headlights MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 18 of 1500

SWS DIAGNOSIS

SIMPLIFIED WIRING SYSTEM (SWS)54B-18

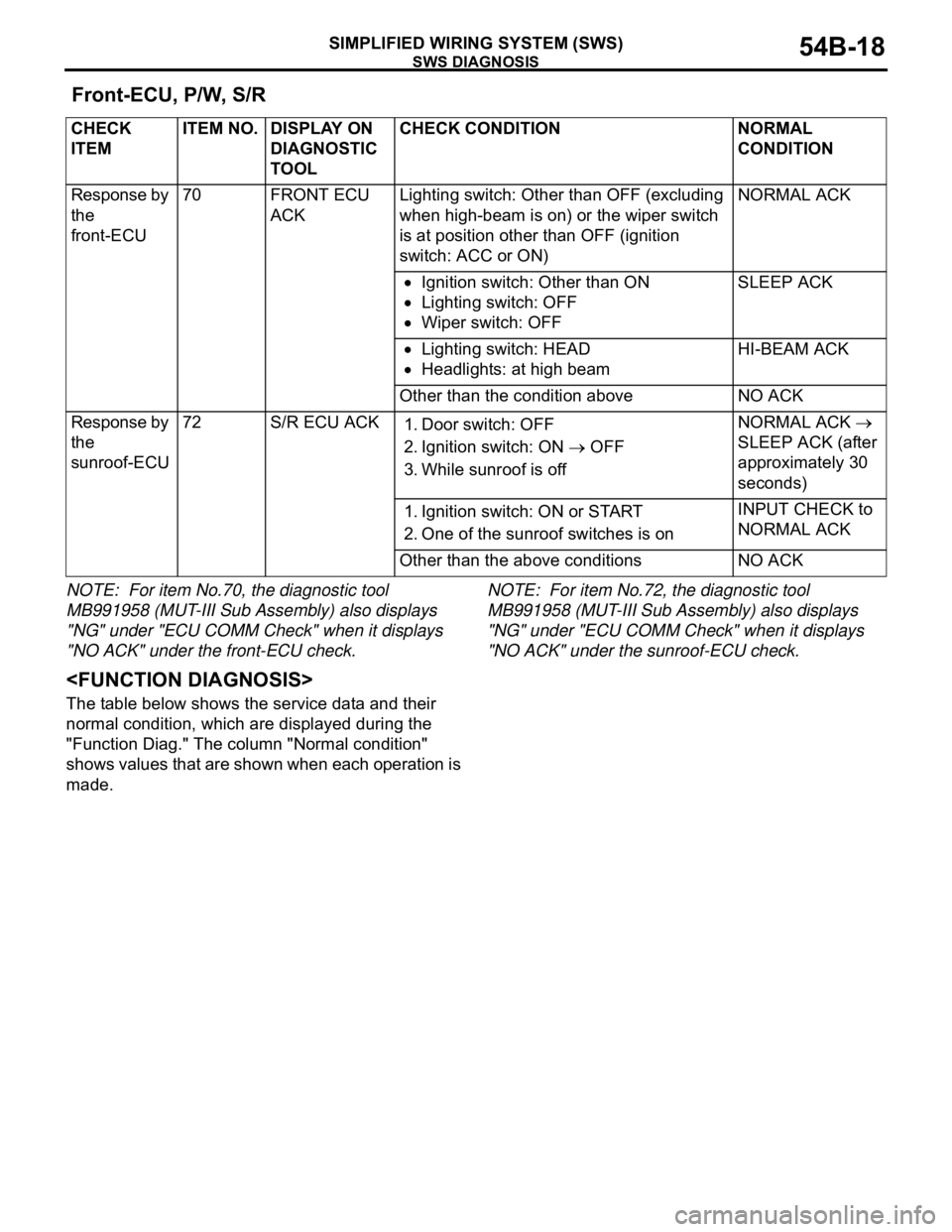

Front-ECU, P/W, S/R

NOTE: For item No.70, the diagnostic tool

MB991958 (MUT-III Sub Assembly) also displays

"NG" under "ECU COMM Check" when it displays

"NO ACK" under the front-ECU check.NOTE: For item No.72, the diagnostic tool

MB991958 (MUT-III Sub Assembly) also displays

"NG" under "ECU COMM Check" when it displays

"NO ACK" under the sunroof-ECU check.

The table below shows the service data and their

normal condition, which are displayed during the

"Function Diag." The column "Normal condition"

shows values that are shown when each operation is

made.

.

CHECK

ITEMITEM NO. DISPLAY ON

DIAGNOSTIC

TOOLCHECK CONDITION NORMAL

CONDITION

Response by

the

front-ECU70 FRONT ECU

ACKLighting switch: Other than OFF (excluding

when high-beam is on) or the wiper switch

is at position other than OFF (ignition

switch: ACC or ON)NORMAL ACK

Ignition switch: Other than ON

Lighting switch: OFF

Wiper switch: OFFSLEEP ACK

Lighting switch: HEAD

Headlights: at high beamHI-BEAM ACK

Other than the condition above NO ACK

Response by

the

sunroof-ECU72 S/R ECU ACK

1. Door switch: OFF

2. Ignition switch: ON

OFF

3. While sunroof is offNORMAL ACK

SLEEP ACK (after

approximately 30

seconds)

1. Ignition switch: ON or START

2. One of the sunroof switches is onINPUT CHECK to

NORMAL ACK

Other than the above conditions NO ACK

Page 59 of 1500

SYMPTOM CHART

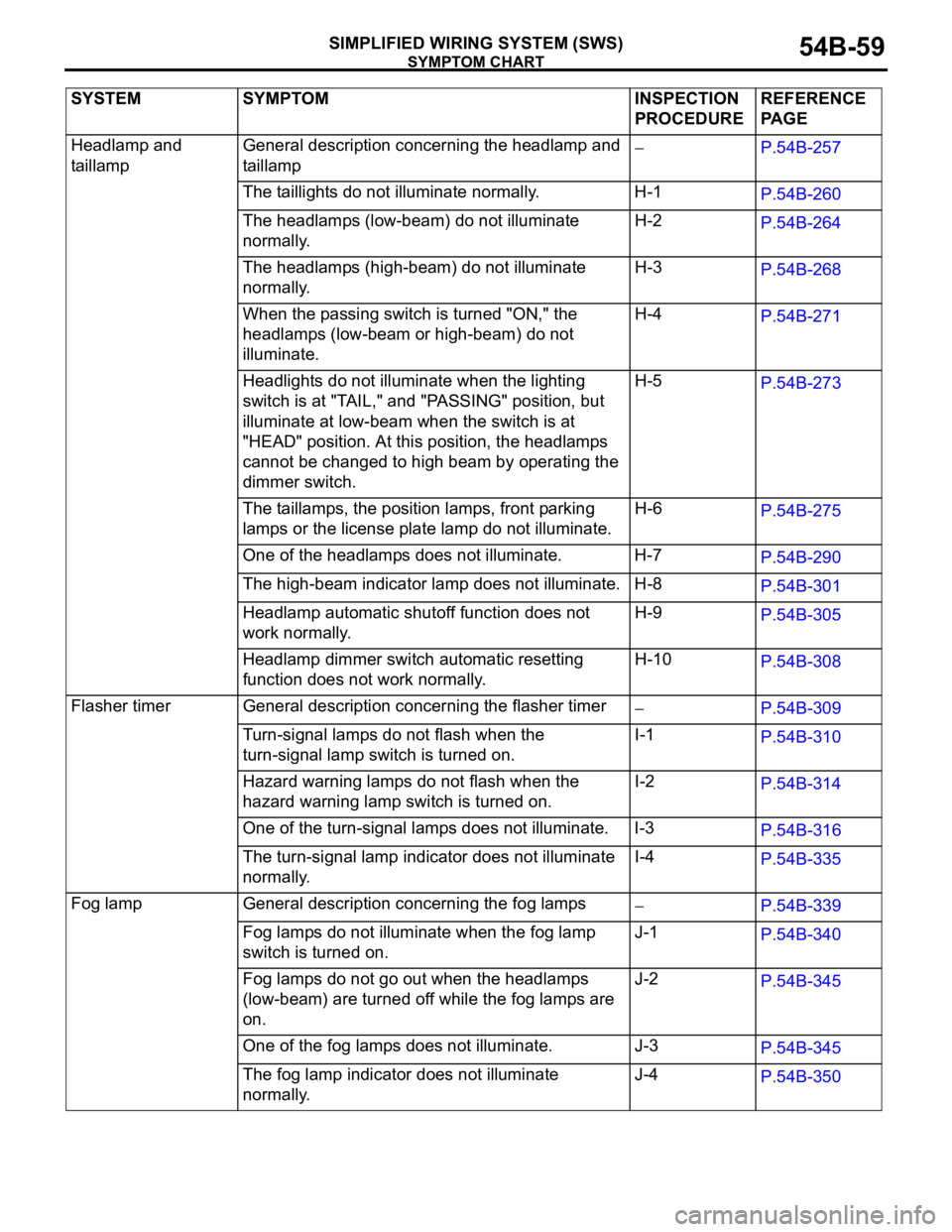

SIMPLIFIED WIRING SYSTEM (SWS)54B-59

Headlamp and

taillampGeneral description concerning the headlamp and

taillampP.54B-257

The taillights do not illuminate normally. H-1

P.54B-260

The headlamps (low-beam) do not illuminate

normally.H-2

P.54B-264

The headlamps (high-beam) do not illuminate

normally.H-3

P.54B-268

When the passing switch is turned "ON," the

headlamps (low-beam or high-beam) do not

illuminate.H-4

P.54B-271

Headlights do not illuminate when the lighting

switch is at "TAIL," and "PASSING" position, but

illuminate at low-beam when the switch is at

"HEAD" position. At this position, the headlamps

cannot be changed to high beam by operating the

dimmer switch.H-5

P.54B-273

The taillamps, the position lamps, front parking

lamps or the license plate lamp do not illuminate.H-6

P.54B-275

One of the headlamps does not illuminate. H-7

P.54B-290

The high-beam indicator lamp does not illuminate. H-8

P.54B-301

Headlamp automatic shutoff function does not

work normally.H-9

P.54B-305

Headlamp dimmer switch automatic resetting

function does not work normally.H-10

P.54B-308

Flasher timer General description concerning the flasher timer

P.54B-309

Turn-signal lamps do not flash when the

turn-signal lamp switch is turned on.I-1

P.54B-310

Hazard warning lamps do not flash when the

hazard warning lamp switch is turned on.I-2

P.54B-314

One of the turn-signal lamps does not illuminate. I-3

P.54B-316

The turn-signal lamp indicator does not illuminate

normally.I-4

P.54B-335

Fog lamp General description concerning the fog lamps

P.54B-339

Fog lamps do not illuminate when the fog lamp

switch is turned on.J-1

P.54B-340

Fog lamps do not go out when the headlamps

(low-beam) are turned off while the fog lamps are

on.J-2

P.54B-345

One of the fog lamps does not illuminate. J-3

P.54B-345

The fog lamp indicator does not illuminate

normally.J-4

P.54B-350 SYSTEM SYMPTOM INSPECTION

PROCEDUREREFERENCE

PA G E

Page 484 of 1500

CHECK AT ECU TERMINAL

SIMPLIFIED WIRING SYSTEM (SWS)54B-484

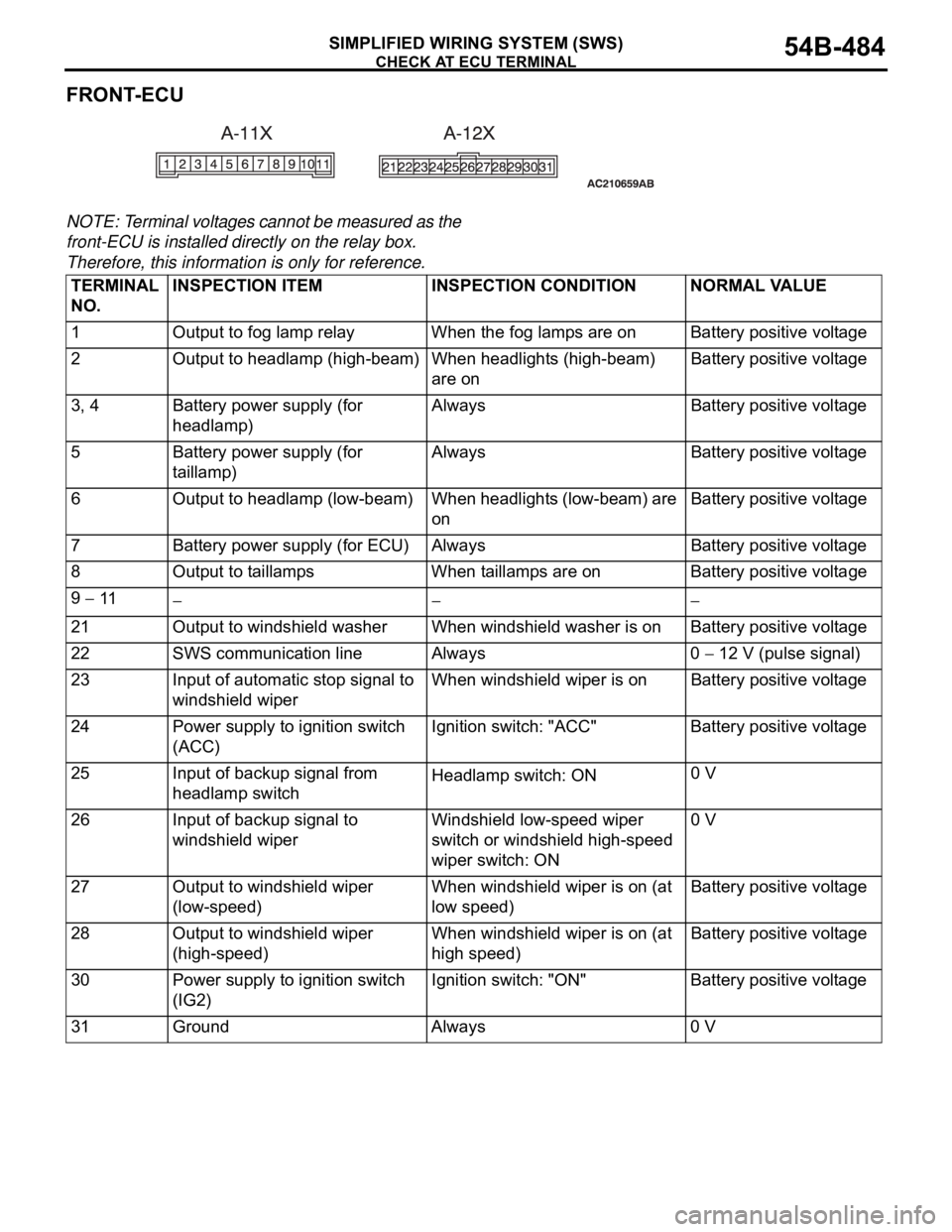

FRONT-ECU

NOTE: Terminal voltages cannot be measured as the

front-ECU is installed directly on the relay box.

Therefore, this information is only for reference.

TERMINAL

NO.INSPECTION ITEM INSPECTION CONDITION NORMAL VALUE

1 Output to fog lamp relay When the fog lamps are on Battery positive voltage

2 Output to headlamp (high-beam) When headlights (high-beam)

are onBattery positive voltage

3, 4 Battery power supply (for

headlamp)Always Battery positive voltage

5 Battery power supply (for

taillamp)Always Battery positive voltage

6 Output to headlamp (low-beam) When headlights (low-beam) are

onBattery positive voltage

7 Battery power supply (for ECU) Always Battery positive voltage

8 Output to taillamps When taillamps are on Battery positive voltage

9

11

21 Output to windshield washer When windshield washer is on Battery positive voltage

22 SWS communication line Always 0

12 V (pulse signal)

23 Input of automatic stop signal to

windshield wiperWhen windshield wiper is on Battery positive voltage

24 Power supply to ignition switch

(ACC)Ignition switch: "ACC" Battery positive voltage

25 Input of backup signal from

headlamp switchHeadlamp switch: ON0 V

26 Input of backup signal to

windshield wiperWindshield low-speed wiper

switch or windshield high-speed

wiper switch: ON0 V

27 Output to windshield wiper

(low-speed)When windshield wiper is on (at

low speed)Battery positive voltage

28 Output to windshield wiper

(high-speed)When windshield wiper is on (at

high speed)Battery positive voltage

30 Power supply to ignition switch

(IG2)Ignition switch: "ON" Battery positive voltage

31 Ground Always 0 V

Page 985 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-8

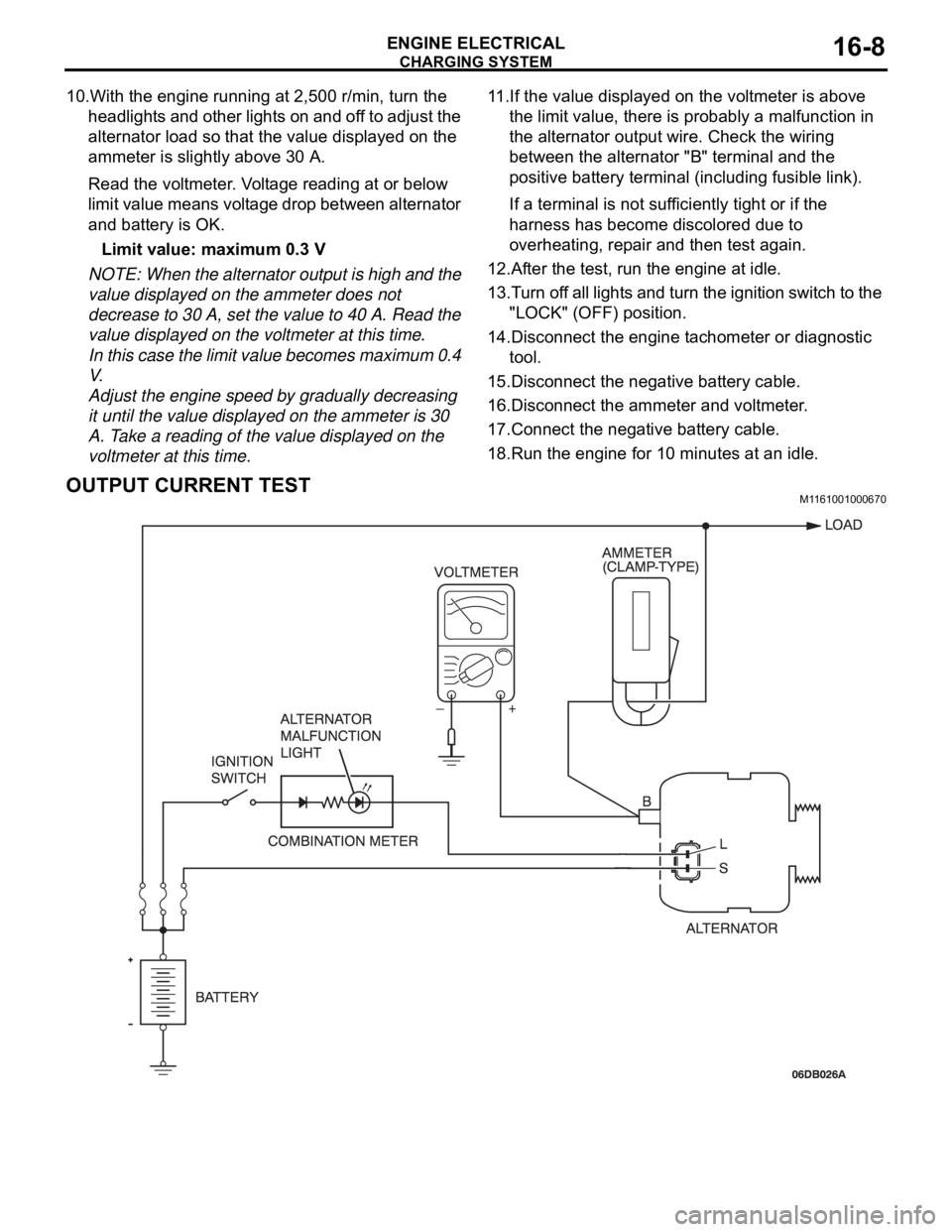

10.With the engine running at 2,500 r/min, turn the

headlights and other lights on and off to adjust the

alternator load so that the value displayed on the

ammeter is slightly above 30 A.

Read the voltmeter. Voltage reading at or below

limit value means voltage drop between alternator

and battery is OK.

Limit value: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease to 30 A, set the value to 40 A. Read the

value displayed on the voltmeter at this time.

In this case the limit value becomes maximum 0.4

V.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire. Check the wiring

between the alternator "B" terminal and the

positive battery terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lights and turn the ignition switch to the

"LOCK" (OFF) position.

14.Disconnect the engine tachometer or diagnostic

tool.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

18.Run the engine for 10 minutes at an idle.

OUTPUT CURRENT TESTM1161001000670

Page 986 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-9

Required Special Tool:

: Diagnostic Tool (MUT-III)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

This test determines whether the alternator outputs

normal current. For best results, use a charging sys-

tem tester. If not available, follow the steps below.

Battery posts, terminals and related acces-

sories contain lead and lead compounds.

WASH HANDS AFTER HANDLING.

1. Before the test, always be sure to check the

following.

Alternator installation

Battery (Refer to GROUP 54A, Chassis Electrical

Battery On-vehicle Service Battery Check

P.54A-5.)

NOTE: The battery to be used should be slightly

discharged. The load in a fully-charged battery

will be insufficient and the test may not be able to

be carried out correctly.

Alternator drive belt tension (Refer to GROUP 00,

General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

Fusible link

Abnormal noise from the alternator while the

engine is running.

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

Never use clips to connect the wire. Loose

connections (for example, using clips) will

lead to a serious accident because of high

current.

4. Connect a clamp-type DC test ammeter with a

range of 0

120 A to the alternator "B" terminal

output wire.

5. Connect a voltmeter with a range of 0

20 V

between the alternator "B" terminal and ground.

(Connect the positive lead of the voltmeter to the

"B" terminal, and then connect the negative lead

of the voltmeter to ground.)

6. Connect the negative battery cable.

7. Connect an engine tachometer or diagnostic tool.

8. Leave the hood open.9. Check to be sure that the reading on the voltmeter

is equal to the battery positive voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery positive

terminal or malfunctioning voltmeter.

10.After turning on the headlights, start the engine.

NOTE: Because the current from the battery will

soon drop after the engine is started, step 11

should be carried out as quickly as possible in

order to obtain the maximum current output value.

11.Immediately after setting the headlights to high

beam and turning the heater blower switch to the

highest position, increase the engine speed to

2,500 r/min and read the maximum current output

value displayed on the ammeter.

Limit value: 70 % of nominal current output

NOTE: For the nominal current output, refer to the

Alternator Specifications.

NOTE: The current output value will depend on

the electrical load and the temperature of the

alternator body.

NOTE: If the electrical load is small while testing,

the specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving the

headlights turned on for some time to discharge

the battery or by using the lighting system in

another vehicle, and then test again.

NOTE: The specified level of current also may not

be output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle speed after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Disconnect the engine tachometer or diagnostic

tool.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter .

18.Connect the negative battery cable.

19.Run the engine for 10 minutes at an idle.

Page 989 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-12

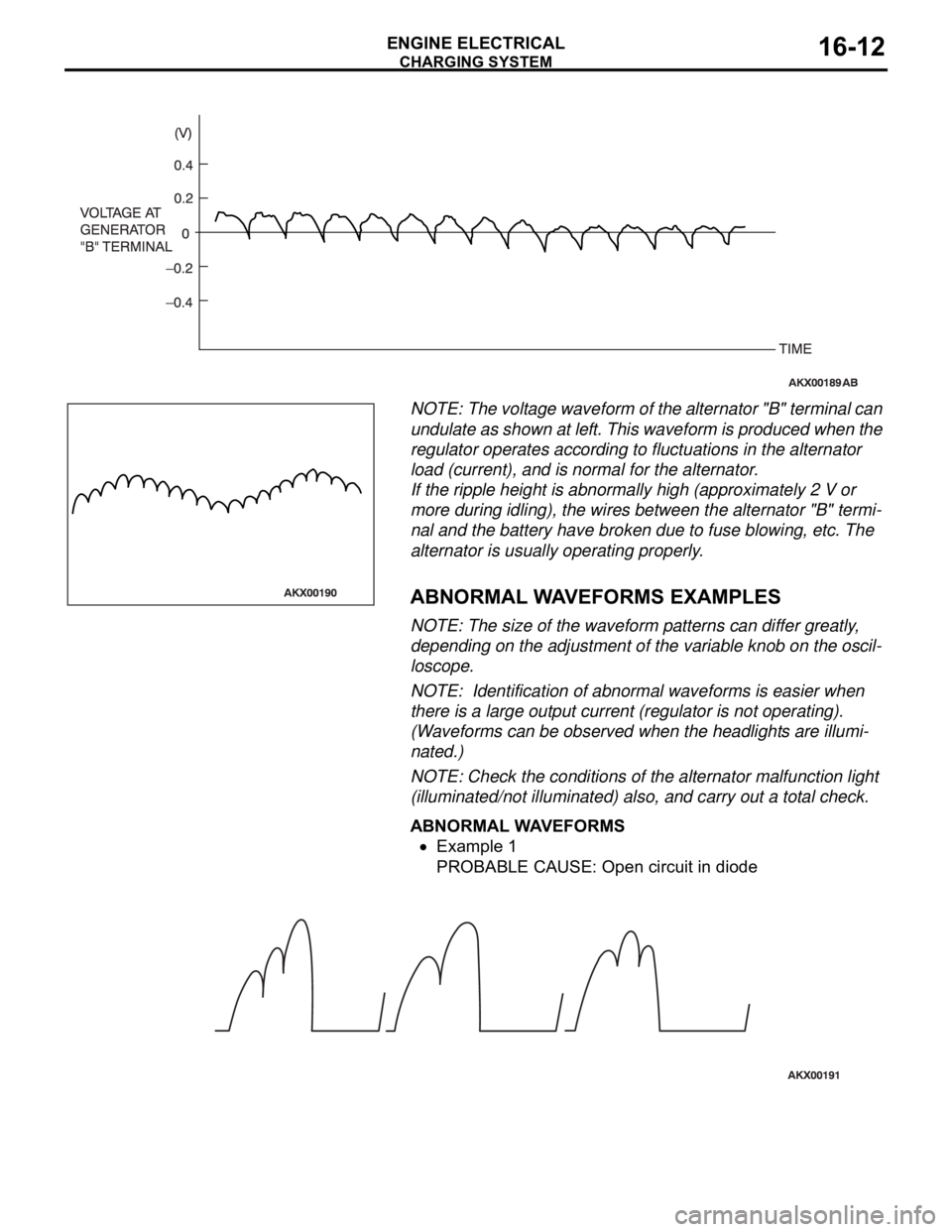

NOTE: The voltage waveform of the alternator "B" terminal can

undulate as shown at left. This waveform is produced when the

regulator operates according to fluctuations in the alternator

load (current), and is normal for the alternator.

If the ripple height is abnormally high (approximately 2 V or

more during idling), the wires between the alternator "B" termi-

nal and the battery have broken due to fuse blowing, etc. The

alternator is usually operating properly.

.

ABNORMAL WAVEFORMS EXAMPLES

NOTE: The size of the waveform patterns can differ greatly,

depending on the adjustment of the variable knob on the oscil-

loscope.

NOTE: Identification of abnormal waveforms is easier when

there is a large output current (regulator is not operating).

(Waveforms can be observed when the headlights are illumi-

nated.)

NOTE: Check the conditions of the alternator malfunction light

(illuminated/not illuminated) also, and carry out a total check.

ABNORMAL WAVEFORMS

Example 1

PROBABLE CAUSE: Open circuit in diode