service indicator MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 919 of 1500

ENGINE COOLING DIAGNOSIS

ENGINE COOLING14-4

INSPECTION PROCEDURE 2: Engine Overheating

DIAGNOSIS

STEP 1. Remove the radiator cap and check for coolant

contamination.

Q: Is the coolant contaminated with rust and oil?

YES : Replace it. Refer to P.14-27.

NO : There is no action to be taken. Go to Step 2.

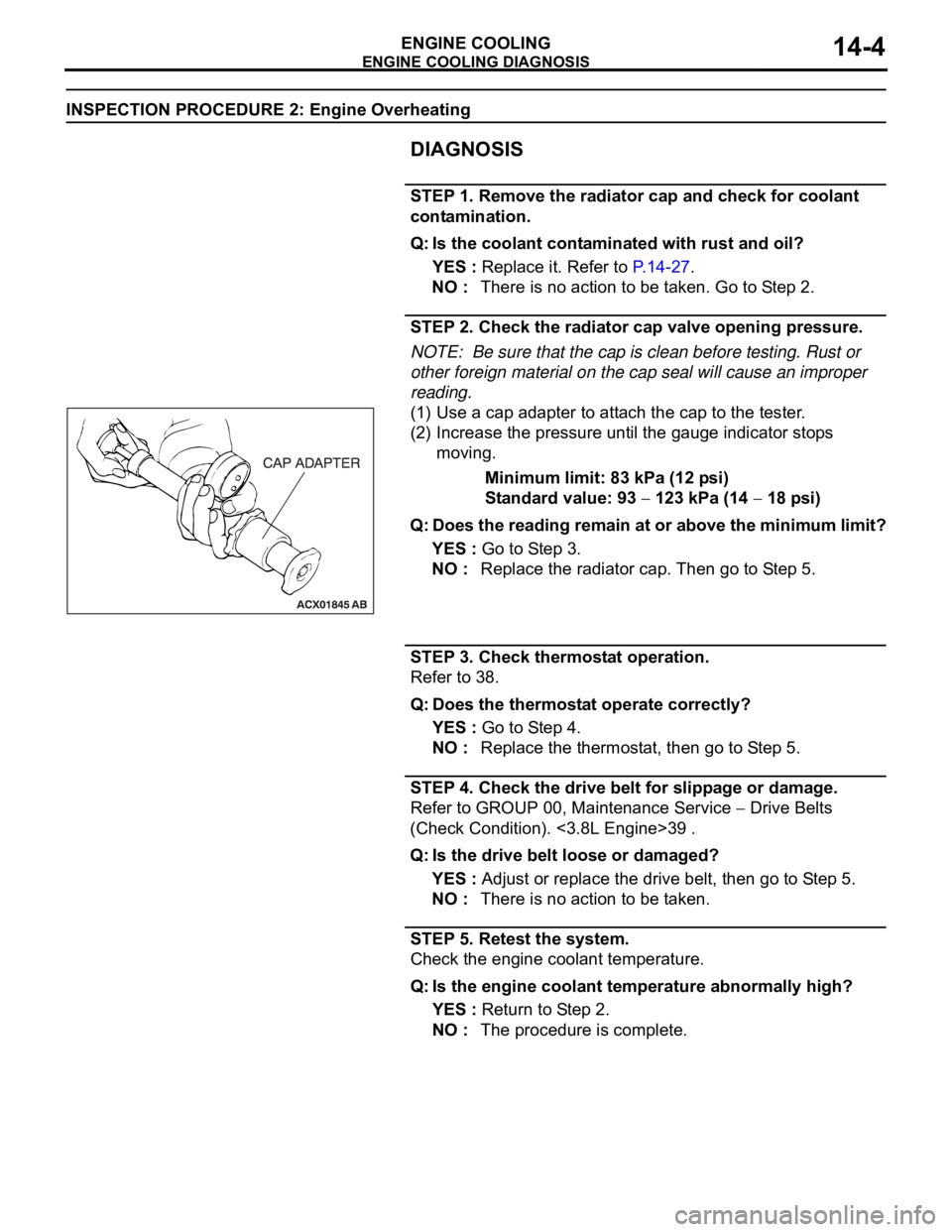

STEP 2. Check the radiator cap valve opening pressure.

NOTE: Be sure that the cap is clean before testing. Rust or

other foreign material on the cap seal will cause an improper

reading.

(1) Use a cap adapter to attach the cap to the tester.

(2) Increase the pressure until the gauge indicator stops

moving.

Minimum limit: 83 kPa (12 psi)

Standard value: 93

123 kPa (14 18 psi)

Q: Does the reading remain at or above the minimum limit?

YES : Go to Step 3.

NO : Replace the radiator cap. Then go to Step 5.

STEP 3. Check thermostat operation.

Refer to 38.

Q: Does the thermostat operate correctly?

YES : Go to Step 4.

NO : Replace the thermostat, then go to Step 5.

STEP 4. Check the drive belt for slippage or damage.

Refer to GROUP 00, Maintenance Service

Drive Belts

(Check Condition). <3.8L Engine>39 .

Q: Is the drive belt loose or damaged?

YES : Adjust or replace the drive belt, then go to Step 5.

NO : There is no action to be taken.

STEP 5. Retest the system.

Check the engine coolant temperature.

Q: Is the engine coolant temperature abnormally high?

YES : Return to Step 2.

NO : The procedure is complete.

Page 942 of 1500

ON-VEHICLE SERVICE

ENGINE COOLING14-27

RADIATOR CAP PRESSURE CHECKM1141001300419

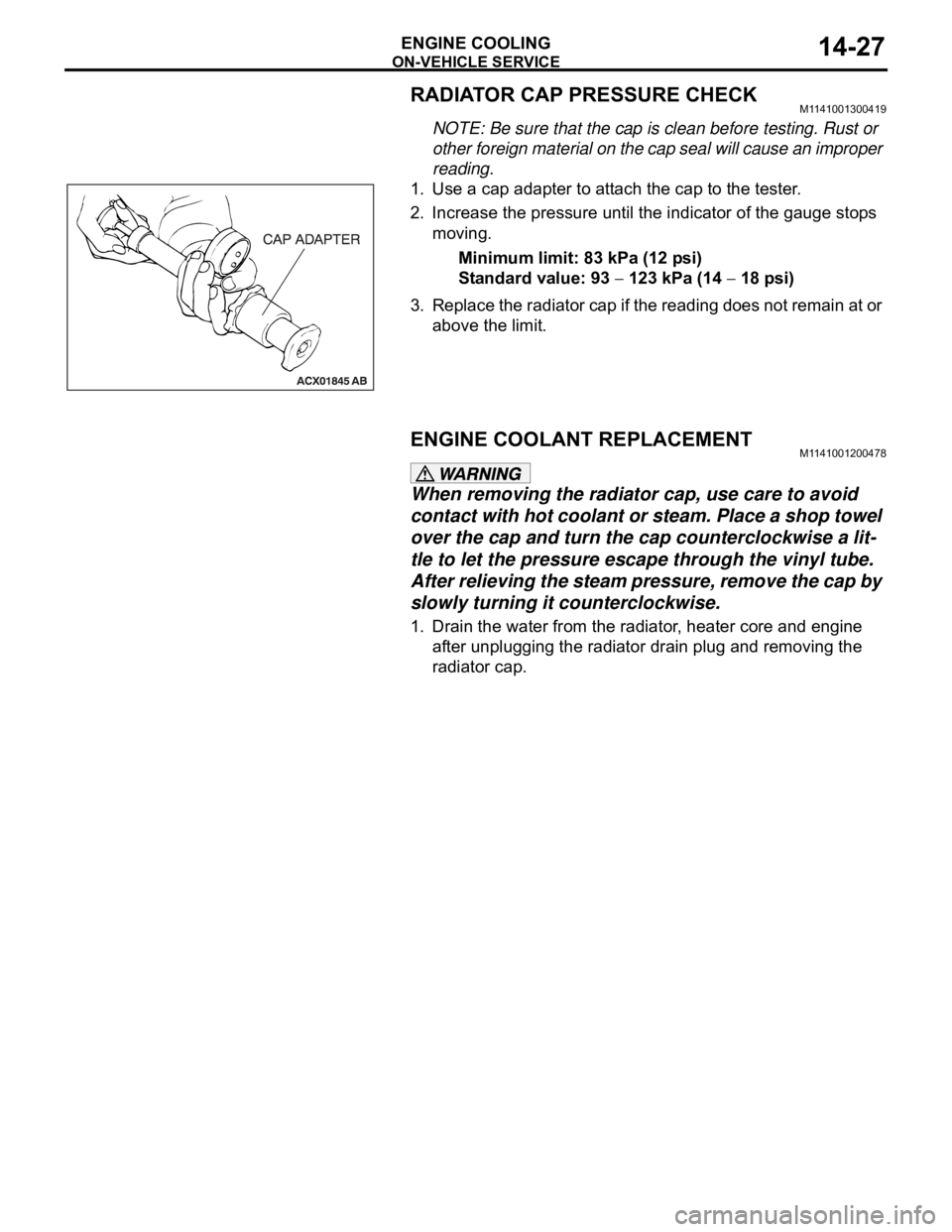

NOTE: Be sure that the cap is clean before testing. Rust or

other foreign material on the cap seal will cause an improper

reading.

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the gauge stops

moving.

Minimum limit: 83 kPa (12 psi)

Standard value: 93

123 kPa (14 18 psi)

3. Replace the radiator cap if the reading does not remain at or

above the limit.

ENGINE COOLANT REPLACEMENTM1141001200478

When removing the radiator cap, use care to avoid

contact with hot coolant or steam. Place a shop towel

over the cap and turn the cap counterclockwise a lit-

tle to let the pressure escape through the vinyl tube.

After relieving the steam pressure, remove the cap by

slowly turning it counterclockwise.

1. Drain the water from the radiator, heater core and engine

after unplugging the radiator drain plug and removing the

radiator cap.

Page 1244 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-23

HOW TO PERFORM VEHICLE IDENTIFICATION

NUMBER (VIN) WRITING

M1001011400063

The Vehicle Identification Number (VIN) is stored in the ECU by

the vehicle manufacture. If the VIN to be stored in the ECU is

eliminated fraudulently, the Malfunction Indicator Lamp (Check

Engine Lamp) illuminates and Diagnostic Trouble Code (DTC)

No.P0630 (VIN malfunction) is shown. When the ECU is

replaced, and entry of the VIN necessary due to DTC No.

P0630 (VIN malfunction). Enter the VIN in accordance with the

procedure as follows:

.

WRITING PROCEDURE

Required Special Tools:

Diagnostic Tool (MUT-III)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (BLUE)

To prevent damage to DIAGNOSTIC TOOL (MUT-III), always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting.

1. Connect Diagnostic Tool to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Confirm DTC No.P0630 (EEPROM malfunction) is not

shown.

NOTE: When DTC No. P0630 (EEPROM malfunction) is

shown, the VIN cannot be stored even if entered. Therefore,

the troubleshooting is performed when this DTC is shown.

4. Select "Coding" form the menu screen.

5. Select "VIN writing" form the menu screen.

6. Enter the VIN.

7. After entry of the VIN, turn the ignition switch to the "LOCK"

(OFF) position. After ten seconds or more passed, turn to

the "ON" position again.

8. Confirm DTC No.P0630 (VIN malfunction) is not shown.

NOTE: When DTC No.P0630 (VIN malfunction) is shown,

enter the VIN again because that would be not appropriate.

Page 1280 of 1500

13C-1

GROUP 13C

TRACTION

CONTROL SYSTEM

(TCL)

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .13C-2

TRACTION CONTROL SYSTEM (TCL)

DIAGNOSIS . . . . . . . . . . . . . . . . . . . .13C-3

INTRODUCTION TO TRACTION CONTROL

SYSTEM (TCL) DIAGNOSIS . . . . . . . . . . . 13C-3

TROUBLESHOOTING STRATEGY . . . . . . 13C-3

DIAGNOSIS FUNCTION. . . . . . . . . . . . . . . 13C-3

DIAGNOSTIC TROUBLE CODE CHART . . 13C-8

DIAGNOSTIC TROUBLE CODE

PROCEDURES . . . . . . . . . . . . . . . . . . . . . . 13C-10

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 13C-23

SYMPTOM PROCEDURES . . . . . . . . . . . . 13C-23

DATA LIST REFERENCE TABLE . . . . . . . 13C-36

ACTUATOR TEST REFERENCE TABLE. . 13C-37

CHECK AT ABS/TCL-ECU RESISTANCE

AND TERMINAL VOLTAGE . . . . . . . . . . . . 13C-38RESISTANCE AND CONTINUITY

BETWEEN ABS-ECU AND WHEEL SPEED

SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . 13C-39

VOLTAGE AND SIGNAL CHECK AT

ABS-ECU USING AN OSCILLOSCOPE . . . 13C-41

SPECIAL TOOLS . . . . . . . . . . . . . . . .13C-45

ON-VEHICLE SERVICE . . . . . . . . . . .13C-47

TCL INDICATOR LIGHT CHECK . . . . . . . . 13C-47

TCL OPERATION CHECK . . . . . . . . . . . . . 13C-47

TCL SWITCH CHECK . . . . . . . . . . . . . . . . . 13C-48

WHEEL SPEED SENSOR CHECK . . . . . . . 13C-48

TCL SWITCH . . . . . . . . . . . . . . . . . . .13C-49

REMOVAL AND INSTALLATION . . . . . . . . 13C-49

WHEEL SPEED SENSOR . . . . . . . . .13C-49

REMOVAL AND INSTALLATION . . . . . . . . 13C-49

ABS/TCL-ECU . . . . . . . . . . . . . . . . . .13C-49

REMOVAL AND INSTALLATION . . . . . . . . 13C-49

Page 1326 of 1500

ON-VEHICLE SERVICE

TRACTION CONTROL SYSTEM (TCL)13C-47

ON-VEHICLE SERVICE

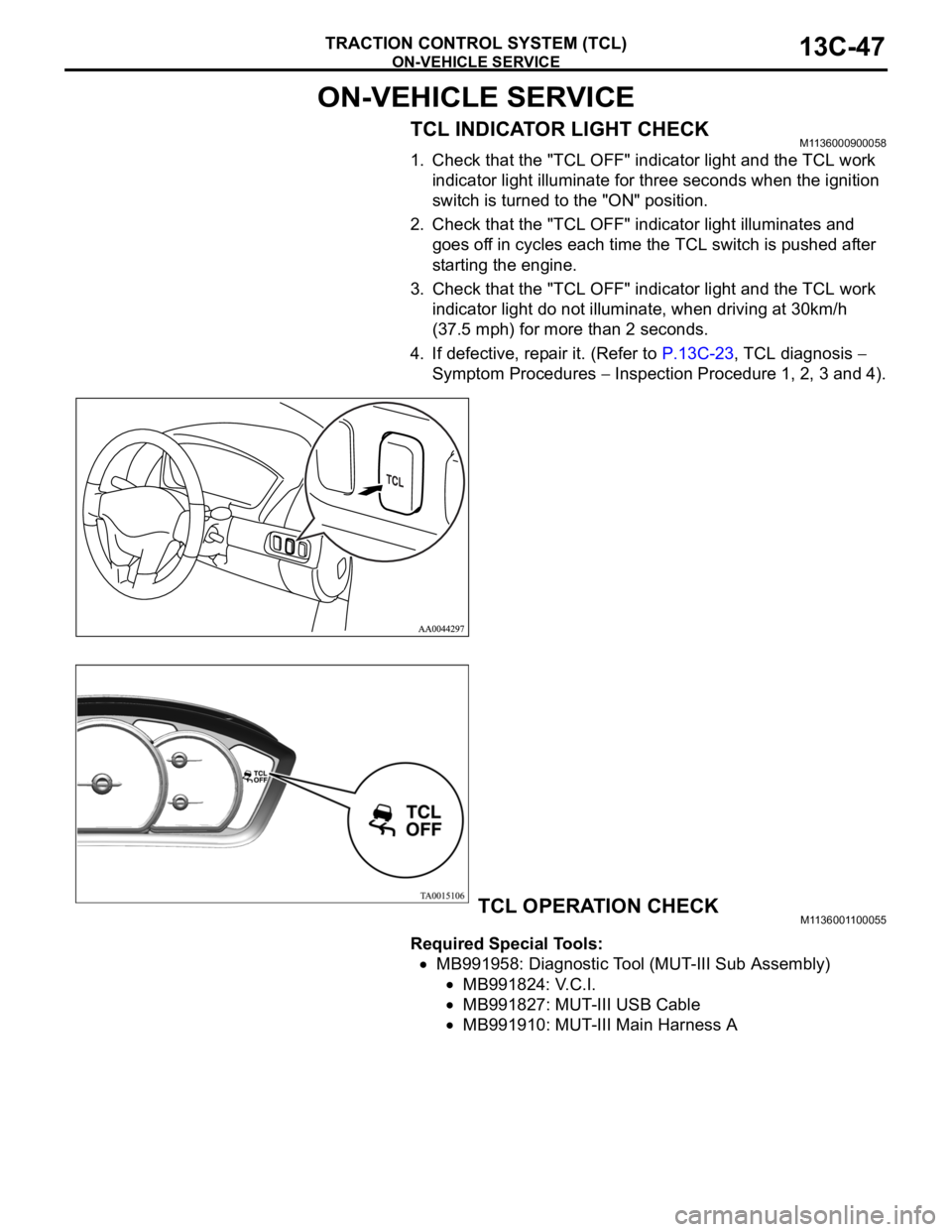

TCL INDICATOR LIGHT CHECKM1136000900058

1. Check that the "TCL OFF" indicator light and the TCL work

indicator light illuminate for three seconds when the ignition

switch is turned to the "ON" position.

2. Check that the "TCL OFF" indicator light illuminates and

goes off in cycles each time the TCL switch is pushed after

starting the engine.

3. Check that the "TCL OFF" indicator light and the TCL work

indicator light do not illuminate, when driving at 30km/h

(37.5 mph) for more than 2 seconds.

4. If defective, repair it. (Refer to P.13C-23, TCL diagnosis

Symptom Procedures

Inspection Procedure 1, 2, 3 and 4).

TCL OPERATION CHECKM1136001100055

Required Special Tools:

MB991958: Diagnostic Tool (MUT-III Sub Assembly)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 1395 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-64

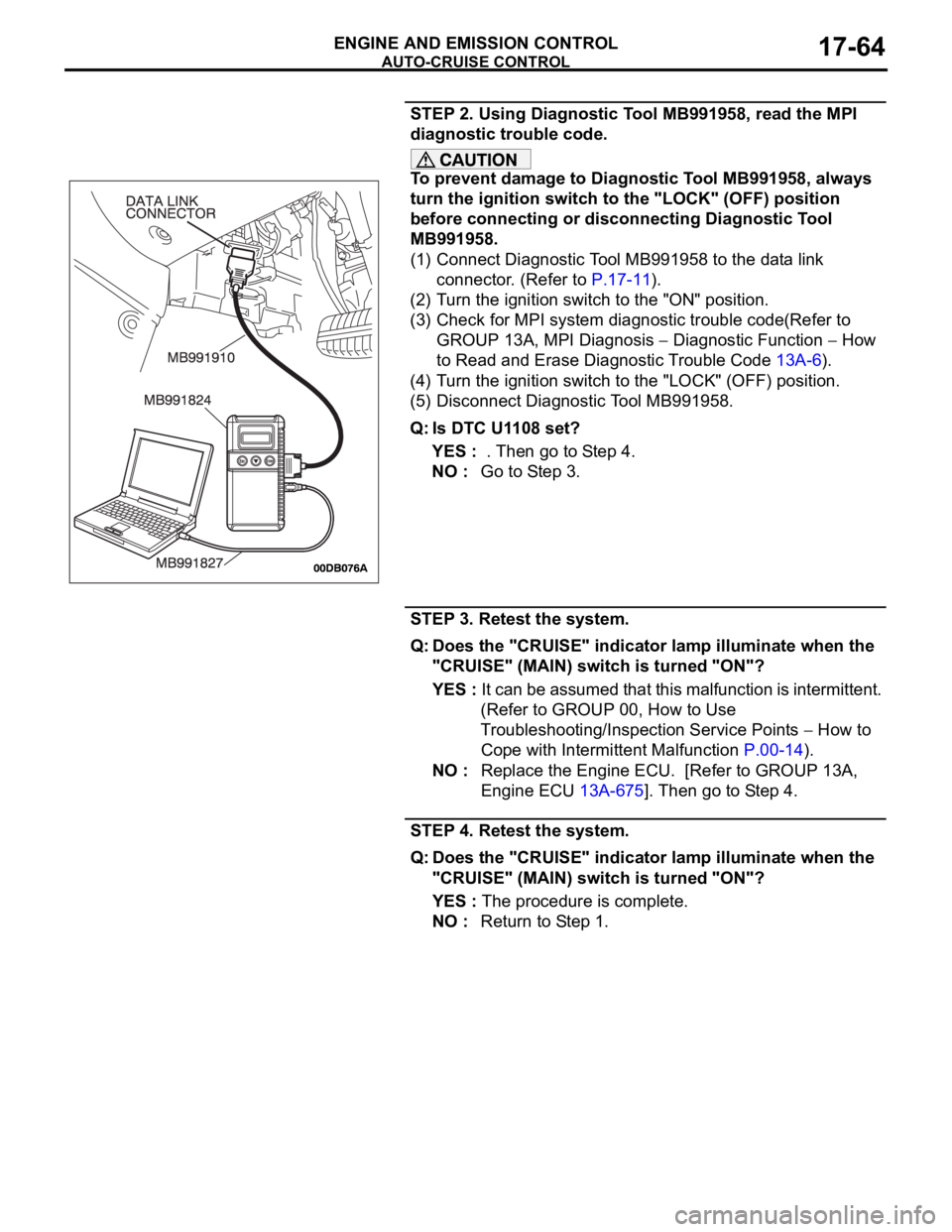

STEP 2. Using Diagnostic Tool MB991958, read the MPI

diagnostic trouble code.

To prevent damage to Diagnostic Tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting Diagnostic Tool

MB991958.

(1) Connect Diagnostic Tool MB991958 to the data link

connector. (Refer to P.17-11).

(2) Turn the ignition switch to the "ON" position.

(3) Check for MPI system diagnostic trouble code(Refer to

GROUP 13A, MPI Diagnosis

Diagnostic Function How

to Read and Erase Diagnostic Trouble Code 13A-6).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

(5) Disconnect Diagnostic Tool MB991958.

Q: Is DTC U1108 set?

YES : . Then go to Step 4.

NO : Go to Step 3.

STEP 3. Retest the system.

Q: Does the "CRUISE" indicator lamp illuminate when the

"CRUISE" (MAIN) switch is turned "ON"?

YES : It can be assumed that this malfunction is intermittent.

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunction P.00-14).

NO : Replace the Engine ECU. [Refer to GROUP 13A,

Engine ECU 13A-675]. Then go to Step 4.

STEP 4. Retest the system.

Q: Does the "CRUISE" indicator lamp illuminate when the

"CRUISE" (MAIN) switch is turned "ON"?

YES : The procedure is complete.

NO : Return to Step 1.

Page 1402 of 1500

AUTO-CRUISE CONTROL

ENGINE AND EMISSION CONTROL17-71

ON-VEHICLE SERVICE

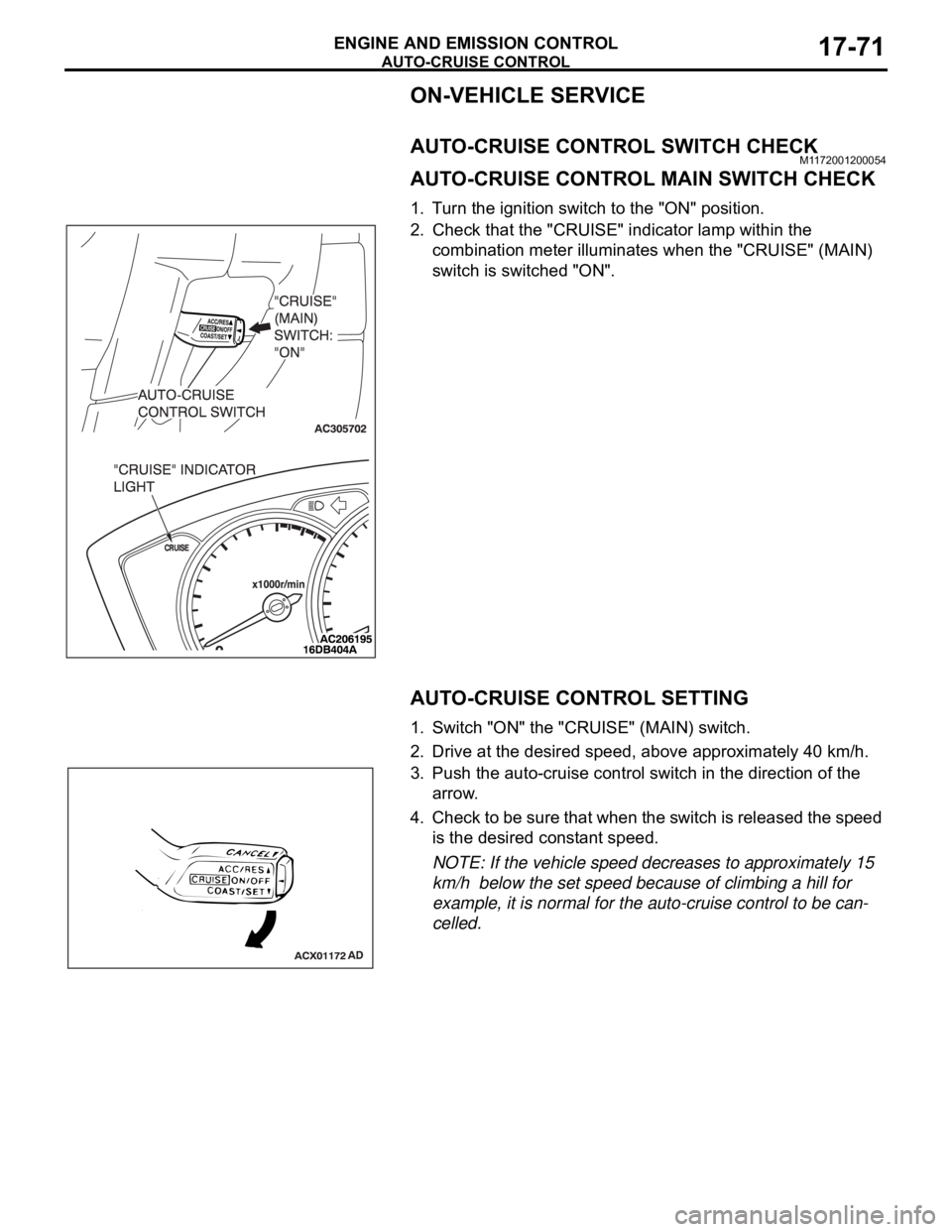

AUTO-CRUISE CONTROL SWITCH CHECKM1172001200054

AUTO-CRUISE CONTROL MAIN SWITCH CHECK

1. Turn the ignition switch to the "ON" position.

2. Check that the "CRUISE" indicator lamp within the

combination meter illuminates when the "CRUISE" (MAIN)

switch is switched "ON".

AUTO-CRUISE CONTROL SETTING

1. Switch "ON" the "CRUISE" (MAIN) switch.

2. Drive at the desired speed, above approximately 40 km/h.

3. Push the auto-cruise control switch in the direction of the

arrow.

4. Check to be sure that when the switch is released the speed

is the desired constant speed.

NOTE: If the vehicle speed decreases to approximately 15

km/h below the set speed because of climbing a hill for

example, it is normal for the auto-cruise control to be can-

celled.

Page 1407 of 1500

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-76

EMISSION CONTROL

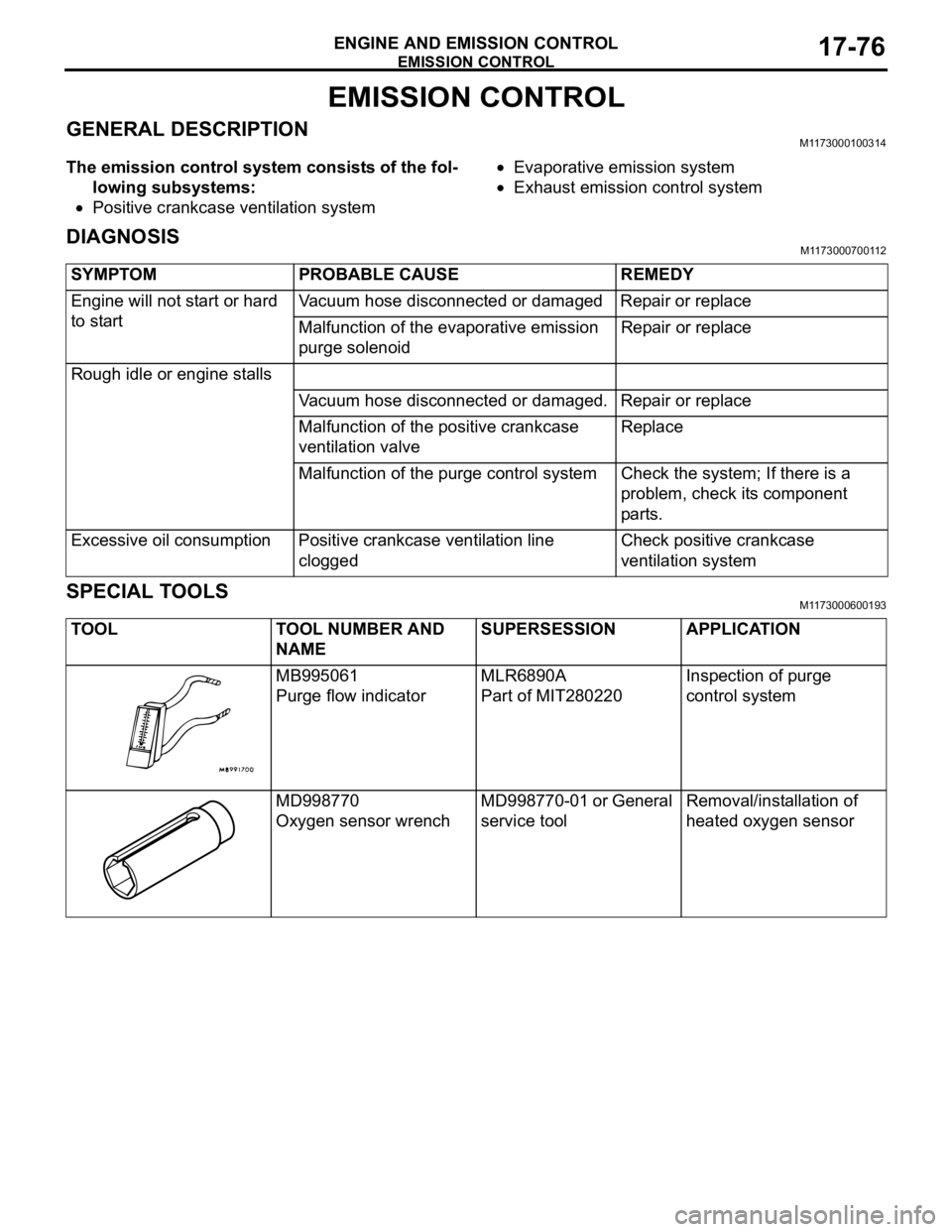

GENERAL DESCRIPTIONM1173000100314

The emission control system consists of the fol-

lowing subsystems:

Positive crankcase ventilation system

Evaporative emission system

Exhaust emission control system

DIAGNOSISM1173000700112

SPECIAL TOOLSM1173000600193

SYMPTOM PROBABLE CAUSE REMEDY

Engine will not start or hard

to startVacuum hose disconnected or damaged Repair or replace

Malfunction of the evaporative emission

purge solenoidRepair or replace

Rough idle or engine stalls

Vacuum hose disconnected or damaged. Repair or replace

Malfunction of the positive crankcase

ventilation valveReplace

Malfunction of the purge control system Check the system; If there is a

problem, check its component

parts.

Excessive oil consumption Positive crankcase ventilation line

cloggedCheck positive crankcase

ventilation system

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB995061

Purge flow indicatorMLR6890A

Part of MIT280220Inspection of purge

control system

MD998770

Oxygen sensor wrenchMD998770-01 or General

service toolRemoval/installation of

heated oxygen sensor

Page 1472 of 1500

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION23A-13

A/T DIAGNOSTIC TROUBLESHOOTING STRATEGYM1231007600339

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will find most A/T mal-

functions.

1. Gather as much information as possible about the

complaint from the customer.

2. Verify that the condition described by the

customer exists.

3. Check the vehicle for any A/T Diagnostic Trouble

Codes (DTCs).

4. If you can not verify the condition and there are no

DTCs, the malfunction is intermittent. For

information on how to cope with intermittent

malfunctions, refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How

to Cope with Intermittent Malfunction P.00-14.

5. If you can verify the condition but there are no

DTCs, or the system can not communicate with

diagnostic tool, refer to the Symptom Chart

P.23A-35.6. If there is a DTC, record the number of the code,

then erase the code from memory using

diagnostic tool.

7. Reconfirm the symptom with a Road Test.

8. If a DTC is set again, go to the Inspection Chart

for Diagnostic Trouble Codes.

9. If a DTC is not set again, the malfunction is

intermittent. For information on how to cope with

intermittent malfunctions, refer to GROUP 00,

How to Use Troubleshooting/Inspection Service

Points

How to Cope with Intermittent

Malfunction P.00-14.

10.After repairs are completed, conduct a Road Test

duplicating the complaint conditions to confirm the

malfunction has been eliminated.

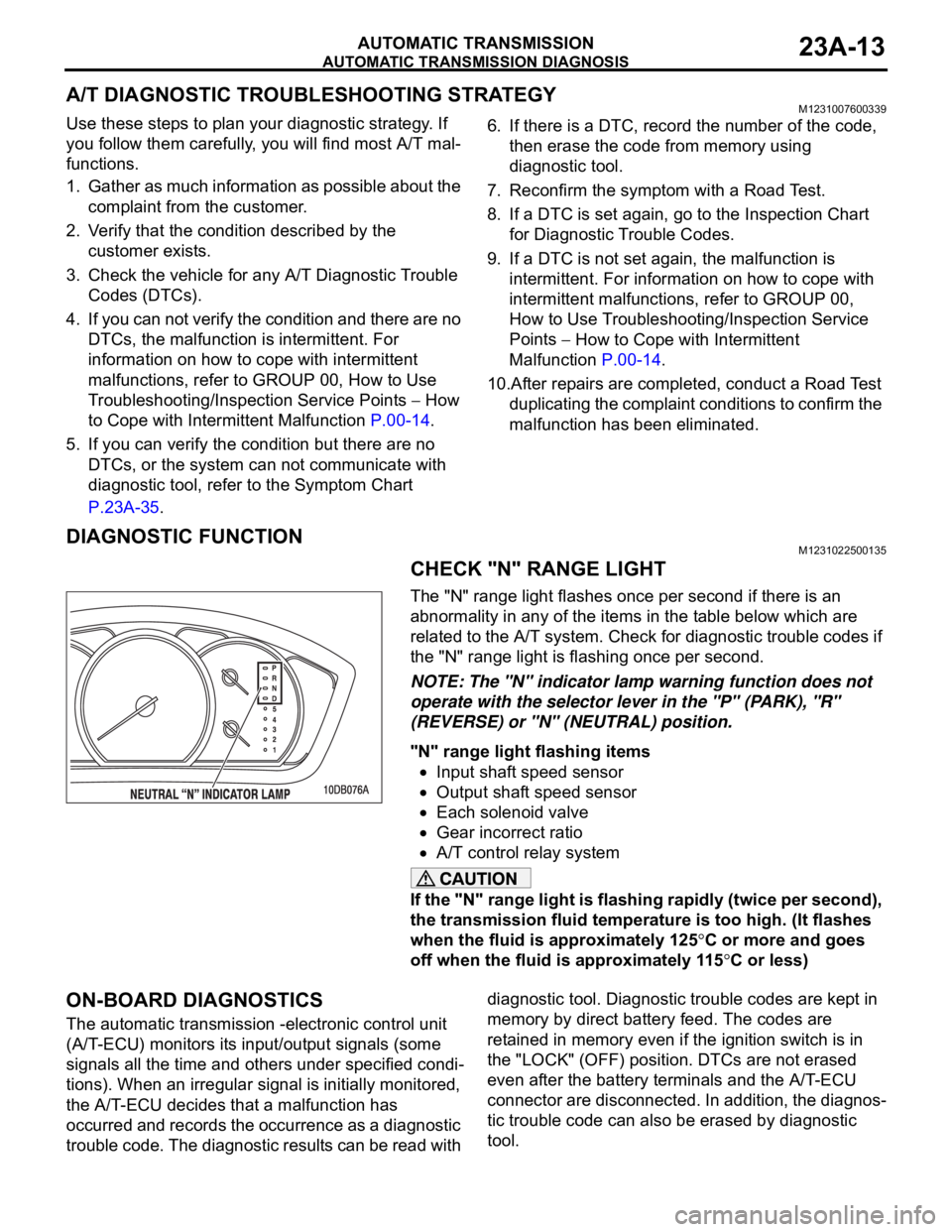

DIAGNOSTIC FUNCTIONM1231022500135

CHECK "N" RANGE LIGHT

The "N" range light flashes once per second if there is an

abnormality in any of the items in the table below which are

related to the A/T system. Check for diagnostic trouble codes if

the "N" range light is flashing once per second.

NOTE: The "N" indicator lamp warning function does not

operate with the selector lever in the "P" (PARK), "R"

(REVERSE) or "N" (NEUTRAL) position.

"N" range light flashing items

Input shaft speed sensor

Output shaft speed sensor

Each solenoid valve

Gear incorrect ratio

A/T control relay system

If the "N" range light is flashing rapidly (twice per second),

the transmission fluid temperature is too high. (It flashes

when the fluid is approximately 125

C or more and goes

off when the fluid is approximately 115

C or less)

ON-BOARD DIAGNOSTICS

The automatic transmission -electronic control unit

(A/T-ECU) monitors its input/output signals (some

signals all the time and others under specified condi-

tions). When an irregular signal is initially monitored,

the A/T-ECU decides that a malfunction has

occurred and records the occurrence as a diagnostic

trouble code. The diagnostic results can be read with diagnostic tool. Diagnostic trouble codes are kept in

memory by direct battery feed. The codes are

retained in memory even if the ignition switch is in

the "LOCK" (OFF) position. DTCs are not erased

even after the battery terminals and the A/T-ECU

connector are disconnected. In addition, the diagnos-

tic trouble code can also be erased by diagnostic

tool.