length MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 996 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-19

2. Check the continuity between the negative rectifier and the

stator coil lead connection terminal with a tester. If there is

continuity between the terminals, the diode is grounded, so

replace the rectifier.

3. Check the continuity of the three diodes by connecting an

ohmmeter to both ends of each diode. If there is continuity

between the directions, or if there is no continuity, the diode

is damaged, so replace the rectifier.

.

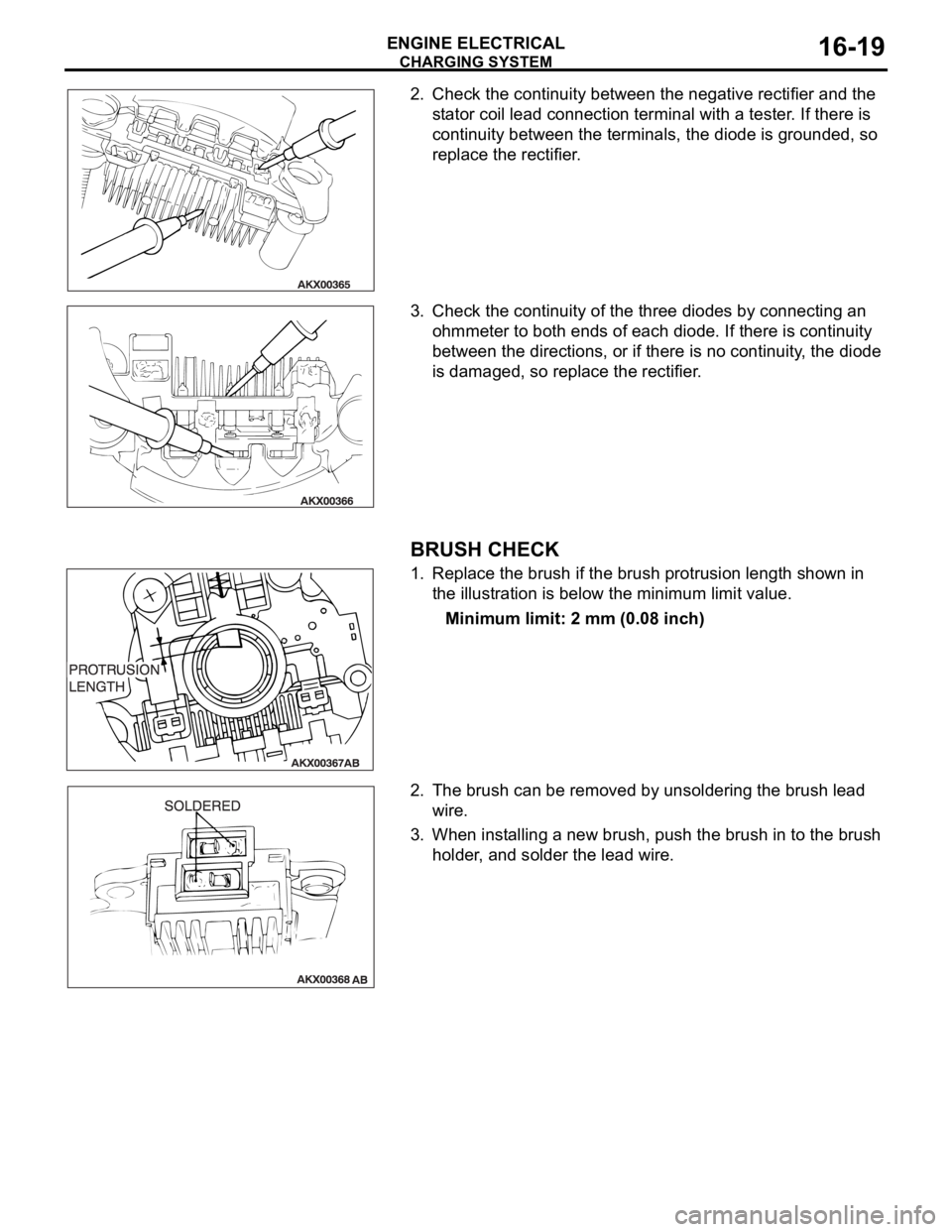

BRUSH CHECK

1. Replace the brush if the brush protrusion length shown in

the illustration is below the minimum limit value.

Minimum limit: 2 mm (0.08 inch)

2. The brush can be removed by unsoldering the brush lead

wire.

3. When installing a new brush, push the brush in to the brush

holder, and solder the lead wire.

Page 1005 of 1500

STARTING SYSTEM

ENGINE ELECTRICAL16-28

INSPECTIONM1162001300102.

COMMUTATOR CHECK

1. Place the armature on a pair of V-blocks, and check the

deflection by using a dial gauge.

Standard value: 0.05 mm (0.002 inch)

Limit: 0.1 mm (0.004 inch)

2. Check the outer diameter of the commutator.

Standard value: 29.4 mm (1.16 inches)

Minimum limit: 28.8 mm (1.13 inches)

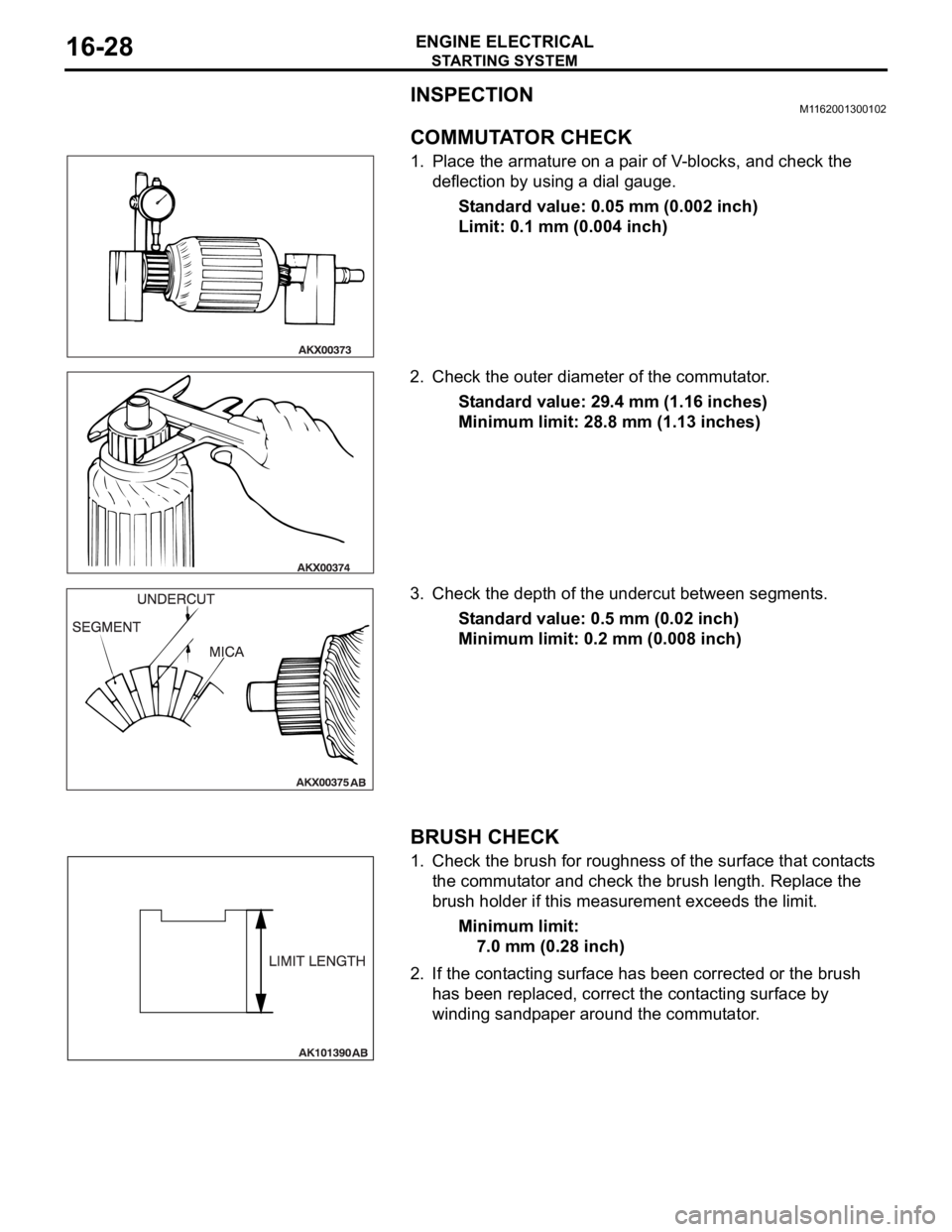

3. Check the depth of the undercut between segments.

Standard value: 0.5 mm (0.02 inch)

Minimum limit: 0.2 mm (0.008 inch)

.

BRUSH CHECK

1. Check the brush for roughness of the surface that contacts

the commutator and check the brush length. Replace the

brush holder if this measurement exceeds the limit.

Minimum limit:

7.0 mm (0.28 inch)

2. If the contacting surface has been corrected or the brush

has been replaced, correct the contacting surface by

winding sandpaper around the commutator.

.

Page 1016 of 1500

SPECIFICATIONS

ENGINE ELECTRICAL16-39

SERVICE SPECIFICATIONSM1161000300322

ITEMS STANDARD VALUE LIMIT

Alternator

Regulated voltage

(Ambient temperature at voltage

regulator)

20C (4F)14.2 15.4

20C (68F) 13.9 14.9

60C (140F) 13.4 14.5

80C (176F) 13.1 14.5

Alternator output wire voltage drop (at 30 A) VMaximum 0.3

Nominal Output current 110A 70 % of normal output

current

Field coil resistance

Approximately 2 5

Brush protrusion length mm (in)Minimum 2 (0.08)

Starter motor

Free running characteristics Terminal voltage

V11

Current A 95

Speed r/min 2,500 or more

Pinion gap mm (in) 0.5 2.0 (0.02 0.07)

Commutator run-out mm (in) 0.05 (0.002) Minimum 0.1 (0.004)

Commutator diameter mm (in) 29.4 (1.16) Minimum 28.8 (1.13)

Undercut depth mm (in) 0.5 (0.02) Minimum 0.2 (0.008)

Ignition parts

Spark plug gap mm 1.0 1.1

Page 1079 of 1500

STRUT TOWER BAR

BODY42-12

STRUT TOWER BAR

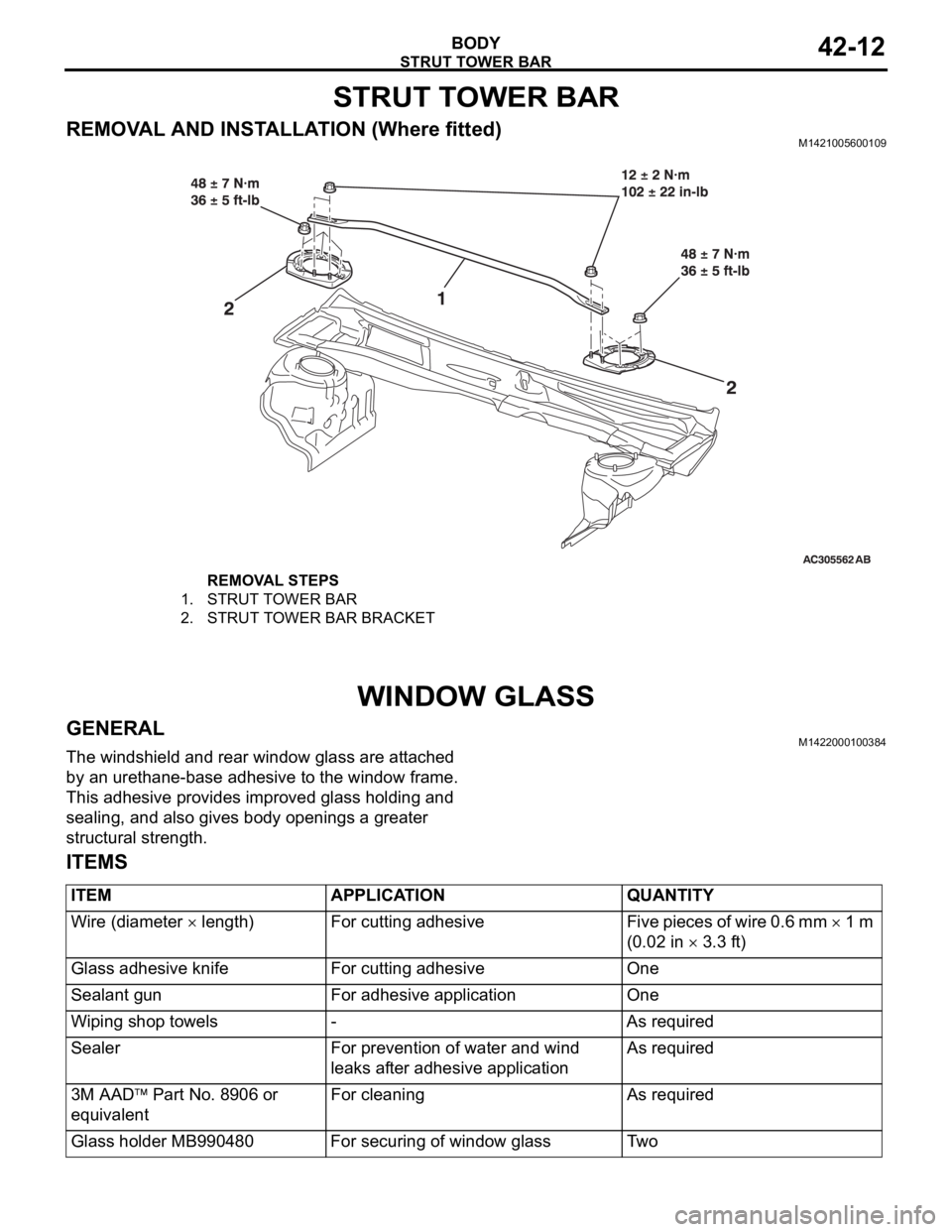

REMOVAL AND INSTALLATION (Where fitted)M1421005600109

WINDOW GLASS

GENERALM1422000100384

The windshield and rear window glass are attached

by an urethane-base adhesive to the window frame.

This adhesive provides improved glass holding and

sealing, and also gives body openings a greater

structural strength.

ITEMS

REMOVAL STEPS

1. STRUT TOWER BAR

2. STRUT TOWER BAR BRACKET

ITEM APPLICATION QUANTITY

Wire (diameter

length) For cutting adhesive Five pieces of wire 0.6 mm 1 m

(0.02 in

3.3 ft)

Glass adhesive knife For cutting adhesive One

Sealant gun For adhesive application One

Wiping shop towels - As required

Sealer For prevention of water and wind

leaks after adhesive applicationAs required

3M AAD

Part No. 8906 or

equivalentFor cleaning As required

Glass holder MB990480 For securing of window glass Two

Page 1154 of 1500

SPECIFICATIONS

BODY42-87

SERVICE SPECIFICATIONSM1421000300299

SEALANT AND ADHESIVESM1421000500204

Door inside handle knob play mm

(in)Front 26.1 - 58.1 (1.028 - 2.287) [Target

value 41 (1.61)]

Rear 30.3 - 58.1 (1.193 - 2.287) [Target

value 41 (1.61)]

Door inside handle lock knob stroke mm (in) 21.6 (0.850)

Door outside handle play mm (in) Front 10

3.5 (0.39 0.138)

Rear 11.2

4 (0.441 0.16)

Power window operation current A 5

1 [Power supply voltage 14.5

0.5V 25

C (77F)]

ITEM STANDARD VALUE

Roof lid glass operation current A 7 or less [at 20

C(68F)]

ITEM SPECIFIED ADHESIVE

Rear window glass 3 M

AAD part No. 8609 super fast urethane and 3 M AAD part No.

8608 super fast urethane primer or equivalent

Windshield

ITEM SPECIFIED SEALANT REMARK

Waterproof film 3 M

AAD Part No. 8633 or equivalent Ribbon sealer

ITEM SPECIFIED ADHESIVE TAPE

Front door opening outer

weatherstripAdhesive tape: Double-sided tape [7 mm (0.28 in) width, 85 mm (3.35

in) length and 0.8 mm (0.03 in) thickness]

Rear door opening outer

weatherstripAdhesive tape: Double-sided tape [7 mm (0.28 in) width, 50 mm (1.97

in) length and 0.8 mm (0.031 in) thickness]

ITEM SPECIFIED SEALANT REMARK

Trunk lid hinge 3 M

AAD part No. 8531 Heavy drip check sealer,

3 M

AAD part No. 8646 Automotive joint and

seam sealer or equivalentBody sealer

Page 1163 of 1500

CLUTCH CONTROL

CLUTCH21A-8

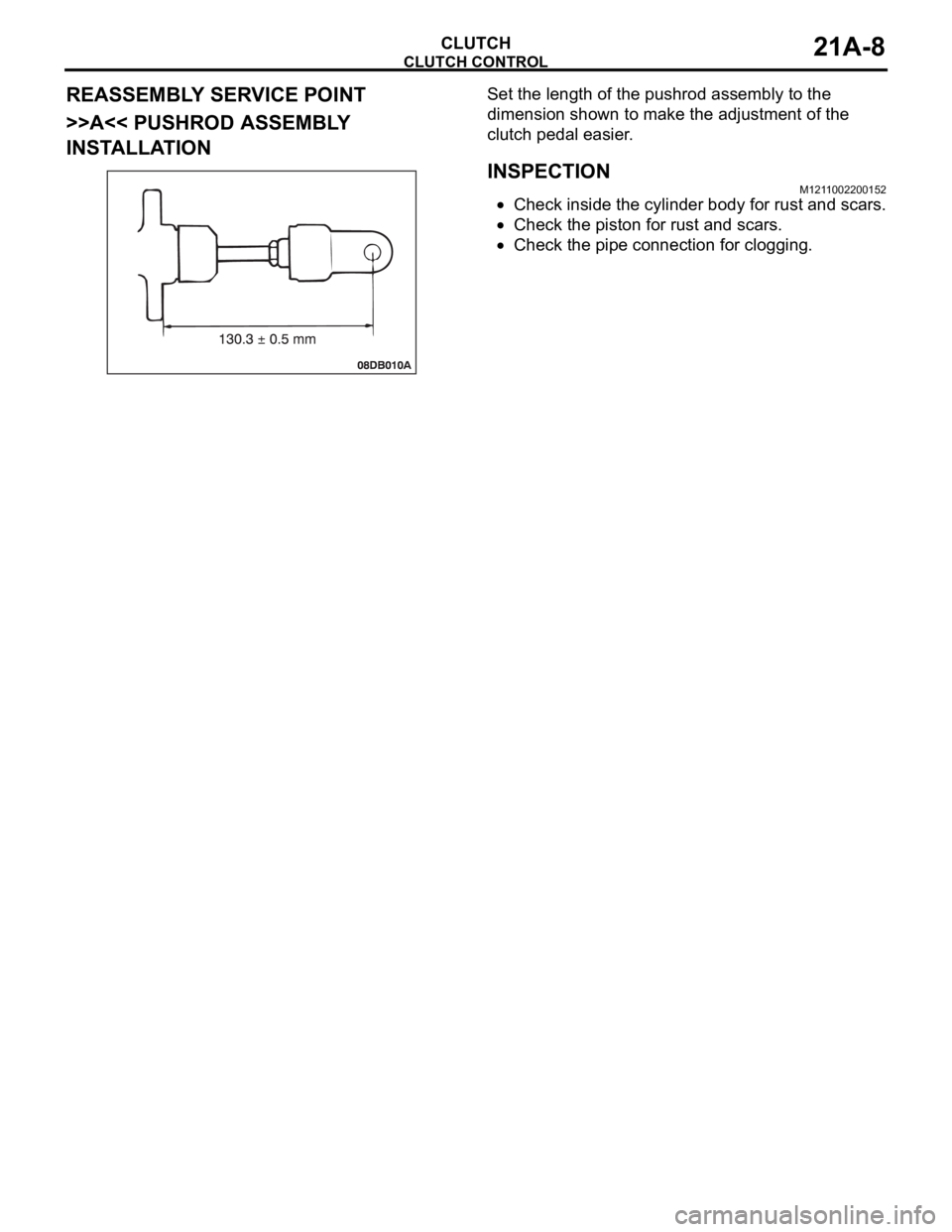

REASSEMBLY SERVICE POINT

>>A<< PUSHROD ASSEMBLY

INSTALLATIONSet the length of the pushrod assembly to the

dimension shown to make the adjustment of the

clutch pedal easier.

INSPECTIONM1211002200152

Check inside the cylinder body for rust and scars.

Check the piston for rust and scars.

Check the pipe connection for clogging.

Page 1193 of 1500

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

BASIC BRAKE SYSTEM35A-28

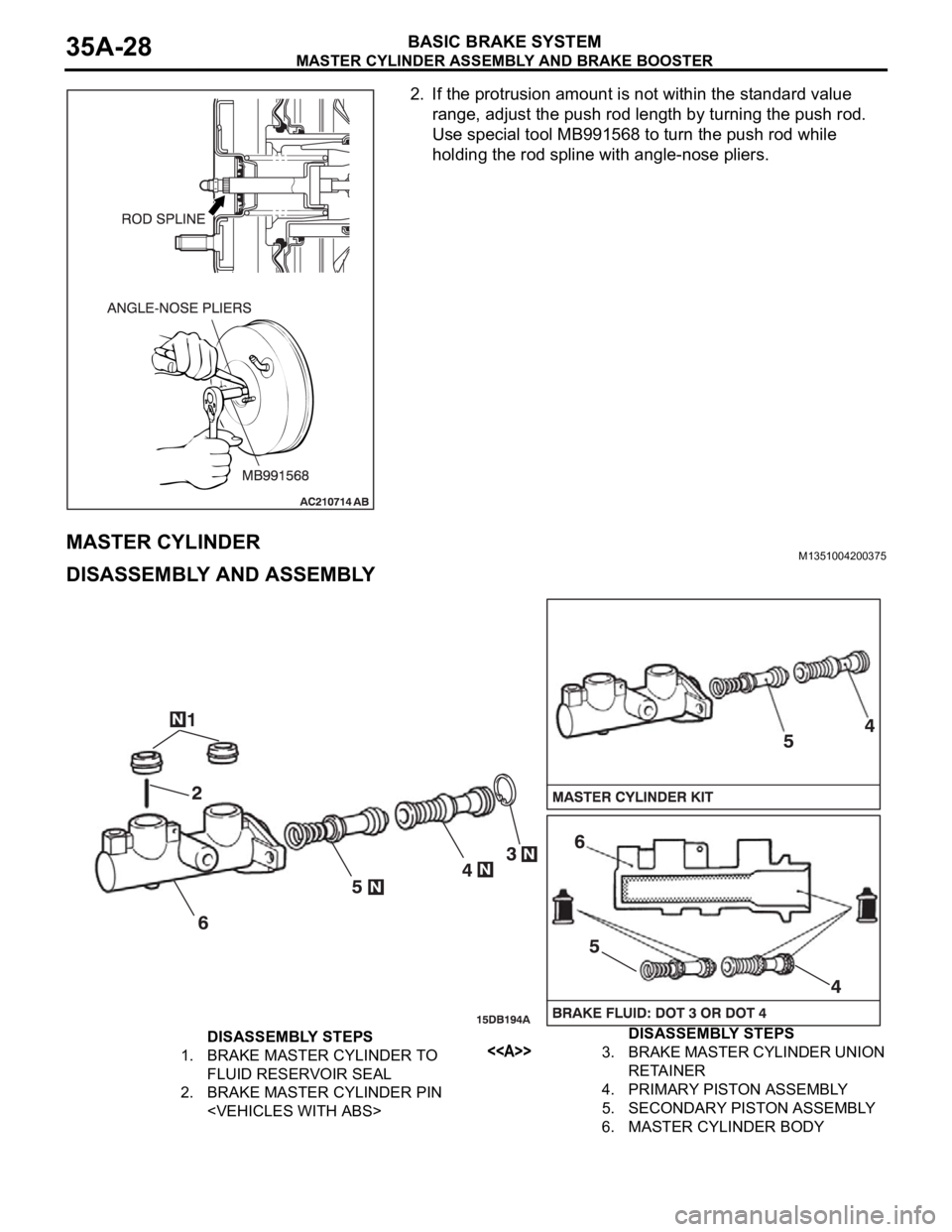

2. If the protrusion amount is not within the standard value

range, adjust the push rod length by turning the push rod.

Use special tool MB991568 to turn the push rod while

holding the rod spline with angle-nose pliers.

MASTER CYLINDERM1351004200375

DISASSEMBLY AND ASSEMBLY

DISASSEMBLY STEPS

1. BRAKE MASTER CYLINDER TO

FLUID RESERVOIR SEAL

2. BRAKE MASTER CYLINDER PIN

RETAINER

4. PRIMARY PISTON ASSEMBLY

5. SECONDARY PISTON ASSEMBLY

6. MASTER CYLINDER BODYDISASSEMBLY STEPS

Page 1206 of 1500

SPECIFICATIONS

BASIC BRAKE SYSTEM35A-41

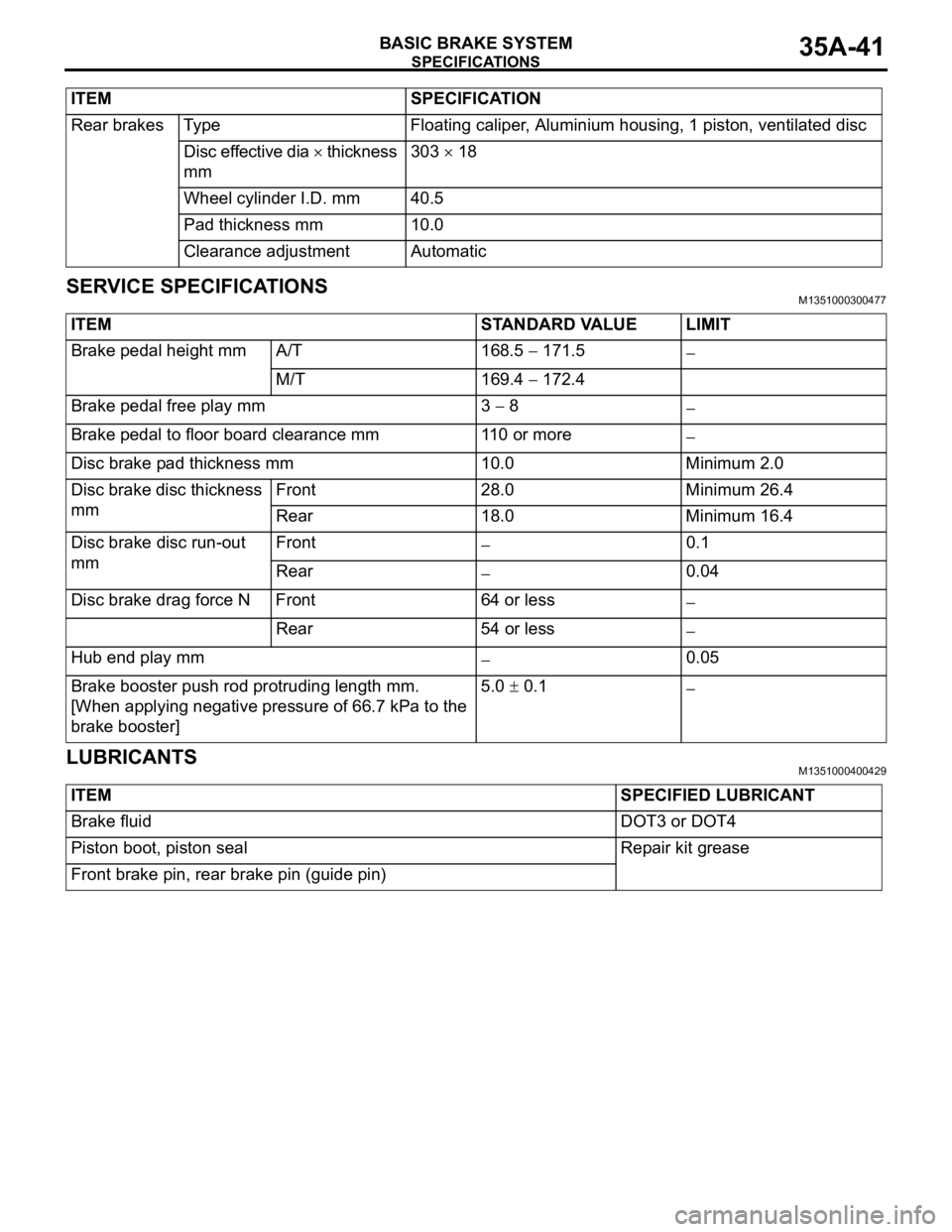

SERVICE SPECIFICATIONSM1351000300477

LUBRICANTSM1351000400429

Rear brakes Type Floating caliper, Aluminium housing, 1 piston, ventilated disc

Disc effective dia

thickness

mm 303 18

Wheel cylinder I.D. mm 40.5

Pad thickness mm 10.0

Clearance adjustment Automatic ITEM SPECIFICATION

ITEM STANDARD VALUE LIMIT

Brake pedal height mm A/T 168.5

171.5

M/T 169.4 172.4

Brake pedal free play mm 3

8

Brake pedal to floor board clearance mm 110 or more

Disc brake pad thickness mm 10.0 Minimum 2.0

Disc brake disc thickness

mm Front 28.0 Minimum 26.4

Rear 18.0 Minimum 16.4

Disc brake disc run-out

mm Front

0.1

Rear

0.04

Disc brake drag force N Front 64 or less

Rear 54 or less

Hub end play mm 0.05

Brake booster push rod protruding length mm.

[When applying negative pressure of 66.7 kPa to the

brake booster]5.0

0.1

ITEM SPECIFIED LUBRICANT

Brake fluid DOT3 or DOT4

Piston boot, piston seal Repair kit grease

Front brake pin, rear brake pin (guide pin)

Page 1252 of 1500

GENERAL DATA AND SPECIFICATIONS

GENERAL00-31

GENERAL DATA AND SPECIFICATIONSM1001000900473.

GENERAL SPECIFICATIONS

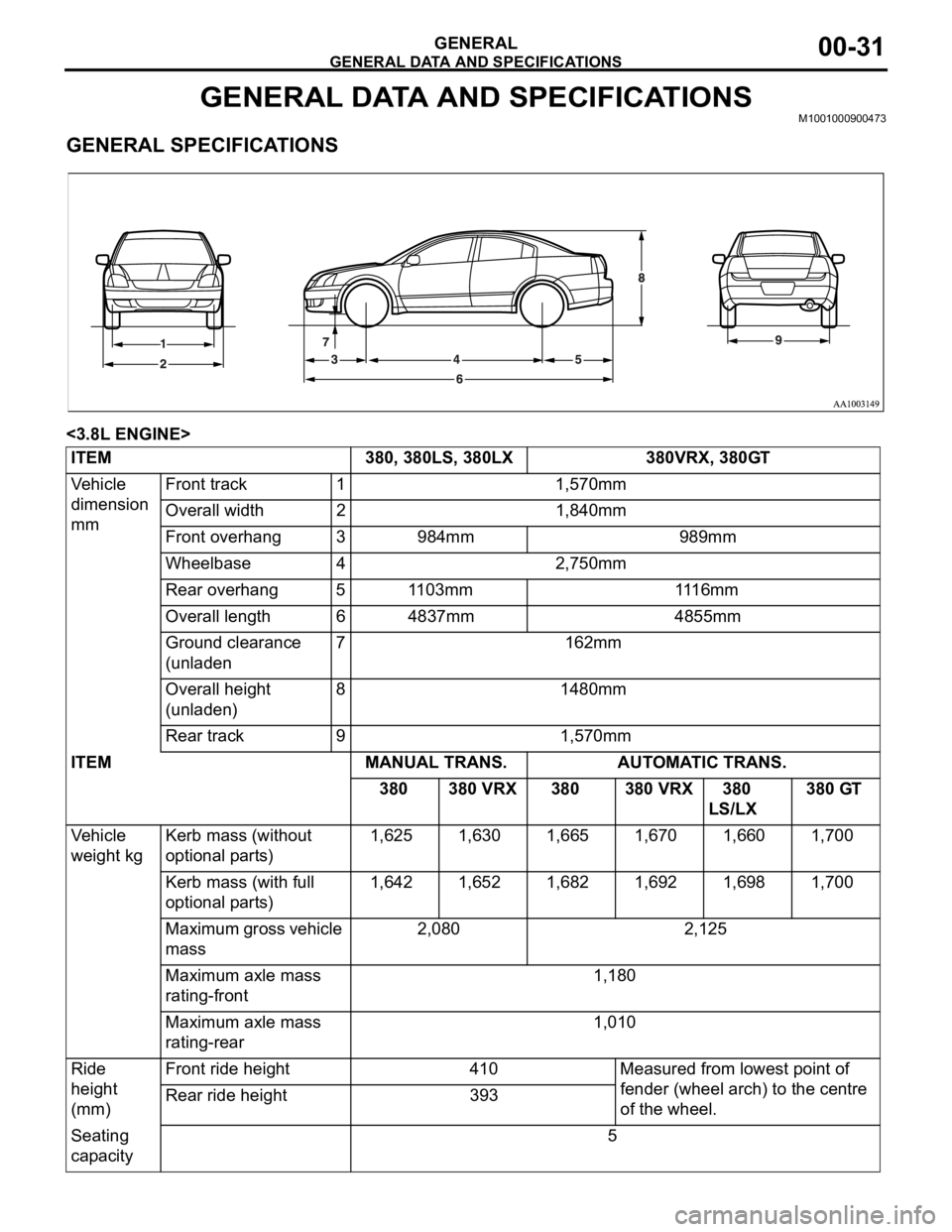

<3.8L ENGINE>

ITEM 380, 380LS, 380LX 380VRX, 380GT

Vehicle

dimension

mmFront track 1 1,570mm

Overall width 2 1,840mm

Front overhang 3 984mm 989mm

Wheelbase 4 2,750mm

Rear overhang 5 1103mm 1116mm

Overall length 6 4837mm 4855mm

Ground clearance

(unladen7 162mm

Overall height

(unladen)8 1480mm

Rear track 9 1,570mm

ITEM MANUAL TRANS. AUTOMATIC TRANS.

380 380 VRX 380 380 VRX 380

LS/LX 380 GT

Vehicle

weight kgKerb mass (without

optional parts) 1,625 1,630 1,665 1,670 1,660 1,700

Kerb mass (with full

optional parts) 1,642 1,652 1,682 1,692 1,698 1,700

Maximum gross vehicle

mass 2,080 2,125

Maximum axle mass

rating-front 1,180

Maximum axle mass

rating-rear 1,010

Ride

height

(mm)Front ride height 410 Measured from lowest point of

fender (wheel arch) to the centre

of the wheel. Rear ride height 393

Seating

capacity 5

Page 1270 of 1500

MAINTENANCE SERVICE

GENERAL00-49

14.Remove the radiator cap after the engine has cooled, and

pour in coolant up to the brim. Reinstall the cap.

Do not overfill the radiator condenser tank assembly.

15.Add coolant to the radiator condenser tank assembly

between the "FULL" and "LOW" mark if necessary.

13. COOLANT HOSES (RADIATOR HOSE,

HEATER HOSE) (INSPECT)

M1001009700034

Inspect the surface of radiator hoses and heater hoses for heat

and mechanical damage. Hard and brittle rubber, cracking,

tears, cuts, abrasions and excessive swelling indicate deterio-

ration of the rubber.

14. DISC BRAKE PADS, ROTORS (INSPECT FOR

WEAR)

M1001003200291

Check for fluid contamination and wear. Replace the complete

set of pads if any one pad is defective.

Thickness of lining

Minimum limit: 2.0 mm

The pads for the right and left wheels should be replaced

at the same time. Never split or intermix brake pad sets. All

four pads must be replaced as a complete set.

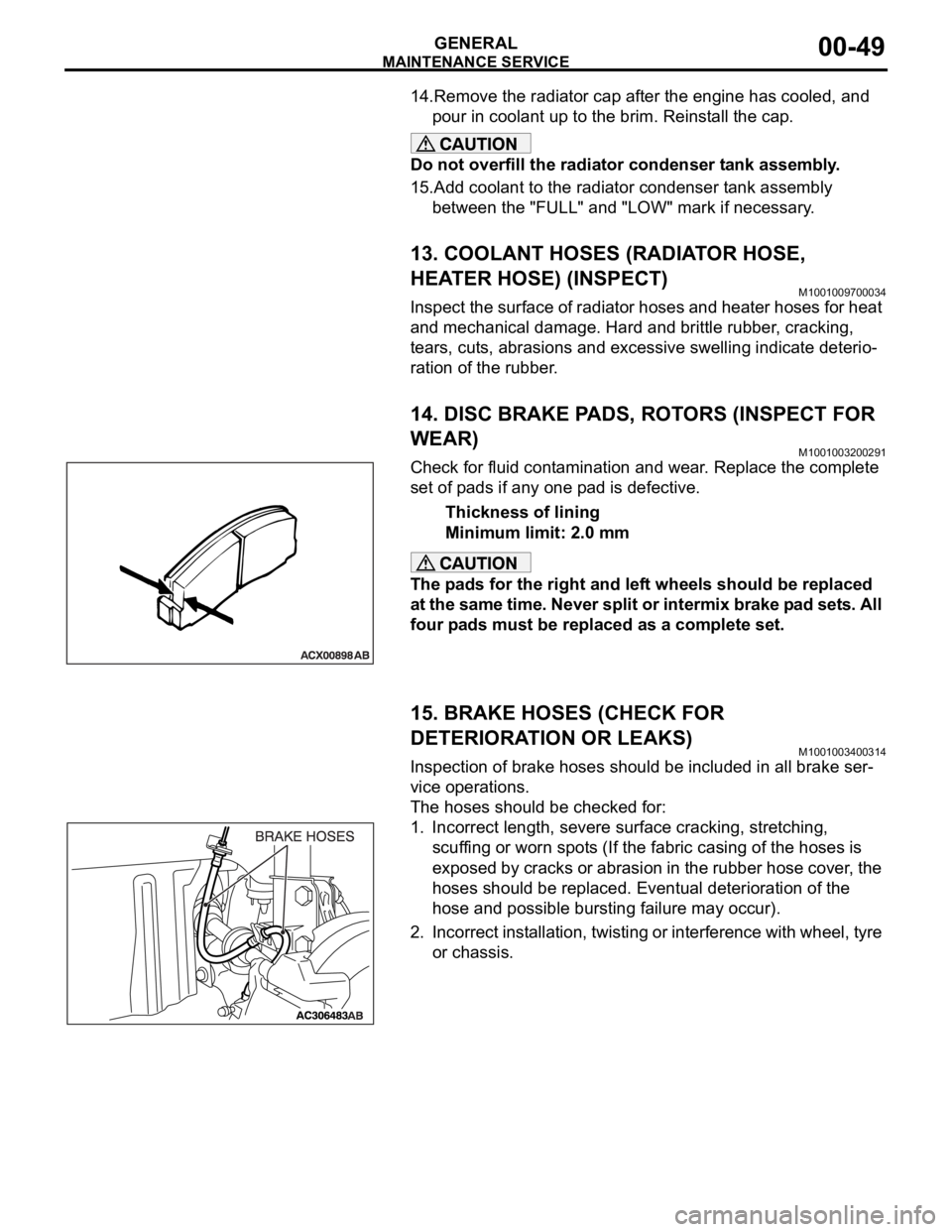

15. BRAKE HOSES (CHECK FOR

DETERIORATION OR LEAKS)

M1001003400314

Inspection of brake hoses should be included in all brake ser-

vice operations.

The hoses should be checked for:

1. Incorrect length, severe surface cracking, stretching,

scuffing or worn spots (If the fabric casing of the hoses is

exposed by cracks or abrasion in the rubber hose cover, the

hoses should be replaced. Eventual deterioration of the

hose and possible bursting failure may occur).

2. Incorrect installation, twisting or interference with wheel, tyre

or chassis.