coolant MITSUBISHI COLT 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 132 of 364

DIAGNOSIS SYSTEM

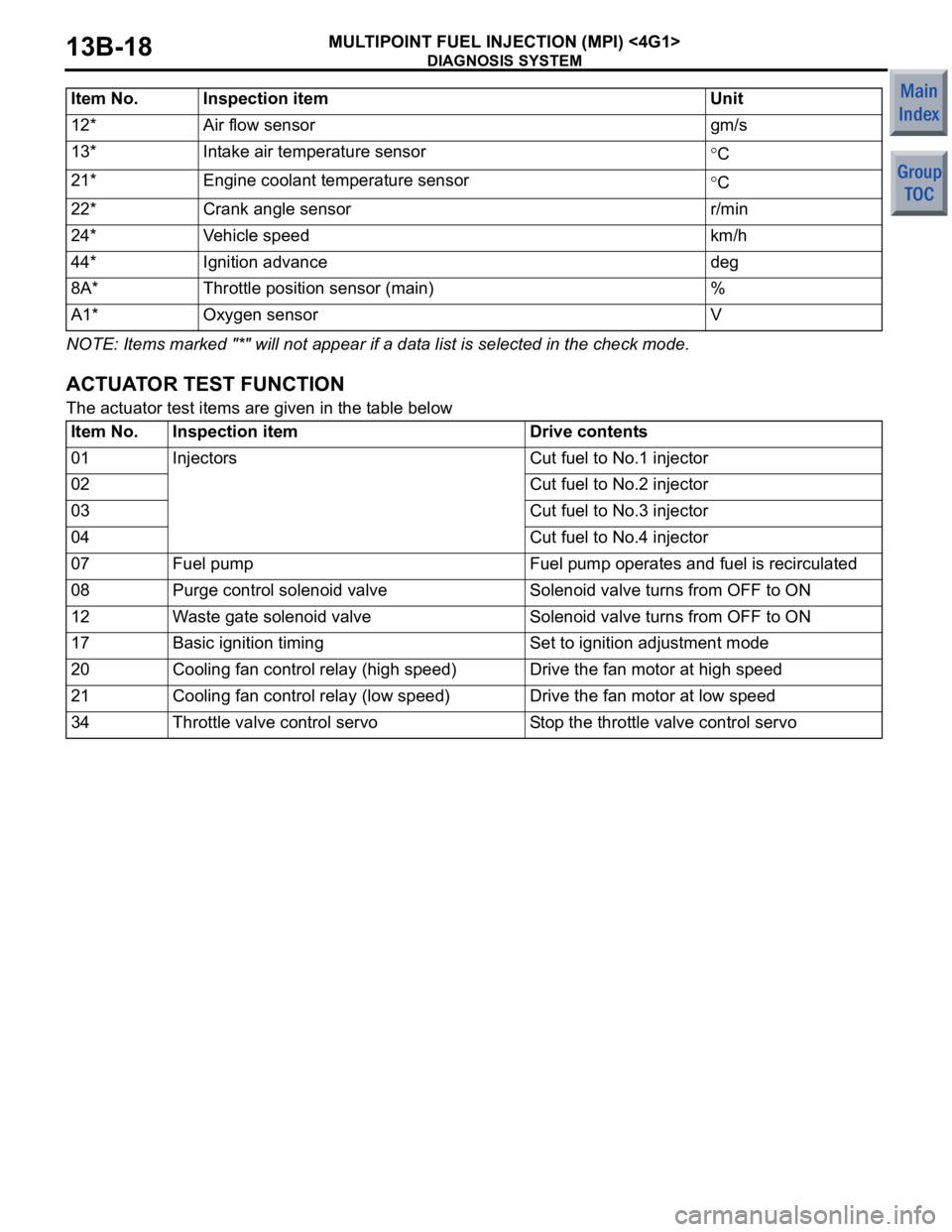

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-18

NOTE: Items marked "*" will not appear if a data list is selected in the check mode.

ACTUATOR TEST FUNCTION

The actuator test items are given in the table below

Item No.Inspection itemDrive contents

01InjectorsCut fuel to No.1 injector

02Cut fuel to No.2 injector

03Cut fuel to No.3 injector

04Cut fuel to No.4 injector

07Fuel pumpFuel pump operates and fuel is recirculated

08Purge control solenoid valveSolenoid valve turns from OFF to ON

12Waste gate solenoid valveSolenoid valve turns from OFF to ON

17Basic ignition timingSet to ignition adjustment mode

20Cooling fan control relay (high speed)Drive the fan motor at high speed

21Cooling fan control relay (low speed)Drive the fan motor at low speed

34Throttle valve control servoStop the throttle valve control servo

12*Air flow sensorgm/s

13*Intake air temperature sensor°C

21*Engine coolant temperature sensor°C

22*Crank angle sensorr/min

24*Vehicle speedkm/h

44*Ignition advancedeg

8A*Throttle position sensor (main)%

A1*Oxygen sensorV

Item No. Inspection item Unit

Page 133 of 364

DIAGNOSIS SYSTEM

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-19

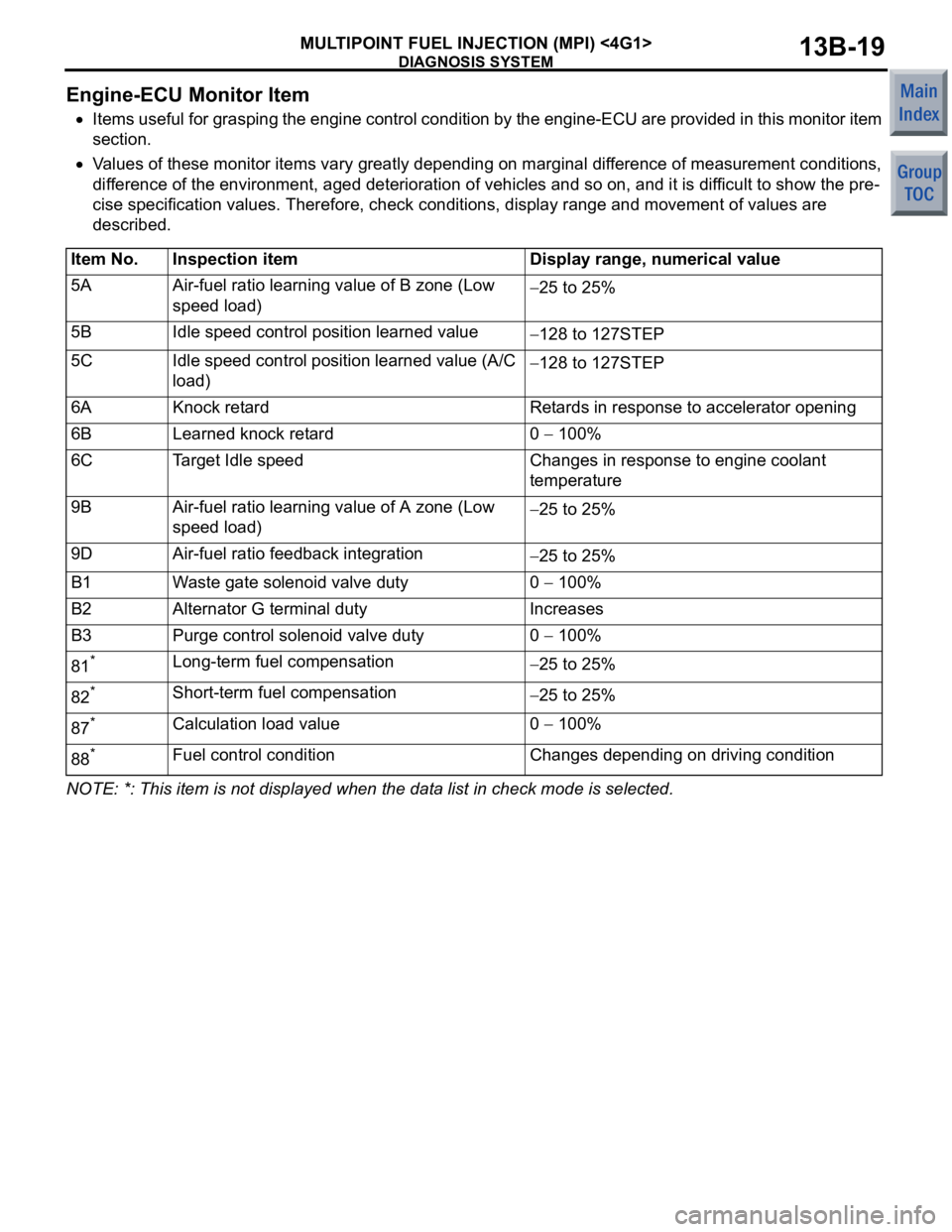

Engine-ECU Monitor Item

•Items useful for grasping the engine control condition by the engine-ECU are provided in this monitor item

section.

•Values of these monitor items vary greatly depending on marginal difference of measurement conditions,

difference of the environment, aged deterioration of vehicl es and so on, and it is difficult to show the pre

-

cise specification values. Therefore, check conditions, display range and movement of values are

described.

Item No.Inspection itemDisplay range, numerical value

5AAir-fuel ratio learning value of B zone (Low

speed load)−25 to 25%

5BIdle speed control position learned value−128 to 127STEP

5CIdle speed control position learned value (A/C

load)−128 to 127STEP

6AKnock retardRetards in response to accelerator opening

6BLearned knock retard0 − 100%

6CTarget Idle speedChanges in response to engine coolant

temperature

9BAir-fuel ratio learning value of A zone (Low

speed load)−25 to 25%

9DAir-fuel ratio feedback integration−25 to 25%

B1Waste gate solenoid valve duty0 − 100%

B2Alternator G terminal dutyIncreases

B3Purge control solenoid valve duty0 − 100%

81*Long-term fuel compensation−25 to 25%

82*Short-term fuel compensation−25 to 25%

87*Calculation load value0 − 100%

88*Fuel control conditionChanges depending on driving condition

NOTE: *: This item is not displayed when the data list in check mode is selected.

Page 181 of 364

COMBINATION METER

CHASSIS ELECTRICAL54A-10

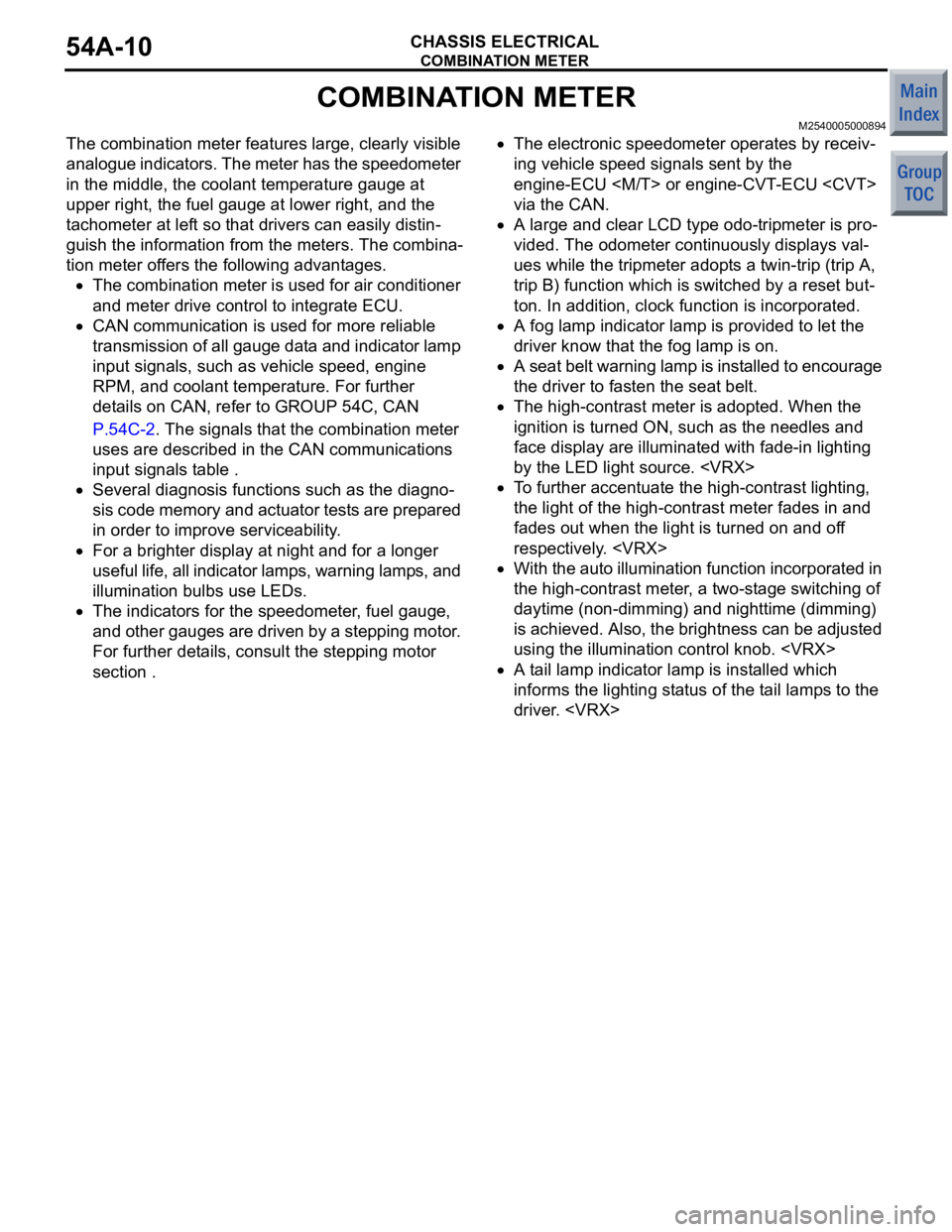

COMBINATION METER

M2540005000894

The combination meter features large, clearly visible

analogue indicators. The meter has the speedometer

in the middle, the coolant temperature gauge at

upper right, the fuel gauge at lower right, and the

tachometer at left so that drivers can easily distin

-

guish the information from the meters. The combina-

tion meter offers the following advantages.

•The combination meter is used for air conditioner

and meter drive control to integrate ECU.

•CAN communication is used for more reliable

transmission of all gauge data and indicator lamp

input signals, such as vehicle speed, engine

RPM, and coolant temperature. For further

details on CAN, refer to GROUP 54C, CAN

P.54C-2. The signals that the combination meter

uses are described in the CAN communications

input signals table

.

•Several diagnosis functions such as the diagno-

sis code memory and actuator tests are prepared

in order to improve serviceability.

•For a brighter display at night and for a longer

useful life, all indicator lamps, warning lamps, and

illumination bulbs use LEDs.

•The indicators for the speedometer, fuel gauge,

and other gauges are driven by a stepping motor.

For further details, consult the stepping motor

section

.

•The electronic speedometer operates by receiv-

ing vehicle speed signals sent by the

engine-ECU

via the CAN.

•A large and clear LCD type odo-tripmeter is pro-

vided. The odometer continuously displays val-

ues while the tripmeter adopts a twin-trip (trip A,

trip B) function which is switched by a reset but

-

ton. In addition, clock function is incorporated.

•A fog lamp indicator lamp is provided to let the

driver know that the fog lamp is on.

•A seat belt warning lamp is installed to encourage

the driver to fasten the seat belt.

•The high-contrast meter is adopted. When the

ignition is turned ON, such as the needles and

face display are illuminated with fade-in lighting

by the LED light source.

•To further accentuate the high-contrast lighting,

the light of the high-contrast meter fades in and

fades out when the light is turned on and off

respectively.

•With the auto illumination function incorporated in

the high-contrast meter, a two-stage switching of

daytime (non-dimming) and nighttime (dimming)

is achieved. Also, the brightness can be adjusted

using the illumination control knob.

•A tail lamp indicator lamp is installed which

informs the lighting status of the tail lamps to the

driver.

Page 183 of 364

COMBINATION METER

CHASSIS ELECTRICAL54A-12

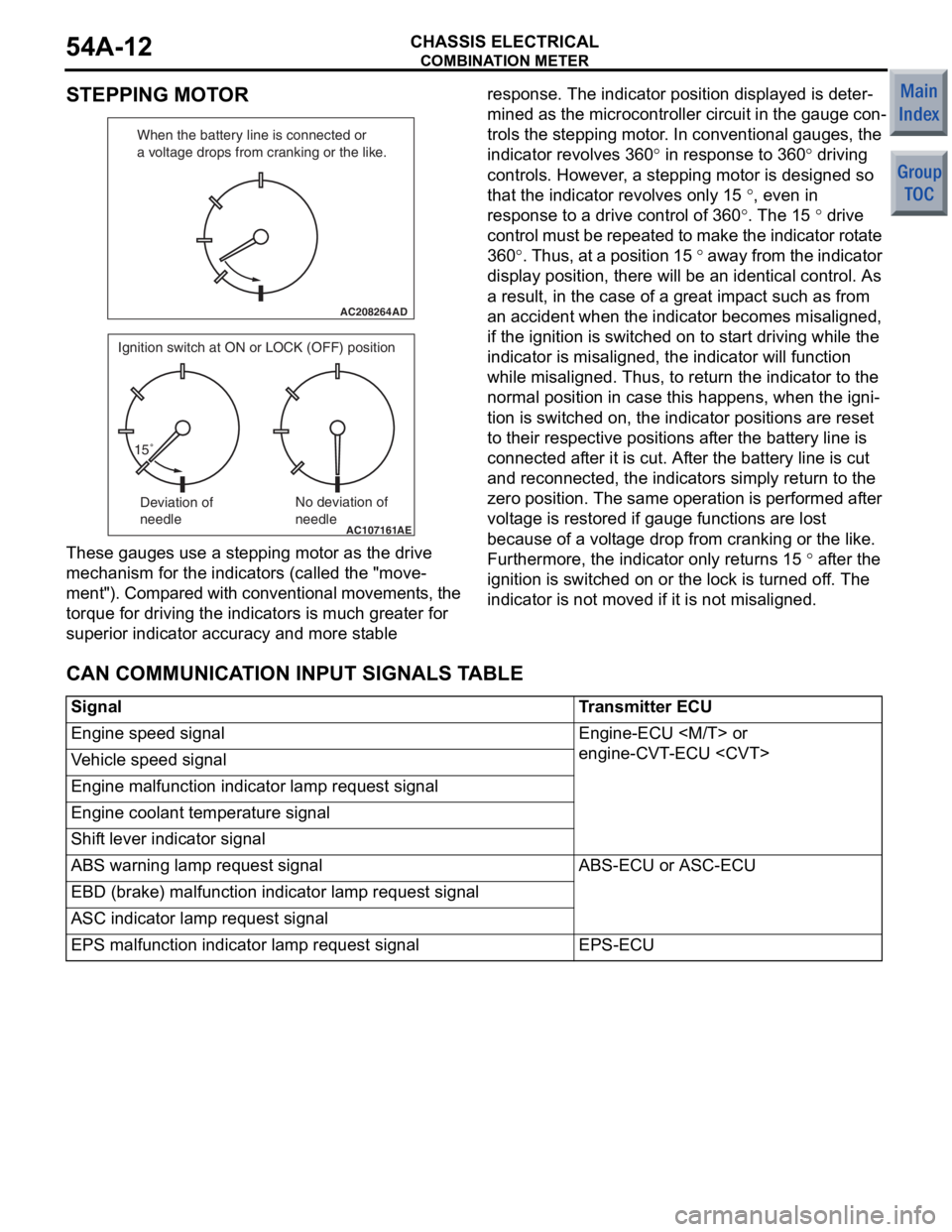

STEPPING MOTOR

AC208264

When the battery line is connected or

a voltage drops from cranking or the like.

AD

AC107161

Deviation of

needleNo deviation of

needle

15˚

AE

Ignition switch at ON or LOCK (OFF) position

These

gauge s use a stepp ing motor a s the drive

mechanism for

the indica tor s (calle d the "move

-

ment"). Compared with conventional movement s, the

torque f

o r driving the indicators is much gre a ter for

supe

rior indicator a ccu racy and more st able respo n se. The indicator po sit i on d i sp layed is dete r

-

min

ed a s t he microcon troller circuit in the gauge co n-

trols the stepping moto r . In conve n tion al gaug es, the

indicato

r revo lves 360

° in response to 3 6 0° driving

contro

ls.

Ho

we

ver

,

a ste

pping

mot

o

r is designed so

that the

ind

i

cat

o

r revolves on

ly

15

°, even in

respo

n

se

to a drive contro

l of 3

6

0

°. The 15 ° drive

c

ont

ro

l m

u

st

be

rep

eat

ed

t

o

ma

ke

th

e

ind

i

cat

o r rot a t e

36

0

°. Th us , at a po sit i o n 15 ° a w a y fr om th e in dicat o r

display positio

n, there

will be an iden tica l control. As

a resu

lt, in the

case of a

great imp a ct such as from

an accide

nt wh

en the indicator becomes misalign ed,

if the

ignition

is

switched o

n

to st art driving while t he

indicato

r is

misaligned,

the indicator will fu nction

wh

ile

misaligned.

Thus, to retu rn the indicator to the

norma

l position in

case this ha ppens, when the ig ni

-

tion is switched on , the indicator p o sitions are re set

to their respective

position s af ter th e batte ry line is

conn

ected af ter it is cut. Af ter th e batte ry line is cut

and reconne

cted , the indicators simply retu rn to th e

zero

positio n. Th e same ope ration is pe rforme d af ter

volt

ag e is resto r ed if gauge functions are lost

beca

u se o f a volt age d r op from cra n king or t he like.

Furthermore, t

he in dicator only re turns 15

° after the

ignition

is switched on

or the

lock is turne

d

of f. The

indicato

r is

not moved

if it is not misa

lig

ned.

CAN COMMUNICA TION INPUT SIGNALS T ABLE

SignalTransmitter ECU

Engine speed signalEngine-ECU

engine-CVT-ECU

Vehicle speed signal

Engine malfunction indicator lamp request signal

Engine coolant temperature signal

Shift lever indicator signal

ABS warning lamp request signalABS-ECU or ASC-ECU

EBD (brake) malfunction indicator lamp request signal

ASC indicator lamp request signal

EPS malfunction indicator lamp request signalEPS-ECU

Page 197 of 364

TECHNICAL FEATURES

GENERAL00-12

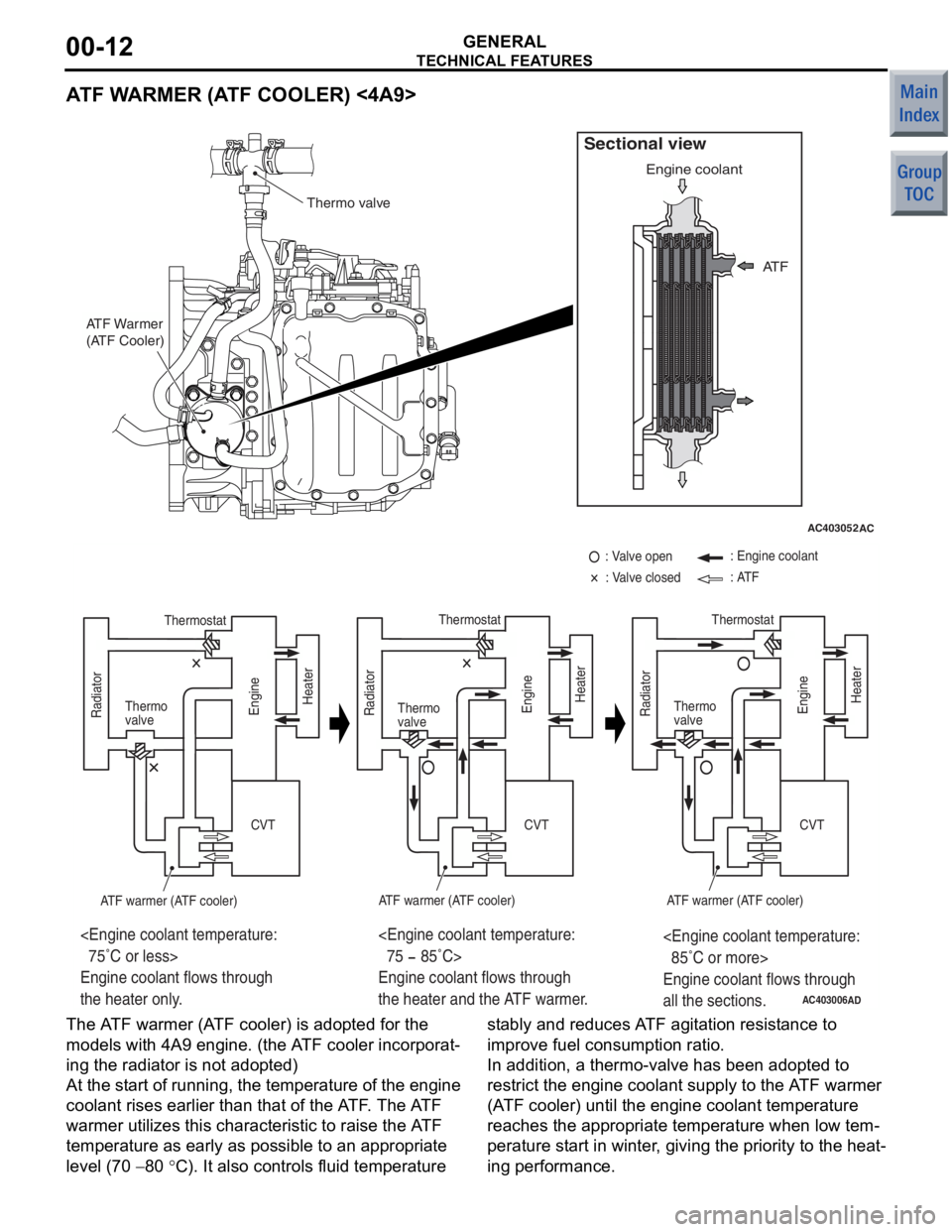

ATF WARMER (ATF COOLER) <4A9>

AC403052AC

AT F

Engine coolant

Sectional view

ATF Warmer

(ATF Cooler)

Thermo valve

AC403006

CVT CVT CVT

Thermostat

Thermo

valve

ATF warmer (ATF cooler)ATF warmer (ATF cooler)

: Engine coolant

: ATF

Engine coolant flows through

all the sections.

- 85˚C>

Engine coolant flows through

the heater and the ATF warmer.

Engine coolant flows through

the heater only.

AD

: Valve open

: Valve closed

Thermostat

Thermo

valve

ATF warmer (ATF cooler)Thermo

valve

Thermostat

Radiator

Engine Heater

Radiator Engine Heater

Radiator

Engine Heater

The A TF warme r (A TF cooler) is adop ted for the

mode ls with 4A9 en gine. (the A TF cooler incorporat

-

ing the radiator is no t adopted)

At the start of runn ing, the tempe rature of th e engine

coolant rises earlier tha n that of the AT F. The A TF

war mer ut ilizes this ch aracteristic to raise the ATF

tempe rature a s ea rly a s po ssible to an a ppropriate

leve l (70

−80 °C). It also co ntrols flu id tempera ture st

ably and reduces A TF agitation resist ance to

imp rove f uel consump tion ra tio.

In addition , a thermo-valve has bee n adopted to

restrict the eng ine coolant supply to the A TF warmer

(A TF coole r) until the engine co olant temperature

reach es th e appro priat e temperature when low tem

-

perature start in winter , giving the priority to th e heat-

ing performance .

Page 231 of 364

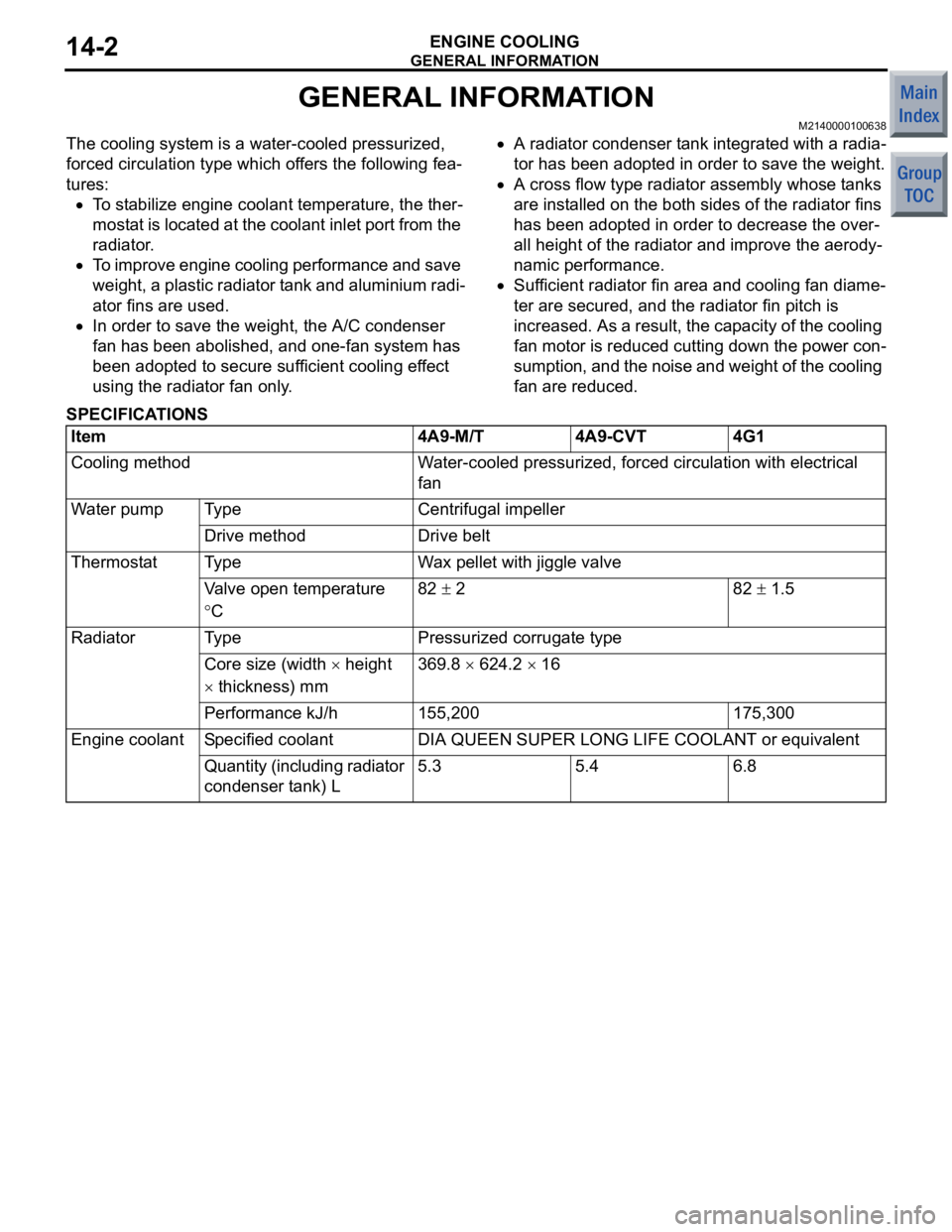

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

M2140000100638

The cooling system is a water-cooled pressurized,

forced circulation type which offers the following fea

-

tures:

•To stabilize engine coolant temperature, the ther-

mostat is located at the coolant inlet port from the

radiator.

•To improve engine cooling performance and save

weight, a plastic radiator tank and aluminium radi

-

ator fins are used.

•In order to save the weight, the A/C condenser

fan has been abolished, and one-fan system has

been adopted to secure sufficient cooling effect

using the radiator fan only.

•A radiator condenser tank integrated with a radia-

tor has been adopted in order to save the weight.

•A cross flow type radiator assembly whose tanks

are installed on the both sides of the radiator fins

has been adopted in order to decrease the over

-

all height of the radiator and improve the aerody-

namic performance.

•Sufficient radiator fin area and cooling fan diame-

ter are secured, and the radiator fin pitch is

increased. As a result, the capacity of the cooling

fan motor is reduced cutting down the power con

-

sumption, and the noise and weight of the cooling

fan are reduced.

SPECIFICATIONS

Item4A9-M/T4A9-CVT4G1

Cooling methodWater-cooled pressurized, forced circulation with electrical

fan

Water pumpTy p eCentrifugal impeller

Drive methodDrive belt

ThermostatTy p eWax pellet with jiggle valve

Valve open temperature

°C

82 ± 282 ± 1.5

RadiatorTy p ePressurized corrugate type

Core size (width × height

× thickness) mm

369.8 × 624.2 × 16

Performance kJ/h155,200175,300

Engine coolantSpecified coolantDIA QUEEN SUPER LONG LIFE COOLANT or equivalent

Quantity (including radiator

condenser tank) L5.35.46.8

Page 353 of 364

CVT

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)23-5

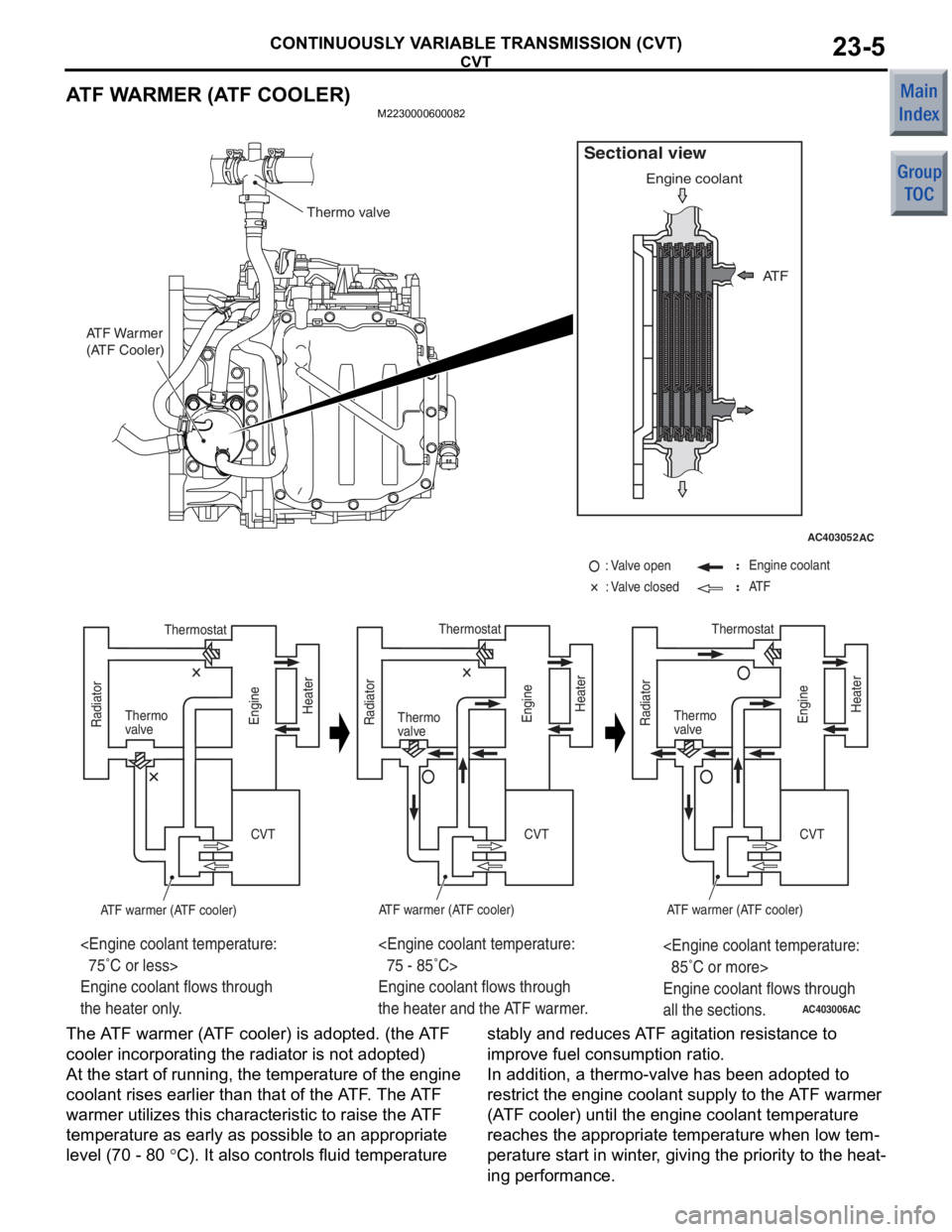

ATF WARMER (ATF COOLER)

M2230000600082

AC403052AC

AT F

Engine coolant

Sectional view

ATF Warmer

(ATF Cooler)

Thermo valve

AC403006

CVT CVT CVT

Thermostat

Thermo

valve

ATF warmer (ATF cooler)ATF warmer (ATF cooler)

: Engine coolant

: AT F

Engine coolant flows through

all the sections.

Engine coolant flows through

the heater and the ATF warmer.

Engine coolant flows through

the heater only.

AC

: Valve open

: Valve closed

Thermostat

Thermo

valve

ATF warmer (ATF cooler)Thermo

valve

Thermostat

Radiator

Engine Heater

Radiator Engine Heater

Radiator

Engine Heater

The A TF warme r (A TF cooler) is adop ted. (th e A TF

cooler in

corpo r ating the rad i ator is n o t ado pted)

At the st art of runn ing, th e tempe r ature of th e engine

coolant rises earlier tha

n that of the A T F . The A TF

war

m er ut ilizes this ch aract e ristic to raise the A TF

tempe

r ature a s ea rly a s po ssible to an a ppropriate

leve

l (70 - 80

°C). It also contro ls fluid temperature st ably and reduces A TF agit a tion resist ance to

imp r ove f uel consump t ion ra tio.

In addition

, a the r mo-valve has bee n adop ted to

restrict the eng

ine coolan t supply to the A TF warmer

(A

TF coole r) until the engine co olan t temperature

reach

e s th e appro p riat e temperature when low tem

-

perature st art in winter , giving the priority to th e heat-

ing pe rformance .