lock MITSUBISHI COLT 2006 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 69 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-21

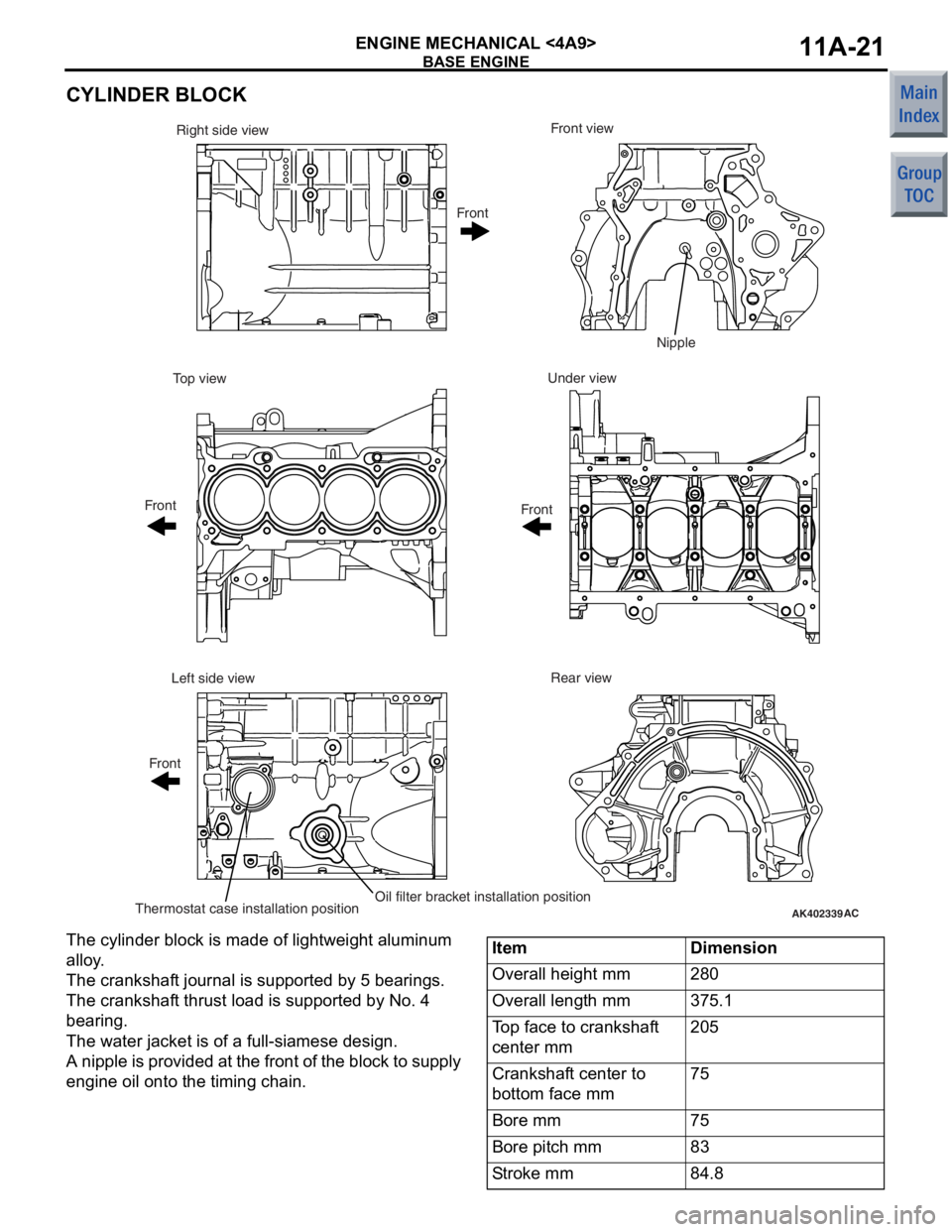

CYLINDER BLOCK

AK402339AC

Front view

Right side view

Under view

Top view

Rear view

Left side view

Thermostat case installation positionOil filter bracket installation position Front

Front Front Front

Nipple

The cylinder b

l ock is ma de of ligh twe i ght aluminum

allo

y .

The crankshaf t jo urnal is supp orted b y 5 b earing s .

The crankshaf

t thru st load is supporte d by No . 4

bearin

g.

The water jacket is of a full-siamese de sig n .

A nipple is p r ovid ed at the fr o n t of the block to su pply

engin

e oil onto the timin g ch ain.

ItemDimension

Overall height mm280

Overall length mm375.1

Top face to crankshaft

center mm205

Crankshaft center to

bottom face mm75

Bore mm75

Bore pitch mm83

Stroke mm84.8

Page 73 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-25

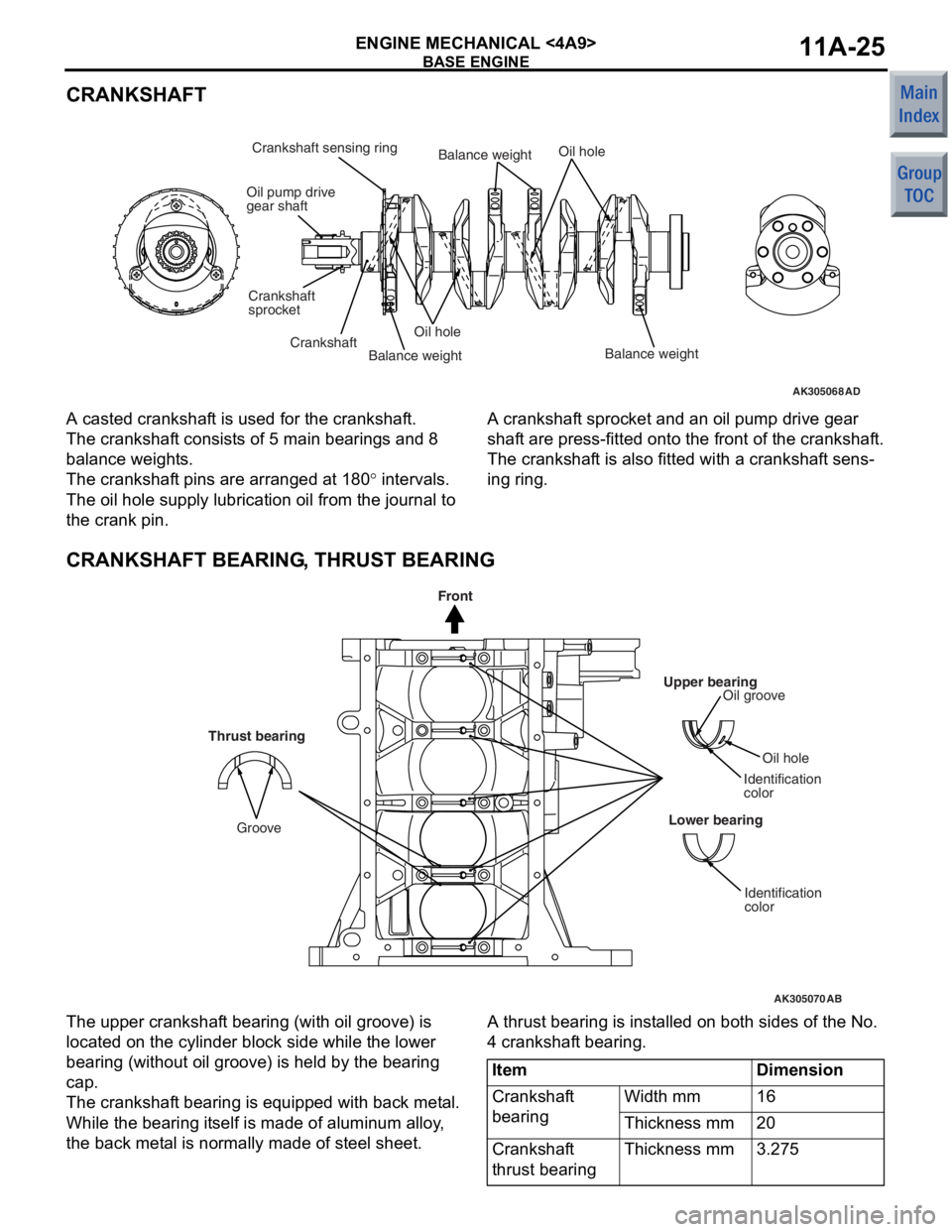

CRANKSHAFT

AK305068AD

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft sensing ring

CrankshaftOil hole

Oil hole

Balance weightBalance weightBalance weight

A casted crankshaf

t is used for t he cr ankshaf t.

The crankshaft consist s o f 5 ma in be aring s an d 8

balan

ce weight s.

The crankshaft pins a r e arrang ed at 1 8 0° inte rval s.

The oil hole supply lu brication oil from t he jo urnal to

the crank p

i n.

A cranksha f t sprocket and an oil pump drive gea r

shaf

t are press-fit t ed on to the f r ont of the crankshaf t.

The crankshaft is also fitt ed with a crankshaf t sens-

ing ring.

CRANKSHAFT BEARING, THRUST BEARING

AK305070

Upper bearingOil groove

Oil hole

Identification

color

Lower bearing

Identification

color

AB

Thrust bearing

Groove

Front

The upp er cra n kshaf t bea ring (with oil groove) is

loca

ted on the cylinder block side wh ile the lo we r

bearin

g (witho ut oil groo ve) is he ld by the b earin g

cap.

The crankshaft bea ring is e quipp ed with back me t a l.

While the b

earin g it self is ma de of a l uminum alloy ,

the back met

a l is no rmally made of steel sheet .

A thrust bearing is inst alle d on b o th sides of th e No.

4 cran

kshaf t bearing.

ItemDimension

Crankshaft

bearingWidth mm16

Thickness mm20

Crankshaft

thrust bearingThickness mm3.275

Page 76 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-28

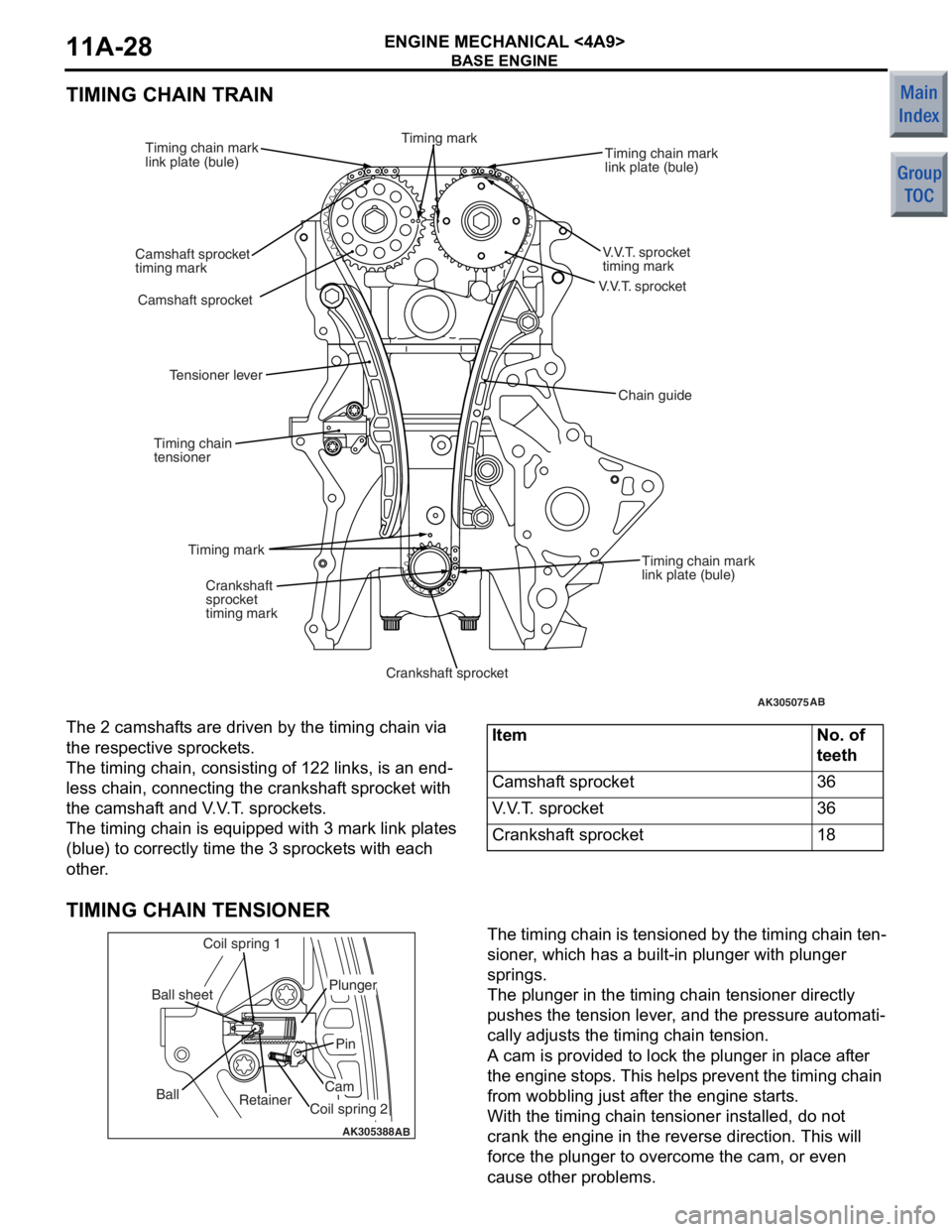

TIMING CHAIN TRAIN

AK305075

V.V.T. sprocket

AB

V.V.T. sprocket

timing mark

Timing chain mark

link plate (bule)

Camshaft sprocket

Camshaft sprocket

timing mark Timing chain mark

link plate (bule)

Timing chain mark

link plate (bule)

Crankshaft

sprocket

timing mark

Crankshaft sprocket

Timing mark

Timing chain

tensioner

Tensioner lever

Chain guide

Timing mark

The 2 camshaf

t s are driven by the t i ming chain via

the res

pec tive spro cke t s .

The timing cha i n, consist i ng o f 122 links, is an end-

less chain, conn ecting the cran ksh af t spro cke t with

the camshaf

t and V . V . T . spro cke t s .

The timing cha i n is eq uippe d with 3 mark link p l ates

(blue)

to co rrectly time t he 3 sprocket s with each

other

.

ItemNo. of

teeth

Camshaft sprocket36

V.V.T. sprocket36

Crankshaft sprocket18

TIMING CHAIN TENSIONER

AK305388AB

Retainer

Ball

Coil spring 1

Ball sheet

Coil spring 2

Cam

Pin

Plunger

The timing chain is tensione

d by th e timing chain te n-

sioner , which ha s a b u ilt-in plunge r with plunge r

springs.

The plunger in the timing chain tension e r dire ctly

push

e s th e tension lever , and the pre s sure aut omati

-

cally ad just s the timing chain tension.

A cam is provided t o lock th e plu nger in pla c e a f te r

the eng

ine stop s. This help s prevent the timing chain

from wob

b lin g just af ter th e eng ine st a r t s .

With the timing cha i n ten s io ner in st alled, do not

crank the

engin e in the reverse directio n. This will

force

the plunger to overcome the cam, or e v en

cause oth

e r problems.

Page 79 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-31

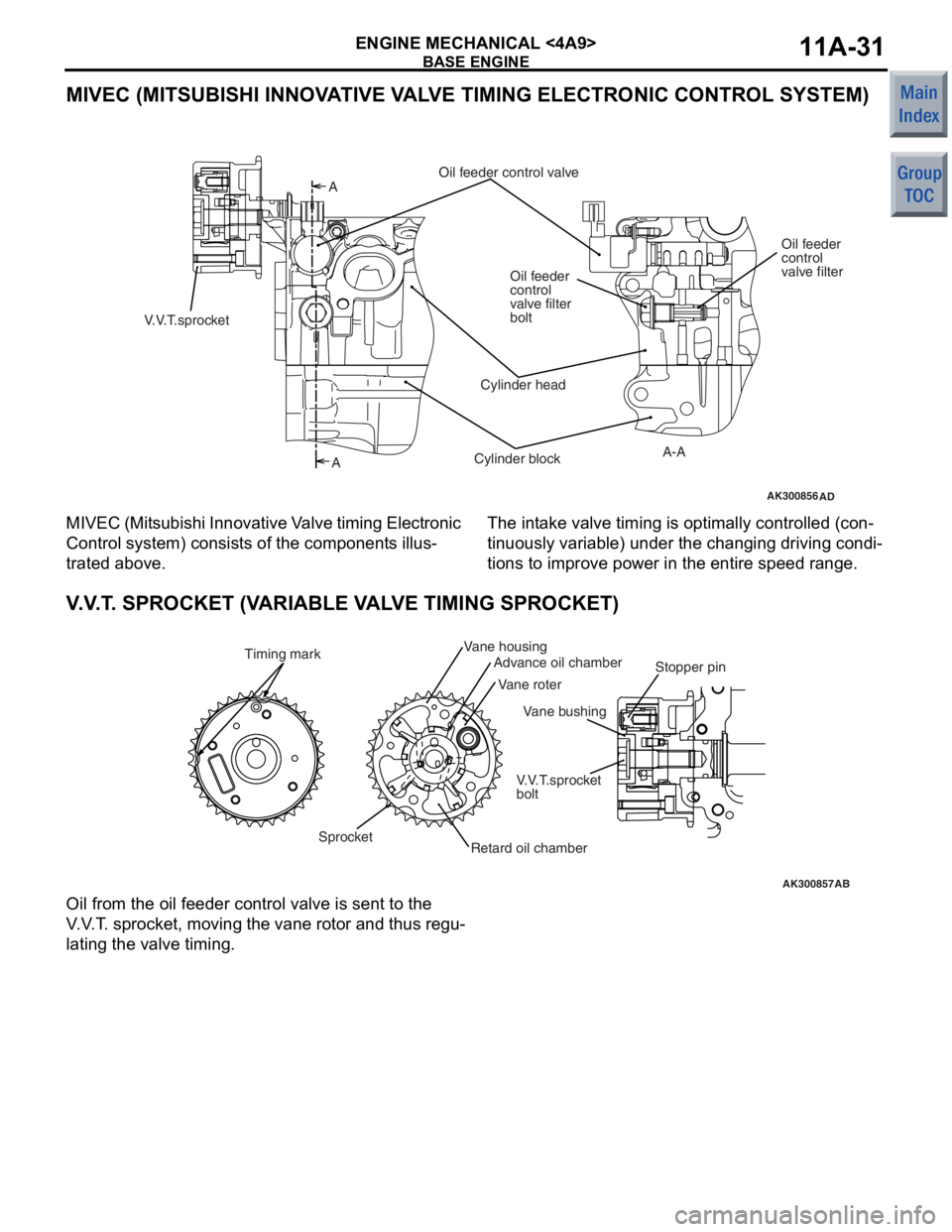

MIVEC (MITSUBISHI INNOVATIVE VALVE TIMING ELECTRONIC CONTROL SYSTEM)

AK300856AD

A

A

A-A

Oil feeder control valve

Oil feeder

control

valve filter

Oil feeder

control

valve filter

bolt

Cylinder head

Cylinder block

V.V.T.sprocket

M I VEC (Mit su bis h i Inn o va tive V a lve tim i ng Elect r o n ic

Con

t rol system) consist s of th e compon ent s illus

-

trated above .

The int a ke valve timing is optimally controlled (con-

tinuously variable) un der the chan ging driving condi-

tions to improv e po we r in th e entire sp eed ra nge.

V. V . T . SPROCKET (V ARIABLE V A L V E TIMING SPROCKET)

AK300857

Vane bushing

AB

SprocketVane roter

V.V.T.sprocket

bolt

Timing mark

Vane housing

Advance oil chamber

Retard oil chamber

Stopper pin

Oil from the oil fe

eder control valve is sent t o the

V

. V . T . sp rocket, moving the vane roto r and thus reg u

-

lating the valve timing.

Page 89 of 364

GENERAL INFORMATION

ENGINE LUBRICATION12-2

GENERAL INFORMATION

M2120000100175

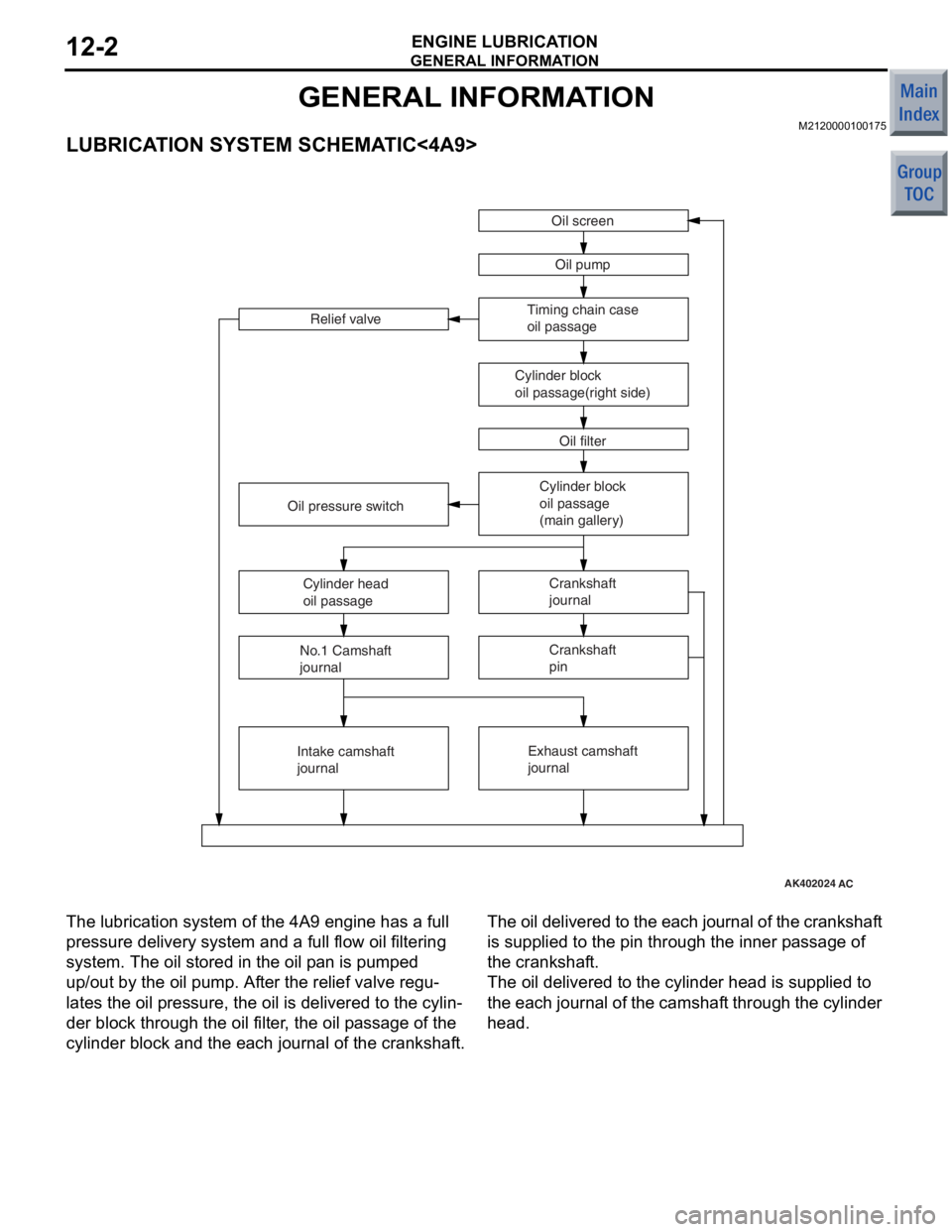

LUBRICATION SYSTEM SCHEMATIC<4A9>

AK402024AC

Oil screenOil pump

Timing chain case

oil passage

Cylinder block

oil passage(right side) Oil filter

Relief valve

Cylinder block

oil passage

(main gallery)Crankshaft

journal

Exhaust camshaft

journal

Oil pressure switch

Cylinder head

oil passage

No.1 Camshaft

journal

Intake camshaft

journal Crankshaft

pin

The lu

brication system of th e 4A9 en gine has a full

pressure de

livery system and a full flow oil filtering

system. The o

il stored in the oil p an is pumped

up/out

by th e oil pump. Af ter the relie f valve regu

-

lates the oil p r essure, th e oil is delivere d to th e cylin-

der block through the o il f ilte r , the o il p a ssag e of the

cylinde

r blo ck a nd the each jou r nal o f the crankshaf t.

The oil del ivered to the ea ch jo urnal of th e cranksh af t

is supplied

to the pin th rough the in ner p a ssage of

the crankshaf

t.

The oil delivered to the cylinder head is supplied t o

the ea

ch journa l of the camshaf t th rough the cylinde r

head.

Page 90 of 364

GENERAL INFORMATION

ENGINE LUBRICATION12-3

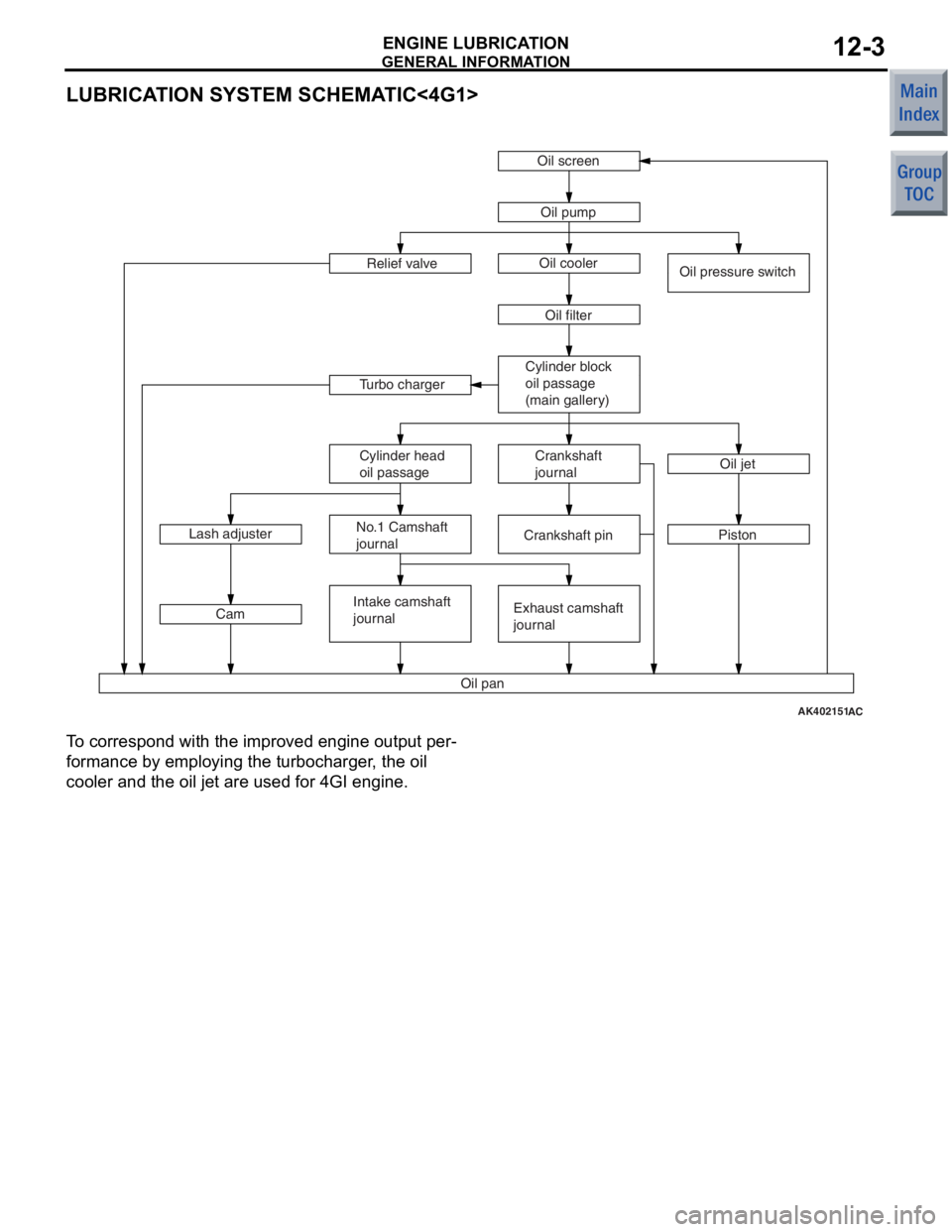

LUBRICATION SYSTEM SCHEMATIC<4G1>

AK402151AC

Oil screen

Oil pump

Oil filter

Relief valve

Cylinder block

oil passage

(main gallery)Crankshaft

journal

Exhaust camshaft

journal

Oil pan Oil pressure switch

Cylinder head

oil passage

No.1 Camshaft

journal

Intake camshaft

journal Crankshaft pin

PistonOil jet

Oil cooler

Turbo charger

Lash adjuster Cam

To correspond with the impr oved engine outp u t per-

formance b y emplo y ing the tu rboch a rger , the oil

cooler and

the oil jet are u s ed for 4GI engine.

Page 92 of 364

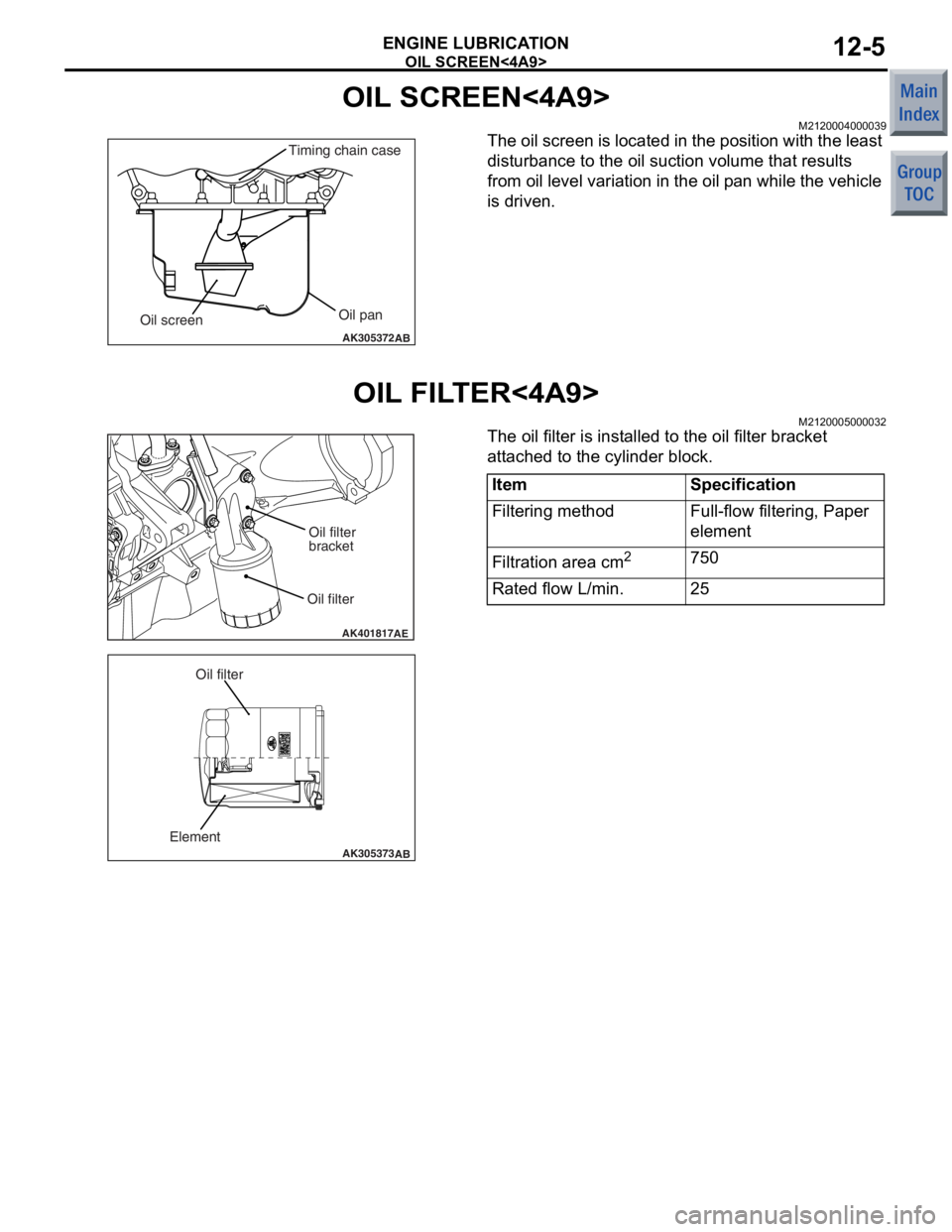

OIL SCREEN<4A9>

ENGINE LUBRICATION12-5

OIL SCREEN<4A9>

M2120004000039

AK305372AB

Timing chain case

Oil pan

Oil screen

The oil screen is located in the po sition with the lea s t

disturbance to

the oil suction vo lume that result s

from oil

level variat ion in the oil p an while the vehicle

is d

r ive n .

OIL FIL T ER<4A9>

M21200050 0003 2

AK401817AE

Oil filterOil filter

bracket

AK305373

AB

Element

Oil filter

The oil filter is inst alled to the oil filter b r acket

att

a che d to the cylin der block.

ItemSpecification

Filtering methodFull-flow filtering, Paper

element

Filtration area cm2750

Rated flow L/min.25

Page 94 of 364

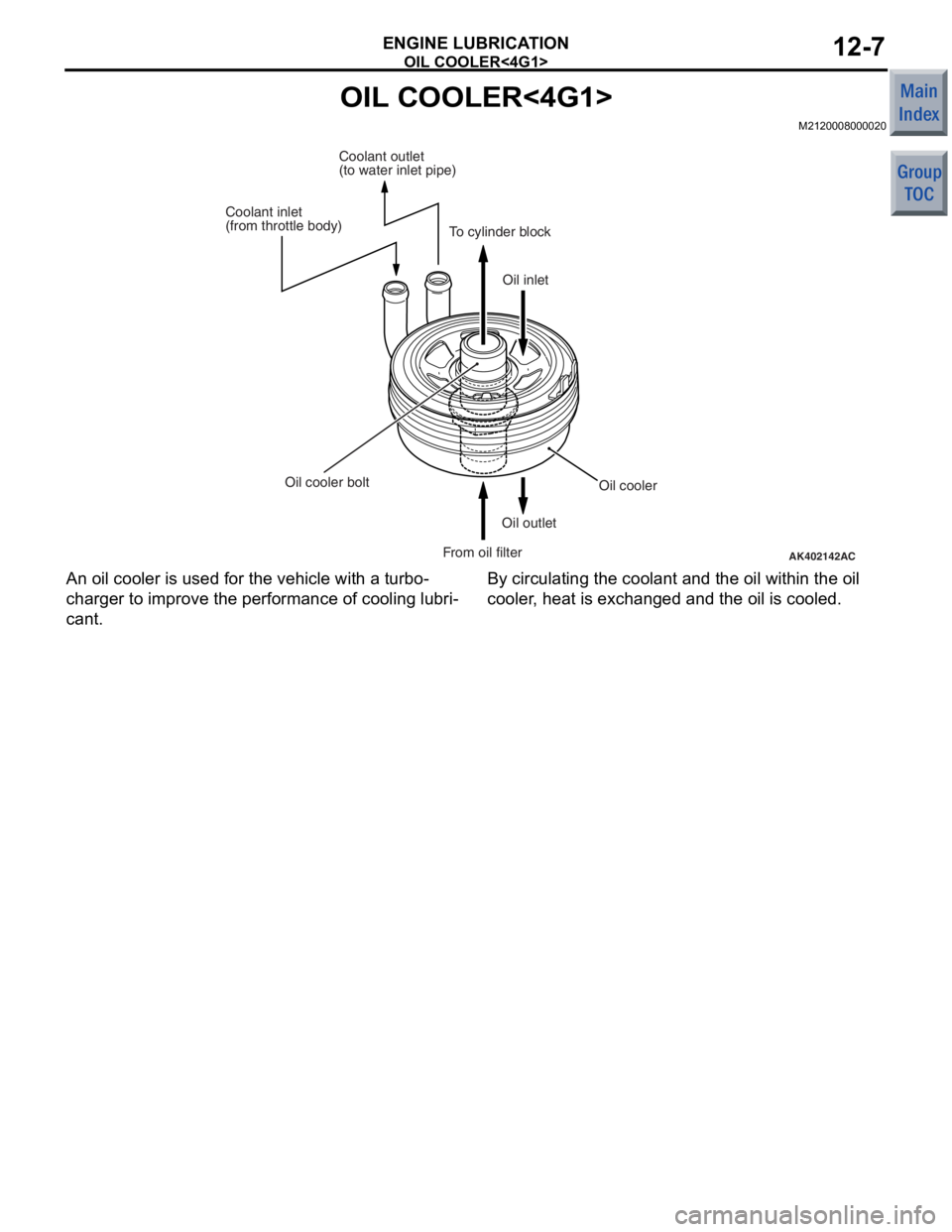

OIL COOLER<4G1>

ENGINE LUBRICATION12-7

OIL COOLER<4G1>

M2120008000020

AK402142

Oil outletOil inlet

To cylinder block

From oil filter

Coolant inlet

(from throttle body)

Coolant outlet

(to water inlet pipe)

Oil cooler boltOil cooler

AC

An

oil cooler is used for the vehicle wit h a turb o-

charge r to improve the per formance of cooling lubri-

cant.

By circulating the coolant an d the o il within t he oil

cooler

, he at is exchang ed an d the o il is coole d .

Page 97 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-3

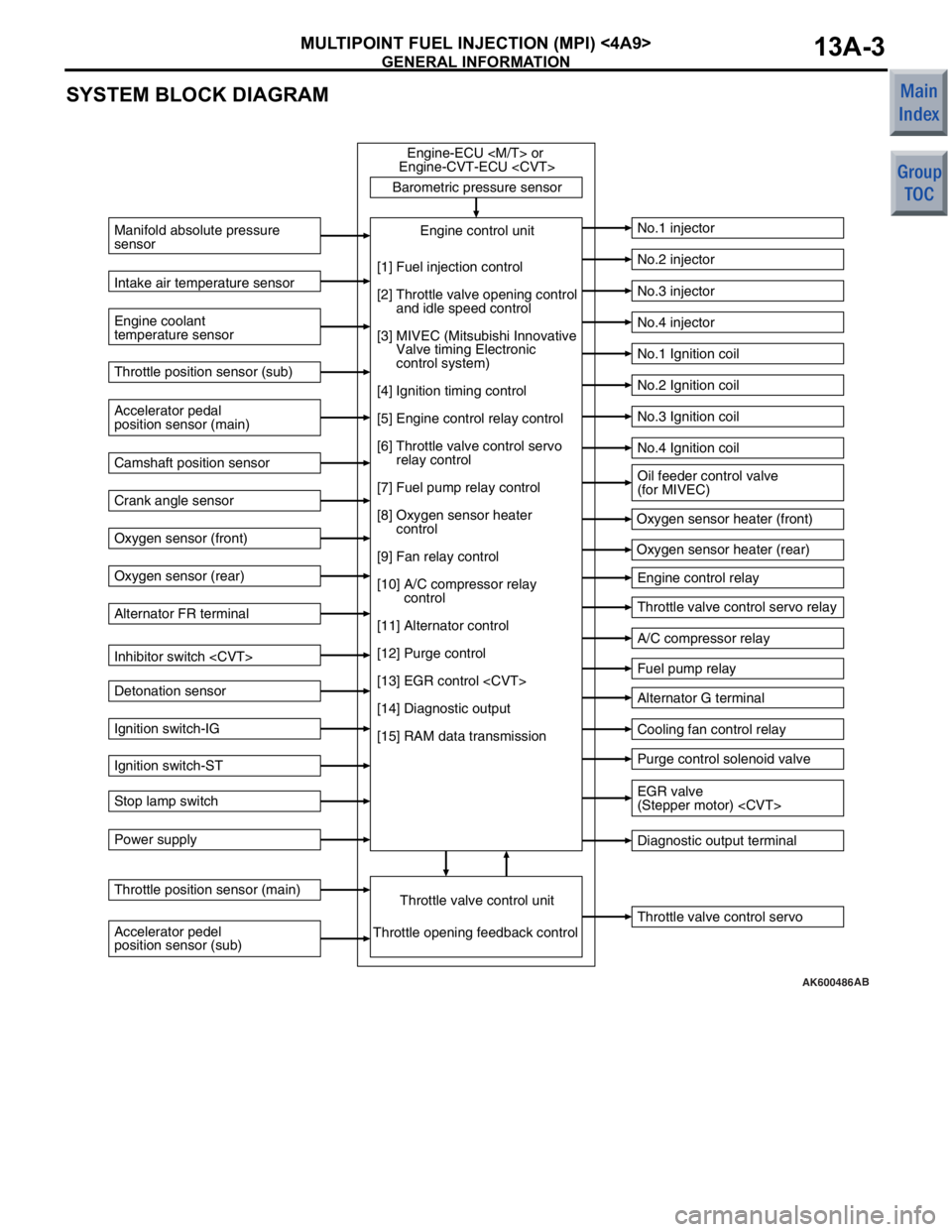

SYSTEM BLOCK DIAGRAM

AK600486

Barometric pressure sensorThrottle valve control servo

Manifold absolute pressure

sensor

Engine coolant

temperature sensor

No.1 injector

No.2 injector

No.3 injector

No.4 injector

No.1 Ignition coil

No.2 Ignition coil

No.3 Ignition coil

No.4 Ignition coil

Engine control relay

Throttle valve control servo relay

A/C compressor relay

Fuel pump relay

Alternator G terminal

Cooling fan control relay

Purge control solenoid valve

Diagnostic output terminal

Intake air temperature sensor

Accelerator pedal

position sensor (main) Throttle position sensor (sub)

Camshaft position sensor

Crank angle sensor

Oxygen sensor (front)

Oxygen sensor (rear)

Alternator FR terminal

Inhibitor switch

Detonation sensor

Ignition switch-IG

Ignition switch-ST

Stop lamp switch

Power supply

Accelerator pedel

position sensor (sub) Throttle position sensor (main)

Throttle valve control unitEngine control unit

Engine-ECU

Engine-CVT-ECU

Throttle opening feedback control Oxygen sensor heater (front)

Oxygen sensor heater (rear)

[1] Fuel injection control

[2] Throttle valve opening control

and idle speed control

[3] MIVEC (Mitsubishi Innovative

Valve timing Electronic

control system)

[4] Ignition timing control

[5] Engine control relay control

[6] Throttle valve control servo

relay control

[7] Fuel pump relay control

[8] Oxygen sensor heater

control

[9] Fan relay control

[10] A/C compressor relay

control

[11] Alternator control

[12] Purge control

[13] EGR control

[14] Diagnostic output

[15] RAM data transmission

Oil feeder control valve

(for MIVEC)

EGR valve

(Stepper motor)

AB

Page 101 of 364

GENERAL INFORMATION

MULTIPOINT FUEL INJECTION (MPI) <4A9>13A-7

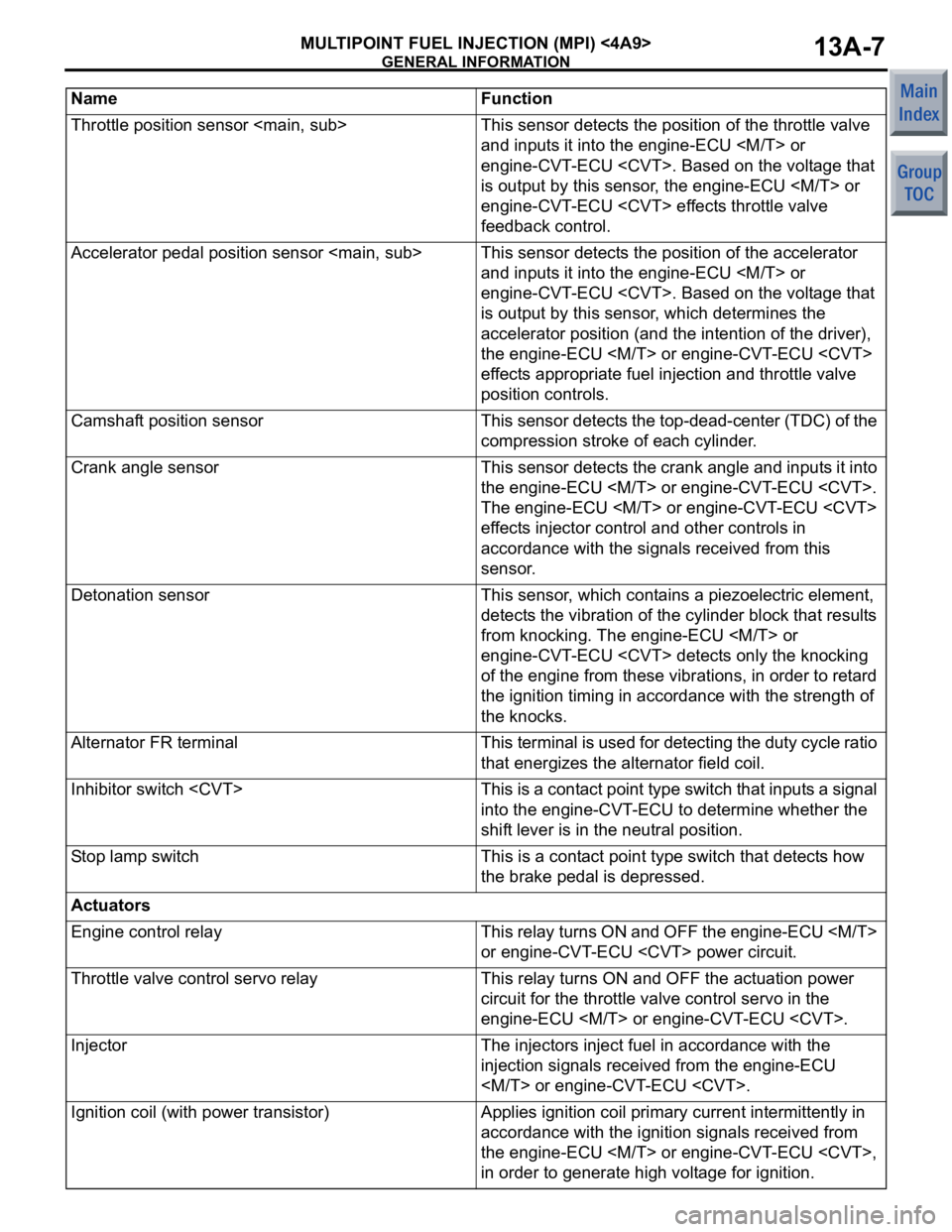

Throttle position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, the engine-ECU

engine-CVT-ECU

feedback control.

Accelerator pedal position sensor

and inputs it into the engine-ECU

engine-CVT-ECU

is output by this sensor, which determines the

accelerator position (and the intention of the driver),

the engine-ECU

effects appropriate fuel injection and throttle valve

position controls.

Camshaft position sensorThis sensor detects the top-dead-center (TDC) of the

compression stroke of each cylinder.

Crank angle sensorThis sensor detects the crank angle and inputs it into

the engine-ECU

The engine-ECU

effects injector control and other controls in

accordance with the signals received from this

sensor.

Detonation sensorThis sensor, which contains a piezoelectric element,

detects the vibration of the cylinder block that results

from knocking. The engine-ECU

engine-CVT-ECU

of the engine from these vibrations, in order to retard

the ignition timing in accordance with the strength of

the knocks.

Alternator FR terminalThis terminal is used for detecting the duty cycle ratio

that energizes the alternator field coil.

Inhibitor switch

into the engine-CVT-ECU to determine whether the

shift lever is in the neutral position.

Stop lamp switchThis is a contact point type switch that detects how

the brake pedal is depressed.

Actuators

Engine control relayThis relay turns ON and OFF the engine-ECU

or engine-CVT-ECU

Throttle valve control servo relayThis relay turns ON and OFF the actuation power

circuit for the throttle valve control servo in the

engine-ECU

InjectorThe injectors inject fuel in accordance with the

injection signals received from the engine-ECU

Ignition coil (with power transistor)Applies ignition coil primary current intermittently in

accordance with the ignition signals received from

the engine-ECU

in order to generate high voltage for ignition.

Name Function