run flat MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1185 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-20

.

BRAKE DISC THICKNESS CHECK

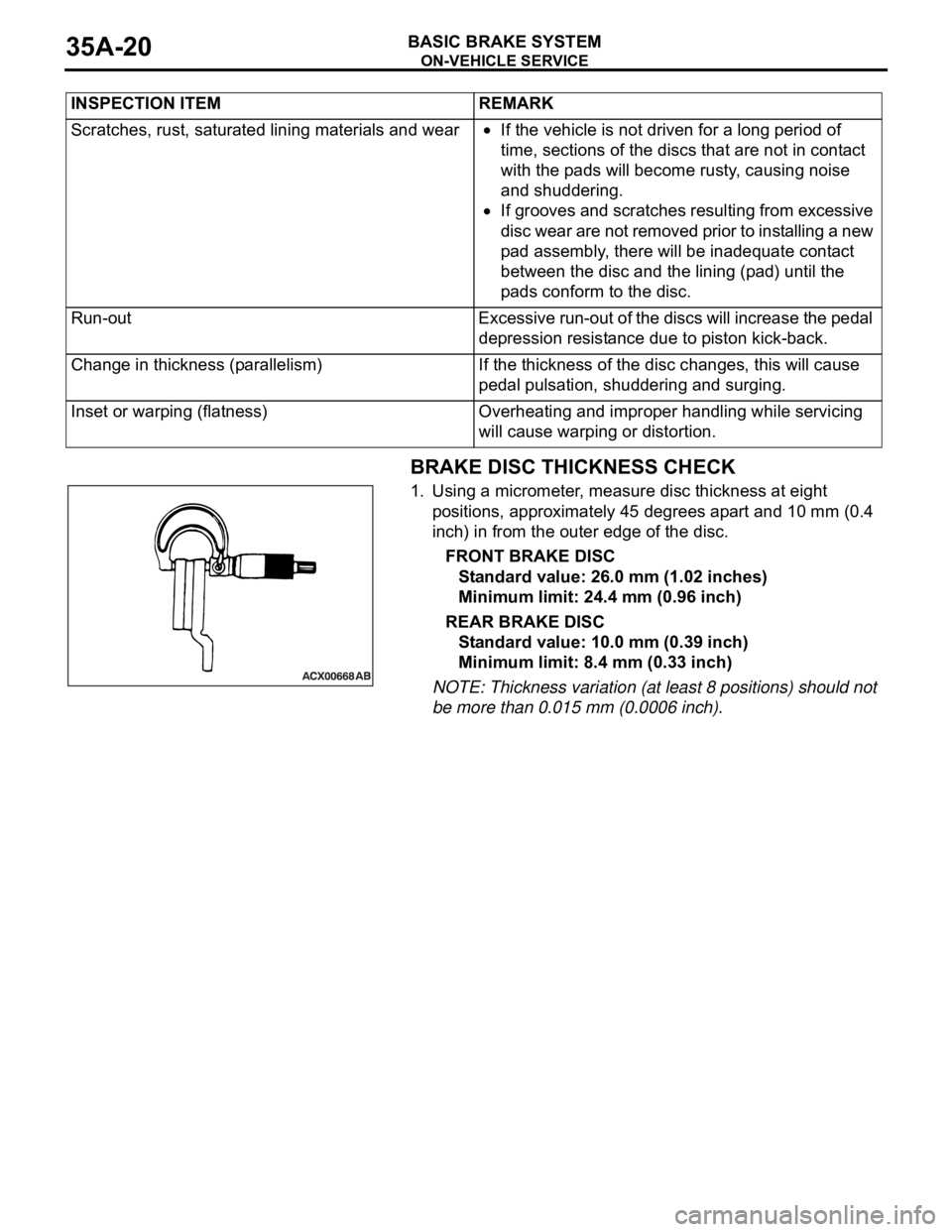

1. Using a micrometer, measure disc thickness at eight

positions, approximately 45 degrees apart and 10 mm (0.4

inch) in from the outer edge of the disc.

FRONT BRAKE DISC

Standard value: 26.0 mm (1.02 inches)

Minimum limit: 24.4 mm (0.96 inch)

REAR BRAKE DISC

Standard value: 10.0 mm (0.39 inch)

Minimum limit: 8.4 mm (0.33 inch)

NOTE: Thickness variation (at least 8 positions) should not

be more than 0.015 mm (0.0006 inch). INSPECTION ITEM REMARK

Scratches, rust, saturated lining materials and wear

If the vehicle is not driven for a long period of

time, sections of the discs that are not in contact

with the pads will become rusty, causing noise

and shuddering.

If grooves and scratches resulting from excessive

disc wear are not removed prior to installing a new

pad assembly, there will be inadequate contact

between the disc and the lining (pad) until the

pads conform to the disc.

Run-out Excessive run-out of the discs will increase the pedal

depression resistance due to piston kick-back.

Change in thickness (parallelism) If the thickness of the disc changes, this will cause

pedal pulsation, shuddering and surging.

Inset or warping (flatness) Overheating and improper handling while servicing

will cause warping or distortion.

Page 1186 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-21

After a new brake disc is installed, always grind the

brake disc with an on-the-car type brake lathe. If this

step is not carried out, the brake disc run-out exceeds

the specified value, resulting in judder.

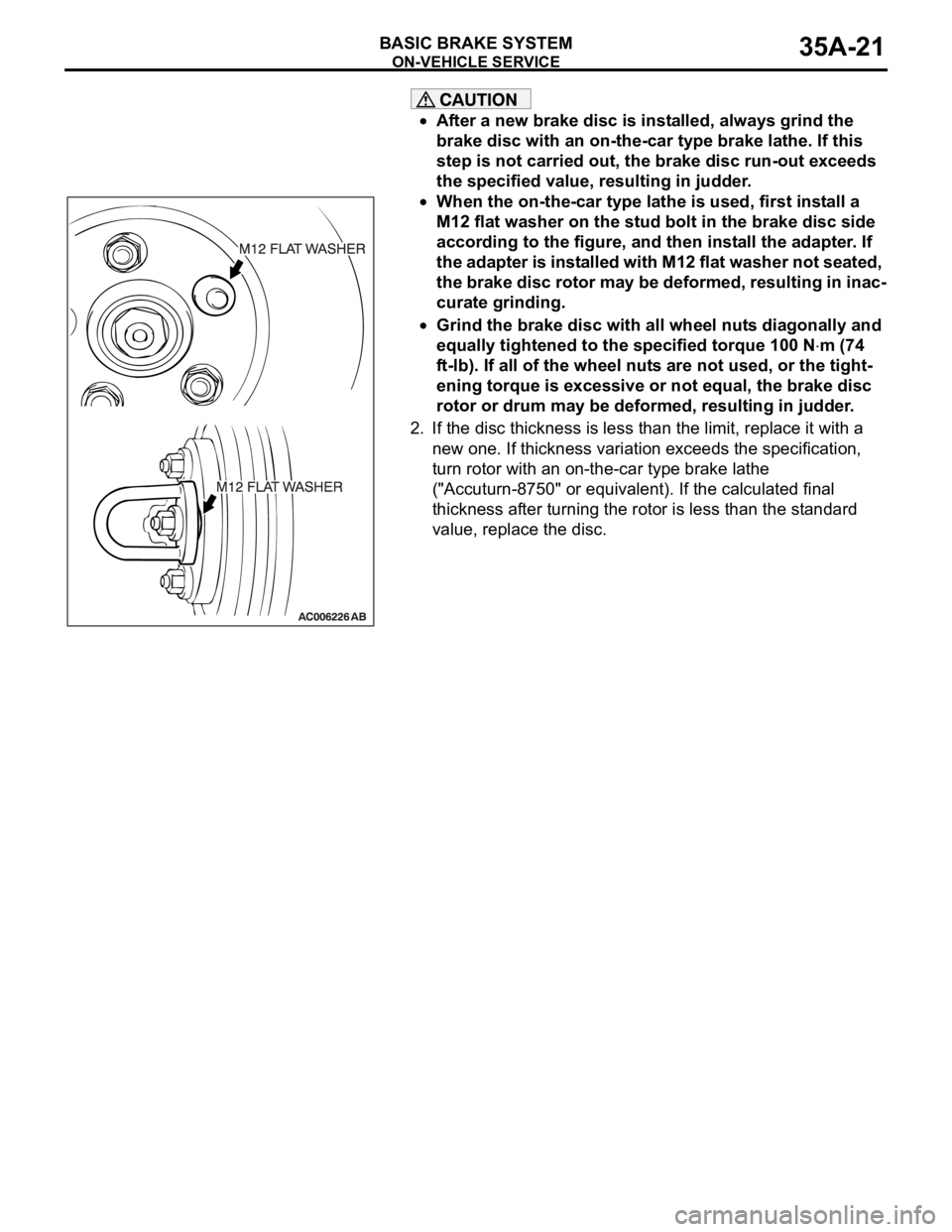

When the on-the-car type lathe is used, first install a

M12 flat washer on the stud bolt in the brake disc side

according to the figure, and then install the adapter. If

the adapter is installed with M12 flat washer not seated,

the brake disc rotor may be deformed, resulting in inac-

curate grinding.

Grind the brake disc with all wheel nuts diagonally and

equally tightened to the specified torque 100 N

m (74

ft-lb). If all of the wheel nuts are not used, or the tight-

ening torque is excessive or not equal, the brake disc

rotor or drum may be deformed, resulting in judder.

2. If the disc thickness is less than the limit, replace it with a

new one. If thickness variation exceeds the specification,

turn rotor with an on-the-car type brake lathe

("Accuturn-8750" or equivalent). If the calculated final

thickness after turning the rotor is less than the standard

value, replace the disc.

.

Page 1188 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-23

After a new brake disc is installed, always grind the

brake disc with an on-the-car type brake lathe. If this

step is not carried out, the brake disc run-out exceeds

the specified value, resulting in judder.

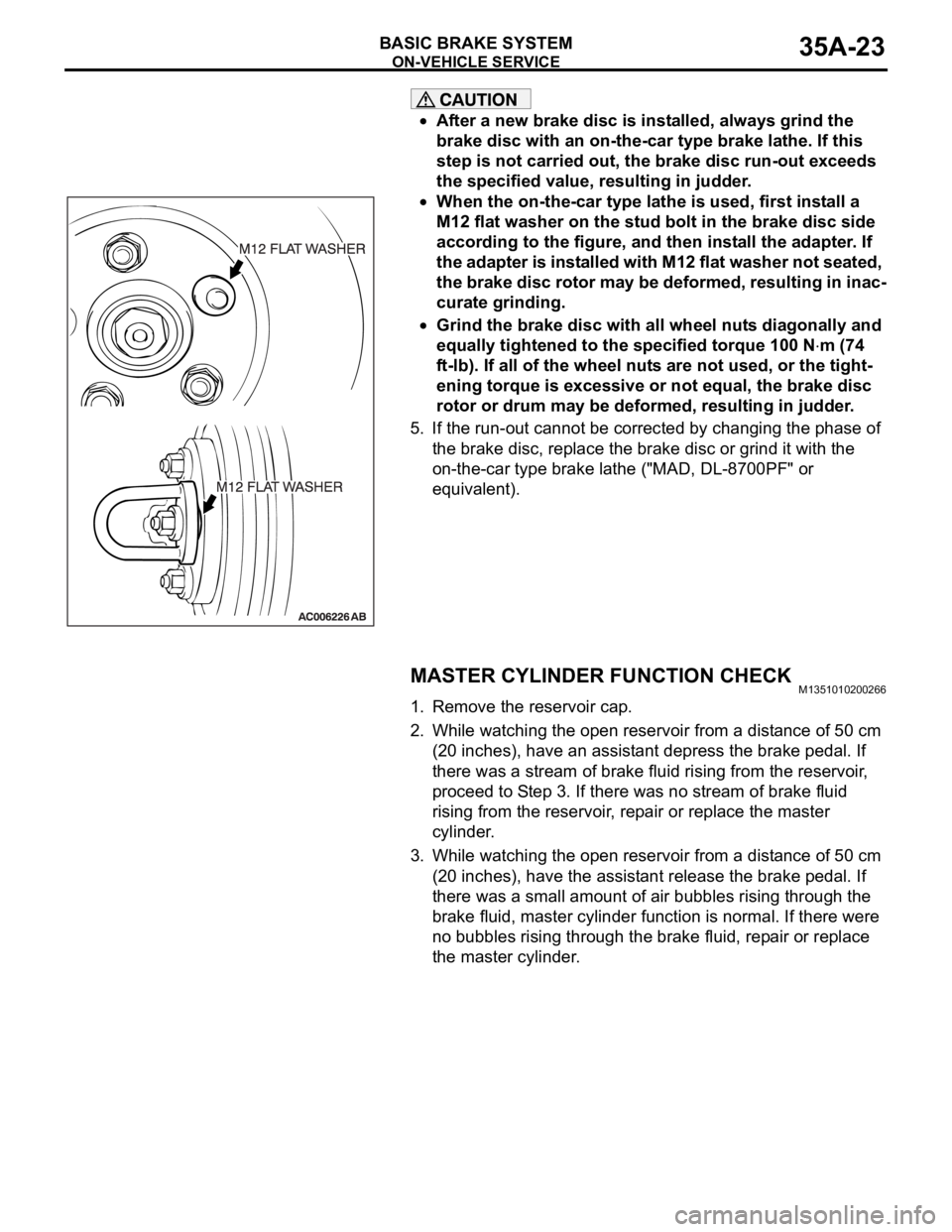

When the on-the-car type lathe is used, first install a

M12 flat washer on the stud bolt in the brake disc side

according to the figure, and then install the adapter. If

the adapter is installed with M12 flat washer not seated,

the brake disc rotor may be deformed, resulting in inac-

curate grinding.

Grind the brake disc with all wheel nuts diagonally and

equally tightened to the specified torque 100 N

m (74

ft-lb). If all of the wheel nuts are not used, or the tight-

ening torque is excessive or not equal, the brake disc

rotor or drum may be deformed, resulting in judder.

5. If the run-out cannot be corrected by changing the phase of

the brake disc, replace the brake disc or grind it with the

on-the-car type brake lathe ("MAD, DL-8700PF" or

equivalent).

MASTER CYLINDER FUNCTION CHECKM1351010200266

1. Remove the reservoir cap.

2. While watching the open reservoir from a distance of 50 cm

(20 inches), have an assistant depress the brake pedal. If

there was a stream of brake fluid rising from the reservoir,

proceed to Step 3. If there was no stream of brake fluid

rising from the reservoir, repair or replace the master

cylinder.

3. While watching the open reservoir from a distance of 50 cm

(20 inches), have the assistant release the brake pedal. If

there was a small amount of air bubbles rising through the

brake fluid, master cylinder function is normal. If there were

no bubbles rising through the brake fluid, repair or replace

the master cylinder.