Coil MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 557 of 1500

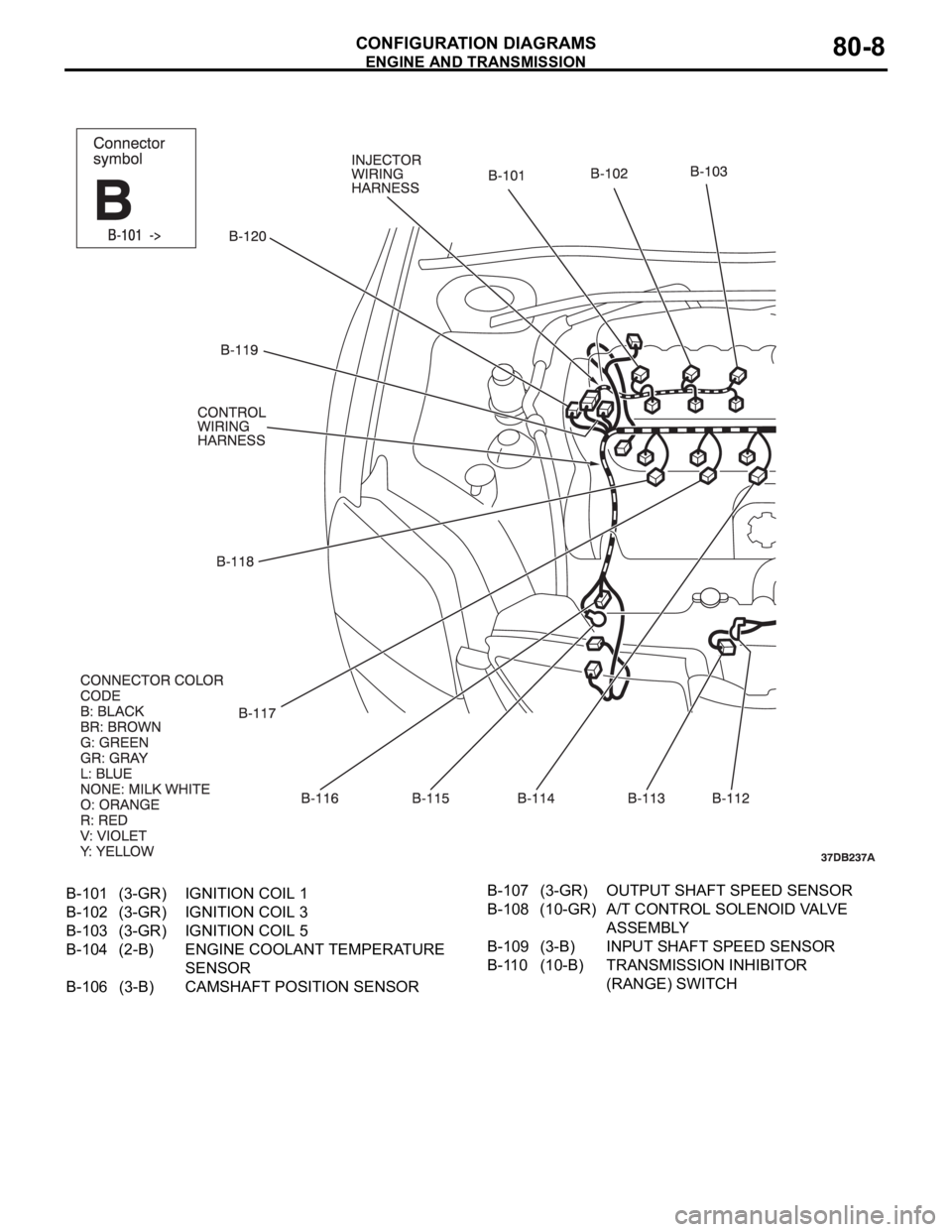

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-8

B-101 (3-GR) IGNITION COIL 1

B-102 (3-GR) IGNITION COIL 3

B-103 (3-GR) IGNITION COIL 5

B-104 (2-B) ENGINE COOLANT TEMPERATURE

SENSOR

B-106 (3-B) CAMSHAFT POSITION SENSORB-107 (3-GR) OUTPUT SHAFT SPEED SENSOR

B-108 (10-GR) A/T CONTROL SOLENOID VALVE

ASSEMBLY

B-109 (3-B) INPUT SHAFT SPEED SENSOR

B-110 (10-B) TRANSMISSION INHIBITOR

(RANGE) SWITCH

Page 558 of 1500

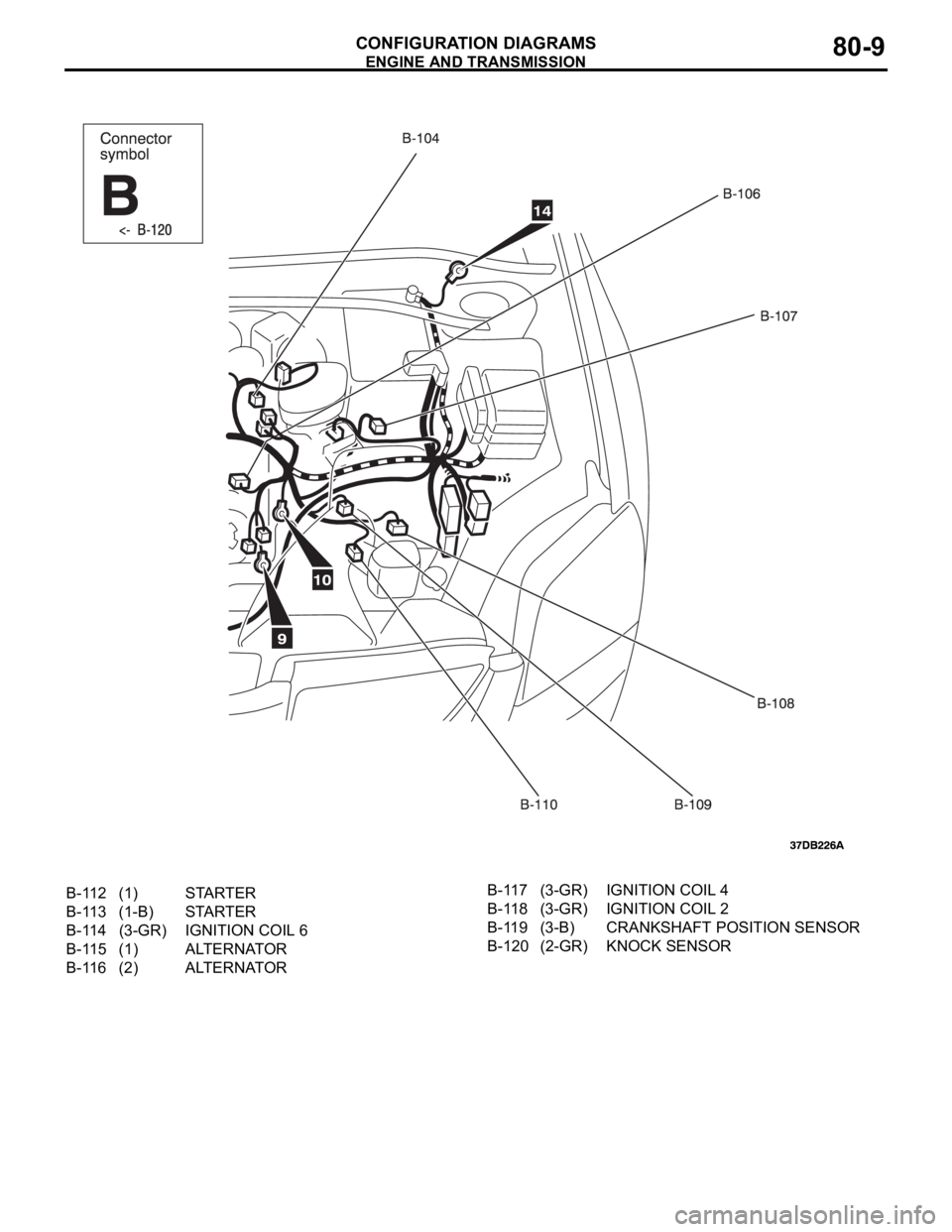

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-9

B-112 (1) STARTER

B-113 (1-B) STARTER

B-114 (3-GR) IGNITION COIL 6

B-115 (1) ALTERNATOR

B-116 (2) ALTERNATORB-117 (3-GR) IGNITION COIL 4

B-118 (3-GR) IGNITION COIL 2

B-119 (3-B) CRANKSHAFT POSITION SENSOR

B-120 (2-GR) KNOCK SENSOR

Page 566 of 1500

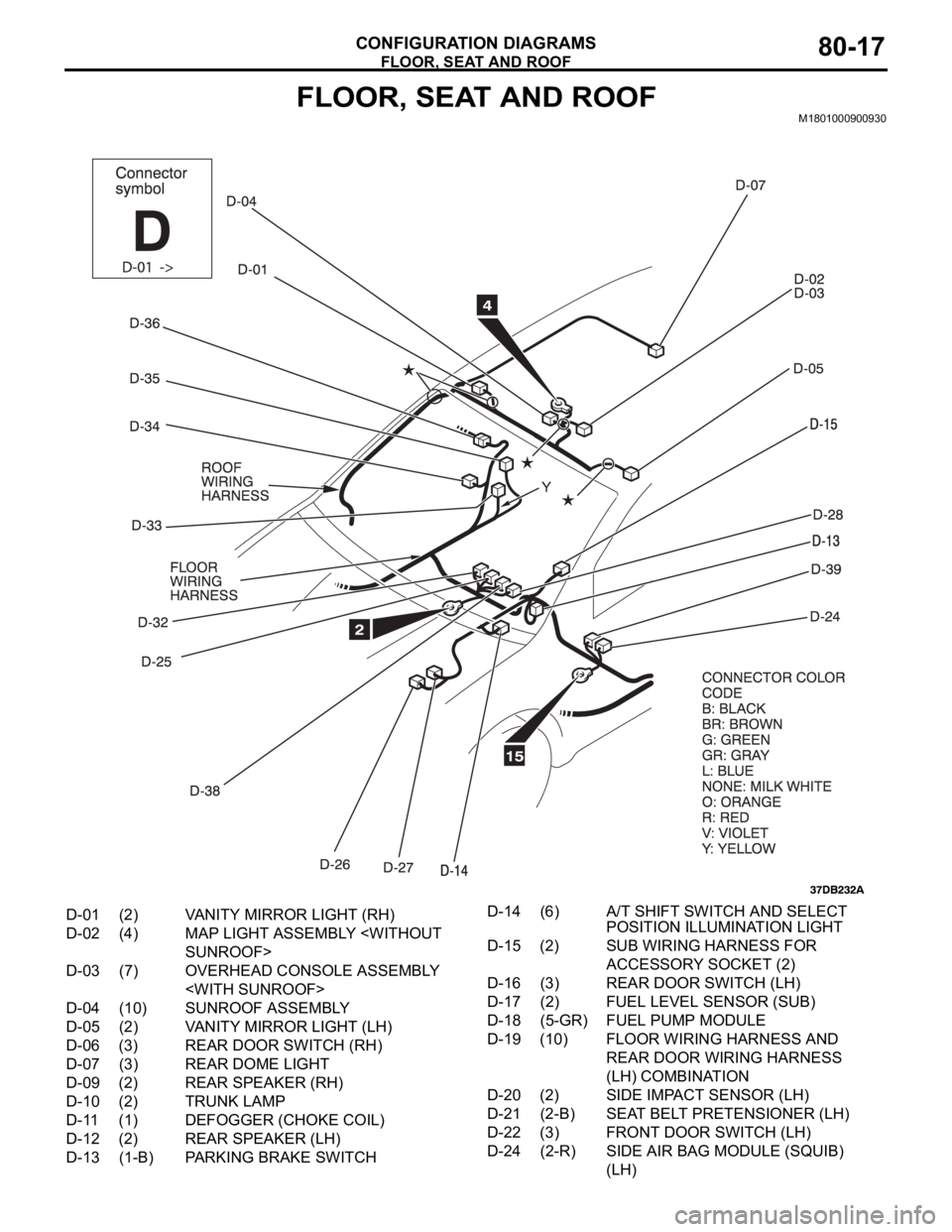

FLOOR, SEAT AND ROOF

CONFIGURATION DIAGRAMS80-17

FLOOR, SEAT AND ROOFM1801000900930

D-01 (2) VANITY MIRROR LIGHT (RH)

D-02 (4) MAP LIGHT ASSEMBLY

D-03 (7) OVERHEAD CONSOLE ASSEMBLY

D-04 (10) SUNROOF ASSEMBLY

D-05 (2) VANITY MIRROR LIGHT (LH)

D-06 (3) REAR DOOR SWITCH (RH)

D-07 (3) REAR DOME LIGHT

D-09 (2) REAR SPEAKER (RH)

D-10 (2) TRUNK LAMP

D-11 (1) DEFOGGER (CHOKE COIL)

D-12 (2) REAR SPEAKER (LH)

D-13 (1-B) PARKING BRAKE SWITCHD-14 (6) A/T SHIFT SWITCH AND SELECT

POSITION ILLUMINATION LIGHT

D-15 (2) SUB WIRING HARNESS FOR

ACCESSORY SOCKET (2)

D-16 (3) REAR DOOR SWITCH (LH)

D-17 (2) FUEL LEVEL SENSOR (SUB)

D-18 (5-GR) FUEL PUMP MODULE

D-19 (10) FLOOR WIRING HARNESS AND

REAR DOOR WIRING HARNESS

(LH) COMBINATION

D-20 (2) SIDE IMPACT SENSOR (LH)

D-21 (2-B) SEAT BELT PRETENSIONER (LH)

D-22 (3) FRONT DOOR SWITCH (LH)

D-24 (2-R) SIDE AIR BAG MODULE (SQUIB)

(LH)

Page 592 of 1500

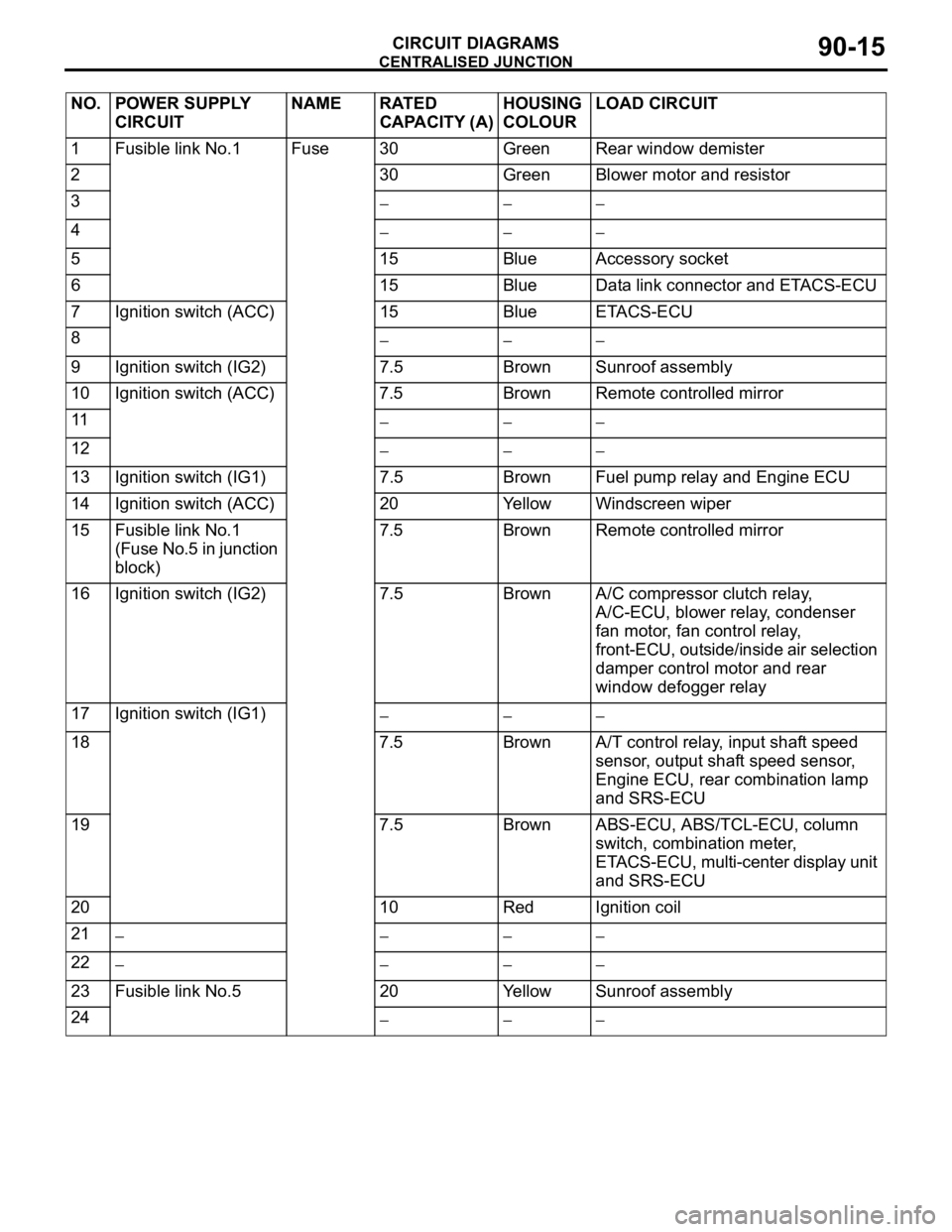

CENTRALISED JUNCTION

CIRCUIT DIAGRAMS90-15

NO. POWER SUPPLY

CIRCUITNAME RATED

CAPACITY (A)HOUSING

COLOURLOAD CIRCUIT

1 Fusible link No.1 Fuse 30 Green Rear window demister

2 30 Green Blower motor and resistor

3

4

5 15 Blue Accessory socket

6 15 Blue Data link connector and ETACS-ECU

7 Ignition switch (ACC) 15 Blue ETACS-ECU

8

9 Ignition switch (IG2) 7.5 Brown Sunroof assembly

10 Ignition switch (ACC) 7.5 Brown Remote controlled mirror

11

12

13 Ignition switch (IG1) 7.5 Brown Fuel pump relay and Engine ECU

14 Ignition switch (ACC) 20 Yellow Windscreen wiper

15 Fusible link No.1

(Fuse No.5 in junction

block)7.5 Brown Remote controlled mirror

16 Ignition switch (IG2) 7.5 Brown A/C compressor clutch relay,

A/C-ECU, blower relay, condenser

fan motor, fan control relay,

front-ECU, outside/inside air selection

damper control motor and rear

window defogger relay

17 Ignition switch (IG1)

18 7.5 Brown A/T control relay, input shaft speed

sensor, output shaft speed sensor,

Engine ECU, rear combination lamp

and SRS-ECU

19 7.5 Brown ABS-ECU, ABS/TCL-ECU, column

switch, combination meter,

ETACS-ECU, multi-center display unit

and SRS-ECU

20 10 Red Ignition coil

21

22

23 Fusible link No.5 20 Yellow Sunroof assembly

24

Page 813 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-112

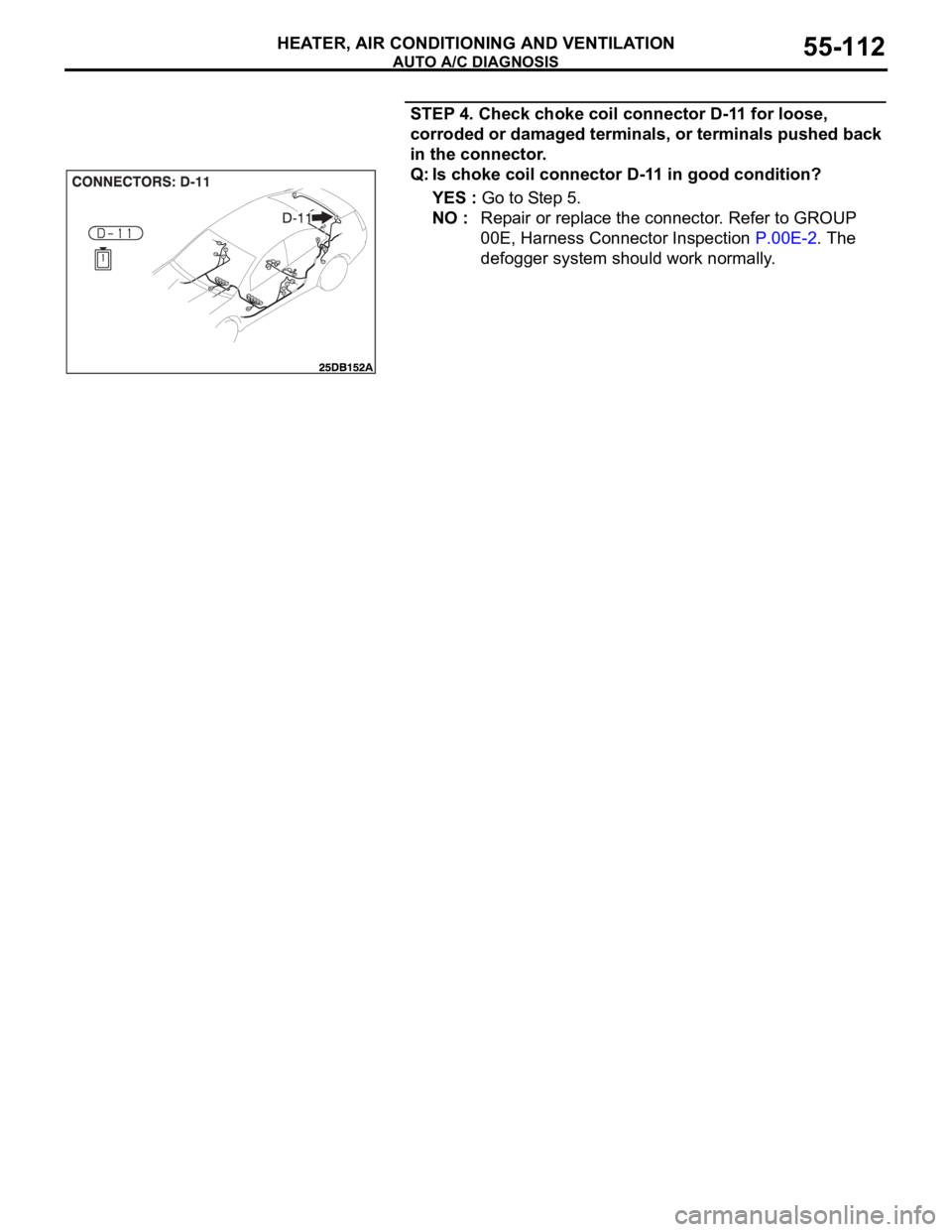

STEP 4. Check choke coil connector D-11 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is choke coil connector D-11 in good condition?

YES : Go to Step 5.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. The

defogger system should work normally.

Page 814 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-113

STEP 5.Measure the voltage at choke coil connector D-11.

(1) Disconnect connector D-11, and measure the voltage at the

harness side.

(2) Disconnect A/C-ECU connector C-15 and ground harness

side terminal No.27.

(3) Turn the ignition switch to the "ON" position.

(4) Measure the voltage between choke coil connector D-11

terminal No.1 and ground.

The measured value should be approximately 12 volts.

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 13.

NO : Go to Step 6.

Page 820 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-119

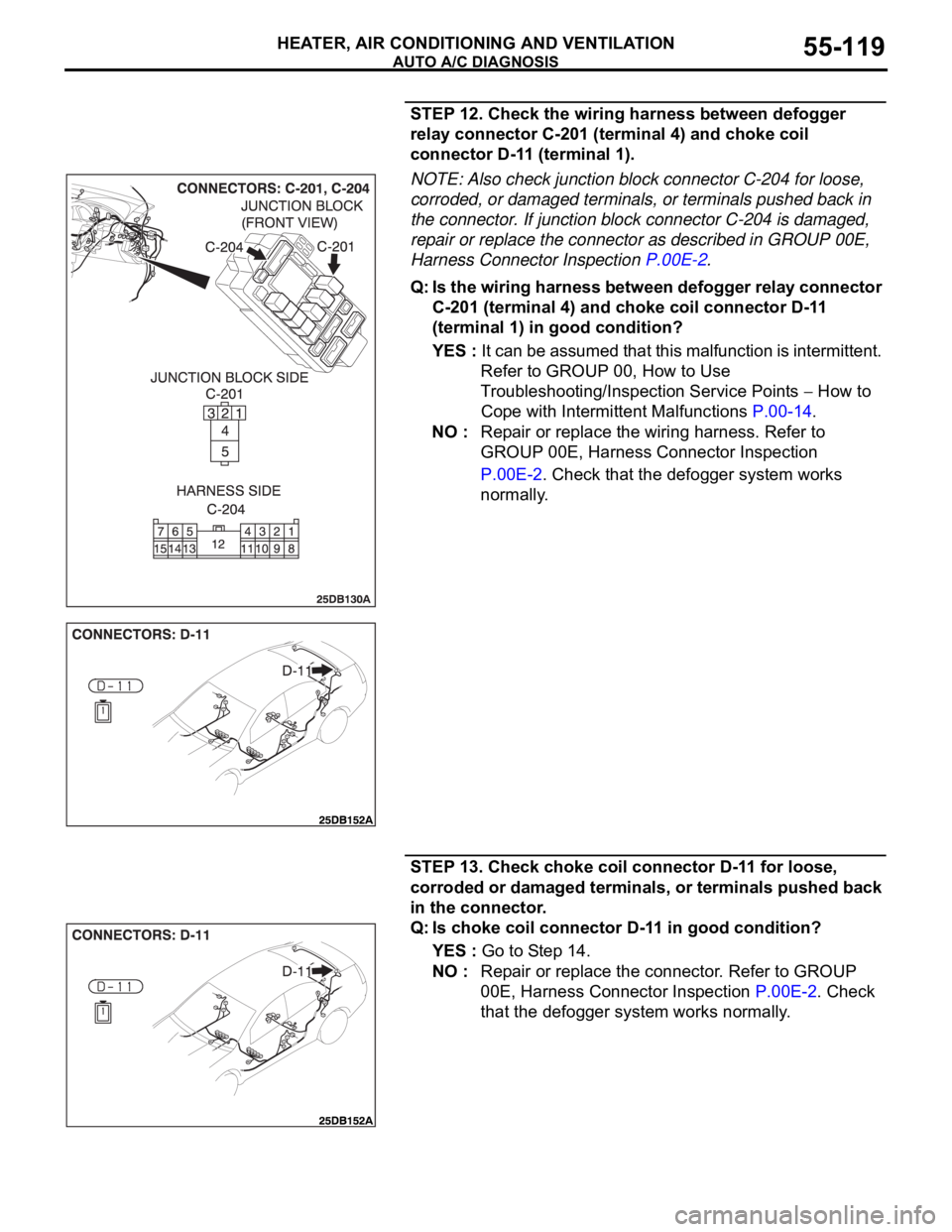

STEP 12. Check the wiring harness between defogger

relay connector C-201 (terminal 4) and choke coil

connector D-11 (terminal 1).

NOTE: Also check junction block connector C-204 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-204 is damaged,

repair or replace the connector as described in GROUP 00E,

Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between defogger relay connector

C-201 (terminal 4) and choke coil connector D-11

(terminal 1) in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair or replace the wiring harness. Refer to

GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the defogger system works

normally.

STEP 13. Check choke coil connector D-11 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is choke coil connector D-11 in good condition?

YES : Go to Step 14.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. Check

that the defogger system works normally.

Page 821 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-120

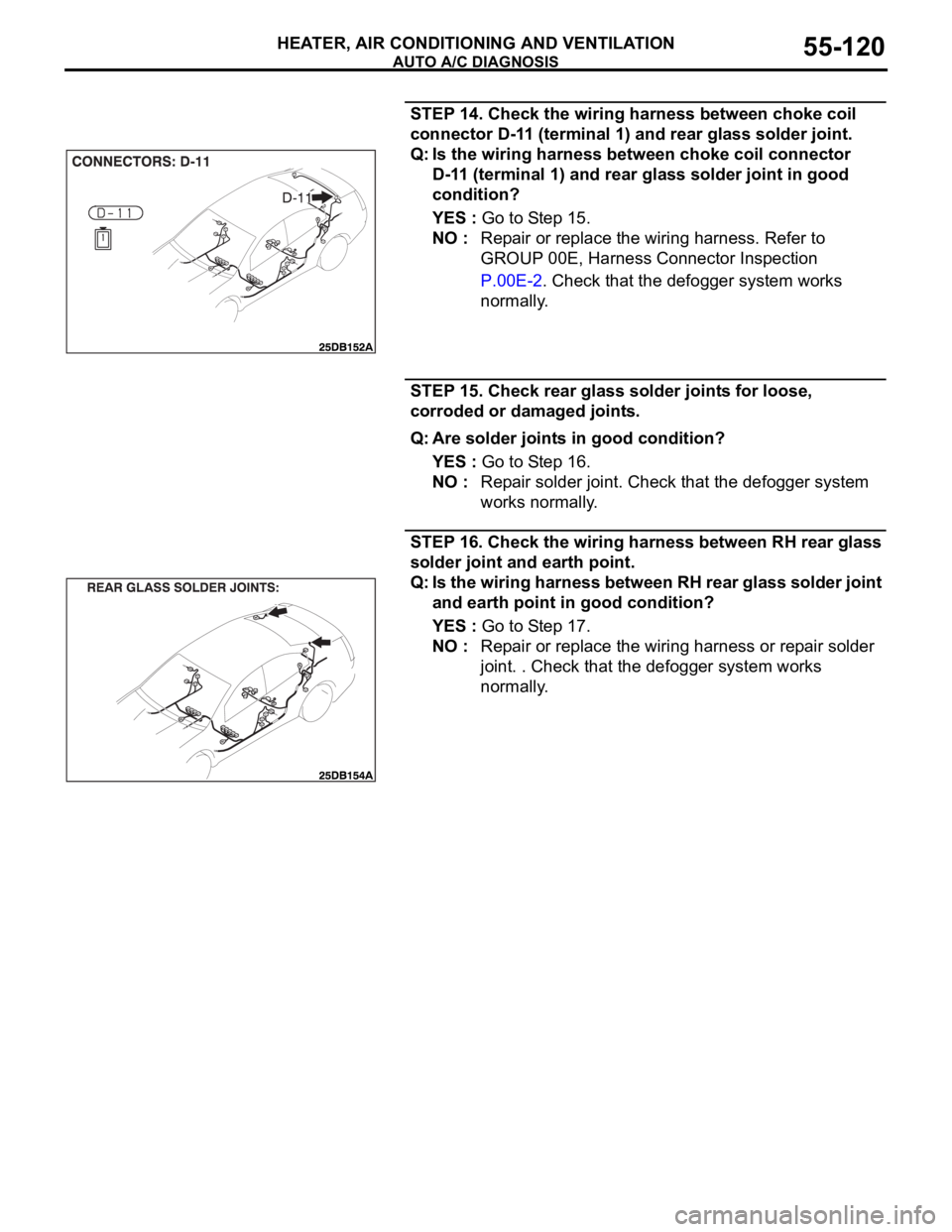

STEP 14. Check the wiring harness between choke coil

connector D-11 (terminal 1) and rear glass solder joint.

Q: Is the wiring harness between choke coil connector

D-11 (terminal 1) and rear glass solder joint in good

condition?

YES : Go to Step 15.

NO : Repair or replace the wiring harness. Refer to

GROUP 00E, Harness Connector Inspection

P.00E-2. Check that the defogger system works

normally.

STEP 15. Check rear glass solder joints for loose,

corroded or damaged joints.

Q: Are solder joints in good condition?

YES : Go to Step 16.

NO : Repair solder joint. Check that the defogger system

works normally.

STEP 16. Check the wiring harness between RH rear glass

solder joint and earth point.

Q: Is the wiring harness between RH rear glass solder joint

and earth point in good condition?

YES : Go to Step 17.

NO : Repair or replace the wiring harness or repair solder

joint. . Check that the defogger system works

normally.

Page 907 of 1500

HOW TO DIAGNOSE

GENERAL

5. Ohmmeter

An ohmmeter is used to check continuity or measure

resistance of a switch or coil. If the measuring range has

been changed, the zero point must be adjusted before

measurement.

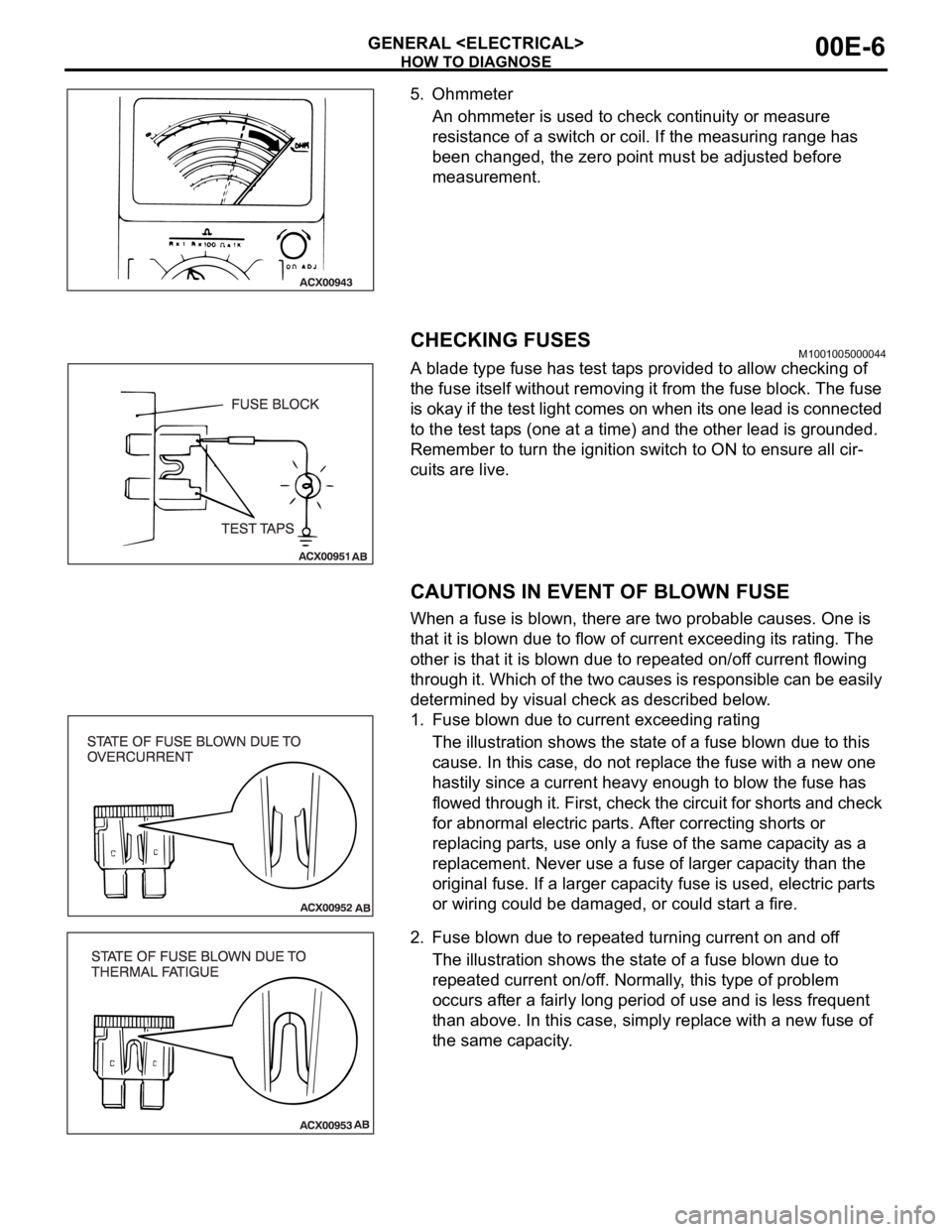

CHECKING FUSESM1001005000044

A blade type fuse has test taps provided to allow checking of

the fuse itself without removing it from the fuse block. The fuse

is okay if the test light comes on when its one lead is connected

to the test taps (one at a time) and the other lead is grounded.

Remember to turn the ignition switch to ON to ensure all cir-

cuits are live.

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes. One is

that it is blown due to flow of current exceeding its rating. The

other is that it is blown due to repeated on/off current flowing

through it. Which of the two causes is responsible can be easily

determined by visual check as described below.

1. Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse with a new one

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorts and check

for abnormal electric parts. After correcting shorts or

replacing parts, use only a fuse of the same capacity as a

replacement. Never use a fuse of larger capacity than the

original fuse. If a larger capacity fuse is used, electric parts

or wiring could be damaged, or could start a fire.

2. Fuse blown due to repeated turning current on and off

The illustration shows the state of a fuse blown due to

repeated current on/off. Normally, this type of problem

occurs after a fairly long period of use and is less frequent

than above. In this case, simply replace with a new fuse of

the same capacity.

Page 909 of 1500

HOW TO DIAGNOSE

GENERAL

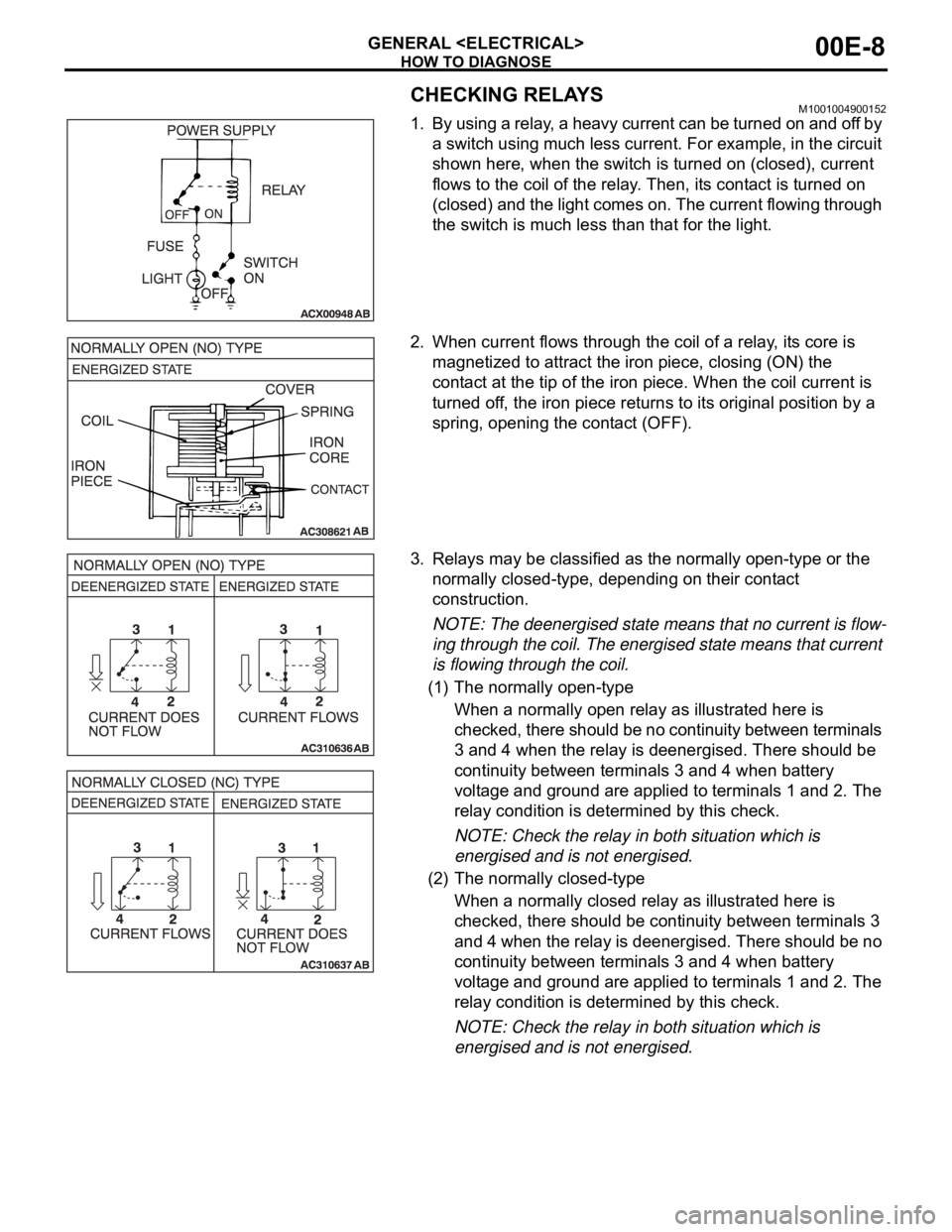

CHECKING RELAYSM1001004900152

1. By using a relay, a heavy current can be turned on and off by

a switch using much less current. For example, in the circuit

shown here, when the switch is turned on (closed), current

flows to the coil of the relay. Then, its contact is turned on

(closed) and the light comes on. The current flowing through

the switch is much less than that for the light.

2. When current flows through the coil of a relay, its core is

magnetized to attract the iron piece, closing (ON) the

contact at the tip of the iron piece. When the coil current is

turned off, the iron piece returns to its original position by a

spring, opening the contact (OFF).

3. Relays may be classified as the normally open-type or the

normally closed-type, depending on their contact

construction.

NOTE: The deenergised state means that no current is flow-

ing through the coil. The energised state means that current

is flowing through the coil.

(1) The normally open-type

When a normally open relay as illustrated here is

checked, there should be no continuity between terminals

3 and 4 when the relay is deenergised. There should be

continuity between terminals 3 and 4 when battery

voltage and ground are applied to terminals 1 and 2. The

relay condition is determined by this check.

NOTE: Check the relay in both situation which is

energised and is not energised.

(2) The normally closed-type

When a normally closed relay as illustrated here is

checked, there should be continuity between terminals 3

and 4 when the relay is deenergised. There should be no

continuity between terminals 3 and 4 when battery

voltage and ground are applied to terminals 1 and 2. The

relay condition is determined by this check.

NOTE: Check the relay in both situation which is

energised and is not energised.