turn signal MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 49 of 408

.~ P.X I_ - “, .- I .-., IS ” .~.I .r

2-2 ENGINE ELECTRICAL

nn

ity and trouble: shooting electrical circuits,

please refer to Section 6 of this manual.

I

The ignition system on the 1.5L, 1993-96 1.8L,

2.OL SOHC, 1994-98 2.4L SOHC, 3.OL SOHC, and

3.5L engines uses a pointless type distributor, whose

advance mechanism is controlled by the Engine Con-

trol Unit (ECU). On the 1.5L, 1.8L, 2.4L and 3.5L en-

gines, the distributor houses a built in ignition coil

and ignition power transistor. The 2.8L SOHC and

3.OL SOHC engines utilize a separate coil and tran-

sister assemblv.

When the ignition switch is turned ON, battery

voltage is applied to the ignition coil primary winding.

As the shaft of the distributor rotates, signals are

transmitted from the oowertrain control module to the

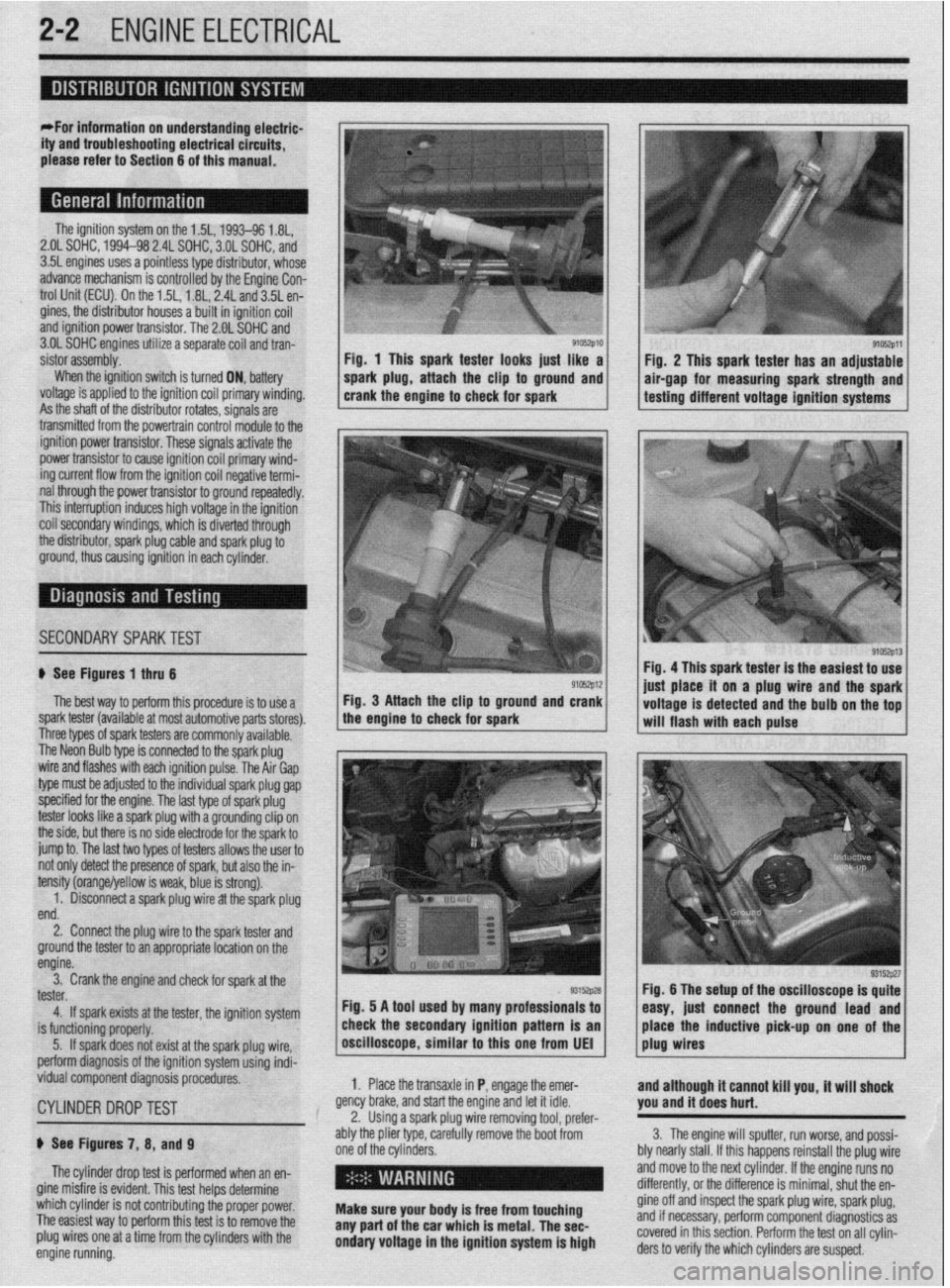

9105zp11 Fig. 1 This spark tester looks iust like a

Fiu. 2 This spark tester has an adjustable

spark plug, attach the clip to ground and air-gap for measuring spark strength and

crank the engine to check for spark testing different voltage ignition systems

.

ignition power trar rsistor. These signals activate the

power transistor to cause ignition coil primary wind-

ing current flow from the ignition coil negative termi-

nal through the power transistor to ground repeatedly.

This interruption induces high voltage in the ignition

coil secondarv windinas, which is diverted throuah

the distributor, spark plug cable and spark plug 6

ground, thus causing ignition in each cylinder.

I

SECONDARYSPARKTEST l;h.4-

! ,L ".~

'$ >,%

If See Figures 1 thru 6

91rJszp12 Fig. 4 This spark tester is the easiest to use

iust alace it on a plug wire and the spark

The best way to perform this procedure is to use a Fig. 3 Attach the clip to ground and crank

spark tester (available at most automotive parts stores). the engine to check for spark

I I voltage is detected and the bulb on the tof

-. will flash with each pulse

I nree types ot spark testers are commonly available.

The Neon Bulb type is connected to the spark plug

wire and flashes with each ignition pulse. The Air Gap

type must be adjusted to the individual spark plug gap

specified for the engine. The last type of spark plug

tester looks like a spark plug with a grounding clip on

the side, but there is no side electrode for the spark to

jump to. The last two types of testers allows the user to

not only detect the presence of spark, but also the in-

tensity (orange/yellow is weak, blue is strong).

1. Disconnect a spark plug wire at the spark plug

end.

2. Connect the plug wire to the spark tester and

ground the tester to an appropriate location on the

engine.

3. Crank the engine and check for spark at the

tester.

4. If spark exists at the tester, the ignition system

is functioning properly.

5. If spark does not exist at the spark plug wire,

perform diagnosis of the ignition system using indi-

vidual component diagnosis procedures,

CYLINDER DROPTEST

p See Figures 7, 8, and 9

The cylinder drop test is performed when an en-

gine misfire is evident. This test helps determine

which cylinder is not contributing the proper power.

The easiest way to perform this test is to remove the

plug wires one at a time from the cylinders with the

engine running. 1. Place the transaxle in P, engage the emer-

gency brake, and start the engine and let it idle.

2. Using a spark plug wire removing tool, prefer-

ably the plier type, carefully remove the boot from

one of the cylinders.

i ’

Make sure your body is free from touching

any part of the car which is metal. The sec-

ondary voltage in the ignition system is high and although it cannot kill you, it will shock

you and it does hurt.

3. The engine will sputter, run worse, and possi-

bly nearly stall. If this happens reinstall the plug wire

and move to the next cylinder. If the engine runs no

differently, or the difference is minimal, shut the en-

gine off and inspect the spark plug wire, spark plug,

and if necessary, perform component diagnostics as

covered in this section. Perform the test on all cylin-

ders to verify the which cylinders are suspect.

Page 52 of 408

ENGlNEELECTRliAL 2-5

Fig. 19 Adjusting the distributor-1.5L en-

gine shown, others similar

4. Install the hold-down nut.

5. Attach the distributor harness connectors.

6. Install the distributor cap.

7. Connect the negative battery cable.

8. Adjust the ignition timing and tighten the hold-

down nut to 8 ft. Ibs. (11 Nm).

For procedures on the position sensors, please re-

fer to Section 4 in this manual.

The ignition system found on the 1.6L, 1997-60

1.8L, 2.OL DOHC, 1999-00 2.4L SOHC, 2.4L DOHC,

and 3.OL DOHC engines is a distributorless type.

The advance of this system, like the distributor type

ignition, is controlled by the Engine Control Unit

(ECU) or Powertrain Control Module (PCM). The

distributorless ignition system contains a crank an-

gle/position sensor which detects the crank angle or

position to each cylinder and converts this data into

pulse signals. These signals are sent to the

ECLVPCM, which calculates the engine rpm and

regulates the fuel injection and ignition timing ac-

cordingly. The system also contains a top dead cen-

ter sensor which detects the top dead center position

of each cylinder and converts this data into pulse

signals. These signals are then sent to the

ECU/PCM, which calculates the sequence of fuel in-

jection and engine rpm.

When the ignition switch is turned ON, battery

voltage is applied to the ignition coil primary wind-

ing. As the crank angle sensor shaft rotates, ignition

signals are transmitted from the multi port injection

control unit to the power transistor. These signals

activate the power transistor to cause ignition coil

primary winding current to flow from the ignition

coil negative terminal through the power transistor

to ground or be interrupted, repeatedly. This action

induces high voltage in the secondary winding of

the ignition coil. From the ignitron coil, the sec-

ondary winding current produced flows through the

spark plug to ground, thus causing ignition in each

cylinder.

Refer to Diagnosis and Testing under Distributor

Ignition in this section,

There are no adjustments to the distributorless ig-

nition system other than the ignition timing adjust-

ment. Refer to section 1 for ignition timing adjust-

ment.

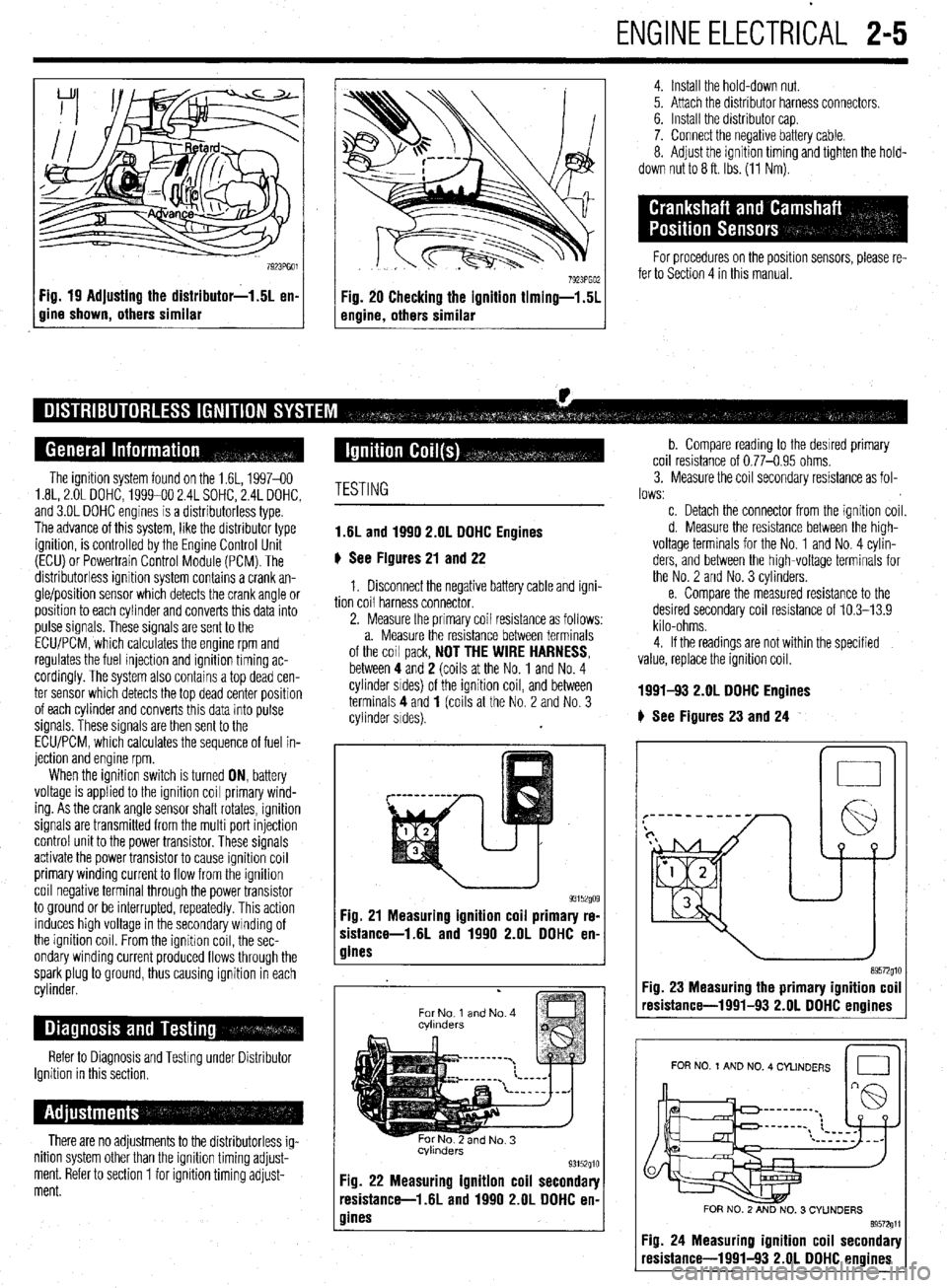

TESTING

1.6L and 1990 2.OL DOHC Engines

6 See Figures 21 and 22

1. Disconnect the negative battery cable and igni-

tion coil harness connector.

2. Measure the primary coil resistance as follows:

a. Measure the resistance between terminals

of the coil pack,

NOT THE WIRE HARNESS, between 4 and 2 (coils at the No. 1 and No. 4

cylinder srdes) of the ignition coil, and between

terminals 4 and

1 (coils at the No. 2 and No. 3

cylinder sides).

93152go9 Fig. 21 Measuring ignition coil primary re-

sistance-1.6L and 1990 2.OL DDHC en-

gines

.

For No 1 and No. 4

cvlmders

Fig. 22 Measuring ignition coil secondary

resistance-l .6L and 1990 2.OL DOHC en-

gines

b. Compare reading to the desrred primary

coil resistance of 0.77-0.95 ohms.

3. Measure the coil secondary resistance as fol-

lows:

c. Detach the connector from the ignition coil.

d. Measure the resistance between the high-

voltage terminals for the No. 1 and No. 4 cylin-

ders, and between the high-voltage terminals for

the No. 2 and No. 3 cylinders.

e. Compare the measured resistance to the

desired secondary coil resistance of 10.3-13.9

kilo-ohms.

4. If the readings are not within the specified

value, replace the ignition coil.

1991-!I3 2.OL DDHC Engines

# See Figures 23 and 24

n 0

Fig. 23 Measuring the primary ignition coil

resistance-1991-93 2.OL DOHC enoines

I I

FOR NO 1 AND NO. 4 CYLINDERS

Id

FOR NO. 2 AND NO. 3 CYUNDERS

89572611

Fig. 24 Measuring ignition coil secondary

resistance-1991-93 2.OL DOHC engines

Page 59 of 408

.

2-12 ENGINEELECTRICAL

*This section describes the operating prina

ciples of sending units, warning lights and

gauges. Sensors which provide information

to the Enafne Control Unit (ECU) or Electronic

or Power&in Control Module (FCM/PCM) are

covered in Section 4 of this manual.

Instrument panels contain a number of indicating

devices (gauges and warning lights). These devices

are composed of two separate components. One is

the sending unit, mounted on the engine or other re-

mote part of the vehicle, and the other is the actual

gauge or light in the instrument panel.

Several types of sending units exist, however most

can be characterized as being either a pressure type

or a resistance type. Pressure type sending units

convert liquid pressure into an electrical signal which

is sent to the gauge. Resistance type sending units

are most often used to measure temperature and use

variable resistance to control the current flow back to

the indicatinq device. Both types of sendinq units are

connected inseries by a wimto the batteryithiough

the ignition switch). When the ignition is turned ON,

current flows from the battery through the indicating

device and on to the sending unit.

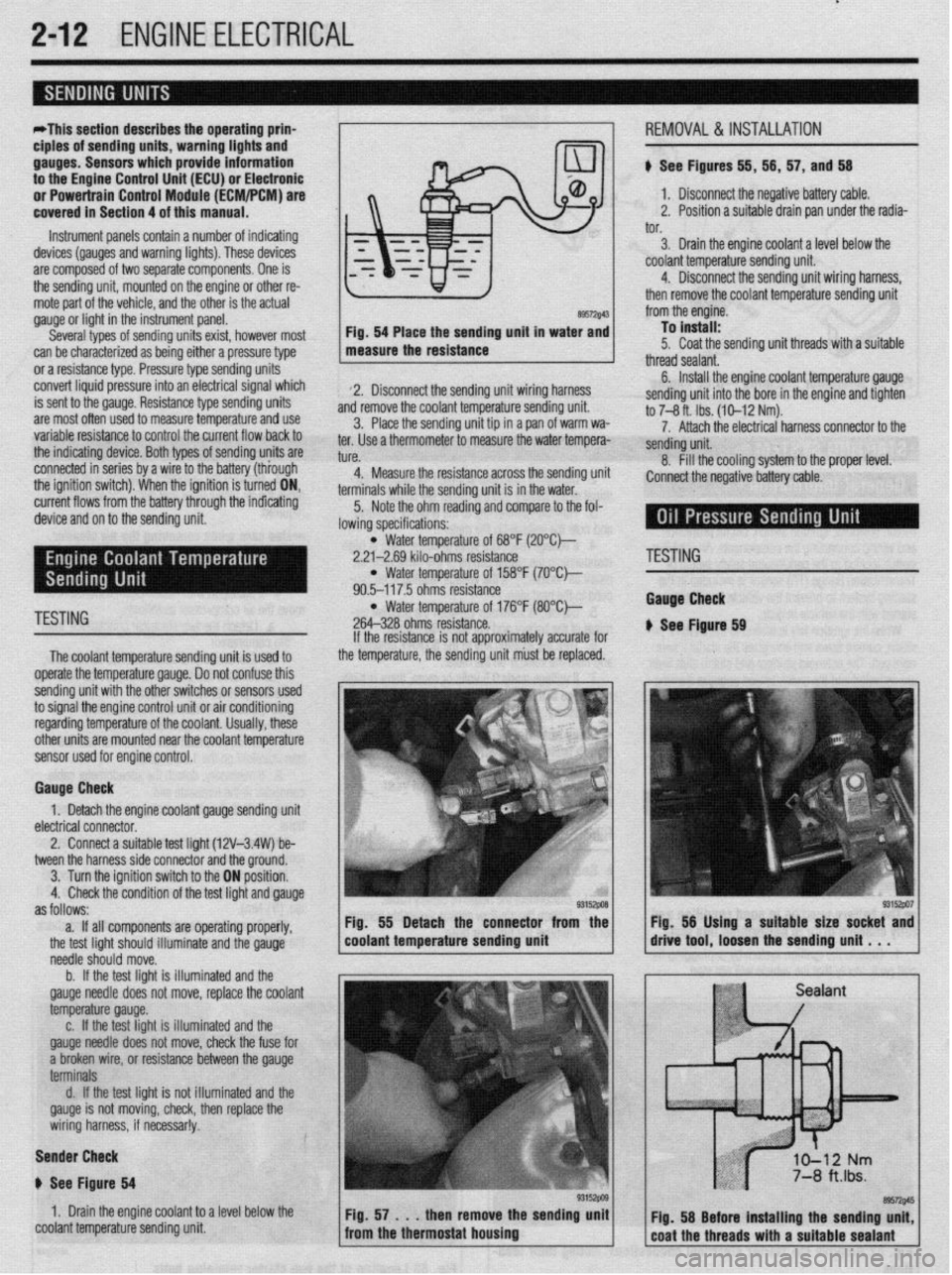

89572$43 Fig. 54 Place the sending unit in water and

measure the resistance

2. Disconnect the sending unit wiring harness

and remove the coolant temperature sending unit.

3. Place the sending unit tip in a pan of warm wa-

ter. Use a thermometer to measure the water tempera-

tl KP

L”,“.

4. Measure the resistance across the sending uni

terminals while the sending unit is in the water.

5. Note the ohm reading and compare to the fol-

lowing specifications: i, 56, 57, and 56

1. Disconnect the negative battery cable.

2. Position a suitable drain pan under the radia-

tor.

3. Drain the engine coolant a level below the

coolant temperature sending unit.

4. Disconnect the sending unit wiring harness,

then remove the coolant temperature sending unit

from the engine.

To install:

5. Coat the sending unit threads with a suitable

thread sealant.

6. Install the engine coolant temperature gauge

sending unit into the bore in the engine and tighten

to 7-8 ft. Ibs. (10-12 Nm).

7. Attach the electrical harness connector to the

sendina unit.

8. fill the cooling system to the proper level.

:onnect the negative battery cable.

l Water temperature of 68°F (2O”C)-

2.21-2.69 kilo-ohms resistance

l Water temperature of 158°F (7O’Ck

90.5-117.5 ohms resistance

TESTING l Water temperature of 176°F (8O”C)-

264-328 ohms resistance.

The coolant temperature sendina unit is used to

operate the temperature gauge. Donot confuse this

sending unit with the other switches or sensors used

to signal the engine control unit or air conditioning

regarding temperature of the coolant. Usually, these

other units are mounted near the coolant temoerature

sensor used for engine control. If the resistance is not approximately accurate for

the temperature, the sending unit must be replaced.

Gauge Check

1. Detach the engine coolant gauge sending unit

electrical connector.

2. Connect a suitable test liaht (12V-3.4W) be-

tween the harness side connector and the around.

I

3. Turn the ignition switch to the ON position.

4. Check the condition of the test light and gauge

as follows:

a. If all components are operating properly,

the test light should illuminate and the gauge

needle should move.

b. If the test light is illuminated and the

gauge needle does not move, replace the coolant

temperature gauge.

c. If the test light is illuminated and the

gauge needle does not move, check the fuse for

a broken wire, or resistance between the gauge

terminals

d. If the test light is not illuminated and the

gauge is not moving, check, then replace the

wiring harness, if necessar!y.

Sender Check

p See Figure 64

1. Drain the engine coolant to a level below the

coolant temperature sending unit Fig. 55 Detach the connector from the

coolant temperature sending unit

'ESTING

tauga Check

See Ftgure 69

Page 152 of 408

DRIVEABILITYAND EMISSIOP JSCONTRiLS 4-9

3. Label and disconnect the H02S from the en-

gine control wiring harness.

*Lubricate the sensor with penetrating oil

prior to removal.

4. Remove the sensor using an oxygen sensor

I To install: - -v- -- ---- ..----. ----...= -..- r... *-

5. Install the sensor in the mounting boss and

hl-li)r\,,.l 0 ,.l.-.f.l, .T‘fi.LI wrench or another suitable tool.

tighten to 27-33 ft. Ibs. (37-45 Nm).

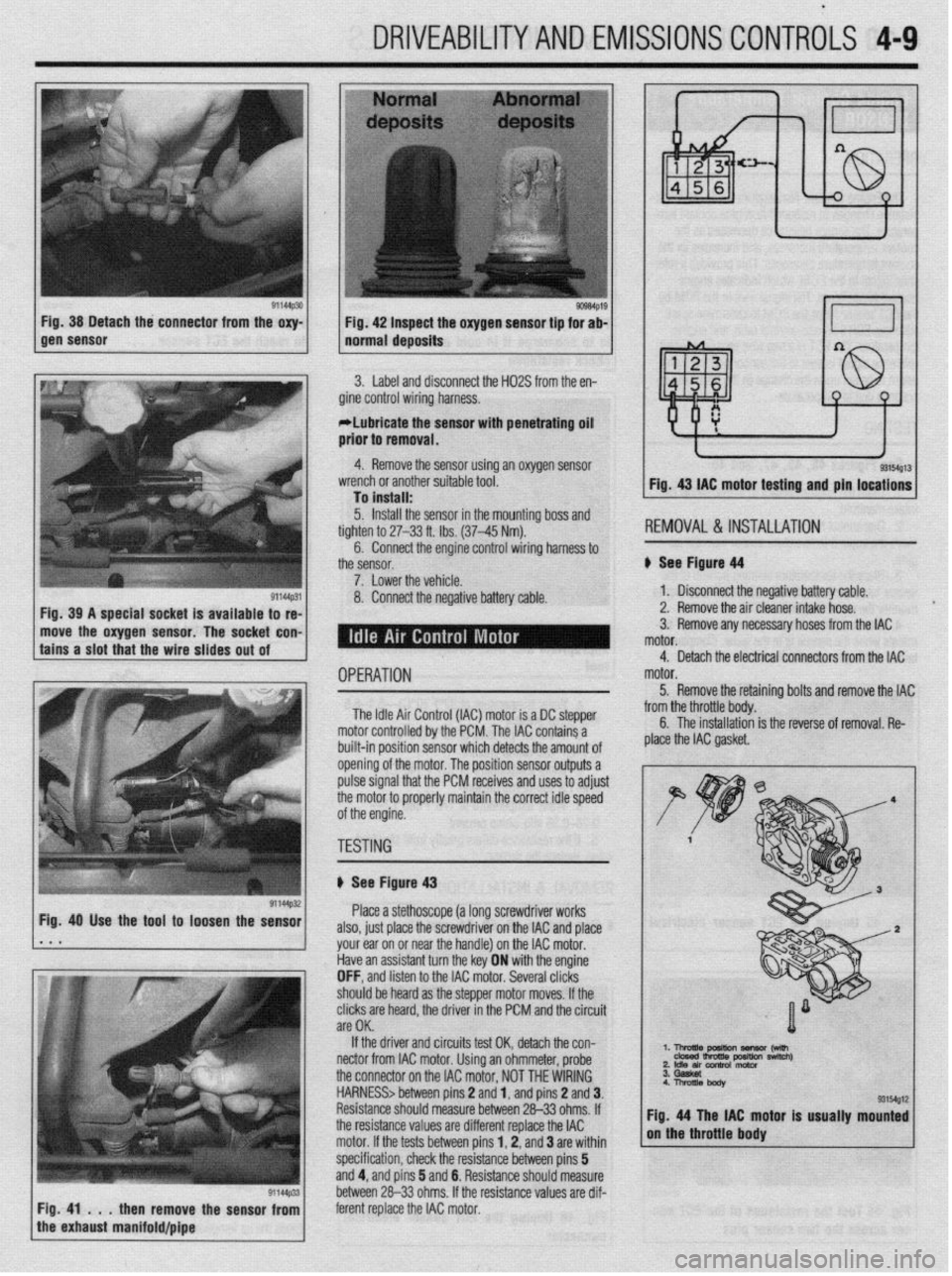

6. Connect the engine control wiring harness to 1 Fia. 43 IAC mntnr tnfitinn and nin Incations 1

KtMUVHL i% IN3 I ALLA I IUN

See Fiaurr! d4

1. Disconnect the negative battery cable.

2. Remove the air cleaner intake hose.

move the oxygen sensor. The socket con- 3. Remove any necessary hoses from the IAC

OPERATION

The Idle Air Control (IAC) motor is a DC stepper

motor controlled by the PCM. The IAC contains a

built-in position sensor which detects the amount of

opening of the motor. The position sensor outputs a

pulse signal that the PCM receives and uses to adjust

the motor to properly maintain the correct idle speed

of the engine. motor.

5. Remove the retainino bolts and remove the IAC

y -_.._ -..- ._... -._ . .._ ._ from the throttle body. C The inc.hllrrti~n a 11o IIIJL(IIIoLIuII is the reverse of removal. Re-

plaie the IAC gasket.

TESTING

I

ti See Figure 43

Place a stethoscope (a long screwdriver works

also, just place the screwdriver on the IAC and place

your ear on or near the handle) on the IAC motor.

Have an assistant turn the key ON with the engine

OFF, and listen to the IAC motor. Several clicks

should be heard as the steooer motor moves. If the

clicks are heard, the driver in the PCM and the circuit

are OK.

If the driver and circuits test OK, detach the con-

nectar from IAC motor. Using an ohmmeter, probe ‘. l-!AEz?rn~ -w

2 Idle an conh0l motor nswltch)

the connector on the IAC motor, NOT THE WIRING

HARNESS> between pins 2 and 1, and pins 2 and 3.

Resistance should measure between 26-33 ohms. If

the resistance values are different replace the IAC tor is usually mounted

motor. If the tests between pins 1,2, and 3 are within

specification, check the resistance between pins 5

and 4, and pins 5 and 6. Resistance should measure

between 26-33 ohms. If the resistance values are dif-

then remove the sensor from ferent replace the IAC motor.

Page 153 of 408

4-10 DRIVEABILITYAND EMISSIONS CONTROLS

I

OPERATION

The Engine Coolant Temperature (ECT) sensor re-

sistance changes in response to engine coolant tem-

perature. The sensor resistance decreases as the

coolant temperature increases, and increases as the

coolant temperature decreases. This provides a refer-

ence signal to the PCM, which indicates engine

coolant temperature. The signal sent to the PCM by

the ECT sensor helps the PCM to determine spark-

advance, EGR flow rate, air/fuel ratio, and engine

temperature. The ECT is a two wire sensor, a 5volt

3. Place the temperature sensing portion of the

sensor into a pan of hot water. Use a thermometer to

monitor the water temperature.

4. Measure the resistance across the sensor ter-

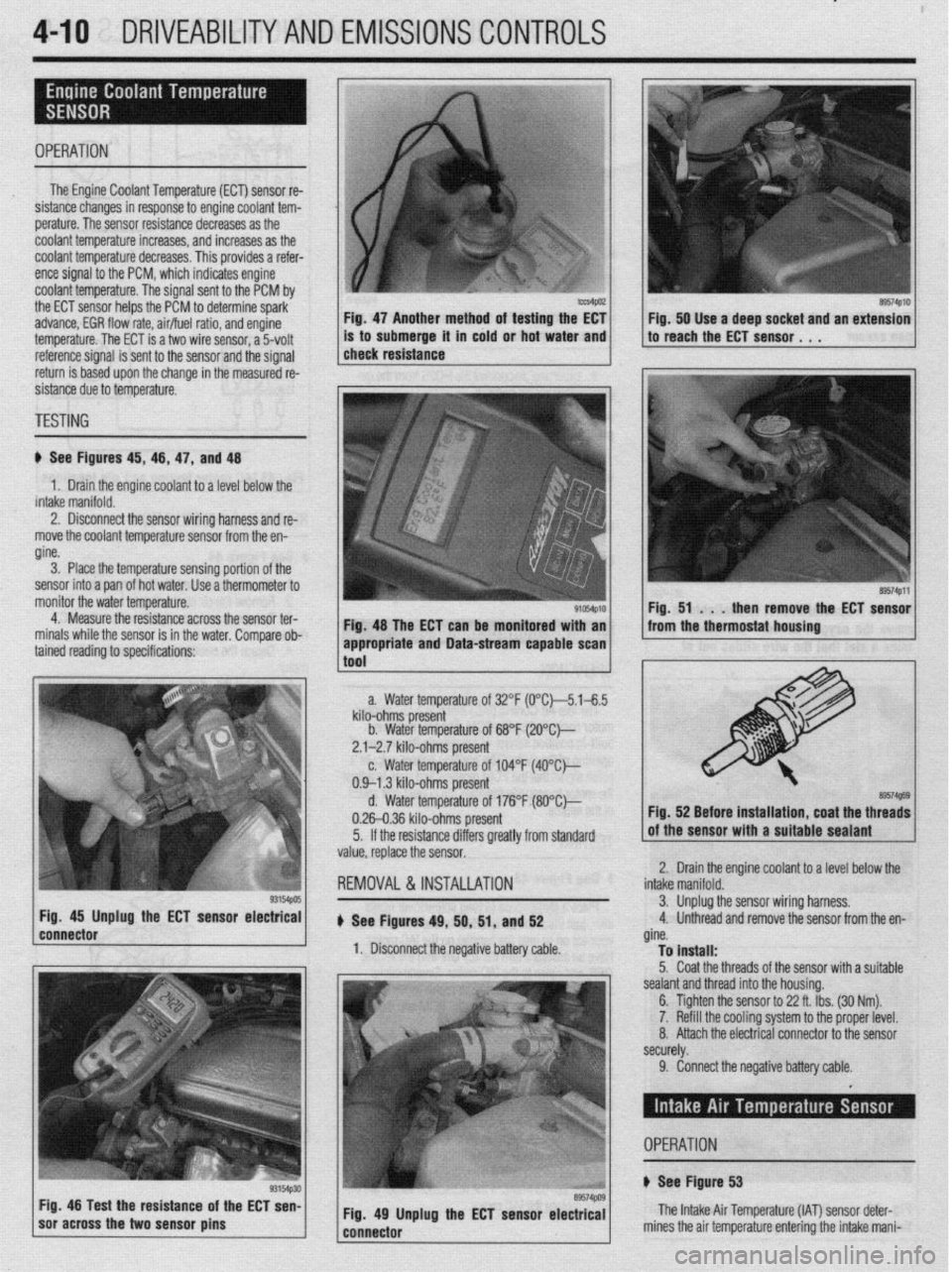

minals while the sensor is in the water. Comoare ob- Fig. 47 Another method of testing the EC1 Fig. 50 Use a deep socket and an extension

is to submerge it in cold or hot water and to reach the ECT sensor. 1 ,

reference signal is sent to the sensor and the signal

return is based upon the change in the measured re-

sistance due to temperature. 1 check resistance

TESTING

ti See Figures 45, 46, 47, and 48

1. Drain the engine coolant to a level below the

intake manifold.

2. Disconnect the sensor wiring harness and re-

move the coolant temperature sensor from the en-

gine.

Fig. 48 The ECT can be monitored with an

tained reading to specifications: ’

93154pos Fig. 45 Unplug the ECT sensor electrical

connector

1 soracross the two sensor pins g3154p30 Fig 48 Test the resistance of the ECT sen-

89574PlO

89574Pll

Fig. 51 . . .

then remove the ECT sensor

from the thermostat housing

a. Water temperature of 32°F (0°C~5.1-6.5

kilo-ohms present

b. Water temperature of 68°F (2O”C)--

2.1-2.7 kilo-ohms present

c. Water temperature of 104°F (4O”C)---

0.9-l .3 kilo-ohms present

d. Water temperature of 176°F (8O”Ck,

0.26-0.36 kilo-ohms present

5. If the resistance differs greatly from standard

value, replace the sensor.

REMOVAL &INSTALLATION

u See Figures 49, 50, 51, and 52

1. Disconnect the negative battery cable. Fig. 52 Before installation, coat the threads

Iolant to a level below the 2. Drain the engine c(

intake manifold.

3. Unplug1 the sensor wiring harness,

4. Unthreac

d and remove the sensor from the en-

gine.

To install:

5. Coat the threads of the sensor with a suitable

sealant and thread into the housing.

6. Tighten the sensor to 22 ft. Ibs. (30 Nm).

7. Refill the cooling system to the proper level.

8. Attach the electrical connector to the sensor

securely. appropriate and Data-stream capable scan 1

1

tnnl

9. Connect the negative battery cable.

Fig. 49 Unplug the ECT sensor electrical

---..^-s-- The Intake Air Temperature (IAT) sensor det

mines the air temnerature enterinn the! intake n er-

- ._ r_ -.-._ _. ._. J . _ ..-. ._

iani- OPERATION

+ See Figure 53

Page 154 of 408

DRIVEABILITYAND EMISSIONS CONTROLi 4-11

fold. Resistance changes in response to the ambient

air temperature. The sensor has a negative tempera-

ture coefficient. As the temperature of the sensor

rises the resistance across the sensor decreases. Thil

provides a signal to the PCM indicating the tempera-

ture of the incoming air charge. This sensor helps the

PCM to determine spark timing and air/fuel ratio. In-

formation from this sensor is added to the pressure

sensor information to calculate the air mass being

sent to the cylinders. The IAT receives a 5-volt refer-

ence signal and the signal return is based upon the

change in the measured resistance due to tempera-

ture.

TESTING

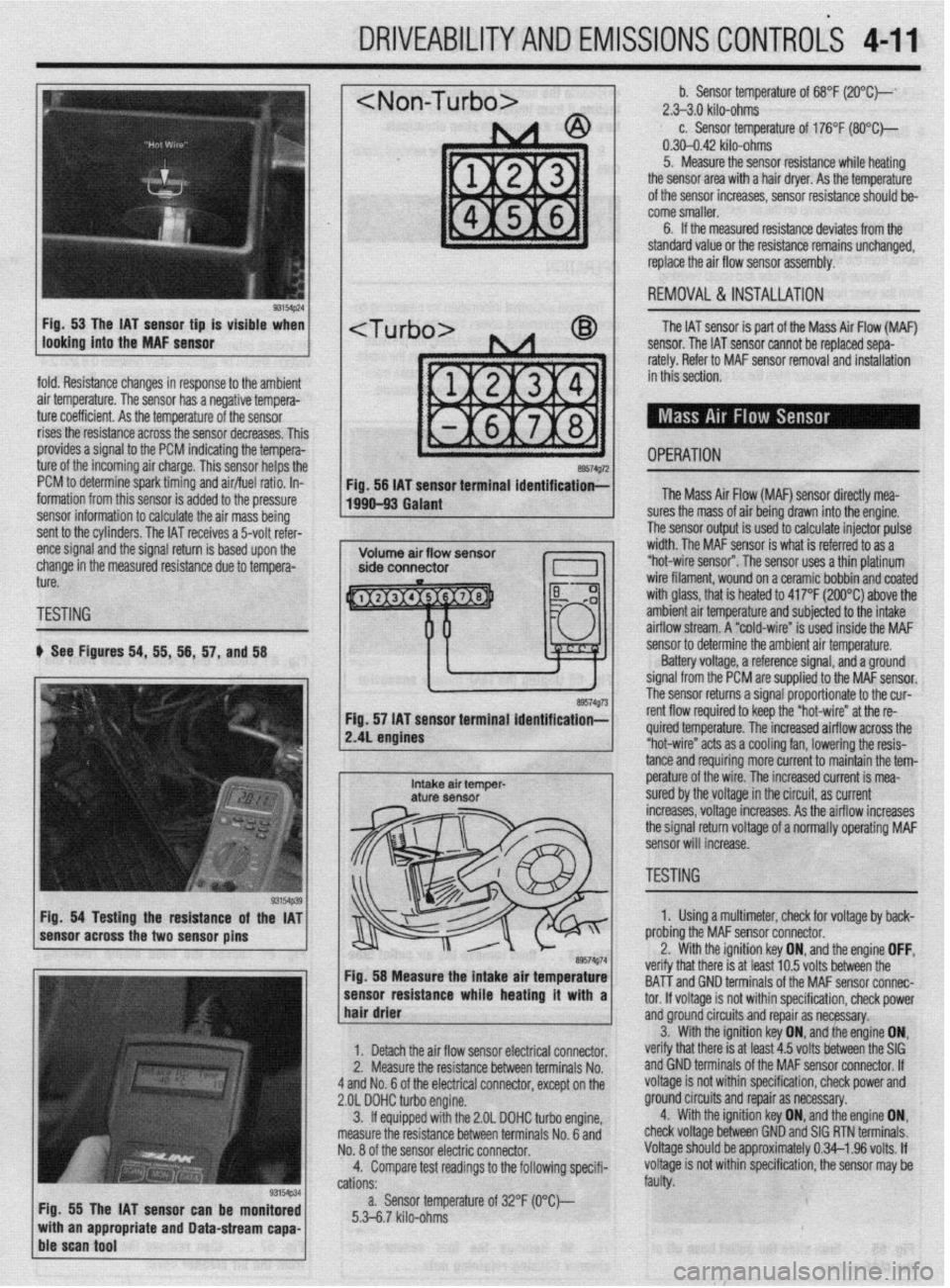

b See Figures 54, 55, 56, 57, and 58

Fig. 54 Testing the resistance of the IAT

sensor across the two sensor pins

Fig. 55 The IAT sensor can be monitored

with an appropriate and Data-stream capa-

ble scan tool

~1 b. Sensor temperature of 68°F (2O”C)--‘ 2.>3.0 kilo-ohms c. Sensor temperature of 176°F (SO*C)-

0.30-0.42 kilo-ohms

5. Measure the sensor resistance while heating

the sensor area with a hair dryer. As the temperature

of the sensor increases, sensor resistance should be-

come smaller.

6. If the measured resistance deviates from the

standard value or the resistance remains unchanged,

replace the air flow sensor assembly.

1 REMOVAL&INSTALLATION

The IAT sensor is part of the Mass Air Flow (MAF)

sensor. The IAT sensor cannot be replaced sepa-

rately. Refer to MAF sensor removal and installation

in this section.

- OPERATION a9574g72 Fig. 56 IAT sensor terminal identification;-

1990-93 Galant The Mass Air Flow (MAF) sensor directly mea-

lres the mass of air being drawn into the engine.

I ?he sensor output is used to calculate injector pulse

width. The MAF sensor is what is referred to as a

“hot-wire sensor”. The sensor uses a thin platinum

wire filament, wound on a ceramic bobbin and coated

with glass, that is heated to 417°F (200°C) above the

amh+en+ nir +PmnPrfijre and subiected to the intake

..I._ ~ ..-.. .“..‘r-,u.. ai mow stream. A “cold-wire” is used inside the MAF

sensor resuirance wnoe nearmg ir wnn a 1

hair drier ‘hat melt: IS al I~“< ,“.., lvllQ UtiLnbtill ,,,=

tnd GND terminals of the MAF sensor connec-

tor. If voltaae is not within specification, check power

1. Detach the air flow sensor electrical connector.

2. Measure the resistance between terminals No.

4 and No. 6 of the electrical connector, except on the

2.OL DOHC turbo engine.

3. ff equipped with the 2.OL DOHC turbo engine,

measure the resistance between terminals No. 6 and

No. 8 of the sensor electric connector.

4. Compare test readings to the following specifi-

cations:

a. Sensor temperature of 32°F (O“C)--

5.3-6.7 kilo-ohms and groundcircuits and repair as necessary.

verify that there is at least 4.5 volts between the SIG 3. With the ignition key ON, and,the engine ON,

and GND terminals of the MAF sensor connector. If

voltage is not within specification, check power and

ground circuits and repair as necessary.

4. With the ignition key ON, and the engine ON,

check voltage between GND and SIG RTN terminals.

Voltage should be approximately 0.34-l .96 volts. If

voltage is not within specification, the sensor may be

faulty.

/ sensor to determine the ambient air temperature.

Battery voltage, a reference signal, and a ground

signal from the PCM are supplied to the MAF sensor.

rho ~pn**r rp+++rns a signal proportionate to the cur-

re. The increased airflow across the

s a cooling fan, lowering the resis-

mo more current to maintain the tem- tance and requir

e^-‘.._^ ^I LL^

I

Intake air temper- pe~a+ure UI me wire. The increased current is mea- aturf sensor sured by the voltage in the circuit, as current

increases, voltage increases. As the airflow increases

the signal return voltage of a normally operating MAF

sensor will increase.

, ~~1 TESTING - II ire” at the re-

89574g74 Fig. 58 Measure the intake air temperature

-----_ ---1-a---- L..- L--1. . . .*a 1. Using a multimeter, check for voltage by back-

nrr\hinn +hn MAF sensor connector.

the ignition key ON, and the engine OFF, .^-^ :- -’ ‘.txt In E; \mltr hahrman tha veriry t

BAT-T i

Page 156 of 408

DRIVEABILITYAND EMISSIONS CONTROiS 4-13

4. If the voltaoe check in sbo 3 was OK. then

check the voltage-between GND’and SIG RTN termi-

nals and suddenly depress the accelerator, the volt-

age should rise and stay at 2.4 volts. If the voltage

OPERATION does not stay at 2.4 volts, replace the MAP sensor.

REMOVAL&INSTALLATION '

ti See Figures 68, 69, and 70

1. Disconnect the negative bat lery cable.

2. Detach the connector for thl e MAP sensor.

3. Remove the sensor mountir ig screws.

4. Lift the sensor up and remove it from the intake

manifold. The Throttle Posii

ti-* \*. Inn ITPl smsnr is 8 Dotentiome- , WI...,". *., . ter that provides a si gnal to the PCM that is directly

proportion: il to the throttle plate position. The TP

sensor is rr iounted on the side of the throttle body

and is connected to the throttle plate shaft. The TP

sensor monitors throttle plate movement and posi-

tion, and transmits an appropriate electrical signal to

the PCM. These signals grp IIQX-I hv rho PCM to ad-

just the air/flnI mivtlI “-- ------li

5. The installation is the reverse of removal. WI I dLfUl U full throttle The TP c

UyI ,,,,,,,:re, spark timing and EGR opera-

ng to engine load at idle, part throttle, or

The TP sensor is not adjustable.

..-

lensor receives a 5 volt reference signal

and a ground circuit from the PCM. A return signal

circuit is connected to a wiper that runs on a resistor

internally on the sensnr ThP fmth@r rho throttle is

opined the winnr mr oP -*lY”, .I,” ..,y’V, 111 Jves along the resistor, at wide

en throttle, the wiper essentially creates a loop be-

tween the reference signal and the signal return re-

turning the full or nearly full 5 volt signal back to the

PCM. At idle, the signal return should be approxi-

rnz

rtely 0.9 volts.

TF

iSTING

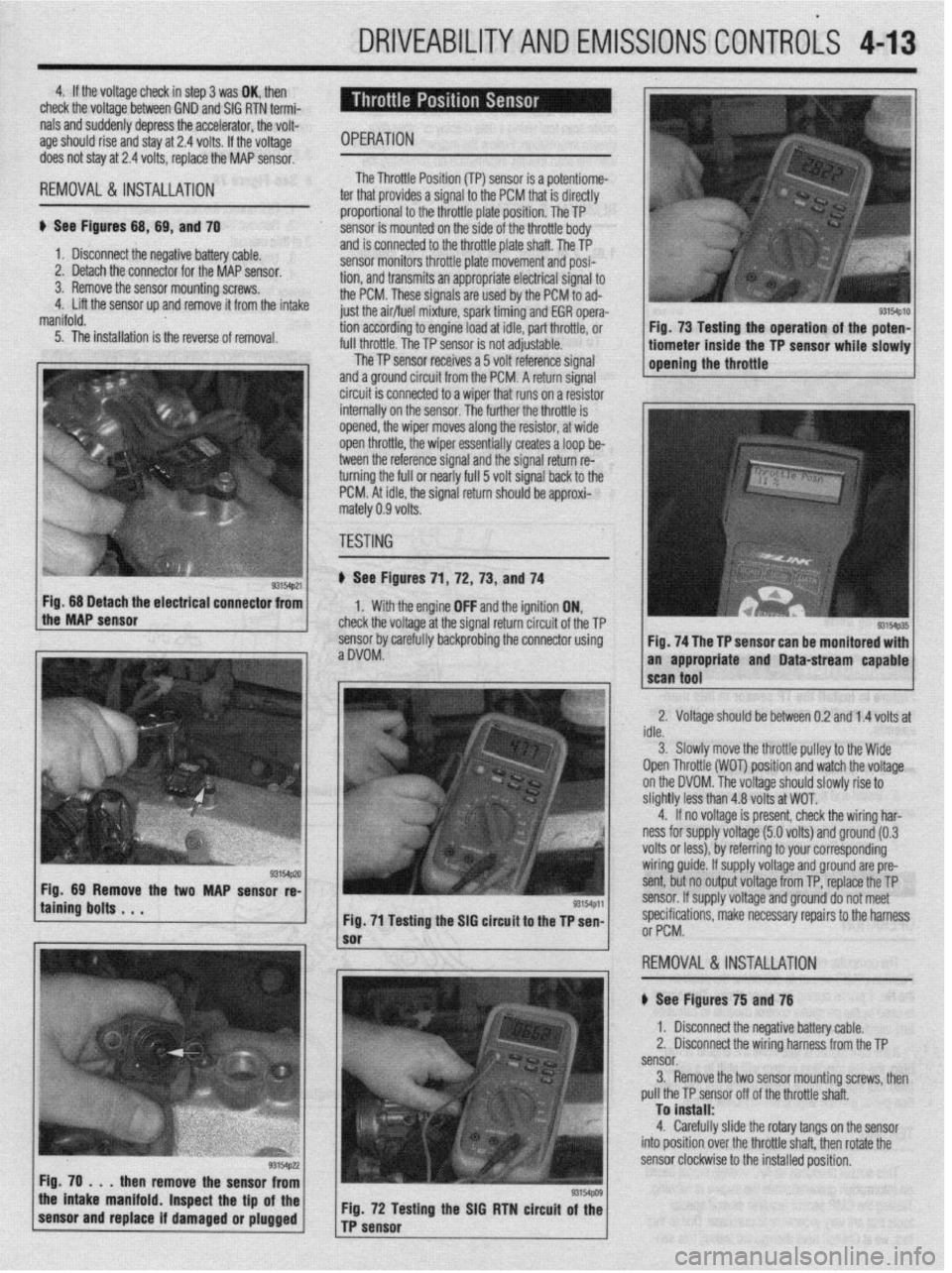

) See Figures 71 ,72, 73, and 74

1. With the engine OFF and the ignition ON,

check the voltage at the signal return circuit of the TP

sensor bv carefullv backorobina the connector using

aDVOM: . ” Fig. 68 Detach the electrical connector from

the MAP sensor

taining bolts . . . WMp,l

Fig. 71 Testing the SIG circuit to the TP sen-

then remove the sensor from

the intake manifold. Inspect the tip of the

sensor and replace if damaged or plugged Fig. 72 Testing the SIG RTN circuit of the

TP sensor

sm4p10 I Fig. 73 Testing the operation of the poten- 1

tiometer inside the TP sensor while slowly 1

opening the throttle

Fig. 74 The TP sensor can be monitored with

an appropriate and Data-stream capable

2. Voltage should be between 0.2 and 1.4 volts at

idle.

3. Slowlv move the throttle oullev to the Wide

Open Throttle (WOT) position and watch the voltage

on the DVOM. The voltage should slowly rise to

slightly less than 4.8 volts at WOT.

4. If no voltage is present, check the wiring har-

ness for supply voltage (5.0 volts) and ground (0.3

volts or less), by referring to your corresponding

wiring guide. If supply voltage and ground are pre-

sent, but no output voltage from TP, replace the TP

sensor. If supply voltage and ground do not meet

specifications, make necessarv reoairs to the harness

or PCM.

,

REMOVAL&INSTALLATION

# See Figures 75 and 76

1. Disconnect the negative battery cable.

2. Disconnect the wiring harness from the TP

sensor.

3. Remove the two sensor mounting screws, then

pull the TP sensor off of the throttle shaft.

To install:

4. Carefully slide the rotary tangs on the sensor

into position over the throttle shaft. then rotate the

sensor clockwise to the installed position.

Page 169 of 408

4-26 DRIVEABILITYAND EMISSIONS CONTROLS

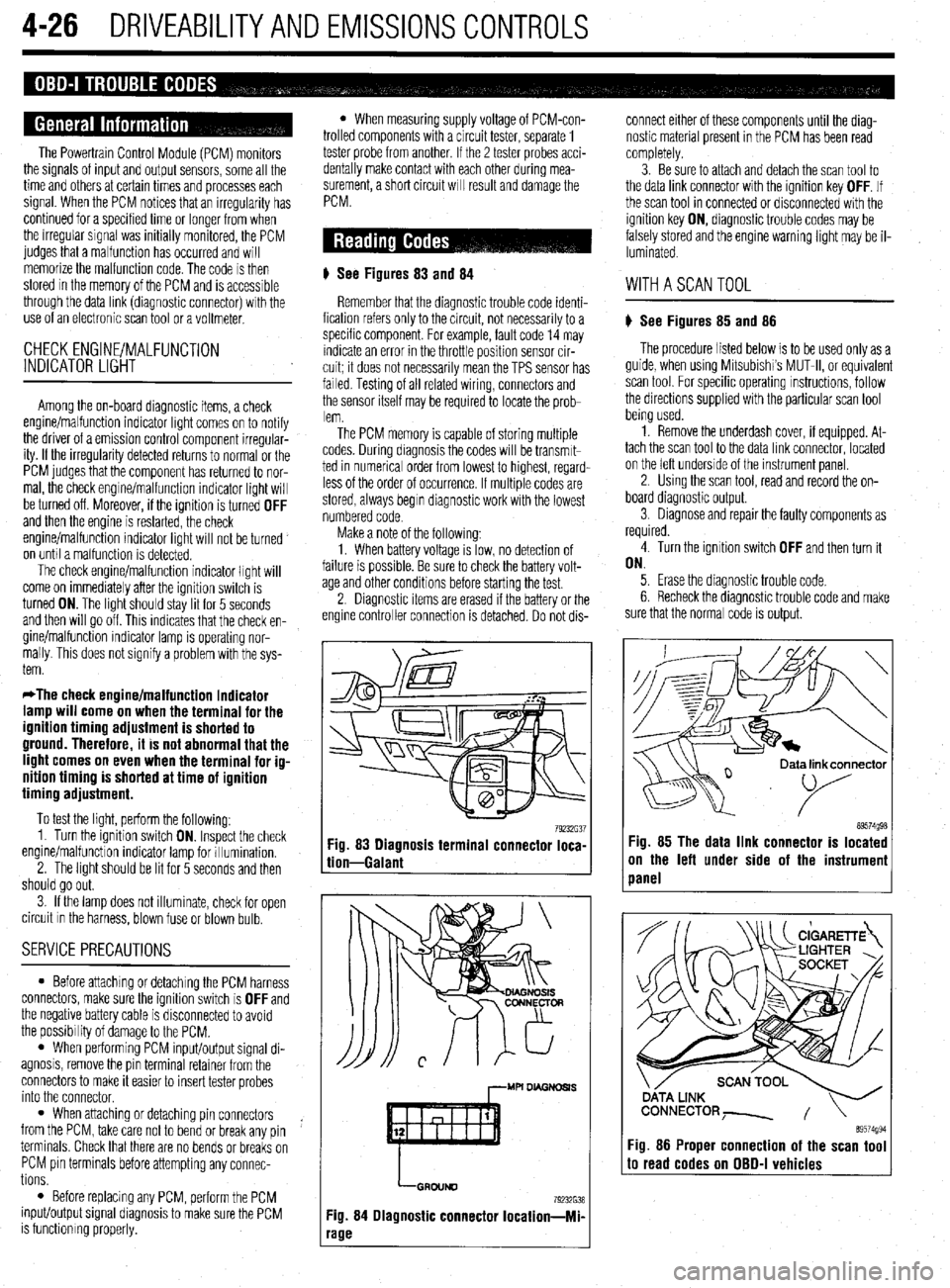

The Powertrain Control Module (PCM) monitors

the signals of input and output sensors, some all the

time and others at certain times and processes each

signal. When the PCM notices that an irregularity has

continued for a specified time or longer from when

the irregular signal was initially monitored, the PCM

judges that a malfunction has occurred and will

memorize the malfunction code. The code is then

stored in the memory of the PCM and is accessible

through the data link (diagnostic connector) with the

use of an electronic scan tool or a voltmeter.

CHECK ENGINE/MALFUNCTION

INDICATOR LIGHT

Among the on-board diagnostic items, a check

engine/malfunction indicator light comes on to notify

the driver of a emission control component irregular-

ity. If the irregularity detected returns to normal or the

PCM judges that the component has returned to nor-

mal, the check engine/malfunction indicator light will

be turned off Moreover, if the ignition is turned OFF

and then the engine is restarted, the check

engine/malfunction indicator light will not be turned

on unttl a malfunction is detected.

The check engine/malfunction indicator light will

come on immediately after the ignition switch is

turned ON. The light should stay lit for 5 seconds

and then will go off. This Indicates that the check en-

gine/malfunction indicator lamp is operating nor-

mally. This does not signify a problem with the sys-

tem.

*The check engine/malfunction indicator

lamp will come on when the terminal for the

ignition timing adjustment is shorted to

ground. Therefore, it is not abnormal that the

light comes on even when the terminal for ig-

nition timing is shorted at time of ignition

timing adjustment.

To test the light, perform the following:

1. Turn the ignition switch ON. Inspect the check

engine/malfunction indicator lamp for Illumination.

2. The light should be lit for 5 seconds and then

should go out.

3. If the lamp does not illuminate, check for open

circuit In the harness, blown fuse or blown bulb.

SERVICE PRECAUTIONS

l Before attachrng or detaching the PCM harness

connectors, make sure the ignition switch is OFF and

the negative battery cable is disconnected to avoid

the possibility of damage to the PCM.

l When performing PCM input/output signal di-

agnosis, remove the pin terminal retainer from the

connectors to make it easier to insert tester probes

into the connector.

l When attaching or detaching pin connectors ,

from the PCM, take care not to bend or break any pin

terminals. Check that there are no bends or breaks on

PCM pin terminals before attempting any connec-

tions.

l Before replacing any PCM, perform the PCM

input/output signal diagnosis to make sure the PCM

is functioning properly.

l When measuring supply voltage of PCM-con-

trolled components with a circuit tester, separate 1

tester probe from another. If the 2 tester probes acci-

dentally make contact with each other during mea-

surement, a short circuit WIII result and damage the

PCM.

# See Figures 83

and 84

Remember that the diagnostic trouble code identi-

fication refers only to the circuit, not necessarily to a

specific component. For example, fault code 14 may

indicate an error in the throttle position sensor cir-

cuit; it does not necessarily mean the TPS sensor has

failed Testing of all related wiring, connectors and

the sensor itself may be required to locate the prob-

lem.

The PCM memory is capable of storing multiple

codes. During diagnosis the codes will be transmlt-

ted in numerical order from lowest to highest, regard-

less of the order of occurrence. If multiple codes are

stored, always begin diagnostic work with the lowest

numbered code

Make a note of the following:

1. When battery voltage IS low, no detection of

failure is possible. Be sure to check the battery volt-

age and other conditions before starting the test.

2. Diagnostic items are erased if the battery or the

engine controller connection is detached. Do not dis- connect either of these components until the diag-

nostic material present in the PCM has been read

completely.

3. Be sure to attach and detach the scan tool to

the data link connector with the ignition key OFF. If

the scan tool in connected or disconnected with the

ignition key ON, diagnostic trouble codes may be

falsely stored and the engine warning light may be il-

luminated. WITHASCANTOOL

) See Figures 85 and 86

The procedure listed below is to be used only as a

guide, when using Mitsubishi’s MUT-II, or equivalent

scan tool. For specific operating instructions, follow

the directions supplied with the particular scan tool

bemg used.

1. Remove the underdash cover, if equipped. At-

tach the scan tool to the data link connector, located

on the left underside of the instrument panel.

2. Using the scan tool, read and record the on-

board diagnostic output.

3. Diagnose and repair the faulty components as

required

4. Turn the ignition switch OFF and then turn it

ON.

5. Erase the diagnostic trouble code.

6 Recheck the diaanostic trouble code and make

sure that the normal &de is output.

79232G37 89574g98 Fig. 83 Diagnosis terminal connector loca-

tion-Galant Fig. 85 The data link connector is located

on the left under side of the instrumeni

panel

,--MU DL4GNDSl.S

LGRDIJND

79232638

Fig. 84 Diagnostic connector Iocation-Mi-

‘age

ata link connector

89574994 Fig. 86 Proper connection of the scan tool to read codes on OBD-I vehicles

Page 170 of 408

DRIVEABILITYAND EMISSIONS CONTROLS 4-27

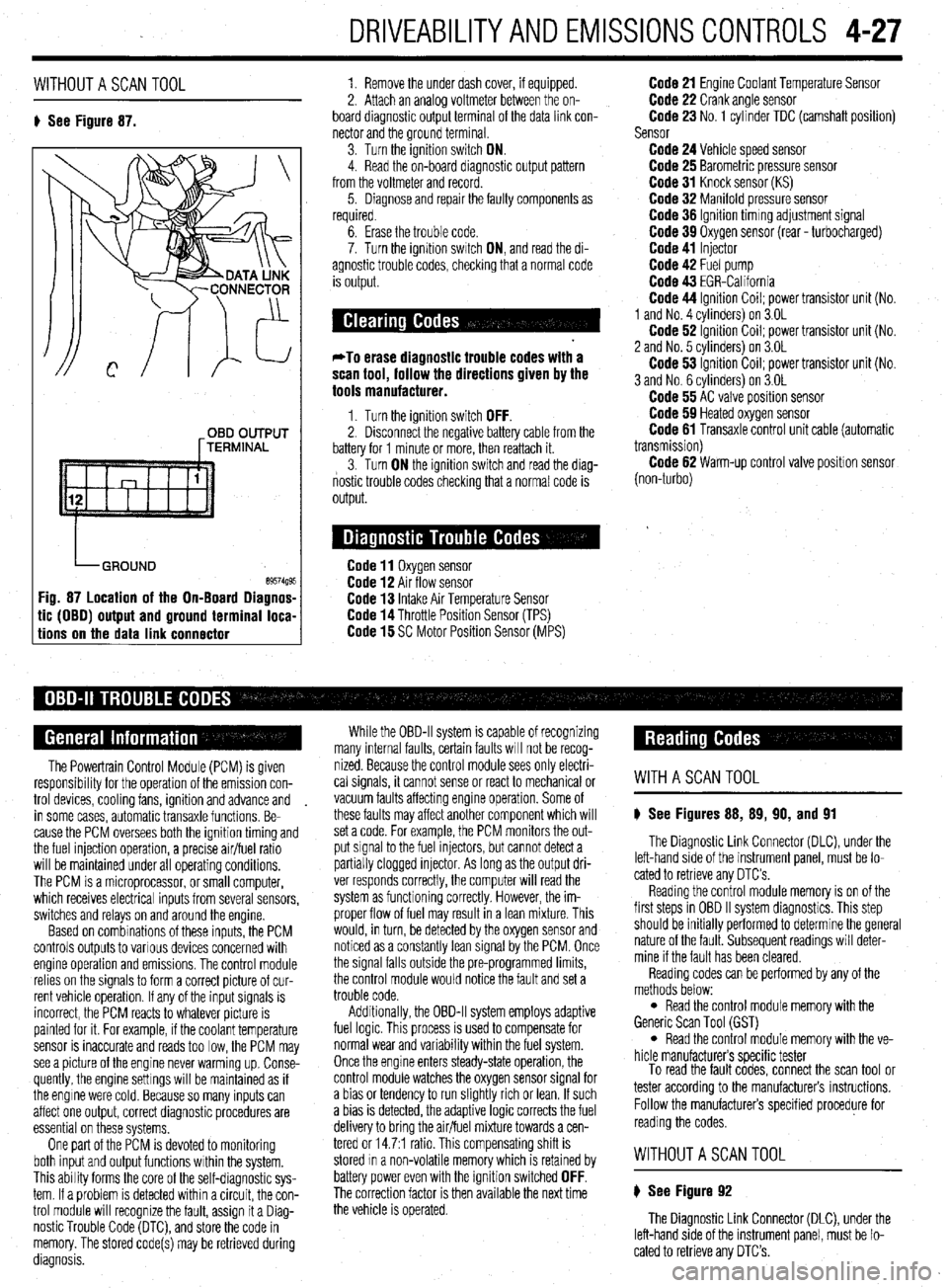

WITHOUTASCANTOOL

8 See Figure 87. 1. Remove the under dash cover, if equipped.

2. Attach an analoa voltmeter between the on-

board diagnostic outpit terminal of the data link con-

nector and the ground terminal

3. Turn the ignition switch ON.

4. Read the on-board diagnostic output pattern

from the voltmeter and record.

5. Diagnose and repair the faulty components as

required.

OBD OUTPUT

[TERMINAL

tic (OBO) output and ground terminal loca-

tions on the data link connector

6. Erase the trouble code.

7. Turn the ignition swatch ON, and read the di-

agnostic trouble codes, checking that a normal code

is output.

*To erase diagnostic trouble codes with a

scan tool, follow the directions given by the

tools manufacturer.

1. Turn the ignition switch OFF. 2. Disconnect the negative battery cable from the

battery for 1 minute or more, then reattach it.

3. Turn ON the ignition switch and read the diag-

nostic trouble codes checking that a normal code is

output.

Code 11 Oxygen sensor Code 12 Air flow sensor Code 13 Intake Air Temperature Sensor Code 14 Throttle Position Sensor (TPS) Code 15 SC Motor Position Sensor (MPS)

Code 21 Engine Coolant Temperature Sensor Code 22 Crank angle sensor Code 23 No. 1 cylinder TDC (camshaft position)

Sensor

Code 24 Vehicle speed sensor Code 25 Barometric pressure sensor Code 31 Knock sensor (KS) Code 32 Manifold pressure sensor Code 36 Ignition timmg adjustment signal Code 39 Oxygen sensor (rear - turbocharged) Code 41 Injector Code 42 Fuel pump Code 43 EGR-California Code 44 Ignition Coil; power transistor unit (No.

1 and No. 4 cvlinders) on 3.OL

Code 62 ignition Coil; power transistor unit (No.

2 and No. 5 cvlinders) on 3.OL

Code 53 ignition Coil; power transistor unit (No.

3 and No. 6 cylinders) on 3.OL

Code 55 AC valve position sensor Code 59 Heated oxygen sensor Code 61 Transaxle control unit cable (automatic

transmission)

Code 62 Warm-up control valve position sensor

(non-turbo)

The Powertrain Control Module (PCM) is given

responsibrlity for the operation of the emission con-

trol devices, cooling fans, ignition and advance and

in some cases, automatic transaxle functions. Be-

cause the PCM oversees both the ignition timing and

the fuel injection operation, a precise air/fuel ratio

will be maintained under all operating conditions,

The PCM is a microprocessor, or small computer,

which receives electrical inputs from several sensors,

switches and relays on and around the engine.

Based on combinations of these inputs, the PCM

controls outputs to various devices concerned with

engine operation and emissions. The control module

relies on the signals to form a correct picture of cur-

rent vehicle operation. If any of the input signals is

incorrect, the PCM reacts to whatever picture is

painted for it. For example, if the coolant temperature

sensor is inaccurate and reads too low, the PCM may

see a picture of the engine never warming up. Conse-

quently, the engine settings will be maintained as if

the engine were cold. Because so many inputs can

affect one output, correct diagnostic procedures are

essential on these systems,

One part of the PCM is devoted to monitoring

both input and output functions within the system.

This ability forms the core of the self-diagnostic sys-

tem. If a problem is detected within a circuit, the con-

trol module will recognize the fault, assign it a Diag-

nostic Trouble Code (DTC), and store the code in

memory. The stored code(s) may be retrieved during

diagnosis. While the OBD-II system is capable of recognizing

many internal faults, certain faults WIII not be recog-

nized. Because the control module sees only electri-

cal signals, it cannot sense or react to mechanical or

vacuum faults affecting engine operation. Some of

these faults may affect another component which will

set a code. For example, the PCM monitors the out-

put signal to the fuel injectors, but cannot detect a

partially clogged injector. As long as the output dri-

ver responds correctly, the computer will read the

system as functioning correctly. However, the im-

proper flow of fuel may result in a lean mixture. This

would, in turn, be detected by the oxygen sensor and

noticed as a constantly lean signal by the PCM. Once

the signal falls outside the pre-programmed limits,

the control module would notice the fault and set a

trouble code.

Additionally, the OBD-II system employs adaptive

fuel logic. This process is used to compensate for

normal wear and variability within the fuel system.

Once the engine enters steady-state operation, the

control module watches the oxygen sensor signal for

a bias or tendency to run slightly rich or lean. If such

a bias is detected, the adaptive logic corrects the fuel

delivery to bring the air/fuel mixture towards a cen-

tered or 14.7:1 ratio. This compensating shift is

stored In a non-volatile memory which is retained by

battery power even with the ignition switched

OFF. The correction factor is then available the next time

the vehicle is operated.

WITHASCANTOOL

8 See Figures 88, 89, 90, and 91

The Diagnostic Link Connector (DLC), under the

left-hand side of the instrument panel, must be lo-

cated to retrieve any OTC’s

Reading the control module memory is on of the

first steps in OBD II system diagnostics. This step

should be initially performed to determine the general

nature of the fault. Subsequent readings will deter-

mine if the fault has been cleared.

Reading codes can be performed by any of the

methods below:

l Read the control module memory with the

Generic Scan Tool (GST)

l Read the control module memory with the ve-

hicle manufacturers specific tester

To read the fault codes, connect the scan tool or

tester according to the manufacturers instructions.

Follow the manufacturers specified procedure for

reading the codes.

WITHOUTASCANTOOL

8 See Figure 92

The Diagnostic Link Connector (DLC), under the

left-hand side of the instrument panel, must be lo-

cated to retrieve any DTC’s.

Page 190 of 408

FUELSYSTEM 513

l Always replace worn fuel fitting O-rings with

new. Do not substitute fuel hose or equivalent, where

I

The Multi-Point Injection (MPI) system is electroni-

rally controlled by the Engine Control Module (ECM),

based on data from various sensors. The ECM controls

the fuel flow, idle speed and ignition timing. fuel pipe is installed.

Fuel is supplied to the injectors by an electric in-

tank fuel pump and is distributed to the respective in-

jectors via the main fuel pipe. The fuel pressure ap-

plied to the injector is constant and higher than the

pressure in the intake manifold. The pressure is con-

trolled by the fuel pressure regulator. The excess fuel

is returned to the fuel tank through the fuel return pipe.

When an electric current flows in the injector, the

injector valve is fully opened to supply fuel. Since the

fuel pressure is constant, the amount of the fuel in-

jetted from the injector into the manifold is increased

or decreased in proportion to the time the electric

current flows. Based on ECU signals, the injectors in-

ject fuel to the cylinder manifold ports in firing order. Fuel injection systems remain under pres-

sure after the engine has been turned OFF.

Properly relieve fuel pressure before discon-

neeting any fuel lines. Failure to do so may

result in fire or personal injury.

1. Turn the ignition to the OFF position.

2. Loosen the fuel filler cap to release fuel tank

pressure.

I

The flow rate of the air drawn through the air

cleaner is measured by the air flow sensor. The air

enters the air intake plenum or manifold through the

throttle body. In the intake manifold, the air is mixed

with the fuel from the injectors and is drawn into the

cylinder, The air flow rate is controlled according to

the degree of the throttle valve and the servo motor

openings. The system is monitored through a num-

ber of sensors which feed information on engine con-

ditions and requirements to the ECM. The ECM cal-

culates the injection time and rate according to the

signals from the sensors,

Safety is the most important factor when perform-

ing not only fuel system maintenance but any type of

maintenance. Failure to conduct maintenance and re-

pairs in a safe manner may result in serious personal

injury or death. Maintenance and testing of the vehi-

cle’s fuel system components can be accomplished

safely and effectively by adhering to the following

rules and guidelines.

l To avoid the possibility of fire and personal in-

jury, always disconnect the negative battery cable un-

less the repair or test procedure requires that battery

voltage be applied.

l Always relieve the fuel system pressure prior to

disconnecting any fuel system component (injector,

fuel rail, pressure regulator, etc.), fitting or fuel line

connection. Exercise extreme caution whenever re- Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or va-

pors to come in contact with a spark or open

flame. Keep a dry chemical fire extinguisher

near the work area. Always keep fuel in a con-

tainer specifically designed for fuel storage;

also, always properly seal fuel containers to

avoid the possibility of fire or explosion.

3. For the Mirage, Diamante, and 1994-00

Galant, remove the rear seat cushion, then remove

the service cover and detach the fuel pump harness

connector.

4. For the 1990-93 FWD Galant, detach the fuel

pump harness connector located in the area of the

fuel tank. It may be necessary to raise the vehicle to

access the connector.

5. For the 1990-93 AWD Galant, remove the car-

pet from the trunk, locate the fuel tank wiring at the

pump access cover, then detach the wiring.

6. Start the vehicle and allow it to run until it

stalls from lack of fuel. Turn the key to the OFF posi-

tion.

7. Disconnect the negative battery cable, then at-

tach the fuel pump connector. Install the access .

cover, cushion or carpet as necessary.

8. Wrap shop towels around the fitting that is be-

ing disconnected to absorb residual fuel in the lines.

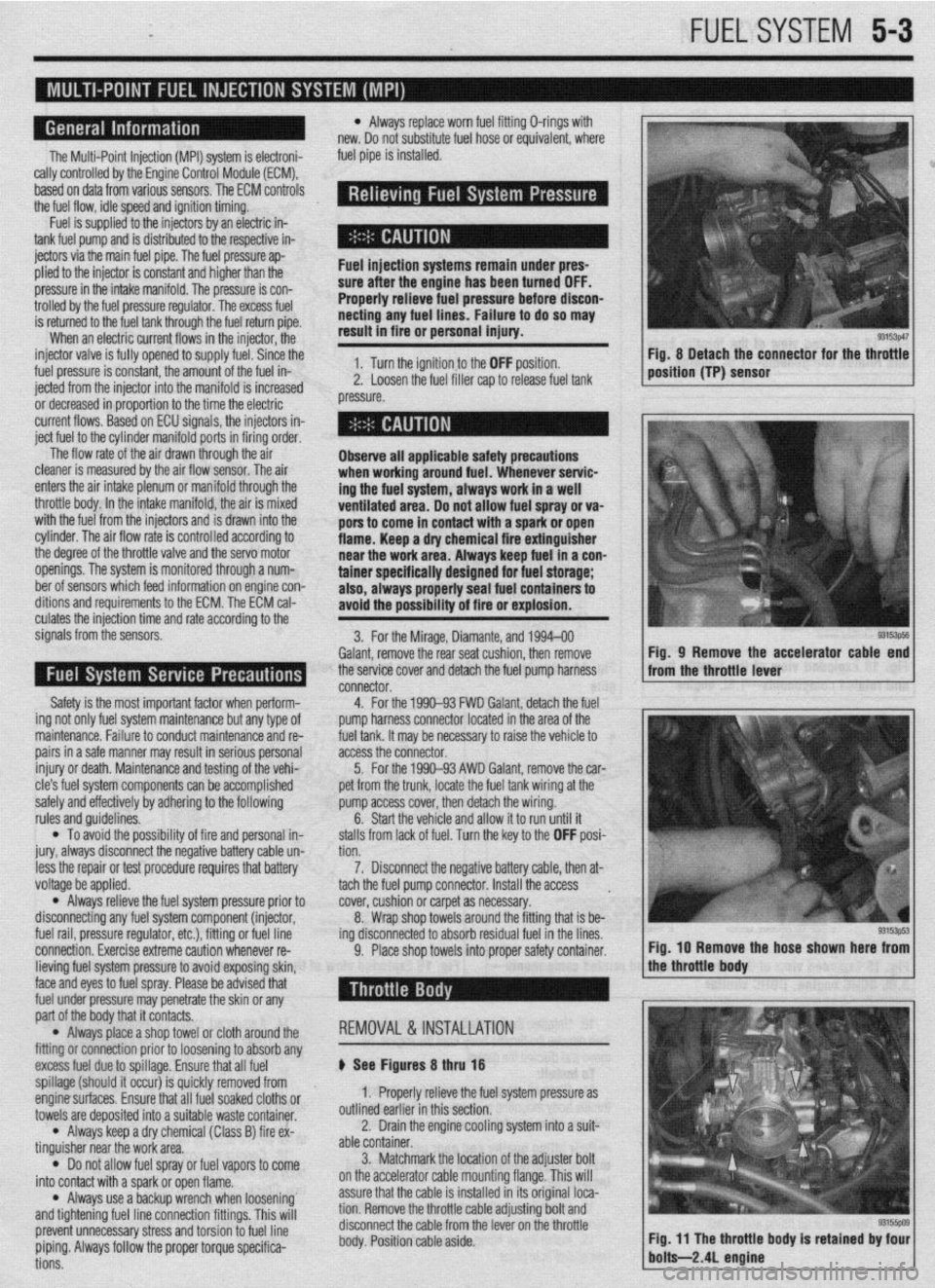

9. Place shop towels into proper safety container. Fig, 8 Detach the connector for the throttle

position (TP) sensor

93153ps5 Fig, 9 Remove the accelerator cable end

from the throttle lever

Fig. IO Remove the hose shown here from

lieving fuel system pressure to avoid exposing skin,

face and eyes to fuel spray. Please be advised that

fuel under pressure may penetrate the skin or any

part of the body that it contacts.

l Always place a shop towel or cloth around the

fitting or connection prior to loosening to absorb any

excess fuel due to spillage. Ensure that all fuel

spillage (should it occur) is quickly removed from

enginesurfaces. Ensure that all fuel soaked cloths or

towels are deposited into a suitable waste container.

l Always keep a dry chemical (Class B) fire ex-

tinguisher near the work area.

l Do not allow fuel spray or fuel vapors to come

into contact with a spark or open flame.

l Always use a backup wrench when loosening’

and tightening fuel line connection fittings. This will

prevent unnecessary stress and torsion to fuel line

piping. Always follow the proper torque specifica-

tions. REMOVAL &INSTALLATION

p See Figures 8 thru 18

1. Properly relieve the fuel system pressure as

outlined earlier in this section.

2. Drain the engine cooling system into a suit-

able container.

3. Matchmark the jocation of the adjuster bolt

on the accelerator cable mounting flange. This will

assure that the cable is installed in its original loca-

tion. Remove the throttle cable adjusting bolt and

disconnect the cable from the lever on the throttle

body. Position cable aside.