coolant capacity MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 40 of 408

.

GENERALINFORMATIONAND MAINTENANCE l-41

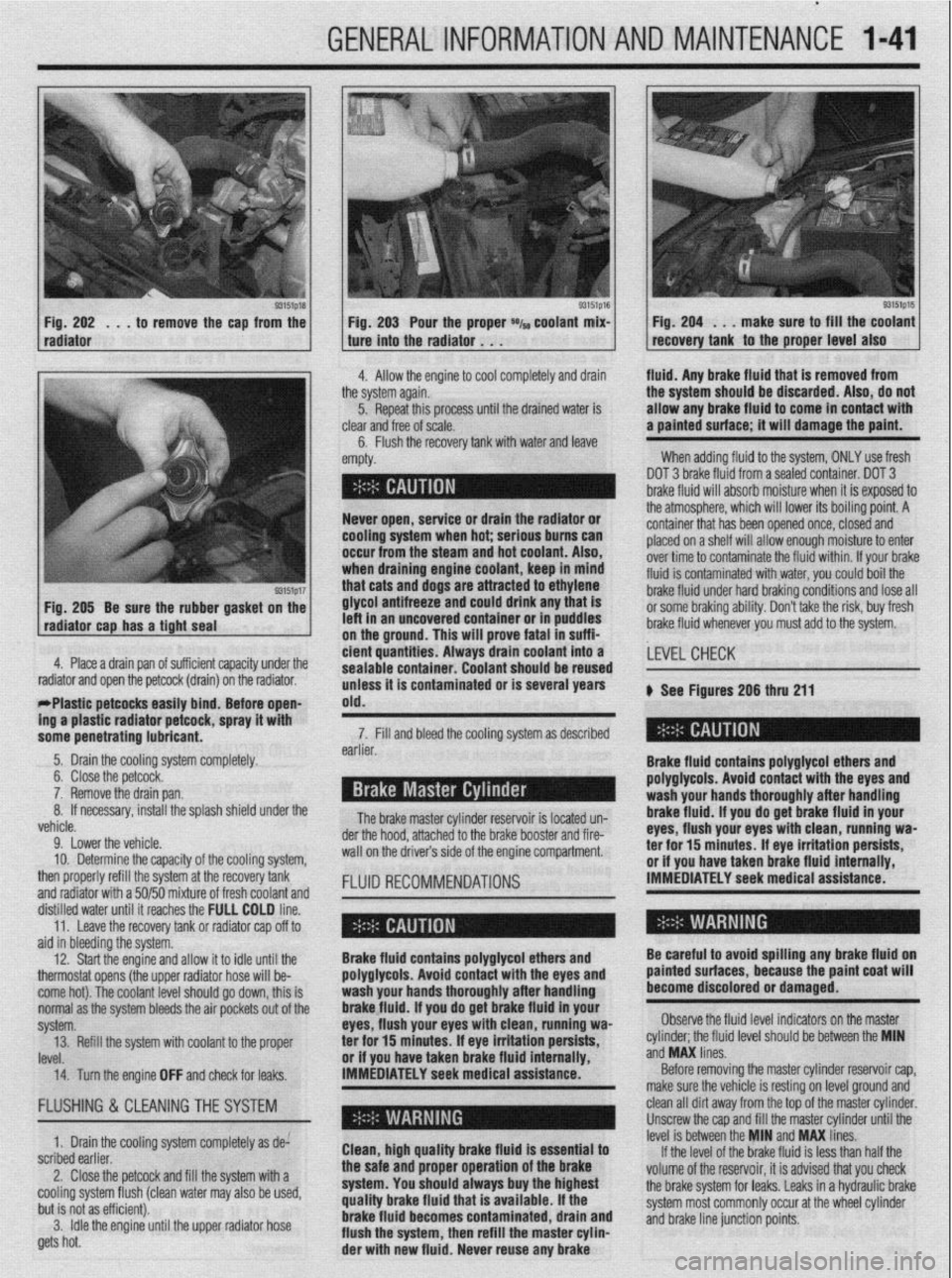

93151p18 Fig. 202 . , . to remove the cap from the

radiator

93151p17 Fig. 205 Be sure the rubber gasket on the

radiator cap has a tight seal e Fig. 203 Pour the proper *I~ coolant mix- 1 Fig. 204 . . . make sure to fill the coolant

recovery tank to the proper level also ture into the radiator . . .

.I

4. Allow the engine to cool completely and drain fluid. Any brake fluid that is removed from

ie system again.

5. Repeat this processuntil the drained water is

lear

and free of scale.

6. Flush the recovery tank with water and leave ’

mpty. the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a painted surface; it will damage the paint.

When adding fluid to the system, ONLY use fresh

DOT 3 brake fluid from a sealed container. DOT 3

brake fluid will absorb moisture when it is exposed to

.a . . . , .*a. . . * .*. . .

- Never open, service or drain the radiator or

cooling system when hot; serious bums can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep In mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

4. Place a drain pan of suff i ’ 1 . . . ..I .I. 1,~ cient quantities. Always tne atmospnere, wnrcn wnr rower 1r.s oourng pomr. A

container that has been opened once, closed and

placed on a shelf will allow enough moisture to enter

over time to contaminate the fluid within. If your brake

fluid is contaminated with water, you could boil the

brake fluid under hard braking conditions and lose all

or some braking ability. Don’t take the risk, buy fresh

brake fluid whenever you must add to the system.

crenr capacrry unaer me

drain) on the radiator.

rrrasuc perwcss easuy bind; Before open-

ing a plastic radiator petcock, spray it with

some penetrating lubricant. drain coolant into a

earner. sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

The brake master cylinder ~a~~~~r,~~ :A I~nnL.4 n-n 7. Fill and bleed the cooling system as described

Brake fluid contains polyglycol ethers and

polyglycols. Avoid contact with the eyes and ,LEVEL CHECK

wash your hands thoroughly after handling

brake fluid. If vou do oet brake fluid in vour

eyes, flush your eyeswith clean, runniug wa-

a-.. ‘Y-- ar -l-..n-- II -.._ I____ k See Figures 206 thru 211

.a-11-- - __-PA._ radiator and open the petcock (

- w&1--x3_ --mm.._..- . . ..-I...

5. Drain the cooling system completely.

6. Close the petcock.

7. Remove the drain pan.

If necessary, install the splash shield under the 8.

L.-l

venicie.

9. Lower the vehicle.

10. Determine the capacity of the cooling system,

then properly refill the system at the recovery tank

and radiator with a 50/50 mixture of fresh coolant and

fKm”“ll 15 IUMLC” “II- brake booster and fire- der the hood, attached to the

wall on the drivers side of the engine compartment.

FLUID RECOMMENDATIONS rer mr 13 mmures. IT eye irriIauon persim, or if you have taken brake fluid internally,

IMMEDIATELY seek medical assistance.

ala in oreerring me sysrem.

12. Start the engine and allow it to idle until the

thermostat opens (the upper radiator hose will be-

come hot). The coolant level should go down, this is

normal as the system bleeds the air pockets out of the

svstem.

IRVf!l ._._. 14. Turn the engine OFF and check for leaks. IMMEDIATELY seek medical assistance.” Brake fluid contains polyglycol ethers and

polyglycols. Avoid contact with the eyes and

wash your hands thoroughly after handling

brakefluid. If you do get brake fluid in your

eyes, flush your eyes with clean, running wa-

or if vou have taken brake fluid internallv.

Before removing the master cylinder reservoir cap,

make sure the vehicle is resting on level ground and Be careful to avoid spilling any brake fluid on

painted surfaces, because the paint coat will

become discolored or damaged.

Observe the fluid level indicators on the master

._ ._ __

‘eve1 should be between the MIN

ano

ivw unes. 13. Refill the system with coolant to the proper ter for 15 minutes; If eye irritation persists, cylinder; the tluld II

..J ..I” I....

FLUSHING & CLEANINGTHE SYSTEM

1. Drain the cooling system completely as de:

scribed earlier.

2. Close the petcock and fill the system with a

cooling system flush (clean water may also be used,

but is not as efficient).

3. Idle the engine until the upper radiator hose

gets hot. Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake clean all dirt away from the top of the master cylinder.

Unscrew the cap and fill the master cylinder until the

level is between the MIN and MAX lines.

If the level of the brake fluid is less than half the

volume of the reservoir, it is advised that you check

the brake system for leaks. Leaks in a hydraulic brake

system most commonly occur at the wheel cylinder

and brake line junction points.

Page 390 of 408

11-8 TROUBLESHOOTING

Ignition systems may be controlled by, or linked to, the engine fuel management sys-

tem. Similar to the fuel injection system, these ignition systems rely on electronic sen-

sors for information to determine the optimum ignition timing for a given engine speed

and load. Some ignition systems no longer allow the ignition timing to be adjusted.

Feedback from low voltage electrical sensors provide information to the control unit to

determine the amount of ignition advance. On these systems, if a failure occurs the failed

component must be replaced. Before replacing suspected failed electrical components,

carefully inspect the wiring and electrical connectors to the related components. Make

sure the electrical connectors are fully connected, clean and not physically damaged. If

necessary, clean the electrical contacts using electrical contact cleaner. The use of clean-

ing agents not specifically designed for electrical contacts should be avoided, as they

could leave a surface film or damage the insulation of the wiring.

1. Engine makes a knocking or pinging noise when accelerating

a. Check the octane rating of the fuel being used. Depending on the type of driving or

driving conditions, it may be necessary to use a higher octane fuel.

b. Verify the ignition system settings and operation. Improperly adjusted ignition timing

or a failed component, such as a knock sensor, may cause the ignition timing to ad-

vance excessively or prematurely. Check the ignition system operation and adjust, or

replace components as needed.

c. Check the spark plug gap, heat range and condition. If the vehicle is operated in se-

vere operating conditions or at continuous high speeds, use a colder heat range spark

plug. Adjust the spark plug gap to the manufacturer’s recommended specification and

replace worn or damaged spark plugs.

2. Sfarter motor grinds when used

a. Examine the starter pinion gear and the engine ring gear for damage, and replace dam-

aged parts.

b. Check the starter mounting bolts and housing. If the housing is cracked or damaged

replace the starter motor and check the mounting bolts for tightness.

3. Engine makes a screeching noise

a. Check the accessory drive belts for looseness and adjust as necessary.

b. Check the accessory drive belt tensioners for seizing or excessive bearing noises and

replace if loose, binding, or excessively noisy.

c. Check for a seizing water pump. The pump may not be leaking; however, the bearing

may be faulty or the impeller loose and jammed. Replace the water pump.

4. Engine makes a growling noise

a. Check for a loose or failing water pump. Replace the pump and engine coolant.

b. Check the accessory drive belt tensioners for excessive bearing noises and replace if

loose or excessively noisy.

5. Engine makes a ticking or tapping noise

a. On vehicles with hydraulic lash adjusters, check for low or dirty engine oil and top off

or replace the engine oil and filter.

b. On vehicles with hydraulic lash adjusters, check for collapsed lifters and replace failed

components.

c. On vehicles with hydraulic lash adjusters, check for low oil pressure caused by a re-

stricted oil filter, worn engine oil pump, or oil pressure relief valve.

d. On vehicles with manually adjusted valves, check for excessive valve clearance or

worn valve train parts. Adjust the valves to specification or replace worn and defective

parts.

e. Check for a loose or improperly tensioned timing belt or timing chain and adjust or re-

place parts as necessary.

f. Check for a bent or sticking exhaust or intake valve. Remove the engine cylinder head

to access and replace.

6. Engine makes a heavy knocking noise

a. Check for a loose crankshaft pulley or flywheel; replace and torque the mounting

bolt(s) to specification.

b. Check for a bent connecting rod caused by a hydro-lock condition. Engine disassem-

bly is necessary to inspect for damaged and needed replacement parts.

c. Check for excessive engine rod bearing wear or damage. This condition is also asso-

ciated with low engine oil pressure and will require engine disassembly to inspect for

damaged and needed replacement parts,

7. Vehicle has a fuel odor when driven ’ a. Check the fuel gauge level. If the fuel gauge registers full, it is possible that the odor is

caused by being filled beyond capacity, or some spillage occurred during refueling.

The odor should clear after driving an hour, or twenty miles, allowing the vapor canis-

ter to purge.

b. Check the fuel filler cap for looseness or seepage. Check the cap tightness and, if

loose, properly secure. If seepage is noted, replace the filler cap.

c. Check for loose hose clamps, cracked or damaged fuel delivery and return lines, or

leaking components or seals, and replace or repair as necessary. d. Check the vehicle’s fuel economy. If fuel consumption has increased due to a failed

component, or if the fuel is not properly ignited due to an ignition related failure, the

catalytic converter may become contaminated. This condition may also trigger the

check engine warning light. Check the spark plugs for a dark, rich condition or verify

the condition by testing the vehicle’s emissions. Replace fuel fouled spark plugs, and

test and replace failed components as necessary.

5. Vehicle has a rotten egg odor when driven

a. Check for a leaking intake gasket or vacuum leak causing a lean running condition. A

lean mixture may result in increased exhaust temperatures, causing the catalytic con-

verter to run hotter than normal. This condition may also trigger the check engine

warning light. Check and repair the vacuum leaks as necessary.

b. Check the vehicle’s alternator and battery condition. If the alternator is overcharging,

the battery electrolyte can be boiled from the battery, and the battery casing may begin

to crack, swell or bulge, damaging or shorting the battery internally. If this has oc-

curred, neutralize the battery mounting area with a suitable baking soda and water

mixture or equivalent, and replace the alternator or voltage regulator. Inspect, service,

and load test the battery, and replace if necessary.

9. Vehicle has a sweet odor when driven

a. Check for an engine coolant leak caused by a seeping radiator cap, loose hose clamp,

weeping cooling system seal, gasket or cooling system hose and replace or repair as

needed.

b. Check for a coolant leak from the radiator, coolant reservoir, heater control valve or

under the dashboard from the heater core, and replace the failed part as necessary.

c. Check the engine’s exhaust for white smoke in addition to a sweet odor. The presence

of white, steamy smoke with a sweet odor indicates coolant leaking into the combus-

tion chamber. Possible causes include a failed head gasket, cracked engine block or

cylinder head. Other symptoms of this condition include a white paste build-up on the

inside of the oil filler cap, and softened, deformed or bulging radiator hoses.

19. Engine vibraies when idling

a. Check for loose, collapsed, or damaged engine or transmission mounts and repair or

replace as necessary.

b. Check for loose or damaged engine covers or shields and secure or replace as neces-

sary.

11. Engine vibrates during acceleration

a. Check for missing, loose or damaged exhaust system hangers and mounts; replace or

repair as necessary.

b. Check the exhaust system routing and fit for adequate clearance or potential rubbing;

repair or adjust as necessary.

7. Battery goes dead while driving

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test. If the battery loses fluid while driving, check for an overcharg-

ing condition. If the alternator is overcharging, replace the alternator or voltage regula-

tor. (A voltage regulator is typically built into the alternator, necessitating alternator re-

placement or overhaul.)

b. Check the battery cable condition. Clean or replace corroded cables and clean the bat-

tery terminals.

c. Check the alternator and voltage regulator operation. If the charging system is over or

undercharging, replace the alternator or voltage regulator, or both.

d. Inspect the wiring and wire connectors at the alternator for looseness, a missing .

ground or defective terminal, and repair as necessary.

e. Inspect the alternator drive belt tension, tensioners and condition. Properly tension the

drive belt, replace weak or broken tensioners, and replace the drive belt if worn or

cracked.

2. Battery goes dead overnight

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test.

b. Check for a voltage draw, such as a trunk light, interior light or glove box light staying

on. Check light switch position and operation, and replace if defective.

c. Check the alternator for an internally failed diode, and replace the alternator if defec-

tive.

1. Engine overheats

a. Check the coolant level. Set the heater temperature to full hot and check for internal air

pockets, bleed the cooling system and inspect for leakage. Top off the cooling system

with the correct coolant mixture.

b. Pressure test the cooling system and radiator cap for leaks. Check for seepage caused

by loose hose clamps, failed coolant hoses, and cooling system components such as

the heater control valve, heater core, radiator, radiator cap, and water pump. Replace

defective parts and fill the cooling system with the recommended coolant mixture.