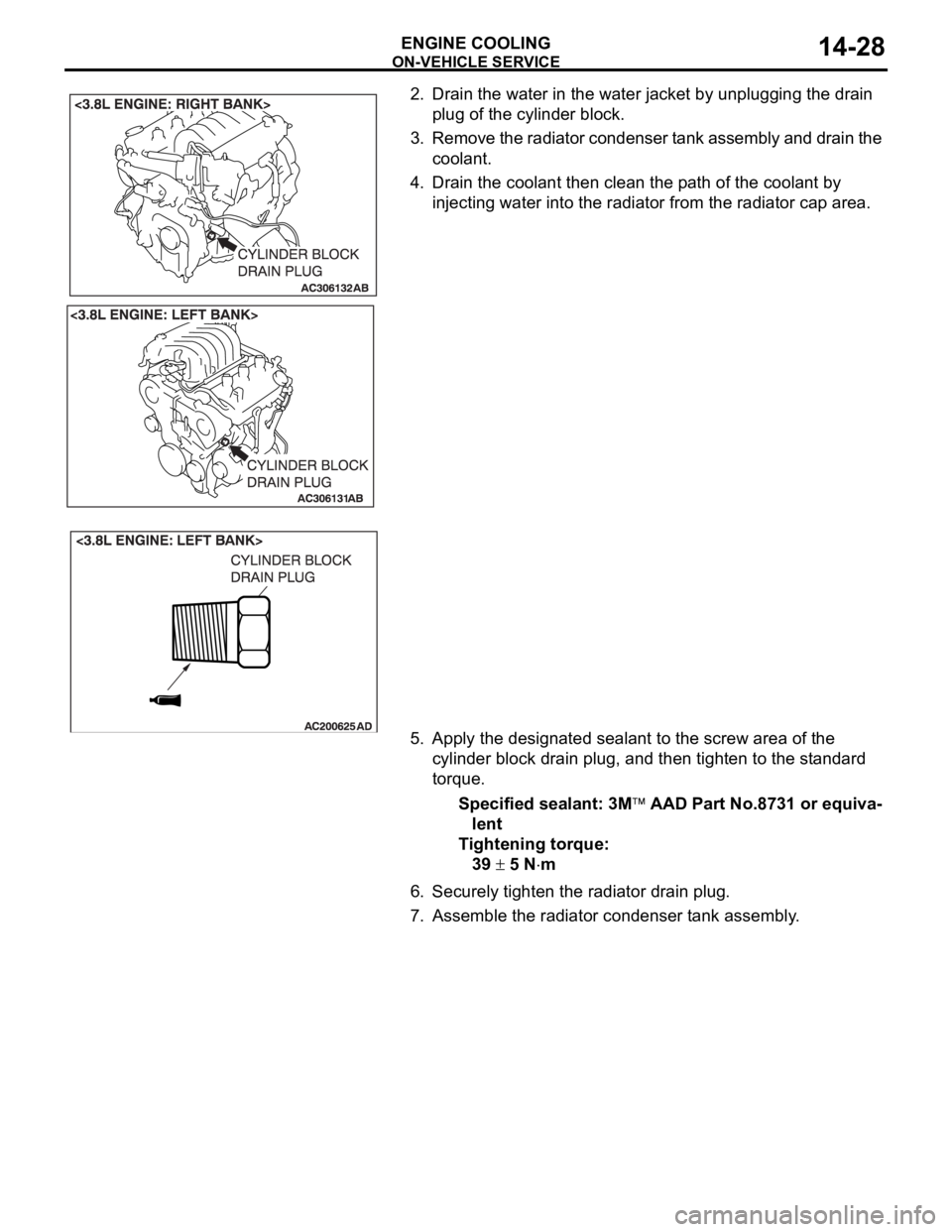

2. Drain the water in the water jacket by unplugging the drain

plug of the cylinder block.

3. Remove the radiator condenser tank assembly and drain the

coolant.

4. Drain the coolant then clean the path of the coolant by

injecting water into the radiator from the radiator cap area.

5. Apply the designated sealant to the screw area of the

cylinder block drain plug, and then tighten to the standard

torque.

Specified sealant: 3M

AAD Part No.8731 or equiva-

lent

Tightening torque:

39

5 Nm

6. Securely tighten the radiator drain plug.

7. Assemble the radiator condenser tank assembly.