cooling MITSUBISHI COLT 2006 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 107 of 364

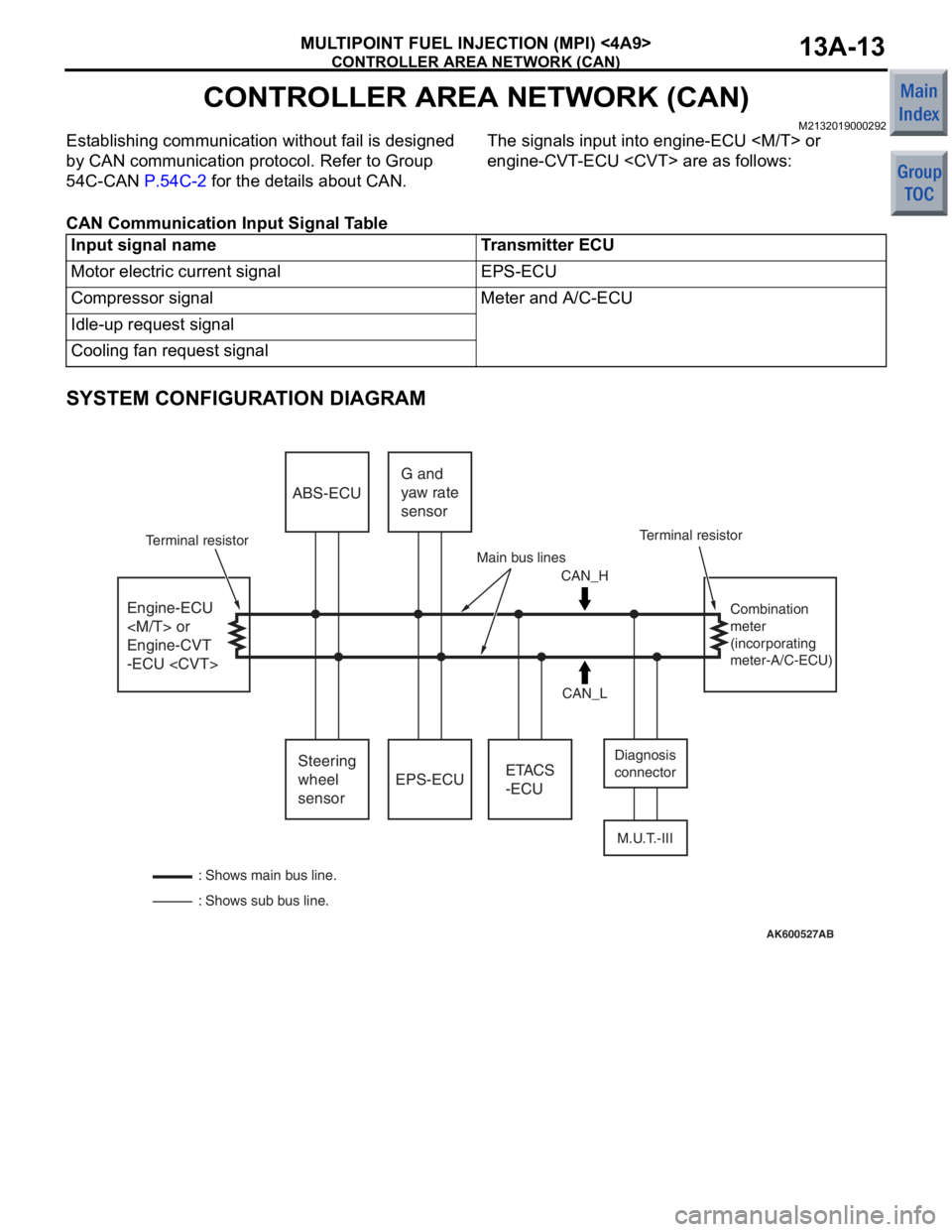

CONTROLLER AREA NETWORK (CAN)

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-13

CONTROLLER AREA NETWORK (CAN)

M2132019000292

Establishing communication without fail is designed

by CAN communication protocol. Refer to Group

54C-CAN

P.54C-2 for the details about CAN.

The signals input into engine-ECU

engine-CVT-ECU

CAN Communication Input Signal Table

Input signal nameTransmitter ECU

Motor electric current signalEPS-ECU

Compressor signalMeter and A/C-ECU

Idle-up request signal

Cooling fan request signal

SYSTEM CONFIGURATION DIAGRAM

AK600527AB

Engine-ECU

Engine-CVT

-ECU

M.U.T.-III

EPS-ECU ETACS

-ECU

Steering

wheel

sensor G and

yaw rate

sensor

ABS-ECU

CAN_H

CAN_L Diagnosis

connector Combination

meter

(incorporating

meter-A/C-ECU)

: Shows sub bus line. : Shows main bus line. Terminal resistor

Terminal resistor

Main bus lines

Page 114 of 364

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-20

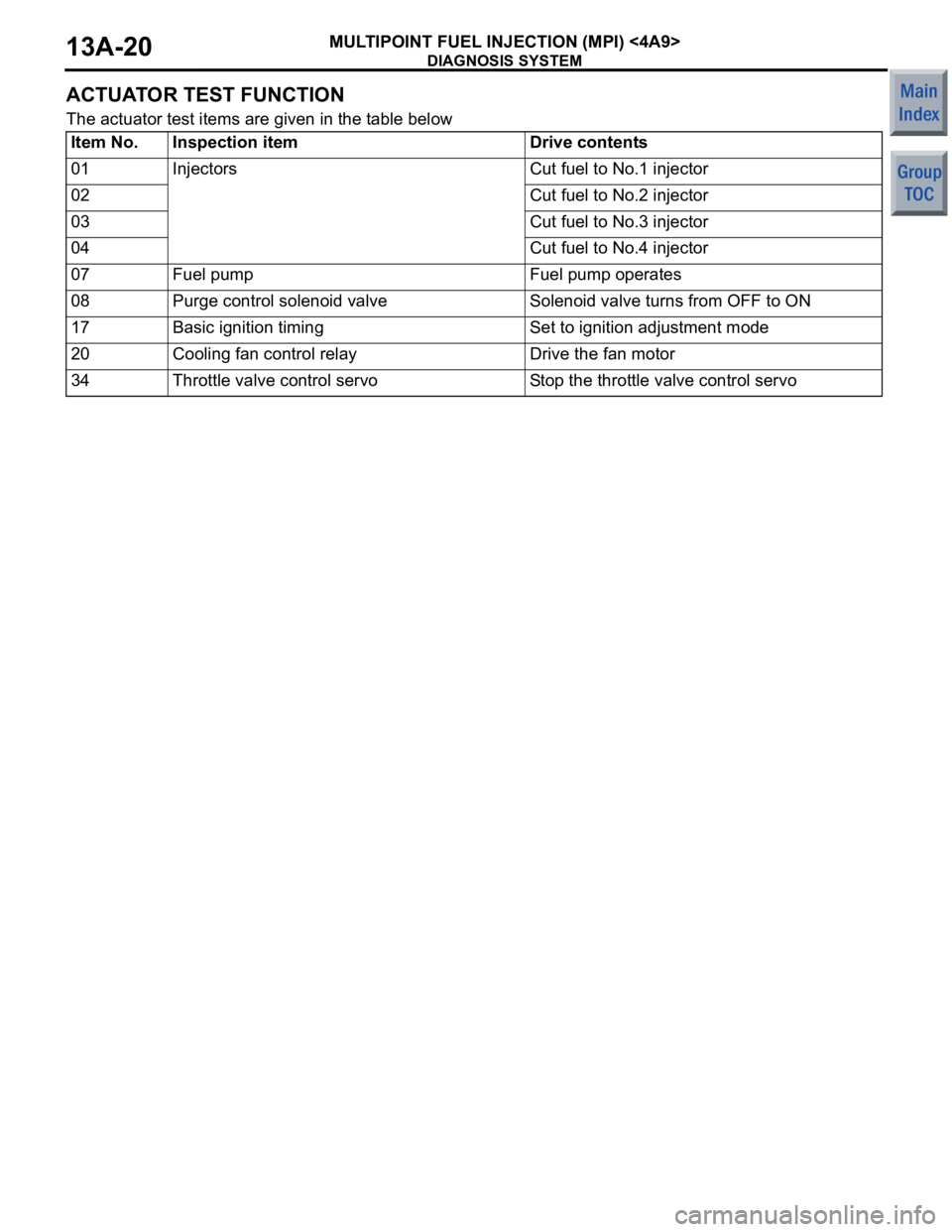

ACTUATOR TEST FUNCTION

The actuator test items are given in the table below

Item No.Inspection itemDrive contents

01InjectorsCut fuel to No.1 injector

02Cut fuel to No.2 injector

03Cut fuel to No.3 injector

04Cut fuel to No.4 injector

07Fuel pumpFuel pump operates

08Purge control solenoid valveSolenoid valve turns from OFF to ON

17Basic ignition timingSet to ignition adjustment mode

20Cooling fan control relayDrive the fan motor

34Throttle valve control servoStop the throttle valve control servo

Page 117 of 364

![MITSUBISHI COLT 2006 Service User Guide

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve open MITSUBISHI COLT 2006 Service User Guide

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve open](/img/19/57093/w960_57093-116.png)

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve opening control

and idle speed control

[3] MIVEC (Mitsubishi Innovative

Valve timing Electronic

control system)

[4] Ignition timing control

[5] Engine control relay control

[6] Throttle valve control servo

relay control

[7] Fuel pump relay control

[8] Oxygen sensor (front) heater

control

[9] Oxygen sensor (rear) heater

control

[10] Fuel pressure control

[11] Waste gate control

[12] Fan relay control

[13] A/C compressor relay

control

[14] Alternator control

[15] Purge control

[16] Diagnostic output

[17] RAM data transmission Throttle valve control unit

Throttle opening feedback control

Engine coolant

temperature sensor Intake air temperature sensor Air flow sensor

Accelerator pedal

position sensor (main) Throttle position sensor (sub)

Camshaft position sensor

Crank angle sensor

Oxygen sensor (front)

Oxygen sensor (rear)

Alternator FR terminal

Clutch switch

Detonation sensor

Ignition switch-IG

Ignition switch-ST

Stop lamp switch

Power supply

Throttle position sensor (main)

Accelerator pedel

position sensor (sub)

Throttle valve control servo No.1 injector

No.2 injector

No.3 injector

No.4 injector

No.1 Ignition coil

No.2 Ignition coil

No.3 Ignition coil

No.4 Ignition coil

Engine control relay

Throttle valve control servo relay

Waste gate solenoid valve

A/C compressor relay

Fuel pump relay

Alternator G terminal

Cooling fan control relay (Hi, Lo)

Purge control solenoid valve

Diagnostic output terminal

Oxygen sensor (front) heater

Oxygen sensor (rear) heater Oil feeder control valve

(for MIVEC)

Fuel pressure control

solenoid valve

AB

Page 118 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-4

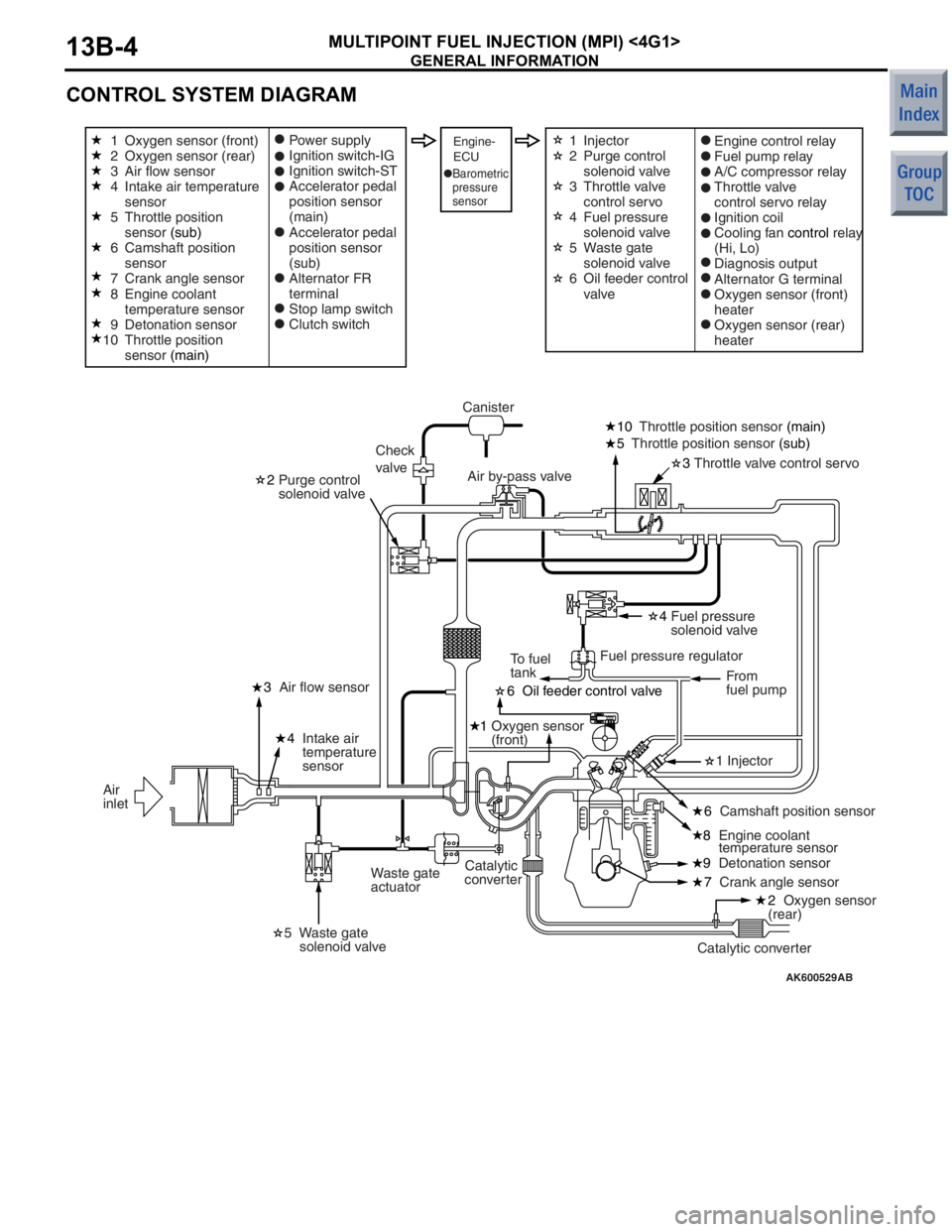

CONTROL SYSTEM DIAGRAM

AK600529AB

6 Oil feeder control valve

1 Oxygen sensor

(front)

8 Engine coolant

temperature sensor

3

Throttle valve control servo

10

Throttle position sensor (main)

5 Throttle position sensor (sub)

2 Purge control

solenoid valve

4 Fuel pressure

solenoid valve

7 Crank angle sensor

9

Detonation sensor

4

Intake air

temperature

sensor

3

Air flow sensor

Waste gate

actuator Canister

Check

valve Air by-pass valve

Fuel pressure regulatorFrom

fuel pump

To fuel

tank

Catalytic converter

Catalytic

converter

Air

inlet

Oxygen sensor (front)

Oxygen sensor (rear)

Air flow sensor

Intake air temperature

sensor

Throttle position

sensor

(sub)

Camshaft position

sensor

Crank angle sensor

Engine coolant

temperature sensor

Detonation sensor

Throttle position

sensor (main) Power supply

Ignition switch-IG

Ignition switch-ST

Accelerator pedal

position sensor

(main)

Accelerator pedal

position sensor

(sub)

Alternator FR

terminal

Stop lamp switch

Clutch switchEngine-

ECUEngine control relay

Fuel pump relay

A/C compressor relay

Throttle valve

control servo relay

Ignition coil

Cooling fan

control relay

(Hi, Lo)

Diagnosis output

Alternator G terminal

Oxygen sensor (front)

heater

Oxygen sensor (rear)

heater

Barometric

pressure

sensor

1 Injector

5 Waste gate

solenoid valve

2 Oxygen sensor

(rear)

6 Camshaft position sensor

1

2

3

4

5

6

7

8

9

10 Injector

Purge control

solenoid valve

Throttle valve

control servo

Fuel pressure

solenoid valve

Waste gate

solenoid valve

Oil feeder control

valve

1

2

3

4

5

6

Page 120 of 364

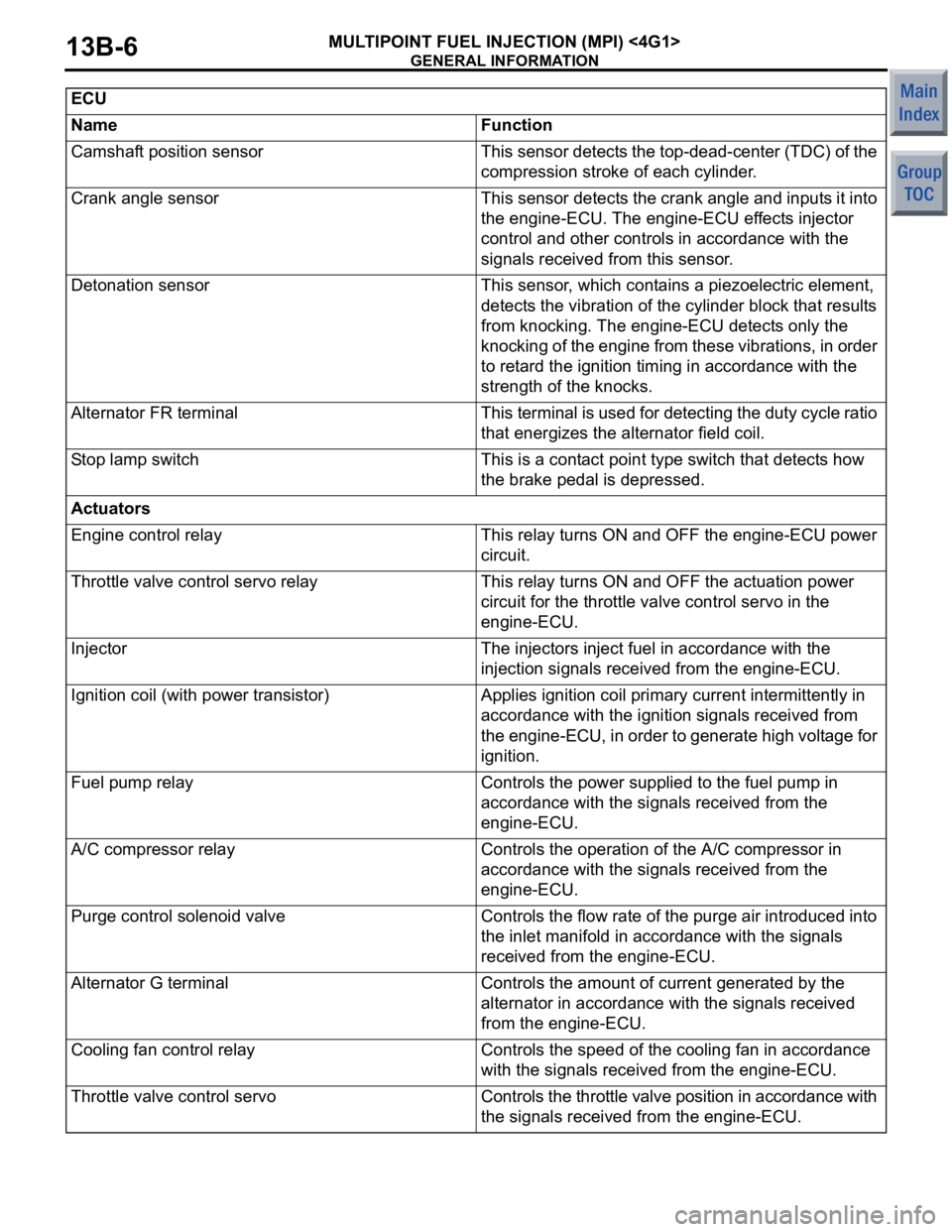

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-6

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU. The engine-ECU effects injector

control and other controls in accordance with the

signals received from this sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU detects only the

knocking of the engine from these vibrations, in order

to retard the ignition timing in accordance with the

strength of the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU power

circuit.

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU.

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU.

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU, in order to generate high voltage for

ignition.

Fuel pump relayControls the power supplied to the fuel pump in

accordance with the signals received from the

engine-ECU.

A/C compressor relayControls the operation of the A/C compressor in

accordance with the signals received from the

engine-ECU.

Purge control solenoid valveControls the flow rate of the purge air introduced into

the inlet manifold in accordance with the signals

received from the engine-ECU.

Alternator G terminalControls the amount of current generated by the

alternator in accordance with the signals received

from the engine-ECU.

Cooling fan control relayControls the speed of the cooling fan in accordance

with the signals received from the engine-ECU.

Throttle valve control servoControls the throttle valve position in accordance with

the signals received from the engine-ECU.

ECU

Name Function

Page 127 of 364

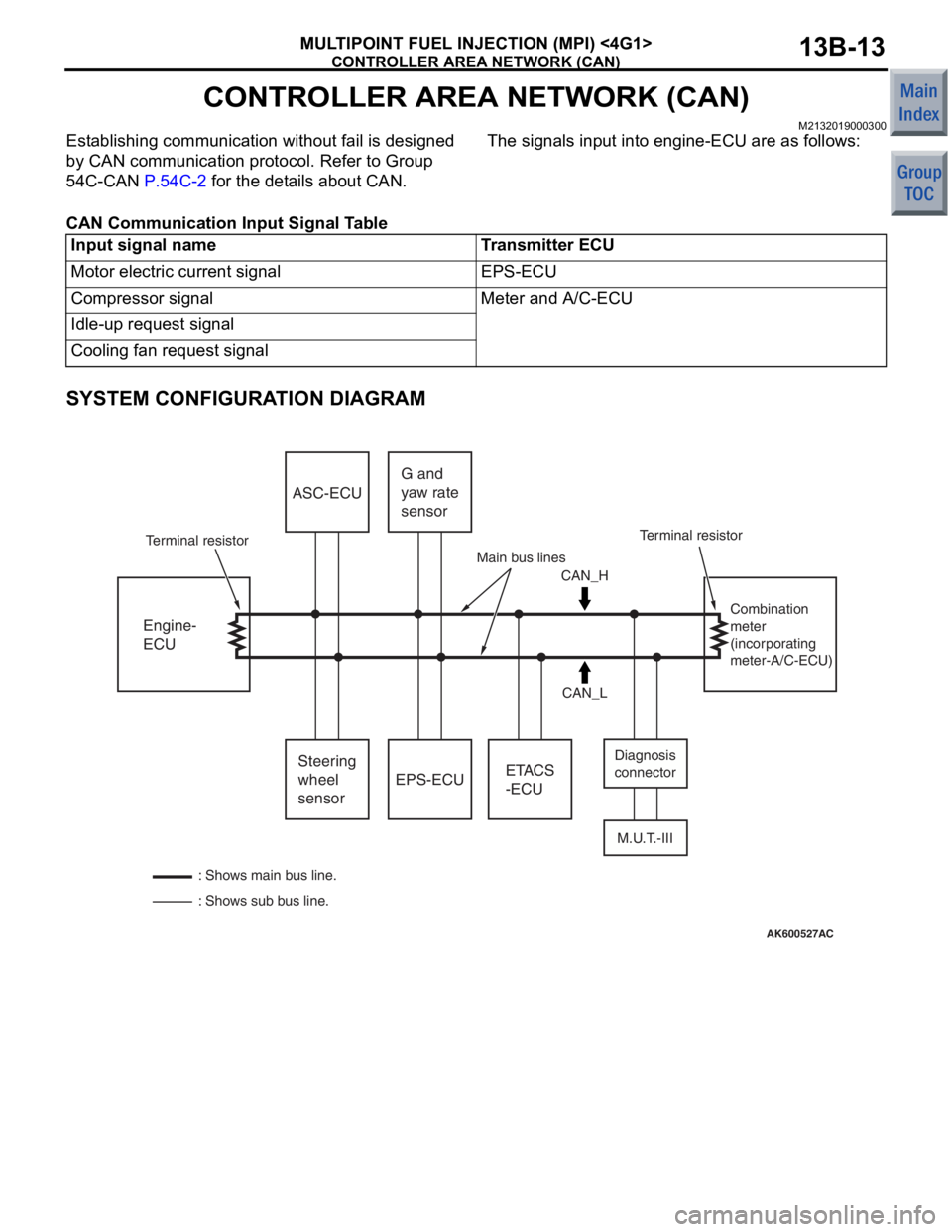

CONTROLLER AREA NETWORK (CAN)

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-13

CONTROLLER AREA NETWORK (CAN)

M2132019000300

Establishing communication without fail is designed

by CAN communication protocol. Refer to Group

54C-CAN

P.54C-2 for the details about CAN.

The signals input into engine-ECU are as follows:

CAN Communication Input Signal Table

Input signal nameTransmitter ECU

Motor electric current signalEPS-ECU

Compressor signalMeter and A/C-ECU

Idle-up request signal

Cooling fan request signal

SYSTEM CONFIGURATION DIAGRAM

AK600527AC

Engine-

ECU

M.U.T.-III

EPS-ECU ETACS

-ECU

Steering

wheel

sensor G and

yaw rate

sensor

ASC-ECU

CAN_H

CAN_L Diagnosis

connector Combination

meter

(incorporating

meter-A/C-ECU)

: Shows sub bus line. : Shows main bus line. Terminal resistor

Terminal resistor

Main bus lines

Page 132 of 364

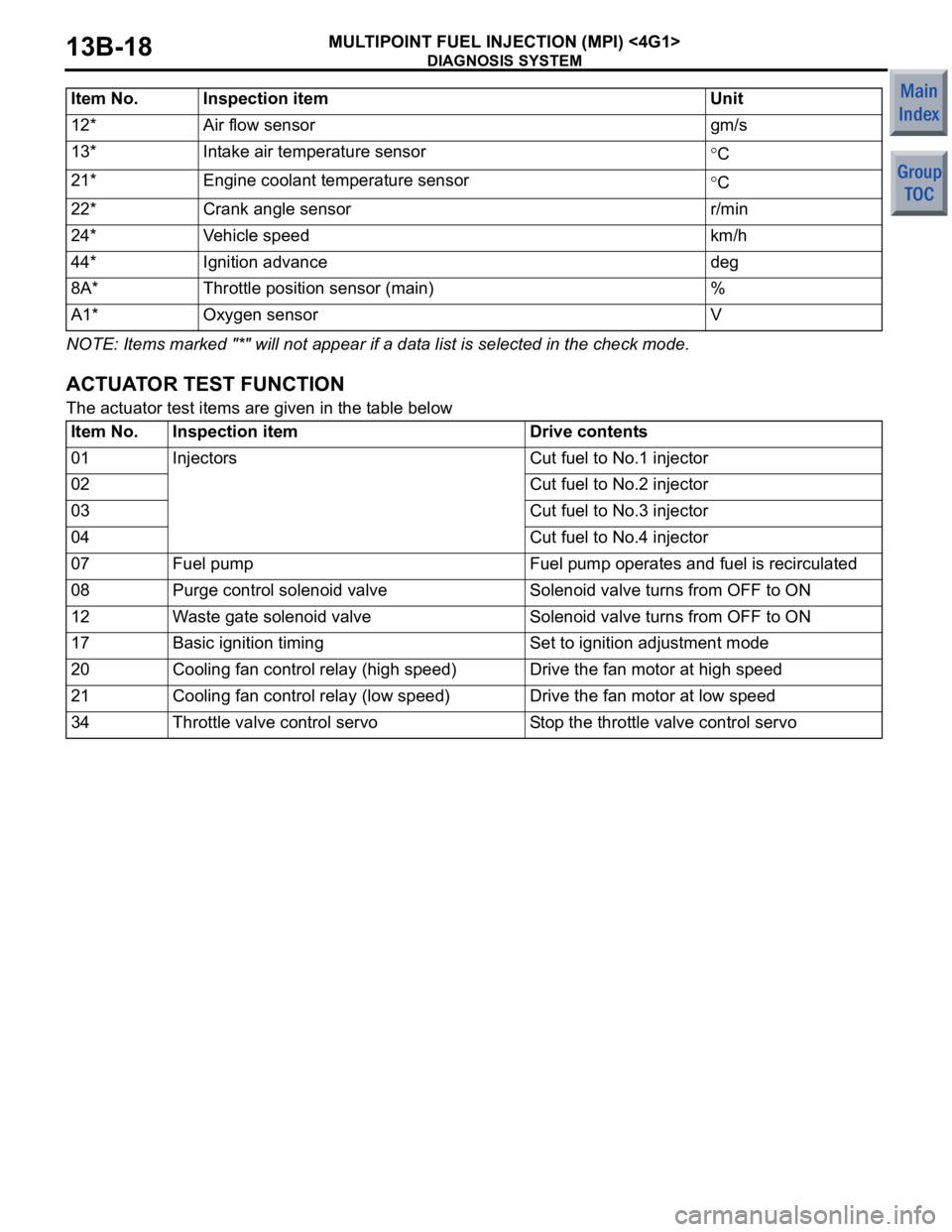

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-18

NOTE: Items marked "*" will not appear if a data list is selected in the check mode.

ACTUATOR TEST FUNCTION

The actuator test items are given in the table below

Item No.Inspection itemDrive contents

01InjectorsCut fuel to No.1 injector

02Cut fuel to No.2 injector

03Cut fuel to No.3 injector

04Cut fuel to No.4 injector

07Fuel pumpFuel pump operates and fuel is recirculated

08Purge control solenoid valveSolenoid valve turns from OFF to ON

12Waste gate solenoid valveSolenoid valve turns from OFF to ON

17Basic ignition timingSet to ignition adjustment mode

20Cooling fan control relay (high speed)Drive the fan motor at high speed

21Cooling fan control relay (low speed)Drive the fan motor at low speed

34Throttle valve control servoStop the throttle valve control servo

12*Air flow sensorgm/s

13*Intake air temperature sensor°C

21*Engine coolant temperature sensor°C

22*Crank angle sensorr/min

24*Vehicle speedkm/h

44*Ignition advancedeg

8A*Throttle position sensor (main)%

A1*Oxygen sensorV

Item No. Inspection item Unit

Page 145 of 364

GENERAL INFORMATION

BODY42-2

GENERAL INFORMATION

M2420000100842

FEATURES

WEIGHT REDUCTION AND HIGH RIGID-

ITY

•Application ranges of high tension steel plate,

antirust steel plate, and uneven thickness steel

plate have been expanded.

•The upper frame outer and front pillar connection

has been strengthened by adopting the upper

frame-to-front pillar brace.

•The radius of each opening corner for the doors

and tailgate has been enlarged.

•Cowl top lower panel and spring house panel are

directly joined for higher rigidity.

•Strut tower bar has been adopted <4G1>.

•A front suspension axle side plate has been

adopted <4G1>.

•The air outlet garnish has been installed to the

hood, improving the sporty image and cooling

efficiency in the engine compartment. <4G1>

REDUCTION OF VIBRATION, NOISE, AND

AERODYNAMIC NOISE

•Straight frame structure has been adopted.

•Curved front floor and uneven thickness steel

plate have been adopted.

•Rigidity of the suspension installation part has

been improved.

IMPROVEMENTS IN SAFETY

•RISE (Reinforced Impact Safety Evolution) has

been used for the main body.

•Features a side door beam to boost safety upon

side impact.

•Direct combination key cylinder and inside lock

cables for the front doors have been adopted to

improve safety upon impact.

IMPROVEMENTS IN OPERATION

QUALITY

•The central door locking system, which

locks/unlocks all the doors and the tailgate, is

adopted.

•"P" position shift linked door-unlock function has

been introduced to the central door locking sys

-

tem(F1C1A).

IMPROVEMENTS OF PRODUCT

PACKAGE AND APPEARANCE

•Rigidity of door sash bottom section has been

improved.

•By improving the engaging sound between the

door latch and striker, the door locking sound

quality has been enhanced.

•UV & heat protect glass has been used for the

windshield.

•UV-reducing glass has been used for the front

door window glasses and rear door window

glasses.

•Privacy glasses have been used for rear door

window glasses, quarter window glasses, and

tailgate window glass (Option).

•Multi-mode keyless entry system (with door mir-

ror retraction/return control function) has been

adopted.

•Protector film has been attached on side sill

•Sunroof has been installed (Option).

Page 153 of 364

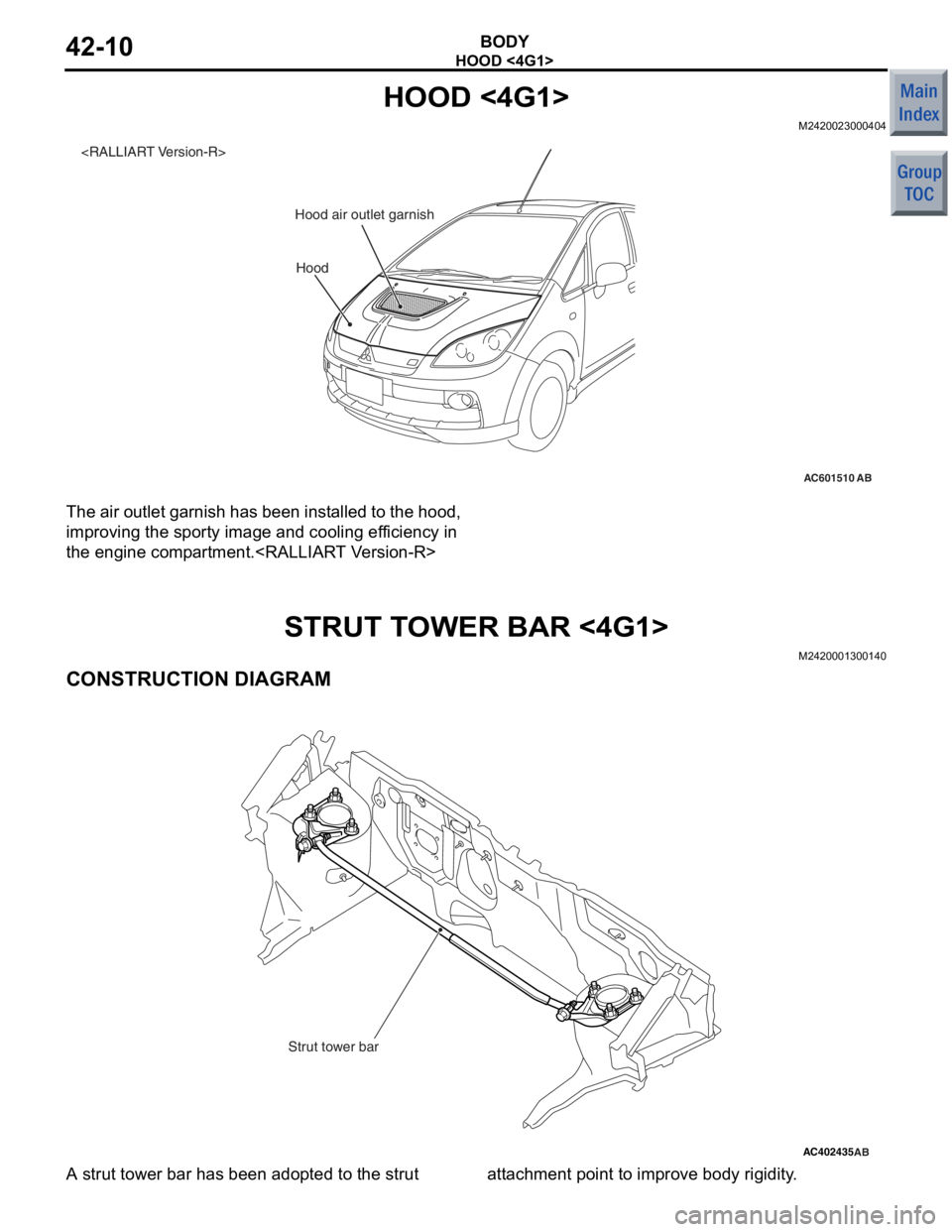

HOOD <4G1>

BODY42-10

HOOD <4G1>

M2420023000404

AC601510 AB

Hood air outlet garnish

The air ou

tlet ga rnish has be en inst alle d to the hoo d,

imp

r oving the sport y image and cooling ef ficiency in

the eng

ine comp a r tment .

STRUT TO WER BAR <4G1>

M24200013 0014 0

CONSTRUCTION DIAGRAM

AC402435AB

Strut tower bar

A strut to we r bar ha s be en ado pted to the strut att a chment p o int t o improve body rigidity .

Page 230 of 364

GROUP 14

ENGINE COOLING

CONTENTS

GENERAL INFORMATION . . . . . . . .14-2