timing belt MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 954 of 1500

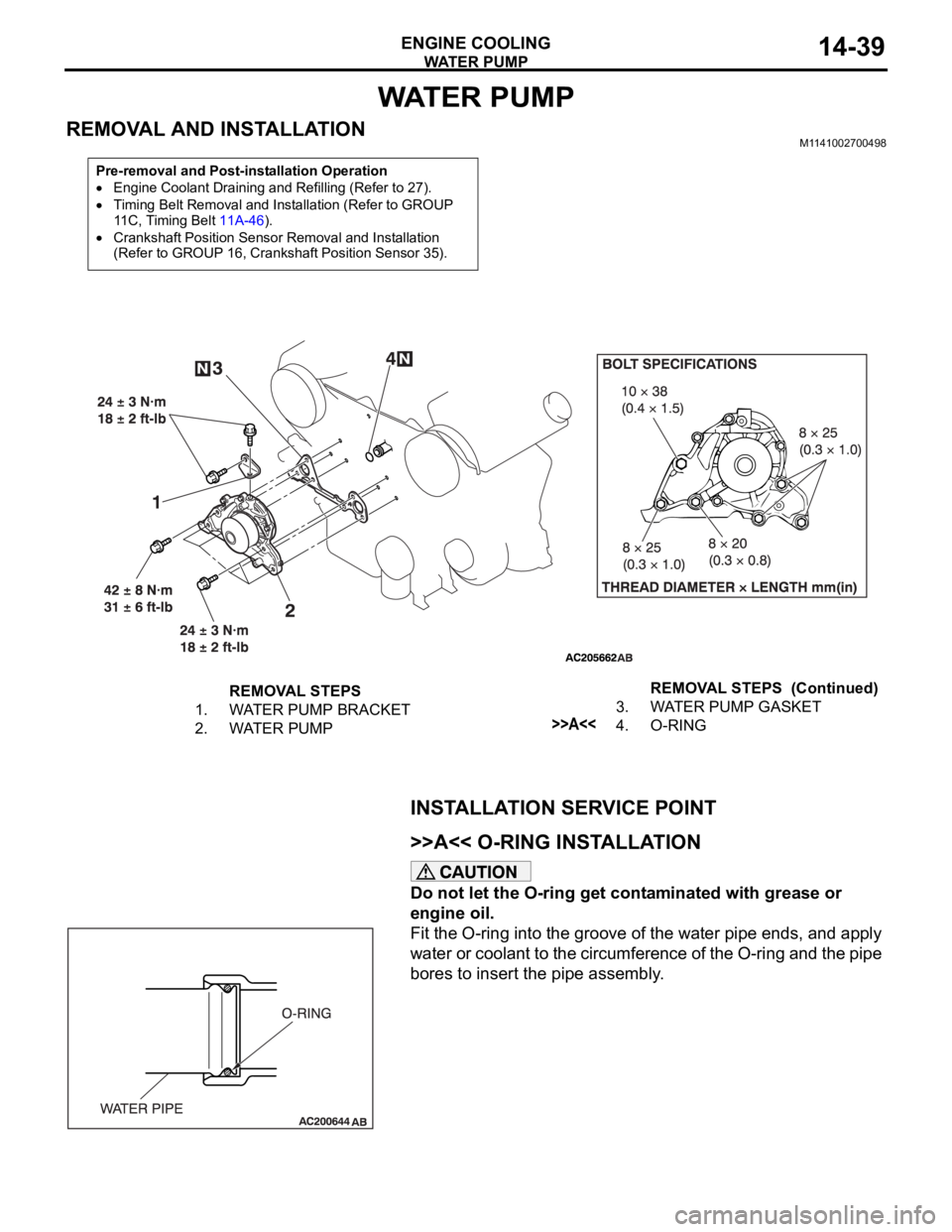

WATE R P U M P

ENGINE COOLING14-39

WAT E R P U M P

REMOVAL AND INSTALLATIONM1141002700498

INSTALLATION SERVICE POINT

.

>>A<< O-RING INSTALLATION

Do not let the O-ring get contaminated with grease or

engine oil.

Fit the O-ring into the groove of the water pipe ends, and apply

water or coolant to the circumference of the O-ring and the pipe

bores to insert the pipe assembly.

Pre-removal and Post-installation Operation

Engine Coolant Draining and Refilling (Refer to 27).

Timing Belt Removal and Installation (Refer to GROUP

11C, Timing Belt 11A-46).

Crankshaft Position Sensor Removal and Installation

(Refer to GROUP 16, Crankshaft Position Sensor 35).

REMOVAL STEPS

1. WATER PUMP BRACKET

2. WATER PUMP3. WATER PUMP GASKET

>>A<<4. O-RINGREMOVAL STEPS (Continued)

Page 966 of 1500

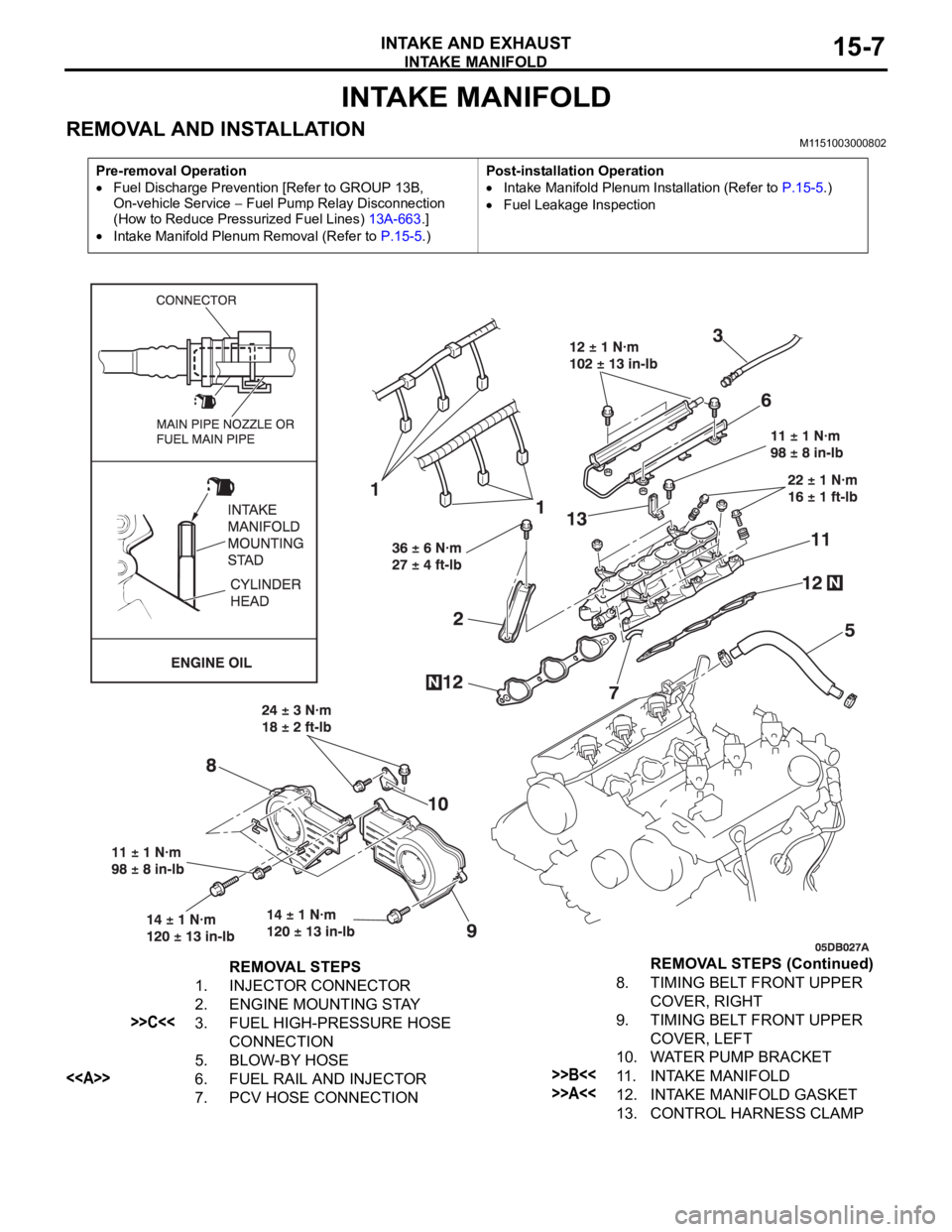

INTAKE MANIFOLD

INTAKE AND EXHAUST15-7

INTAKE MANIFOLD

REMOVAL AND INSTALLATION M1151003000802

Pre-removal Operation

Fuel Discharge Prevention [Refer to GROUP 13B,

On-vehicle Service

Fuel Pump Relay Disconnection

(How to Reduce Pressurized Fuel Lines) 13A-663.]

Intake Manifold Plenum Removal (Refer to P.15-5.)Post-installation Operation

Intake Manifold Plenum Installation (Refer to P.15-5.)

Fuel Leakage Inspection

REMOVAL STEPS

1. INJECTOR CONNECTOR

2. ENGINE MOUNTING STAY

>>C<<3. FUEL HIGH-PRESSURE HOSE

CONNECTION

5. BLOW-BY HOSE

<>6. FUEL RAIL AND INJECTOR

7. PCV HOSE CONNECTION8. TIMING BELT FRONT UPPER

COVER, RIGHT

9. TIMING BELT FRONT UPPER

COVER, LEFT

10. WATER PUMP BRACKET>>B<<11. INTAKE MANIFOLD

>>A<<12. INTAKE MANIFOLD GASKET

13. CONTROL HARNESS CLAMPREMOVAL STEPS (Continued)

Page 975 of 1500

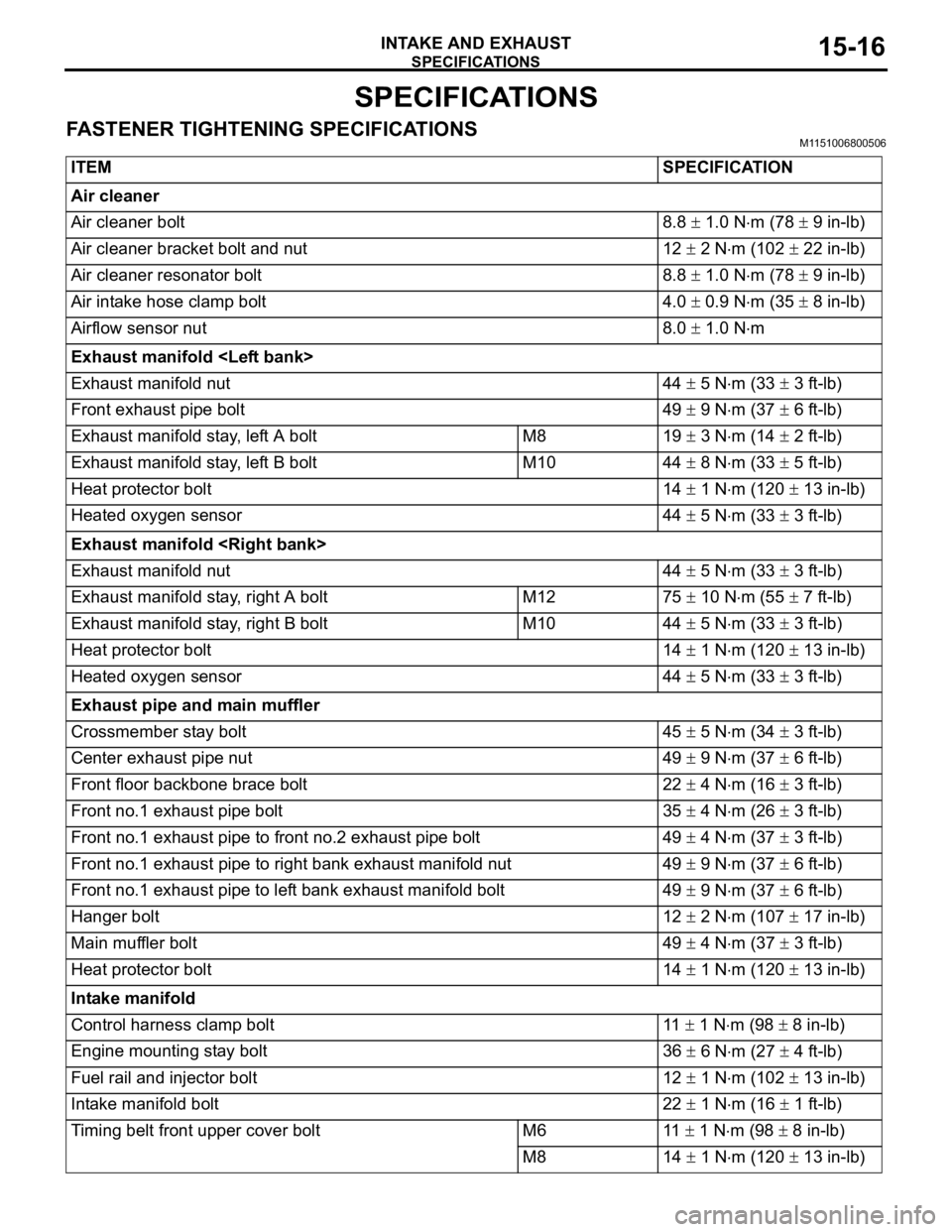

SPECIFICATIONS

INTAKE AND EXHAUST15-16

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1151006800506

ITEMSPECIFICATION

Air cleaner

Air cleaner bolt 8.8

1.0 Nm (78 9 in-lb)

Air cleaner bracket bolt and nut 12

2 Nm (102 22 in-lb)

Air cleaner resonator bolt 8.8

1.0 Nm (78 9 in-lb)

Air intake hose clamp bolt 4.0

0.9 Nm (35 8 in-lb)

Airflow sensor nut 8.0

1.0 Nm

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Front exhaust pipe bolt 49

9 Nm (37 6 ft-lb)

Exhaust manifold stay, left A bolt M8 19

3 Nm (14 2 ft-lb)

Exhaust manifold stay, left B bolt M10 44

8 Nm (33 5 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust manifold

Exhaust manifold nut 44

5 Nm (33 3 ft-lb)

Exhaust manifold stay, right A bolt M12 75

10 Nm (55 7 ft-lb)

Exhaust manifold stay, right B bolt M10 44

5 Nm (33 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Heated oxygen sensor 44

5 Nm (33 3 ft-lb)

Exhaust pipe and main muffler

Crossmember stay bolt 45

5 Nm (34 3 ft-lb)

Center exhaust pipe nut 49

9 Nm (37 6 ft-lb)

Front floor backbone brace bolt 22

4 Nm (16 3 ft-lb)

Front no.1 exhaust pipe bolt 35

4 Nm (26 3 ft-lb)

Front no.1 exhaust pipe to front no.2 exhaust pipe bolt 49

4 Nm (37 3 ft-lb)

Front no.1 exhaust pipe to right bank exhaust manifold nut 49

9 Nm (37 6 ft-lb)

Front no.1 exhaust pipe to left bank exhaust manifold bolt 49

9 Nm (37 6 ft-lb)

Hanger bolt 12

2 Nm (107 17 in-lb)

Main muffler bolt 49

4 Nm (37 3 ft-lb)

Heat protector bolt 14

1 Nm (120 13 in-lb)

Intake manifold

Control harness clamp bolt 11

1 Nm (98 8 in-lb)

Engine mounting stay bolt 36

6 Nm (27 4 ft-lb)

Fuel rail and injector bolt 12

1 Nm (102 13 in-lb)

Intake manifold bolt 22

1 Nm (16 1 ft-lb)

Timing belt front upper cover bolt M6 11

1 Nm (98 8 in-lb)

M8 14

1 Nm (120 13 in-lb)

Page 1012 of 1500

IGNITION SYSTEM

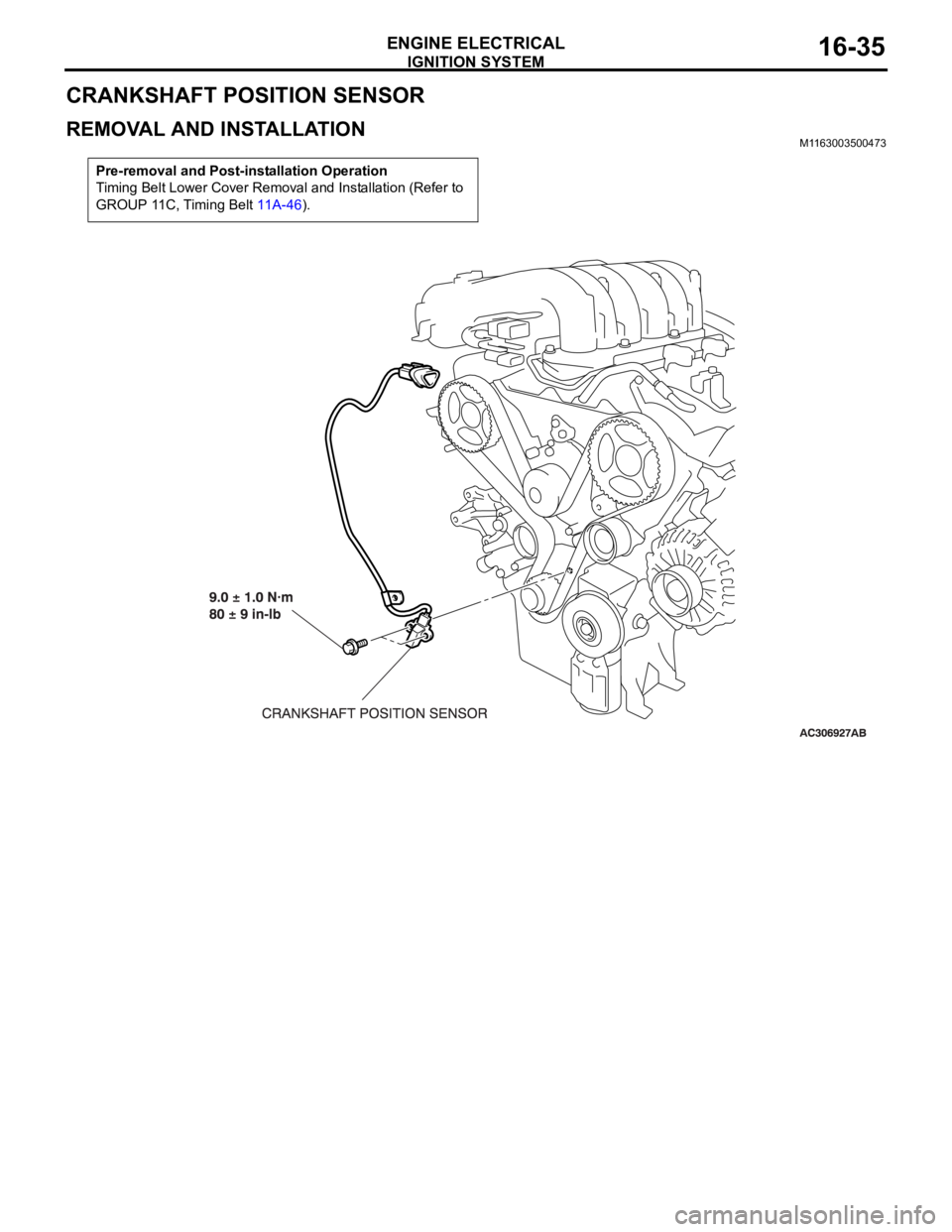

ENGINE ELECTRICAL16-35

CRANKSHAFT POSITION SENSOR

REMOVAL AND INSTALLATION M1163003500473

Pre-removal and Post-installation Operation

Timing Belt Lower Cover Removal and Installation (Refer to

GROUP 11C, Timing Belt 11A-46).

Page 1223 of 1500

GENERAL00-2

MAINTENANCE SERVICE . . . . . . . .00-37

1. FUEL SYSTEM (TANK, PIPE LINE AND

CONNECTION, AND FUEL TANK FILLER

TUBE CAP) (CHECK FOR LEAKS) . . . . . . 00-37

2. FUEL HOSES (CHECK CONDITION) . . 00-37

3. AIR CLEANER FILTER (REPLACE). . . . 00-37

4. EVAPORATIVE EMISSION SYSTEM

(EXCEPT EVAPORATIVE EMISSION

CANISTER) (CHECK FOR CLOGGING) . . 00-37

5. SPARK PLUGS (REPLACE). . . . . . . . . . 00-38

7. TIMING BELT (REPLACE) . . . . . . . . . . . 00-38

8. DRIVE BELTS (FOR ALTERNATOR, POWER

STEERING PUMP AND AIR CONDITIONING)

(CHECK) . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-39

9. EXHAUST SYSTEM (CONNECTIONS

PORTION OF MUFFLER, MUFFLER PIPES

AND CONVERTER HEAT SHIELDS) (CHECK

AND SERVICE AS REQUIRED) . . . . . . . . . 00-44

10. ENGINE OIL (CHANGE) . . . . . . . . . . . . 00-4411. ENGINE OIL FILTER (REPLACE) . . . . 00-44

12. TRANSMISSION FLUID . . . . . . . . . . . . 00-45

13. ENGINE COOLANT (CHANGE) . . . . . . 00-47

14. COOLANT HOSES (RADIATOR HOSE,

HEATER HOSE) (INSPECT). . . . . . . . . . . . 00-49

15. DISC BRAKE PADS, ROTORS

(INSPECT FOR WEAR) . . . . . . . . . . . . . . . 00-49

16. BRAKE HOSES (CHECK FOR

DETERIORATION OR LEAKS) . . . . . . . . . . 00-49

17. BALL JOINT AND STEERING LINKAGE

SEALS (INSPECT FOR GREASE LEAKS

AND DAMAGE) . . . . . . . . . . . . . . . . . . . . . . 00-50

18. DRIVE SHAFT BOOTS (INSPECT FOR

GREASE LEAKS AND DAMAGE) . . . . . . . . 00-50

19. SUSPENSION SYSTEM (INSPECT FOR

LOOSENESS AND DAMAGE) . . . . . . . . . . 00-51

20. SRS AIR BAG (INSPECT FOR SRS

SYSTEM). . . . . . . . . . . . . . . . . . . . . . . . . . . 00-51

21. TYRES (ROTATE). . . . . . . . . . . . . . . . . 00-58

Page 1259 of 1500

MAINTENANCE SERVICE

GENERAL00-38

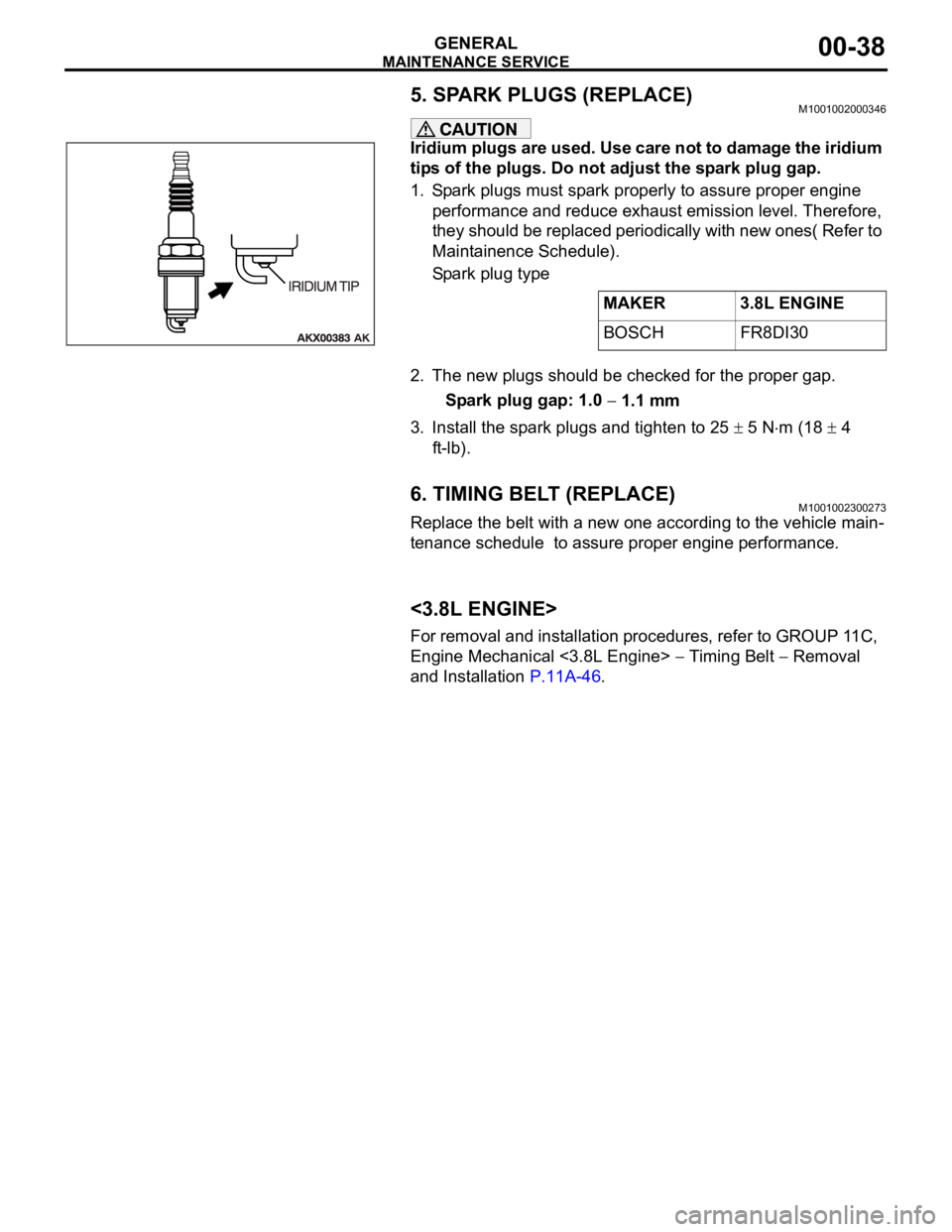

5. SPARK PLUGS (REPLACE)M1001002000346

Iridium plugs are used. Use care not to damage the iridium

tips of the plugs. Do not adjust the spark plug gap.

1. Spark plugs must spark properly to assure proper engine

performance and reduce exhaust emission level. Therefore,

they should be replaced periodically with new ones( Refer to

Maintainence Schedule).

Spark plug type

2. The new plugs should be checked for the proper gap.

Spark plug gap: 1.0

1.1 mm

3. Install the spark plugs and tighten to 25

5 Nm (18 4

ft-lb).

6. TIMING BELT (REPLACE)M1001002300273

Replace the belt with a new one according to the vehicle main-

tenance schedule to assure proper engine performance.

<3.8L ENGINE>

For removal and installation procedures, refer to GROUP 11C,

Engine Mechanical <3.8L Engine>

Timing Belt Removal

and Installation P.11A-46.MAKER 3.8L ENGINE

BOSCH FR8DI30