steering MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 14 of 1500

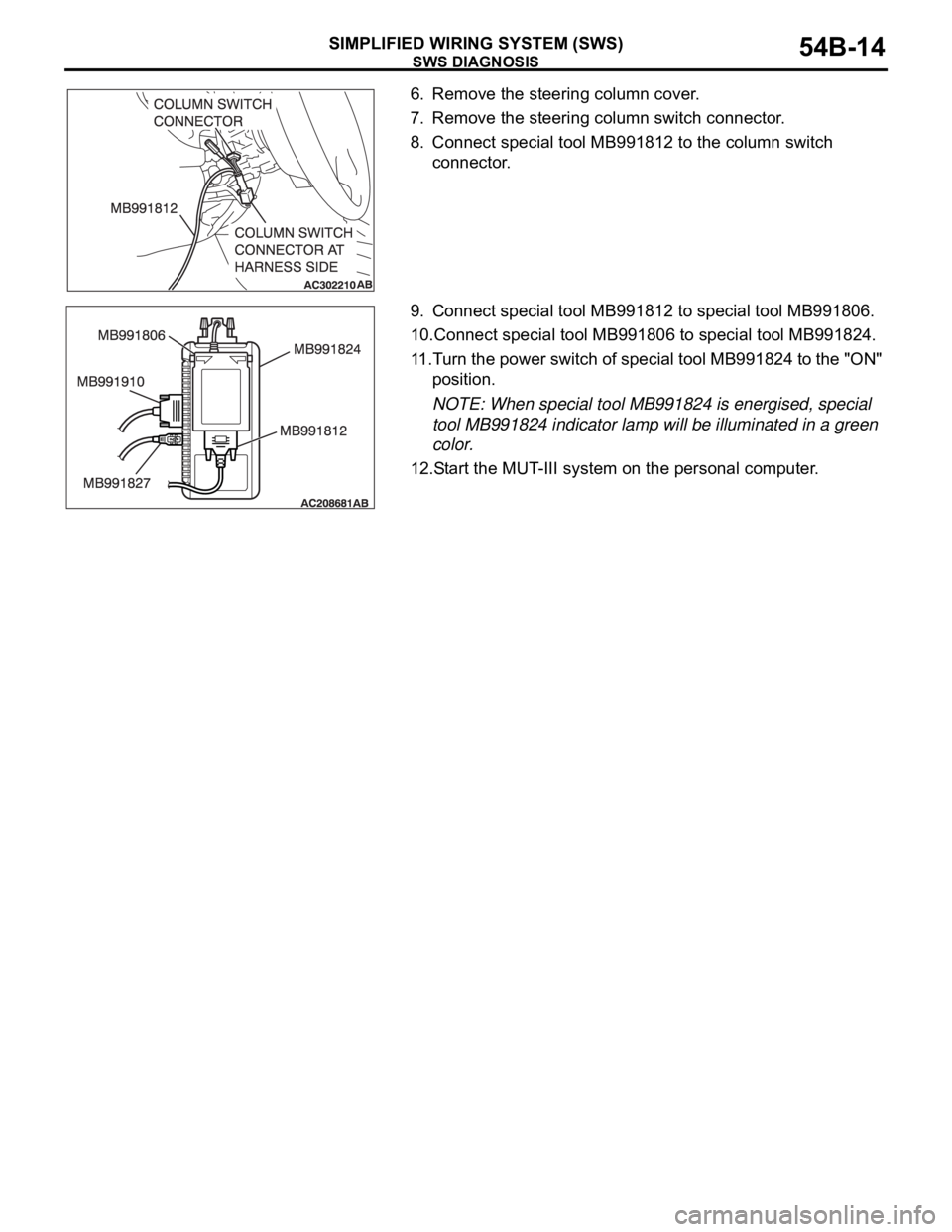

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-14

6. Remove the steering column cover.

7. Remove the steering column switch connector.

8. Connect special tool MB991812 to the column switch

connector.

9. Connect special tool MB991812 to special tool MB991806.

10.Connect special tool MB991806 to special tool MB991824.

11.Turn the power switch of special tool MB991824 to the "ON"

position.

NOTE: When special tool MB991824 is energised, special

tool MB991824 indicator lamp will be illuminated in a green

color.

12.Start the MUT-III system on the personal computer.

Page 495 of 1500

INSTRUMENT PANEL ASSEMBLY

INTERIOR52A-6

6. RADIO AND CD PLAYER,

ASSEMBLY

7. RADIO, CD PLAYER AND CD

CHANGER ASSEMBLY

8. CONSOLE METER HOOD

11. MULTI-CENTER DISPLAY

ASSEMBLY

12. INSTRUMENT DIGITAL CLOCK

ASSEMBLY

13. CENTER CONSOLE ASSEMBLY

14. INSTURMENT PANEL GARNISH

15. COMBINATION METER

ASSEMBLY

FRONT PILLAR TRIM (REFER TO

P.52A-11.)

16. FRONT SPEAKER GARNISH

17. TWEETER

18. INSTRUMENT PANEL SIDE

COVER

19. INSTRUMETN PANEL SIDE AIR

OUTLET

AIR BAG MODULE ASSEMBLY

(DRIVER’S SIDE) (REFER TO

GROUP 52B, AIR BAG MODULE

AND CLOCK SPRING P.52B-237.)

STEERING WHEEL ASSEMBLY

(REFER TO GROUP 37,

STEERING WHEEL P.37-23.)

20. STEERING COLUMN COVERREMOVAL STEPS (Continued)

<>CLOCK SPRING CONNECTOR

<>COLUMN SWITHC CONNECTOR

CLOCK SPRING AND COLUMN

SWITCH ASSEMBLY (REFER TO

GROUP 37, STEERING SHAFT

P.37-25.)

21. INTERIOR TEMPERATURE

SENSOR (GROUP 55B,

SENSORS 55-160.)

22. INSTRUMENT PANEL FRONT

END GARNISH

23. PHOTO SENSOR (GROUP 55B,

SENSORS 55-160.) AND

SECURITY LED.

FLOOR CONSOLE ASSEMBLY

(REFER TO P.52A-10.)

COWL SIDE TRIM (REFER TO

P.52A-11.)

<>AIR BAG MODULE CONNECTOR

(PASSENGER’S SIDE) (REFER

TO GROUP 52B, AIR BAG

MODULE AND CLOCK SPRING

P.52B-237.)

25. INSTRUMENT PANEL ASSEMBLYREMOVAL STEPS (Continued)

Page 556 of 1500

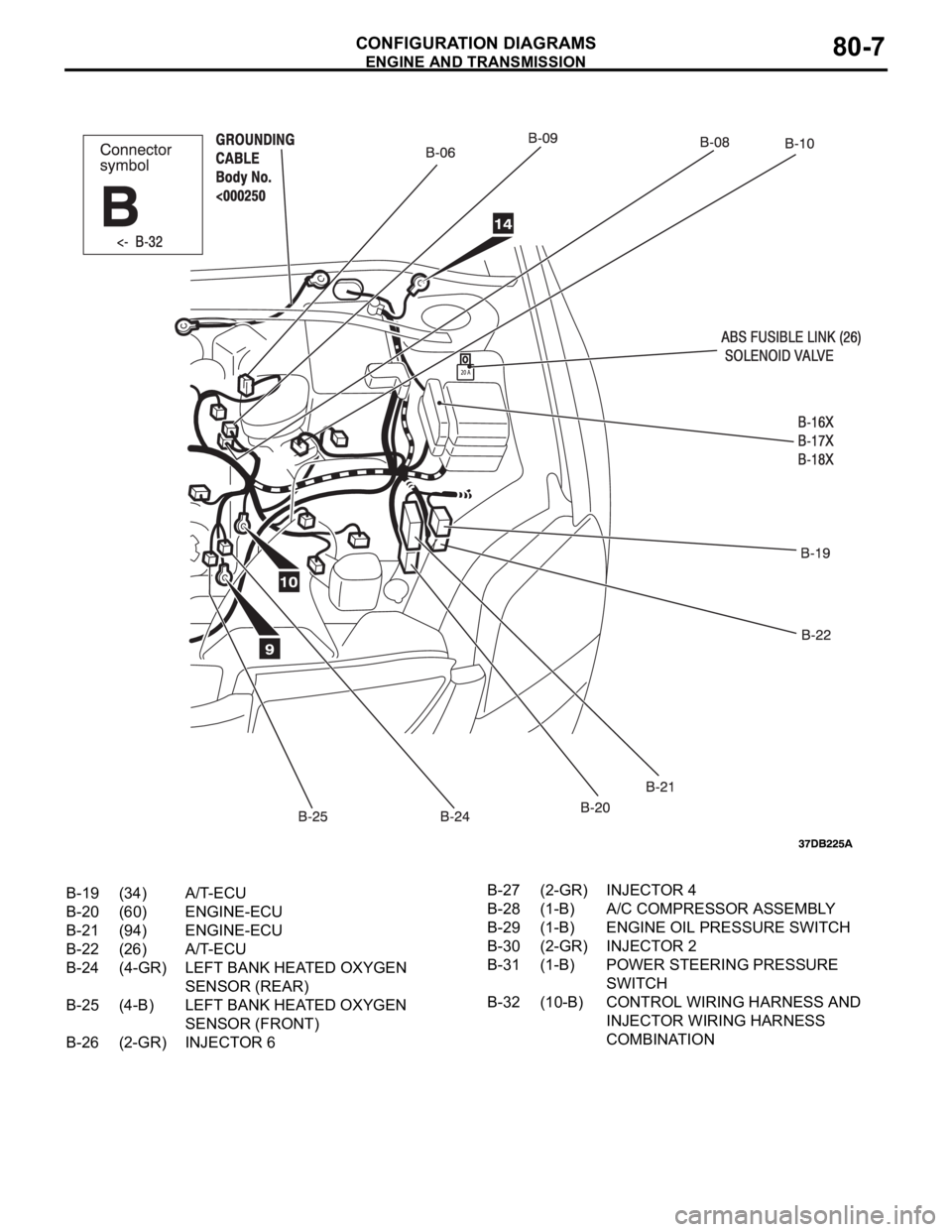

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-7

B-19 (34) A/T-ECU

B-20 (60) ENGINE-ECU

B-21 (94) ENGINE-ECU

B-22 (26) A/T-ECU

B-24 (4-GR) LEFT BANK HEATED OXYGEN

SENSOR (REAR)

B-25 (4-B) LEFT BANK HEATED OXYGEN

SENSOR (FRONT)

B-26 (2-GR) INJECTOR 6B-27 (2-GR) INJECTOR 4

B-28 (1-B) A/C COMPRESSOR ASSEMBLY

B-29 (1-B) ENGINE OIL PRESSURE SWITCH

B-30 (2-GR) INJECTOR 2

B-31 (1-B) POWER STEERING PRESSURE

SWITCH

B-32 (10-B) CONTROL WIRING HARNESS AND

INJECTOR WIRING HARNESS

COMBINATION

Page 847 of 1500

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION55-146

Sharper bends will reduce the flow of refrigerant. The flexible

hose lines should be routed so that they are at least 80 mm

(3.1 inches) from the exhaust manifold. It is good practice to

inspect all flexible hose lines at least once a year to make sure

they are in good condition and properly routed.

On standard plumbing fittings with O-rings, these O-rings are

not reusable.

AIR CONDITIONING NOISE TEST

You must first know the conditions when the noise occurs.

These conditions are: weather, vehicle speed, in gear or neu-

tral, engine temperature or any other special conditions.

Noises that develop during A/C operation can often be mislead-

ing. For example: what sounds like a failed front bearing or

connecting rod, may be caused by loose bolts, nuts, mounting

brackets, or a loose clutch assembly. Verify accessory drive

belt tension (power steering or generator).

Improper accessory drive belt tension can cause a misleading

noise when the compressor is engaged and little or no noise

when the compressor is disengaged.

Drive belts are speed-sensitive. That is, at different engine

speeds, and depending upon belt tension, belts can develop

unusual noises that are often mistaken for mechanical prob-

lems within the compressor.

Normal air conditioning operation will generate some level of

operational noise. To judge what is normal and abnormal,

requires an understanding of the air conditioning system. This

test is to detail the most common noise complaints and the

repair methods.

VEHICLE CONDITION

1. Ensure the system is not over or under charged.(Refer to

P.55-142).

2. Tighten all compressor mounting bolts, clutch mounting

bolts and compressor drive belt.

3. Inspect layout of the system is correct, ie no interference

between hoses and all retaining clamps are in place.

Page 850 of 1500

ON-VEHICLE SERVICE

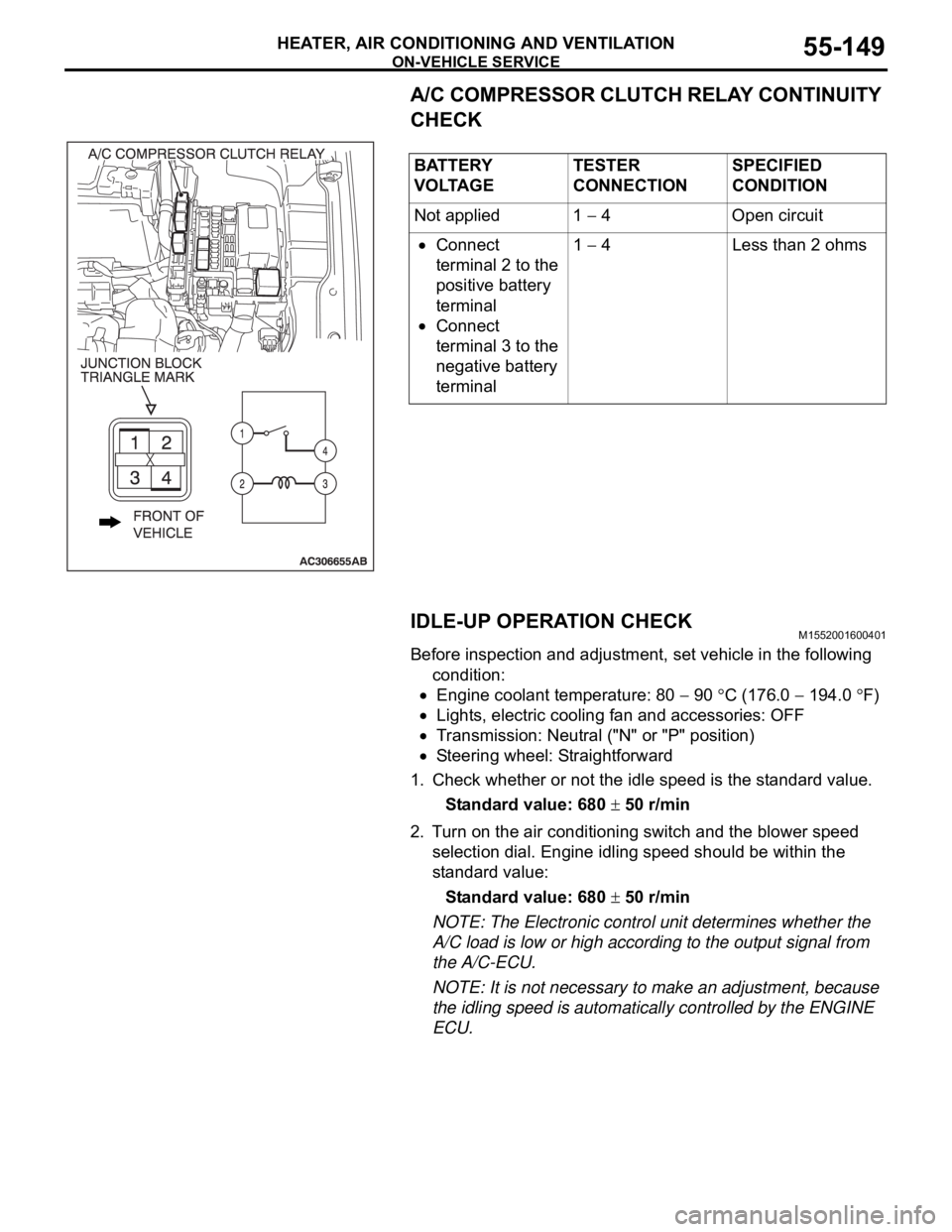

HEATER, AIR CONDITIONING AND VENTILATION55-149

A/C COMPRESSOR CLUTCH RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600401

Before inspection and adjustment, set vehicle in the following

condition:

Engine coolant temperature: 80 90 C (176.0 194.0 F)

Lights, electric cooling fan and accessories: OFF

Transmission: Neutral ("N" or "P" position)

Steering wheel: Straightforward

1. Check whether or not the idle speed is the standard value.

Standard value: 680

50 r/min

2. Turn on the air conditioning switch and the blower speed

selection dial. Engine idling speed should be within the

standard value:

Standard value: 680

50 r/min

NOTE: The Electronic control unit determines whether the

A/C load is low or high according to the output signal from

the A/C-ECU.

NOTE: It is not necessary to make an adjustment, because

the idling speed is automatically controlled by the ENGINE

ECU. BATTERY

V O LTA G ETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 1

4 Open circuit

Connect

terminal 2 to the

positive battery

terminal

Connect

terminal 3 to the

negative battery

terminal1

4 Less than 2 ohms

Page 852 of 1500

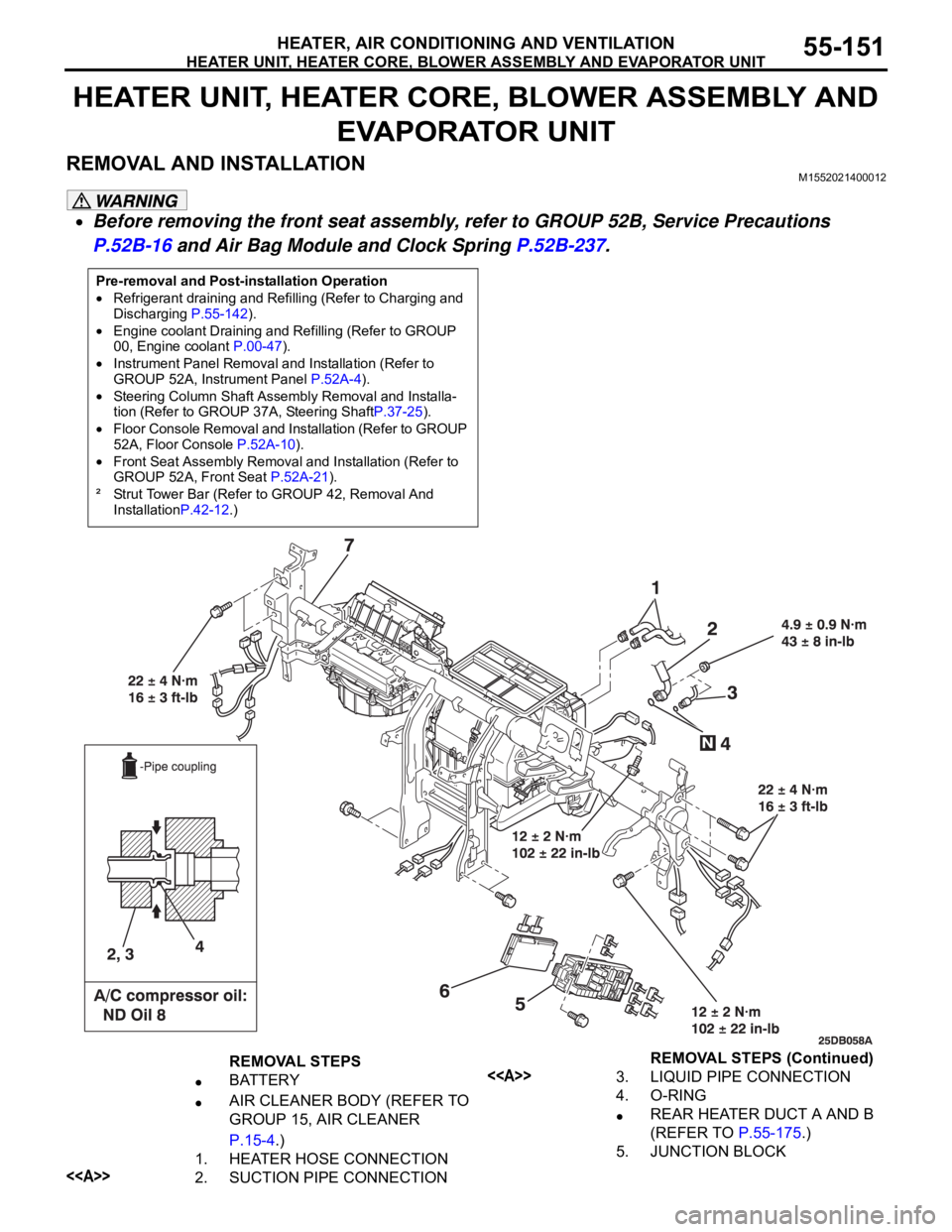

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONING AND VENTILATION55-151

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND

EVAPORATOR UNIT

REMOVAL AND INSTALLATIONM1552021400012

Before removing the front seat assembly, refer to GROUP 52B, Service Precautions

P.52B-16 and Air Bag Module and Clock Spring P.52B-237.

Pre-removal and Post-installation Operation

Refrigerant draining and Refilling (Refer to Charging and

Discharging P.55-142).

Engine coolant Draining and Refilling (Refer to GROUP

00, Engine coolant P.00-47).

Instrument Panel Removal and Installation (Refer to

GROUP 52A, Instrument Panel P.52A-4).

Steering Column Shaft Assembly Removal and Installa-

tion (Refer to GROUP 37A, Steering ShaftP.37-25).

Floor Console Removal and Installation (Refer to GROUP

52A, Floor Console P.52A-10).

Front Seat Assembly Removal and Installation (Refer to

GROUP 52A, Front Seat P.52A-21).

² Strut Tower Bar (Refer to GROUP 42, Removal And

InstallationP.42-12.)

REMOVAL STEPS

BATTERY

AIR CLEANER BODY (REFER TO

GROUP 15, AIR CLEANER

P.15-4.)

1. HEATER HOSE CONNECTION

<>2. SUCTION PIPE CONNECTION

<>3. LIQUID PIPE CONNECTION

4. O-RING

REAR HEATER DUCT A AND B

(REFER TO P.55-175.)

5. JUNCTION BLOCKREMOVAL STEPS (Continued)

Page 868 of 1500

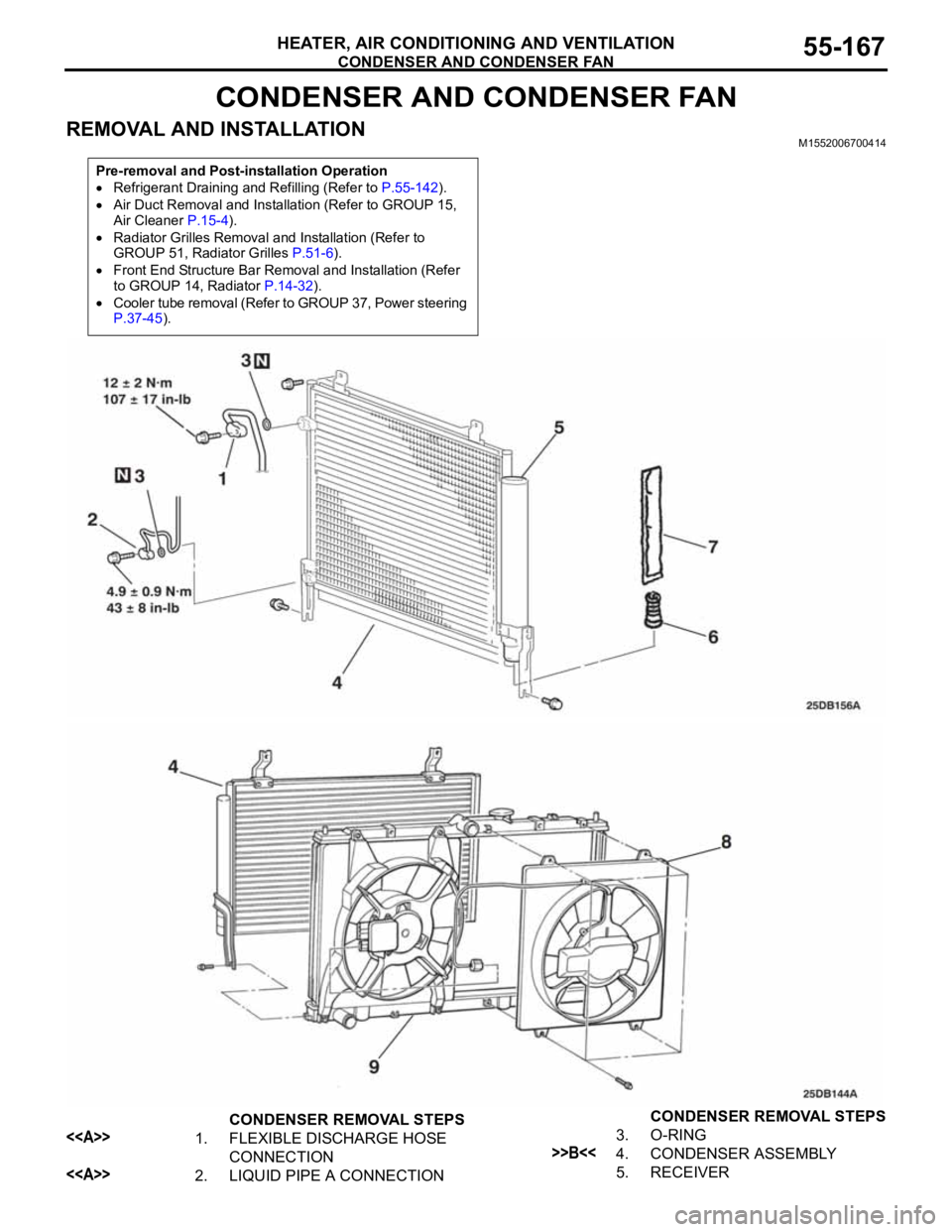

CONDENSER AND CONDENSER FAN

HEATER, AIR CONDITIONING AND VENTILATION55-167

CONDENSER AND CONDENSER FAN

REMOVAL AND INSTALLATIONM1552006700414

Pre-removal and Post-installation Operation

Refrigerant Draining and Refilling (Refer to P.55-142).

Air Duct Removal and Installation (Refer to GROUP 15,

Air Cleaner P.15-4).

Radiator Grilles Removal and Installation (Refer to

GROUP 51, Radiator Grilles P.51-6).

Front End Structure Bar Removal and Installation (Refer

to GROUP 14, Radiator P.14-32).

Cooler tube removal (Refer to GROUP 37, Power steering

P.37-45).

CONDENSER REMOVAL STEPS

<>1. FLEXIBLE DISCHARGE HOSE

CONNECTION

<>2. LIQUID PIPE A CONNECTION3. O-RING

>>B<<4. CONDENSER ASSEMBLY

5. RECEIVER CONDENSER REMOVAL STEPS

Page 897 of 1500

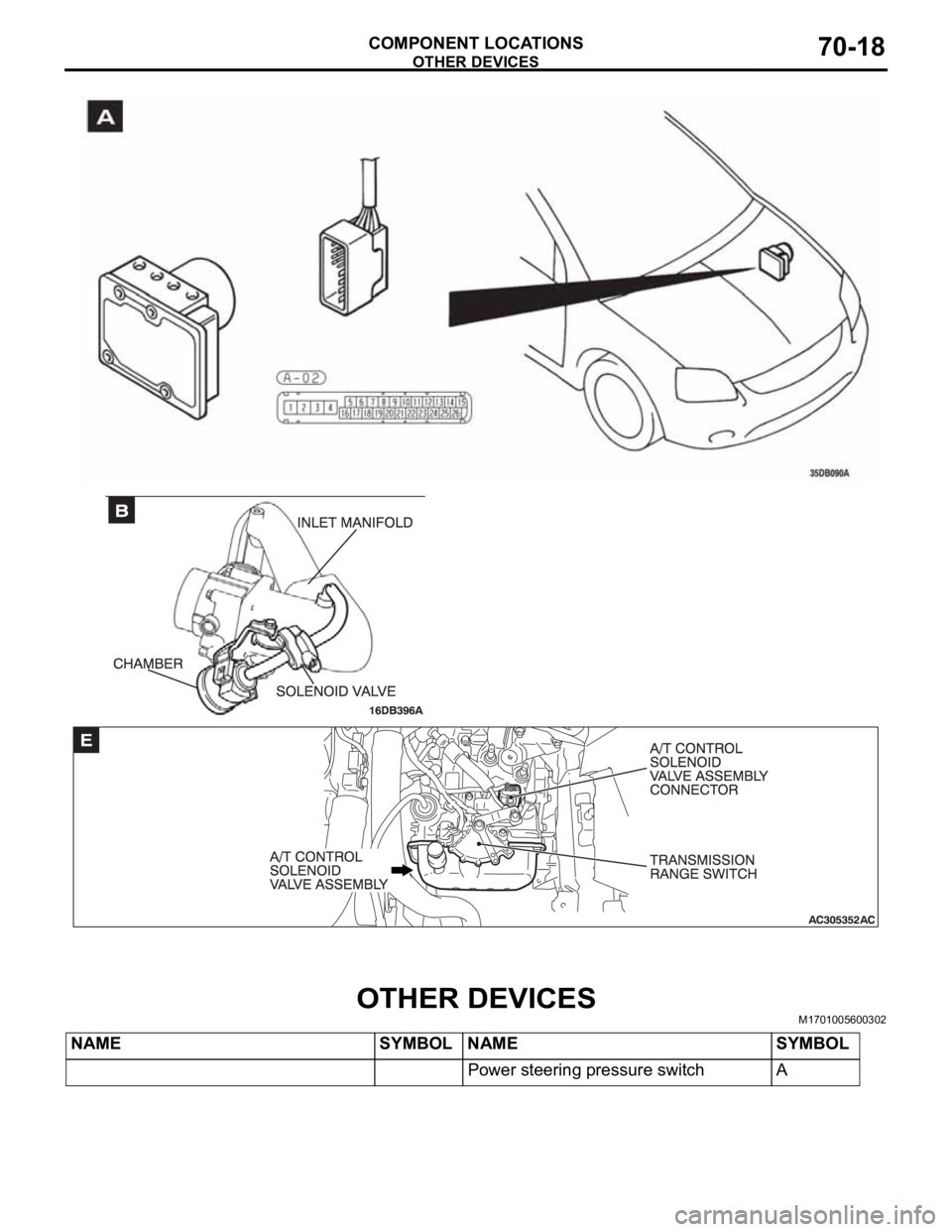

OTHER DEVICES

COMPONENT LOCATIONS70-18

OTHER DEVICESM1701005600302

NAME SYMBOL NAME SYMBOL

Power steering pressure switch A

Page 950 of 1500

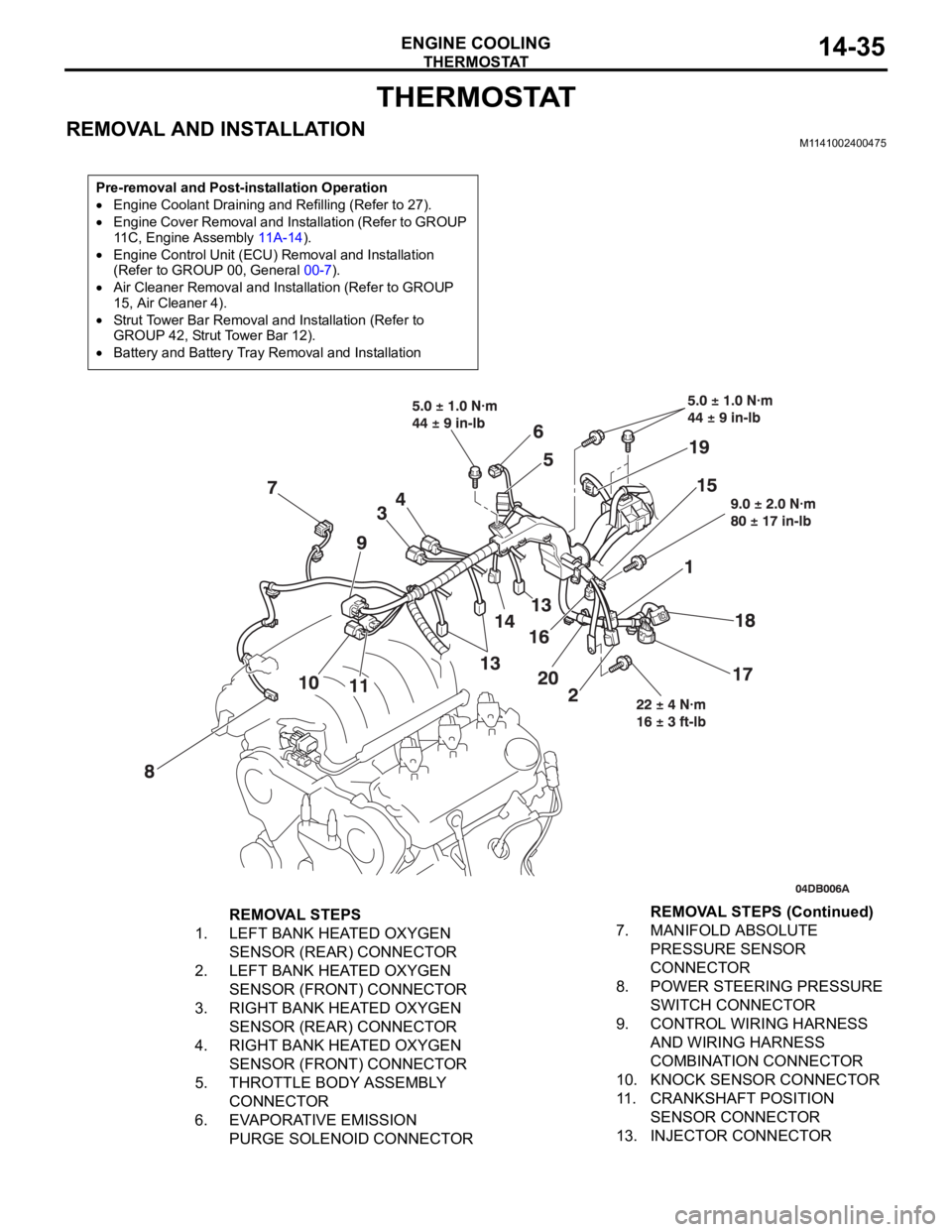

THERMOSTAT

ENGINE COOLING14-35

THERMOSTAT

REMOVAL AND INSTALLATIONM1141002400475

Pre-removal and Post-installation Operation

Engine Coolant Draining and Refilling (Refer to 27).

Engine Cover Removal and Installation (Refer to GROUP

11C, Engine Assembly 11A-14).

Engine Control Unit (ECU) Removal and Installation

(Refer to GROUP 00, General 00-7).

Air Cleaner Removal and Installation (Refer to GROUP

15, Air Cleaner 4).

Strut Tower Bar Removal and Installation (Refer to

GROUP 42, Strut Tower Bar 12).

Battery and Battery Tray Removal and Installation

REMOVAL STEPS

1. LEFT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

2. LEFT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

3. RIGHT BANK HEATED OXYGEN

SENSOR (REAR) CONNECTOR

4. RIGHT BANK HEATED OXYGEN

SENSOR (FRONT) CONNECTOR

5. THROTTLE BODY ASSEMBLY

CONNECTOR

6. EVAPORATIVE EMISSION

PURGE SOLENOID CONNECTOR7. MANIFOLD ABSOLUTE

PRESSURE SENSOR

CONNECTOR

8. POWER STEERING PRESSURE

SWITCH CONNECTOR

9. CONTROL WIRING HARNESS

AND WIRING HARNESS

COMBINATION CONNECTOR

10. KNOCK SENSOR CONNECTOR

11. CRANKSHAFT POSITION

SENSOR CONNECTOR

13. INJECTOR CONNECTORREMOVAL STEPS (Continued)

Page 965 of 1500

INTAKE MANIFOLD PLENUM

INTAKE AND EXHAUST15-6

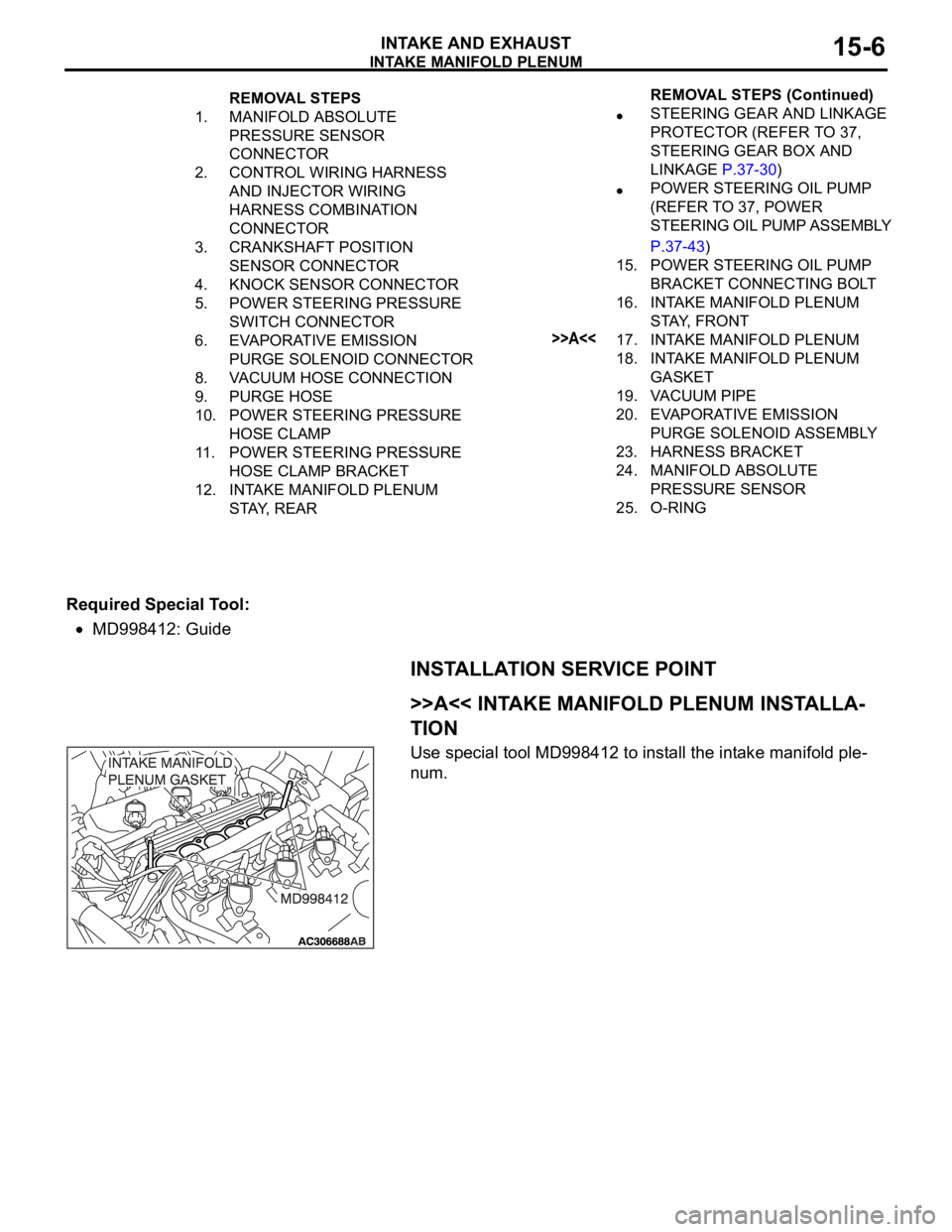

Required Special Tool:

MD998412: Guide

INSTALLATION SERVICE POINT

.

>>A<< INTAKE MANIFOLD PLENUM INSTALLA-

TION

Use special tool MD998412 to install the intake manifold ple-

num.

REMOVAL STEPS

1. MANIFOLD ABSOLUTE

PRESSURE SENSOR

CONNECTOR

2. CONTROL WIRING HARNESS

AND INJECTOR WIRING

HARNESS COMBINATION

CONNECTOR

3. CRANKSHAFT POSITION

SENSOR CONNECTOR

4. KNOCK SENSOR CONNECTOR

5. POWER STEERING PRESSURE

SWITCH CONNECTOR

6. EVAPORATIVE EMISSION

PURGE SOLENOID CONNECTOR

8. VACUUM HOSE CONNECTION

9. PURGE HOSE

10. POWER STEERING PRESSURE

HOSE CLAMP

11. POWER STEERING PRESSURE

HOSE CLAMP BRACKET

12. INTAKE MANIFOLD PLENUM

STAY, REARSTEERING GEAR AND LINKAGE

PROTECTOR (REFER TO 37,

STEERING GEAR BOX AND

LINKAGE P.37-30)

POWER STEERING OIL PUMP

(REFER TO 37, POWER

STEERING OIL PUMP ASSEMBLY

P.37-43)

15. POWER STEERING OIL PUMP

BRACKET CONNECTING BOLT

16. INTAKE MANIFOLD PLENUM

STAY, FRONT

>>A<<17. INTAKE MANIFOLD PLENUM

18. INTAKE MANIFOLD PLENUM

GASKET

19. VACUUM PIPE

20. EVAPORATIVE EMISSION

PURGE SOLENOID ASSEMBLY

23. HARNESS BRACKET

24. MANIFOLD ABSOLUTE

PRESSURE SENSOR

25. O-RINGREMOVAL STEPS (Continued)