jump cable MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 17 of 408

l

1-18 GENERALINFORMATIONAND MAINTENANCE

the clamps and remove the cables, negative cable

first. On batteries with posts on top, the use of a

puller specially made for this purpose is recom-

mended. These are inexoensive and available in most alternator or turn the adjusting bolt to adjust belt ten-

sion. Once the desired value is reached, secure the

bolt or locknut and recheck tension.

d”t” lJdlL> X”lt;>. 31°C LtXlllllldl lJdllt2)’ MLJIC, dlt’ X- cured with a small bolt. ST& I REMOVAL &INSTALLATION

Clean the cable clamps and the battery terminal I

with a wire brush, until all corrosion, grease, etc., is

removed and the metal is shinv. It is esneciallv imnnr-

tant to c

knife is useful nere), since a smart

material or oxidation there will pre Clean the cable clamps and the battery terminal

with a wire brush, until all corrosion, grease, etc., is

removed and the metal is shiny. It is especially impor-

tant to clean the inside of the clamp thoroughly (an old

knife is useful here), since a small deposit of foreign

material or oxidation there will prevent a sound electri-

cal connection and inhibit either starting or charging.

Special tools are available for cleaning these parts,

one type for conventional top post batteries and an-

other type for side terminal batteries. It is also a good

idea to apply some dielectric grease to the terminal, as

this will aid in the prevention of corrosion,

After the clamps and terminals are clean, reinstall

the cables, negative cable last; DO NOT hammer the

clamps onto battery posts. Tighten the clamps se-

curely, but do not distort them. Give the clamps and

terminals a thin external coating of grease after in-

stallation, to retard corrosion.

Check the cables at the same time that the terminals

are cleaned. If the cable insulation is cracked or bro-

ken, or if the ends are frayed, the cable should be re-

placed with a new cable of the same length and gauge.

CHARGING

the cables, negative cable last; DO NOT hammer the

curely, but do not distort them. Give the clamps and

terminals a thin external coating of grease after in-

stallation, to retard corrosion.

Check the cables at the same time that the terminals

are cleaned. If the cable insulation is cracked or bro-

ken, or if the ends are frayed, the cable should be re-

placed with a new cable of the same length and aauae.

CHARGING

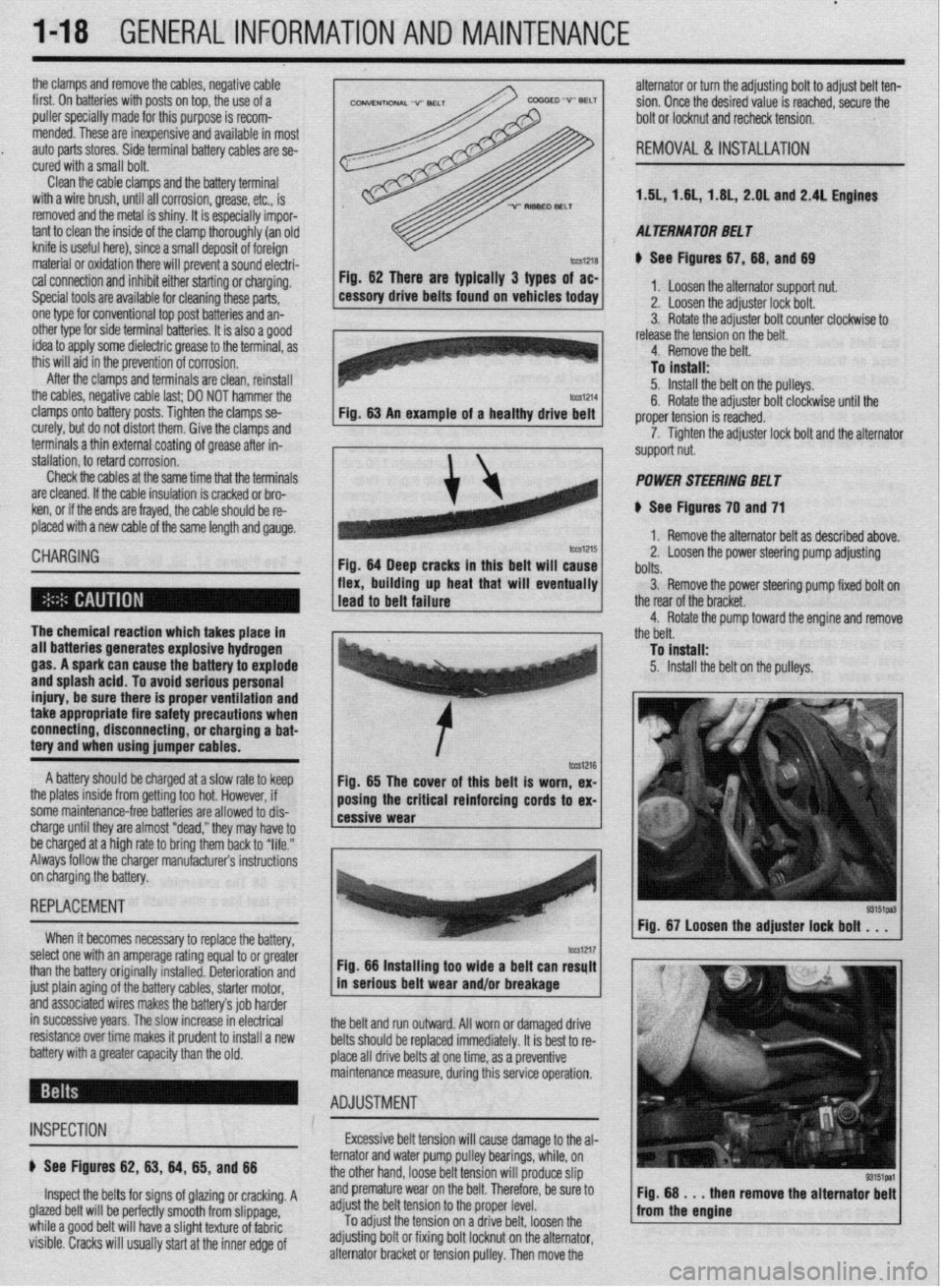

Fig. 62 mere are typically 3 types of ac-

cessory drive belts found on vehicles today 1. Loosen the alternator support nut.

2. Loosen the adjuster lock bolt.

3. Rotate the adjuster bolt counter clockwise to

I .I , . . . * . .

I Tn i”et*ll* Fig. 62 There are typically 3 types of ac-

Fig. 64 Deep cracks in this belt will cause

flex, building up heat that will eventually 11, 1.8L, 2.OL and 2.4L Engines

cal connection and inhibit either starting or charging.

Special tools are available for cleaning these parts,

one type for conventional top post batteries and an-

other type for side terminal batterin, I+ if QI@* 3 nnnd

idea to apply some dielectric grr

this will aid in the prevention of ,,vIIuaIUII.

After the clamps and terminals are clean, reinstall 1.5L, 1.6

AL TERNA TOR BE1 T

e See Figures 67,68, and 69

1. Loosen the alternator support nut.

2. Loosen the adjuster lock bolt.

3. Rotate the adjuster bolt counter clockwise to

release the tension on the belt.

4. Remove the belt.

To install:

5. Install the belt on the pulleys.

6. Rotate the adjuster bolt clockwise until the

proper tension is reached.

7. Tighten the adjuster lock bolt and the alternator

support nut.

POWER STEERING BELT

8 See Figures 70 and 71

1. Remove the alternator belt as described above.

2. Loosen the power steering pump adjusting

bolts.

3. Remove the power steering oumo fixed bolt on

R Rntatn the cxiillrtm hnit A&+,& until the r -r- .- .- ._.. ._ .______

7. Tighten the adjuster lock bolt and the alternator

support nut.

POWER STEERING BELT

1 ..“‘.I ““..Y...Y up II”“. ..IU. ..m.*

1 lead to belt failure V.

I

I

The chemical reaction which takes place in - 1 the rear of the bracket.

4. Rotate the pump toward the engine and remove

the belt.

all batteries generates explosive hydrogen

gas. A spark can cause the battery to explode

and splash acid. To avoid serious personal

injury, be sure there is proper ventilation and

take appropriate fire safety precautions when

connecting, disconnecting, or charging a bat-

tery and when using jumper cables. To fnstall:

5. Install the belt on the pulleys.

A battery should be charged at a slow rate to keep

the plates inside from getting too hot. However, if

some maintenance-free batteries are allowed to dis-

charge until they are almost “dead,” they may have to

be charged at a high rate to bring them back to “life.”

Always follow the charger manufacturers instructions

on charging the battery. 85 The cover of this belt ex-

Fig. is worn,

REPLACEMENT

When it becomes necessary to reolace thn haeoN

‘” yyL’“‘J’ I or oreMer

select one with an amperage rating equal tc .

a ----

than the battery originally installed. Deterioration and

just plain aging of the battery cables, starter motor,

and associated wires makes the battery’s job harder

in successive years. The slow increase in electrical

resistance over time makes it prudent to install a new

battery with a greater capacity than the old. 1 Fig. 67 Loosen the adjuster lock bolt . . .

I ‘-

I -. -_ tm1217 Fig. 66 Installing too wide a belt can resylt

in serious belt wear and/or breakage

the belt and run outward. All worn or damaged drive

belts should be replaced immediately. It is best to re-

place all drive belts at one time, as a preventive

uring this service operation. maintenance measure, d

- ADJUSTMENT : *

INSPECTION Excessive belt tension will cause damage to the al-

e See Figures 62, 83, 64, 65, and 88

Inspect the belts for signs of glazing or cracking. A

glazed belt will be perfectly smooth from slippage,

while a good belt will have a slight texture of fabric

visible. Cracks will usually start at the inner edge of pulley bearings, while, on

It tension will

Droduce slin ternator and water pump

the other hand, loose be

r ------ r

and premature wear on the belt. Therefore, be sure to

adjust the belt tension to the proper level.

To

adjust the tension ’ ’ ’ ” ’ ‘* adjusting bolt or fixing b

alternator bracket or tens on a onve Den. loosen me I Fig. 68 . . . then

from the engine remove the alternator

bolt locknut on the alternator,

iion pulley. Then move the

Page 22 of 408

t

GENERALINFORMATIONAND MAINTENANCE l-23

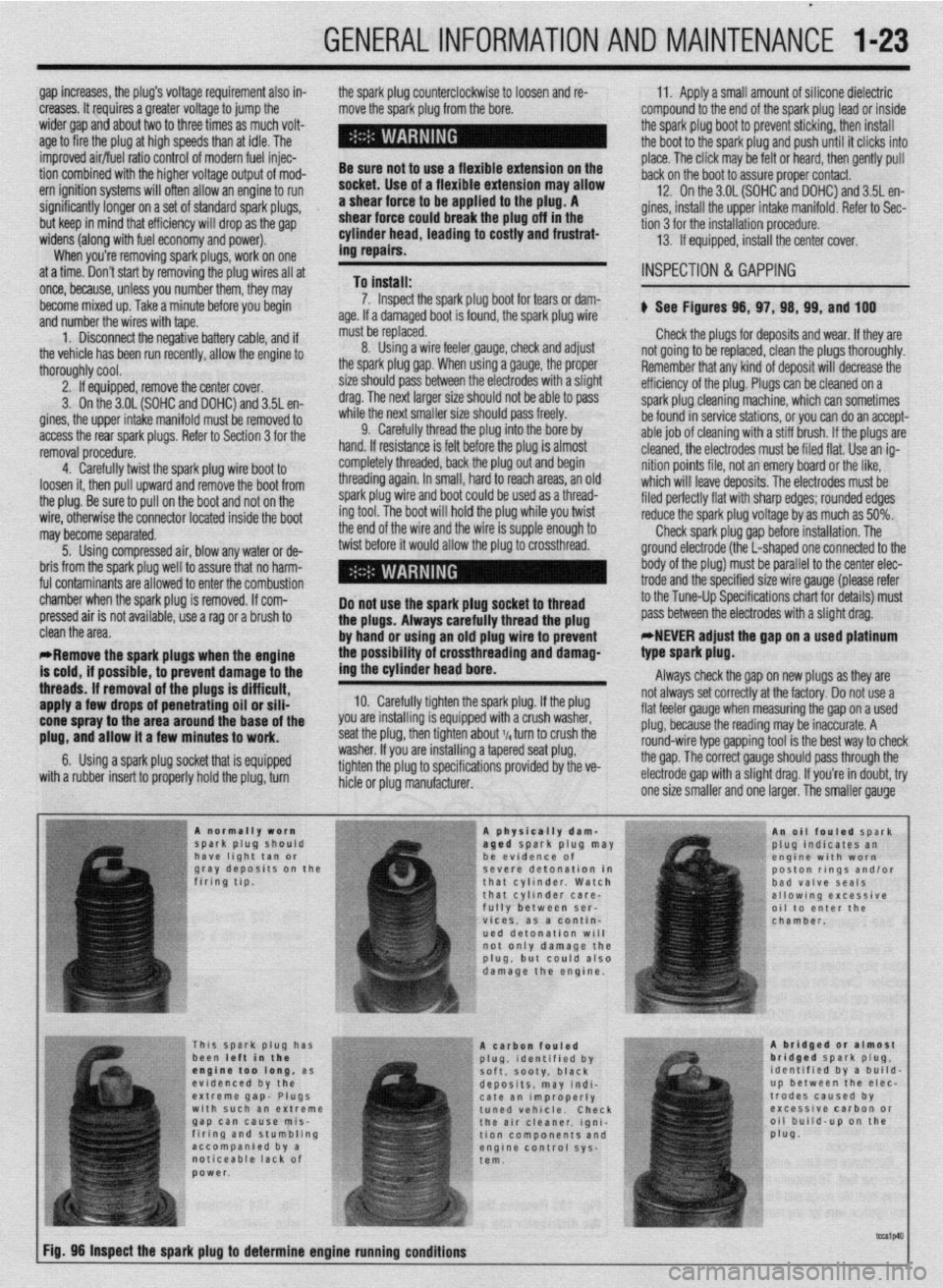

gap increases, the plug’s voltage requirement also in-

creases. It requires a greater voltage to jump the the spark plug counterclockwise to loosen and re-

move the spark plug from the bore.

wider gap and about &o to three times as much volt-

age to fire the plug at high speeds than at idle. The

improved air/fuel ratio control of modern fuel injec-

tion combined with the higher voltage output of mod- Be sure not to use a flexible extension on the place. The click may be felt or heard, then gently pull

ern ignition systems will often allow an engine to run socket. Use of a flexible extension may allow back on the boot to assure proper contact.

.___. . _

significantly longer on a set of standard spark plugs, a shear force to be agptf’ ea to me plug.

A 12. On the 3.OL fSOHC and DOHC) and 3.5L en-

LL_ _I___ -u I_ IL-

but keep in mind that efficiency will drop as the gap shear force could break tne pug on III me

tion 3 for the installation procedure.

widens (along with fuel economy and power). cylinder head, leading to costly and frustrat-

13. If equipped, install the center cover.

When you’re removing spark plugs, work on one ing repairs.

at a time. Don’t start by removing the plug wires all at

once, because, unless you number them, they may To install:

INSPECTION & GAPPING

11. Apply a small amount of silicone dielectric

compound to the end of the spark plug lead or inside

the spark plug boot to prevent sticking, then install

the boot to the spark plug and push until it clicks into

gines, install the upper intake manifold. Refer to Sec-

,,Y” ..1111 uy”’ 1 the neaative bat&v cable and if become mixed up. Take a minute before you begin

and number the wrrpc with +sne

1. Disconnect. ~~.~

--..-., -..-.-, -..-

thevehicle has been run recently, allow the engine to

thoroughly cool.

2. If equipped, remove the center cover.

3. On the 3.OL (SOHC and DOHC) and 3.5L en-

gines, the upper intake manifold must be removed to

access the rear spark plugs. Refer to Section 3 for the

removal procedure.

4. Carefully twist the spark plug wire boot to

loosen it, then pull upward and remove the boot from

the plug. Be sure to pull on the boot and not on the

wire, otherwise the connector located inside the boot

may become separated.

5. Using compressed air, blow any water or de-

bris from the spark plug well to assure that no harm-

ful contaminants are allowed to enter the combustion

chamber when the spark plug is removed. If com-

pressed air is not available, use a raa or a brush to must be replaced.

Check the plugs for deposits and wear, If they are 7. Inspect the spark plug boot for tears or dam-

age. If.a damaged boot is found, the spark plug wire

8. Using a wire feelergauge, check and adjust

the spark plug gap. When using a gauge, the proper

size should pass between the electrodes with a slight

drag. The next larger size should not be able to pass

while the next smaller size should pass freely.

9. Carefully thread the plug into the bore by

hand. If resistance is felt before the plug is almost

completely threaded, back the plug out and begin

threading again. In small, hard to reach areas, an old

spark plug wire and boot could be used as a thread-

ing tool. The boot will hold the plug while you twist

the end of the wire and the wire is supple enough to

twist before it would allow the plug to crossthread.

Do not use the spark plug sock?

l -- K-rrA tha nhme Alwmm rarntdlv thw GL I” IlllGa”

the possibility of crossthreading and damag- lad the plug

. ..Y f..“YY. rn”Y,‘““mY*“.‘, .I**” by hand or using an old plug wire to prevent

ing the cylinder head bore.

10. Carefully tighten the spark plug. If the plug

you are installing is equipped with a crush washer,

seat the plug, then tighten about I/, turn to crush the

washer. If you are installing a tapered seat plug,

tighten the plug to specifications provided by the ve-

hicle or plug manufacturer. b See Figures 98, 97, 98, 99, and 100

not going to be replaced, clean the plugs thoroughly.

Remember that any kind of deposit will decrease the

efficiency of the plug. Plugs can be cleaned on a

spark plug cleaning machine, which can sometimes

be found in service stations, or you can do an accept-

able job of cleaning with a stiff brush. If the plugs are’

cleaned, the electrodes must be filed flat. Use an ig-

nition points file, not an emery board or the like,

which will leave deposits. The electrodes must be

filed perfectly flat with sharp edges; rounded edges

reduce the spark plug voltage by as much as 50%.

Check spark plug gap before installation. The

ground electrode (the L-shaped one connected to the

body of the plug) must be parallel to the center elec-

trode and the specified size wire gauge (please refer

to the Tune-Up Specifications chart for details) must

pass between the electrodes with a slight drag:

*,NEVER adjust the gap on a used platinum

. clean the area.

*Remove the spark plugs when the engine

is cold, if possible, to prevent damage to the

threads. If removal of the plugs is difficult,

apply a few drops of penetrating oil or sili-

cone spray to the area around the base of the

plug, and allow it a few minutes to work.

6. Using a spark plug socket that is equipped

with a rubber insert to properly hold the plug, turn type spark plug.

Always check the gap on new plugs as they are

not always set correctly at the factory. Do not use a

flat feeler gauge when measuring the gap on a used

plug, because the reading may be inaccurate. A

round-wire type gapping tool is the best way to check

the gap. The correct gauge should pass through the

electrode gap with a slight drag. If you’re in doubt, try

one size smaller and one laraer. The smaller aauqe

Page 44 of 408

GENERALINFORMATIONAND MAINTENANCE 1-45

SLING TYPE

WHEEL LIFT TYPE

cles

SUNG TYPE

WHEEL LIFT TYPE

FLAT BED TYPE

Fig. 220 Rear towing position-FWD vehi

cles

personal injury. Remember that batteries contain a

small amount of explosive hydrogen gas which is a

by-product of battery charging. Sparks should always

be avoided when working around batteries, especially

when attaching jumper cables. To minimize the pos-

sibility of accidental sparks, follow the procedure

carefully.

NEVER hook the batteries up in a series cir-

cuit or the entire electrical system will go up

in smoke. includino the starter!

Vehicles equipped with a diesel engine may utilize

two 12 volt batteries. If so, the batteries are con-

nected in a parallel circuit (positive terminal to posi-

tive terminal, negative terminal to negative terminal).

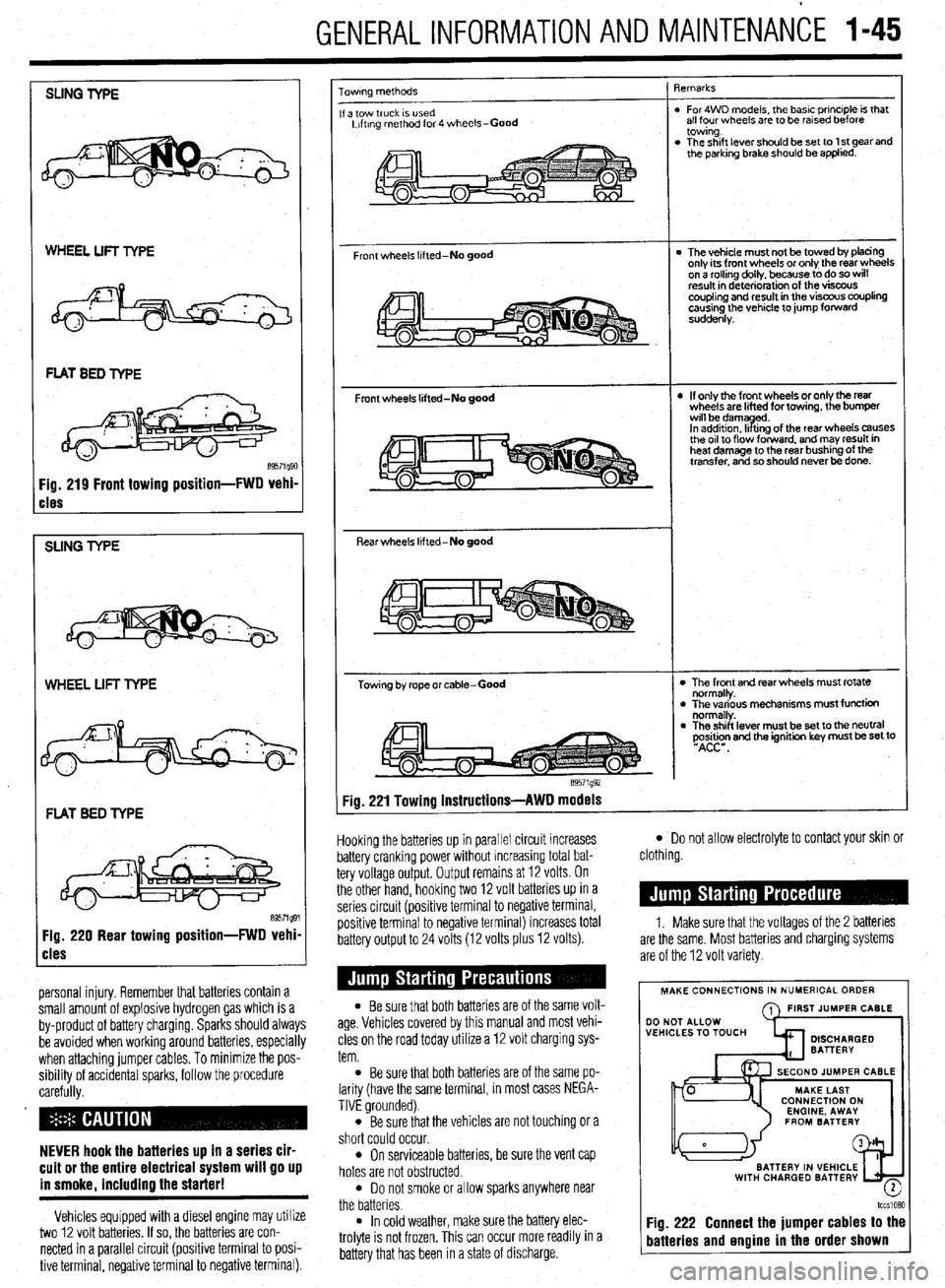

owrng methods

a tow truck IS used

Lrftrng method for 4 wheels-Good

Front wheels lifted-No good

Front wheels lifted-No good

Rear wheels lifted-No good

Towing by rope or cable-Good

e9571g92 qemarks

. For4WD models, the basic principle is that

all four wheels are to be rarsed before

towing.

. The shift lever should be set to 1 st gear and

the parking brake should be applied.

l The vehicle must not be towed by tofacing

only its front wheels or only the rear wheels

on a rollino dollv, because to do so will

result in d&e&ration of the visfx~s

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.

l If only the front wheels or only the rear

wheels are lifted for towing, the bumper

wrll bedamyd.

In addrtron. II trng of the rear wheels causes

the or1 to flow forward. and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

l The front and rear wheels must rotate

normally.

l The various mechanisms must function

normally.

l The shift lever must be set to the neutral

~Asi&n and the ignition key must be set to

Fig. 221 Towing instructions-AWD models

Hooking the batteries up in parallel circuit increases

battery cranking power without increasing total bat-

tery voltage output. Output remains at 12 volts. On

the other hand, hooking two 12 volt batteries up in a

series circuit (positive terminal to negative terminal,

positive terminal to negative terminal) increases total

battery output to 24 volts (12 volts plus 12 volts).

l Be sure that both batteries are of the same volt-

age. Vehicles covered by this manual and most vehi-

cles on the road today utilize a 12 volt charging sys-

tem.

l Be sure that both batteries are of the same po-

larity (have the same terminal, in most cases NEGA-

TIVE grounded).

l Be sure that the vehicles are not touching or a

short could occur.

l On serviceable batteries, be sure the vent cap

holes are not obstructed.

l Do not smoke or allow sparks anywhere near

the batteries.

l In cold weather, make sure the battery elec-

trolyte is not frozen, This can occur more readily in a

battery that has been in a state of discharge.

l Do not allow electrolyte to contact your skin or

clothing.

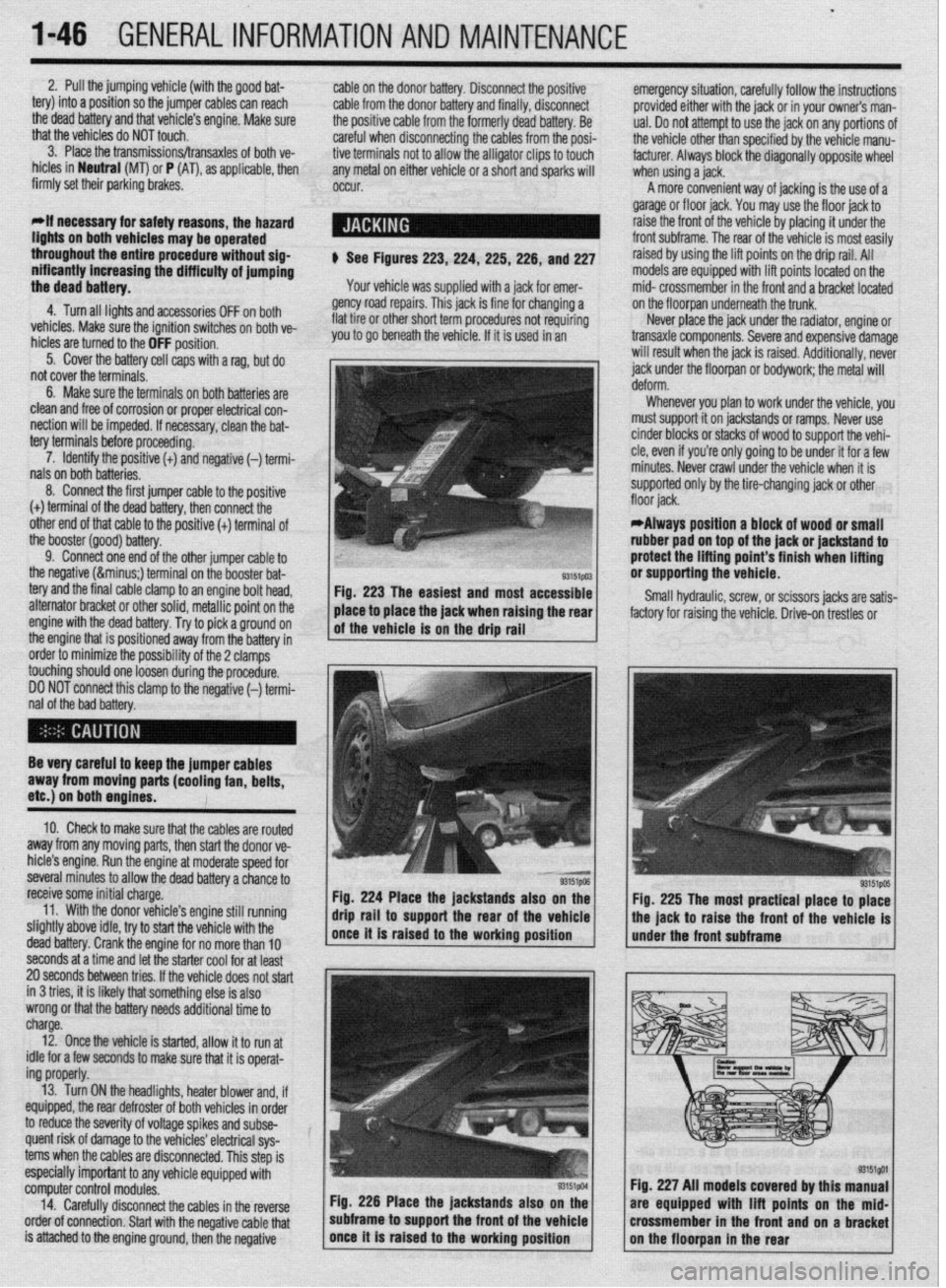

1. Make sure that the voltages of the 2 batteries

are the same. Most batteries and charging systems

are of the 12 volt variety.

MAKE CONNECTIONS IN NUMERICAL ORDER

A FIRST JUMPER CABLE

WITH CHARGED BATTERY

-

lccslQ?,Q

Fig. 222 Connect the jumper cables to the

batteries and engine in the order shown

Page 45 of 408

.

I-46 GENERALINFORMATIONAND MAINTENANCE

2. Pull the jumping vehicle (with the good bat-

tery) into a position so the jumper cables can reach

the dead battery and that vehicle’s engine. Make sure

that the vehicles do NOT touch.

3. Place the transmissions/transaxles of both ve-

hicles in Neutral (MT) or P (AT), as applicable, then

firmly set their parking brakes.

*ff necessary for safety reasons, the hazard

lights on both vehicles may be operated

throughout the entire procedure without sig-

nificantiy increasing the diff icuity of jumping

the dead battery.

4. Turn all lights and accessories OFF on both

vehicles. Make sure the ignition switches on both ve-

hicles are turned to the OFF position.

5. Cover the battery cell caps with a rag, but do

not cover the terminals.

6. Make sure the terminals on both batteries are

clean and free of corrosion or proper electrical con-

nection will be impeded. If necessary, clean the bat-

tery terminals before proceeding.

7. Identify the positive (+) and negative (-) termi-

nals on both batteries.

8. Connect the first jumper cable to the positive

(t) terminal of the dead battery, then connect the

other end of that cable to the positive (t) terminal of

the booster (good) battery.

9. Connect one end of the other jumper cable to

the negative (−) terminal on the booster bat-

tery and the final cable clamp to an engine bolt head,

alternator bracket or other solid, metallic point on the

engine with the dead battery. Try to pick a ground on

the engine that is positioned away from the battery in

order to minimize the possibility of the 2 clamps

touching should one loosen during the procedure.

DO NOT connect this clamp to the negative (-) termi-

nal of the bad battery. cable on the donor battery. Disconnect the positive

cable from the donor battery and finally, disconnect

the positive cable from the formerly dead battery. Be

careful when disconnecting the cables from the posi-

tive terminals not to allow the alligator clips to touch

any metal on either vehicle or a short and sparks will

occur.

I

$ See Figures 223,224, 225,226, and 227

Your vehicle was supplied with a jack for emer-

gency road repairs. This jack is fine for changing a

flat tire or other short term procedures not requiring

you to go beneath the vehicle. If it is used in an emergency situation, carefully follow the instructions

provided either with the jack or in your owners man-

ual. Do not attempt to use the jack on any portions of

the vehicle other than specified by the vehicle manu-

facturer. Always block the diagonally opposite wheel

when using a jack.

A more convenient way of jacking is the use of a

garage or floor jack. You may use the floor jack to

raise the front of the vehicle by placing it under the

front subframe. The rear of the vehicle is most easily

raised by using the lift points on the drip rail. All

models are equipped with lift points located on the

mid- crossmember in the front and a bracket located

on the floorpan underneath the trunk.

Never place the jack under the radiator, engine or

transaxle components. Severe and expensive damage

will result when the jack is raised. Additionally, never

jack under the floorpan or

bodywork; the

metal will

Whenever you plan to work under the vehicle, you

must support it on jackstands or ramps. Never use

cinder blocks or stacks of wood to support the vehi-

cle, even if you’re only going to be under it for a few

minutes. Never crawl under the vehicle when it is

supported only by the tire-changing jack or other

*Always position a block of wood or small

rubber pad on top of the jack or jackstand to

protect the lifting point’s finish when lifting

or supporting the vehicle.

Small hydraulic, screw, or scissors jacks are satis-

factory for raising the vehicle. Drive-on trestles or

Be very careful to keep the jumper cables

away from moving parts (cooling fan, belts,

etc.) on both engines.

10. Check to make sure that the cables are routed

away from any moving parts, then start the donor ve-

hicle’s engine. Run the engine at moderate speed for

several minutes to allow the dead battery a chance to

receive some initial charge.

11. With the donor vehicle’s engine still running

slightly above idle, try to start the vehicle with the

dead battery. Crank the engine for no more than 10 &stands also on the

Fig. 225 The most practical place to place

front of the vehicle is

seconds at a time and let the starter cool for at least

20 seconds between tries. If the vehicle does not start

in 3 tries, it is likely thatsomething else is also

wrong or that the battery needs additional time to

charge.

12. Once the vehicle is started, allow it to run at

idle for a few seconds to make sure that it is operat-

ing properly.

13. Turn ON the headlights, heater blower and, if

equipped, the rear defroster of both vehicles in order

to reduce the severity of voltage spikes and subse-

quent risk of damage to the vehicles’ electrical sys-

tems when the cables are disconnected. This step is

especially important to any vehicle equipped with

computer control modules.

14. Carefully disconnect the cables in the’reverse

order of connection. Start with the negative cable that

is attached to the engine ground, then the negative Fig. 226 Place the jackstands also

subframe to support the front of the Fig. 227 All models covered by this

are equipped with lift points on t

crossmember in the front and on a

Page 49 of 408

.~ P.X I_ - “, .- I .-., IS ” .~.I .r

2-2 ENGINE ELECTRICAL

nn

ity and trouble: shooting electrical circuits,

please refer to Section 6 of this manual.

I

The ignition system on the 1.5L, 1993-96 1.8L,

2.OL SOHC, 1994-98 2.4L SOHC, 3.OL SOHC, and

3.5L engines uses a pointless type distributor, whose

advance mechanism is controlled by the Engine Con-

trol Unit (ECU). On the 1.5L, 1.8L, 2.4L and 3.5L en-

gines, the distributor houses a built in ignition coil

and ignition power transistor. The 2.8L SOHC and

3.OL SOHC engines utilize a separate coil and tran-

sister assemblv.

When the ignition switch is turned ON, battery

voltage is applied to the ignition coil primary winding.

As the shaft of the distributor rotates, signals are

transmitted from the oowertrain control module to the

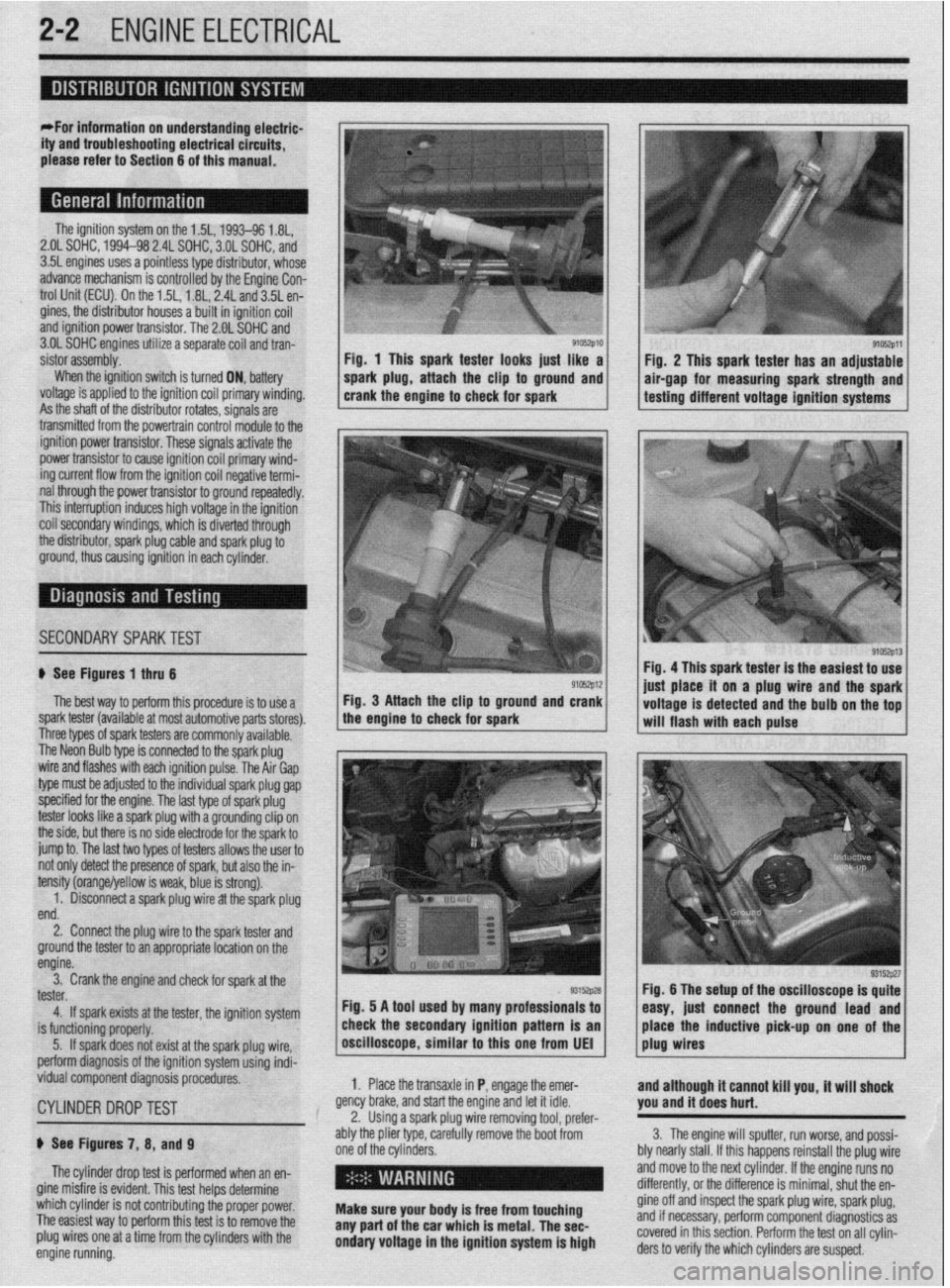

9105zp11 Fig. 1 This spark tester looks iust like a

Fiu. 2 This spark tester has an adjustable

spark plug, attach the clip to ground and air-gap for measuring spark strength and

crank the engine to check for spark testing different voltage ignition systems

.

ignition power trar rsistor. These signals activate the

power transistor to cause ignition coil primary wind-

ing current flow from the ignition coil negative termi-

nal through the power transistor to ground repeatedly.

This interruption induces high voltage in the ignition

coil secondarv windinas, which is diverted throuah

the distributor, spark plug cable and spark plug 6

ground, thus causing ignition in each cylinder.

I

SECONDARYSPARKTEST l;h.4-

! ,L ".~

'$ >,%

If See Figures 1 thru 6

91rJszp12 Fig. 4 This spark tester is the easiest to use

iust alace it on a plug wire and the spark

The best way to perform this procedure is to use a Fig. 3 Attach the clip to ground and crank

spark tester (available at most automotive parts stores). the engine to check for spark

I I voltage is detected and the bulb on the tof

-. will flash with each pulse

I nree types ot spark testers are commonly available.

The Neon Bulb type is connected to the spark plug

wire and flashes with each ignition pulse. The Air Gap

type must be adjusted to the individual spark plug gap

specified for the engine. The last type of spark plug

tester looks like a spark plug with a grounding clip on

the side, but there is no side electrode for the spark to

jump to. The last two types of testers allows the user to

not only detect the presence of spark, but also the in-

tensity (orange/yellow is weak, blue is strong).

1. Disconnect a spark plug wire at the spark plug

end.

2. Connect the plug wire to the spark tester and

ground the tester to an appropriate location on the

engine.

3. Crank the engine and check for spark at the

tester.

4. If spark exists at the tester, the ignition system

is functioning properly.

5. If spark does not exist at the spark plug wire,

perform diagnosis of the ignition system using indi-

vidual component diagnosis procedures,

CYLINDER DROPTEST

p See Figures 7, 8, and 9

The cylinder drop test is performed when an en-

gine misfire is evident. This test helps determine

which cylinder is not contributing the proper power.

The easiest way to perform this test is to remove the

plug wires one at a time from the cylinders with the

engine running. 1. Place the transaxle in P, engage the emer-

gency brake, and start the engine and let it idle.

2. Using a spark plug wire removing tool, prefer-

ably the plier type, carefully remove the boot from

one of the cylinders.

i ’

Make sure your body is free from touching

any part of the car which is metal. The sec-

ondary voltage in the ignition system is high and although it cannot kill you, it will shock

you and it does hurt.

3. The engine will sputter, run worse, and possi-

bly nearly stall. If this happens reinstall the plug wire

and move to the next cylinder. If the engine runs no

differently, or the difference is minimal, shut the en-

gine off and inspect the spark plug wire, spark plug,

and if necessary, perform component diagnostics as

covered in this section. Perform the test on all cylin-

ders to verify the which cylinders are suspect.

Page 171 of 408

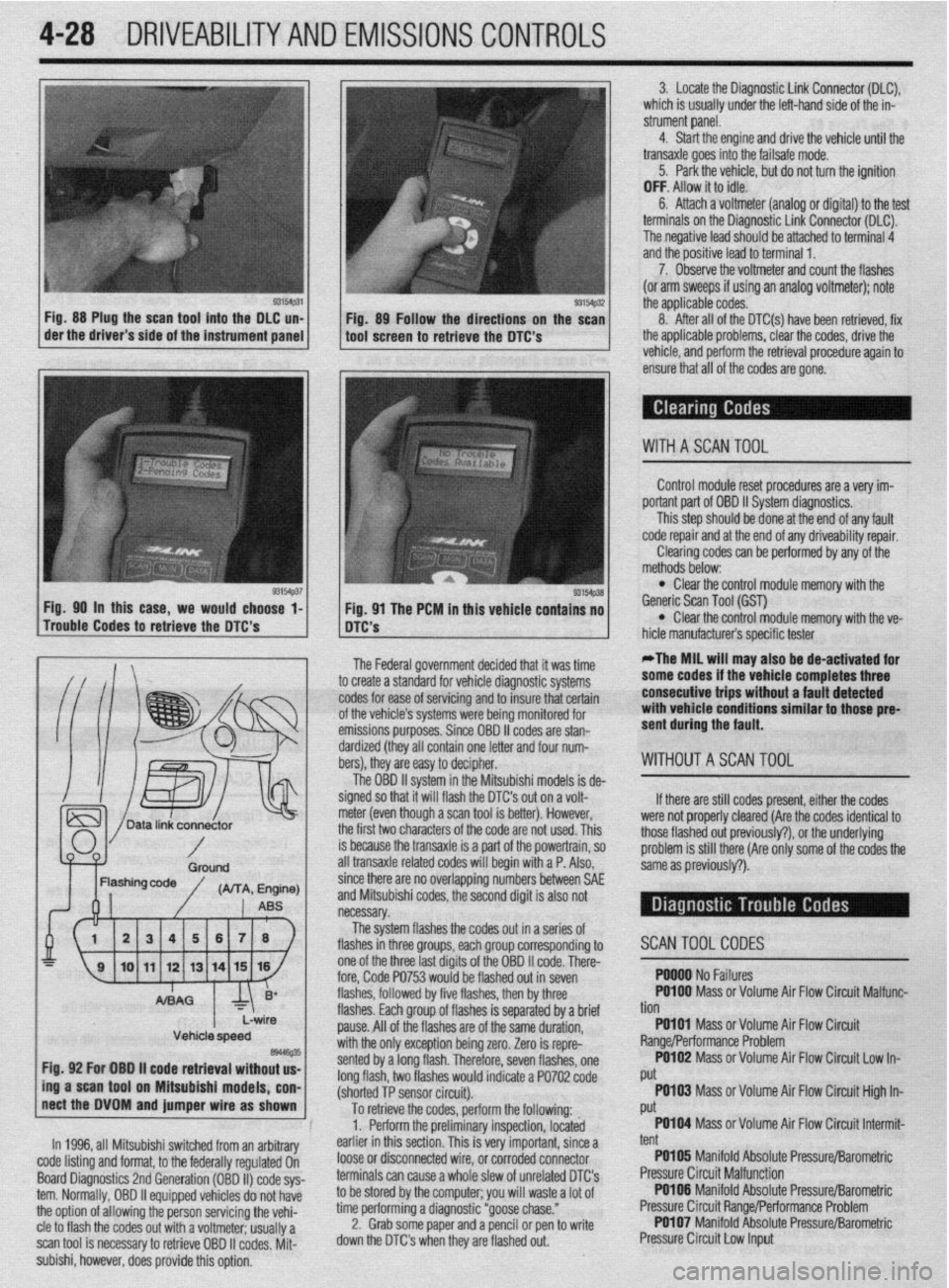

4-28 DRIVEABILITYAND EMISSIONS CONTROLS

Fig. 88 Plug the scan tool into the DLC un-

Fig. 89 Follow the directions on the scan

der the driver’s side of the instrument panel

tool screen to retrieve the DTC’s 3. Locate the Diagnostic Link Connector (DLC),

which is usually under the left-hand side of the in-

strument panel.

4. Start the engine and drive the vehicle until the

transaxle goes into the failsafe mode.

5. Park the vehicle, but do not turn the ignition

OFF. Allow it to idle.

6. Attach a voltmeter (analog or digital) to the test

terminals on the Diagnostic Link Connector (DLC).

The negative lead should be attached to terminal 4

and the positive lead to terminal 1.

7. Observe the voltmeter and count the flashes

(or arm sweeps if using an analog voltmeter); note

the applicable codes.

- 8. After all of the DTC(s) have been retrieved, fix

the applicable problems, clear the codes, drive the

vehicle, and perform the retrieval procedure again to

ensure that all of the codes are gone.

WITHASCANTOOL

Control module reset procedures are a very im-

portant part of OBD II System diaqnostics.

This step should be done at the end of any fault

code repair and at the end of any driveability repair.

Clearing codes can be performed by any of the

Fig. 90 in this case, we would choor- A ’ ma*-. . . * .

Trouble Codes to retrieve the DTC’s

-.- -

A mere mar

. . methods below: l Clear the control module memory with the

se l-

I I ng. vi me rtim In mts venicie contains no Generic Scan Tool (GST) l DTC’S Clear the control module memory with the ve-

L’-‘m iufacturer’s specific tester

The Federal government decided that it was time

to create a standard for vehicle diagnostic systems

codes for ease of servicing and to insure that certain

of the vehicle’s systems were being monitored for

emissions purposes. Since OBD II codes are stan-

dardized (they all contain one letter and four num-

bers), they are easy to decipher.

The OBD II system in the Mitsubishi models is de-

signed so that it will flash the DTC’s out on a volt-

meter (even though a scan tool is better). However,

the first two characters of the code are not used. This

is because the transaxle is a part of the powertrain, so

all transaxle related codes will begin with a P. Also, *The MIL will may also be de-activated for

some codes if the vehicle completes three

consecutive trips without a fault detected

with vehicle conditions similar to those pre-

sent during the fault.

WITHOUTASCAN TOOL

If there are still codes p

resent, either the codes

were not properly cleared f

:Are the codes identical to

those flashed out previous

I$‘), or the underlying

problem is still there (Are I

only some of the codes the

same as oreviouslv?).

since there are no overlapping numbers between SAE

and Mitsubishi codes, the second digit is also not

necessary.

The system flashes the codes o

ut ma series of

flashes in

three nmm mh nrnlll -- J.-lr-, ---.. ~.--

p corresponding to

one of the

three last diaits of the OBD II code. There-

fore, Code WJJ wuuw UC:

IIKWAJ WI III XVWI flashes, followed by five flashes, then by three

flashes. Each group of flashes is se

pause. All of the flashes are of the (

witi the or$, nvrontinn hoinn mm sented by z

long flash,

(shorted Tt SWIWI LIIW. rparated by a brief

;ame duration,

88, “rw”I.‘L’“‘I uv,,,y LUI”.

Zero is repre-

1 long flash. Therefore, seven flashes, one

two flashes would indicate a PO702 code

3 nnmn^r ,.:*....:I I r

SCANTOOLCODES

. YYY” I ‘I” I cuI”I”.J PO100 Mass or Volume Air Flow Circuit Malfunc-

Lb

non

PO101 Mass orVolume Air Flow Circuit

Range/Performance Problem

PO102 Mass or Volume Air Flow Circuit Low In-

Put

.

To retrieve the codes, perform the following: PO103 Mass or Volume Air Flow Circuit High In-

i Put

1. Perform the preliminary inspection, located PO104 Mass or Volume Air Flow Circuit Intermit-

-;

Vehicle speed es446e35 Fig. 92 For OBO ii code retrieval without us-

ing a scan tool on Mitsubishi models, con-

nect the DVOM and jumper wire as shown

In 1996, all Mitsubishi switched from an arbitrary

code listing and format, to the federally regulated On

Board Diagnostics 2nd Generation (OBD II) code sys-

tern. Normally, OBD II equipped vehicles do not have

the option of allowing the person servicing the vehi-

cle to flash the codes out with a voltmeter; usually a

scan tool is necessary to retrieve OBD II codes. Mit-

subishi, however, does provide this option, earlier in this section. This is very important, since a

loose or disconnected wire, or corroded connector

terminals can cause a whole slew of unrelated DTC’s

to be stored by the computer; you will waste a lot of

time performing a diagnostic “goose chase.”

2. Grab some paper and a pencil or pen to write

down the DTC’s when they are flashed out. tent

PO105 Manifold Absolute Pressure/Barometric

Pressure Circuit Malfunction

PO106 Manifold Absolute Pressure/Barometric

Pressure Circuit Range/Performance Problem

PO107 Manifold Absolute Pressure/Barometric

Pressure Circuit Low Input

Page 204 of 408

UNDERSTANDING AND

TROUBLESHOOTING

ELECTRICAL SYSTEMS 6-2

BASIC ELECTRICALTHEORY 6-2

HOW DOES ELECTRICITY WORK:

THEWATERANALOGY 6-2

OHM'S LAW 6-2

ELECTRICALCOMPONENTS 6-2

POWERSOURCE 6-2

GROUND 6-3

PROTECTIVE DEVICES 6-3

SWITCHES&RELAYS 6-3

LOAD 6-3

WIRING & HARNESSES 6-3

CONNECTORS 6-4

TEST EQUIPMENT 6-4

JUMPER WIRES 6-4

TEST LIGHTS 6-4

MULTIMETERS 6-5

TROUBLESHOOTING ELECTRICAL

SYSTEMS 6-5

TESTING 6-5

OPEN CIRCUITS 6-5

SHORT CIRCUITS 6-6

VOLTAGE 6-6

VOLTAGE DROP 6-6

RESISTANCE 6-8

WIRE AND CONNECTORREPAIR 6-6

BATTERY CABLES 6-7

DISCONNECTING THE CABLES 6-7

AIR BAG (SUPPLEMENTAL

RESTRAINT SYSTEM) 6-7

GENERALINFORMATION 6-7

SERVICE PRECAUTIONS 6-7

DISARMING 6-7

REARMING 6-7

HEATING AND AIR

CONDITIONING 6-7

BLOWER MOTOR 6-7

REMOVAL &INSTALLATION 6-7

HEATER CORE 6-9 INSTRUMENTS AND SWITCHES 6-17

INSTRUMENTCLUSTER 6-17

REMOVAL &INSTALLATION 6-17

GAUGES 6-18

REMOVAL&INSTALLATION 6-18

WINDSHIELD WIPER SWITCH 6-19

REMOVAL&INSTALLATION 6-19

REARWINDOWWIPERSWITCH 6-19

REMOVAL &INSTALLATION 6-19

DIMMER SWITCH 6-19

REMOVAL & INSTALLATION 6-19 .

HEADLIGHT SWITCH 6-19

REMOVAL & INSTALLATION 6-19

LIGHTING 6-19

HEADLIGHTS 6-19

REMOVAL &INSTALLATION 6-19

AIMINGTHEHEADLIGHTS 6-20

SIGNAL AND MARKER LIGHTS 6-21

REMOVAL &INSTALLATION 6-21

CIRCUIT PROTECTION 6-27

FUSES 6-27

REPLACEMENT 6-27

FUSIBLE LINKS 6-27

CIRCUIT BREAKERS 6-28

RESETTING AND/OR

REPLACEMENT 6-28

FLASHERS 6-28

REPLACEMENT 6-28

WIRING DIAGRAMS 6-31

REMOVAL & INSTALLATION 6-9

AIR CONDITIONING COMPONENTS 6-11

REMOVAL & INSTALLATION 6-11

CONTROLCABLES 6-12

ADJUSTMENT 6-12

CONTROL PANEL 6-12

REMOVAL & INSTALLATION 6-12

CRUISE CONTROL 6-13

ENTERTAINMENT SYSTEMS 6-14

RADIO RECEIVER/AMPLIFIER/TAPE

PLAYER/CD PLAYER 6-14

SPEAKERS 6-14

REMOVAL & INSTALLATION 6-14

WINDSHIELD WIPERS AND

WASHERS 6-15

WINDSHIELD WIPER BLADE AND

ARM 6-15

REMOVAL & INSTALLATION 6-15

WINDSHIELD WIPER MOTOR 6-16 _

REMOVAL &INSTALLATION 6-16

WINDSHIELD WASHER PUMP 6-17

REMOVAL &INSTALLATION 6-17

Page 210 of 408

I I

CHASSIS ELECTRICAL 6-7

When working on any electrical component on the

vehicle, it is always a good idea to disconnect the

negative (-) battery cable. This will prevent potential

damage to many sensitive electrical components

such as the Powertrain Control Module (PCM), radio,

alternator, etc.

*Any time you disengage the battery cables,

it is recommended that you disconnect the negative (-) battery cable first. This will pre-

vent your accidentally grounding the positive

(+) terminal to the body of the vehicle when

disconnecting it, thereby preventing damage

to the above mentioned components.

Before you disconnect the cable(s), first turn the

ignition to the OFF position. This will prevent a draw

on the battery which could cause arcing (electricity

trying to ground itself to the body of a vehicle, just

like a spark plug jumping the gap) and, of course, damaging some components such as the alternator

diodes.

When the battery cable(s) are reconnected (nega-

tive cable last), be sure to check that your lights,

windshield wipers and other electrically operated

safety components are all working correctly. If your

vehicle contains an Electronically Tuned Radio (ETR),

don’t forget to also reset your radio stations. Ditto for

the clock.

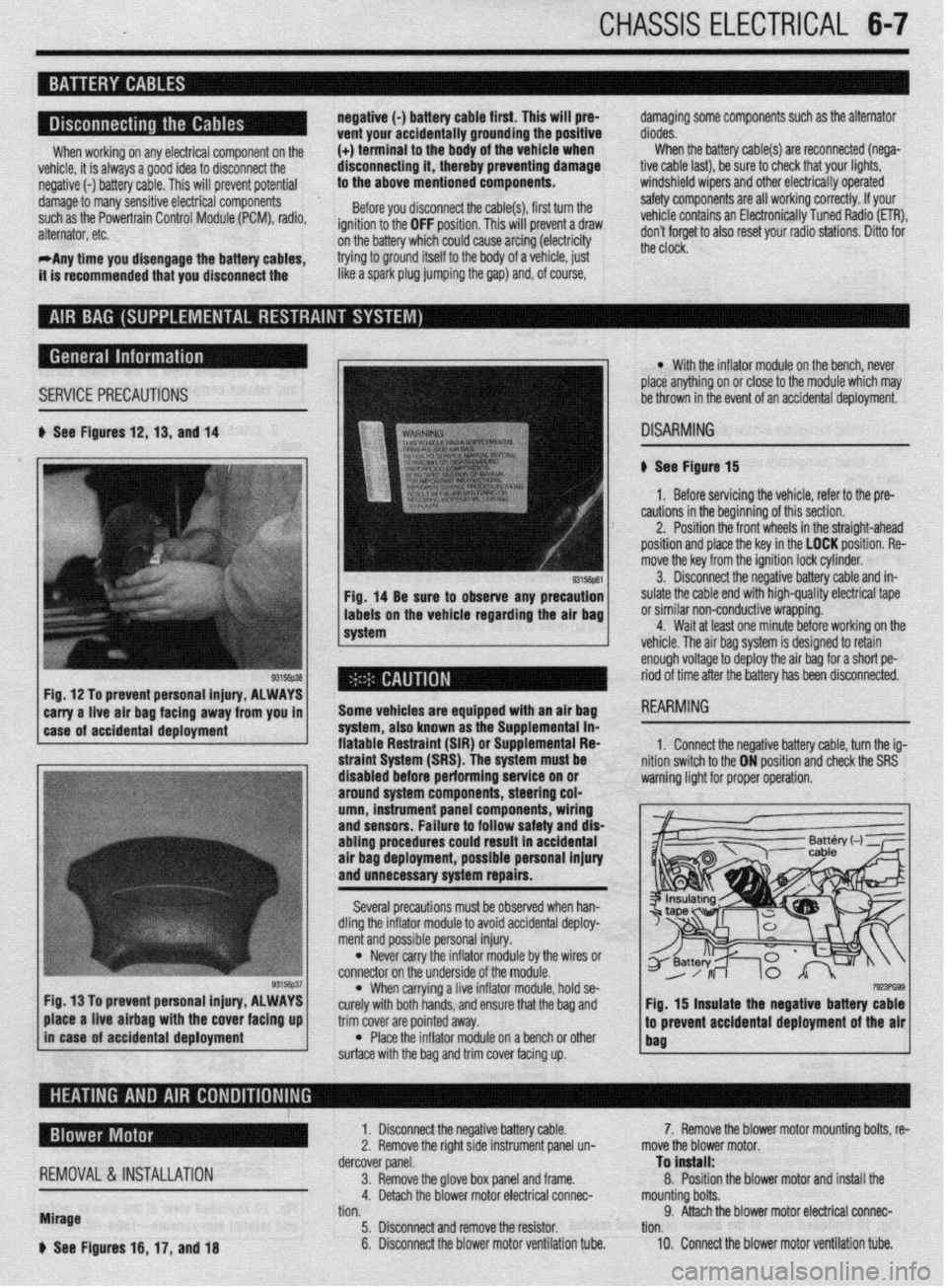

SERVICE PRECAUTIONS

b See Figures 12,13, and 14

Fig, 14 Be sure to observe any precaution

labels on the vehicle regarding the air bag

system

Fig. 12 To prevent personal injury, ALWAYS

*

carry a-live -ah bag fac!ng away from you in 1

1 case of accidental deployment Some vehicles are equipped wtth an air bag

-.-‘--

syr1em, aiscl Known as I11 -I-- ‘------- -- sLe Supplemental in- fiatable Restraint (SIR) o r Suouiementai Fiea

l With the inflator module on the bench, never

place anything on or close to the module which may

be thrown in the event of an accidental deployment.

DISARMING

# See Figure 15

1. Before servicing the vehicle, refer to the pre-

cautions in the beginning of this section.

2. Position the front wheels in the straight-ahead

position and place the key in the LOCK position. Re-

move the key from the ignition lock cylinder.

3. Disconnect the negative battery cable and in-

sulate the cable end with high-quality electrical tape

or similar non-conductive wrapping.

4. Wait at least one minute before working on the

vehicle. The air baa svstem is desianed to retain

enough voltage to deploy the air bag for a short pe-

riod of time after the battery has been disconnected.

1. Connect the neoative batters cable. turn the ia-

3, hold se-

e bag and

trim cover are pointed away.

l Place the inflator module on a bench or other

surface with the bag and trim cover facing up.

7!r!3PG93 Fig. 15 insulate the negative battery cable

.I

to prevent accidental deployment of the air

bag place a live airbag with the cover facing up

in case of accidental deployment

REMOVAL &INSTALLATION

Mirage

b See Figures 16, 17, and 18 1. Disconnect the negative battery cable.

2. Remove the right side instrument panel un-

dercover panel.

3. Remove the glove box panel and frame.

4. Detach the blower motor electrical connec-

tion.

5. Disconnect and remove the resistor.

6. Disconnect the blower motor ventilation tube. 7. Remove the blower motor mounting bolts, re-

move the blower motor.

To install:

8. Position the blower motor and install the

mounting bolts.

9. Attach the blower motor electrical connec-

tion.

10. Connect the blower motor ventilation tube.

Page 392 of 408

II-10 TROUBLESHOOTING

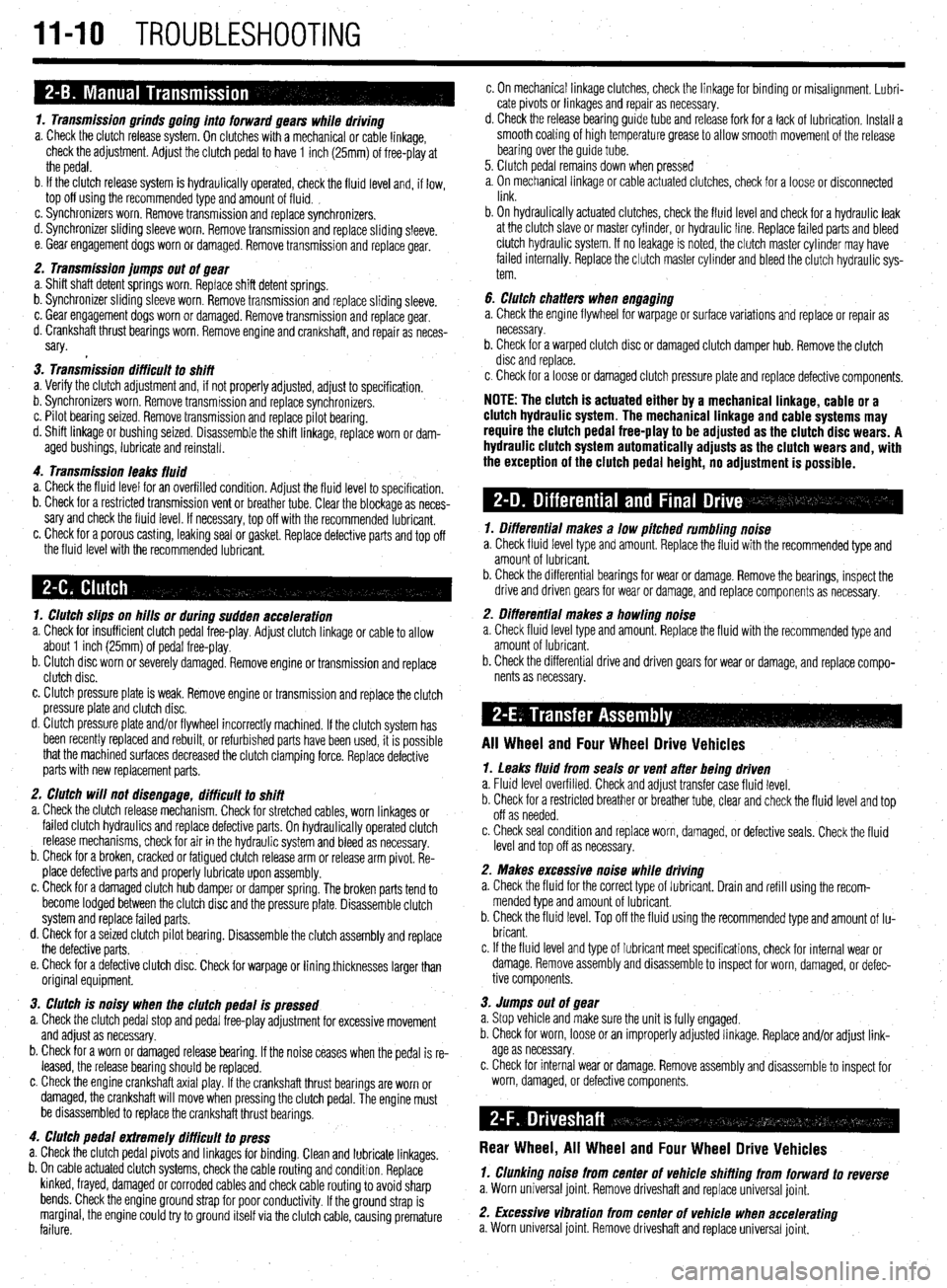

1. Transmission grinds going into forward gears while driving

a. Check the clutch release system. On clutches with a mechanical or cable linkage,

check the adjustment. Adjust the clutch pedal to have 1 inch (25mm) of free-play at

the pedal.

b. If the clutch release system is hydraulically operated, check the fluid level and, if low,

top off using the recommended type and amount of fluid. ,

c. Synchronizers worn. Remove transmission and replace synchronizers.

d. Synchronizer sliding sleeve worn. Remove transmission and replace sliding sleeve.

e. Gear engagement dogs worn or damaged. Remove transmission and replace gear.

2. Transmission jumps out of gear

a. Shift shaft detent springs worn. Replace shift detent springs.

b. Synchronizer sliding sleeve worn. Remove transmission and replace sliding sleeve.

c. Gear engagement dogs worn or damaged. Remove transmission and replace gear.

d. Crankshaft thrust bearings worn. Remove engine and crankshaft, and repair as neces-

sary.

3. Transmission difficult to shift

a. Verify the clutch adjustment and, if not properly adjusted, adjust to specification.

b. Synchronizers worn. Remove transmission and replace synchronizers.

c. Pilot bearing seized. Remove transmission and replace pilot bearing.

d. Shift linkage or bushing seized. Disassemble the shift linkage, replace worn or dam-

aged bushings, lubricate and reinstall.

4. Transmission leaks fluid

a. Check the fluid level for an overfilled condition. Adjust the fluid level to specification.

b. Check for a restricted transmission vent or breather tube. Clear the blockage as neces-

sary and check the fluid level. If necessary, top off with the recommended lubricant.

c. Check for a porous casting, leaking seal or gasket. Replace defective parts and top off

the fluid level with the recommended lubricant.

1. Clutch slips on hills or during sudden acceleration

a. Check for insufficient clutch pedal free-play. Adjust clutch linkage or cable to allow

about 1 inch (25mm) of pedal free-play.

b. Clutch disc worn or severely damaged. Remove engine or transmission and replace

clutch disc.

c. Clutch pressure plate is weak. Remove engine or transmission and replace the clutch

pressure plate and clutch disc.

d. Clutch pressure plate and/or flywheel incorrectly machined. If the clutch system has

been recently replaced and rebuilt, or refurbished parts have been used, it is possible

that the machined surfaces decreased the clutch clamping force. Replace defective

parts with new replacement parts.

2. Clutch will not disengage, difficult to shift

a. Check the clutch release mechanism. Check for stretched cables, worn linkages or

failed clutch hydraulics and replace defective parts. On hydraulically operated clutch

release mechanisms, check for air in the hydraulic system and bleed as necessary.

b. Check for a broken, cracked or fatigued clutch release arm or release arm pivot. Re-

place defective parts and properly lubricate upon assembly.

c. Check for a damaged clutch hub damper or damper spring. The broken parts tend to

become lodged between the clutch disc and the pressure plate. Disassemble clutch

system and replace failed parts.

d. Check for a seized clutch pilot bearing. Disassemble the clutch assembly and replace

the defective parts.

e. Check for a defective clutch disc. Check for warpage or liningthicknesses larger than

original equipment.

3. Clutch is noisy when the clutch pedal is pressed

a. Check the clutch pedal stop and pedal free-play adjustment for excessive movement

and adjust as necessary.

b. Check for a worn or damaged release bearing. If the noise ceases when the pedal is re-

leased, the release bearing should be replaced.

c. Check the engine crankshaft axial play. If the crankshaft thrust bearings are worn or

damaged, the crankshaft will move when pressing the clutch pedal. The engine must

be disassembled to replace the crankshaft thrust bearings.

4. Clutch pedal extremely difficult to press

a. Check the clutch pedal pivots and linkages for binding. Clean and lubricate linkages.

b. On cable actuated clutch systems, check the cable routing and condition. Replace

kinked, frayed, damaged or corroded cables and check cable routing to avoid sharp

bends. Check the engine ground strap for poor conductivity. If the ground strap is

marginal, the engine could try to ground itself via the clutch cable, causing premature

failure. c. On mechanical linkage clutches, check the linkage for binding or misalignment. Lubri-

cate pivots or linkages and repair as necessary.

d. Check the release bearing guide tube and release fork for a lack of lubrication. Install a

smooth coating of high temperature grease to allow smooth movement of the release

bearing over the guide tube.

5. Clutch pedal remains down when pressed

a, On mechanical linkage or cable actuated clutches, check for a loose or disconnected

link.

b. On hydraulically actuated clutches, check the fluid level and check for a hydraulic leak

at the clutch slave or master cylinder, or hydraulic line. Replace failed parts and bleed

clutch hydraulic system. If no leakage is noted, the clutch master cylinder may have

failed internally. Replace the clutch master cylinder and bleed the clutch hydraulic sys-

tem.

6. clutch chatters when engaging

a. Check the engine flywheel for warpage or surface variations and replace or repair as

necessary.

b. Check for a warped clutch disc or damaged clutch damper hub. Remove the clutch

disc and replace.

c. Check for a loose or damaged clutch pressure plate and replace defective components.

NOTE: The clutch is actuated either by a mechanical linkage, cable or a

clutch hydraulic system. The mechanical linkage and cable systems may

require the clutch pedal free-play to be adjusted as the clutch disc wears. A

hydraulic clutch system automatically adjusts as the clutch wears and, with

the exception of the clutch pedal height, no adjustment is possible.

1. Differential makes a low pitched rumbling noise

a. Check fluid level type and amount. Replace the fluid with the recommended type and

amount of lubricant.

b. Check the differential bearings for wear or damage. Remove the bearings, inspect the

drive and driven gears for wear or damage, and replace components as necessary.

2. Differential makes a howling noise

a. Check fluid level type and amount. Replace the fluid with the recommended type and

amount of lubricant.

b. Check the differential drive and driven gears for wear or damage, and replace compo-

nents as necessary.

All Wheel and Four Wheel Drive Vehicles

1. Leaks fluid from seals or vent after being driven

a. Fluid level overfilled. Check and adjust transfer case fluid level.

b. Check for a restricted breather or breather tube, clear and check the fluid level and top

off as needed.

c. Check seal condition and replace worn, damaged, or defective seals. Check the fluid

level and top off as necessary.

2. Makes excessive noise while driving

a. Check the fluid for the correct type of lubricant. Drain and refill using the recom-

mended type and amount of lubricant.

b. Check the fluid level. Top off the fluid using the recommended type and amount of lu-

bricant.

c. If the fluid level and type of lubricant meet specifications, check for internal wear or

damage. Remove assembly and disassemble to inspect for worn, damaged, or defec-

tive components.

3. Jumps out of gear

a. Stop vehicle and make sure the unit is fully engaged.

b. Check for worn, loose or an improperly adjusted linkage. Replace and/or adjust link-

age as necessary.

c. Check for internal wear or damage. Remove assembly and disassemble to inspect for

worn, damaged, or defective components.

Rear Wheel, All Wheel and Four Wheel Drive Vehicles

1. Clunking noise from center of Vehicle shifting from forward to reverse

a. Worn universal joint. Remove driveshaft and replace universal joint.

2. Excessive vibration from center of vehicle when accelerating

a. Worn universal joint. Remove driveshaft and replace universal joint.