OBD port MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 151 of 408

.

4-8 DRIVEABILITYAND EMISSIONS CONTROLS

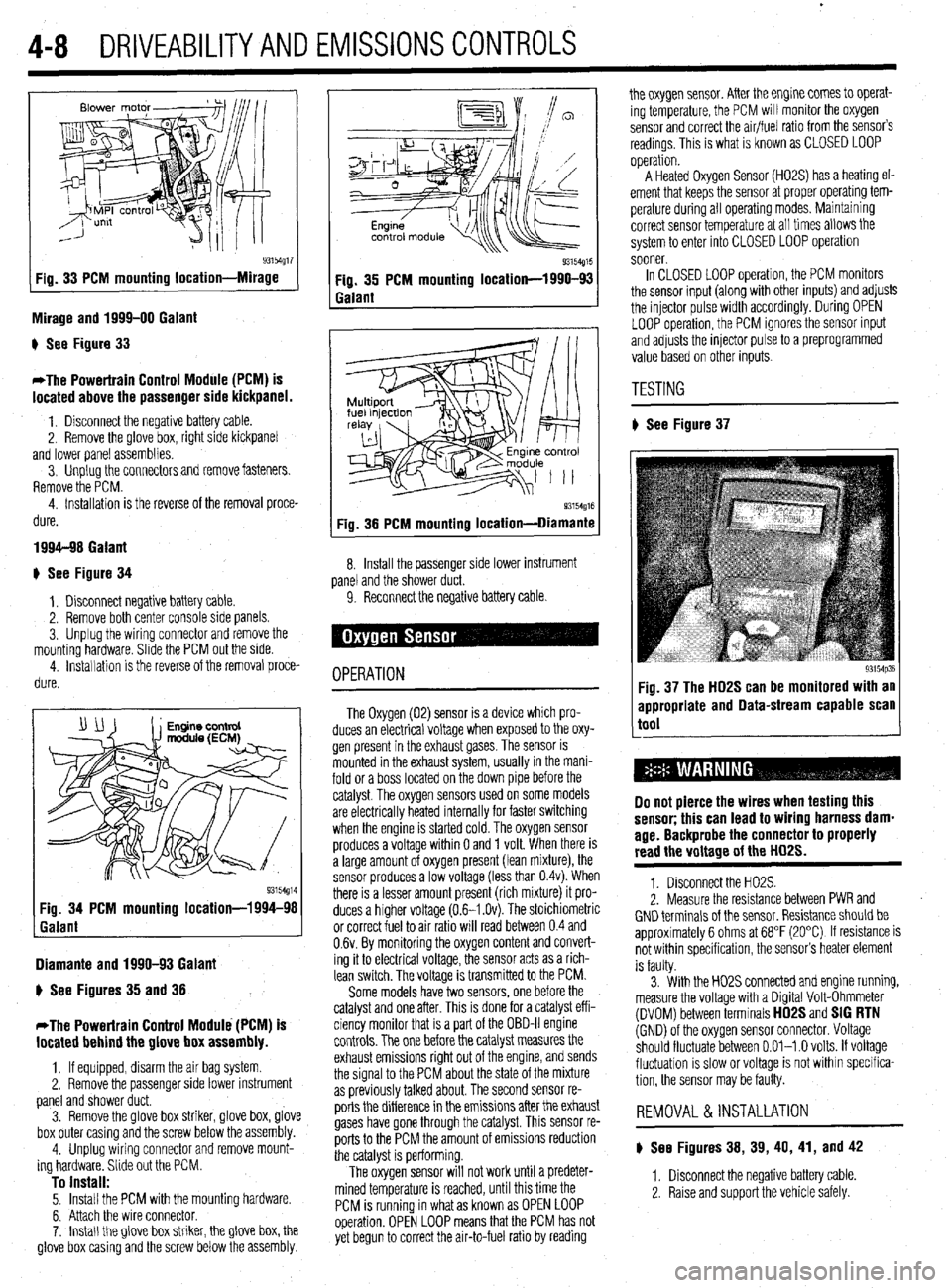

93154g17 Fig. 33 PCM mounting location-Mirage

Mirage and 1999-00 Galant

) See Figure 33

*The Powertrain Control Module (PCM) is

located above the passenger side kickpanel.

1. Disconnect the negative battery cable.

2. Remove the @love box, right side kickpanel

and lower panel assemblies.

3. Unplug the connectors and remove fasteners.

Remove the PCM.

4. Installation is the reverse of the removal proce-

dure.

1994-98 Galant

+ See Figure 34

1, Disconnect negative battery cable.

2. Remove both center console side panels.

3. Unplug the wiring connector and remove the

mounting hardware. Slide the PCM out the side.

4. installation is the reverse of the removal proce-

dure.

Diamante and 1990-93 Galant

) See Figures 35 and 38

*The Powertrain Control Module (PCM) is

located behind the glove box assembly.

1, If equipped, disarm the air bag system

2. Remove the passenger side lower instrument

panel and shower duct.

3. Remove the glove box striker, glove box, glove

box outer casing and the screw below the assembly.

4. Unplug wiring connector and remove mount-

ing hardware. Slide out the PCM.

To install: 5. Install the PCM with the mounting hardware.

6. Attach the wire connector.

7. Install the glove box striker, the glove box, the

glove box casing and the screw below the assembly.

Q3154g15 Fig. 35 PCM mounting location-1990-93

Galant

93154g16 Fig. 38 PCM mounting location-Diamante

8. Install the passenger side lower instrument

panel and the shower duct.

9. Reconnect the negative battery cable

OPERATION

The Oxygen (02) sensor is a device which pro-

duces an electrical voltage when exposed to the oxy-

gen present in the exhaust gases. The sensor is

mounted in the exhaust system, usually in the mani-

fold or a boss located on the down pipe before the

catalyst. The oxygen sensors used on some models

are electrically heated internally for faster switching

when the engine is started cold. The oxygen sensor

produces a voltage within 0 and 1 volt. When there is

a large amount of oxygen present (lean mixture), the

sensor produces a low voltage (less than 0.4~). When

there is a lesser amount present (rich mixture) it pro-

duces a higher voltage (0.6-I .Ov). The stoichiometric

or correct fuel to air ratio will read between 0.4 and

0.6~. By monitoring the oxygen content and convert-

ing it to electrical voltage, the sensor acts as a rich-

lean switch. The voltage is transmitted to the PCM.

Some models have two sensors, one before the

catalyst and one after. This is done for a catalyst eff i-

ciency monitor that is a part of the OBD-II engine

controls. The one before the catalyst measures the

exhaust emissions right out of the engine, and sends

the signal to the PCM about the state of the mixture

as previously talked about. The second sensor re-

ports the difference in the emissions after the exhaust

gases have gone through the catalyst. This sensor re-

ports to the PCM the amount of emissions reduction

the catalyst is performing.

The oxygen sensor will not work until a predeter-

mined temperature is reached, until this time the

PCM is running in what as known as OPEN LOOP

operation. OPEN LOOP means that the PCM has not

yet begun to correct the air-to-fuel ratio by reading the oxygen sensor. After the engine comes to operat-

ing temperature, the PCM will monitor the oxygen

sensor and correct the air/fuel ratio from the sensor’s

readings. This is what is known as CLOSED LOOP

operation.

A Heated Oxygen Sensor (H02S) has a heating el-

ement that keeps the sensor at proper operatmg tem-

perature during all operating modes. Maintaining

correct sensor temperature at all times allows the

system to enter into CLOSED LOOP operation

sooner.

In CLOSED LOOP operation, the PCM monitors

the sensor input (along with other inputs) and adjusts

the injector pulse width accordingly. During OPEN

LOOP operation, the PCM ignores the sensor input

and adjusts the injector pulse to a preprogrammed

value based on other inputs.

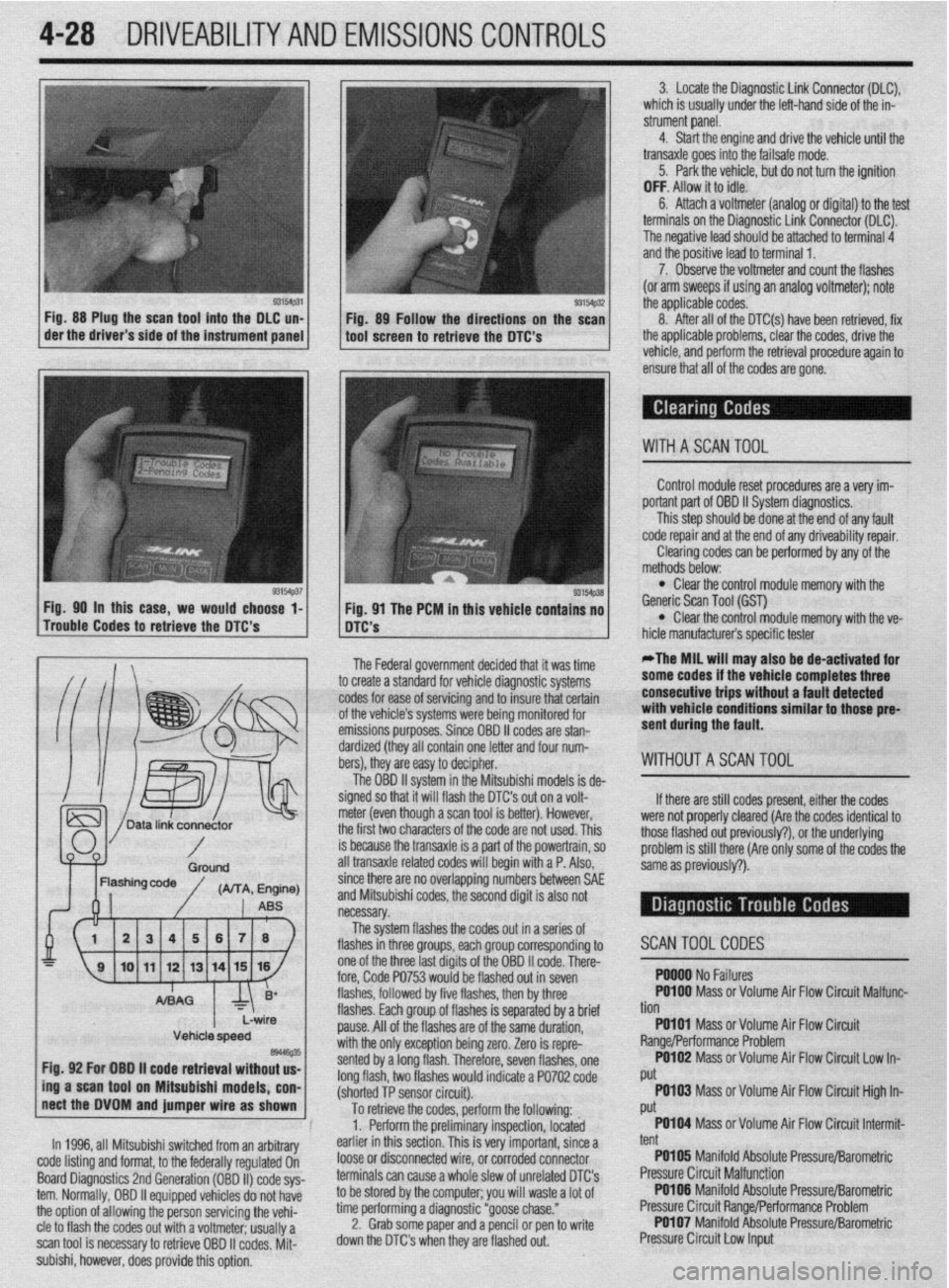

TESTING

# See Figure 37

93154p36 Fig. 37 The HD2S can be monitored with an

appropriate and Data-stream capable scan

tool

Do not pierce the wires when testing this

sensor; this can lead to wiring harness dam-

age. Backprobe the connector to properly

read the voltage of the HD2S.

1. Disconnect the H02S.

2. Measure the resistance between PWR and

GND terminals of the sensor. Resistance should be

approximately 6 ohms at 68°F (20°C) If resistance is

not within specification, the sensor’s heater element

is faulty.

3. With the H02S connected and engine running,

measure the voltage with a Digital Volt-Ohmmeter

(DVOM) between terminals

HD2S and SIG RTN (GND) of the oxygen sensor connector. Voltage

should fluctuate between 0.01-l .O volts. If voltage

fluctuation is slow or voltage is not within specifica-

tion, the sensor may be faulty.

REMOVAL &INSTALLATION

) See Figures 38, 39, 40, 41, and 42

1. Disconnect the negative battery cable

2. Raise and support the vehicle safely.

Page 171 of 408

4-28 DRIVEABILITYAND EMISSIONS CONTROLS

Fig. 88 Plug the scan tool into the DLC un-

Fig. 89 Follow the directions on the scan

der the driver’s side of the instrument panel

tool screen to retrieve the DTC’s 3. Locate the Diagnostic Link Connector (DLC),

which is usually under the left-hand side of the in-

strument panel.

4. Start the engine and drive the vehicle until the

transaxle goes into the failsafe mode.

5. Park the vehicle, but do not turn the ignition

OFF. Allow it to idle.

6. Attach a voltmeter (analog or digital) to the test

terminals on the Diagnostic Link Connector (DLC).

The negative lead should be attached to terminal 4

and the positive lead to terminal 1.

7. Observe the voltmeter and count the flashes

(or arm sweeps if using an analog voltmeter); note

the applicable codes.

- 8. After all of the DTC(s) have been retrieved, fix

the applicable problems, clear the codes, drive the

vehicle, and perform the retrieval procedure again to

ensure that all of the codes are gone.

WITHASCANTOOL

Control module reset procedures are a very im-

portant part of OBD II System diaqnostics.

This step should be done at the end of any fault

code repair and at the end of any driveability repair.

Clearing codes can be performed by any of the

Fig. 90 in this case, we would choor- A ’ ma*-. . . * .

Trouble Codes to retrieve the DTC’s

-.- -

A mere mar

. . methods below: l Clear the control module memory with the

se l-

I I ng. vi me rtim In mts venicie contains no Generic Scan Tool (GST) l DTC’S Clear the control module memory with the ve-

L’-‘m iufacturer’s specific tester

The Federal government decided that it was time

to create a standard for vehicle diagnostic systems

codes for ease of servicing and to insure that certain

of the vehicle’s systems were being monitored for

emissions purposes. Since OBD II codes are stan-

dardized (they all contain one letter and four num-

bers), they are easy to decipher.

The OBD II system in the Mitsubishi models is de-

signed so that it will flash the DTC’s out on a volt-

meter (even though a scan tool is better). However,

the first two characters of the code are not used. This

is because the transaxle is a part of the powertrain, so

all transaxle related codes will begin with a P. Also, *The MIL will may also be de-activated for

some codes if the vehicle completes three

consecutive trips without a fault detected

with vehicle conditions similar to those pre-

sent during the fault.

WITHOUTASCAN TOOL

If there are still codes p

resent, either the codes

were not properly cleared f

:Are the codes identical to

those flashed out previous

I$‘), or the underlying

problem is still there (Are I

only some of the codes the

same as oreviouslv?).

since there are no overlapping numbers between SAE

and Mitsubishi codes, the second digit is also not

necessary.

The system flashes the codes o

ut ma series of

flashes in

three nmm mh nrnlll -- J.-lr-, ---.. ~.--

p corresponding to

one of the

three last diaits of the OBD II code. There-

fore, Code WJJ wuuw UC:

IIKWAJ WI III XVWI flashes, followed by five flashes, then by three

flashes. Each group of flashes is se

pause. All of the flashes are of the (

witi the or$, nvrontinn hoinn mm sented by z

long flash,

(shorted Tt SWIWI LIIW. rparated by a brief

;ame duration,

88, “rw”I.‘L’“‘I uv,,,y LUI”.

Zero is repre-

1 long flash. Therefore, seven flashes, one

two flashes would indicate a PO702 code

3 nnmn^r ,.:*....:I I r

SCANTOOLCODES

. YYY” I ‘I” I cuI”I”.J PO100 Mass or Volume Air Flow Circuit Malfunc-

Lb

non

PO101 Mass orVolume Air Flow Circuit

Range/Performance Problem

PO102 Mass or Volume Air Flow Circuit Low In-

Put

.

To retrieve the codes, perform the following: PO103 Mass or Volume Air Flow Circuit High In-

i Put

1. Perform the preliminary inspection, located PO104 Mass or Volume Air Flow Circuit Intermit-

-;

Vehicle speed es446e35 Fig. 92 For OBO ii code retrieval without us-

ing a scan tool on Mitsubishi models, con-

nect the DVOM and jumper wire as shown

In 1996, all Mitsubishi switched from an arbitrary

code listing and format, to the federally regulated On

Board Diagnostics 2nd Generation (OBD II) code sys-

tern. Normally, OBD II equipped vehicles do not have

the option of allowing the person servicing the vehi-

cle to flash the codes out with a voltmeter; usually a

scan tool is necessary to retrieve OBD II codes. Mit-

subishi, however, does provide this option, earlier in this section. This is very important, since a

loose or disconnected wire, or corroded connector

terminals can cause a whole slew of unrelated DTC’s

to be stored by the computer; you will waste a lot of

time performing a diagnostic “goose chase.”

2. Grab some paper and a pencil or pen to write

down the DTC’s when they are flashed out. tent

PO105 Manifold Absolute Pressure/Barometric

Pressure Circuit Malfunction

PO106 Manifold Absolute Pressure/Barometric

Pressure Circuit Range/Performance Problem

PO107 Manifold Absolute Pressure/Barometric

Pressure Circuit Low Input

Page 406 of 408

l

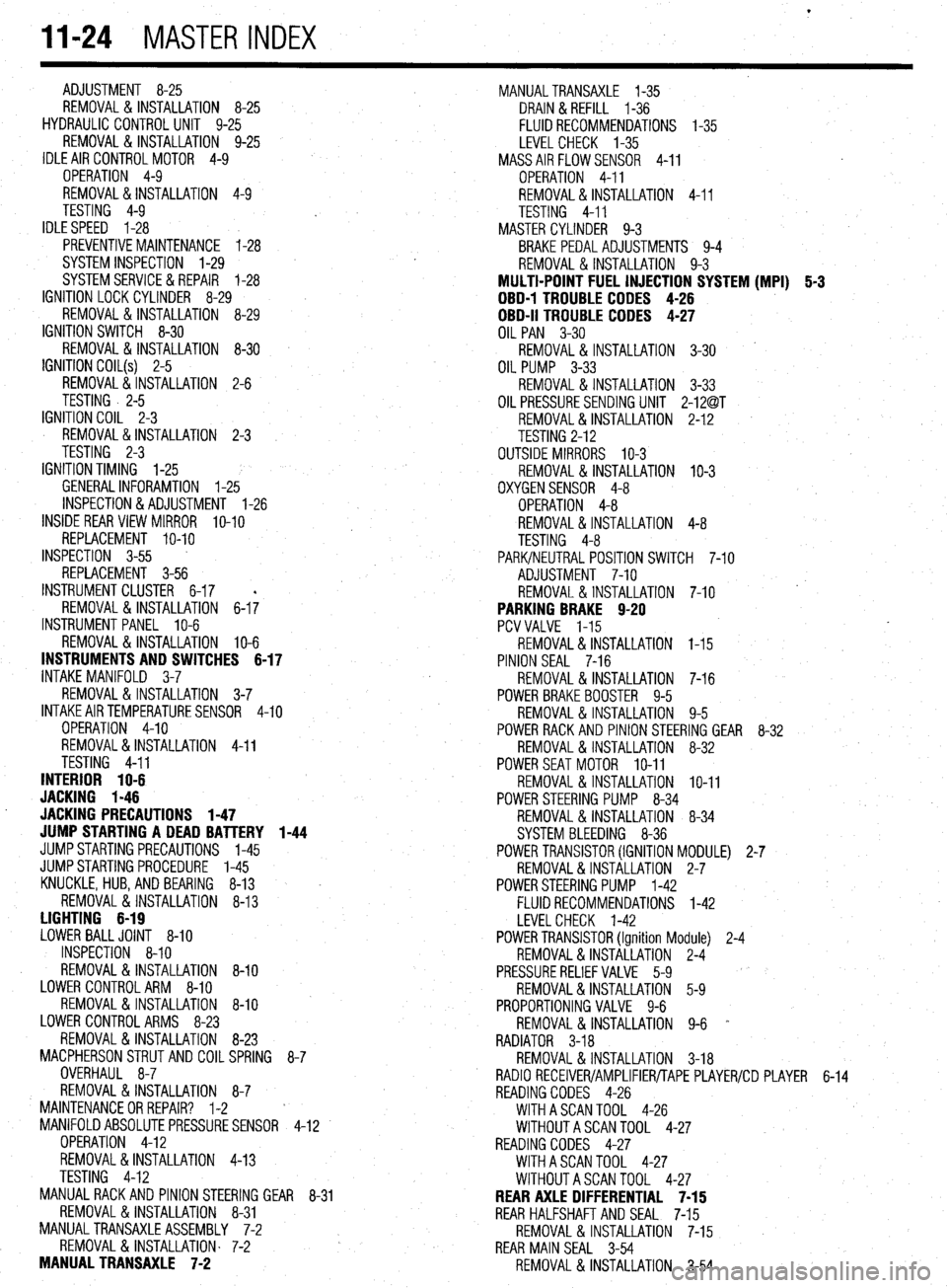

II-24 MASTER INDEX

ADJUSTMENT 8-25

REMOVAL &INSTALLATION 8-25

HYDRAULIC CONTROL UNIT 9-25

REMOVAL & INSTALLATION 9-25

IDLE AIR CONTROLMOTOR 4-9

OPERATION 4-9

REMOVAL&INSTALLATION 4-9

TESTING 4-9

IDLESPEED 1-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION 1-29

SYSTEMSERVlCE&REPAlR 1-28

IGNITION LOCK CYLINDER 8-29

REMOVAL & INSTALLATION 8-29

IGNITION SWITCH 8-30

REMOVAL & INSTALLATION 8-30

IGNITION COIL(s) 2-5

REMOVAL&INSTALLATION 2-6

TESTING . 2-5

IGNITION COIL 2-3

REMOVAL&INSTALLATION 2-3

TESTING 2-3

IGNITION TIMING l-25

GENERALINFORAMTION l-25

INSPECTION&ADJUSTMENT l-26

INSIDE REAR VIEW MIRROR

IO-IO

REPLACEMENT IO-IO

INSPECTION 3-55

REPLACEMENT 3-56

INSTRUMENT CLUSTER 6-17

REMOVAL&INSTALLATION 6-I;

INSTRUMENTPANEL IO-6

REMOVAL &INSTALLATION IO-6

INSTRUMENTS AND SWITCHES 6-17

INTAKE MANIFOLD 3-7

REMOVAL &INSTALLATION 3-7

INTAKEAIRTEMPERATURESENSOR 4-10

OPERATION 4-10

REMOVAL&INSTALLATION 4-11

TESTING 4-11

INTERIOR 1 O-6

JACKING I-46

. JACKING PRECAUTIONS 1-47

JUMP STARTING A DEAD BATTERY 1-44

JUMPSTARTING PRECAUTIONS l-45

JUMPSTARTING PROCEDURE l-45

KNUCKLE,HUB, AND BEARING 8-13

REMOVAL &INSTALLATION 8-13

LIGHTING 6-19

LOWER BALLJOINT 8-10

INSPECTION 8-10

REMOVAL & INSTALLATION 8-10

LOWER CONTROLARM 8-10

REMOVAL&INSTALLATION 8-10

LOWER CONTROL ARMS 8-23

REMOVAL & INSTALLATION 8-23

MACPHERSONSTRUTAND COILSPRING

8-7

OVERHAUL 8-7

REMOVAL & INSTALLATION 8-7

MAINTENANCEORREPAIR? l-2

MANIFOLDABSOLUTEPRESSURESENSOR

4-12

OPERATION 4-12

REMOVAL&INSTALLATION 4-13

TESTING 4-12

MANUAL RACK AND PINION STEERING GEAR

8-31

REMOVAL & INSTALLATION 8-31

MANUALTRANSAXLEASSEMBLY 7-2

REMOVAL & INSTALLATION. 7-2

MANUAL TRANSAXLE 7-2 MANUALTRANSAXLE l-35

DRAIN &REFILL l-36

FLUID RECOMMENDATIONS l-35

LEVEL CHECK l-35

MASSAIRFLOWSENSOR 4-11

OPERATION 4-11

REMOVAL&INSTALLATION 4-11

TESTING 4-11

MASTER CYLINDER 9-3

BRAKE PEDALADJUSTMENTS 9-4

REMOVAL & INSTALLATION 9-3

MULTI-POINT FUEL INJECTION SYSTEM (MPI) 5-3

DBD-1 TROUBLE CODES 4-26

OBD-II TROUBLE CODES 4-27

OIL PAN 3-30

REMOVAL & INSTALLATION 3-30

OIL PUMP 3-33

REMOVAL & INSTALLATION 3-33

OIL PRESSURESENDING UNIT 2-12@T

REMOVAL&INSTALLATION 2-1.2

TESTING 2-12

OUTSIDE MIRRORS IO-3

REMOVAL&INSTALLATION IO-3

OXYGENSENSOR 4-8

OPERATION 4-8

REMOVAL&INSTALLATION 4-8

TESTING 4-8

PARK/NEUTRAL POSITIONSWITCH 7-10

ADJUSTMENT 7-10

REMOVAL & INSTALLATION 7-10

PARKING BRAKE 9-20

PCVVALVE l-15

REMOVAL&INSTALLATION I-15

PINION SEAL 7-16

REMOVAL &INSTALLATION 7-16

POWER BRAKEBOOSTER 9-5

REMOVAL &INSTALLATION 9-5

POWER RACK AND PINION STEERING GEAR 8-32

REMOVAL &INSTALLATION 8-32

POWERSEATMOTOR IO-11

REMOVAL & INSTALLATION IO-11

POWER STEERING PUMP 8-34

REMOVAL & INSTALLATION 8-34

SYSTEM BLEEDING 8-36

POWER TRANSlSTOR(IGNITION MODULE) 2-7

REMOVAL&INSTALLATION 2-7

POWERSTEERING PUMP l-42

FLUID RECOMMENDATIONS l-42

LEVELCHECK l-42

POWER TRANSlSTOR(Ignition Module) 2-4

REMOVAL&INSTALLATION 2-4

PRESSURERELIEFVALVE 5-9

REMOVAL&INSTALLATION 5-9

PROPORTIONING VALVE 9-6

REMOVAL & INSTALLATION 9-6 *

RADIATOR 3-18

REMOVAL &INSTALLATION 3-18

RADIO RECEIVER/AMPLIFIER/TAPE PLAYER/CD PLAYER 6-14

READING CODES 4-26

WITHASCANTOOL 4-26

WITHOUTASCANTOOL 4-27

READING CODES 4-27

WITHASCANTOOL 4-27

WITHOUTASCANTOOL 4-27

REAR AXLE DIFFERENTIAL 7-15

REAR HALFSHAFTAND SEAL 7-15

REMOVAL&INSTALLATION 7-15

REAR MAIN SEAL 3-54

REMOVAL & INSTALLATION 3-54