Plug MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 508 of 1500

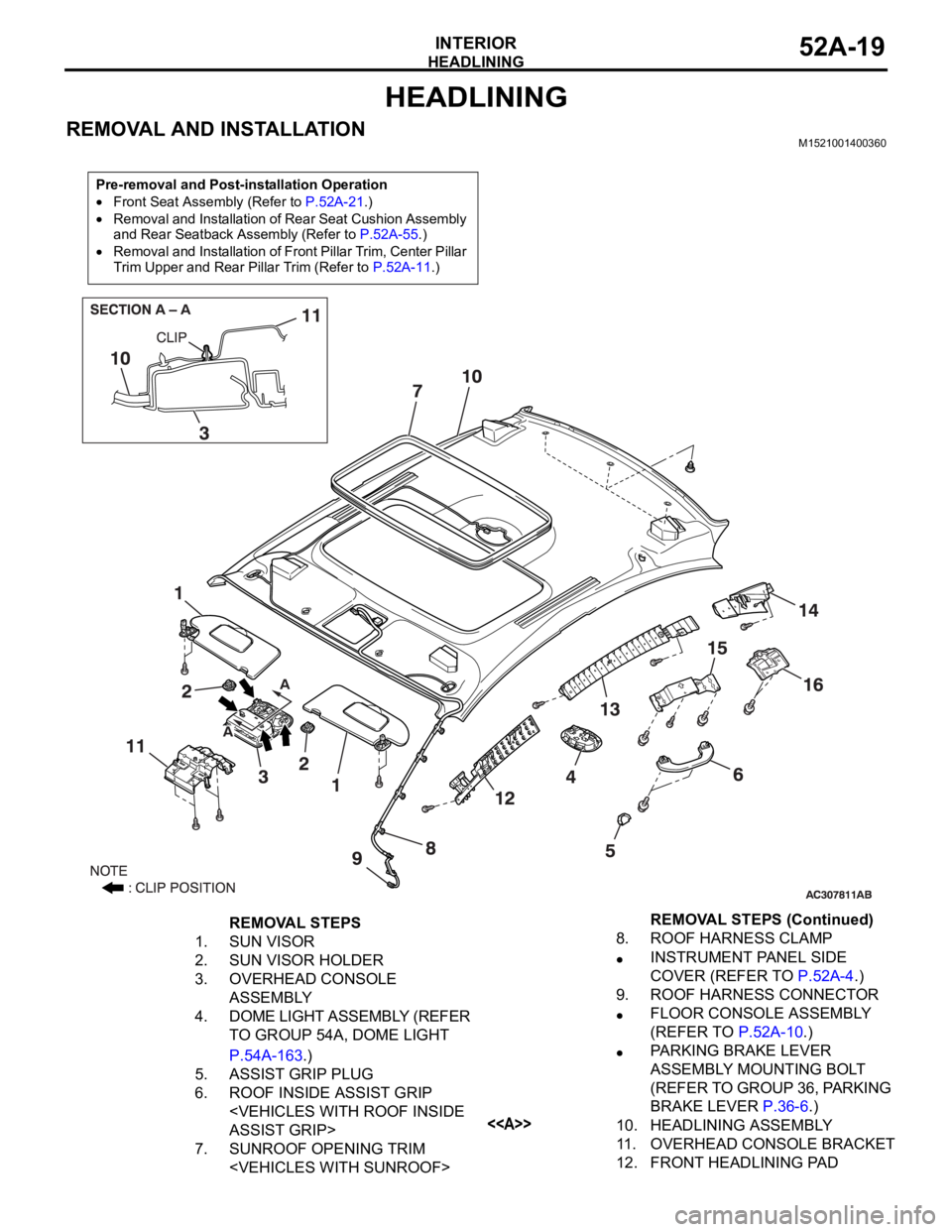

HEADLINING

INTERIOR52A-19

HEADLINING

REMOVAL AND INSTALLATIONM1521001400360

Pre-removal and Post-installation Operation

Front Seat Assembly (Refer to P.52A-21.)

Removal and Installation of Rear Seat Cushion Assembly

and Rear Seatback Assembly (Refer to P.52A-55.)

Removal and Installation of Front Pillar Trim, Center Pillar

Trim Upper and Rear Pillar Trim (Refer to P.52A-11.)

REMOVAL STEPS

1. SUN VISOR

2. SUN VISOR HOLDER

3. OVERHEAD CONSOLE

ASSEMBLY

4. DOME LIGHT ASSEMBLY (REFER

TO GROUP 54A, DOME LIGHT

P.54A-163.)

5. ASSIST GRIP PLUG

6. ROOF INSIDE ASSIST GRIP

7. SUNROOF OPENING TRIM

INSTRUMENT PANEL SIDE

COVER (REFER TO P.52A-4.)

9. ROOF HARNESS CONNECTOR

FLOOR CONSOLE ASSEMBLY

(REFER TO P.52A-10.)

PARKING BRAKE LEVER

ASSEMBLY MOUNTING BOLT

(REFER TO GROUP 36, PARKING

BRAKE LEVER P.36-6.)

<>10. HEADLINING ASSEMBLY

11. OVERHEAD CONSOLE BRACKET

12. FRONT HEADLINING PAD REMOVAL STEPS (Continued)

Page 853 of 1500

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONING AND VENTILATION55-152

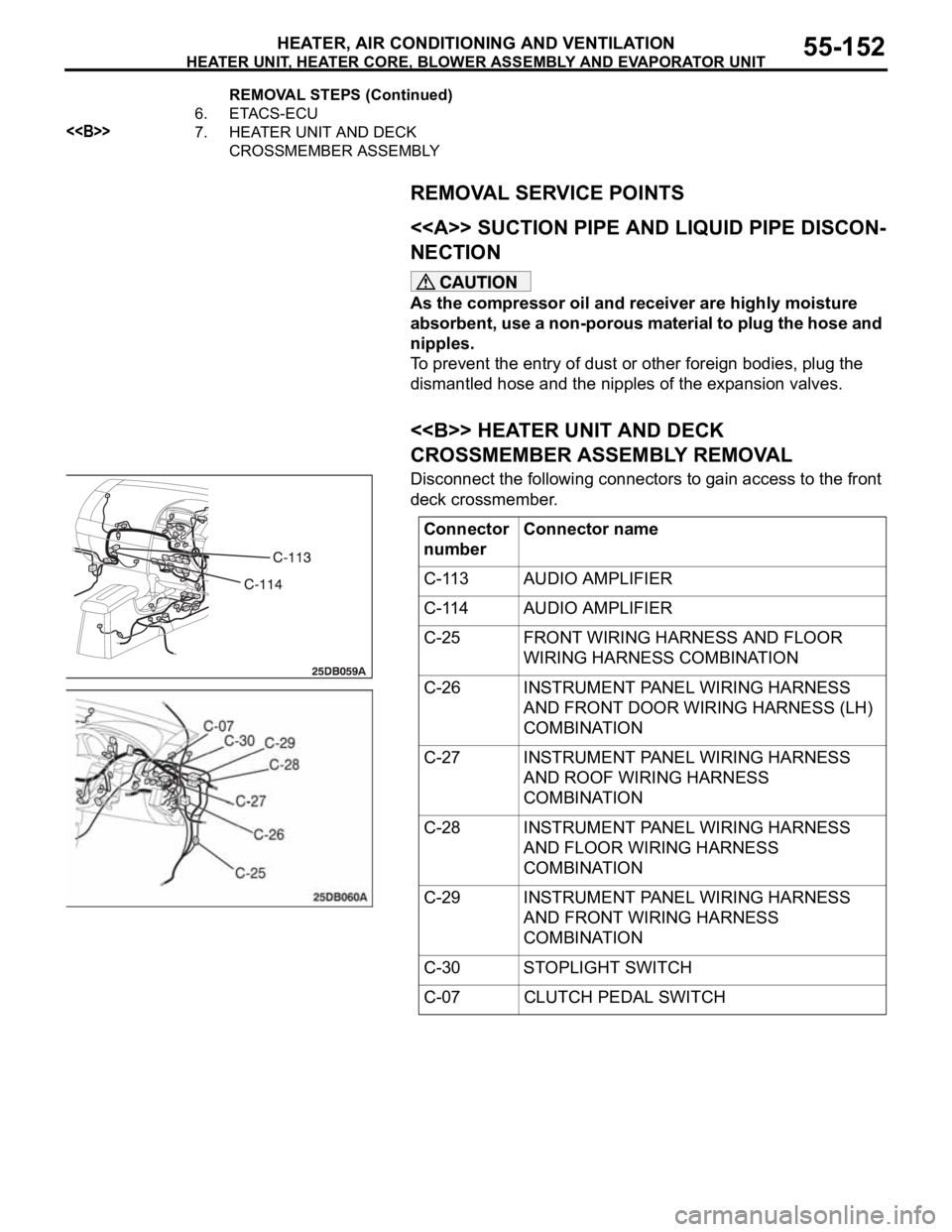

REMOVAL SERVICE POINTS

.

<> SUCTION PIPE AND LIQUID PIPE DISCON-

NECTION

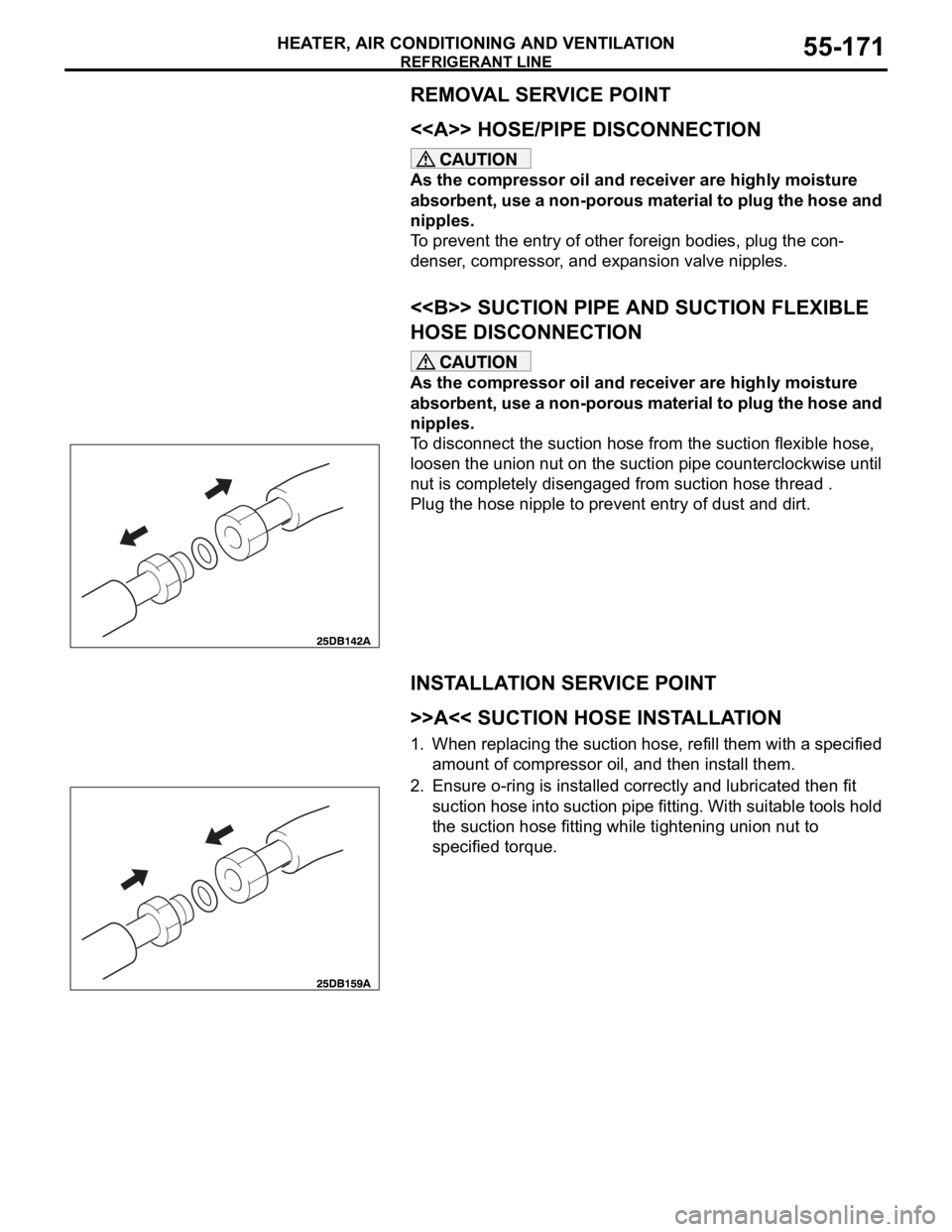

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose and

nipples.

To prevent the entry of dust or other foreign bodies, plug the

dismantled hose and the nipples of the expansion valves.

.

<> HEATER UNIT AND DECK

CROSSMEMBER ASSEMBLY REMOVAL

Disconnect the following connectors to gain access to the front

deck crossmember.

6. ETACS-ECU

<>7. HEATER UNIT AND DECK

CROSSMEMBER ASSEMBLY REMOVAL STEPS (Continued)

Connector

numberConnector name

C-113 AUDIO AMPLIFIER

C-114 AUDIO AMPLIFIER

C-25 FRONT WIRING HARNESS AND FLOOR

WIRING HARNESS COMBINATION

C-26 INSTRUMENT PANEL WIRING HARNESS

AND FRONT DOOR WIRING HARNESS (LH)

COMBINATION

C-27 INSTRUMENT PANEL WIRING HARNESS

AND ROOF WIRING HARNESS

COMBINATION

C-28 INSTRUMENT PANEL WIRING HARNESS

AND FLOOR WIRING HARNESS

COMBINATION

C-29 INSTRUMENT PANEL WIRING HARNESS

AND FRONT WIRING HARNESS

COMBINATION

C-30 STOPLIGHT SWITCH

C-07 CLUTCH PEDAL SWITCH

Page 866 of 1500

Page 869 of 1500

Page 872 of 1500

Page 942 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-27

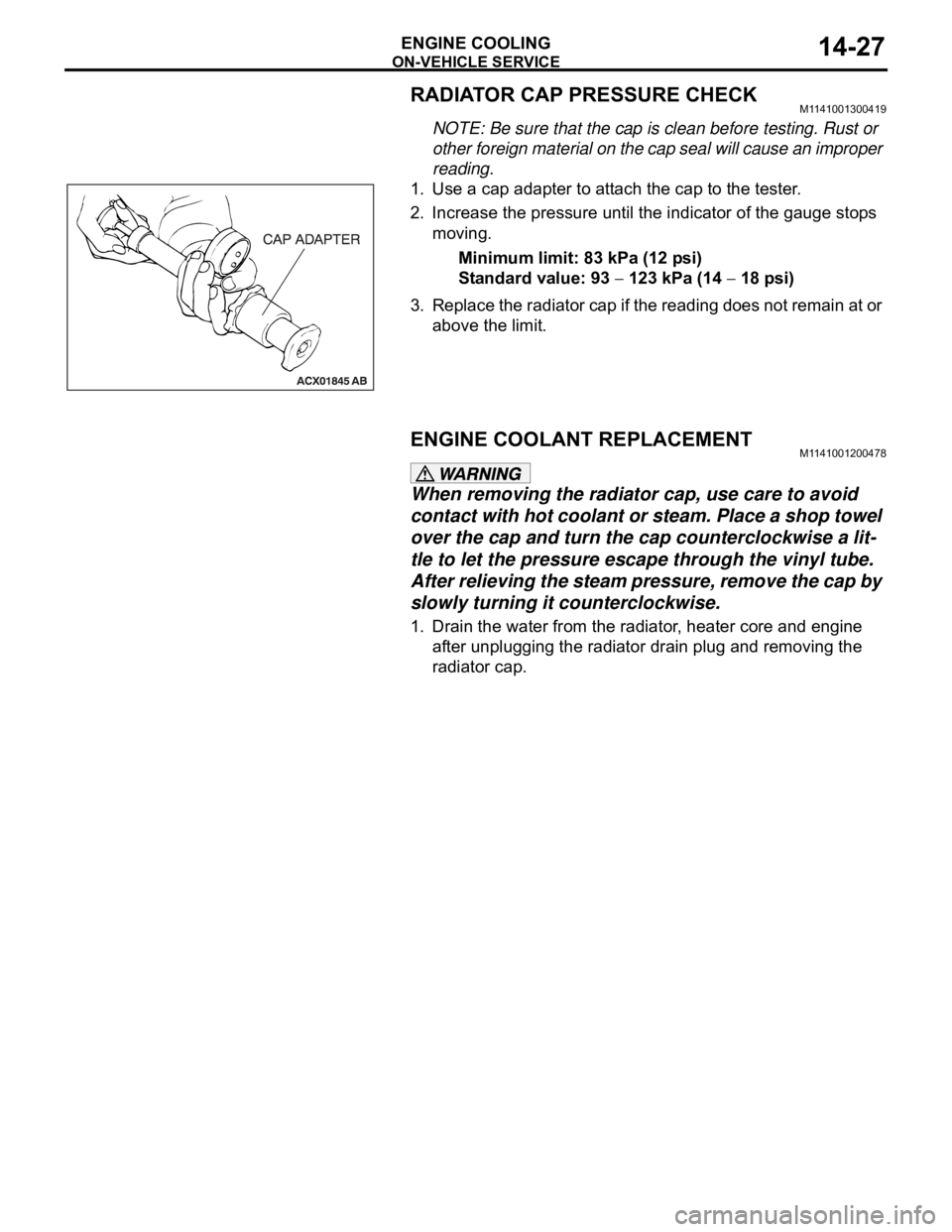

RADIATOR CAP PRESSURE CHECKM1141001300419

NOTE: Be sure that the cap is clean before testing. Rust or

other foreign material on the cap seal will cause an improper

reading.

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the gauge stops

moving.

Minimum limit: 83 kPa (12 psi)

Standard value: 93

123 kPa (14 18 psi)

3. Replace the radiator cap if the reading does not remain at or

above the limit.

ENGINE COOLANT REPLACEMENTM1141001200478

When removing the radiator cap, use care to avoid

contact with hot coolant or steam. Place a shop towel

over the cap and turn the cap counterclockwise a lit-

tle to let the pressure escape through the vinyl tube.

After relieving the steam pressure, remove the cap by

slowly turning it counterclockwise.

1. Drain the water from the radiator, heater core and engine

after unplugging the radiator drain plug and removing the

radiator cap.

Page 943 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-28

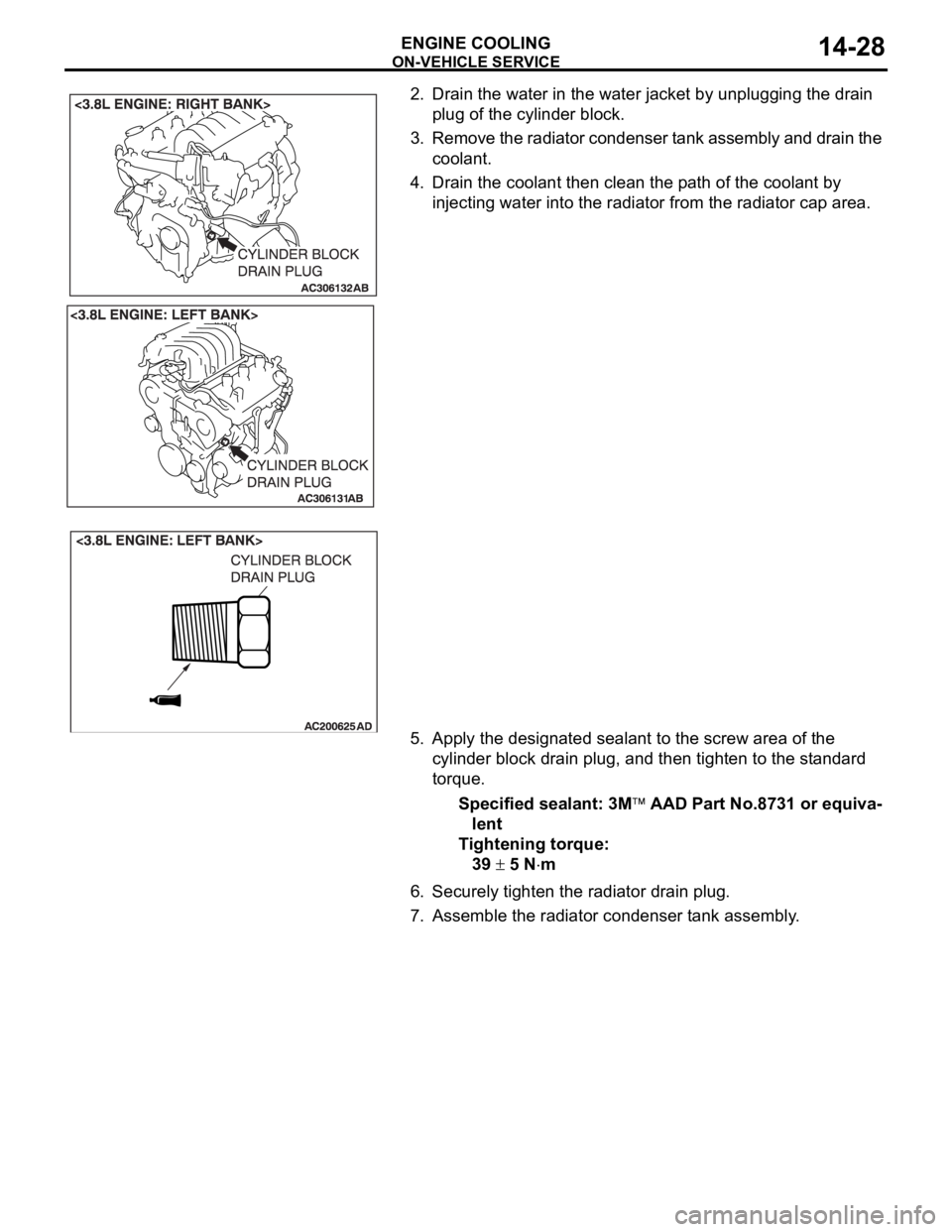

2. Drain the water in the water jacket by unplugging the drain

plug of the cylinder block.

3. Remove the radiator condenser tank assembly and drain the

coolant.

4. Drain the coolant then clean the path of the coolant by

injecting water into the radiator from the radiator cap area.

5. Apply the designated sealant to the screw area of the

cylinder block drain plug, and then tighten to the standard

torque.

Specified sealant: 3M

AAD Part No.8731 or equiva-

lent

Tightening torque:

39

5 Nm

6. Securely tighten the radiator drain plug.

7. Assemble the radiator condenser tank assembly.

Page 949 of 1500

Page 957 of 1500

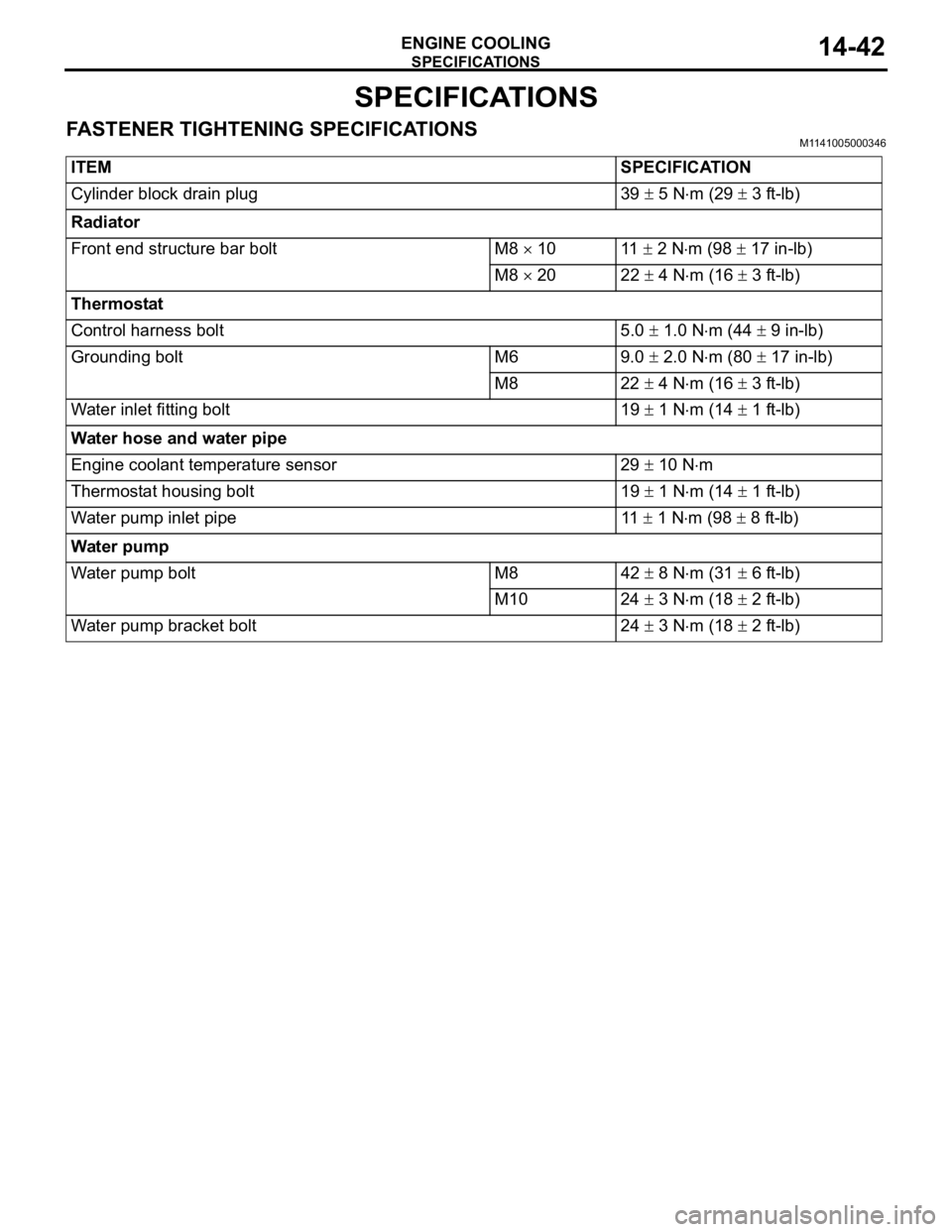

SPECIFICATIONS

ENGINE COOLING14-42

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONSM1141005000346

ITEM SPECIFICATION

Cylinder block drain plug 39

5 Nm (29 3 ft-lb)

Radiator

Front end structure bar bolt M8

10 11 2 Nm (98 17 in-lb)

M8

20 22 4 Nm (16 3 ft-lb)

Thermostat

Control harness bolt 5.0

1.0 Nm (44 9 in-lb)

Grounding bolt M6 9.0

2.0 Nm (80 17 in-lb)

M8 22

4 Nm (16 3 ft-lb)

Water inlet fitting bolt 19

1 Nm (14 1 ft-lb)

Water hose and water pipe

Engine coolant temperature sensor 29

10 Nm

Thermostat housing bolt 19

1 Nm (14 1 ft-lb)

Water pump inlet pipe 11

1 Nm (98 8 ft-lb)

Water pump

Water pump bolt M8 42

8 Nm (31 6 ft-lb)

M10 24

3 Nm (18 2 ft-lb)

Water pump bracket bolt 24

3 Nm (18 2 ft-lb)

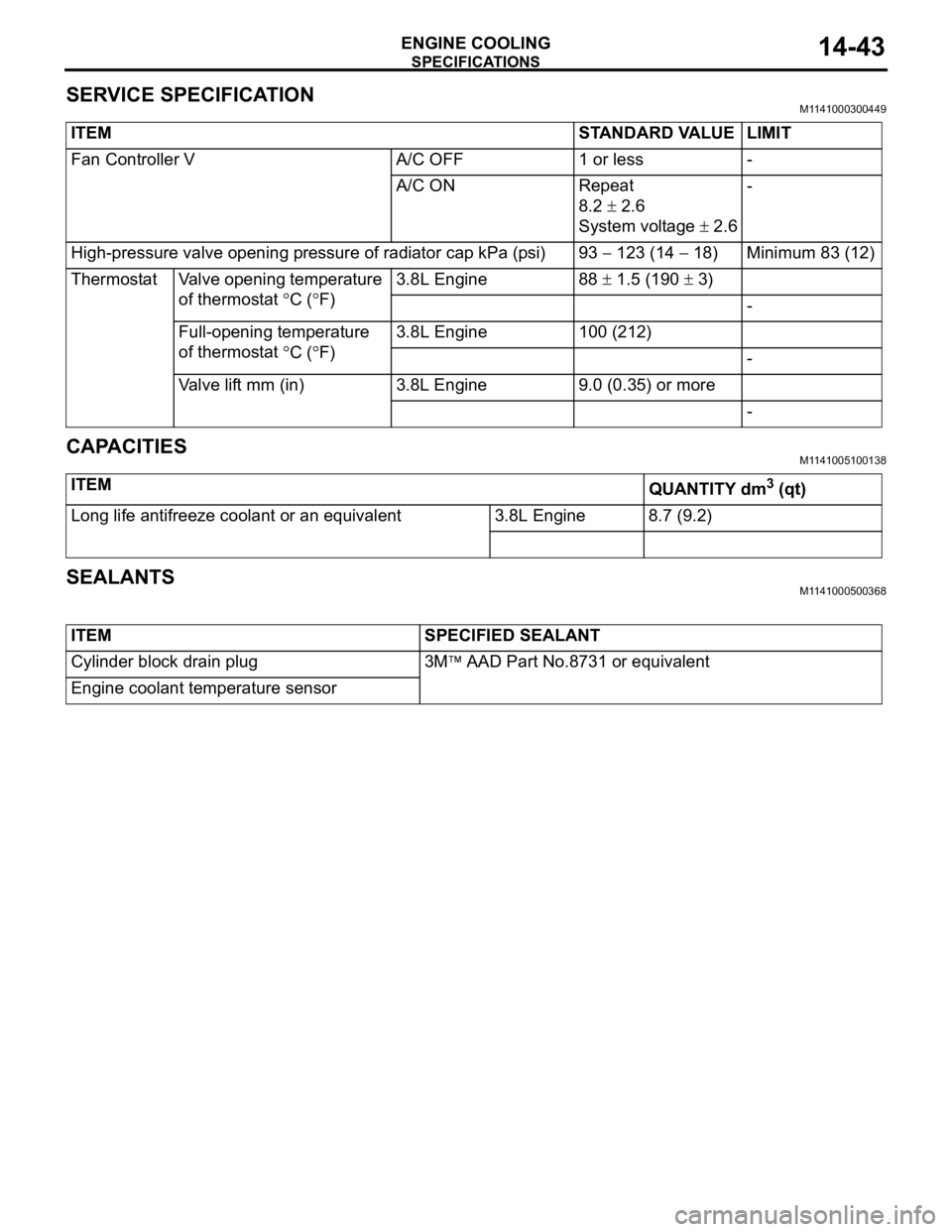

Page 958 of 1500

SPECIFICATIONS

ENGINE COOLING14-43

SERVICE SPECIFICATIONM1141000300449

CAPACITIESM1141005100138

SEALANTSM1141000500368

ITEM STANDARD VALUE LIMIT

Fan Controller V A/C OFF 1 or less -

A/C ON Repeat

8.2

2.6

System voltage

2.6-

High-pressure valve opening pressure of radiator cap kPa (psi) 93

123 (14 18) Minimum 83 (12)

Thermostat Valve opening temperature

of thermostat

C (F)3.8L Engine 88

1.5 (190 3)

-

Full-opening temperature

of thermostat

C (F)3.8L Engine 100 (212)

-

Valve lift mm (in) 3.8L Engine 9.0 (0.35) or more

-

ITEM

QUANTITY dm3 (qt)

Long life antifreeze coolant or an equivalent 3.8L Engine 8.7 (9.2)

ITEM SPECIFIED SEALANT

Cylinder block drain plug 3M

AAD Part No.8731 or equivalent

Engine coolant temperature sensor