lock MITSUBISHI COLT 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 117 of 364

![MITSUBISHI COLT 2006 Service Owners Manual

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve open MITSUBISHI COLT 2006 Service Owners Manual

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve open](/img/19/57093/w960_57093-116.png)

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-3

SYSTEM BLOCK DIAGRAM

AK600528

Barometric pressure sensorEngine control unitEngine-ECU

[1] Fuel injection control

[2] Throttle valve opening control

and idle speed control

[3] MIVEC (Mitsubishi Innovative

Valve timing Electronic

control system)

[4] Ignition timing control

[5] Engine control relay control

[6] Throttle valve control servo

relay control

[7] Fuel pump relay control

[8] Oxygen sensor (front) heater

control

[9] Oxygen sensor (rear) heater

control

[10] Fuel pressure control

[11] Waste gate control

[12] Fan relay control

[13] A/C compressor relay

control

[14] Alternator control

[15] Purge control

[16] Diagnostic output

[17] RAM data transmission Throttle valve control unit

Throttle opening feedback control

Engine coolant

temperature sensor Intake air temperature sensor Air flow sensor

Accelerator pedal

position sensor (main) Throttle position sensor (sub)

Camshaft position sensor

Crank angle sensor

Oxygen sensor (front)

Oxygen sensor (rear)

Alternator FR terminal

Clutch switch

Detonation sensor

Ignition switch-IG

Ignition switch-ST

Stop lamp switch

Power supply

Throttle position sensor (main)

Accelerator pedel

position sensor (sub)

Throttle valve control servo No.1 injector

No.2 injector

No.3 injector

No.4 injector

No.1 Ignition coil

No.2 Ignition coil

No.3 Ignition coil

No.4 Ignition coil

Engine control relay

Throttle valve control servo relay

Waste gate solenoid valve

A/C compressor relay

Fuel pump relay

Alternator G terminal

Cooling fan control relay (Hi, Lo)

Purge control solenoid valve

Diagnostic output terminal

Oxygen sensor (front) heater

Oxygen sensor (rear) heater Oil feeder control valve

(for MIVEC)

Fuel pressure control

solenoid valve

AB

Page 120 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4G1>13B-6

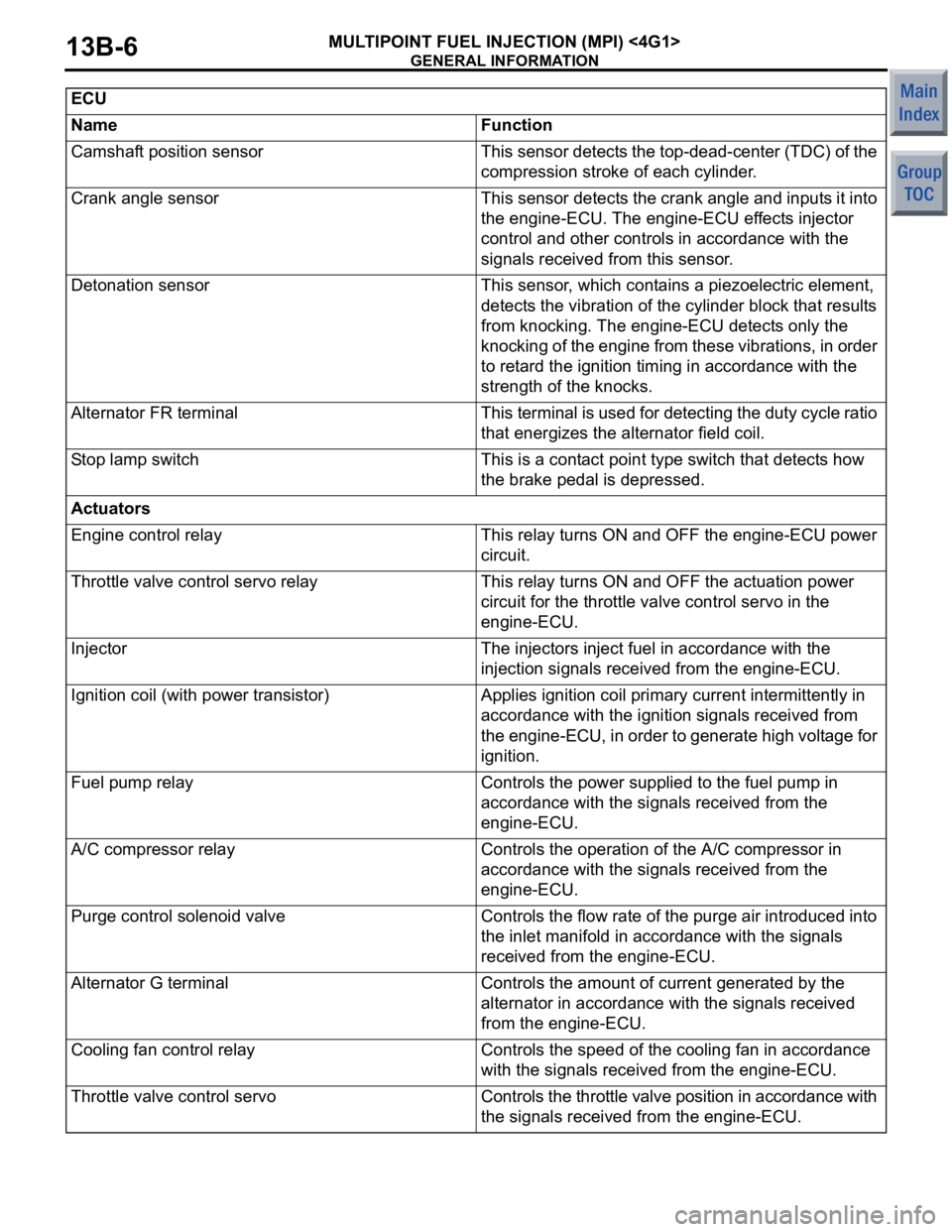

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU. The engine-ECU effects injector

control and other controls in accordance with the

signals received from this sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU detects only the

knocking of the engine from these vibrations, in order

to retard the ignition timing in accordance with the

strength of the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU power

circuit.

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU.

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU.

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU, in order to generate high voltage for

ignition.

Fuel pump relayControls the power supplied to the fuel pump in

accordance with the signals received from the

engine-ECU.

A/C compressor relayControls the operation of the A/C compressor in

accordance with the signals received from the

engine-ECU.

Purge control solenoid valveControls the flow rate of the purge air introduced into

the inlet manifold in accordance with the signals

received from the engine-ECU.

Alternator G terminalControls the amount of current generated by the

alternator in accordance with the signals received

from the engine-ECU.

Cooling fan control relayControls the speed of the cooling fan in accordance

with the signals received from the engine-ECU.

Throttle valve control servoControls the throttle valve position in accordance with

the signals received from the engine-ECU.

ECU

Name Function

Page 144 of 364

GROUP 42

BODY

CONTENTS

GENERAL INFORMATION . . . . . . . .42-2

MAIN BODY . . . . . . . . . . . . . . . . . . . .42-3

BODY PANELING . . . . . . . . . . . . . . . . . . . . 42-3

BODY SHELL . . . . . . . . . . . . . . . . . . . . . . . 42-4

QUIETNESS . . . . . . . . . . . . . . . . . . . . . . . . 42-9

BODY COLOUR CHARTS . . . . . . . . . . . . . 42-9

HOOD <4G1> . . . . . . . . . . . . . . . . . . .42-10

STRUT TOWER BAR <4G1>. . . . . . .42-10

DOOR . . . . . . . . . . . . . . . . . . . . . . . . .42-11

DOOR LOCK . . . . . . . . . . . . . . . . . . . . . . . . 42-11

KEYLESS ENTRY SYSTEM . . . . . . . . . . . . 42-13

POWER WINDOW . . . . . . . . . . . . . . . . . . . 42-15

WEATHERSTRIP . . . . . . . . . . . . . . . . . . . . 42-17

PROTECTOR FILM. . . . . . . . . . . . . . .42-17

WINDOW GLASS . . . . . . . . . . . . . . . .42-18

SUNROOF. . . . . . . . . . . . . . . . . . . . . .42-20

LOOSE PANELS <4G1> . . . . . . . . . .42-22

Page 145 of 364

GENERAL INFORMATION

BODY42-2

GENERAL INFORMATION

M2420000100842

FEATURES

WEIGHT REDUCTION AND HIGH RIGID-

ITY

•Application ranges of high tension steel plate,

antirust steel plate, and uneven thickness steel

plate have been expanded.

•The upper frame outer and front pillar connection

has been strengthened by adopting the upper

frame-to-front pillar brace.

•The radius of each opening corner for the doors

and tailgate has been enlarged.

•Cowl top lower panel and spring house panel are

directly joined for higher rigidity.

•Strut tower bar has been adopted <4G1>.

•A front suspension axle side plate has been

adopted <4G1>.

•The air outlet garnish has been installed to the

hood, improving the sporty image and cooling

efficiency in the engine compartment. <4G1>

REDUCTION OF VIBRATION, NOISE, AND

AERODYNAMIC NOISE

•Straight frame structure has been adopted.

•Curved front floor and uneven thickness steel

plate have been adopted.

•Rigidity of the suspension installation part has

been improved.

IMPROVEMENTS IN SAFETY

•RISE (Reinforced Impact Safety Evolution) has

been used for the main body.

•Features a side door beam to boost safety upon

side impact.

•Direct combination key cylinder and inside lock

cables for the front doors have been adopted to

improve safety upon impact.

IMPROVEMENTS IN OPERATION

QUALITY

•The central door locking system, which

locks/unlocks all the doors and the tailgate, is

adopted.

•"P" position shift linked door-unlock function has

been introduced to the central door locking sys

-

tem(F1C1A).

IMPROVEMENTS OF PRODUCT

PACKAGE AND APPEARANCE

•Rigidity of door sash bottom section has been

improved.

•By improving the engaging sound between the

door latch and striker, the door locking sound

quality has been enhanced.

•UV & heat protect glass has been used for the

windshield.

•UV-reducing glass has been used for the front

door window glasses and rear door window

glasses.

•Privacy glasses have been used for rear door

window glasses, quarter window glasses, and

tailgate window glass (Option).

•Multi-mode keyless entry system (with door mir-

ror retraction/return control function) has been

adopted.

•Protector film has been attached on side sill

•Sunroof has been installed (Option).

Page 154 of 364

DOOR

BODY42-11

DOOR

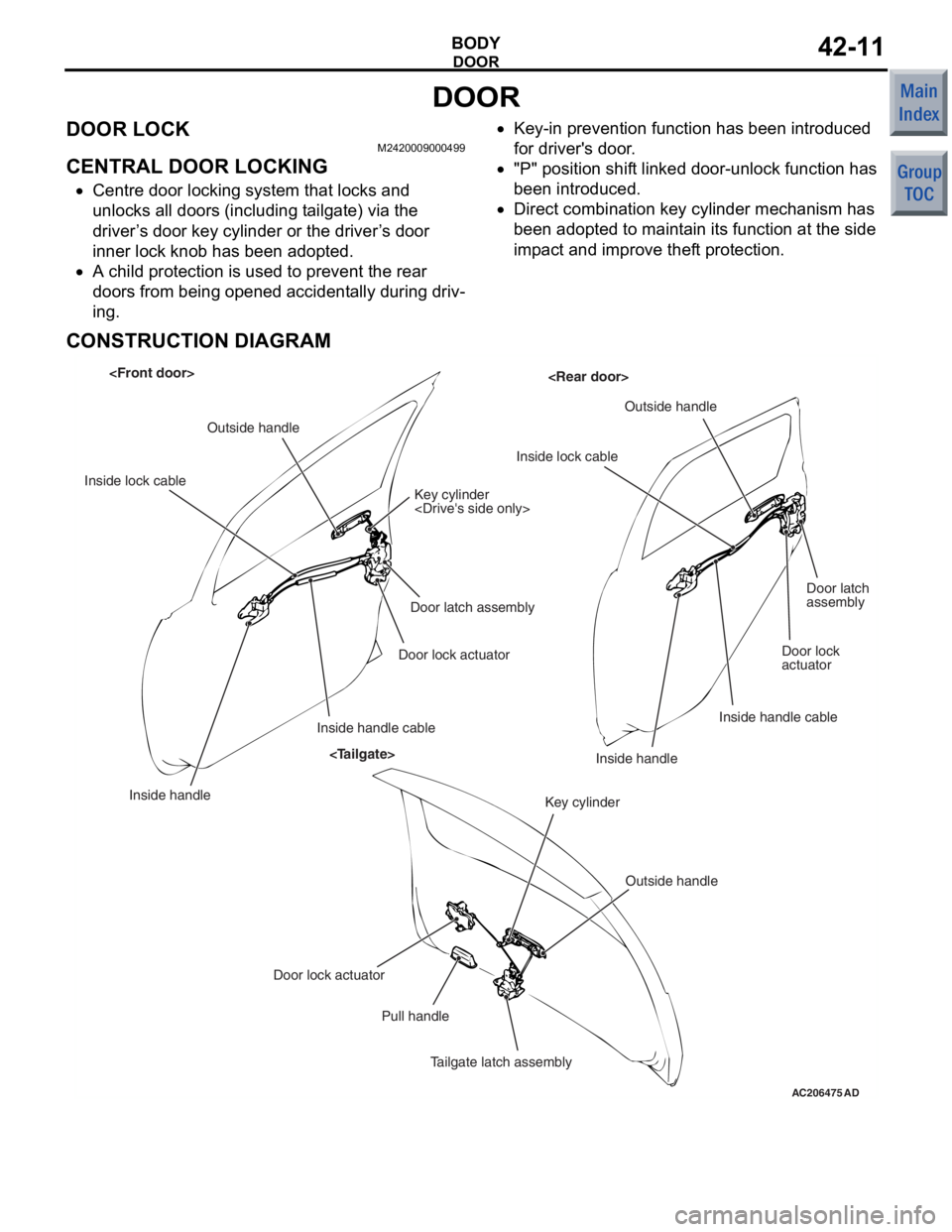

DOOR LOCKM2420009000499

CENTRAL DOOR LOCKING

•Centre door locking system that locks and

unlocks all doors (including tailgate) via the

driver’s door key cylinder or the driver’s door

inner lock knob has been adopted.

•A child protection is used to prevent the rear

doors from being opened accidentally during driv

-

ing.

•Key-in prevention function has been introduced

for driver's door.

•"P" position shift linked door-unlock function has

been introduced.

•Direct combination key cylinder mechanism has

been adopted to maintain its function at the side

impact and improve theft protection.

CONSTRUCTION DIAGRAM

AC206475 AD

Outside handle

Inside lock cable Key cylinder

Door latch assembly

Door lock actuator

Inside handle cable

Inside handle Inside lock cable

Outside handle

Door latch

assembly

Door lock

actuator

Inside handle cable

Inside handle

Door lock actuator Pull handle

Tailgate latch assembly Key cylinder

Outside handle

Page 155 of 364

DOOR

BODY42-12

DESCRIPTION OF STRUCTURE AND

OPERATION

CENTRAL DOOR LOCKING

•When the driver's door inner lock knob is oper-

ated to the lock position with all doors closed, all

the doors (including tailgate) will lock.

•The driver’s door can be opened by pulling the

driver’s door inner handle even when the driver’s

door inner lock knob is in the lock position. This

function is called "Override function". All doors

and tailgate can be unlocked at the same time

that the driver's door is opened.

KEY-IN PREVENTION FUNCTION

If the driver’s door remained open, it cannot be

locked even though the driver’s door key cylinder or

driver’s side inside lock knob is pushed. This pre

-

vents the ignition key from being left in the passenger

compartment.

"P" POSITION SHIFT LINKED

DOOR-UNLOCK FUNCTION

When the selector lever is shifted to the "P" (parking)

position, all the doors (including tailgate) will unlock,

improving passengers' conv enience during alighting.

Using an adjustment function*, "P" position shift

linked door-unlock function can be changed to

"Active", or "Inactive". The initial setting at factory is

"Inactive".

NOTE: *: "P" position shift linked door-unlock func-

tion can be changed as a customise function. Refer

to GROUP 54B, Customise Function

P.54B-25.

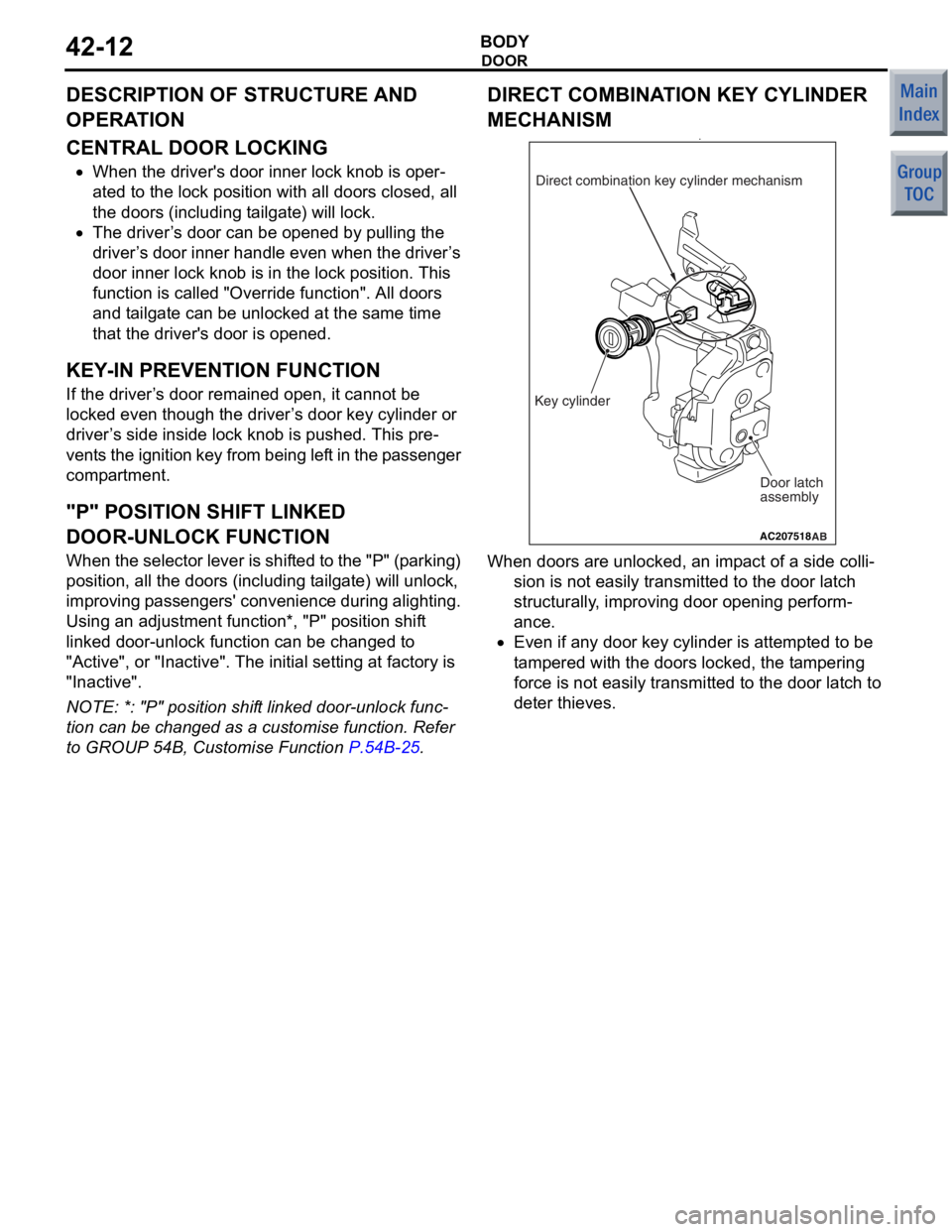

DIRECT COMBINATION KEY CYLINDER

MECHANISM

•

AC207518AB

Door latch

assembly

Key cylinder Direct combination key cylinder mechanism

When d

oors a r e unlocked, a n imp a ct of a side colli-

sion is not easily transmitted to the do or lat c h

structu

r ally , imp r oving do or open ing p e rform

-

ance.

•Even if a n y d oor ke y cylinder is a ttemp ted to b e

t

a mp ered wit h the d oors locked, t he t a mp ering

force is not

easily transmitt ed to t he doo r latch to

det

er thie ves.

Page 156 of 364

DOOR

BODY42-13

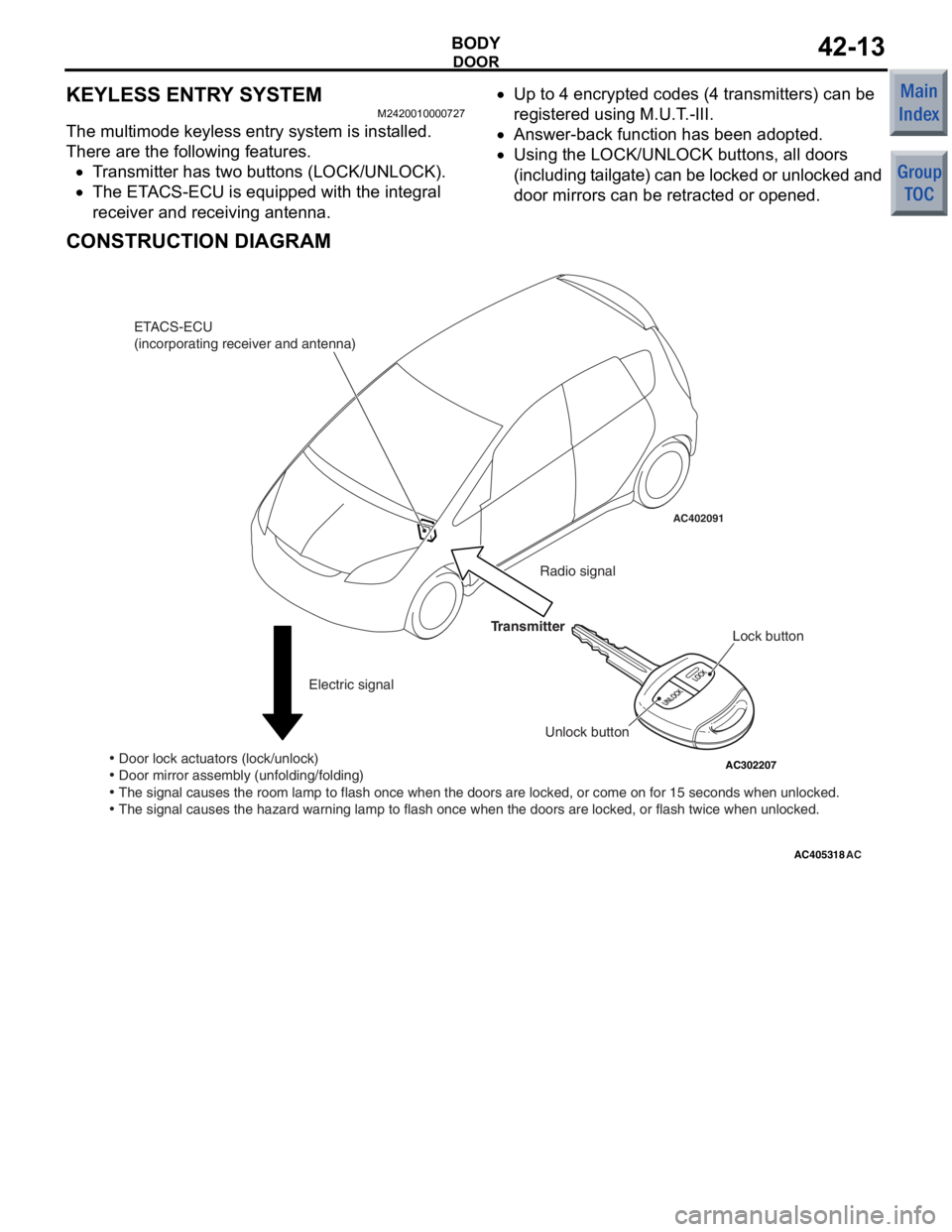

KEYLESS ENTRY SYSTEM

M2420010000727

The multimode keyless entry system is installed.

There are the following features.

•Transmitter has two buttons (LOCK/UNLOCK).

•The ETACS-ECU is equipped with the integral

receiver and receiving antenna.

•Up to 4 encrypted codes (4 transmitters) can be

registered using M.U.T.-III.

•Answer-back function has been adopted.

•Using the LOCK/UNLOCK buttons, all doors

(including tailgate) can be locked or unlocked and

door mirrors can be retracted or opened.

CONSTRUCTION DIAGRAM

AC405318

AC206461

AC302207

AC402091

AC

ETACS-ECU

(incorporating receiver and antenna)

Electric signal Radio signal

Lock button

Unlock button

Transmitter

• Door lock actuators (lock/unlock)

• Door mirror assembly (unfolding/folding)

• The signal causes the room lamp to flash once when the doors are locked\

, or come on for 15 seconds when unlocked.

• The signal causes the hazard warning lamp to flash once when the doors \

are locked, or flash twice when unlocked.

Page 157 of 364

DOOR

BODY42-14

DESCRIPTION OF STRUCTURE AND

OPERATION

TRANSMITTER•

AC309781 AC309891

AC302207AC

Lock button

Unlock button Three-diamond markIndicator lamp

The tran

smitter is integra t ed in to the master key .

•When eit her butt on is pressed , the tra n smitter

emit

s a radio sig nal re prese n ting a sp ecific ID

code.

•There a r e two butto ns o n th e tra n smitte r; th e lo ck

but

ton and the u n lock bu tton.

•An indicator lamp, which illumina tes when signals

are

transmitt ed, is add ed on t he ke y grip. This

in

dicator lamp informs you of the signa l transmis

-

sion sta t us a nd warns you of flat batt e ry .

•A brilliant silver Three -d ia mond mark is st amped

on

the back side of the key grip to improve

app

earance.

•A signal transmissi on circuit (p rinted circuit ) and

a b

a ttery are ho used in on e ca se. T he ca se is

hou

sed in the key grip, thus improving re sist ance

to wat

e r ing r ess.

•A coin type b a ttery , CR1616 is used in th e trans-

mitter.

•The transmit t er butto n ope ration allows the sys-

tem to operate a s follows:

System operationThe transmitter is operated.

All doors (including the tailgate) are locked.Press the lock button once.

All doors (including the tailgate) are unlocked.Press the unlock button once.

The door mirrors are retracted.Press the lock button once to lock all doors (including

the tailgate), and within 30 seconds press the lock

button twice quickly.

The door mirrors return to the unfold position.Press the unlock button once to unlock all doors, and

within 30 seconds press the unlock button twice

quickly.

Page 158 of 364

DOOR

BODY42-15

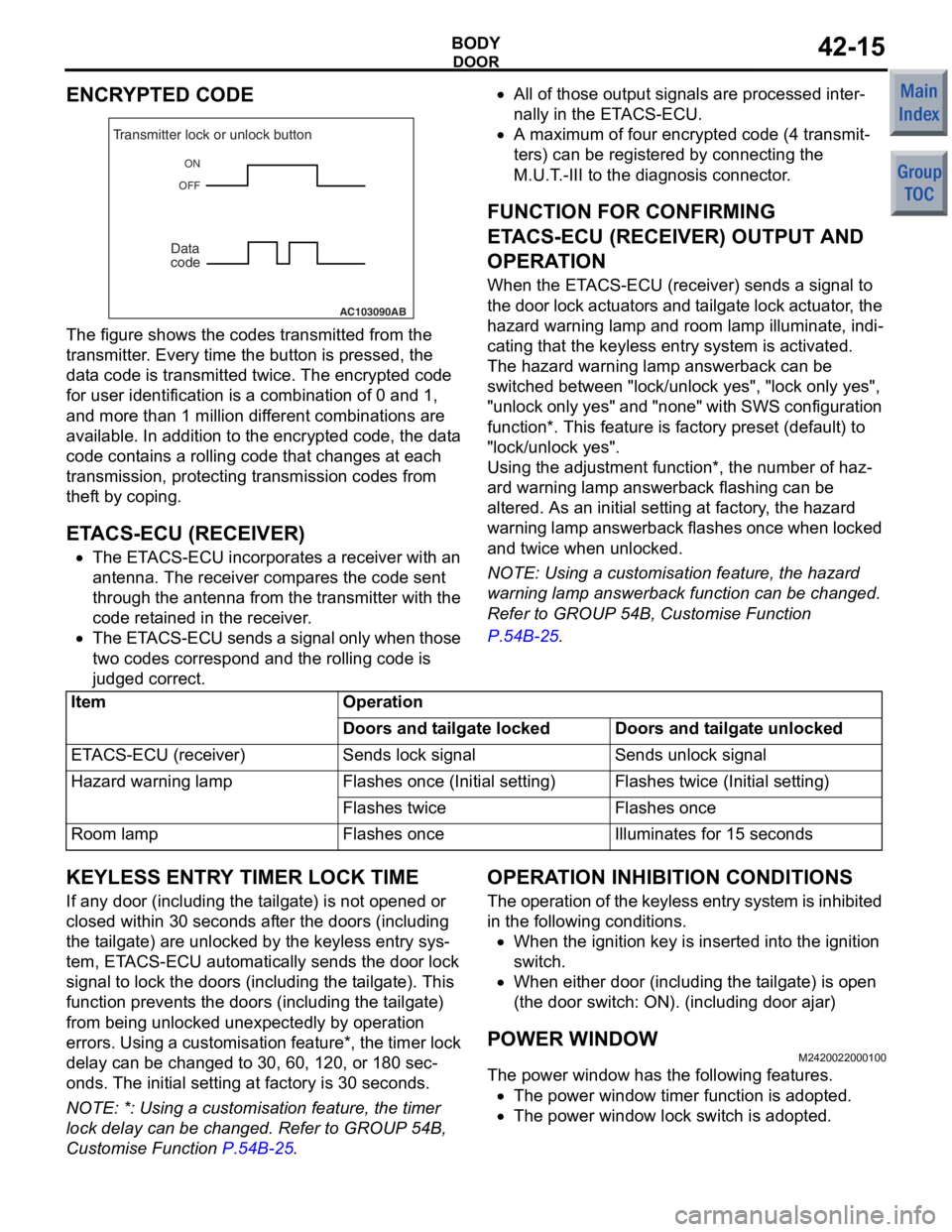

ENCRYPTED CODE

AC103090AB

ON

OFF

Transmitter lock or unlock button

Data

code

The figure shows th e co des transmitte d from the

transmitte

r . Every time the butto n is pressed, the

dat

a cod e is transmitted tw ice. Th e encrypte d co de

for user ide

n tification is a comb ination o f 0 and 1,

and more tha

n 1 million dif f erent comb inations are

available. In a

ddition to t he encrypt ed co de, the dat a

code

cont ains a rolling code t hat change s at e a ch

transmission, prot

ecting tran smission code s from

thef

t by coping.

ETACS-ECU (RECEIVER)

•The ET ACS-ECU incorp orates a receiver with a n

ant

enna. T he receiver co mp ares the code sent

thro

ugh t he an tenna from the transmit t er with the

co

de ret a ined in the re ceiver .

•The ET ACS-ECU send s a si gnal only whe n t hose

two codes corre

spon d and the rollin g co de is

ju

dged correct.

•All of tho s e o u tput sign als are processed inter-

nally in the ETACS-ECU.

•A maximum of fou r encr y pted cod e (4 tran smit-

ters) can be re gistered by co nnecting the

M.U.

T . -III t o the d i agn osis co nnector .

FUNCTION FOR CONFIRMING

ET

ACS-ECU (RECEIVER) OUT P UT AND

OPERA

T ION

When the ET ACS-ECU (receiver) send s a sign al to

the

do or lock actua t o r s an d t a ilga te lo ck actua t or , t h e

haza

r d warnin g lamp an d room lamp illumina te, in di

-

cating that the keyless ent ry syste m is activated.

The hazard warn ing lamp answe rback ca n be

switched b

e tween "lock/unlock yes", "lock o n ly yes",

"unlock o

n ly yes" and "non e" with SW S co nfigurat ion

funct

i on*. Th is f eature is fa ctory preset (de f ault ) to

"lock/unlock ye

s".

Using the ad justment function*, th e number of haz-

ard warning lamp a n swerba ck flashing can be

altere

d. As a n initial set t ing a t factory , the haza r d

wa

rnin g lamp an swerb a ck flashes once wh en locked

and twice when

unlo cke d.

NOTE: Using a cust omisation fea t ure, th e hazard

wa

rning lamp answe rback fun c tio n ca n be change d.

Re

fer to GROUP 54B, Customise Function

P.54B-25.

ItemOperation

Doors and tailgate lockedDoors and tailgate unlocked

ETACS-ECU (receiver)Sends lock signalSends unlock signal

Hazard warning lampFlashes once (I nitial setting)Flashes twice (Initial setting)

Flashes twiceFlashes once

Room lampFlashes onceIlluminates for 15 seconds

KEYLESS ENTR Y TIMER LOCK TIME

If any door (includin g the t a ilgat e) is not op ened or

closed within 3

0 se cond s af ter th e doo rs (in c lu ding

the t

a ilgate) a r e unlocked by the keyless ent ry sys

-

tem, ETACS-ECU aut omatically sen d s th e door lock

sign

al to lock the doors (includ i ng t he t a ilgate). T h is

funct

i on p r even t s the d oors (including the t a ilga te)

from b

e ing unlocke d unex pectedly by opera t ion

errors.

Using a customisa t ion fea t ure*, the timer lock

delay ca

n be chang ed to 3 0 , 60, 120, or 180 sec

-

onds. The initial setting at fa ctory is 30 secon d s.

NOTE: *: Using a custo m isation fea t ure, the timer

lock delay can b e ch anged. Re fer to GROUP 54B,

Customise Function

P.54B-25.

OPERA T ION INHIBITION CONDITIONS

The operation of t he keyless entry system is inhibited

in the

following cond itio ns.

•When the ignition key is inse rted into the ignition

sw

itc h .

•When eit her doo r (including th e t a ilg ate) is ope n

(the

door switch : ON). (includin g doo r ajar)

POWER WI NDOW

M24200220 0010 0

The powe r window ha s the following f eatures.

•The power wind ow timer functio n is adopt ed.

•The power wind ow lock switch is adopte d .

Page 159 of 364

DOOR

BODY42-16

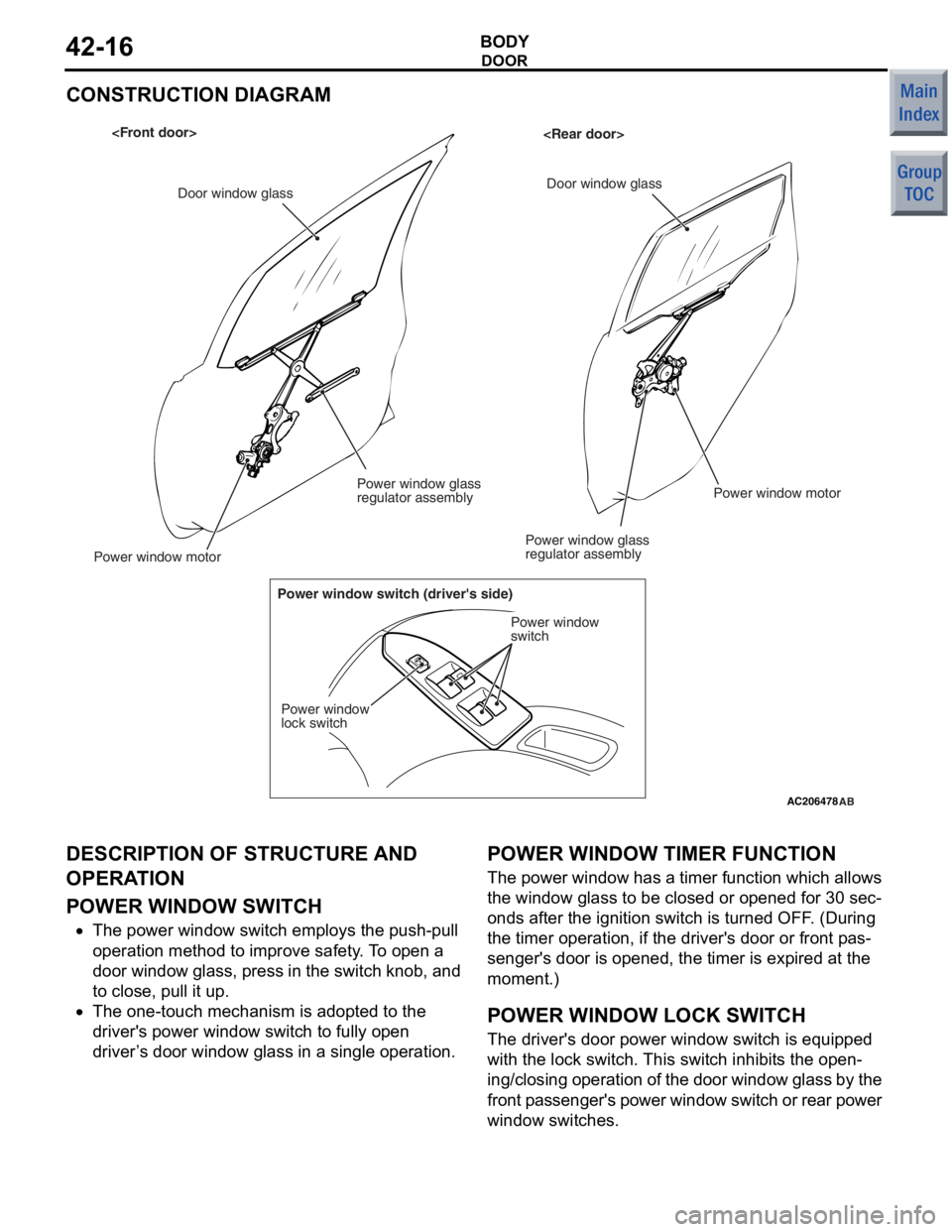

CONSTRUCTION DIAGRAM

AC206478AB

Door window glass Door window glass

Power window motor

Power window glass

regulator assembly

Power window glass

regulator assembly

Power window motor

Power window switch (driver's side) Power window

switch

Power window

lock switch

DESCRIPTION OF STRUCTURE AND

OPERA

T ION

POWE R W I NDOW SWITCH

•The power wind ow switch employs t he push-pull

ope

ration meth od to imp r ove safety . T o o pen a

doo

r windo w glass, p r ess in the switch kno b , and

to close, pu

ll it up.

•The one-to uch mechanism is a dopted to the

driver's power win

dow swit ch to fully op en

driver

’ s door win dow gla s s in a sin g le o peration.

POWER WI NDOW TIMER FUNCTION

The po wer wind ow has a t i me r function which allows

the wind

ow glass t o be closed or o pened for 30 sec

-

onds after the ignition switch is turned OFF . (Durin g

the timer o

peration, if the driver's doo r or fron t p a s

-

senger's d oor is open ed, th e timer is expired at the

moment.)

POWER WI NDOW LOCK SWITCH

The driver's door power wind ow switch is equ ipped

with the

lock switch. This swit ch inhib i t s the open

-

ing/ clos ing ope ra tio n o f t h e do or wind ow gl ass b y t he

f

r ont p a ssenger's power window switch or rear power

window switche

s .