park MITSUBISHI 380 2005 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1217 of 1500

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-10

INSTALLATION SERVICE POINTS

.

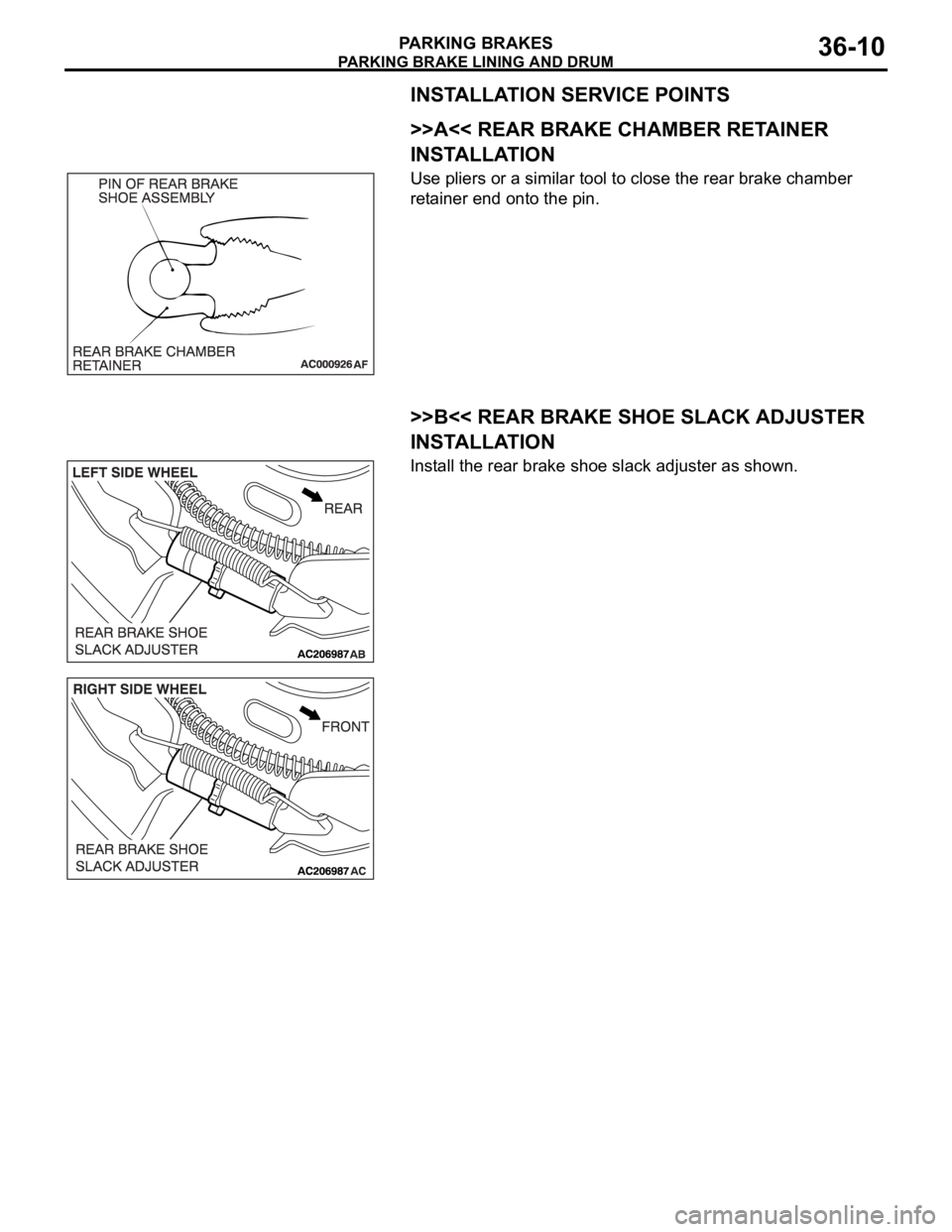

>>A<< REAR BRAKE CHAMBER RETAINER

INSTALLATION

Use pliers or a similar tool to close the rear brake chamber

retainer end onto the pin.

.

>>B<< REAR BRAKE SHOE SLACK ADJUSTER

INSTALLATION

Install the rear brake shoe slack adjuster as shown.

.

Page 1218 of 1500

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-11

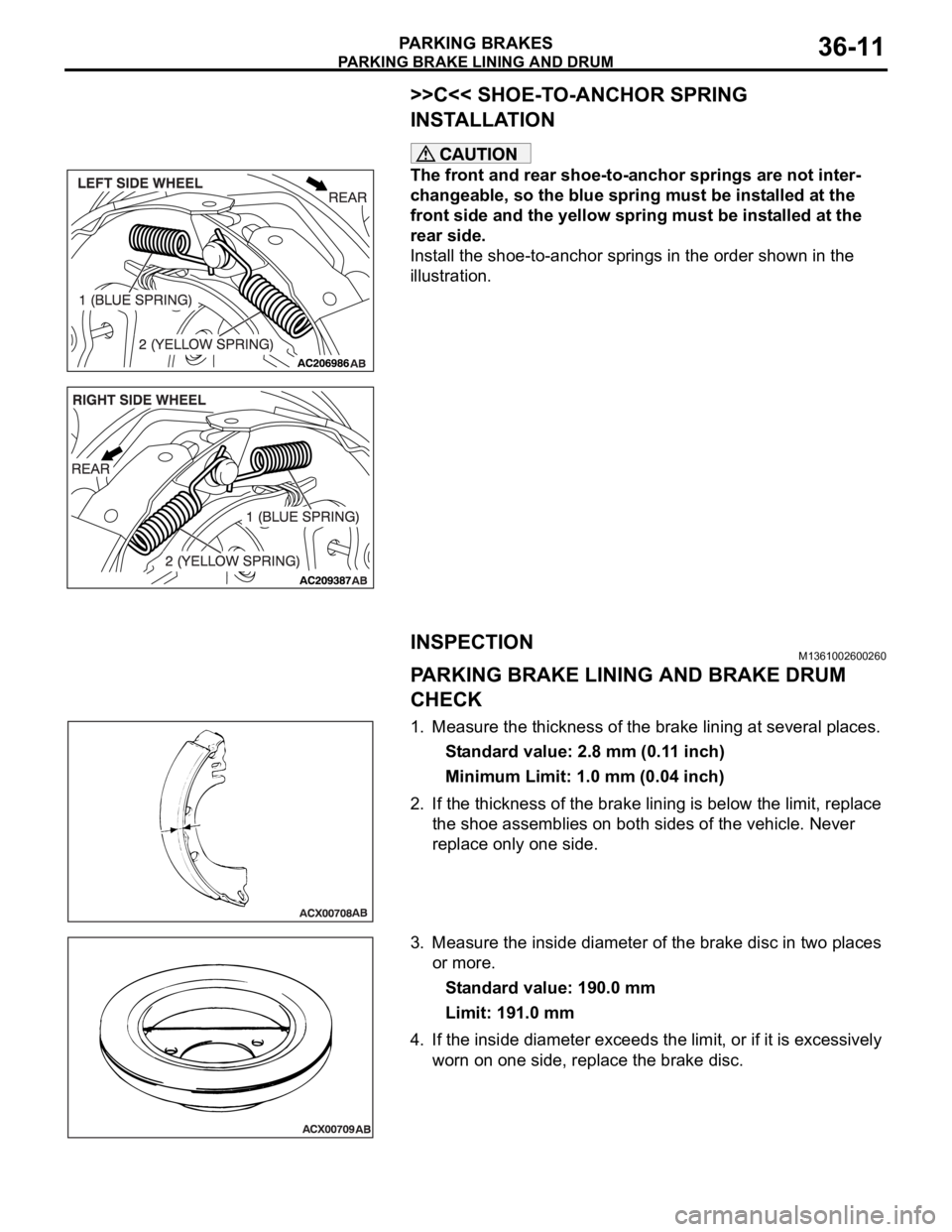

>>C<< SHOE-TO-ANCHOR SPRING

INSTALLATION

The front and rear shoe-to-anchor springs are not inter-

changeable, so the blue spring must be installed at the

front side and the yellow spring must be installed at the

rear side.

Install the shoe-to-anchor springs in the order shown in the

illustration.

INSPECTIONM1361002600260

PARKING BRAKE LINING AND BRAKE DRUM

CHECK

1. Measure the thickness of the brake lining at several places.

Standard value: 2.8 mm (0.11 inch)

Minimum Limit: 1.0 mm (0.04 inch)

2. If the thickness of the brake lining is below the limit, replace

the shoe assemblies on both sides of the vehicle. Never

replace only one side.

3. Measure the inside diameter of the brake disc in two places

or more.

Standard value: 190.0 mm

Limit: 191.0 mm

4. If the inside diameter exceeds the limit, or if it is excessively

worn on one side, replace the brake disc.

Page 1219 of 1500

SPECIFICATIONS

PARKING BRAKES36-12

SPECIFICATIONS

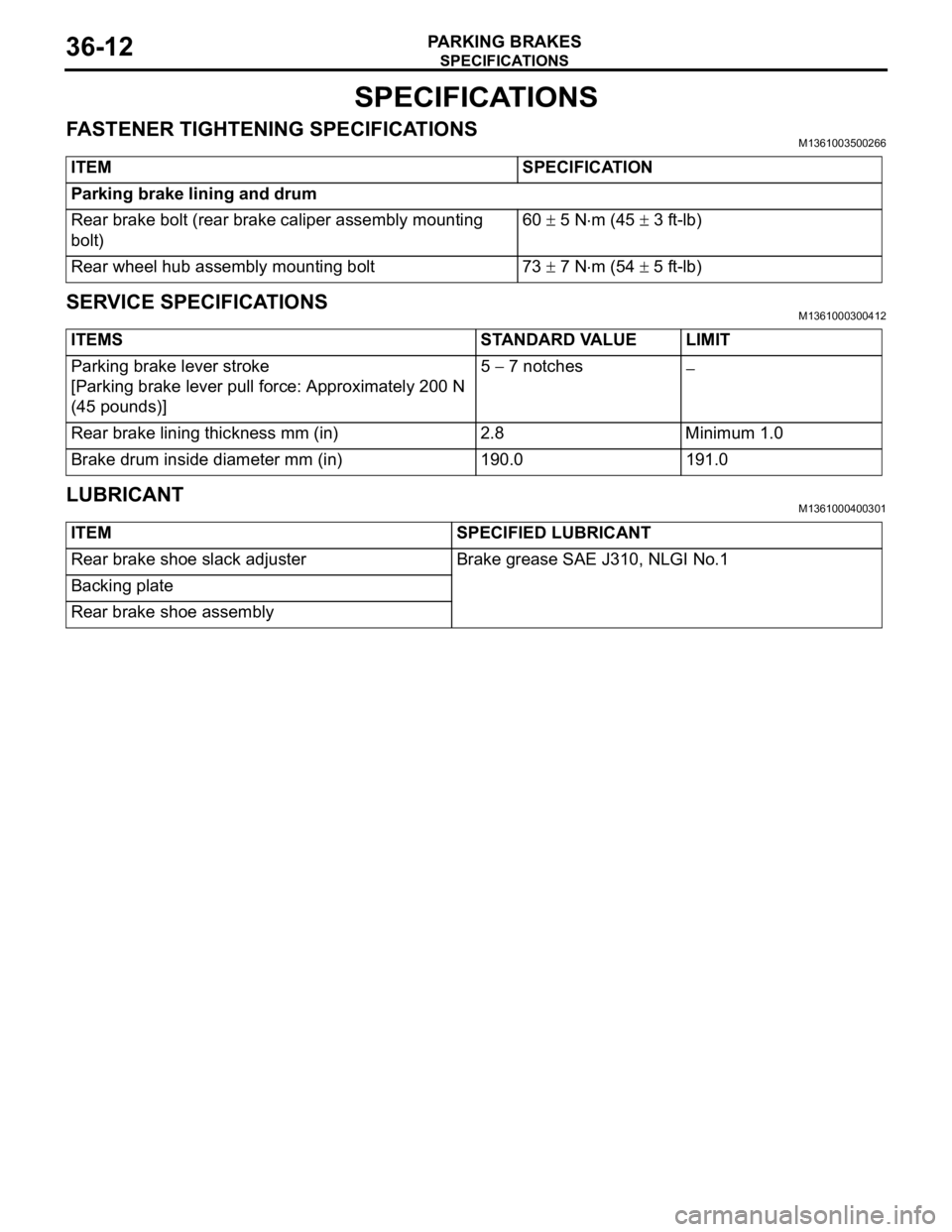

FASTENER TIGHTENING SPECIFICATIONSM1361003500266

SERVICE SPECIFICATIONSM1361000300412

LUBRICANTM1361000400301

ITEM SPECIFICATION

Parking brake lining and drum

Rear brake bolt (rear brake caliper assembly mounting

bolt)60

5 Nm (45 3 ft-lb)

Rear wheel hub assembly mounting bolt 73

7 Nm (54 5 ft-lb)

ITEMS STANDARD VALUE LIMIT

Parking brake lever stroke

[Parking brake lever pull force: Approximately 200 N

(45 pounds)]5

7 notches

Rear brake lining thickness mm (in) 2.8 Minimum 1.0

Brake drum inside diameter mm (in) 190.0 191.0

ITEM SPECIFIED LUBRICANT

Rear brake shoe slack adjuster Brake grease SAE J310, NLGI No.1

Backing plate

Rear brake shoe assembly

Page 1221 of 1500

SPECIFICATIONS

PARKING BRAKES36-14

Page 1223 of 1500

GENERAL00-2

MAINTENANCE SERVICE . . . . . . . .00-37

1. FUEL SYSTEM (TANK, PIPE LINE AND

CONNECTION, AND FUEL TANK FILLER

TUBE CAP) (CHECK FOR LEAKS) . . . . . . 00-37

2. FUEL HOSES (CHECK CONDITION) . . 00-37

3. AIR CLEANER FILTER (REPLACE). . . . 00-37

4. EVAPORATIVE EMISSION SYSTEM

(EXCEPT EVAPORATIVE EMISSION

CANISTER) (CHECK FOR CLOGGING) . . 00-37

5. SPARK PLUGS (REPLACE). . . . . . . . . . 00-38

7. TIMING BELT (REPLACE) . . . . . . . . . . . 00-38

8. DRIVE BELTS (FOR ALTERNATOR, POWER

STEERING PUMP AND AIR CONDITIONING)

(CHECK) . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-39

9. EXHAUST SYSTEM (CONNECTIONS

PORTION OF MUFFLER, MUFFLER PIPES

AND CONVERTER HEAT SHIELDS) (CHECK

AND SERVICE AS REQUIRED) . . . . . . . . . 00-44

10. ENGINE OIL (CHANGE) . . . . . . . . . . . . 00-4411. ENGINE OIL FILTER (REPLACE) . . . . 00-44

12. TRANSMISSION FLUID . . . . . . . . . . . . 00-45

13. ENGINE COOLANT (CHANGE) . . . . . . 00-47

14. COOLANT HOSES (RADIATOR HOSE,

HEATER HOSE) (INSPECT). . . . . . . . . . . . 00-49

15. DISC BRAKE PADS, ROTORS

(INSPECT FOR WEAR) . . . . . . . . . . . . . . . 00-49

16. BRAKE HOSES (CHECK FOR

DETERIORATION OR LEAKS) . . . . . . . . . . 00-49

17. BALL JOINT AND STEERING LINKAGE

SEALS (INSPECT FOR GREASE LEAKS

AND DAMAGE) . . . . . . . . . . . . . . . . . . . . . . 00-50

18. DRIVE SHAFT BOOTS (INSPECT FOR

GREASE LEAKS AND DAMAGE) . . . . . . . . 00-50

19. SUSPENSION SYSTEM (INSPECT FOR

LOOSENESS AND DAMAGE) . . . . . . . . . . 00-51

20. SRS AIR BAG (INSPECT FOR SRS

SYSTEM). . . . . . . . . . . . . . . . . . . . . . . . . . . 00-51

21. TYRES (ROTATE). . . . . . . . . . . . . . . . . 00-58

Page 1239 of 1500

VEHICLE IDENTIFICATION

GENERAL00-18

VEHICLE IDENTIFICATION

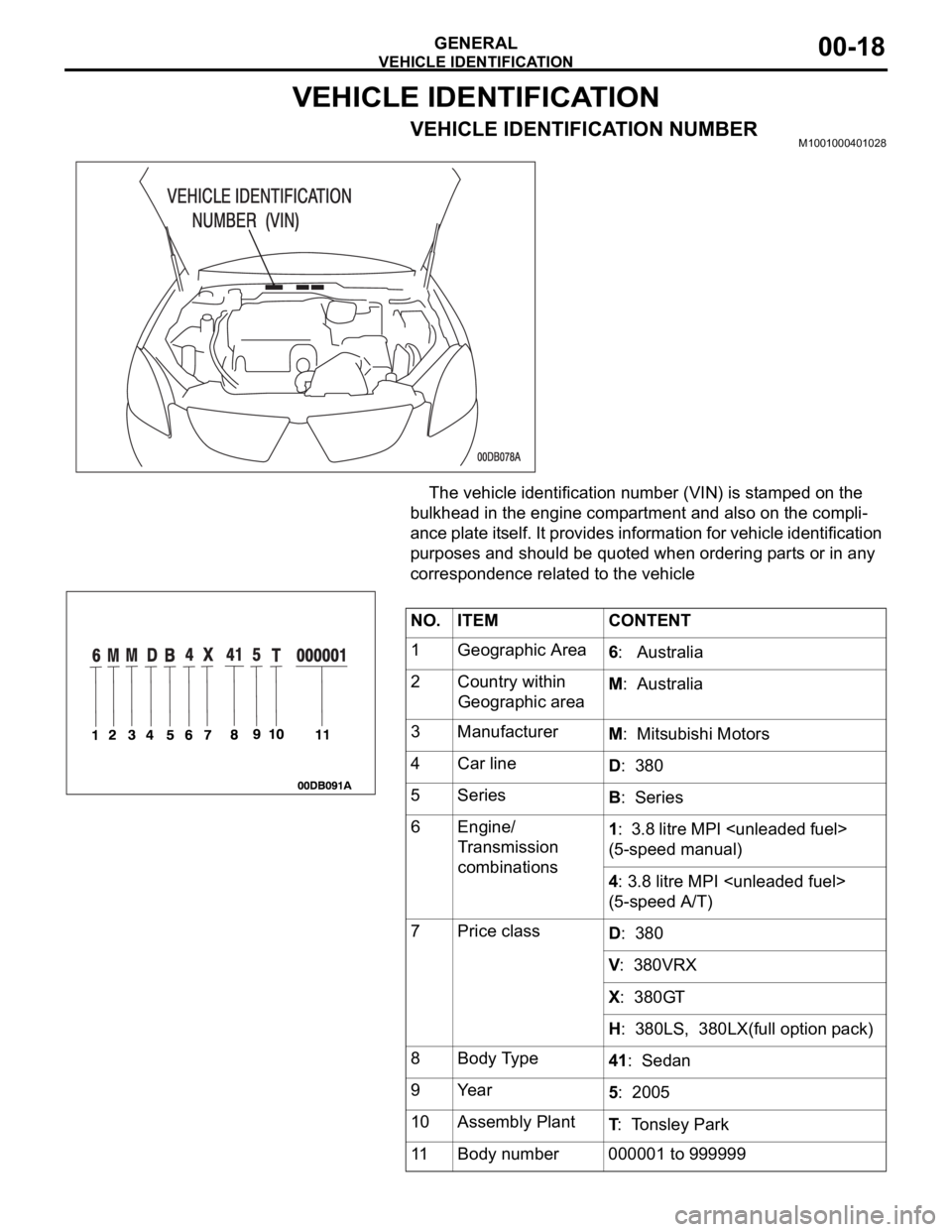

VEHICLE IDENTIFICATION NUMBERM1001000401028

The vehicle identification number (VIN) is stamped on the

bulkhead in the engine compartment and also on the compli-

ance plate itself. It provides information for vehicle identification

purposes and should be quoted when ordering parts or in any

correspondence related to the vehicle

NO. ITEM CONTENT

1 Geographic Area

6: Australia

2 Country within

Geographic areaM: Australia

3 Manufacturer

M: Mitsubishi Motors

4 Car line

D: 380

5Series

B: Series

6 Engine/

Transmission

combinations1: 3.8 litre MPI

(5-speed manual)

4: 3.8 litre MPI

(5-speed A/T)

7Price class

D: 380

V: 380VRX

X: 380GT

H: 380LS, 380LX(full option pack)

8 Body Type

41: Sedan

9Year

5: 2005

10 Assembly Plant

T: Tonsley Park

11 Body number 000001 to 999999

Page 1247 of 1500

TOWING AND HOISTING

GENERAL00-26

TOWING AND HOISTINGM1001000800380

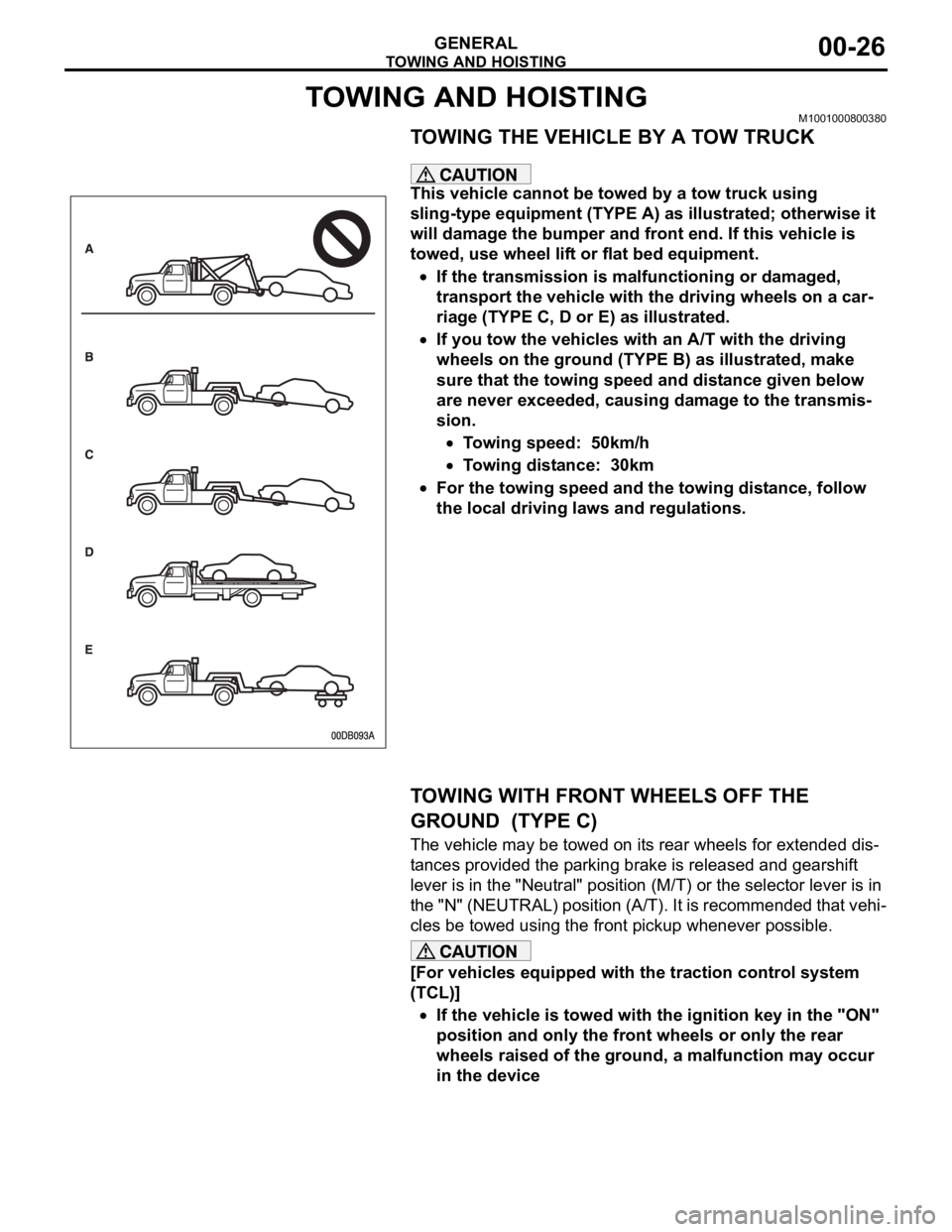

TOWING THE VEHICLE BY A TOW TRUCK

.

This vehicle cannot be towed by a tow truck using

sling-type equipment (TYPE A) as illustrated; otherwise it

will damage the bumper and front end. If this vehicle is

towed, use wheel lift or flat bed equipment.

If the transmission is malfunctioning or damaged,

transport the vehicle with the driving wheels on a car-

riage (TYPE C, D or E) as illustrated.

If you tow the vehicles with an A/T with the driving

wheels on the ground (TYPE B) as illustrated, make

sure that the towing speed and distance given below

are never exceeded, causing damage to the transmis-

sion.

Towing speed: 50km/h

Towing distance: 30km

For the towing speed and the towing distance, follow

the local driving laws and regulations.

.

TOWING WITH FRONT WHEELS OFF THE

GROUND (TYPE C)

The vehicle may be towed on its rear wheels for extended dis-

tances provided the parking brake is released and gearshift

lever is in the "Neutral" position (M/T) or the selector lever is in

the "N" (NEUTRAL) position (A/T). It is recommended that vehi-

cles be towed using the front pickup whenever possible.

[For vehicles equipped with the traction control system

(TCL)]

If the vehicle is towed with the ignition key in the "ON"

position and only the front wheels or only the rear

wheels raised of the ground, a malfunction may occur

in the device

.

Page 1248 of 1500

TOWING AND HOISTING

GENERAL00-27

TOWING WITH REAR WHEELS OFF THE

GROUND (TYPE B)

Place the gearshift lever in the "Neutral" position (M/T) or the

selector lever in the "N" (NEUTRAL) position (A/T). Turn the

ignition key to the "ACC" position and secure the steering

wheel in a straight-ahead position with a rope or tie-down strap.

Never place the ignition key in the "LOCK" position when tow-

ing.

Never tow an A/T vehicle with the rear wheels up (and

the front wheels on the ground) when the automatic

transmission fluid level is low. this may cause serious

and expensive damage to the transmission.

Do not use the steering column lock to secure the front

wheels for towing.

Make sure the transaxle is in Neutral if vehicle will have

drive wheels on the ground.

If these requirements cannot be met, the front wheels

must be placed on a tow dolly.

.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not avail-

able, the vehicle may be lifted and towed from the front, pro-

vided the parking brake is released. If not released, the rear

wheels should be placed on a tow dolly.

.

SAFETY PRECAUTIONS

The following precautions should be taken when towing the

vehicle:

1. DO NOT LIFT OR TOW THE VEHICLE BY ATTACHING

TO OR WRAPPING AROUND THE BUMPER.

2. Any loose, protruding, or damaged parts such as hoods,

doors, fenders, trim, etc. should be secured or removed

prior to moving the vehicle.

Page 1259 of 1500

MAINTENANCE SERVICE

GENERAL00-38

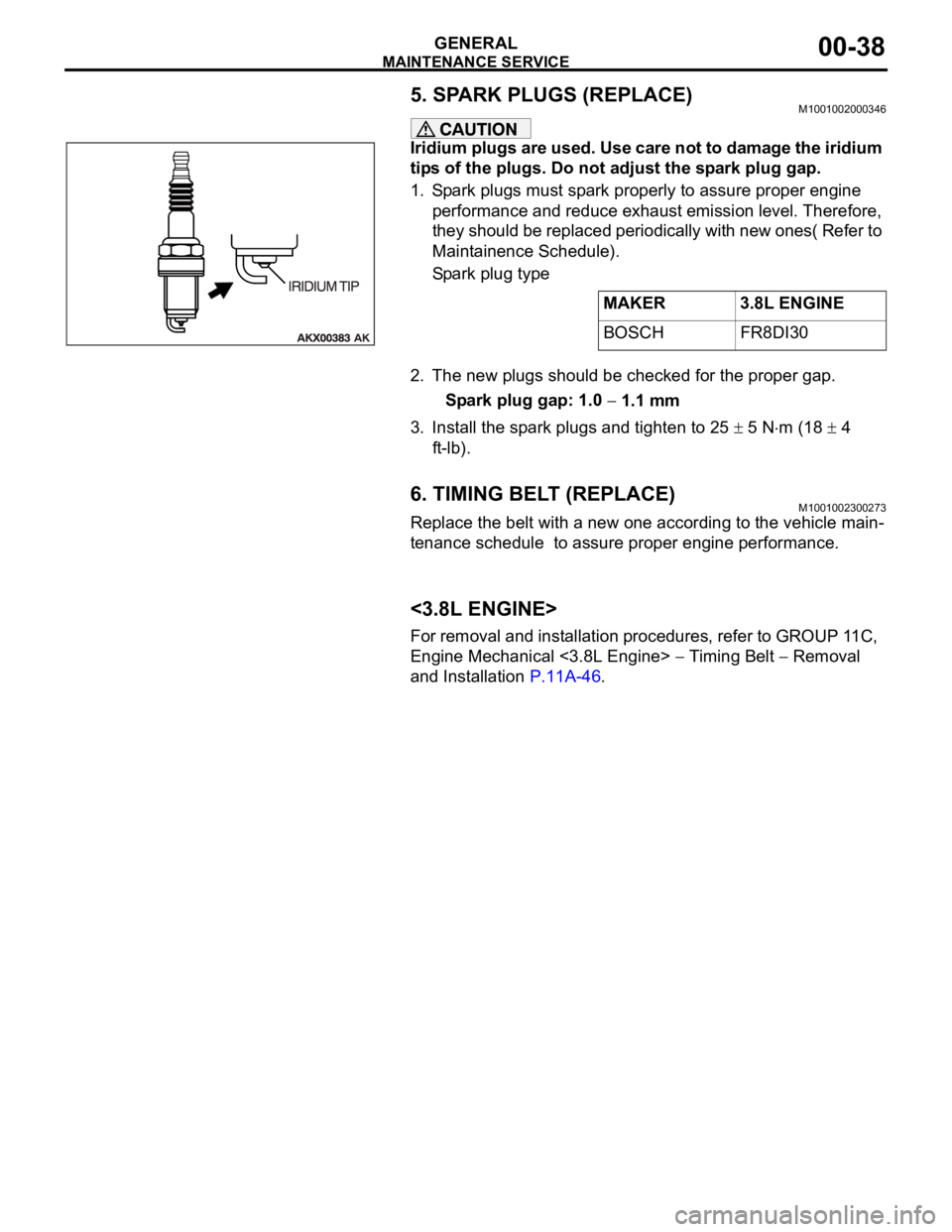

5. SPARK PLUGS (REPLACE)M1001002000346

Iridium plugs are used. Use care not to damage the iridium

tips of the plugs. Do not adjust the spark plug gap.

1. Spark plugs must spark properly to assure proper engine

performance and reduce exhaust emission level. Therefore,

they should be replaced periodically with new ones( Refer to

Maintainence Schedule).

Spark plug type

2. The new plugs should be checked for the proper gap.

Spark plug gap: 1.0

1.1 mm

3. Install the spark plugs and tighten to 25

5 Nm (18 4

ft-lb).

6. TIMING BELT (REPLACE)M1001002300273

Replace the belt with a new one according to the vehicle main-

tenance schedule to assure proper engine performance.

<3.8L ENGINE>

For removal and installation procedures, refer to GROUP 11C,

Engine Mechanical <3.8L Engine>

Timing Belt Removal

and Installation P.11A-46.MAKER 3.8L ENGINE

BOSCH FR8DI30

Page 1267 of 1500

![MITSUBISHI 380 2005 Service Manual MAINTENANCE SERVICE

GENERAL00-46

NOTE: If it takes some amount of time until the transmission

fluid reaches its normal operating temperature [70

80C

(158

176F)], check the transmission fluid lev MITSUBISHI 380 2005 Service Manual MAINTENANCE SERVICE

GENERAL00-46

NOTE: If it takes some amount of time until the transmission

fluid reaches its normal operating temperature [70

80C

(158

176F)], check the transmission fluid lev](/img/19/57086/w960_57086-1266.png)

MAINTENANCE SERVICE

GENERAL00-46

NOTE: If it takes some amount of time until the transmission

fluid reaches its normal operating temperature [70

80C

(158

176F)], check the transmission fluid level by refer-

ring to the left diagram.

2. Park the vehicle on a level surface.

3. Move the selector lever through all positions to fill the torque

converter and the hydraulic circuits with fluid, and then move

the selector lever to the "N" position.

4. After wiping off any dirt around the dipstick, remove the

dipstick and check the condition of the transmission fluid.

NOTE: If the transmission fluid smells as if it is burnt, it

means that the transmission fluid has been contaminated by

fine particles from the bushings and friction materials. Tran-

saxle overhaul and cooler line flushing may be necessary.

5. Check transmission fluid level is at the "HOT" mark on the

dipstick. If the transmission fluid level is less than this, add

DIAMOND ATF SP III until the level reaches the "HOT"

mark.

NOTE: If the transmission fluid level is too low, the oil pump

will draw in air along with the transmission fluid, which will

cause to form bubbles. If the transmission fluid level is too

high, rotating components inside the transaxle will churn the

fluid and air into a foamy liquid. Both conditions (level too

low or too high) will cause the hydraulic pressure to drop,

which will result in late shifting and slipping of the clutches

and brakes.

NOTE: In either case, air bubbles can interfere with normal

valve, clutch, and brake operation. Also, foaming can cause

transmission fluid to escape from the transaxle vent where it

may be mistaken for a leak.