drive MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 2 of 364

GENERAL INFORMATION

ANTI-SKID BRAKE SYSTEM (ABS)35B-2

GENERAL INFORMATION

M2351000100409

FEATURES

The ABS ensures directional stability and controlla-

bility during hard braking.

For vehicles with this type of ABS, 4 sensors (4

channels) are installed on front and rear wheels

allowing independent left and right control.

The system has the following features:

•EBD (Electronic Brake-force Distribution system)

control has been added to provide the ideal brak

-

ing force for the rear wheels.

•Magnetic encoder for wheel speed detection has

been installed as a sensing device instead of the

rotor.

•For wiring harness saving and secure data com-

munication, CAN* bus has been adopted as a

tool of communication with another ECU.

NOTE: *: For more information about CAN (Control-

ler Area Network), refer to Group 54C, General Infor-

mation P.54C-2.

EBD CONTROL

In ABS, electronic control is used so the rear wheel

brake hydraulic pressure during braking is regulated

by rear wheel control solenoid valves in accordance

with the vehicle's rate of deceleration, and the front

and rear wheel slippage which are calculated from

the signals received from the various wheel speed

sensors. EBD control provides a high level of control

for both vehicle braking force and vehicle stability.

The system has the following features:

•Because the system provides the optimum rear

wheel braking force regardless of vehicle load

condition and the condition of the road surface,

the system reduces the required pedal depres

-

sion force, particularly when the vehicle is heavily

loaded or driven on road surfaces with high fric

-

tional coefficients.

•Because the duty placed on the front brakes is

reduced, the increase in pad temperature can be

controlled during brakes application to improve

the wear resistance characteristics of the pad.

•Control valves such as the proportioning valve

are not required.

SPECIFICATIONS

ItemSpecification

ABS control method4-sensor, 4-channel

Wheel speed

sensorMagnetic encoderFront86 (N pole:43 S pole:43)

Rear86 (N pole:43 S pole:43)

Ty p eSemiconductor

Page 3 of 364

GENERAL INFORMATION

ANTI-SKID BRAKE SYSTEM (ABS)35B-3

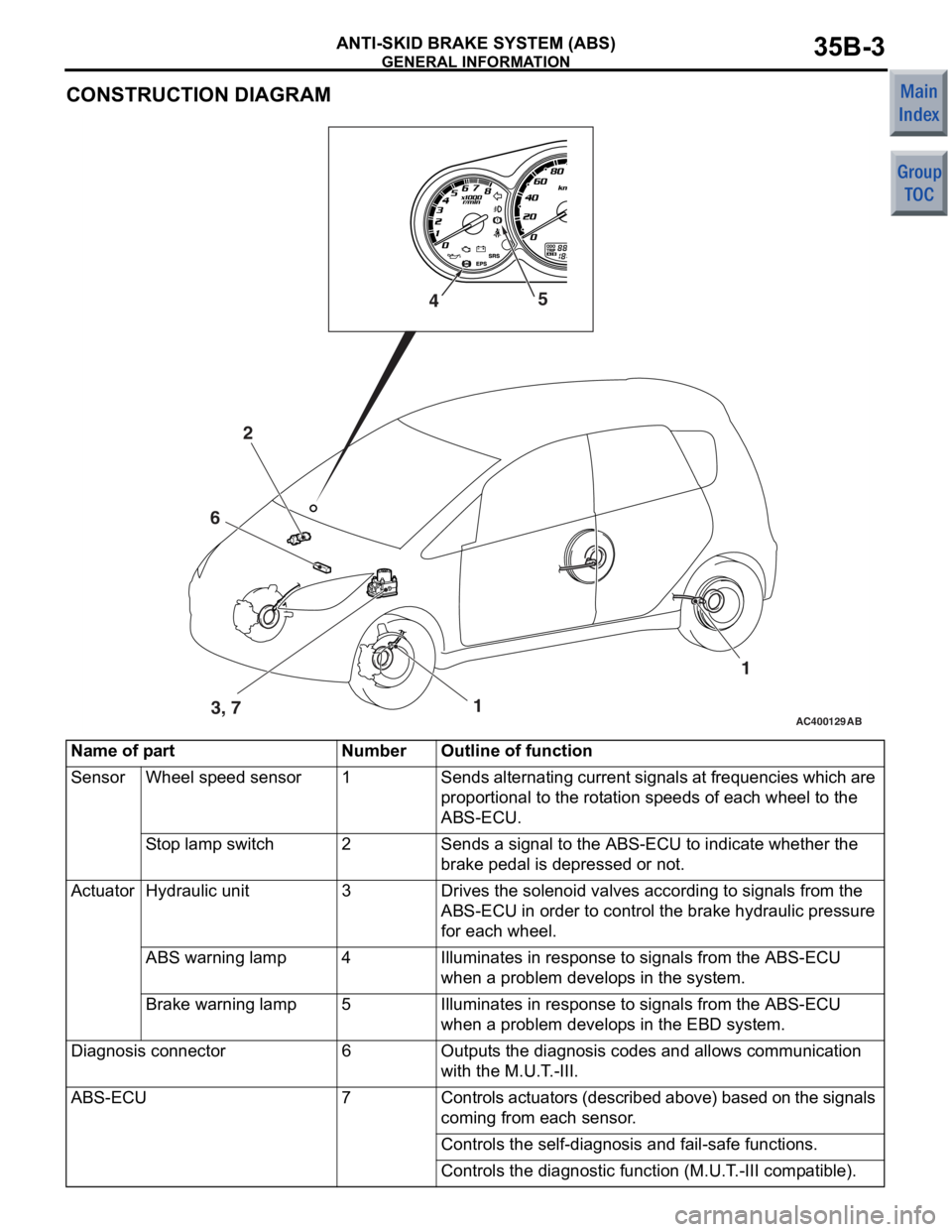

CONSTRUCTION DIAGRAM

AC400129AB1

2

3, 7 1

4

5

6

Name of partNumberOutline of function

SensorWheel speed sensor1Sends alternating current signals at frequencies which are

proportional to the rotation speeds of each wheel to the

ABS-ECU.

Stop lamp switch2Sends a signal to the ABS-ECU to indicate whether the

brake pedal is depressed or not.

ActuatorHydraulic unit3Drives the solenoid valves according to signals from the

ABS-ECU in order to control the brake hydraulic pressure

for each wheel.

ABS warning lamp4Illuminates in response to signals from the ABS-ECU

when a problem develops in the system.

Brake warning lamp5Illuminates in response to signals from the ABS-ECU

when a problem develops in the EBD system.

Diagnosis connector6Outputs the diagnosis codes and allows communication

with the M.U.T.-III.

ABS-ECU7Controls actuators (described above) based on the signals

coming from each sensor.

Controls the self-diagnosis and fail-safe functions.

Controls the diagnostic function (M.U.T.-III compatible).

Page 12 of 364

CONSTRUCTION DESCRIPTION

ANTI-SKID BRAKE SYSTEM (ABS)35B-12

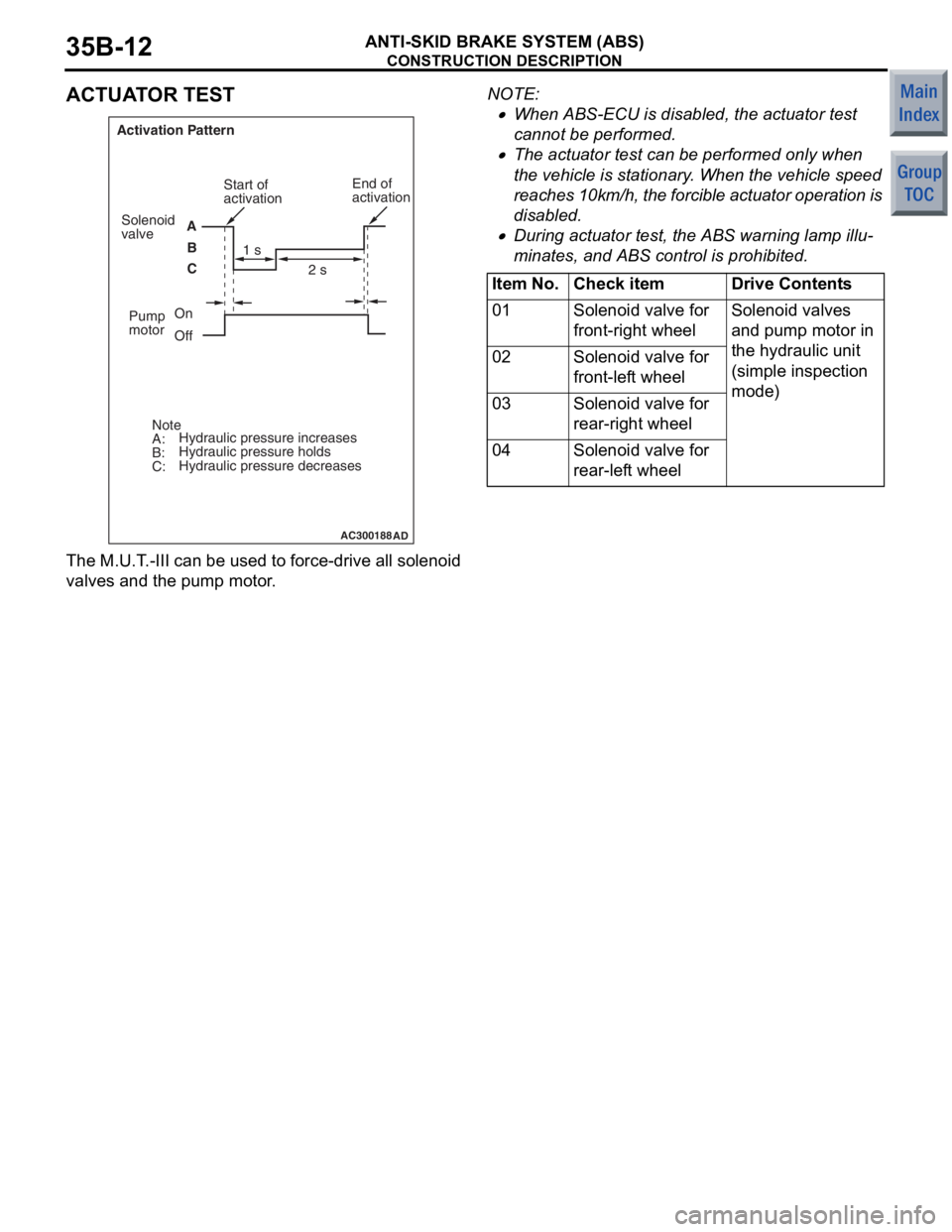

ACTUATOR TEST

AC300188AD

Activation PatternAB

C Start of

activation

1 s 2 s

On

Off

Note

A:

B:

C: Hydraulic pressure increases

Hydraulic pressure holds

Hydraulic pressure decreases End of

activation

Solenoid

valve

Pump

motor

The M.U.T . -III can be u s ed to force-drive a ll sole noid

valves and th

e pump mo tor .

NOTE: .

•Whe n ABS-ECU is disabled, the actu ator te st

cannot b

e perfo rmed.

•The actu ator test can be p e rformed on ly whe n

the

veh i cle is st a t iona ry . Whe n the ve hicle speed

rea

c h e s 10km/h, the f o rcible a c t uator operation is

disabled.

•During actuator test, the ABS warning lamp illu-

minates , an d ABS contro l is proh ibit ed.

Item No.Check itemDrive Contents

01Solenoid valve for

front-right wheelSolenoid valves

and pump motor in

the hydraulic unit

(simple inspection

mode)

02Solenoid valve for

front-left wheel

03Solenoid valve for

rear-right wheel

04Solenoid valve for

rear-left wheel

Page 22 of 364

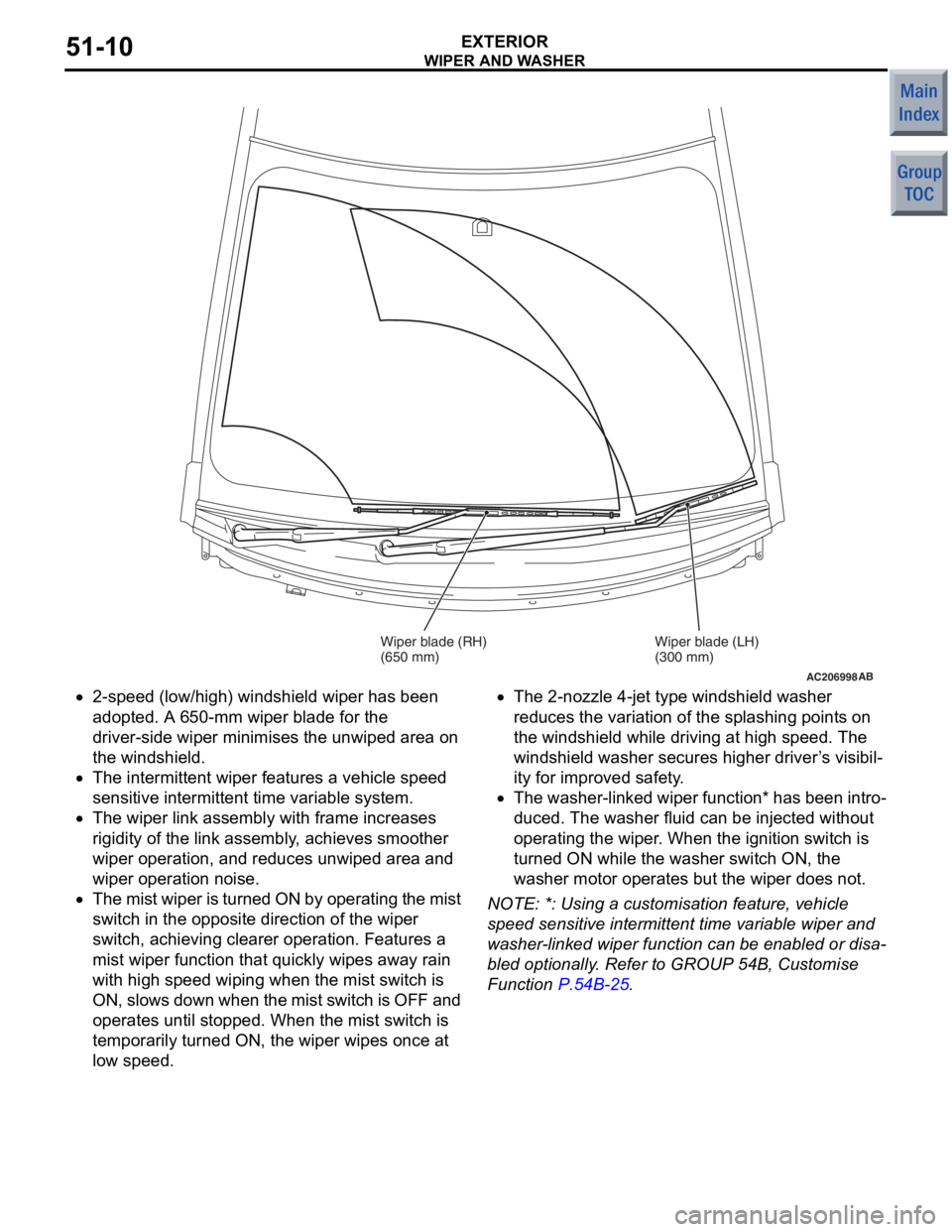

AC206998AB

Wiper blade (RH)

(650 mm)Wiper blade (LH)

(300 mm)

WIPE

R AN D W A SHER

EXTERIOR51-10

•2-speed (low/high) wind shield wip e r has been

ado

pted. A 6 50-mm wipe r blad e for th e

driver-side

wiper minimises the unwiped are a on

the

windshield.

•The intermitte nt wipe r feature s a vehicle spe ed

se

nsitive inte rmit tent time varia b le system.

•The wiper link assemb ly with frame in creases

rig

i dit y of t he link a s sembly , achieves smo o ther

wipe

r operat ion, a nd red u ces unwip ed area and

wipe

r operat ion n o ise.

•The mist wip e r is tu rned ON by o pera t ing the mist

switch in the

opposite direction of the wiper

switch,

achieving cleare r operat ion. F eatures a

mist wiper fun

c tio n that quickly wipe s away rain

with

high spee d wiping when t he mist switch is

ON,

slows down whe n th e mist switch is OFF and

ope

rates until sto pped. When th e mist switch is

temporarily turned

ON, the wiper wip e s o n ce a t

lo

w speed .

•The 2-nozzle 4-je t type windshield wash er

redu

ces the varia t ion of the spla shing point s on

the

windshield while dr iving at high speed. The

wind

shield washer secu res h i gher driver ’ s visibil

-

ity for impro v ed safe ty .

•The washer-linke d wiper function * has b een int r o-

duced. The wash er flu i d can be injected withou t

ope

rating the wip e r . Whe n the ignition switch is

turn

ed ON while t he wash er switch ON, the

washer mo

tor ope rates but th e wiper d oes not.

NOTE: *: Using a cust omisation fea t ure, vehicle

spee

d sen s it ive intermitte nt time variab le wip e r and

wa

sher

-lin ked wiper fun c tio n ca n be e nable d or disa

-

bled optio nally . Refer to GROUP 54 B, Cu stomise

Funct

i on

P.54B-25.

Page 35 of 364

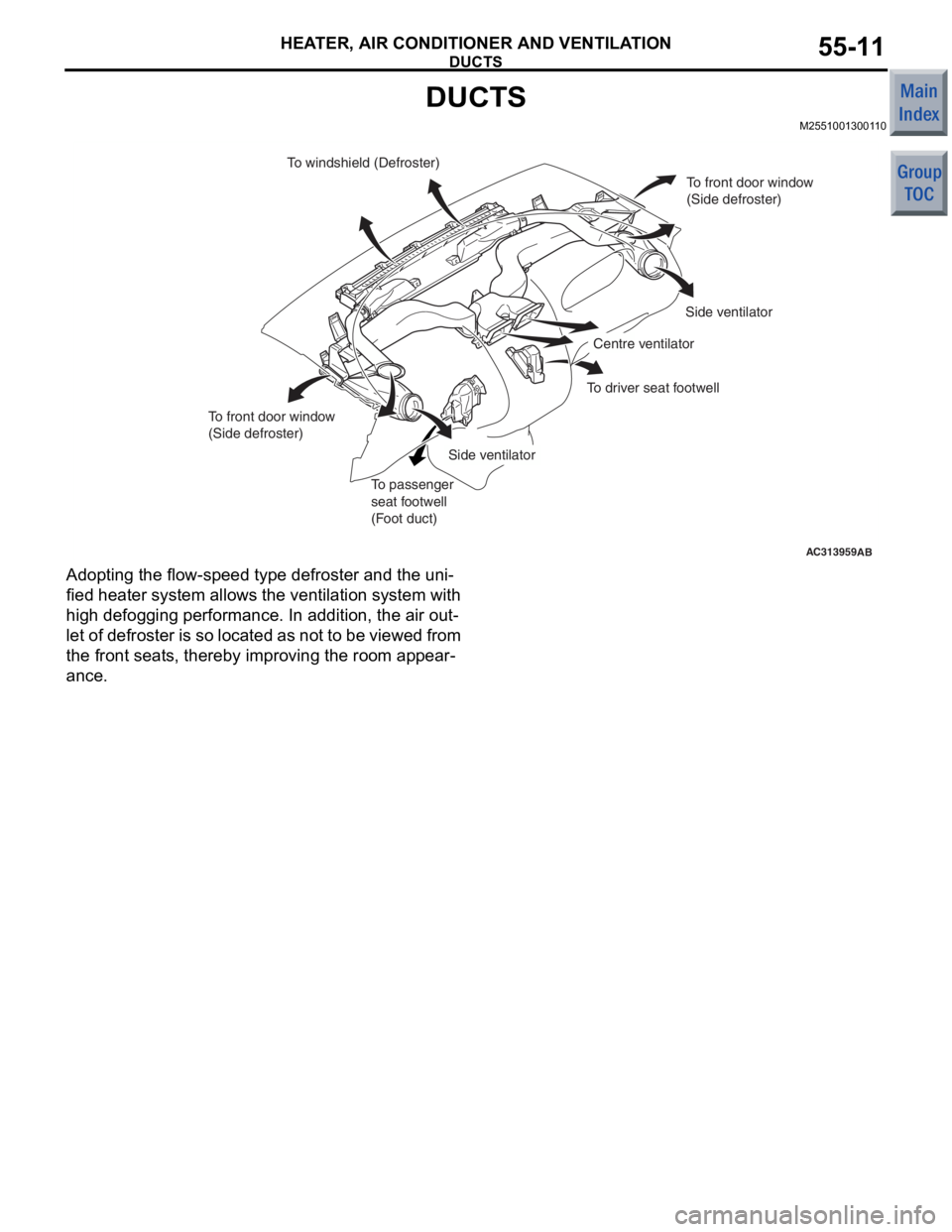

DUCTS

HEATER, AIR CONDITIONER AND VENTILATION55-11

DUCTS

M2551001300110

AC313959AB

To windshield (Defroster)To front door window

(Side defroster)

Side ventilator

Side ventilator Centre ventilator

To passenger

seat footwell

(Foot duct)

To front door window

(Side defroster)

To driver seat footwell

Ad

optin g the f l ow-sp eed type de froste r and th e uni-

fied heate r syst em allows th e ventilation system with

high

defogg ing p e rformance . In ad dition, the air ou t

-

let of defroster is so located as no t to be vie w e d from

the fron

t sea t s, there b y impro v ing the ro om ap pear

-

ance.

Page 57 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-9

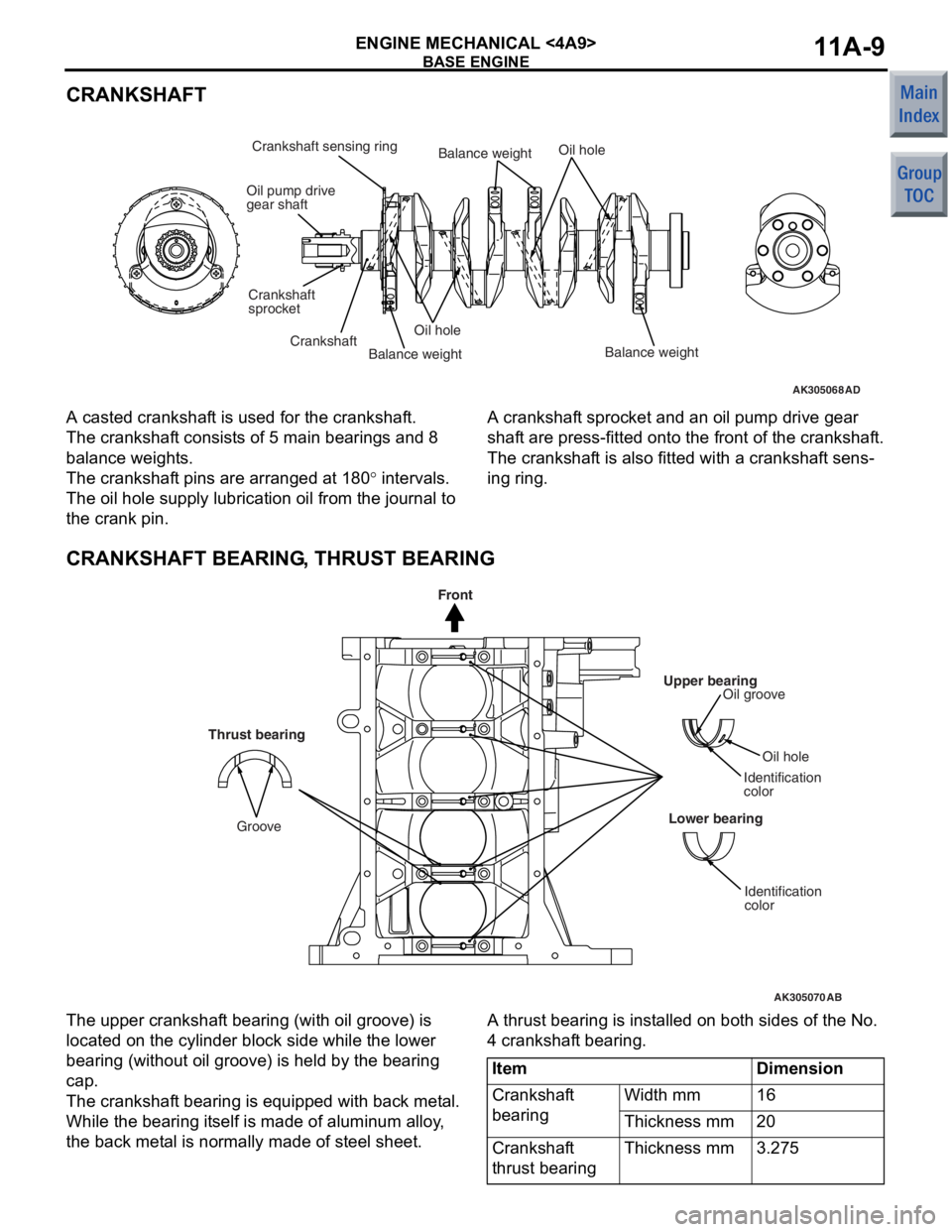

CRANKSHAFT

AK305068AD

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft sensing ring

CrankshaftOil hole

Oil hole

Balance weightBalance weightBalance weight

A casted crankshaf

t is used for t he cr ankshaf t.

The crankshaft consist s o f 5 ma in be aring s an d 8

balan

ce weight s.

The crankshaft pins a r e arrang ed at 1 8 0° inte rval s.

The oil hole supply lu brication oil from t he jo urnal to

the crank p

i n.

A cranksha f t sprocket and an oil pump drive gea r

shaf

t are press-fit t ed on to the f r ont of the crankshaf t.

The crankshaft is also fitt ed with a crankshaf t sens-

ing ring.

CRANKSHAFT BEARING, THRUST BEARING

AK305070

Upper bearingOil groove

Oil hole

Identification

color

Lower bearing

Identification

color

AB

Thrust bearing

Groove

Front

The upp er cra n kshaf t bea ring (with oil groove) is

loca

ted on the cylinder block side wh ile the lo we r

bearin

g (witho ut oil groo ve) is he ld by the b earin g

cap.

The crankshaft bea ring is e quipp ed with back me t a l.

While the b

earin g it self is ma de of a l uminum alloy ,

the back met

a l is no rmally made of steel sheet .

A thrust bearing is inst alle d on b o th sides of th e No.

4 cran

kshaf t bearing.

ItemDimension

Crankshaft

bearingWidth mm16

Thickness mm20

Crankshaft

thrust bearingThickness mm3.275

Page 58 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-10

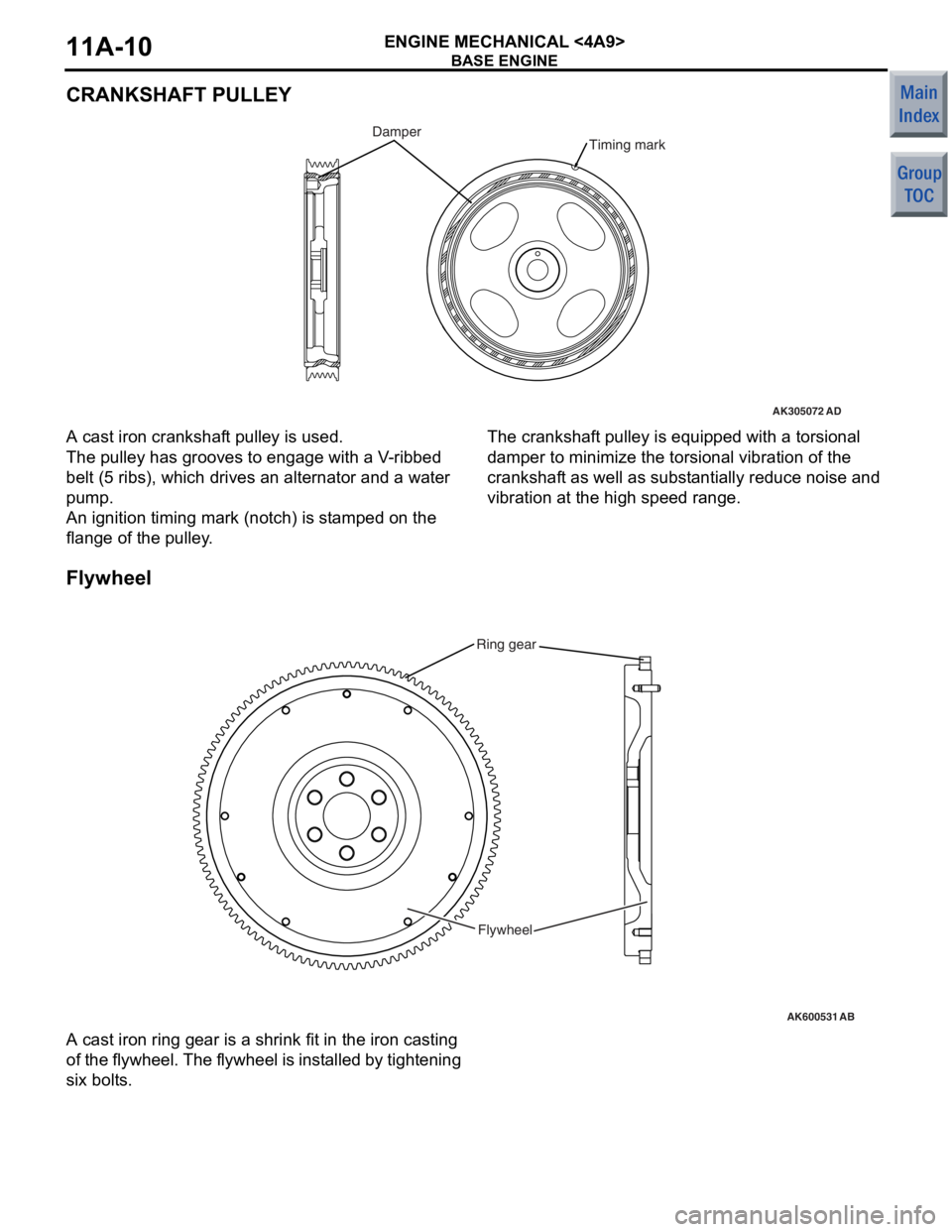

CRANKSHAFT PULLEY

AK305072AD

Timing markDamper

A cast iron cranksh af t pulley is used.

The pulley has grooves to eng age with a V -rib bed

belt (5

ribs), which drives an alternat or and a water

pump

.

An ignition timing mark (notch) is st amp ed on the

flang

e of the pulley .

The crankshaft pulley is equipped with a to rsio nal

damp

e r to minimize the torsional vibratio n of th e

cranksha

f t as well as sub s t antia lly redu ce no ise and

vib

r ation at the high spee d rang e.

Flyw he el

AK600531

Ring gear

Flywheel

AB

A cast iron ring g ear is a shrink fit in th e iron casting

of

t h e f l yw he el. T h e f l yw he el is in st a l le d by tigh t e n i n g

six bolt

s .

Page 59 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-11

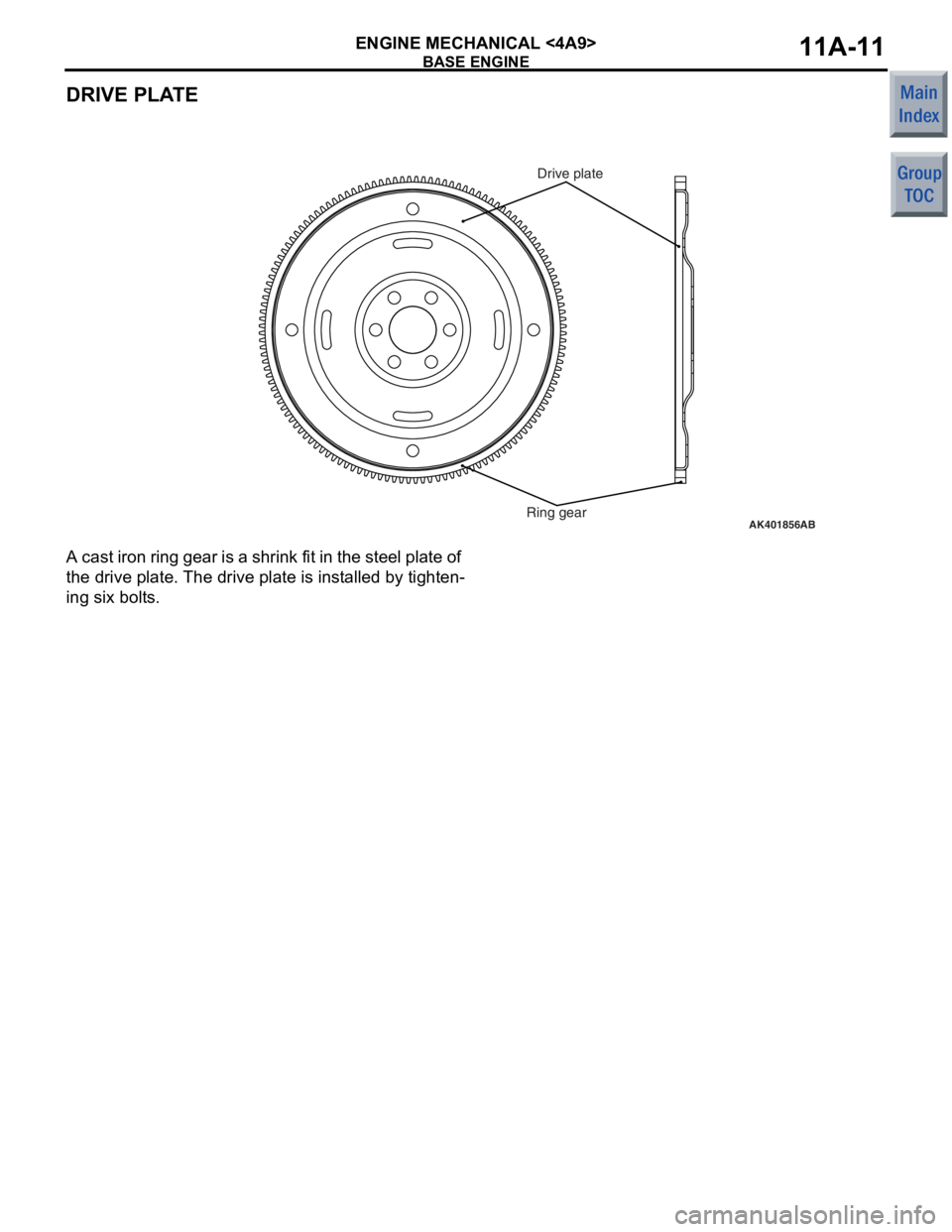

DRIVE PLATE

AK401856Ring gearDrive plateAB

A cast iron

ring g ear is a shrin k fit in th e ste e l plate o f

the drive p

l ate. The drive p l ate is inst alled b y tighten

-

ing six bolts .

Page 60 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-12

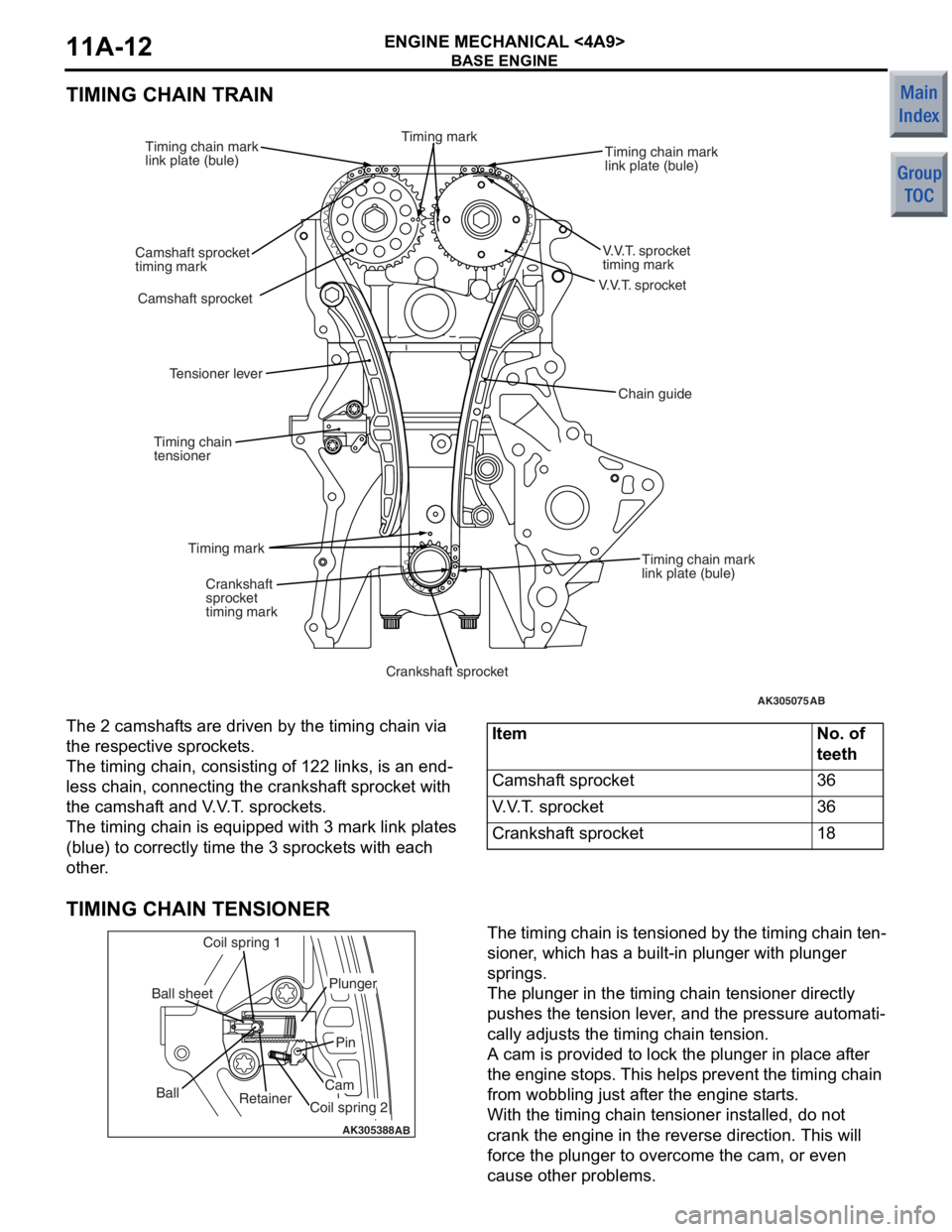

TIMING CHAIN TRAIN

AK305075

V.V.T. sprocket

AB

V.V.T. sprocket

timing mark

Timing chain mark

link plate (bule)

Camshaft sprocket

Camshaft sprocket

timing mark Timing chain mark

link plate (bule)

Timing chain mark

link plate (bule)

Crankshaft

sprocket

timing mark

Crankshaft sprocket

Timing mark

Timing chain

tensioner

Tensioner lever

Chain guide

Timing mark

The 2 camshaf

t s are driven by the t i ming chain via

the res

pec tive spro cke t s .

The timing cha i n, consist i ng o f 122 links, is an end-

less chain, conn ecting the cran ksh af t spro cke t with

the camshaf

t and V . V . T . spro cke t s .

The timing cha i n is eq uippe d with 3 mark link p l ates

(blue)

to co rrectly time t he 3 sprocket s with each

other

.

ItemNo. of

teeth

Camshaft sprocket36

V.V.T. sprocket36

Crankshaft sprocket18

TIMING CHAIN TENSIONER

AK305388AB

Retainer

Ball

Coil spring 1

Ball sheet

Coil spring 2

Cam

Pin

Plunger

The timing chain is tensione

d by th e timing chain te n-

sioner , which ha s a b u ilt-in plunge r with plunge r

springs.

The plunger in the timing chain tension e r dire ctly

push

e s th e tension lever , and the pre s sure aut omati

-

cally ad just s the timing chain tension.

A cam is provided t o lock th e plu nger in pla c e a f te r

the eng

ine stop s. This help s prevent the timing chain

from wob

b lin g just af ter th e eng ine st a r t s .

With the timing cha i n ten s io ner in st alled, do not

crank the

engin e in the reverse directio n. This will

force

the plunger to overcome the cam, or e v en

cause oth

e r problems.

Page 73 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-25

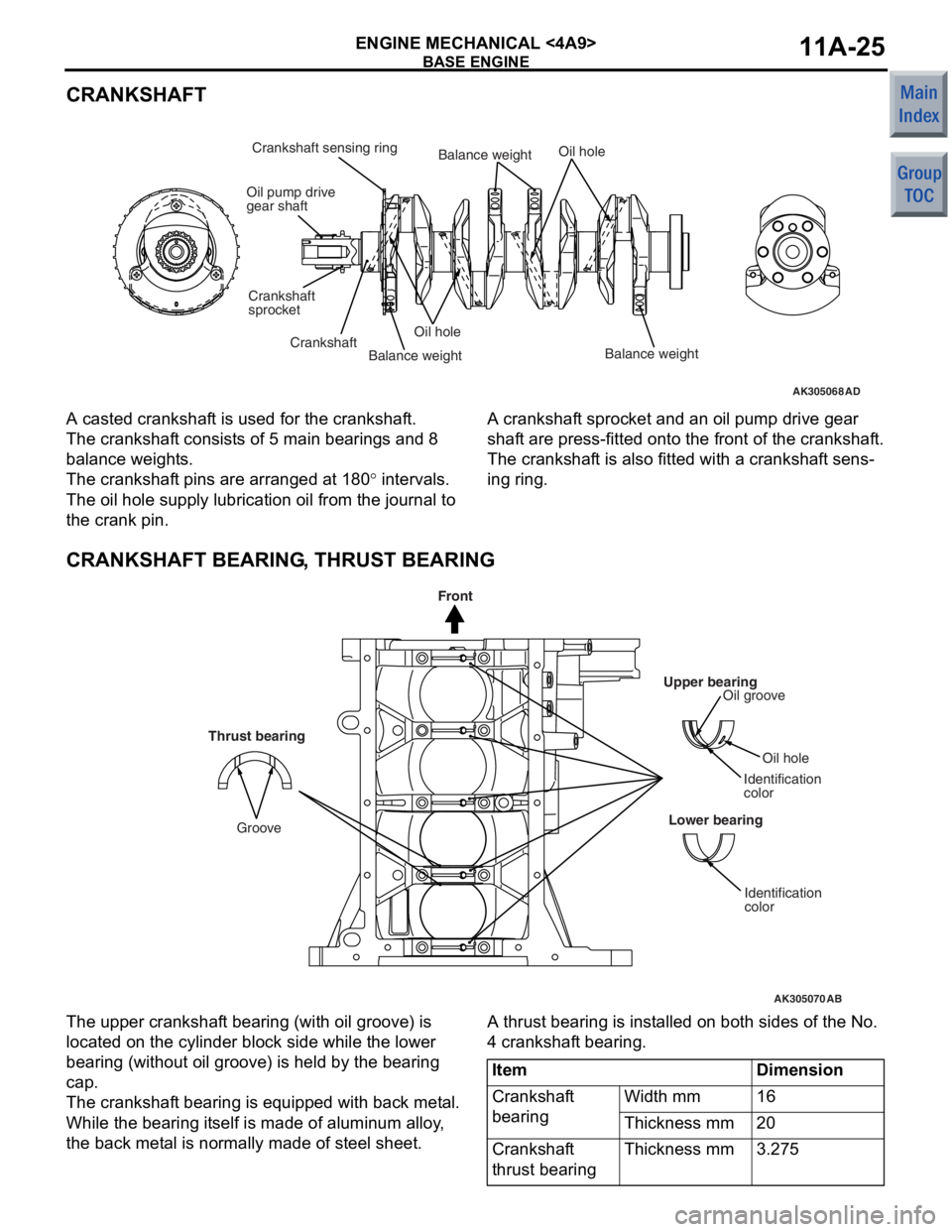

CRANKSHAFT

AK305068AD

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft sensing ring

CrankshaftOil hole

Oil hole

Balance weightBalance weightBalance weight

A casted crankshaf

t is used for t he cr ankshaf t.

The crankshaft consist s o f 5 ma in be aring s an d 8

balan

ce weight s.

The crankshaft pins a r e arrang ed at 1 8 0° inte rval s.

The oil hole supply lu brication oil from t he jo urnal to

the crank p

i n.

A cranksha f t sprocket and an oil pump drive gea r

shaf

t are press-fit t ed on to the f r ont of the crankshaf t.

The crankshaft is also fitt ed with a crankshaf t sens-

ing ring.

CRANKSHAFT BEARING, THRUST BEARING

AK305070

Upper bearingOil groove

Oil hole

Identification

color

Lower bearing

Identification

color

AB

Thrust bearing

Groove

Front

The upp er cra n kshaf t bea ring (with oil groove) is

loca

ted on the cylinder block side wh ile the lo we r

bearin

g (witho ut oil groo ve) is he ld by the b earin g

cap.

The crankshaft bea ring is e quipp ed with back me t a l.

While the b

earin g it self is ma de of a l uminum alloy ,

the back met

a l is no rmally made of steel sheet .

A thrust bearing is inst alle d on b o th sides of th e No.

4 cran

kshaf t bearing.

ItemDimension

Crankshaft

bearingWidth mm16

Thickness mm20

Crankshaft

thrust bearingThickness mm3.275