roof MITSUBISHI COLT 2006 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 46 of 364

GENERAL INFORMATION

ENGINE MECHANICAL <4G1>11B-2

GENERAL INFORMATION

M2112000101010

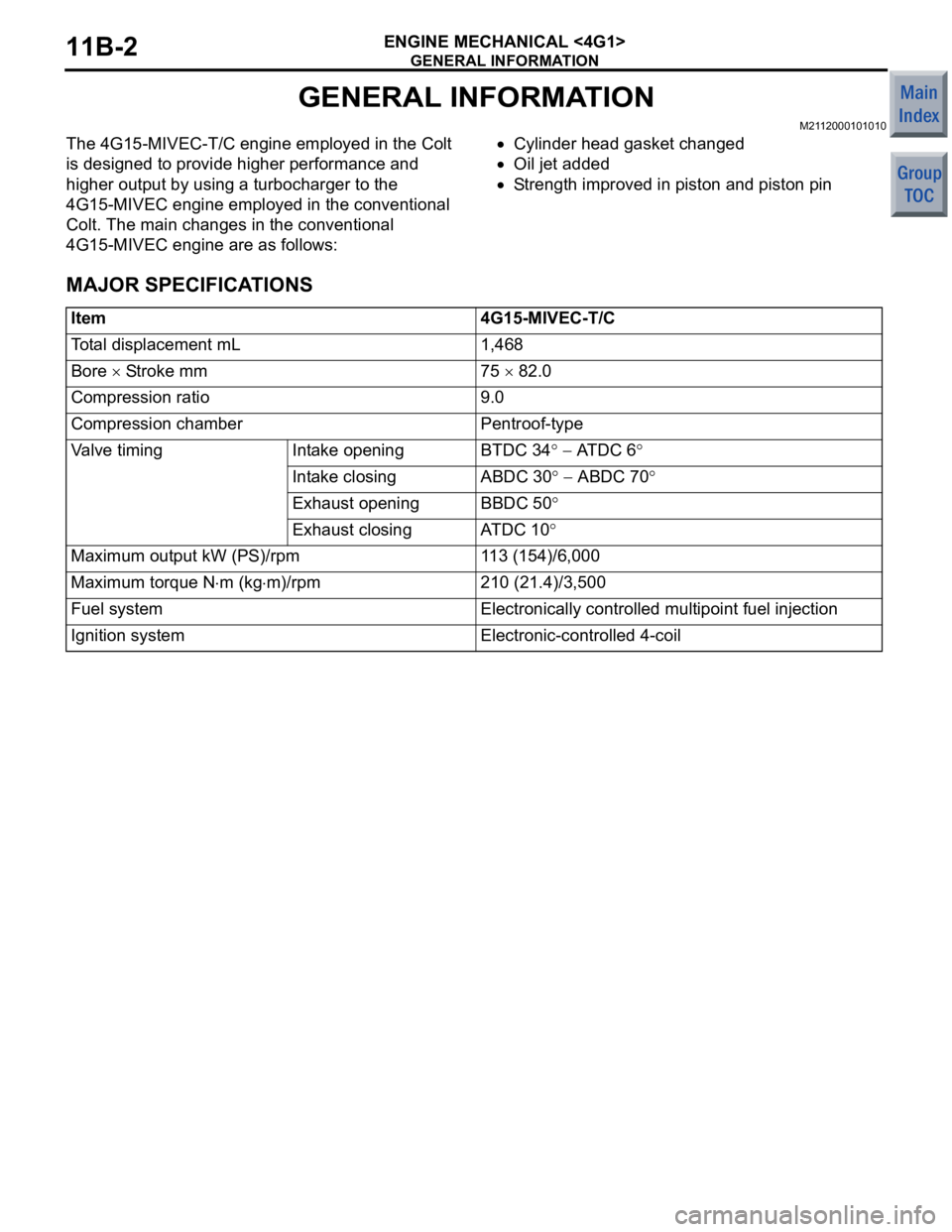

The 4G15-MIVEC-T/C engine employed in the Colt

is designed to provide higher performance and

higher output by using a turbocharger to the

4G15-MIVEC engine employed in the conventional

Colt. The main changes in the conventional

4G15-MIVEC engine are as follows:•Cylinder head gasket changed

•Oil jet added

•Strength improved in piston and piston pin

MAJOR SPECIFICATIONS

Item4G15-MIVEC-T/C

Total displacement mL1,468

Bore × Stro ke mm75 × 82.0

Compression ratio9.0

Compression chamberPentroof-type

Va l v e t i m i n gIntake openingBTDC 34° − AT D C 6°

Intake closingABDC 30° − ABDC 70°

Exhaust openingBBDC 50°

Exhaust closingATDC 10°

Maximum output kW (PS)/rpm113 (154)/6,000

Maximum torque N⋅m (kg⋅m)/rpm210 (21.4)/3,500

Fuel systemElectronically controlled multipoint fuel injection

Ignition systemElectronic-controlled 4-coil

Page 50 of 364

GENERAL INFORMATION

ENGINE MECHANICAL <4A9>11A-2

GENERAL INFORMATION

M2112000100697

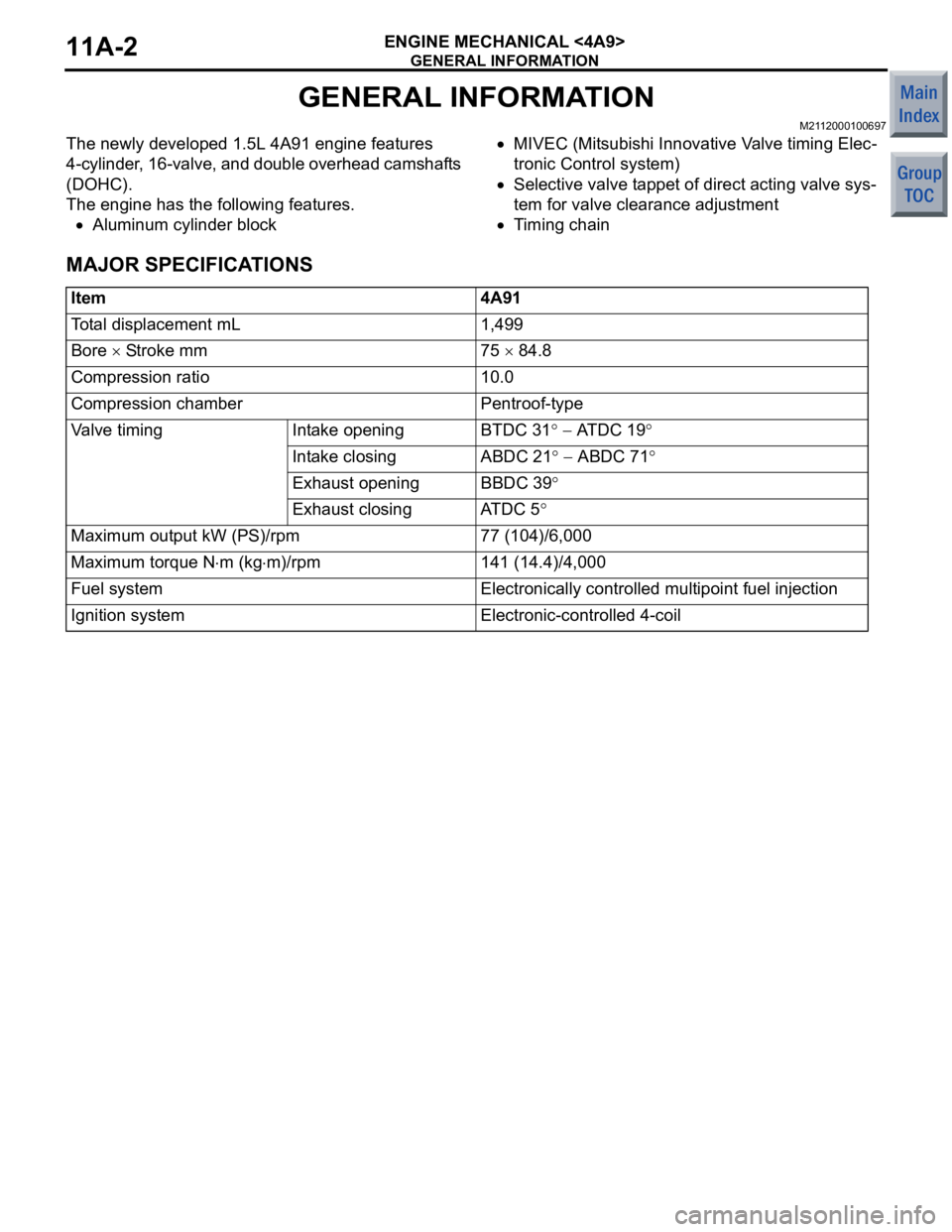

The newly developed 1.5L 4A91 engine features

4-cylinder, 16-valve, and double overhead camshafts

(DOHC).

The engine has the following features.

•Aluminum cylinder block

•MIVEC (Mitsubishi Innovative Valve timing Elec-

tronic Control system)

•Selective valve tappet of direct acting valve sys-

tem for valve clearance adjustment

•Timing chain

MAJOR SPECIFICATIONS

Item4A91

Total displacement mL1,499

Bore × Stro ke mm75 × 84.8

Compression ratio10.0

Compression chamberPentroof-type

Va l v e t i m i n gIntake openingBTDC 31° − AT D C 1 9°

Intake closingABDC 21° − ABDC 71°

Exhaust openingBBDC 39°

Exhaust closingATDC 5°

Maximum output kW (PS)/rpm77 (104)/6,000

Maximum torque N⋅m (kg⋅m)/rpm141 (14.4)/4,000

Fuel systemElectronically controlled multipoint fuel injection

Ignition systemElectronic-controlled 4-coil

Page 51 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-3

BASE ENGINE

M2112001000864

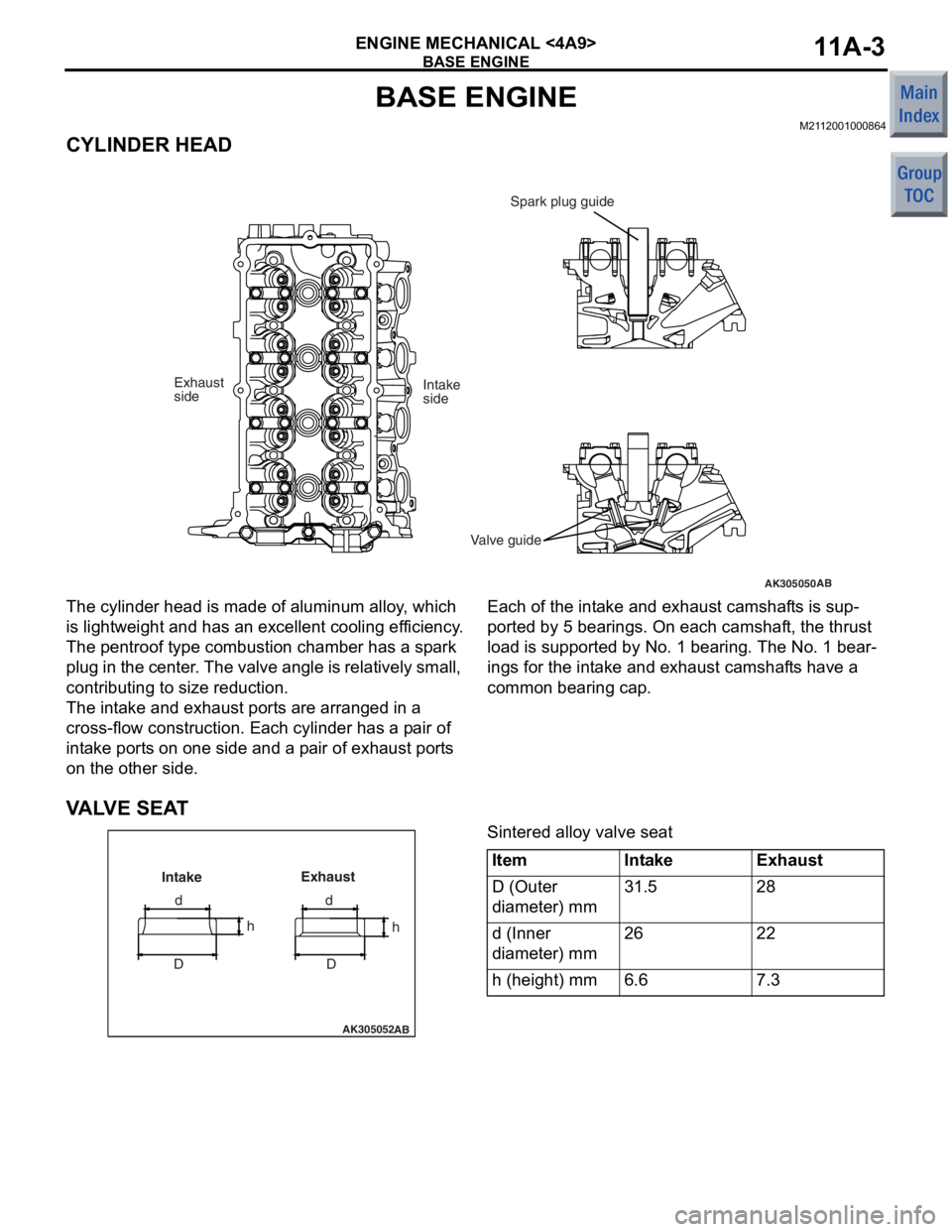

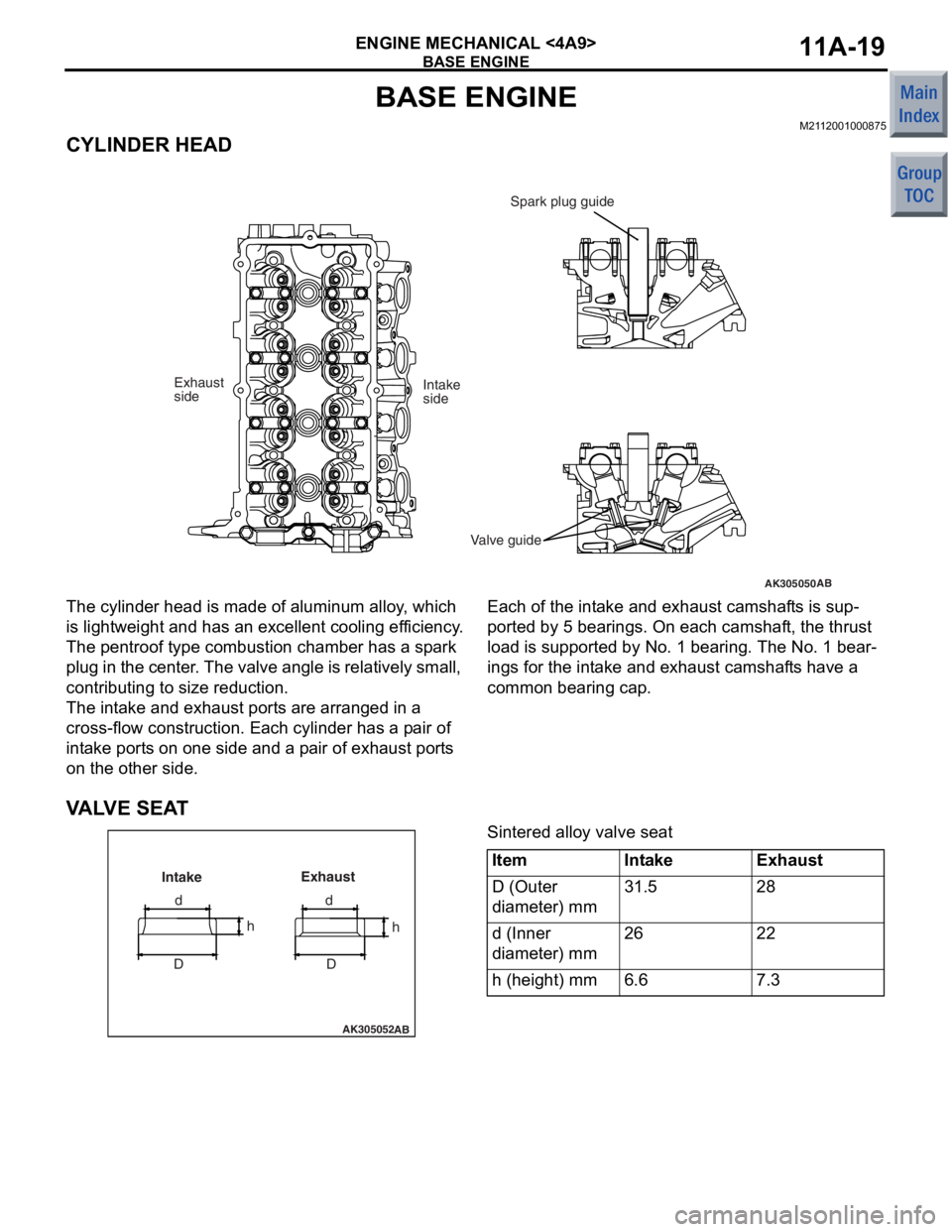

CYLINDER HEAD

AK305050AB

Spark plug guide

Intake

side

Exhaust

side

Valve guide

The cylinder head is made of aluminu m alloy , which

is light

we ight a nd ha s an excelle nt co oling ef ficiency .

The pentroof type comb ustion chamb e r has a sp a r k

plug in the

cent er . The valve an gle is relatively small,

contributing to size redu

ctio n.

The int a ke an d exhaust port s a r e arrang ed in a

cross-flow construction.

Ea ch cylinde r has a p a ir of

int

a ke port s on one side and a p a ir of e x hau st po rt s

on the

other side .

Each o f the int a ke a nd exhaust ca msh a f t s is sup-

ported by 5 bearin gs. On ea ch camshaf t, th e thrust

load

is suppo rted by No. 1 b earin g. The No . 1 bea r

-

ings for the int a ke and exha ust camshaf t s ha ve a

common bearing

ca p.

VALV E S E AT

AK305052

d

AB

d

DD h

h

Intake

Exhaust

Sintered

alloy valve seat

ItemIntakeExhaust

D (Outer

diameter) mm31.528

d (Inner

diameter) mm2622

h (height) mm6.67.3

Page 66 of 364

GENERAL INFORMATION

ENGINE MECHANICAL <4A9>11A-18

GENERAL INFORMATION

M2112000101009

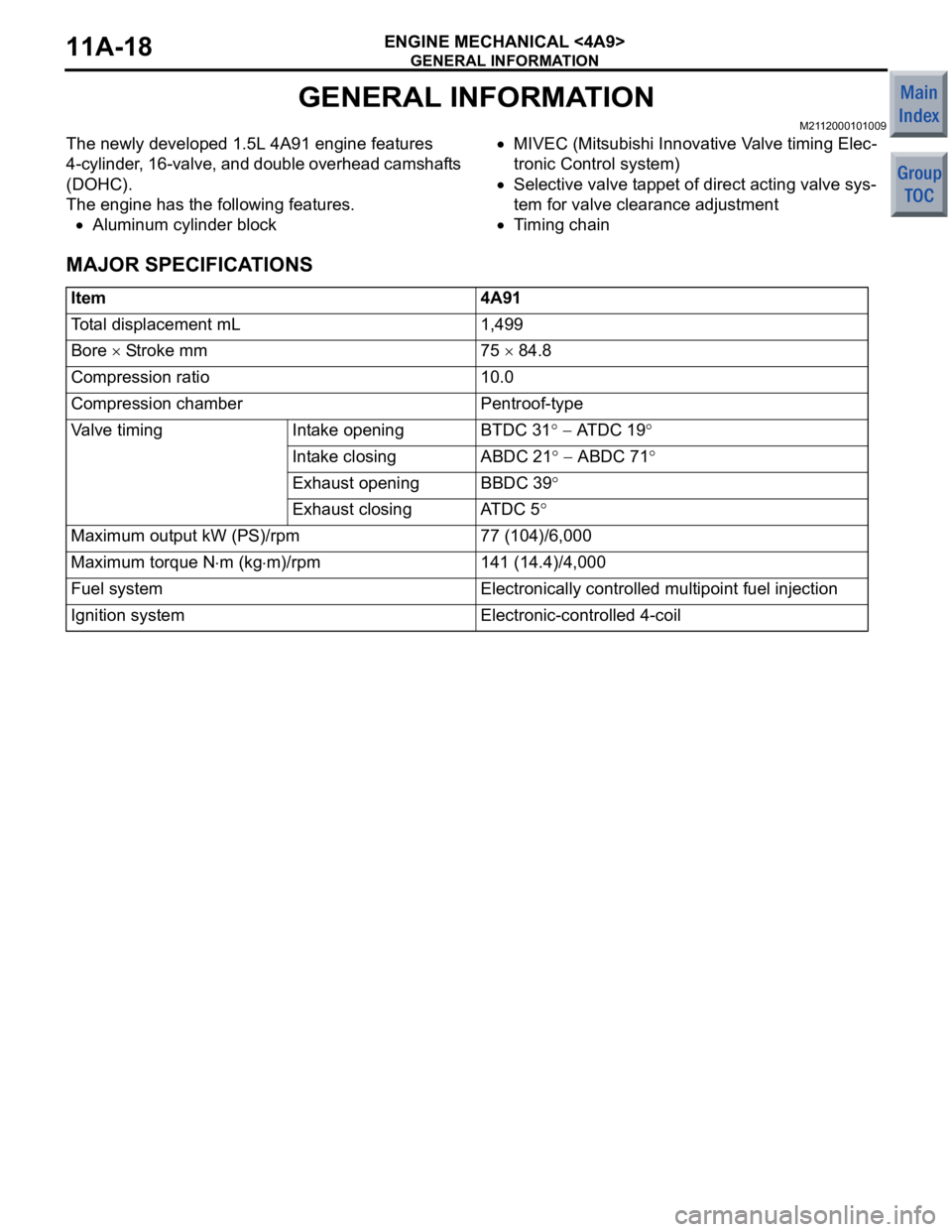

The newly developed 1.5L 4A91 engine features

4-cylinder, 16-valve, and double overhead camshafts

(DOHC).

The engine has the following features.

•Aluminum cylinder block

•MIVEC (Mitsubishi Innovative Valve timing Elec-

tronic Control system)

•Selective valve tappet of direct acting valve sys-

tem for valve clearance adjustment

•Timing chain

MAJOR SPECIFICATIONS

Item4A91

Total displacement mL1,499

Bore × Stro ke mm75 × 84.8

Compression ratio10.0

Compression chamberPentroof-type

Va l v e t i m i n gIntake openingBTDC 31° − AT D C 1 9°

Intake closingABDC 21° − ABDC 71°

Exhaust openingBBDC 39°

Exhaust closingATDC 5°

Maximum output kW (PS)/rpm77 (104)/6,000

Maximum torque N⋅m (kg⋅m)/rpm141 (14.4)/4,000

Fuel systemElectronically controlled multipoint fuel injection

Ignition systemElectronic-controlled 4-coil

Page 67 of 364

BASE ENGINE

ENGINE MECHANICAL <4A9>11A-19

BASE ENGINE

M2112001000875

CYLINDER HEAD

AK305050AB

Spark plug guide

Intake

side

Exhaust

side

Valve guide

The cylinder head is made of aluminu m alloy , which

is light

we ight a nd ha s an excelle nt co oling ef ficiency .

The pentroof type comb ustion chamb e r has a sp a r k

plug in the

cent er . The valve an gle is relatively small,

contributing to size redu

ctio n.

The int a ke an d exhaust port s a r e arrang ed in a

cross-flow construction.

Ea ch cylinde r has a p a ir of

int

a ke port s on one side and a p a ir of e x hau st po rt s

on the

other side .

Each o f the int a ke a nd exhaust ca msh a f t s is sup-

ported by 5 bearin gs. On ea ch camshaf t, th e thrust

load

is suppo rted by No. 1 b earin g. The No . 1 bea r

-

ings for the int a ke and exha ust camshaf t s ha ve a

common bearing

ca p.

VALV E S E AT

AK305052

d

AB

d

DD h

h

Intake

Exhaust

Sintered

alloy valve seat

ItemIntakeExhaust

D (Outer

diameter) mm31.528

d (Inner

diameter) mm2622

h (height) mm6.67.3

Page 144 of 364

GROUP 42

BODY

CONTENTS

GENERAL INFORMATION . . . . . . . .42-2

MAIN BODY . . . . . . . . . . . . . . . . . . . .42-3

BODY PANELING . . . . . . . . . . . . . . . . . . . . 42-3

BODY SHELL . . . . . . . . . . . . . . . . . . . . . . . 42-4

QUIETNESS . . . . . . . . . . . . . . . . . . . . . . . . 42-9

BODY COLOUR CHARTS . . . . . . . . . . . . . 42-9

HOOD <4G1> . . . . . . . . . . . . . . . . . . .42-10

STRUT TOWER BAR <4G1>. . . . . . .42-10

DOOR . . . . . . . . . . . . . . . . . . . . . . . . .42-11

DOOR LOCK . . . . . . . . . . . . . . . . . . . . . . . . 42-11

KEYLESS ENTRY SYSTEM . . . . . . . . . . . . 42-13

POWER WINDOW . . . . . . . . . . . . . . . . . . . 42-15

WEATHERSTRIP . . . . . . . . . . . . . . . . . . . . 42-17

PROTECTOR FILM. . . . . . . . . . . . . . .42-17

WINDOW GLASS . . . . . . . . . . . . . . . .42-18

SUNROOF. . . . . . . . . . . . . . . . . . . . . .42-20

LOOSE PANELS <4G1> . . . . . . . . . .42-22

Page 145 of 364

GENERAL INFORMATION

BODY42-2

GENERAL INFORMATION

M2420000100842

FEATURES

WEIGHT REDUCTION AND HIGH RIGID-

ITY

•Application ranges of high tension steel plate,

antirust steel plate, and uneven thickness steel

plate have been expanded.

•The upper frame outer and front pillar connection

has been strengthened by adopting the upper

frame-to-front pillar brace.

•The radius of each opening corner for the doors

and tailgate has been enlarged.

•Cowl top lower panel and spring house panel are

directly joined for higher rigidity.

•Strut tower bar has been adopted <4G1>.

•A front suspension axle side plate has been

adopted <4G1>.

•The air outlet garnish has been installed to the

hood, improving the sporty image and cooling

efficiency in the engine compartment. <4G1>

REDUCTION OF VIBRATION, NOISE, AND

AERODYNAMIC NOISE

•Straight frame structure has been adopted.

•Curved front floor and uneven thickness steel

plate have been adopted.

•Rigidity of the suspension installation part has

been improved.

IMPROVEMENTS IN SAFETY

•RISE (Reinforced Impact Safety Evolution) has

been used for the main body.

•Features a side door beam to boost safety upon

side impact.

•Direct combination key cylinder and inside lock

cables for the front doors have been adopted to

improve safety upon impact.

IMPROVEMENTS IN OPERATION

QUALITY

•The central door locking system, which

locks/unlocks all the doors and the tailgate, is

adopted.

•"P" position shift linked door-unlock function has

been introduced to the central door locking sys

-

tem(F1C1A).

IMPROVEMENTS OF PRODUCT

PACKAGE AND APPEARANCE

•Rigidity of door sash bottom section has been

improved.

•By improving the engaging sound between the

door latch and striker, the door locking sound

quality has been enhanced.

•UV & heat protect glass has been used for the

windshield.

•UV-reducing glass has been used for the front

door window glasses and rear door window

glasses.

•Privacy glasses have been used for rear door

window glasses, quarter window glasses, and

tailgate window glass (Option).

•Multi-mode keyless entry system (with door mir-

ror retraction/return control function) has been

adopted.

•Protector film has been attached on side sill

•Sunroof has been installed (Option).

Page 160 of 364

PROTECTOR FILM

BODY42-17

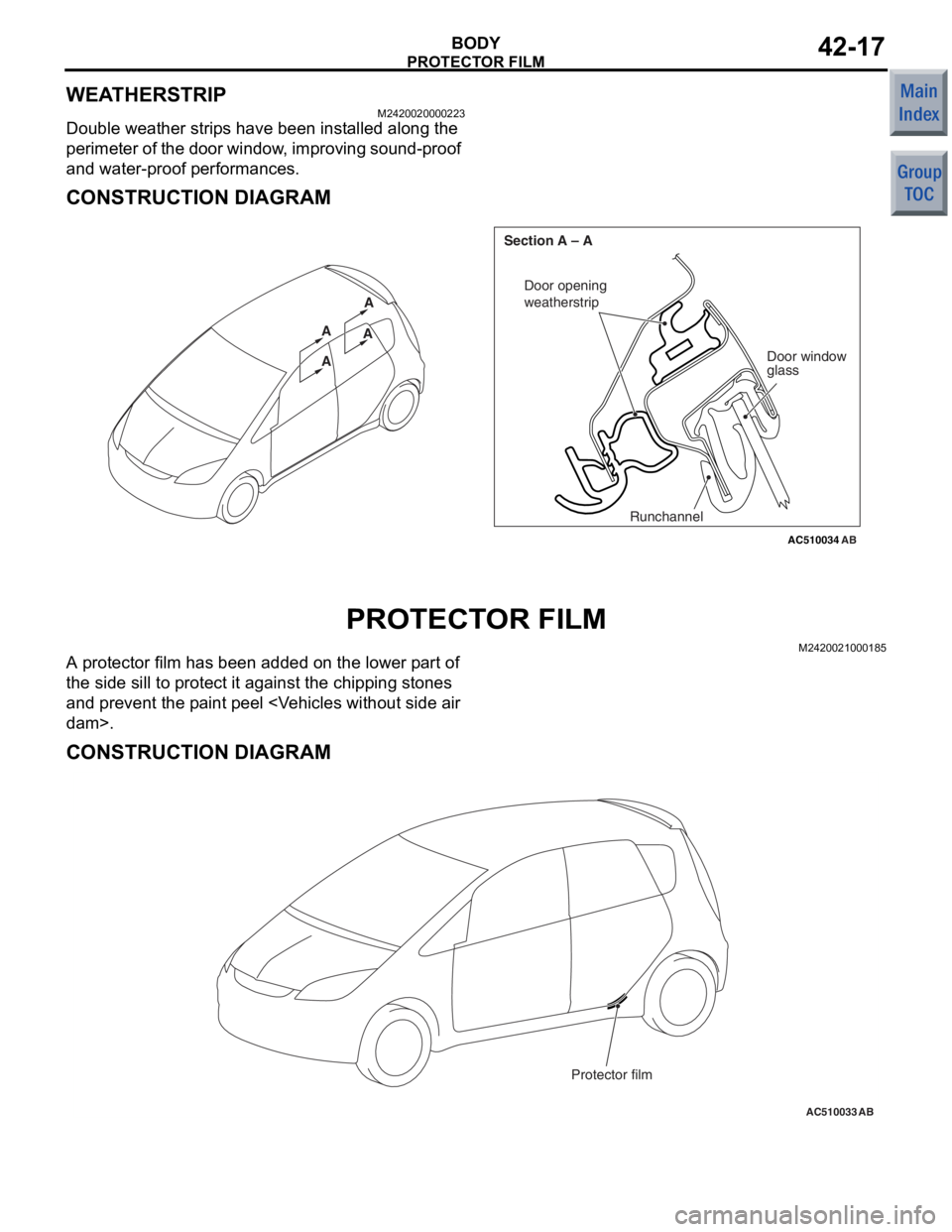

WEATHERSTRIP

M2420020000223

Double weather strips have been installed along the

perimeter of the door window, improving sound-proof

and water-proof performances.

CONSTRUCTION DIAGRAM

AC510034AB

AA A

A

Door opening

weatherstrip

Door window

glass

Runchannel

Section A – A

PROTECT

O R FILM

M24200210 0018 5

A pr otector film h a s be en ad ded on the lower p a rt of

the side sill to pr

otect it ag ainst the chip ping ston es

and p

r even t the p a int peel

CONSTRUCTION DIAGRAM

AC510033AB

Protector film

Page 161 of 364

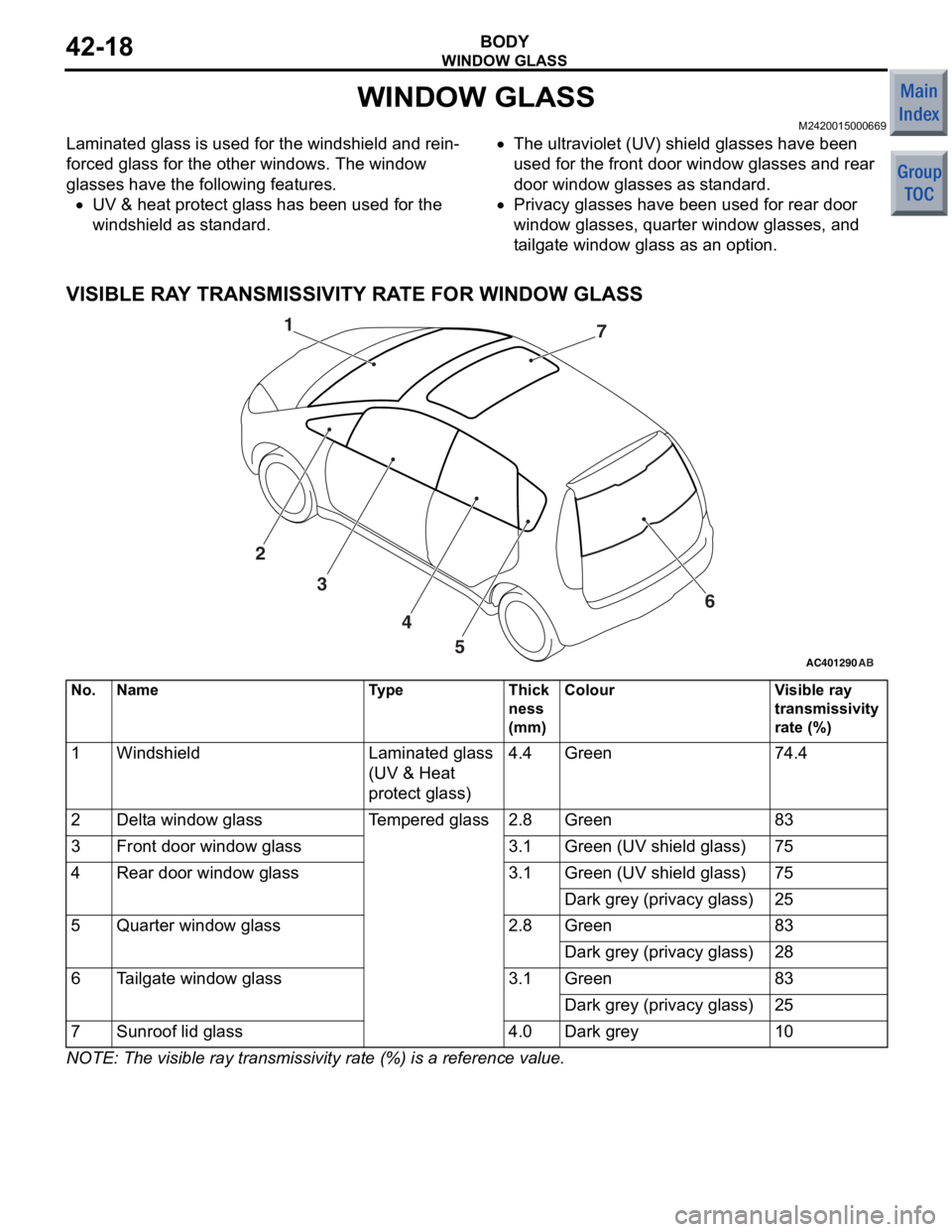

WINDOW GLASS

BODY42-18

WINDOW GLASS

M2420015000669

Laminated glass is used for the windshield and rein-

forced glass for the other windows. The window

glasses have the following features.

•UV & heat protect glass has been used for the

windshield as standard.

•The ultraviolet (UV) shield glasses have been

used for the front door window glasses and rear

door window glasses as standard.

•Privacy glasses have been used for rear door

window glasses, quarter window glasses, and

tailgate window glass as an option.

VISIBLE RAY TRANSMISSIVITY RATE FOR WINDOW GLASS

AC401290AC206463AB

1

2 3

45 6

7

No.NameTy p eThick

ness

(mm)ColourVisible ray

transmissivity

rate (%)

1WindshieldLaminated glass

(UV & Heat

protect glass)4.4Green74.4

2Delta window glassTempered glass2.8Green83

3Front door window glass3.1Green (UV shield glass)75

4Rear door window glass3.1Green (UV shield glass)75

Dark grey (privacy glass)25

5Quarter window glass2.8Green83

Dark grey (privacy glass)28

6Tailgate window glass3.1Green83

Dark grey (privacy glass)25

7Sunroof lid glass4.0Dark grey10

NO

TE: The visible ray transmissivity ra t e (%) is a re ference va lue.

Page 163 of 364

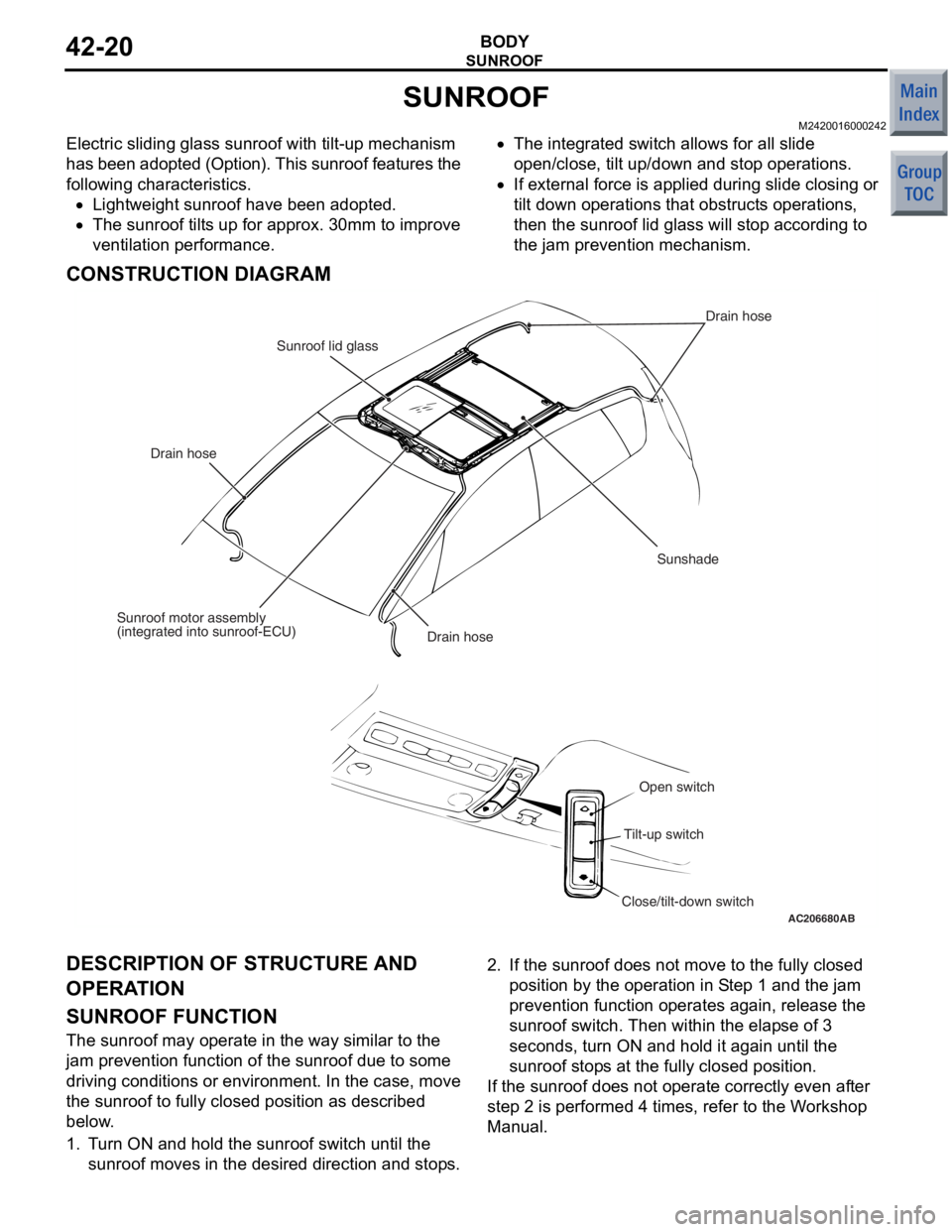

SUNROOF

BODY42-20

SUNROOF

M2420016000242

Electric sliding glass sunroof with tilt-up mechanism

has been adopted (Option). This sunroof features the

following characteristics.

•Lightweight sunroof have been adopted.

•The sunroof tilts up for approx. 30mm to improve

ventilation performance.

•The integrated switch allows for all slide

open/close, tilt up/down and stop operations.

•If external force is applied during slide closing or

tilt down operations that obstructs operations,

then the sunroof lid glass will stop according to

the jam prevention mechanism.

CONSTRUCTION DIAGRAM

AC206680 AB

Sunroof lid glass Drain hose

Drain hose

Sunroof motor assembly

(integrated into sunroof-ECU) Sunshade

Open switch

Tilt-up switch

Close/tilt-down switch

Drain hose

DESCRIPTION OF

STRUCTURE AND

OPERA

T ION

SUNROOF FUNCTION

The sunroof may operat e in the way similar to th e

jam preve

n tion function of the sunro o f due to so me

driving condition

s or environment. In the case, move

the sunroof t

o fully closed po sit i on a s described

below

.

1.T u rn ON and hold the sunroo f switch un til t he

sunroo f moves in the desired d i rection and stop s.

2.If the sunroof does not move to the fully closed

p o sit i on b y the operat ion in S t ep 1 and the jam

p r even tion f unction op erat es again, release the

sunroo f switch. Th en within the elap se of 3

seco nds, turn ON and ho ld it again until th e

sunroo f stop s at the fully closed position.

If the sunroof does not o perate corre ctly even af ter

step

2 is performed 4 times, re fer to th e W o rksh op

Manu

al.