alternator MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 32 of 364

A/C-ECU

HEATER, AIR CONDITIONER AND VENTILATION55-8

A/C-ECU

M2551001200179

CONTROL SYSTEM

The manual and automatic A/Cs have the following

control functions.

ControlManual A/CAutomatic A/C

Automatic wind temperature change controlApplicableApplicable

Automatic outside/inside air selection controlApplicableApplicable

Idle-up controlApplicableApplicable

Cooling fun load controlApplicableApplicable

Cooling controlApplicableApplicable

Detection control for refrigerant leaksApplicableApplicable

MAX A/C controlNot applicableApplicable

Estimation control for compressor torqueApplicableApplicable

Defroster linked controlNot applicableApplicable

AUTOMATIC CHANGE CONTROL OF

BLOW WIND TEMPERATURE

(COMPRESSOR

ENERGY-CONSERVATION CONTROL)

Optimum ON/OFF control of the compressor is

achieved according to the outside/inside air mode,

air temperature (air temperature sensor), and insula

-

tion.

OUTSIDE/INSIDE AIR AUTO SWITCHING

CONTROL

When the A/C is turned on in high ambient tempera-

ture, the recirculation function is automatically acti-

vated to cool down the passenger compartment and

improve fuel consumption.

COOLING FUN LOAD CONTROL

Depending on the A/C load, the cooling fan cycle

time is controlled and the exterior noise in the inter

-

mediary stage is decreased. Also, the load of the

alternator is decreased to improve the fuel economy.

COOLING CONTROL

If air temperature is high, the CVT rotates at a high

speed to prevent deterioration in cooling perform

-

ance.

DETECTION CONTROL FOR

REFRIGERANT LEAKS

When it is judged from the air temperature (air tem-

perature sensor) and the refrigerant pressure (A/C

pressure sensor) that the refrigerant amount is the

specified value or less, or the refrigerant pressure is

abnormal, the compressor is forced to be cut off to

protect the A/C system.

MAX A/C CONTROL

When MAX COOL position is set, automatically the

mode is changed to the inside air mode before the

A/C is turned ON, thereby facilitating the operation

for obtaining maximum cooling performance.

ESTIMATION CONTROL FOR

COMPRESSOR TORQUE

Communication between the engine⋅CVT-ECU and

A/C-ECU is made to control the engine according to

the compressor torque for higher drivability and

reduction in fuel consumption.

FORCIBLE DEFROSTER CONTROL

When the defroster vents are selected, the A/C is

automatically turned ON. At this time, the out

-

side/inside air selection damper is operated to the

fresh-air position to defrost the windshield glass

quickly.

Page 97 of 364

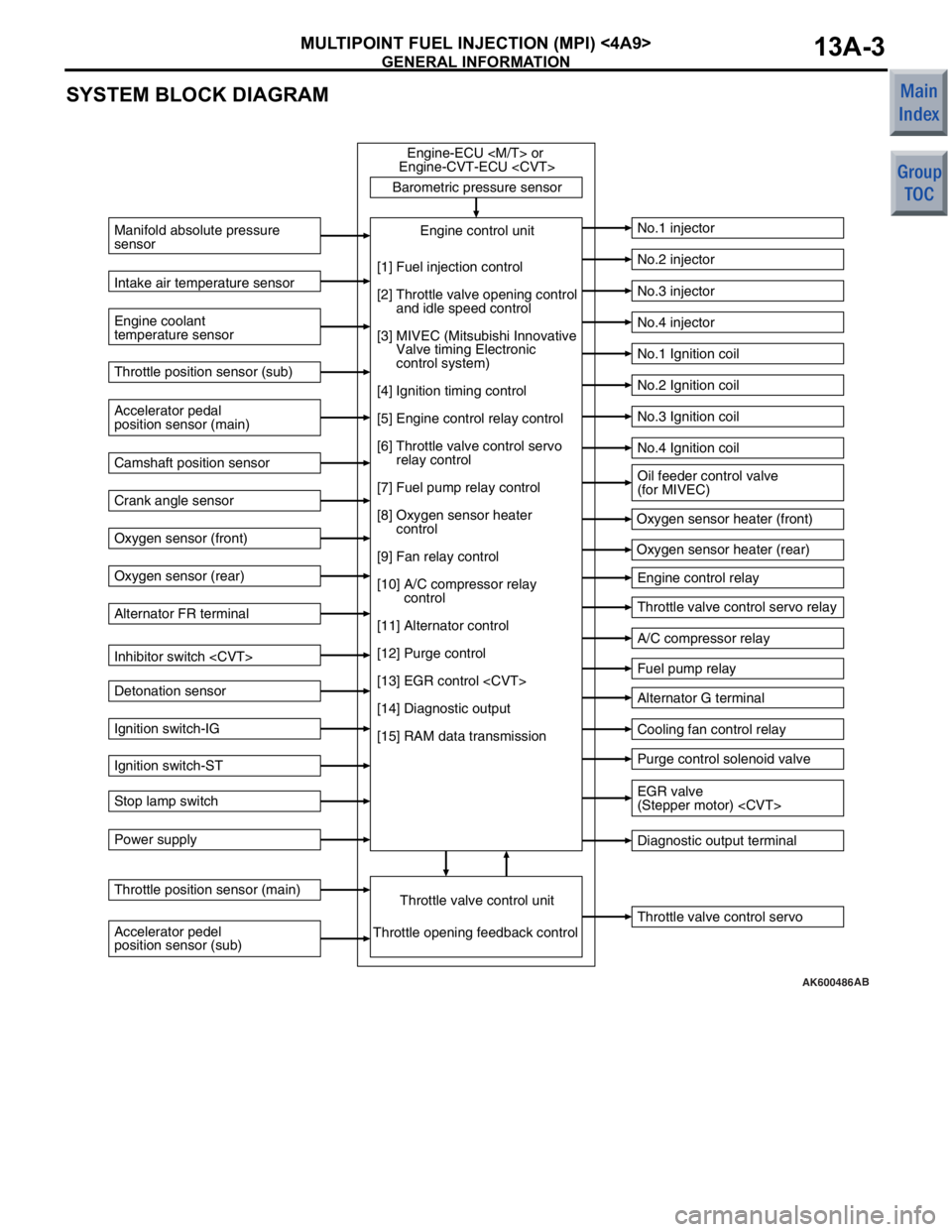

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-3

SYSTEM BLOCK DIAGRAM

AK600486

Barometric pressure sensorThrottle valve control servo

Manifold absolute pressure

sensor

Engine coolant

temperature sensor

No.1 injector

No.2 injector

No.3 injector

No.4 injector

No.1 Ignition coil

No.2 Ignition coil

No.3 Ignition coil

No.4 Ignition coil

Engine control relay

Throttle valve control servo relay

A/C compressor relay

Fuel pump relay

Alternator G terminal

Cooling fan control relay

Purge control solenoid valve

Diagnostic output terminal

Intake air temperature sensor

Accelerator pedal

position sensor (main) Throttle position sensor (sub)

Camshaft position sensor

Crank angle sensor

Oxygen sensor (front)

Oxygen sensor (rear)

Alternator FR terminal

Inhibitor switch

Detonation sensor

Ignition switch-IG

Ignition switch-ST

Stop lamp switch

Power supply

Accelerator pedel

position sensor (sub) Throttle position sensor (main)

Throttle valve control unitEngine control unit

Engine-ECU

Engine-CVT-ECU

Throttle opening feedback control Oxygen sensor heater (front)

Oxygen sensor heater (rear)

[1] Fuel injection control

[2] Throttle valve opening control

and idle speed control

[3] MIVEC (Mitsubishi Innovative

Valve timing Electronic

control system)

[4] Ignition timing control

[5] Engine control relay control

[6] Throttle valve control servo

relay control

[7] Fuel pump relay control

[8] Oxygen sensor heater

control

[9] Fan relay control

[10] A/C compressor relay

control

[11] Alternator control

[12] Purge control

[13] EGR control

[14] Diagnostic output

[15] RAM data transmission

Oil feeder control valve

(for MIVEC)

EGR valve

(Stepper motor)

AB

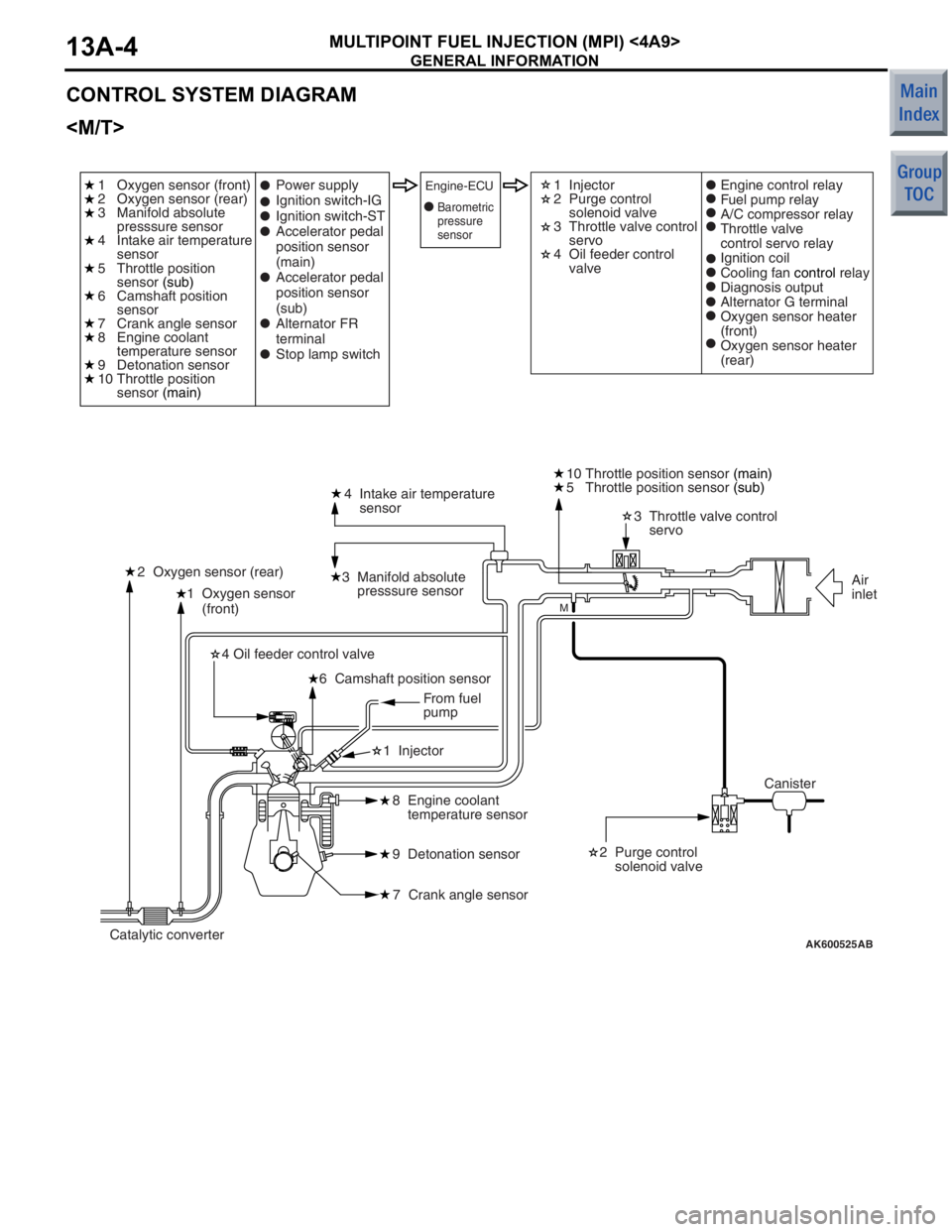

Page 98 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-4

CONTROL SYSTEM DIAGRAM

AK600525

1 Oxygen sensor

(front)4 Intake air temperature

sensor

3 Manifold absolute

presssure sensor

2 Oxygen sensor (rear) 3 Throttle valve control

servo

10 Throttle position sensor

(main)

2 Purge control

solenoid valve

8 Engine coolant

temperature sensor

9 Detonation sensor

7 Crank angle sensor

6 Camshaft position sensor

4 Oil feeder control valve

1 Injector

AB

M

1 Oxygen sensor (front)

2 Oxygen sensor (rear)

3 Manifold absolute

presssure sensor

4 Intake air temperature

sensor

5 Throttle position

sensor

(sub)

6 Camshaft position

sensor

7 Crank angle sensor

8 Engine coolant

temperature sensor

9 Detonation sensor

10 Throttle position

sensor (main) 1 Injector

2 Purge control

solenoid valve

3 Throttle valve control

servo

4 Oil feeder control

valve

Power supply

Ignition switch-IG

Ignition switch-ST

Accelerator pedal

position sensor

(main)

Accelerator pedal

position sensor

(sub)

Alternator FR

terminal

Stop lamp switchEngine-ECUEngine control relay

Fuel pump relay

A/C compressor relay

Throttle valve

control servo relay

Ignition coil

Cooling fan

control relay

Diagnosis output

Alternator G terminal

Oxygen sensor heater

(front)

Oxygen sensor heater

(rear)

Canister Air

inlet

Catalytic converter From fuel

pump

5 Throttle position sensor

(sub)

Barometric

pressure

sensor

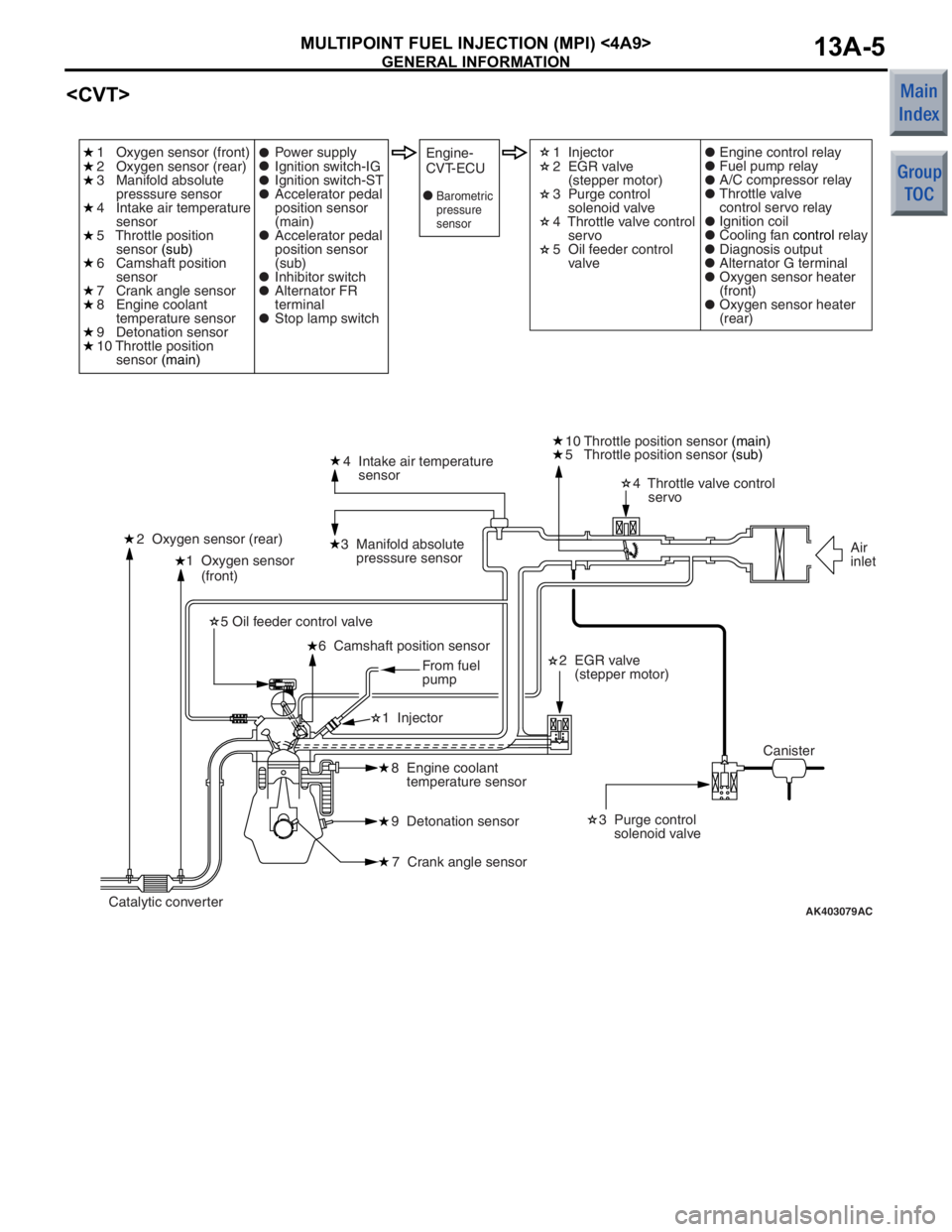

Page 99 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-5

AK403079

1 Oxygen sensor

(front)4 Intake air temperature

sensor

3 Manifold absolute

presssure sensor

2 Oxygen sensor (rear) 4 Throttle valve control

servo

10 Throttle position sensor

(main)

2 EGR valve

(stepper motor) 3 Purge control

solenoid valve

8 Engine coolant

temperature sensor

9 Detonation sensor

7 Crank angle sensor

6 Camshaft position sensor

5 Oil feeder control valve

1 Injector

AC

1 Oxygen sensor (front)

2 Oxygen sensor (rear)

3 Manifold absolute

presssure sensor

4 Intake air temperature

sensor

5 Throttle position

sensor (sub)

6 Camshaft position

sensor

7 Crank angle sensor

8 Engine coolant

temperature sensor

9 Detonation sensor

10 Throttle position

sensor (main) 1 Injector

2 EGR valve

(stepper motor)

3 Purge control

solenoid valve

4 Throttle valve control

servo

5 Oil feeder control

valve

Power supply

Ignition switch-IG

Ignition switch-ST

Accelerator pedal

position sensor

(main)

Accelerator pedal

position sensor

(sub)

Inhibitor switch

Alternator FR

terminal

Stop lamp switchEngine-

CVT-ECUEngine control relay

Fuel pump relay

A/C compressor relay

Throttle valve

control servo relay

Ignition coil

Cooling fan

control relay

Diagnosis output

Alternator G terminal

Oxygen sensor heater

(front)

Oxygen sensor heater

(rear)

Canister Air

inlet

Catalytic converter From fuel

pump

5 Throttle position sensor

(sub)

Barometric

pressure

sensor

Page 101 of 364

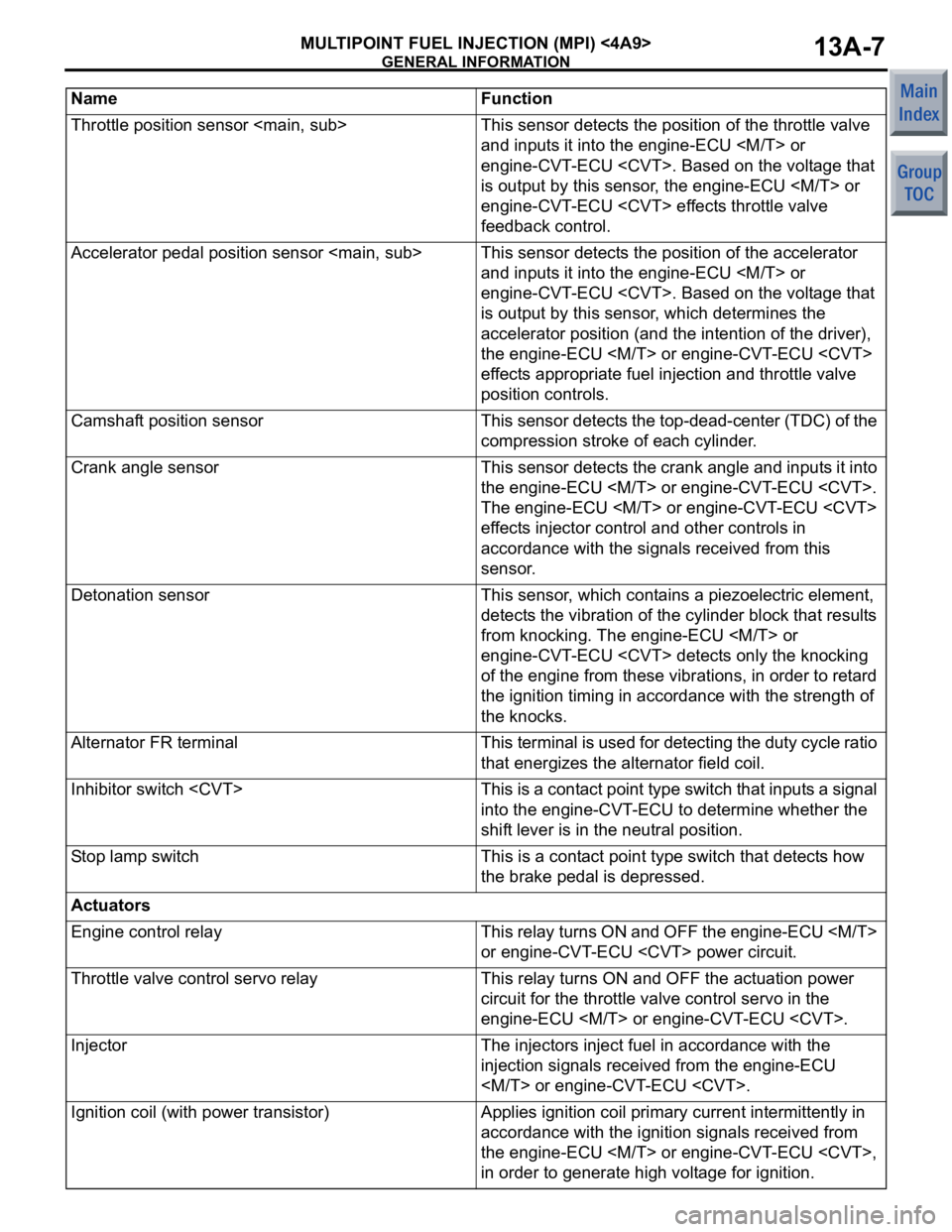

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-7

Throttle position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, the engine-ECU

engine-CVT-ECU

feedback control.

Accelerator pedal position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, which determines the

accelerator position (and the intention of the driver),

the engine-ECU

effects appropriate fuel injection and throttle valve

position controls.

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU

The engine-ECU

effects injector control and other controls in

accordance with the signals received from this

sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU

engine-CVT-ECU

of the engine from these vibrations, in order to retard

the ignition timing in accordance with the strength of

the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Inhibitor switch

into the engine-CVT-ECU to determine whether the

shift lever is in the neutral position.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU

or engine-CVT-ECU

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU

in order to generate high voltage for ignition.

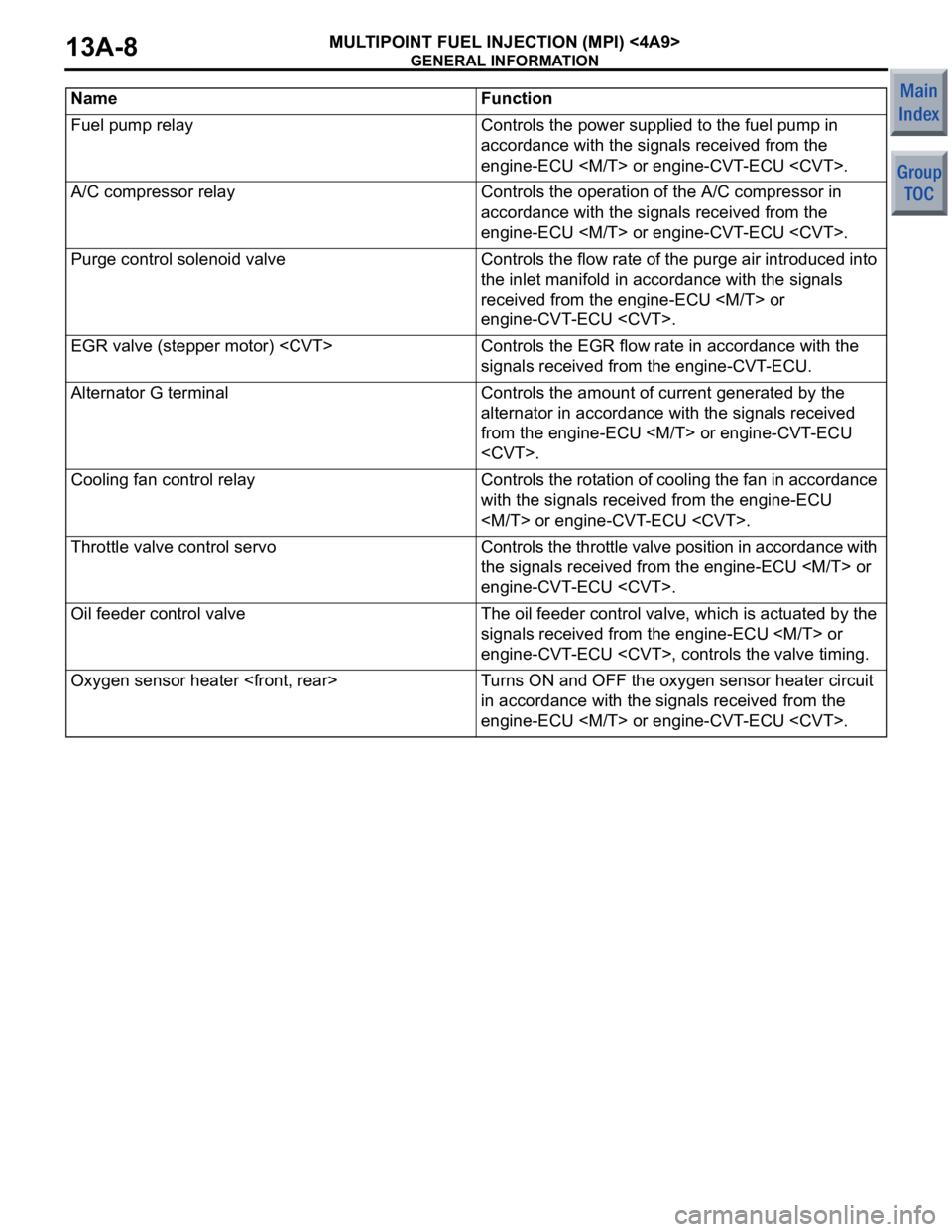

Name Function

Page 102 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-8

Fuel pump relayControls the power supplied to the fuel pump in

accordance with the signals received from the

engine-ECU

A/C compressor relayControls the operation of the A/C compressor in

accordance with the signals received from the

engine-ECU

Purge control solenoid valveControls the flow rate of the purge air introduced into

the inlet manifold in accordance with the signals

received from the engine-ECU

engine-CVT-ECU

EGR valve (stepper motor)

signals received from the engine-CVT-ECU.

Alternator G terminalControls the amount of current generated by the

alternator in accordance with the signals received

from the engine-ECU

Cooling fan control relayControls the rotation of cooling the fan in accordance

with the signals received from the engine-ECU

Throttle valve control servoControls the throttle valve position in accordance with

the signals received from the engine-ECU

engine-CVT-ECU

Oil feeder control valveThe oil feeder control valve, which is actuated by the

signals received from the engine-ECU

engine-CVT-ECU

Oxygen sensor heater

in accordance with the signals received from the

engine-ECU

Name Function

Page 110 of 364

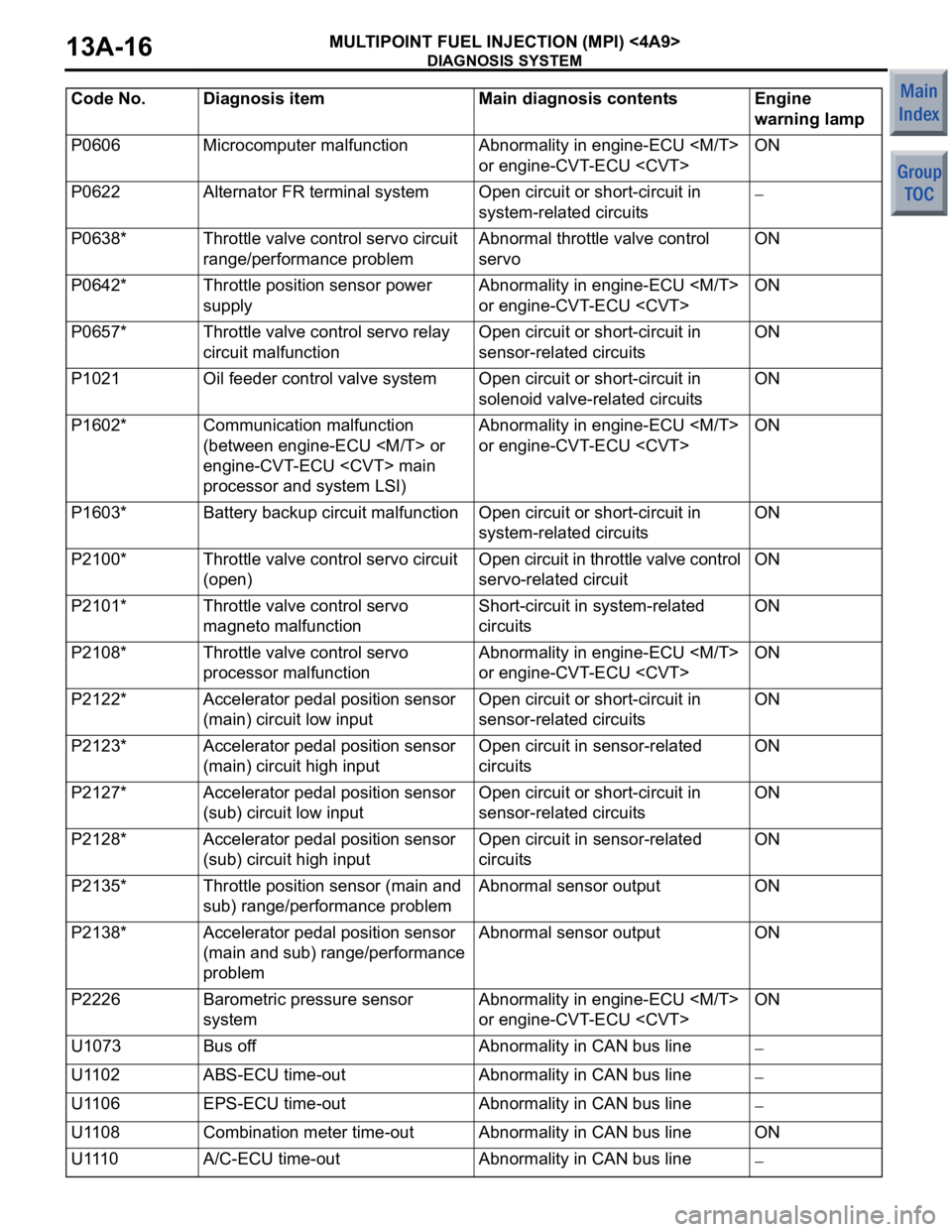

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-16

P0606Microcomputer malfunctionAbnormality in engine-ECU

or engine-CVT-ECU

P0622Alternator FR terminal systemOpen circuit or short-circuit in

system-related circuits−

P0638*Throttle valve control servo circuit

range/performance problemAbnormal throttle valve control

servoON

P0642*Throttle position sensor power

supplyAbnormality in engine-ECU

or engine-CVT-ECU

P0657*Throttle valve control servo relay

circuit malfunctionOpen circuit or short-circuit in

sensor-related circuitsON

P1021Oil feeder control valve systemOpen circuit or short-circuit in

solenoid valve-related circuitsON

P1602*Communication malfunction

(between engine-ECU

engine-CVT-ECU

processor and system LSI)Abnormality in engine-ECU

or engine-CVT-ECU

P1603*Battery backup circuit malfunctionOpen circuit or short-circuit in

system-related circuitsON

P2100*Throttle valve control servo circuit

(open)Open circuit in throttle valve control

servo-related circuitON

P2101*Throttle valve control servo

magneto malfunctionShort-circuit in system-related

circuitsON

P2108*Throttle valve control servo

processor malfunctionAbnormality in engine-ECU

or engine-CVT-ECU

P2122*Accelerator pedal position sensor

(main) circuit low inputOpen circuit or short-circuit in

sensor-related circuitsON

P2123*Accelerator pedal position sensor

(main) circuit high inputOpen circuit in sensor-related

circuitsON

P2127*Accelerator pedal position sensor

(sub) circuit low inputOpen circuit or short-circuit in

sensor-related circuitsON

P2128*Accelerator pedal position sensor

(sub) circuit high inputOpen circuit in sensor-related

circuitsON

P2135*Throttle position sensor (main and

sub) range/performance problemAbnormal sensor outputON

P2138*Accelerator pedal position sensor

(main and sub) range/performance

problemAbnormal sensor outputON

P2226Barometric pressure sensor

systemAbnormality in engine-ECU

or engine-CVT-ECU

U1073Bus offAbnormality in CAN bus line−

U1102ABS-ECU time-outAbnormality in CAN bus line−

U1106EPS-ECU time-outAbnormality in CAN bus line−

U1108Combination meter time-outAbnormality in CAN bus lineON

U 111 0A/C-ECU time-outAbnormality in CAN bus line−

Code No. Diagnosis item Main diagnosis contents Engine

warning lamp

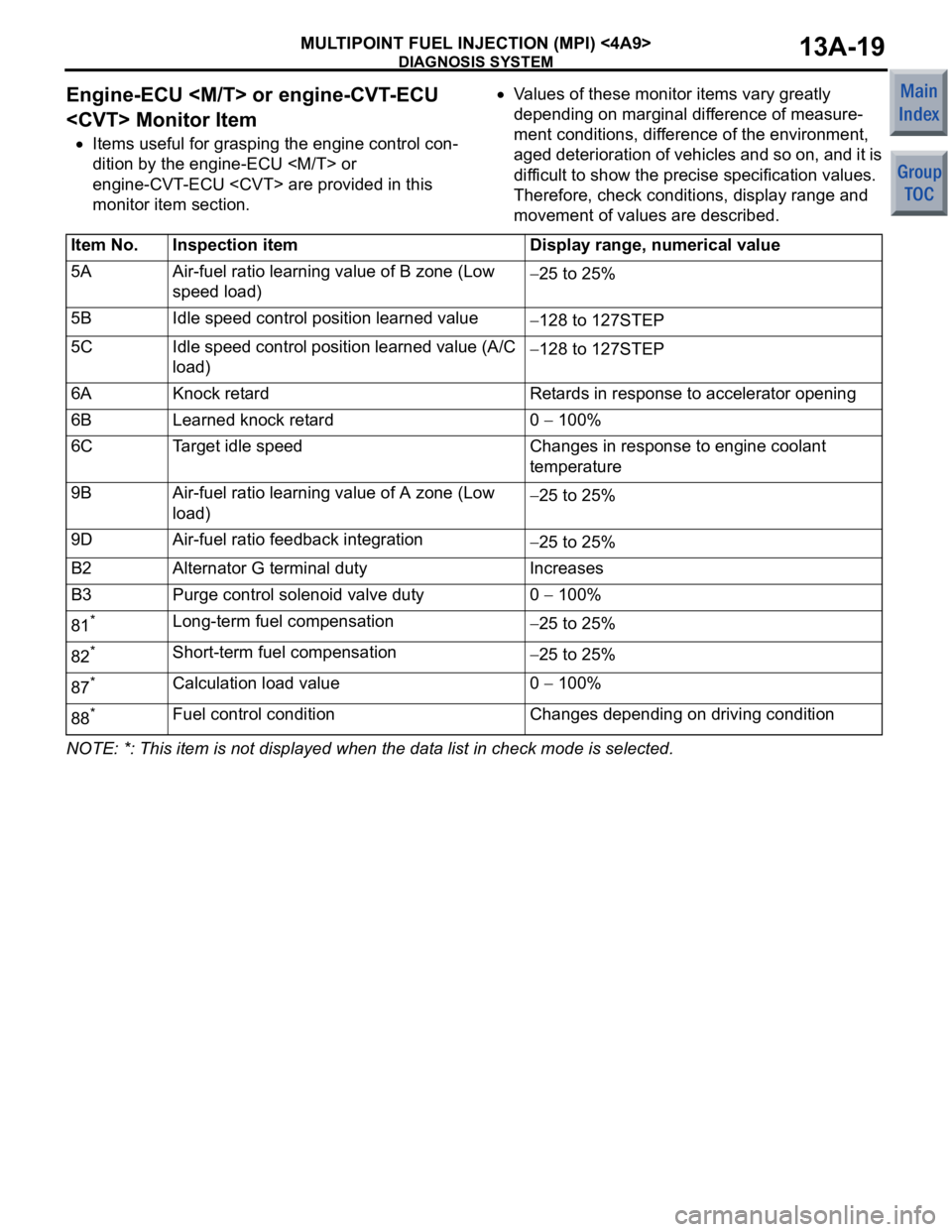

Page 113 of 364

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-19

Engine-ECU

•Items useful for grasping the engine control con-

dition by the engine-ECU

engine-CVT-ECU

monitor item section.

•Values of these monitor items vary greatly

depending on marginal difference of measure

-

ment conditions, difference of the environment,

aged deterioration of vehicles and so on, and it is

difficult to show the precise specification values.

Therefore, check conditi ons, display range and

movement of values are described.

Item No.Inspection itemDisplay range, numerical value

5AAir-fuel ratio learning value of B zone (Low

speed load)−25 to 25%

5BIdle speed control position learned value−128 to 127STEP

5CIdle speed control position learned value (A/C

load)−128 to 127STEP

6AKnock retardRetards in response to accelerator opening

6BLearned knock retard0 − 100%

6CTarget idle speedChanges in response to engine coolant

temperature

9BAir-fuel ratio learning value of A zone (Low

load)−25 to 25%

9DAir-fuel ratio feedback integration−25 to 25%

B2Alternator G terminal dutyIncreases

B3Purge control solenoid valve duty0 − 100%

81*Long-term fuel compensation−25 to 25%

82*Short-term fuel compensation−25 to 25%

87*Calculation load value0 − 100%

88*Fuel control conditionChanges depending on driving condition

NOTE: *: This item is not displayed when the data list in check mode is selected.

Page 117 of 364

![MITSUBISHI COLT 2006 Service Repair Manual

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve open MITSUBISHI COLT 2006 Service Repair Manual

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve open](/img/19/57093/w960_57093-116.png)

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve opening control

and idle speed control

[3] MIVEC (Mitsubishi Innovative

Valve timing Electronic

control system)

[4] Ignition timing control

[5] Engine control relay control

[6] Throttle valve control servo

relay control

[7] Fuel pump relay control

[8] Oxygen sensor (front) heater

control

[9] Oxygen sensor (rear) heater

control

[10] Fuel pressure control

[11] Waste gate control

[12] Fan relay control

[13] A/C compressor relay

control

[14] Alternator control

[15] Purge control

[16] Diagnostic output

[17] RAM data transmission Throttle valve control unit

Throttle opening feedback control

Engine coolant

temperature sensor Intake air temperature sensor Air flow sensor

Accelerator pedal

position sensor (main) Throttle position sensor (sub)

Camshaft position sensor

Crank angle sensor

Oxygen sensor (front)

Oxygen sensor (rear)

Alternator FR terminal

Clutch switch

Detonation sensor

Ignition switch-IG

Ignition switch-ST

Stop lamp switch

Power supply

Throttle position sensor (main)

Accelerator pedel

position sensor (sub)

Throttle valve control servo No.1 injector

No.2 injector

No.3 injector

No.4 injector

No.1 Ignition coil

No.2 Ignition coil

No.3 Ignition coil

No.4 Ignition coil

Engine control relay

Throttle valve control servo relay

Waste gate solenoid valve

A/C compressor relay

Fuel pump relay

Alternator G terminal

Cooling fan control relay (Hi, Lo)

Purge control solenoid valve

Diagnostic output terminal

Oxygen sensor (front) heater

Oxygen sensor (rear) heater Oil feeder control valve

(for MIVEC)

Fuel pressure control

solenoid valve

AB

Page 118 of 364

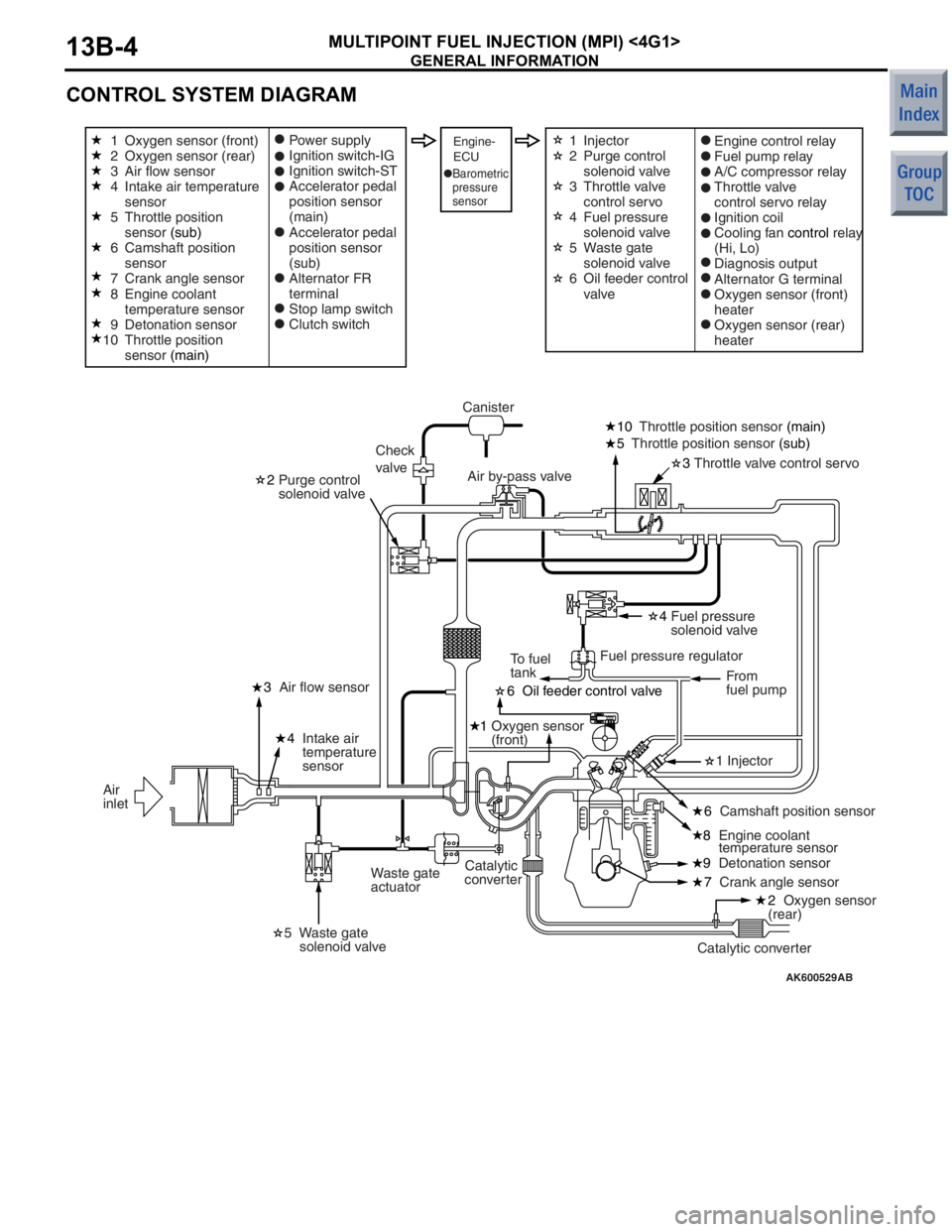

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-4

CONTROL SYSTEM DIAGRAM

AK600529AB

6 Oil feeder control valve

1 Oxygen sensor

(front)

8 Engine coolant

temperature sensor

3

Throttle valve control servo

10

Throttle position sensor (main)

5 Throttle position sensor (sub)

2 Purge control

solenoid valve

4 Fuel pressure

solenoid valve

7 Crank angle sensor

9

Detonation sensor

4

Intake air

temperature

sensor

3

Air flow sensor

Waste gate

actuator Canister

Check

valve Air by-pass valve

Fuel pressure regulatorFrom

fuel pump

To fuel

tank

Catalytic converter

Catalytic

converter

Air

inlet

Oxygen sensor (front)

Oxygen sensor (rear)

Air flow sensor

Intake air temperature

sensor

Throttle position

sensor

(sub)

Camshaft position

sensor

Crank angle sensor

Engine coolant

temperature sensor

Detonation sensor

Throttle position

sensor (main) Power supply

Ignition switch-IG

Ignition switch-ST

Accelerator pedal

position sensor

(main)

Accelerator pedal

position sensor

(sub)

Alternator FR

terminal

Stop lamp switch

Clutch switchEngine-

ECUEngine control relay

Fuel pump relay

A/C compressor relay

Throttle valve

control servo relay

Ignition coil

Cooling fan

control relay

(Hi, Lo)

Diagnosis output

Alternator G terminal

Oxygen sensor (front)

heater

Oxygen sensor (rear)

heater

Barometric

pressure

sensor

1 Injector

5 Waste gate

solenoid valve

2 Oxygen sensor

(rear)

6 Camshaft position sensor

1

2

3

4

5

6

7

8

9

10 Injector

Purge control

solenoid valve

Throttle valve

control servo

Fuel pressure

solenoid valve

Waste gate

solenoid valve

Oil feeder control

valve

1

2

3

4

5

6