roof MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 13 of 408

l

l-14 GENERALINFORMATIONAND MAINTENANCE

Proper maintenance and tune-up is the key to long

and trouble-free vehicle life, and the work can yield

its own rewards. Studies have shown that a properly

tuned and maintained vehicle can achieve better gas

mileage than an out-of-tune vehicle. As a conscien-

tious owner and driver, set aside a Saturday morning,

say once a month, to check or replace items which

could cause major problems later. Keep your own

personal log to jot down which services you per-

formed, how much the parts cost you, the date, and

the exact odometer reading at the time. Keep all re-

selfer, these receipts are the only proof you have that ceipts for such items as engine oil and filters, so that

they may be referred tp in case of related problems or

to determine operating expenses. As a do-it-your- the required maintenance was performed. In the event

of a warranty problem, these receipts will be invalu-

able.

The literature provided with your vehicle when it

was originally delivered includes the factory recom-

mended maintenance schedule. If you no longer have

this literature, replacement copies are usually avail-

able from the dealer. A maintenance schedule is pro-

vided later in this section, in case you do not have

the factory literature. *

REMOVAL &INSTALLATION

Except 2.gL Turbocharged Engine

b See Figures 36 thru 41 9. Place a new air cleaner element inside the

lower housing. Make sure the seal on the element is

fully seated in the groove.

10. Install the upper air cleaner housing and inlet

tube onto the lower housing.

11. Tighten the clamp on the inlet tube at the

throttle body.

12. Attach the breather hose onto the air inlet tube.

13. Plug the connector into the MAF sensor.

14. Attach the air cleaner housing retaining clips.

15. Connect the negative battery cable.

2.DL Turbocharged Engine

b See Figure 42

1. Disconnect the negative battery cable.

2. Detach the air flow sensor connector.

3. Unfasten the boost hose.

4. Disconnect the solenoid valve with hoses.

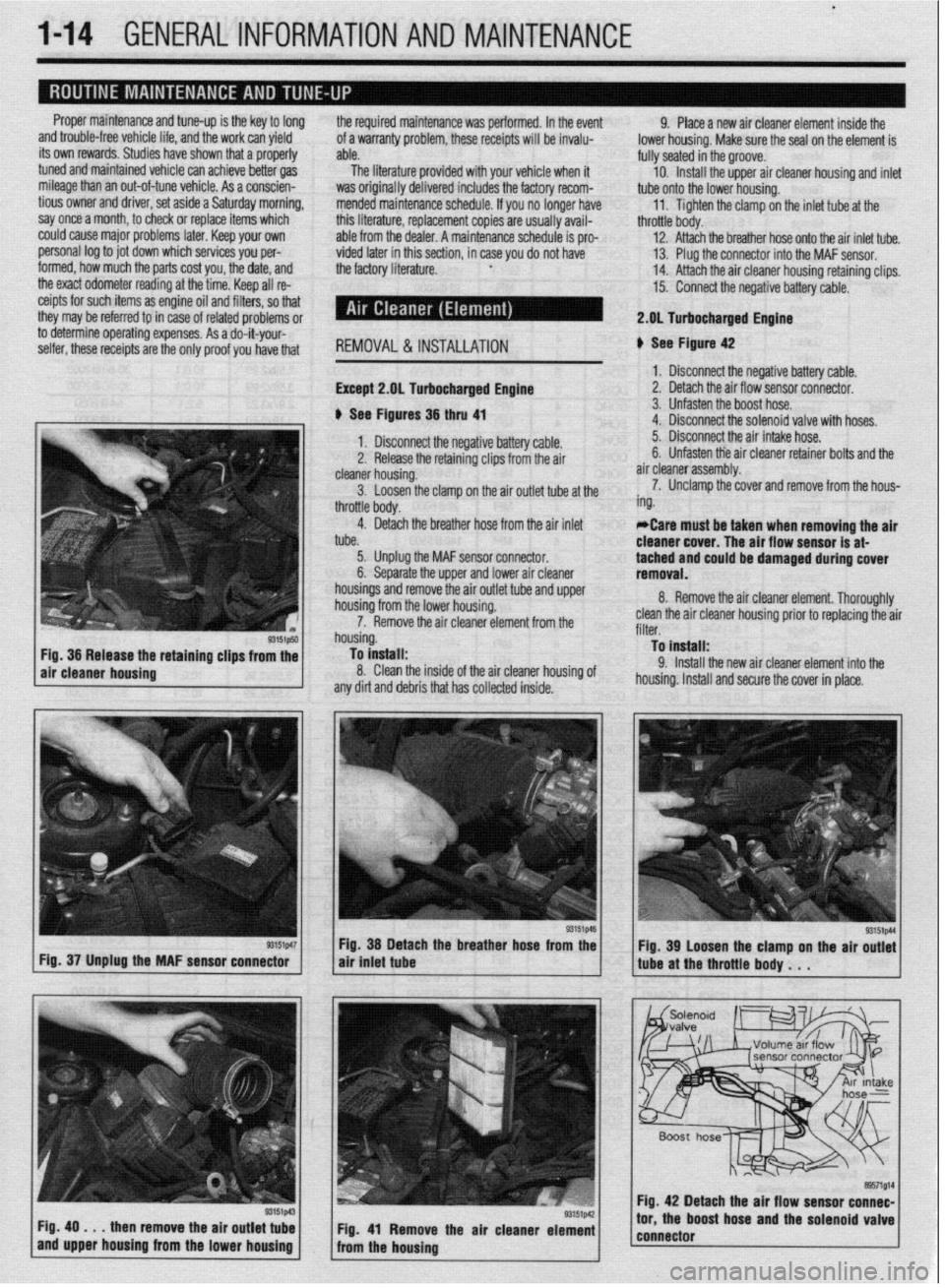

93151p50 Fig. 36 Release the retaining clips from the

air cleaner housing

r3151p47 Fig. 37 Unplug the MAF sensor connector

Fig. 49

. . . then remove the air outlet tube

and upper housing from the lower housing 1. Disconnect the negative battery cable. 5. Disconnect the air intake hose.

2. Release the retaining clips from the air 6. Unfasten tie air cleaner retainer bolts and the

cleaner housing. air cleaner assembly.

3. Loosen the clamp on the air outlet tube at the 7. Unclamp the cover and remove from the hous-

throttle body. ing.

4. Detach the breather hose from the air inlet

tube. *Care must be taken when removing the air

cleaner cover. The air flow sensor is at-

5. Unplug the MAF sensor connector.

6. Separate the upper and lower air cleaner tached and could be damaged during cover

removal.

housings and remove the air outlet tube and upper

housing from the lower housing.

7. Remove the air cleaner element from the

housing.

To install:

8. Clean the inside of the air cleaner housing of

any dirt and debris that has collected inside. 8. Remove the air cleaner element. Thoroughly

clean the air cleaner housing prior to replacing the air

filter.

To install:

9. Install the new air cleaner element into the

housing. Install and secure the cover in place.

Fig. 38 Detach the breather hose from the

air tniet tube

Fig. 41 Remove the air cleaner element

from the housing Fig. 39 Loosen the clamp on the air outlet

tube at the throttle body . . .

Fig. 42 Detach the air flow sensor connec-

tor, the boost hose and the solenoid valve

connector

Page 25 of 408

.

1-26 GENERALINFORMATIONAND MAINTENANCE

TDC of the compression stroke. If this happens, the

piston WIII be at the beginning of the power stroke

just as the compressed and ignited air/fuel mixture

forces the piston down and turns the crankshaft. Be-

cause it takes a fraction of a second for the spark

plug to ignite the mixture in the cylinder, the spark

plug must fire a little before the piston reaches TDC.

Otherwise, the mixture will not be completely ignited

as the piston passes TDC and the full power of the

explosion will not be used by the engine.

The timing measurement is given in degrees of

crankshaft rotation before the piston reaches TDC

(BTDC). If the setting for the ignition timing is 10”

BTDC, each spark plug must fire 10 degrees before

each piston reaches TDC. This only holds true, how-

ever, when the engine is at idle speed. The combus-

tion process must be complete by 23”ATDC to main-

tain proper engine performance, fuel mileage, and

low emissions.

As the engine speed increases, the pistons go

faster. The spark plugs have to ignite the fuel even

sooner if it IS to be completely ignited when the pis-

ton reaches TDC. If the ignition is set too far ad-

vanced (BTDC), the ignition and expansion of the fuel

in the cylinder wtll occur too soon and tend to force

the piston down while it is still traveling up. Thus

causes pre ignition or “knockmg and pinging”. If the

ignition spark is set too far retarded, or after TDC

(ATDC), the piston will have already started on its

way down when the fuel is ignited. The piston will be

forced down for only a portion of its travel, resulting

in poor engine performance and lack of power.

Timing marks or scales can be found on the rim of

the crankshaft pulley and the timing cover. The marks

on the pulley correspond to the posrtion of the piston

in the No. 1 cylinder. A stroboscopic (dynamic) tim-

ing light is hooked onto the No. 1 cylinder spark plug

wrre. Every time the spark plug fires, the timing light

flashes. By aiming the light at the timing marks while

the engine is running, the exact position of the piston

within the cylinder can be easily read (the flash of

light makes the mark on the pulley appear to be

standing still). Proper timing is indicated when the

mark and scale are in specified alignment.

When checking timing with the engine run-

ning, take care not to get the timing light

wires tangled in the tan blades and/or drive

belts.

INSPECTION &ADJUSTMENT

1990-96 Models

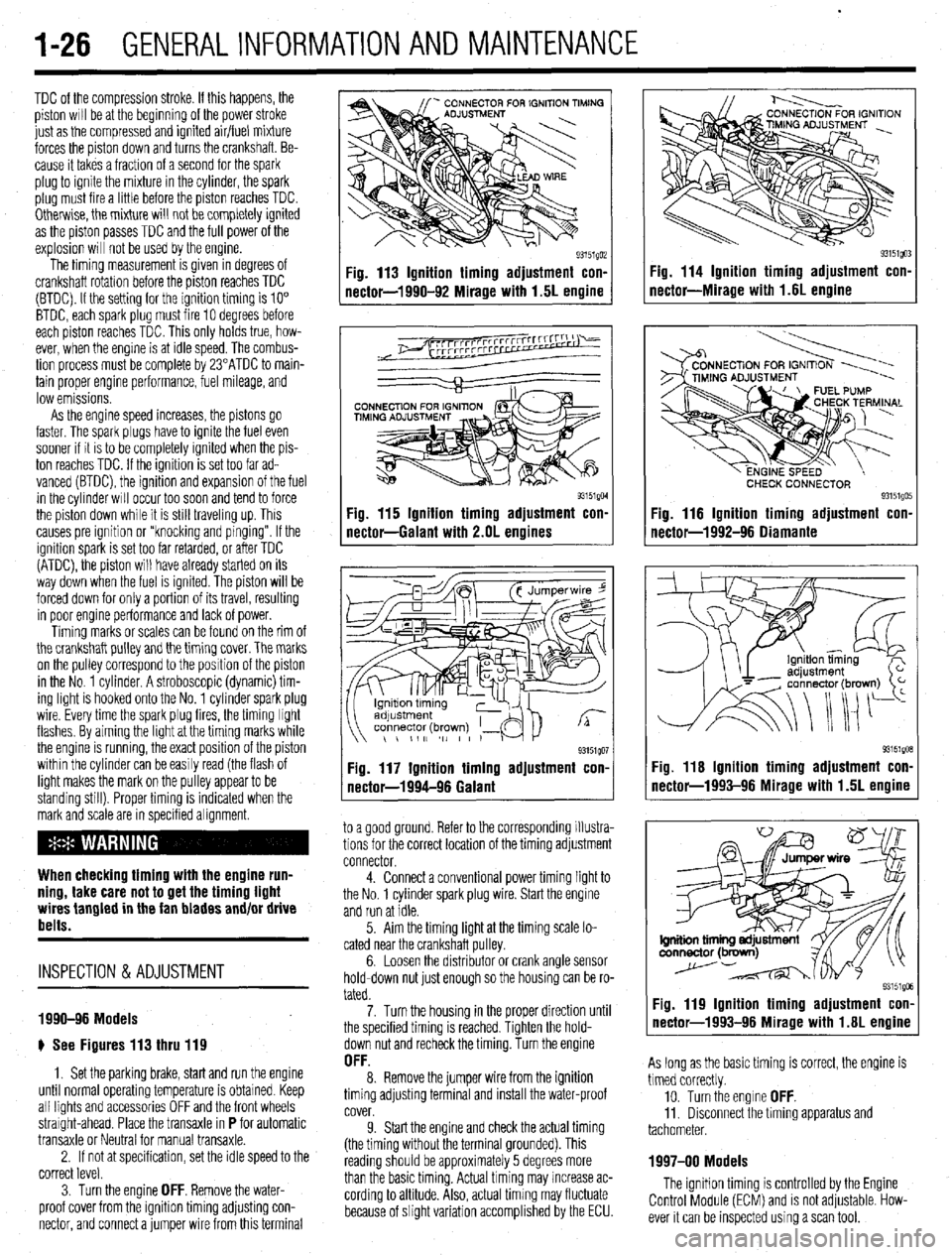

e See Figures 113 thru 119

1. Set the parking brake, start and run the engine

until normal operating temperature is obtained. Keep

all lights and accessories OFF and the front wheels

straight-ahead. Place the transaxle in

P for automatic

transaxle or Neutral for manual transaxle.

2. If not at specification, set the idle speed to the

correct level.

3. Turn the engine

OFF. Remove the water-

proof cover from the igmtion timing adjusting con-

nector, and connect a jumper wire from this terminal

Fig. 113 Ignition timing adjustment con-

nector-1990-92 Mirage with 1.5L engine

93151QM Fig. 115 Ignition timing adjustment con-

nectar-Galant with 2.OL engines

93151QO1 Fig. 117 Ignition timing adjustment con.

nectar-1994-96 Galant

to a good ground. Refer to the corresponding illustra-

tions for the correct location of the timing adjustment

connector.

4. Connect a conventional power timing light to

the No. 1 cylinder spark plug wire. Start the engine

and run at idle.

5. Aim the timing light at the timing scale lo-

cated near the crankshaft pulley.

6. Loosen the distributor or crank angle sensor

hold-down nut just enough so the housing can be ro-

tated.

7. Turn the housing in the proper direction until

the specified timing is reached. Tighten the hold-

down nut and recheck the timing. Turn the engine

OFF. 8. Remove the jumper wire from the ignition

timing adjusting terminal and install the water-proof

cover.

9. Start the engine and check the actual timing

(the timing without the terminal grounded). This

reading should be approximately 5 degrees more

than the basic timing. Actual timing may increase ac-

cording to altitude. Also, actual timing may fluctuate

because of slight variation accomplished by the ECU.

Fig. 114 Ignition timing adjustment con-

nectar-Miracle with 1.6L enaine

CHECK CONNECTOR 93151QO! Fig. 116 Ignition timing adjustment con.

nectar-1992-96 Oiamante

93151gOB Fig. 116 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.5L engine

Fig. 119 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.6L engine

As long as the basic timing is correct, the engine is

timed correctly.

10. Turn the engine

OFF. 11. Disconnect the timing apparatus and

tachometer.

1997-00 Models

The ignition timing is controlled by the Engine

Control Module (ECM) and is not adjustable. How-

ever it can be inspected using a scan tool.

Page 43 of 408

1-44 GENERALINFORMATIONAND MAINTENANCE

INTERIOR CLEANING

Upholstery

Fabric can usually be cleaned with soapy water or

a proper detergent. For more difficult spots caused by

oil, ice cream, soda, etc., use a fabric cleaner avail-

able at most parts stores. Be sure when purchasing

the cleaner to read the label to ensure it is safe to use

on your type of fabric. A safe method of testing the

cleaner is to apply a small amount to an area usually

unseen, such as under a seat, or other areas. Wart a

while, perhaps even a day to check the spot for fad-

ing, discoloring, etc., as some cleaners will only

cause these problems after they have dried

Leather upholstery requrres special care, it can be

cleaned with a mild soap and a soft cloth. It is recom-

mended that a special leather cleaner be used to

clean but also treat the leather surfaces in your vehi-

cle. Leather surfaces can age quickly and can crack if

not properly taken care of, so it is vital that the leather

surfaces be maintained.

Floor Mats and Carpet

The floor mats and carpet should be vacuumed or

brushed regularly. They can be cleaned with a mild

soap and water. Special cleaners are available to

clean the carpeted surfaces of your vehicle, but take

care in choosing them, and again it is best to test

them in a usually unseen spot.

Dashboard, Console, Door Panels, Etc.

The dashboard, console, door panels, and other

plastic, vinyl, or wood surfaces can be cleaned using

a mild soap and water. Caution must be taken to keep

water out of electronic accessories and controls to

avoid shorts or ruining the components Again spe-

cial cleaners are available to clean these surfaces, as

with other cleaners care must taken in purchasmg

and using such cleaners.

There are protectants available which can treat the

various surfaces in your car giving them a “shiny new

look”, however some of these protectants can cause

more harm than good in the long run. The shine that

is placed on your dashboard attracts sunlight accel-

erating the aging, fading and possibly even cracking

the surfaces. These protectants also attract more dust

to stick to the surfaces they treat, Increasing the cleaning you must do to maintain the appearance of

your vehicle. Personal discretion is advised here.

On most models covered by this manual, the

wheel bearmgs used are sealed units and do not re-

quire routine maintenance. However on some Galant

and Mirage models, the rear wheel bearing do require

periodic repacking. For removal and installation in-

structions, please refer to Section 7 (for rear bear-

ings) or Section 8 (for front bearings).

REPACKING

*Sodium based grease is not compatible

with lithium based grease. Read the package

labels and be careful not to mix the two

types. If there is any doubt as to the type of

grease used, completely clean the old

grease from the bearing and hub before re-

placing.

Before handling the bearings, there are a few

things that you should remember to do and not to do.

DO the following: l Remove all outside dirt from the housing be-

fore exposing the bearing.

l Treat a used bearing as gently as you would a

new one.

l Work with clean tools in clean surroundings. l Use clean, dry gloves, or at least clean, dry

hands.

l Clean solvents and flushing fluids are a must. l Use clean paper when laying out the bearings

to dry.

l Protect drsassembled bearings from rust and

dirt. Cover them up.

l Use clean, lint-free rags to wipe the bearings. l Keep the bearings in oil-proof paper when they

are to be stored or are not in use.

l Clean the inside of the housing before replac-

ing the bearin

Do NOT do he followino: El, l Do not work in dirty sirroundings. l Do not use dirty, chipped or damaged tools. l Do not work on wooden work benches or use

wooden mallets.

l Do not handle bearings with dirty or moist

hands.

l Do not use gasoline for cleaning. Use a safe

solvent.

l Do not spin dry bearings with compressed air.

They will be damaged.

l Do not use cotton waste or dirty cloths to wipe

bearings.

l Do not scratch or nick bearing surfaces. l Do not allow the bearina to come in contact

” with dirt or rust at any time.

The rear wheel bearinas on some Galant and Mi-

rage models require periodic maintenance. A pre-

mium high melting point grease meeting Grade

Multipurpose Grease NLGI Grade #2 or equivalent

must be used. Long fiber type greases must not be

used. This service is recommended every 30,000

miles (48,000 km).

*For information on Wheel Bearing removal

and installation, refer to Section 7 of this

manual.

1. Remove the wheel bearing.

2. Clean all parts in a non-flammable solvent and

let them air dry.

*Only use lint-free rags to dry the bearings.

Never spin-dry a bearing with compressed

air, as this will damage the rollers.

3. Check for excessive wear and damage. Replace

the bearing as necessary.

*Packina wheel bearinos with arease is

best accomplished by u&g a wheel bearing

packer (available at most automotive parts

stores).

4. If a wheel bearing packer is not available, the

bearings may be packed by hand.

a. Place a “healthy’ glob of grease in the

palm of one hand.

b. Force the edge of the bearing into the

grease so that the grease fills the space between

the rollers and the bearing cage.

c. Keep rotating the bearing while continuing

to push the grease through.

d. Continue until the grease is forced out the

other side of the bearing.

5. Place the packed bearing on a clean surface

and cover it until it is time for installation.

6. Install the wheel bearing.

# See Figures 219 and 220

To prevent the bumper from deforming, these vehi-

cles cannot be towed by a wrecker using sling-type

equipment. If these vehicles require towing, use a

wheel lift or flat bed equipment. It is recommended

that the vehicle be towed from the front If a flat bed is

not available.

Manual transaxle vehicles may be towed from the

rear provided that the transaxle is in Neutral and the

driveline has not been damaged. The steering wheel

must be clamped in the straight-ahead positron with a

steering wheel clamping device designed for towing

service use.

Do not use the steering column lock to secure

the front wheel uosition for towina.

Automatic transaxle vehicles may be towed on the

front wheels at speeds not to exceed 30 mph (50

km/h) for a distance not to exceed 18 miles (30 km).

If these limits can not be met, then the front wheels

must be placed on a tow dolly.

# See Figure 221

All Wheel Drive (AWD) vehicles should only be

towed with all 4 wheels on the ground or lifted from

the road surface. This means that the vehicle is to be

towed either with flatbed equipment, with all wheels

on dollies or flat towed. Damage to the viscous cou-

pling may result if the vehicle is towed with only 2

wheels on the ground.

p See Figure 222

Whenever a vehicle is jump started, precautions

must be followed In order to prevent the possibility of

Page 81 of 408

.

3-20 ENGINEANDENGINEOVERHAUL

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the overflow hose and disconnect

the upper radiator hose.

*It is recommended that each clamp be

matchmarked to the hose. Observe the marks

and reinstall the clamps exactly when rein-

stalling the radiator.

4. If equipped with an automatic transaxle, re-

move and plug the fluid cooler hoses.

5. Unplug the electrical connector(s) from the

coolant fan motor.

6. Remove the mounting bolts, then remove the

fan and shroud assembly from the vehicle.

7. Remove the fan blade retainer nut from the

shaft on the fan motor and separate the fan from the

motor.

8. Remove the motor to shroud attaching

screws and the motor from the shroud.

To tnstall: 9. Install the motor to the shroud and secure

with the mounting bolts.

10. Install the remaining components in the re-

verse order of removal.

11. Fill the coohng system. Connect the negative

battery cable and check the cooling fan for proper op-

eration.

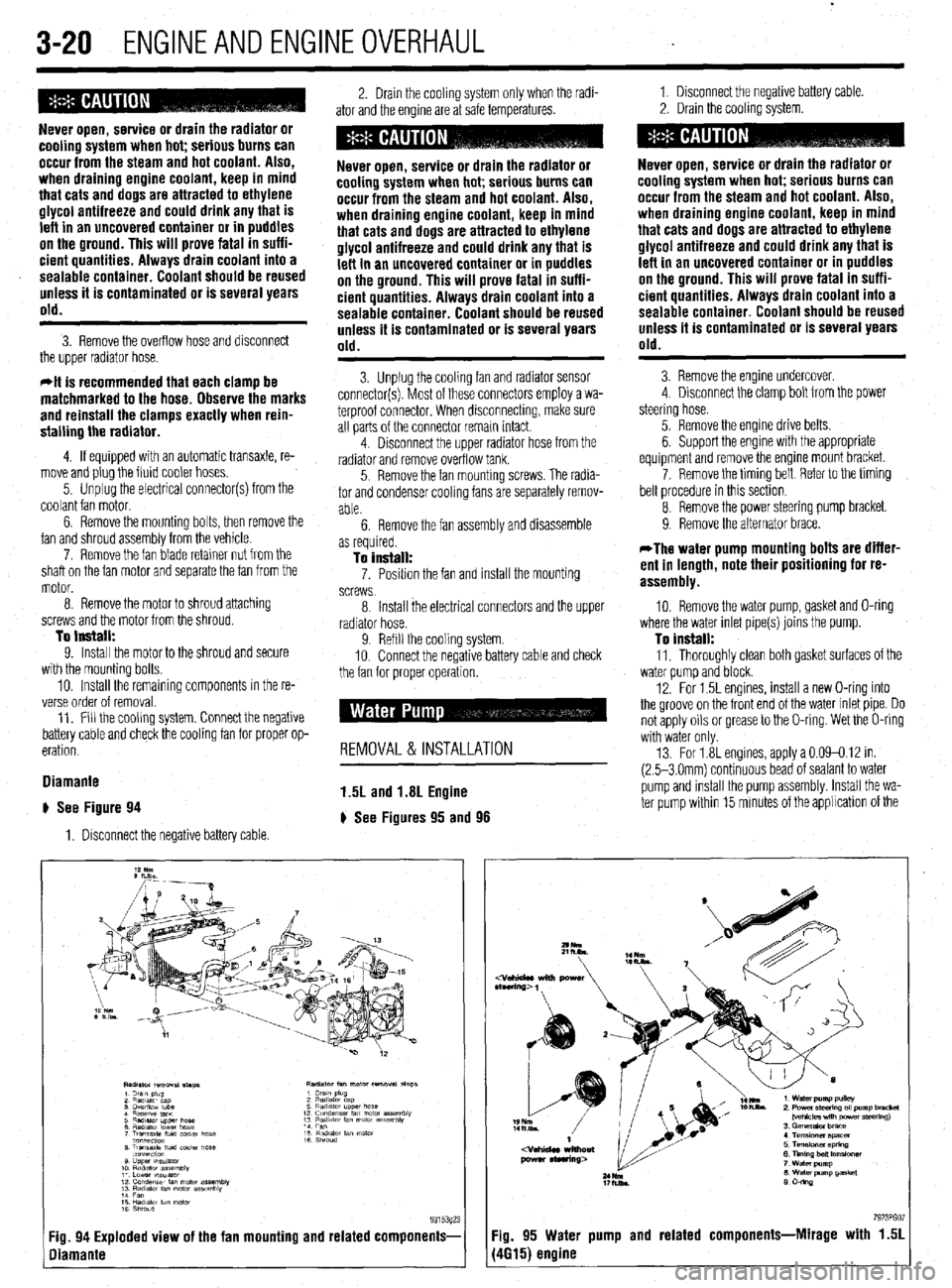

Diamante

# See Figure 94

1. Disconnect the negative battery cable 2. Drain the cooling system only when the radi-

ator and the engine are at safe temperatures. 1. Disconnect the negative battery cable

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Unplug the cooling fan and radiator sensor

connector(s). Most of these connectors employ a wa-

terproof connector. When disconnecting, make sure

all parts of the connector remain intact.

4. Disconnect the upper radiator hose from the

radiator and remove overflow tank.

5. Remove the fan mounting screws. The radia-

tor and condenser cooling fans are separately remov-

able.

6. Remove the fan assembly and disassemble

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the engine undercover.

4 Disconnect the clamp bolt from the power

steering hose.

5. Remove the engine drive belts.

6. Support the engine with the appropriate

equipment and remove the engine mount bracket.

7. Remove the timing belt Reier to the timing

belt procedure in this section

8 Remove the power steering pump bracket.

9. Remove the alternator brace.

as required.

To install: 7. Posrtion the fan and install the mounting

screws

*The water pump mounting bolts are differ-

ent in length, note their positioning for re-

assembly.

8 Install the electrical connectors and the upper

radiator hose.

9. Refill the cooling system.

IO. Connect the negative battery cable and check

the fan for orooer ooeration. 10. Remove the water pump, gasket and O-ring

where the water inlet pipe(s) joins the pump.

To install: 11, Thoroughly clean both gasket surfaces of the

water oumo and block.

12. For 1.5L engines, install a new O-ring into

the groove on the front end of the water inlet pipe. Do

not apply oils or grease to the O-ring. Wet the O-ring

with water only

13. For 1.8L engines, apply a 0.09-0.12 in.

(2.5-3 Omm) continuous bead of sealant to water

pump and rnstall the pump assembly. Install the wa-

ter pump within 15 minutes of the applrcation of the

REMOVAL & INSTALLATION

1.5L and 1.8L Engine

) See Figures 95 and 98

7923PGO :ig. 94 Exploded view of the fan mounting and related components- Fig. 95 Water pump and related components-Mirage with 1.51

liamante (4615) engine

Page 207 of 408

I

6-4 CHASSIS ELECTRICAL

I

printed circuit is sandwiched between two sheets of

plastic for more protection and flexibility. A complete l Weatherproof-these connectors are most the jumper wire is of too small a gauge, it

printed circuit, consisting of conductors, insulating commonly used where the connector is exposed to

may overheat and possibly melt. Never use

material and connectors for lamps or other compo- the elements. Terminals are protected against mois-

nents is called a printed circuit board. Printed cir- ture and dirt by sealing rings which provide a weath- jumpers to bypass high resistance loads in a

et-tight seal. All repairs require the use of a special circuit. Bypassing resistances, in effect, cre-

cuitry is used in place of individual wires or har- ates a short circuit. This may, in turn, cause

nesses in places where space is limited, such as terminal and the tool required to service it. Unlike

behind instrument panels. standard blade type terminals, these weatherproof damage and fire. Jumper wires should only

be used to bypass lengths of wire or to simu-

Since automotive electrical systems are very sen- terminals cannot be straightened once they are bent. late switches.

sitive to changes in resistance, the selection of prop- ‘Make certain that the connectors are properly seated

erly sized wires is critical when systems are repaired, and all of the sealing rings are in place when con-

netting leads. Jumper wires are simple, yet extremely valuable,

A loose or corroded connection or a replacement wire pieces of test equipment. They are basically test wires

that is too small for the circuit will add extra resis-

l Molded-these connectors require complete which are used to bypass sections of a circuit. Al-

replacement of the connector if found to be defective.

tance and an additional voltage drop to the circuit. though jumper wires can be purchased, they are usu-

The wire gauge number is an expression of the This means splicing a new connector assembly into ally fabricated from lengths of standard automotive

cross-section area of the conductor. Vehicles from the harness. All splices should be soldered to insure

proper contact. Use care when probing the connec- wire and whatever type of connector (alligator clip,

countries that use the metric system will typically de- spade connector or pin connector) that is required for

scribe the wire size as its cross-sectional area in tions or replacing terminals in them, as it is possible

square millimeters. In this method, the larger the to create a short circuit between opposite terminals. If the particular application being tested. In cramped,

hard-to-reach areas, it is advisable to have insulated

wire, the greater the number. Another common sys- this happens to the wrong terminal pair, it is possible

to damage certain components. Always use jumper boots over the jumper wire terminals in order to pre-

tern for expressing wire size is the American Wire vent accidental grounding. It is also advisable to in-

Gauge (AWG) system. As gauge number increases, wires between connectors for circuit checking and

NEVER probe through weatherproof seals. elude a standard automotive fuse in any jumper wire.

area decreases and the wire becomes smaller. An 18

gauge wire is smaller than a 4 gauge wire. A wire

l Hard Shell-unlike molded connectors, the This is commonly referred to as a “fused jumper”. By

inserting an in-line fuse holder between a set of test

terminal contacts in hard-shell connectors can be re-

with a higher gauge number will carry less current

placed. Replacement usually involves the use of a leads, a fused jumper wire can be used for bypassing :

than a wire with a lower gauge number. Gauge wire open circuits. Use a 5 amp fuse to provide protection

size refers to the size of the strands of the conductor, special terminal removal tool that depresses the lock- against voltage spikes.

not the size of the complete wire with insulator. It is ing tangs (barbs) on the connector terminal and al-

lows the connector to be removed from the rear of the Jumper wires are used primarily to locate open

possible, therefore, to have two wires of the same

shell. The connector shell should be replaced if it electrical circuits, on either the ground (-) side of the

gauge with different diameters because one may have

thicker insulation than the other. shows any evidence of burning, melting, cracks, or circuit or on the power (+) side. If an electrical corn-

breaks. Replace individual terminals that are burnt, ponent fails to operate, connect the jumper wire be-

It is essential to understand how a circuit works

corroded, distorted or loose. tween the component and a good ground. If the corn-

before trying to figure out why it doesn’t. An electrical ponent operates only with the jumper installed, the

schematic shows the electrical current paths when a ground circuit is open. If the ground circuit is good,

circuit is operating properly. Schematics break the but the component does not operate, the circuit be-

entire electrical system down into individual circuits. tween the power feed and component may be open. ’

In a schematic, usually no attempt is made to repre- Pinpointing the exact cause of trouble in an elec- By moving the jumper wire successively back from

trical circuit is most times accomplished by the use the component toward the power source, you can

; : sent wiring and components as they physically ap-

pear on the vehicle; switches and other components of special test equipment. The following describes isolate the area of the circuit where the open is lo-

are shown as simply as possible. Face views of har- different types of commonly used test equipment and cated. When the component stops functioning, or the f

j

ness connectors show the cavity or terminal locations briefly explains how to use them in diagnosis. In ad- power is cut off, the open is in the segment of wire j

in all multi-pin connectors to help locate test points. dition to the information covered below, the tool between the jumper and the point previously tested.

! manufacturer’s instructions booklet (provided with You can sometimes connect the jumper wire di-

the tester) should be read and clearly under.$ood be- rectly from the battery to the “hot” terminal of the I

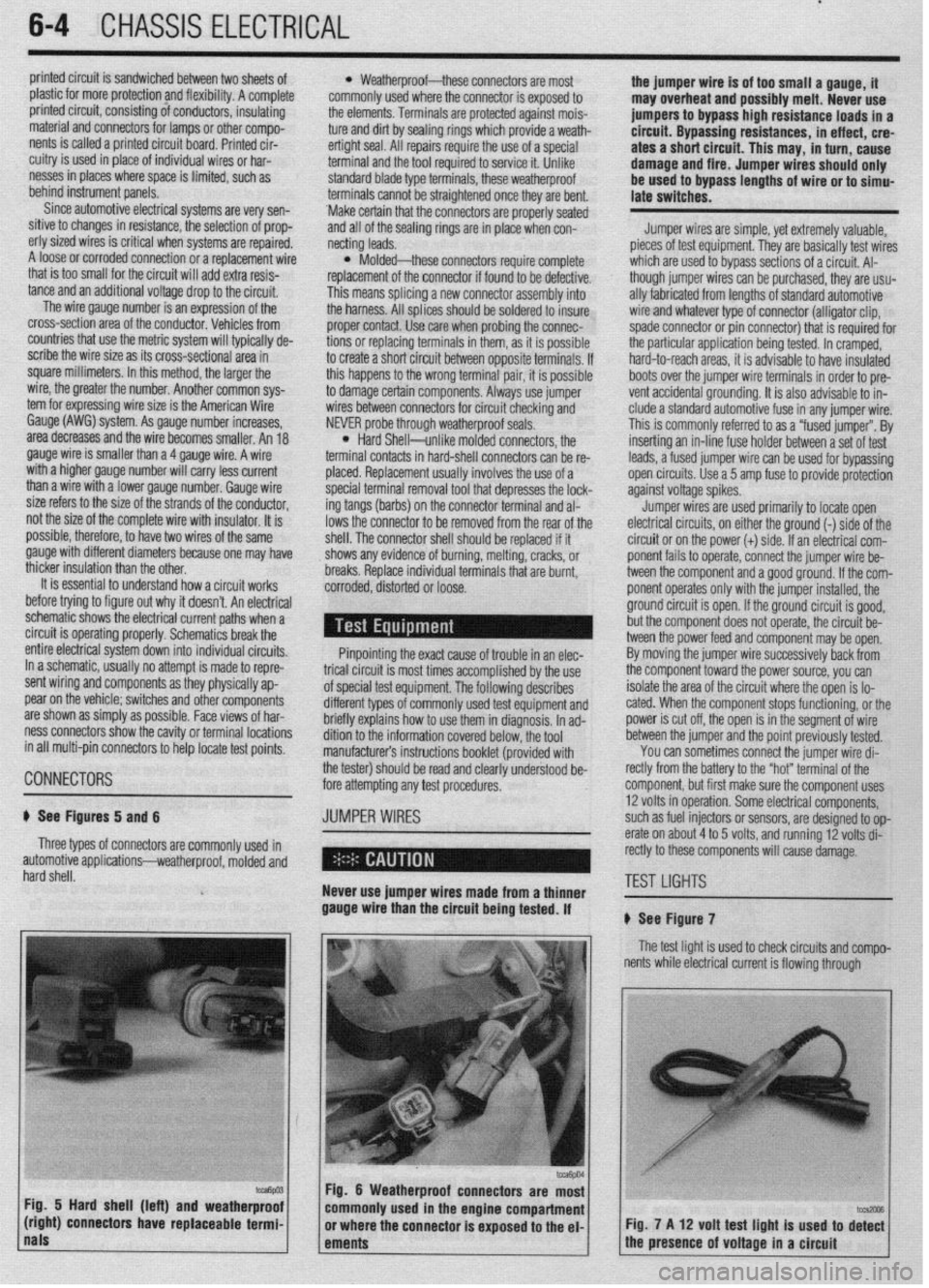

CONNECTORS 1 fore attempting any test procedures. component, but first make sure the component uses 1

# See Figures 5 and 6 JUMPER WIRES 12 volts in operation. Some electrical components, i

such as fuel injectors or sensors, are designed to op-

Three types of connectors are commonly used in erate on about 4 to 5 volts, and running 12 volts di- j

)

automotive applications-weatherproof, molded and rectly to these components will cause damage.

hard shell.

Never use jumper wires made from a thinner TEST LIGHTS I

gauge wire than the circuit being tested. If

# See Figure 7

The test light is used to check circuits and compo-

I nents while electrical current is flowing through

Fig. 5 Hard shell (left) and weatherproof

(right) connectors have replaceable termi- Fig. 7 A 12 volt test light is used to di%

nals

ements 1 the presence of voltage in a circuit

Page 209 of 408

.

6-6 CHASSIS ELECTRICAL

This test already assumes the existence of an open

in the circuit and it is used to help locate the open

portion

1. Isolate the circuit from power and ground.

2. Connect the self-powered test light or ohmme-

ter ground clip to the ground side of the circuit and

probe sections of the circuit sequentially.

3. If the light is out or there is infinite resistance,

the open is between the probe and the circuit ground.

4. If the light is on or the meter shows continuity,

the open is between the probe and the end of the cir-

cuit toward the power source.

SHORT CIRCUITS

*Never use a self-powered test tight to per-

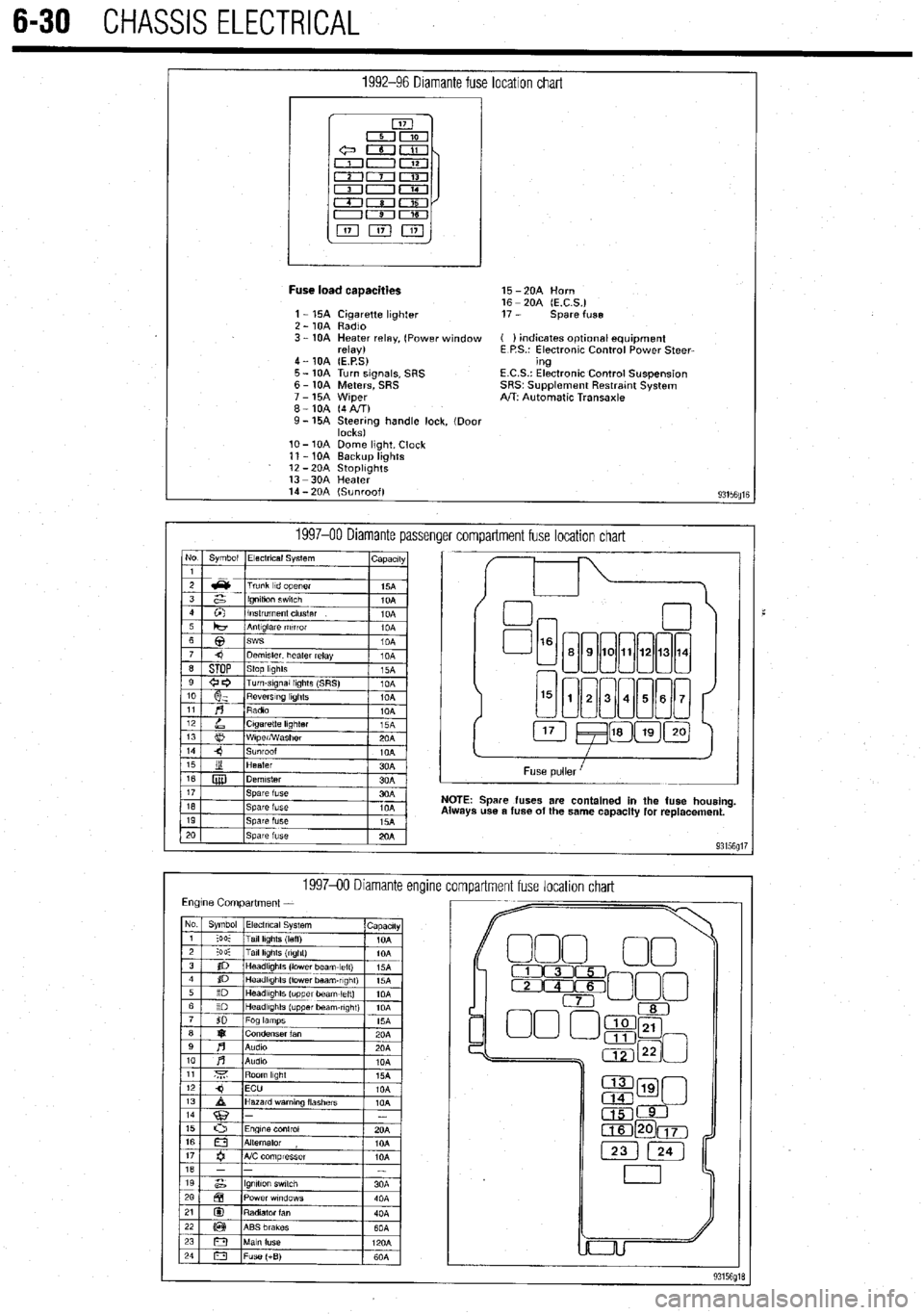

form checks for opens or shorts when power Fig. 10 Checking the resistance of a coolant

temperature sensor with an ohmmeter.

Reading is 1.04 kilohms

is applied to the circuit under test. The test

linht man he dmn~nsrl hu nutnitls nnuva~ if there is more than one load in the circuit, since all m.3.m. “Y.. “1 “ulll”y”” u, ““..7IYG p”“lz’.

1. Isolate the circuit from power and ground.

2. Connect the self-powered ’ .,.*. ,

ted ugnt or onmme-

ter ground clip to a good ground

and probe any easy-

to-reach point in the circuit.

3. If the light comes on or there is continuity,

there is a short somewhere in the circuit.

4. To isolate the short, probe a test point at either

end of the isolated circuit (the light should be on or

the meter should indicate continuity).

5. Leave the test light probe engaged and se- voltage drops are cumulative.

1. Set the voltmeter selector switch to the 20 volt

^,.^X^..

pJbl1IUII.

2. Connect the multimeter negative lead to a

good ground.

3. Operate the circuit and check the voltage prior

.

to the hrst component (load).

4. There should be little or no voltage drop in the

circuit prior to the first component. If a voltage drop

exists, the wire or connectors in the circuit are sus-

WY.+

)JGW 5. While operating the first component in the cir-

.

positive meter lead and observe the voltage readings.

A small voltage drop should be noticed. This voltage

drop is caused by the resistance of the component.

6. Repeat the test for each component (load)

de .-IL- .‘.. .I

uuwn me crrcun. quentially open connectors or switches, remove

parts, etc. until the light goes out or continuity is bro-

ken

6. When the light goes out, the short is between

the last two circuit components which were opened,

nl -r*l?I-

VuLlHbt

This test determines voltage available from the

battery and should be the first step in any electrical

troubleshooting procedure after visual inspection,

Many electrical problems, esoeciallv on comouter

controlled systems, can be caused by a low state of 7. If a large voltage drop is noticed, the preceding

component, wire or connector is suspect.

# See Figures

10 and 11

charge in the battery. Excessive corrosion at the bat-

tery cable terminals can cause poor contact that will

prevent proper charging and full battery current flow,

1. Set the voltmeter selector switch to the 20V

position.

2. Connect the multimeter negative lead to the

h*+tnn,‘n nnn,,,;~,,. , ..^,a ^-L.--:^^l --_I ‘I- ---!I?... Never use an ohmmeter with power applied

to the circuit. The ohmmeter is designed to

operate on its 0 wn power supply. The normal

1^

. . . . . Fig. 11 Spark plug wires can be checke;

MW~ 3 IlG~dllYt: t-1 pUSI UI Lellllllldl allU lilt, pUSlIlVe lead to the battery’s positive (t) post or terminal.

3. Turn the ignition switch ON to provide a load,

4. A well charged battery should register over 12

volts. If the meter reads below 11 5 vnlts tha hq*anr

_ _ .-, . power may be insufficient to operate the eler ii! volt electrical system voltage could dam-

age the meter!

1. Isolate the circuit from the vehicle’s power

CnlOrAn I)““IW. 2. Ensure that the ignition key is OFF when dis- Almost anyone can replace damaged wires, as

long as the proper tools and parts are available. Wire

and terminals are available to fit almost any need.

Even the specialized weatherproof, molded and hard

shell connectors are now cl mdicm available from aftermarket

system properly.

connecting any components or the battery. ““yp,8w’“.

3. Where necessary, also isolate at least one side Be sure the ends of all the wires are fitted with the

VOLTAGEDROP of the circuit to be checked, in order to avoid reading proper terminal hardware and connectors. Wrapping

parallel resistances. Parallel circuit resistances will a wire around a stud is never a permanent solution

# See Figure 9 always give a lower reading than the actual resistance and will only cause trouble later. Replace wires one at

When current flows through a load, the voltage be- of eifhy n< +hn hmnnh-r

GI “I II It: “I a lb1 It?>. a time to avoid confusion. Always route wires exactly

4.

Connect the meter leads to both sides of the the same as the factory.

yond the load drops. This voltage drop is due to the

resistance created by the load and also by small re- circuit (wire or component) and read the actual mea-

sured ohms on the meter scale. Make sure the selec- *If connector repair is necessary, only at-

sistances created by corrosion at the connectors and

tor switch is set to the proper ohm scale for the cir- tempt it if you have the proper tools. Weath-

damaged insulation on the wires. The maximum al- erproof and hard shell connectors require

lowable voltage drop under load is critical, especially cuit being tested, to avoid misreading the ohmmeter

test value. spectal tools to release the pins inside the

connector. Attempting to repair these con-

nectors with conventional hand tools will

damage them.

Page 232 of 408

CHASSIS ELECTRlCiL 6-29

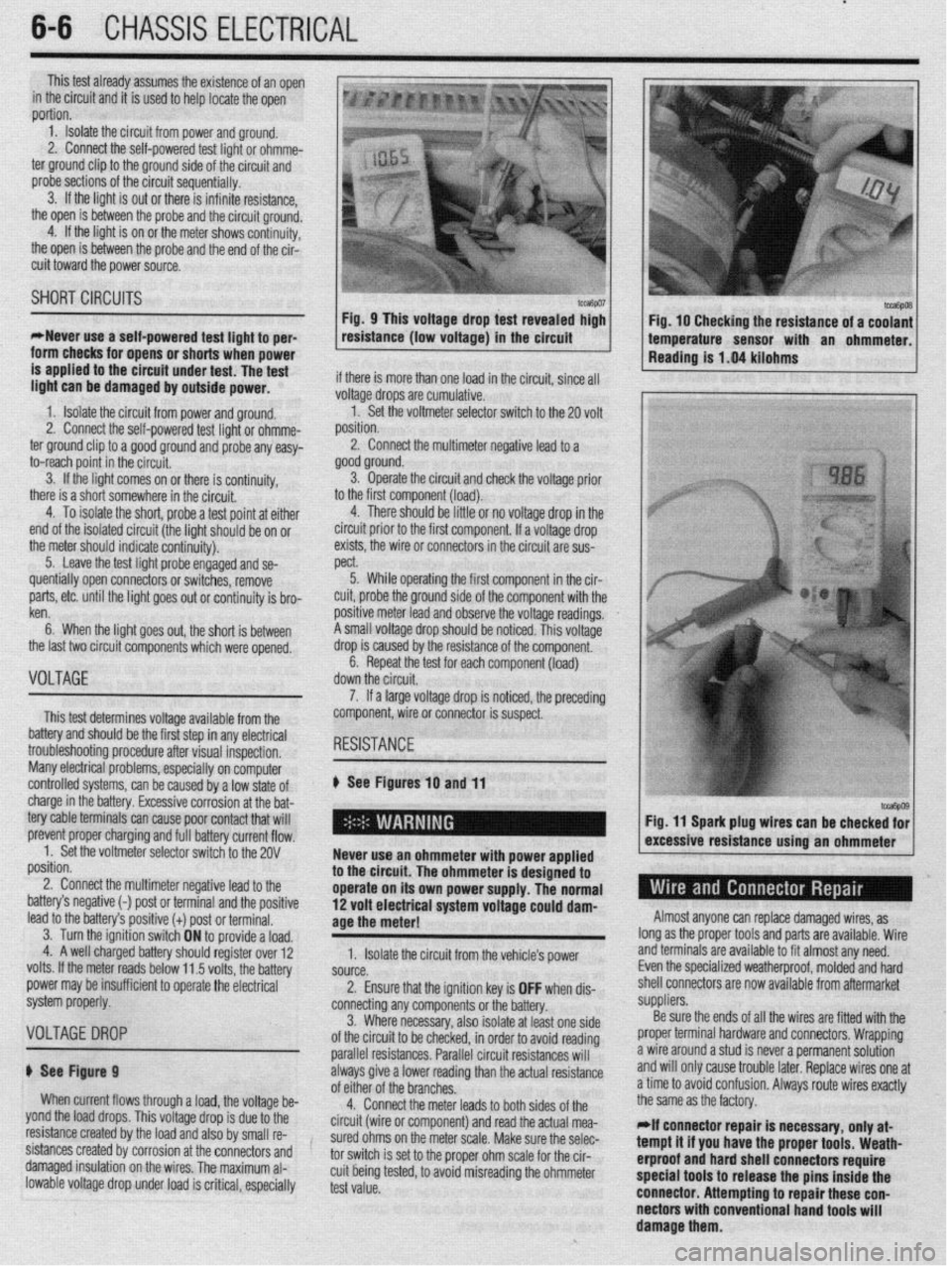

1990-93 Galant fuse location chart Fuse Load Capacities

l-15A Cigarette hghter

Z-10A Radm

3-10A Heater relay

4-10A (E P S.)

5-10A Belt

6-10A Turn signals

7-10A Meters

6-10A Horn

9-15A Wiper

lo-10A (4 A/T)

ll-15A (Door locks)

12-10A Dome hght, clock

13-10A Backup hghts

14-15A Stop hghts

15-30A Heater

16m20A (Sunroof)

17-20A (ECS)

1% spare fuse

ldentlfxation of fuse

10A Red

15A Light blue

20A Yellow

30A Green

93156g13

1994-98 Galant fuse location chart

Passenger compartment

1. 15A StoplIghts

2- 10A Turn signals

3- 1 OA Backup Itghts

4. 30A Heater

5. i5A Wiper

6- IOA Meters

7. 30A Rear wndow defogger

;: fo& fl$oof)

IO- 15A Cagaretle lighler

11. 10A Heater relay

12. IOA Horn

13. Spare fuse

( ): II so equipped

A!T Automallc transaxle Engine compartment

Fusible links

I- 30A Ignition swlch

2. 50A (ABS)

3. 30A Radiator fan

4. 40A Headkghts

5. 30A Power wndow

Fuse

6- 30A (ABS)

7. 30A Condenser fan

6. 10A Hazard

9. 20A Engine

10. 10A (Au conditioning)

11. 10AHigh beam

12. 10ATall lkghts

13. 10A (Theft)

14. i5A Fog lkghls

( ): If so equipped

93156g14

1999-00 Galant fuse location chart

Page 233 of 408

6-30 CHASSIS ELECTRICAL

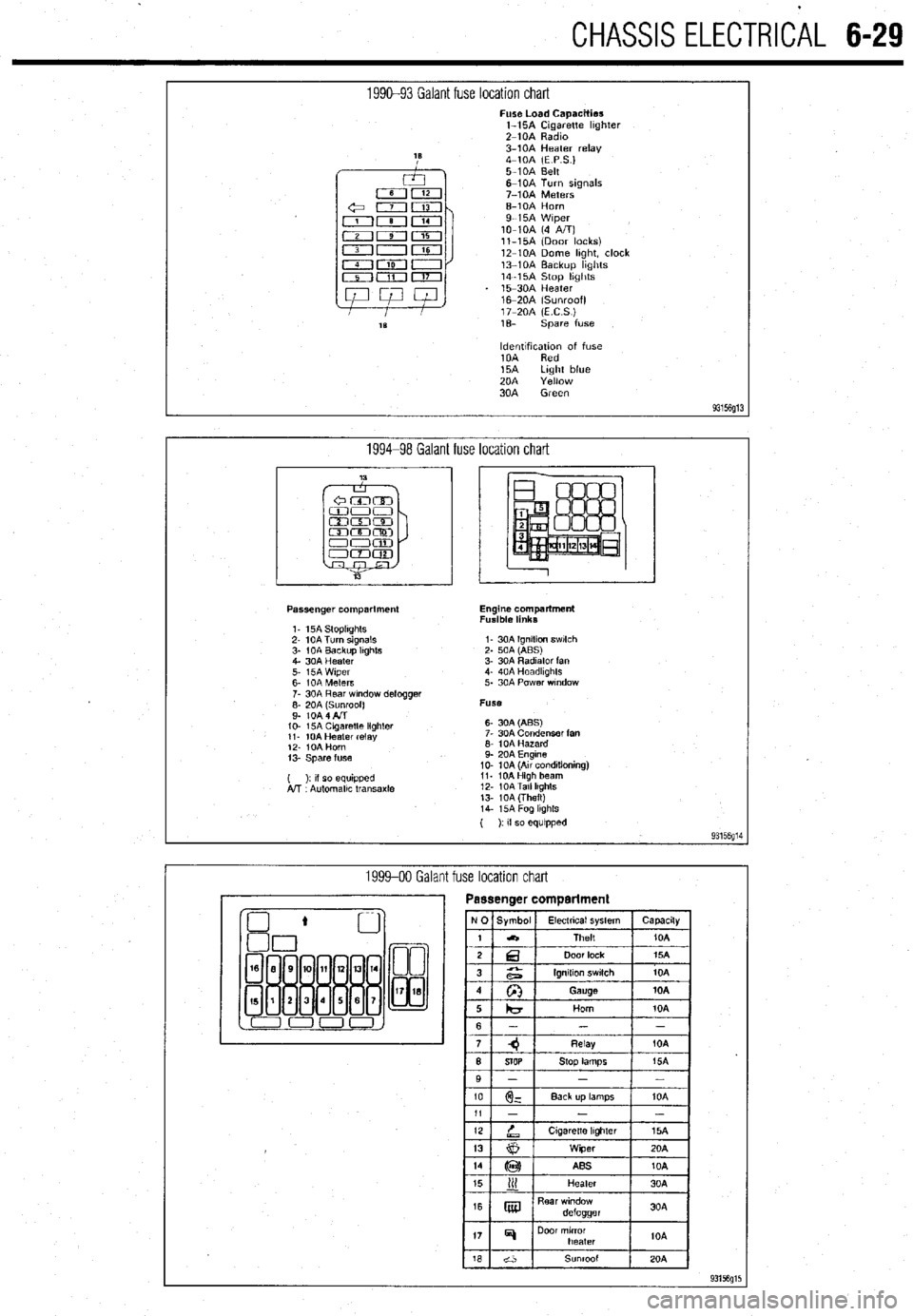

1992-96 Diamante fuse location chart

I

Fuse load caaacities 15 -2OA Horn

16 - 20A (E.C.S.)

1 - 15A Cigarette lighter 17 - spare fuse

2 - 10A Radio

3 - 10A Heater relay, (Power window ( ) indicates optlonal equipment

relay) E P.S.: Electronic Control Power Steer-

4 - 10A (E.P.S) ing

5 - 10A Turn signals, SRS E.C.S.: Electronic Control Suspension

6 - 10A Meters, SRS SRS~ Supplement Restratnt System

7 - 15A Wiper A/T: Automatic Transaxle

8-10A (4AIT)

9- 15A Steering handle lock, (Door

locks)

lo- 10A Dome light, Clock

11 - 10A Backup lights

12 -2OA StoplIghts

13 -3OA Heater

14 - 20A (Sunroof)

93156fllE

1997-00 Diamante passenger compartment fuse location chart No Symbol Electrical System

I capactty

I

Spare fuses are contained in the fuse housing

use a fuse of the same capacity for replacement.

199740 Diamante encline

compartment fuse location chart

Page 372 of 408

10-4 BODYANDTRIM

Fig. 8 Tailgate assembly mounting-Dia-

mante Wagon

6. Remove the tailgate from the vehicle and place

it in a safe place.

7. The installation is the reverse of removal.

Tighten the hinge

nuts to IO ft. Ibs. (14 Nm).

8. Check the alignment of the tailgate.

ALIGNMENT

To adjust the tailgate, loosen the tailgate hinge-to-

body bolts or tailgate latch assembly mounting

screws and adjust as necessary.

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable.

2. Open the trunk lid. Identify the trunk release

cable running from the latch to the body.

3. Disconnect the cable from the latch.

4. Detach any necessary electrical connectors.

5. Outline the position of the hinges on the

trunk lid.

6. Support the trunk lid in the open position.

7. If equipped, insert a small prytool into the

lock cover slit, remove the lock covers, then remove

the trunk lid gas springs.

8. Unfasten the retaining bolts, then remove the

trunk lid hinges.

9. Remove the trunk lid from the vehicle

10. Installation is the reverse of the removal pro-

cedure.

11. If necessary, align the trunk lid.

ALIGNMENT

1. Close the lid and check both the seam width

all around and the closed height. The trunk lid must

be flush with the adjacent panels. Minor height ad-

justments may be made by turning the rubber

bumpers on the trunk lid. Additional adjustments re-

quire loosening and repositioning of the latch and/or

striker.

REMOVAL &INSTALLATION

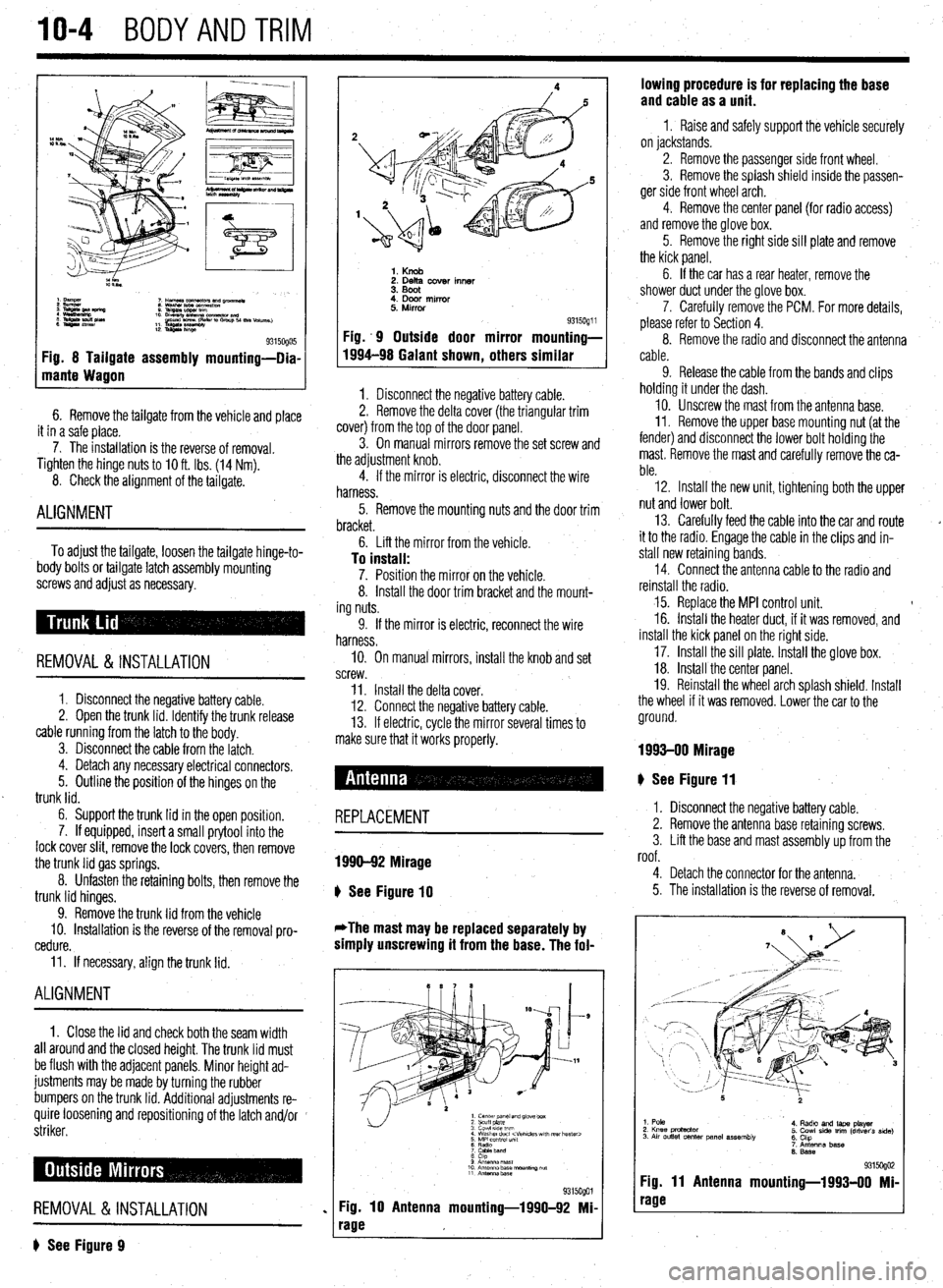

? See Figure 9

1. Knob 2. Delta cover inner

3. Boot

4. Door mirror

5. Mirror

Fig. .9 Outside door mirror

1994-98 Galant shown

, others 9315oQ1 i mounting-

similar

1. Disconnect the negative battery cable.

2. Remove the delta cover (the triangular trim

cover) from the top of the door panel.

3. On manual mirrors remove the set screw and

the adjustment knob.

4. If the mirror is electric, disconnect the wire

harness.

5. Remove the mounting nuts and the door trim

bracket.

6. Lift the mirror from the vehicle.

To install: 7. Position the mirror on the vehicle.

8. Install the door trim bracket and the mount-

ing nuts.

9. If the mirror is electric, reconnect the wire

harness.

IO. On manual mirrors, install the knob and set

screw.

11. Install the delta cover.

12. Connect the negative battery cable.

13. If electric, cycle the mirror several times to

make sure that it works properly.

# See Figure 11

REPLACEMENT

1990-92 Mirage

b

See Figure 10

*The mast may be replaced separately by

simply unscrewing it from the base. The fol-

1. center panel and glove box

2 scuff plate

3 cowl 51ae wm

4 Washer duct

7 CaMeband

8 cap

9 Anrsnna mast

10 Antenna base “ourmng ““f

11 Antennz.base

%i%Qol

Fig. 10 Antenna mounting-1990-92 Mi-

rage lowing procedure is for replacing the base

and cable as a unit.

1 I Raise and safely support the vehicle securely

on jackstands.

2. Remove the passenger side front wheel.

3. Remove the splash shield inside the passen-

ger side front wheel arch.

4. Remove the center panel {for radio access)

and remove the glove box.

5. Remove the right side sill plate and remove

the kick panel.

6. If the car has a rear heater, remove the

shower duct under the glove box.

7. Carefully remove the PCM. For more details,

please refer to Section 4.

8. Remove the radio and disconnect the antenna

cable.

9. Release the cable from the bands and clips

holding it under the dash.

10. Unscrew the mast from the antenna base.

II. Remove the upper base mounting nut (at the

fender) and disconnect the lower bolt holding the

mast. Remove the mast and carefully remove the ca-

ble.

12. Install the new unit, tightening both the upper

nut and lower bolt.

13. Carefully feed the cable into the car and route

it to the radio. Engage the cable in the clips and in-

stall new retaining bands.

14. Connect the antenna cable to the radio and

reinstall the radio.

15. Replace the MPI control unit. t

16. Install the heater duct, if it was removed, and

install the kick panel on the right side.

17. Install the sill plate. Install the glove box.

18. Install the center panel.

19. Reinstall the wheel arch splash shield. Install

the wheel if it was removed. Lower the car to the

ground.

1993-00 Mirage

I. Disconnect the negative battery cable.

2. Remove the antenna base retaining screws.

3. Lift the base and mast assembly up from the

roof.

4. Detach the connector for the antenna.

5. The installation is the reverse of removal.

1. Pole

2. Knee protactor

3. Air outlet center panel assembly 4. Radto and laps player

5. Cowl side trim (driver’s side)

6. Chp

7. Antenna base

6. Base

931 !iogo2 Fig. 11 Antenna mounting-1993-00 Mi-

rage

Page 379 of 408

BODYANDTRiVl 1041

8. llnm all mtainar din!: xc! .wnnratmi rmnnve -.*I-_.. .I._. ..I. -..r-~.--“* -.-.- I( .” .I._._ the dot jr panel assembly.

9. Carefully remove any retainer clips that re-

mained in the door during panel removal. If dam-

aaed. reolace the retainer clios.

- 10. if necessary, remove’the waterproof film from

the door.

To install:

11. If removed, install the waterproof film from

. .

tne aoor.

12. Install and missing or damaged retainer clips

into the door panel.

- .- ” - 13. . - Install the door panel onto the vehicle. Push . - -. ” - ret;liners intn the hnlss in the rlnnr until thev lnck intn . - - - -. -. . . . “, - ” . .- position. If any clips do not lock, replace with new 4. Remove the lock cylinder from the trunk lid,

hatch, or tailgate. T- 1-a-11.

REMOVAL &INSTALLATION

1. Disconnect the r

negative battery cable.

2. If necessary, ren love any trim in on the under-

side of the trunk lid, hz

Itch, or tailgate.

3. Release locking tab retaining the lock cylinder

to outside handle.

9315opo5 1 Fig. 46 Remove the two front door panel re-

taining screws . , . IU Inrlall; 5. Place the lock cylinder into the opening on the

ones.

14. The remainder of installation is the reverse of

removal. trunk lid, hatch, or tailsate. -

6. Snap the locking tab into place retaining the

lock cylinder to the outside handle.

7. If removed, install any trim in on the underside

of the trunk lid, hatch, or tailgate.

8. Connect the negative battery able:

REMOVAL &INSTALLATION

II See Figurd 50

1‘ &connect the negative battery cable. REMOVAL&INSTALLATION

9315ctpm Fig. 47 . . .

and also the rear retaining

screws from the door panel 2. Remove the door panel.

3. Peel back the weathproofing film from the

door.

4. Remove the retaining clip and the lock rod

from the handle assembly.

5. Remove the retaining hardware and remove the

handle from the door.

6. The installation is the reverse of removal. 1. Disconnect the negative battery cable.

2. Remove the hatch/tailgate trim cover.

3. Remove the retaining clip and the lock rod

from the handle assembly.

4. Remove the retaining hardware and.remove the

handle from the hatch/tailgate.

5. The installation is the reverse of removal.

I 1. Disconnect the neaative batterv cable. ) See Figures 51, 52, 53/ 54, and 55 REMOVAL&INSTALLATION REMOVAL&INSTALLATION

2. Remove the door ~andle/latchassembly.

3. Release locking tab retaining the lock cylinder

to the outside handle.

4. Remove the lock cylinder from the outside

handle and feed the illumination wire through the

opening in the handle.

To install:

5. Route the illumination wire through the handle

and install the lock cylinder.

6. Snap the locking tab into place retaining the

lock cvlinder to the outside handle.

7. ‘Install the door handle/latch assembly.

8. Connect the negative battery cable. 1. Lower the door glass. ‘1,

2. Remove the door panel and moisture barrier.

3. Using a non-marring tool and a cloth pad,

gently pry the belt molding up and off the door.

4. Remove the inner glass sthbilizers.

5. On front doors only, remove the glass guide

/

slider.

6. Support the bottom of the door glass and re-

move the two mounting bolts holdirtg the glass to the

regulator. If the glass is not supporfed, it will fail into

+I%? Ann. . ..hmn hr. l..4+s are remove&.

9315opa Fig, 49 . . . then remove the door panel from

the vehicle 50 Common door handle/latch mount-

I

, Flg. 51 After the door panel is removed, re-

move the Insulation from the door