wipers MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 28 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-29

i

*Bug screens which are mounted in front of

the condenser (unless they are original

equipment) are regarded as obstructtons.

l The condensation drain tube expels any water

which accumulates on the bottom of the evaporator

housing into the engine compartment. If this tube is

obstructed, the air conditioning performance can be

restricted and condensation buildup can spill over

onto the vehicle’s floor.

l Make sure the air passage selection lever is

operating correctly. Start the engine and warm it to

normal operating temperature, then make sure the

temperature selection lever is operating correctly.

-w

~1 ELEMENT(REFILL)CARE& REPLACEMENT

SYSTEM INSPECTION

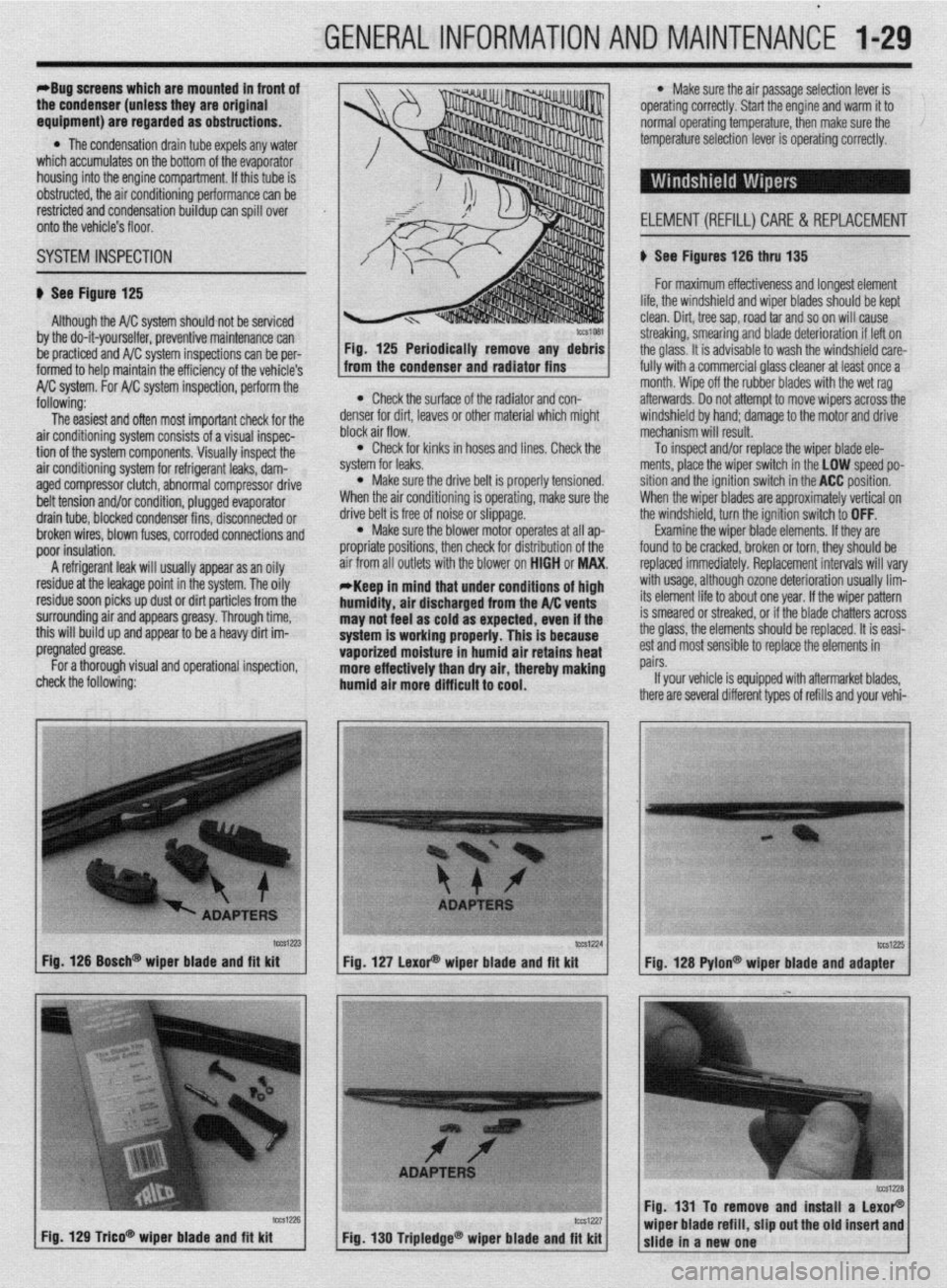

b See Figure 125 b See Figures 126 thru 135

For maximum effectiveness and longest element

Although the A/C system should not be serviced

by the do-it-yourselfer, preventive maintenance can

be practiced and A/C system inspections can be per-

formed to help maintain the efficiency of the vehicle’s

A/C system. For A/C system inspection, perform the

following:

The easiest and often most important check for the

air conditioning system consists of a visual inspec-

tion of the system components. Visually inspect the

air conditioning system for refrigerant leaks, dam-

aged compressor clutch, abnormal compressor drive

belt tension and/or condition, plugged evaporator

drain tube, blocked condenser fins, disconnected or

broken wires, blown fuses, corroded connections and

poor insulation.

A refrigerant leak will usually appear as an oily

residue at the leakage point in the system. The oily

residue soon picks up dust or dirt particles from the

surrounding air and appears greasy. Through time,

this will build up and appear to be a heavy dirt im-

pregnated grease.

For a thorough visual and operational inspection,

check the following: * Check the surface of the radiator and con-

denser for dirt, leaves or other material which might

block air flow.

l Check for kinks in hoses and lines. Check the

system for leaks.

l Make sure the drive belt is properly tensioned.

When the air conditioning is operating, make sure the

drive belt is free of noise or slippage.

l Make sure the blower motor operates at all ap-

propriate positions, then check for distribution of the

air from all outlets with the blower on HIGH or MAX.

*Keep in mind that under conditions of high

humidity, air discharged from the A/C vents

may not feel as cold as expected, even if the

system is working properly. This is because

vaporized moisture in humid air retains heat

more effectively than dry air, thereby making

humid air more difficult to cool.

lifp thp winrkhi&i nnri winor hlarlP~ shmM hP kmt . ..“. .I.” . . * ““I.. “.” I..” ...r”* “.“““” “, ,““,” “” ,~“r~ clean. Dirt, tree sap, road tar and so on will cause

streaking, smearing and blade deterioration if left on

the glass. It is advisable to wash the windshield care-

fully with a commercial glass cleaner at least once a

month. Wipe off the rubber blades with the wet rag

afterwards. Do not attempt to move wipers across the

windshield by hand; damage to the motor and drive

mechanism will result.

To inspect and/or replace the wiper blade ele-

ments, place the wiper switch in the LOW speed po-

sition and the ignition switch in the ACC position.

When the wiper blades are approximately vertical on

the windshield, turn the ignition switch to OFF.

Examine the wiper blade elements. If they are

found to be cracked, broken or torn, they should be

replaced immediately. Replacement intervals will vary

with usage, although ozone deterioration usually lim-

its element life to about one year. If the wiper pattern

is smeared or streaked, or if the blade chatters across

the glass, the elements should be replaced. It is easi-

est and most sensible to replace the elements in

pairs.

If your vehicle is equipped with aftermarket blades,

there are several different types of refills and your vehi-

tcca-23 Fig. 126 Bosch@ wiper blade and fft kit

Fig. 129 T&o* wioer blade and fit kit tCS1224

lW1Z?5 Fig. 127 LexoP wiper blade and fit kit

Fig. 128 Pylon@ wiper blade and adapter

Fig. 131 To remove and install a LexoP

Fig, 130 Tripledge@ wiper blade and fit kit wiper blade refill, slip out the old insert and

slide in a new one

Page 42 of 408

GENERALINFORMATIONAND MAINTENANCE l-43

l Special car washing detergent is the best to

use. Liquid dishwashing detergent can remove wax

and leave the car’s paint unprotected and in addition

some liquid detergents contains abrasives which can

scratch the paint.

l Bird droppings should be removed from the

paintwork as soon as possible, otherwise the finish

may be permanently stained.

When the car is driven immediately after be-

ing washed, apply the brakes several times

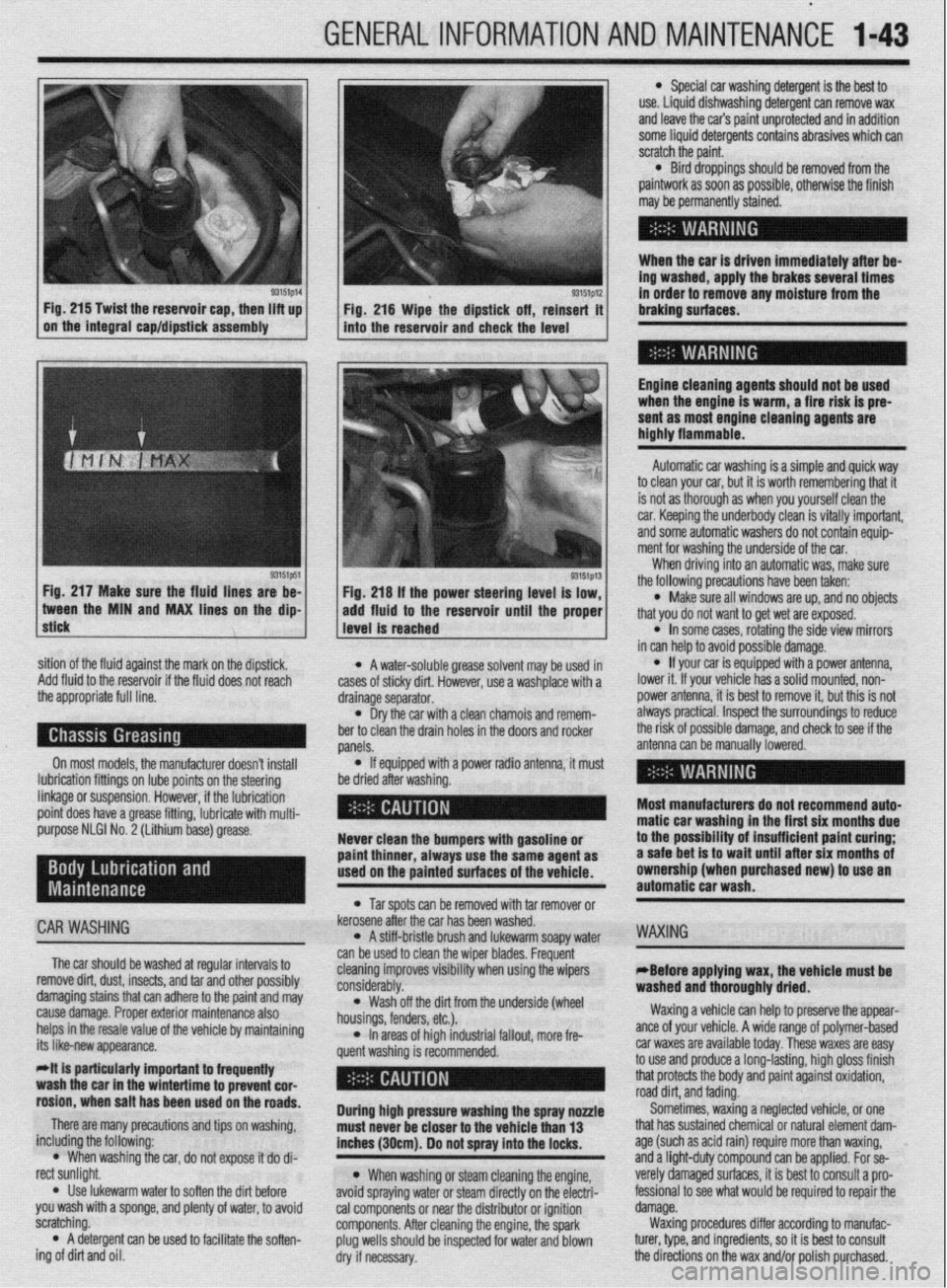

93151p14 93151p12 Fig. 215 Twist the reservoir cap, then lift up

I I

in order to remove any moisture from the

Fig. 216 Wipe the dipstick off, reinsert it braking surfaces.

on the integral cap/dipstick assembly

into the reservoir and check the level

I

Engine cleaning agents should not be used

when the engine is warm, a fire risk is pre-

sent as most engine cleaning agents are

highly flammable.

sition of the fluid against the mark on the dipstick,

Add fluid to the reservoir if the fluid does not reach

the appropriate full line.

On most models, the manufacturer doesn’t install

lubrication fittings on lube points on the steering

linkage or suspension. However, if the lubrication

point does have a grease fitting, lubricate with multi-

purpose NLGI No. 2 (Lithium base) grease.

CAR WASHING

The car should be washed at regular intervals to

remove dirt, dust, insects, and tar and other possibly

damaging stains that can adhere to the paint and may

cause damage. Proper exterior maintenance also

helps in the resale value of the vehicle by maintaining

its like-new appearance.

Mt is particularly important ta frequentiy

wash the car in the wintertime to prevent cor-

rosion, when salt has been used on the roads.

There are many precautions and tips on washing,

including the following:

l When washing the car, do not expose it do di-

rect sunlight.

. Use lukewarm water to soften the dirt before

you wash with a sponge, and plenty of water, to avoid

scratching.

l A detergent can be used to facilitate the soften-

ing of dirt and oil. * A water-soluble grease solvent may be used in

cases of sticky dirt. However, use a washplace with a

drainage separator.

l Dry the car with a clean chamois and remem-

ber to clean the drain holes in the doors and rocker

panels.

l If equipped with a power radio antenna, it must

be dried after washing.

Never clean the bumpers with gasoline or

paint thinner, always use the same agent as

used on the painted surfaces of the vehicle.

l Tar spots can be removed with tar remover or

kerosene after the car has been washed.

l A stiff-bristle brush and lukewarm soapy water

can be used to clean the wiper blades. Frequent

cleaning improves visibility when using the wipers

considerably.

l Wash off the did from the underside (wheel

housings, fenders, etc.).

l In areas of high industrial fallout, more fre-

quent washing is recommended.

During high pressure washing the spray nonle

must never be closer to the vehicle than 13

inches (30cm). Do not spray into the locks.

l When washing or steam cleaning the engine,

avoid spraying water or steam directly on the electri-

cal components or near the distributor or ignition

components. After cleaning the engine, the spark

plug wells should be inspected for water and blown

dry if necessary. Automatic car washing is a simple and quick way

to clean your car, but it is worth remembering that it

is not as thorough as when you yourself clean the

car. Keeping the underbody clean is vitally important,

and some automatic washers do not contain equip-

ment for washing the underside of the car.

When driving into an automatic was, make sure

the following precautions have been taken:

l Make sure all windows are up, and no objects

that you do not want to get wet are exposed.

l In some cases, rotating the side view mirrors

in can help to avoid possible damage.

l If your car is equipped with a power antenna,

lower it. If your vehicle has a solid mounted, non-

power antenna, it is best to remove it, but this is not

always practical. Inspect the surroundings to reduce

the risk of possible damage, and check to see if the

antenna can be manually lowered.

Most manufacturers do not recommend auto-

matic car washing in the first six months due

to the possibility of insufficient paint curing;

a safe bet is to wait until after six months of

ownership (when purchased new) to use an

automatic car wash.

WAXING

eBefore applying wax, the vehicle must be

washed and thoroughly dried.

Waxing a vehicle can help to preserve the appear-

ante of your vehicle. A wide range of polymer-based

car waxes are available today. These waxes are easy

to use and produce a long-lasting, high gloss finish

that protects the body and paint against oxidation,

road dirt, and fading.

Sometimes, waxing a neglected vehicle, or one

that has sustained chemical or natural element dam-

age (such as acid rain) require more than waxing,

and a light-duty compound can be applied. For se-

verely damaged surfaces, it is best to consult a pro-

fessional to see what would be required to repair the

damage.

Waxing procedures differ according to manufac-

turer, type, and ingredients, so it is best to consult

the directions on the wax and/or polish purchased.

Page 56 of 408

ENGlNEELECTRldAL 2-9

TESTING

Voltage Test able for use by customers. An alternator

bench test is the most definitive way to de-

termine the condition of your alternator.

REMOVAL&INSTALLATION

1. Make sure the engine is OFF, and turn the 1.51,1.61, 1.6L, 2.OL and 2.4L Engines

headlights on for 15-20 seconds to remove any sur-

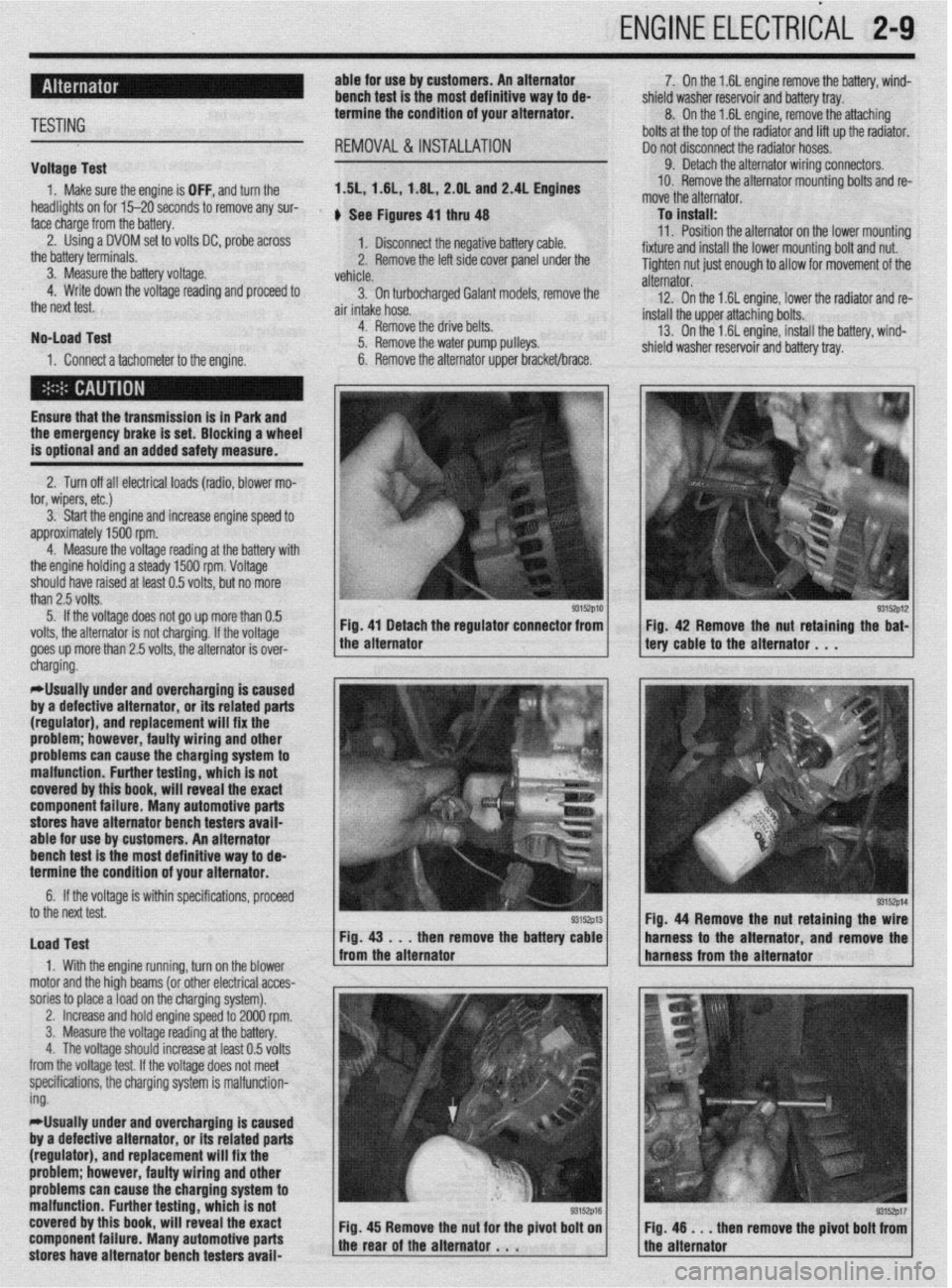

face charge from the battery. , See Figures 4, thru 48

2. Using a DVOM set to volts DC, probe across

1. Disconnect the negative battery cable.

the battery terminals.

3. Measure the battery voltage. 2. Remove the left side cover panel under the

vehicle.

4. Write down the voltage reading and proceed to

3. On turbocharaed Galant models, remove the

the next test.

air intake hose. -

No-load Test

1. Connect a tachometer to the engine. 4. Remove the drive belts.

5. Remove the water pump pulleys.

6. Remove the alternator upper bracket/brace.

Ensure that the transmission

is in Park and the emergency brake is set. Blocking a wheel

is optional and an added safety measure.

2. Turn off all electrical loads (radio, blower mo-

tor, wipers, etc.)

3. Start the engine and increase engine speed to

approximately 1500 rpm.

4. Measure the voltage reading at the battery with

the engine holding a steady 1500 rpm. Voltage

should have raised at least 0.5 volts, but no more

than 2.5 volts.

5. If the voltage does not go up more than 0.5

volts, the alternator is not charging. If the voltage

goes up more than 2.5 volts, the alternator is over-

* 7. On the 1.6L engine remove the battery, wind-

shield washer reservoir and battery tray.

8. On the 1.6L engine, remove the attaching

bolts at the top of the radiator and lift up the radiator.

Do not disconnect the radiator hoses.

9. Detach the alternator wiring connectors.

10. Remove the alternator mounting bolts and re-

move the alternator.

To install:

11. Position the alternator on the lower mountina

fixture and install the lower mounting bolt and nut. U

Tighten nut just enough to allow for movement of the

alternator.

12. On the 1.6L engine, lower the radiator and re-

install the upper attaching bolts.

13. On the 1.6L engine, install the battery, wind-

shield washer reservoir and battery tray.

/ tery cable to the alternator . , . 93152p12 Fig 42 Remove the nut retaining the bat-

cnargmg.

*Usually under and overcharging is‘caused

by a defective alternator, or its related parts

(regulator), and replacement will fix the

problem; however, faulty wiring and other

problems can

cause the charging system to

malfunction. Further testing, which is not

covered by this book, will reveal the exact

component failure. Many automotive parts

stores have alternator bench testers avaii-

able for use by customers. An alternator

bench test is the most definitive way to de-

termine the condition of your alternator.

6. If the voltage is within specifications, proceeU

to the next test.

Load Test

1. With the engine running, turn on the blower

motor and the hioh beams (or other electrical acces-

sories to place aioad on the charging system). Fig. 44 Remove the nut retaining the

then remove the batte harness to the alternator and remov

,

2. Increase and hold engine speed to 2000 rpm.

3. Measure the voltage reading at the battery.

4. The voltage should increase at least 0.5 volts

from the voltage test. If the voltage does not meet

specifications, the charging system is malfunction-

ing.

*Usually under and overcharging is caused

by a defective alternator, or its related parts

(regulator), and replacement will fix the

problem; however, faulty wiring and other

problems can cause the charging system to

malfunction. Further testing, which is not

covered by this book, will reveal the exact

component failure. Many automotive parts

stores have alternator bench testers avaii-

93152p17 en remove the pivot bolt from

Page 204 of 408

UNDERSTANDING AND

TROUBLESHOOTING

ELECTRICAL SYSTEMS 6-2

BASIC ELECTRICALTHEORY 6-2

HOW DOES ELECTRICITY WORK:

THEWATERANALOGY 6-2

OHM'S LAW 6-2

ELECTRICALCOMPONENTS 6-2

POWERSOURCE 6-2

GROUND 6-3

PROTECTIVE DEVICES 6-3

SWITCHES&RELAYS 6-3

LOAD 6-3

WIRING & HARNESSES 6-3

CONNECTORS 6-4

TEST EQUIPMENT 6-4

JUMPER WIRES 6-4

TEST LIGHTS 6-4

MULTIMETERS 6-5

TROUBLESHOOTING ELECTRICAL

SYSTEMS 6-5

TESTING 6-5

OPEN CIRCUITS 6-5

SHORT CIRCUITS 6-6

VOLTAGE 6-6

VOLTAGE DROP 6-6

RESISTANCE 6-8

WIRE AND CONNECTORREPAIR 6-6

BATTERY CABLES 6-7

DISCONNECTING THE CABLES 6-7

AIR BAG (SUPPLEMENTAL

RESTRAINT SYSTEM) 6-7

GENERALINFORMATION 6-7

SERVICE PRECAUTIONS 6-7

DISARMING 6-7

REARMING 6-7

HEATING AND AIR

CONDITIONING 6-7

BLOWER MOTOR 6-7

REMOVAL &INSTALLATION 6-7

HEATER CORE 6-9 INSTRUMENTS AND SWITCHES 6-17

INSTRUMENTCLUSTER 6-17

REMOVAL &INSTALLATION 6-17

GAUGES 6-18

REMOVAL&INSTALLATION 6-18

WINDSHIELD WIPER SWITCH 6-19

REMOVAL&INSTALLATION 6-19

REARWINDOWWIPERSWITCH 6-19

REMOVAL &INSTALLATION 6-19

DIMMER SWITCH 6-19

REMOVAL & INSTALLATION 6-19 .

HEADLIGHT SWITCH 6-19

REMOVAL & INSTALLATION 6-19

LIGHTING 6-19

HEADLIGHTS 6-19

REMOVAL &INSTALLATION 6-19

AIMINGTHEHEADLIGHTS 6-20

SIGNAL AND MARKER LIGHTS 6-21

REMOVAL &INSTALLATION 6-21

CIRCUIT PROTECTION 6-27

FUSES 6-27

REPLACEMENT 6-27

FUSIBLE LINKS 6-27

CIRCUIT BREAKERS 6-28

RESETTING AND/OR

REPLACEMENT 6-28

FLASHERS 6-28

REPLACEMENT 6-28

WIRING DIAGRAMS 6-31

REMOVAL & INSTALLATION 6-9

AIR CONDITIONING COMPONENTS 6-11

REMOVAL & INSTALLATION 6-11

CONTROLCABLES 6-12

ADJUSTMENT 6-12

CONTROL PANEL 6-12

REMOVAL & INSTALLATION 6-12

CRUISE CONTROL 6-13

ENTERTAINMENT SYSTEMS 6-14

RADIO RECEIVER/AMPLIFIER/TAPE

PLAYER/CD PLAYER 6-14

SPEAKERS 6-14

REMOVAL & INSTALLATION 6-14

WINDSHIELD WIPERS AND

WASHERS 6-15

WINDSHIELD WIPER BLADE AND

ARM 6-15

REMOVAL & INSTALLATION 6-15

WINDSHIELD WIPER MOTOR 6-16 _

REMOVAL &INSTALLATION 6-16

WINDSHIELD WASHER PUMP 6-17

REMOVAL &INSTALLATION 6-17

Page 210 of 408

I I

CHASSIS ELECTRICAL 6-7

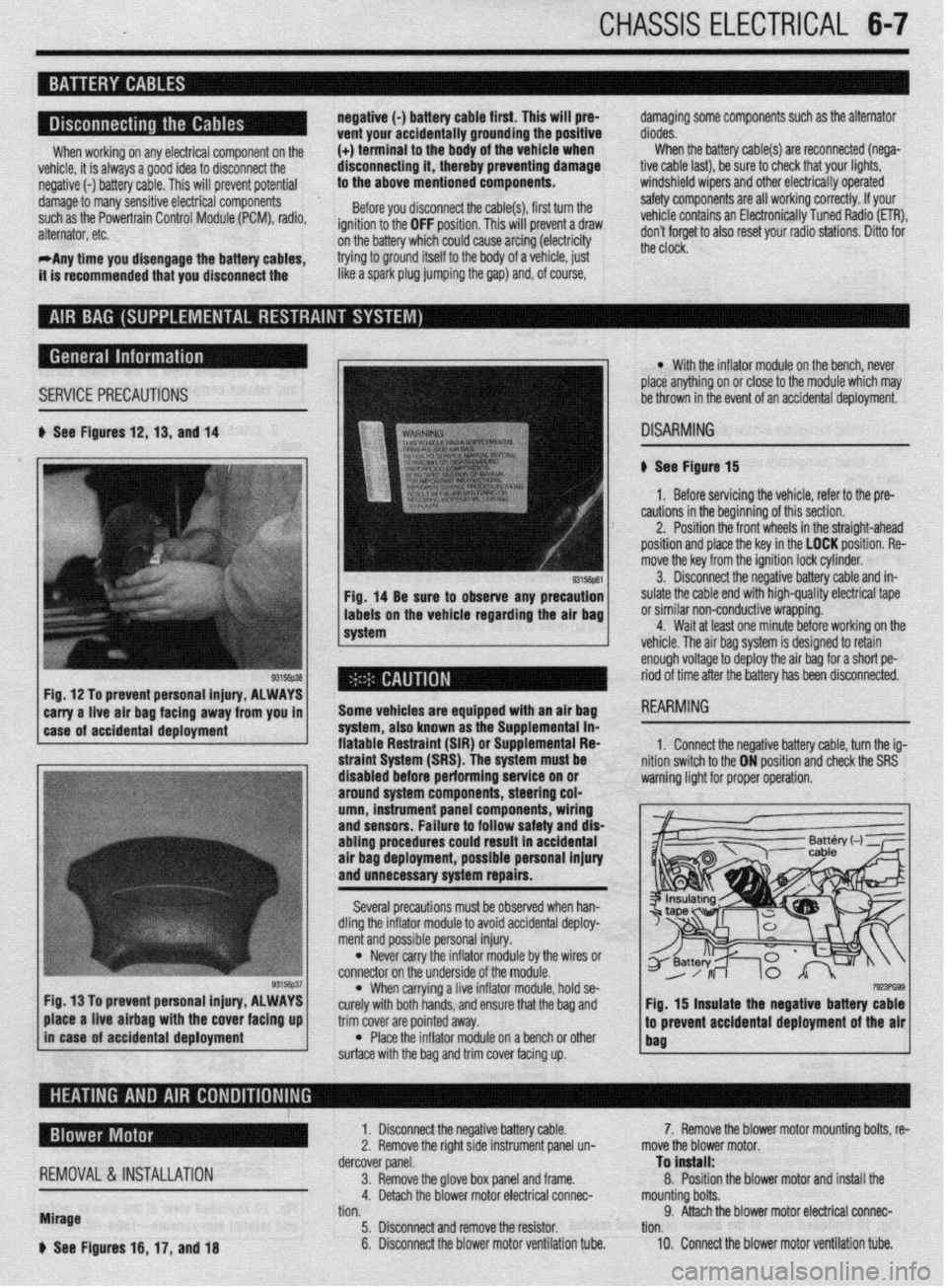

When working on any electrical component on the

vehicle, it is always a good idea to disconnect the

negative (-) battery cable. This will prevent potential

damage to many sensitive electrical components

such as the Powertrain Control Module (PCM), radio,

alternator, etc.

*Any time you disengage the battery cables,

it is recommended that you disconnect the negative (-) battery cable first. This will pre-

vent your accidentally grounding the positive

(+) terminal to the body of the vehicle when

disconnecting it, thereby preventing damage

to the above mentioned components.

Before you disconnect the cable(s), first turn the

ignition to the OFF position. This will prevent a draw

on the battery which could cause arcing (electricity

trying to ground itself to the body of a vehicle, just

like a spark plug jumping the gap) and, of course, damaging some components such as the alternator

diodes.

When the battery cable(s) are reconnected (nega-

tive cable last), be sure to check that your lights,

windshield wipers and other electrically operated

safety components are all working correctly. If your

vehicle contains an Electronically Tuned Radio (ETR),

don’t forget to also reset your radio stations. Ditto for

the clock.

SERVICE PRECAUTIONS

b See Figures 12,13, and 14

Fig, 14 Be sure to observe any precaution

labels on the vehicle regarding the air bag

system

Fig. 12 To prevent personal injury, ALWAYS

*

carry a-live -ah bag fac!ng away from you in 1

1 case of accidental deployment Some vehicles are equipped wtth an air bag

-.-‘--

syr1em, aiscl Known as I11 -I-- ‘------- -- sLe Supplemental in- fiatable Restraint (SIR) o r Suouiementai Fiea

l With the inflator module on the bench, never

place anything on or close to the module which may

be thrown in the event of an accidental deployment.

DISARMING

# See Figure 15

1. Before servicing the vehicle, refer to the pre-

cautions in the beginning of this section.

2. Position the front wheels in the straight-ahead

position and place the key in the LOCK position. Re-

move the key from the ignition lock cylinder.

3. Disconnect the negative battery cable and in-

sulate the cable end with high-quality electrical tape

or similar non-conductive wrapping.

4. Wait at least one minute before working on the

vehicle. The air baa svstem is desianed to retain

enough voltage to deploy the air bag for a short pe-

riod of time after the battery has been disconnected.

1. Connect the neoative batters cable. turn the ia-

3, hold se-

e bag and

trim cover are pointed away.

l Place the inflator module on a bench or other

surface with the bag and trim cover facing up.

7!r!3PG93 Fig. 15 insulate the negative battery cable

.I

to prevent accidental deployment of the air

bag place a live airbag with the cover facing up

in case of accidental deployment

REMOVAL &INSTALLATION

Mirage

b See Figures 16, 17, and 18 1. Disconnect the negative battery cable.

2. Remove the right side instrument panel un-

dercover panel.

3. Remove the glove box panel and frame.

4. Detach the blower motor electrical connec-

tion.

5. Disconnect and remove the resistor.

6. Disconnect the blower motor ventilation tube. 7. Remove the blower motor mounting bolts, re-

move the blower motor.

To install:

8. Position the blower motor and install the

mounting bolts.

9. Attach the blower motor electrical connec-

tion.

10. Connect the blower motor ventilation tube.

Page 215 of 408

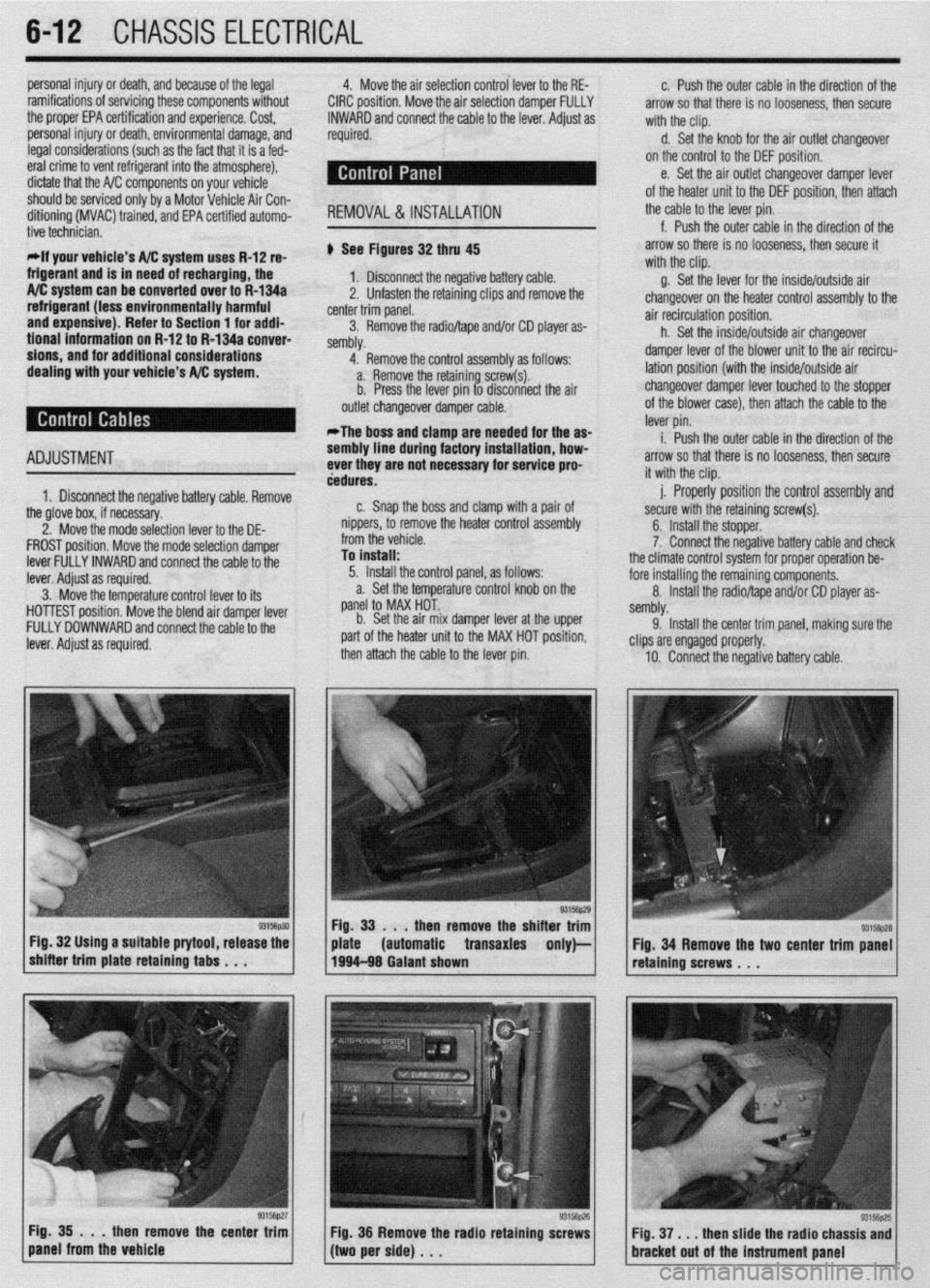

6-12 CHASSIS ELECTRICAL

personal injury or death, and because of the legal

ramifications of servicing these components without

the proper EPA certification and experience. Cost,

personal injury or death, environmental damage, and

legal considerations (such as the fact that it is a fed-

eral crime to vent refrigerant into the atmosphere),

dictate that the A/C comoonents on your vehicle 4. Move the air selection controi lever to the RE-

CIRC position. Move the air selection damper FULLY

INWARD and connect the cable to the lever. Adjust as

required. C. Push the outer cable in the direction of the

arrow so that there is no looseness, then secure

should be serviced only’by a Motor Vehicle Air Con-

ditioning (MVAC) trained, and EPA certified automo-

REMOVAL&INSTALLATION tive technician. with the clip.

d. Set the knob for the air outlet changeover

on the control to the DEF position.

e. Set the air outlet changeover damper lever

of the heater unit to the DEF position, then attach

the cable to the lever pin.

f. Push the outer cable in the direction of the

arrow so there is no loosen&s, then secure it

with the clip. *If your vehicle’s A/C system uses R-12 re-

frlgerant and is in need of recharging, the

AK system can be converted over to R-Ma

refrigerant (less environmentally harmful

and expensive). Refer to Section 1 for addi-

tional information on R-12 to R-134a eonver-

sions, and for additional considerations

dealing with your vehicle’s A/C system. ti See Figures 32 thru 45

1. Disconnect the negative battery cable.

2, Unfasten the retaining clips and remove the

center trim panel.

3. Remove the radioltape and/or CD player as-

sembly,

4. Remove the control assembly as follows:

a. Remove the retaining screw(s).

b. Press the lever pin to disconnect the air

outlet changeover damper cable.

*The boss and clamp are needed for the as-

ADJUSTMENT

1. Disconnect the negative battery cable. Remove sembly line d

ever they are

dedures.

n Cnan i luring factory installation, how-

not necessary for service pro-

the glove box, if necessary,

2. Move the mode selection lever to the DE-

FROST position. Move the mode selection damper

lever FULLY INWARD and connect the cable to the

lever. Adiust as required.

3. M&e tht

3 temperature control lever to its

HOlli

5ST position. Move the blend air damper lever

FULL’t

’ DOWNWARD and connect the cable to the

lever. i

4djust as required. b,. dIIal, the boss and clamp with a pair of

nippers, to remove the heater control assembly

from the vehicle.

To install:

5. Install the control panel, as follows:

a. Set the temperature control knob on the

panel to MAX HOT..

b. Set the air mix damper lever at the upper

part of the heater unit to the MAX HOT position,

then attach the cable to the lever pin.

then remove the shi

Fig. 32 Using a suitable prytool, release the

automatic transaxles

93156p27 Fig. 35 . . .

then remove the center trim

panel from the vehicle

/(twiperside)... y Fig 36 Remove the radio retaining screws g. Set the lever for the inside/outside air

changeover on the heater control assemblv to the

air recirculation position.

h. Set the inside/outside air changeover

damper lever of the blower unit to the air recircu-

lation position (with the inside/outside air

changeover damper lever touched to the stopper

of the blower case), then attach the cable to the

lever pin.

i. Push the outer cable in the direction of the

arrow so that there is no looseness, then secure

it with the clip.

j. Properly position the control assembly and

secure with the retaining screw(s).

6. Install the stopper.

7. Connect the negative battery cable and check

the climate control system for proper operation be-

fore installing the remaining components.

8. Install the radio/tape and/or CD player as-

sembly.

9. Install the center trim oanel, makina sure the

clips are engaged properly. -

10. Connect the negative battery cable.

Fig. 34 Remove the two center trim panel

retaining screws . . .

Fig. 37, . . then slide the radio chassis and

bracket out of the instrument Dane1

Page 235 of 408

6-32 CHASSIS ELECTRICAL

INDEX OF WIRING DIAGRAMS

DIAGRAM 28 1990-93 Galant Wipers Chassis Schematics

DIAGRAM 29 1990-93 Galant Wipers w/ ETACS Control Unit Chassis Schematics

DIAGRAM 30 1990-93 Galant Power Door Locks Chassis Schematics

DIAGRAM 31 1990-93 Galant Power Door Locks wl ETACS Control Unit Chassis Schematics

DIAGRAM 32 1996-00 Galant Starting System Chassis Schematics

DIAGRAM 33 1994-00 Galant Charging System Chassis Schematics

DIAGRAM 34 1994-00 Galant Charging System Chassis Schematics

DIAGRAM 35 1994-00 Galant Headlights Chassis Schematics

DIAGRAM 36 1994-00 Galant Taillights Chassis Schematics

DIAGRAM 37 1994-00 Galant Brake Lights/Backup Lights/Horn Chassis Schematics

DIAGRAM 38 1994-00 Galant Turn Signal Chassis Schematics

DIAGRAM 39 1994-00 Galant Power Windows Chassis Schematics

m

DIAGRAM 40 1994-00 Galant Wipers Chassis Schematics

b

DIAGRAM 41 1994 Galant Power Door Locks w/ ETACS Control Unit Chassis Schematics

DIAGRAM 42 1994-00 Galant Power Door Locks Chassis Schematics

DIAGRAM 43 1992-00 Diamante Starting System Chassis Schematics

DIAGRAM 44 1992-00 Diamante Charging System Chassis Schematic

DIAGRAM 45 1992-93 Diamante Cabling System Chassis Schematic

DIAGRAM 46 1994-95 Diamante Cooling System Chassis Schematics

DIAGRAM 47 1996-00 Diamante Headlights Chassis Schematics

DIAGRAM 48 1992-95 Diamante Taillights/Backup Lights Chassis Schematics

DIAGRAM 49 1992-95 Diamante Turn Signal Chassis Schematics

DIAGRAM 50 1992-00 Diamante Brake Lights, Horn Chassis Schematic

DIAGRAM 51 1992-95 Diamante Power Windows Chassis Schematics

DIAGRAM 52 1992-95 Diamante Wipers Chassis Schematics

DIAGRAM 53 1992-93 Diamante Power Door Locks Chassis Schematics

Page 236 of 408

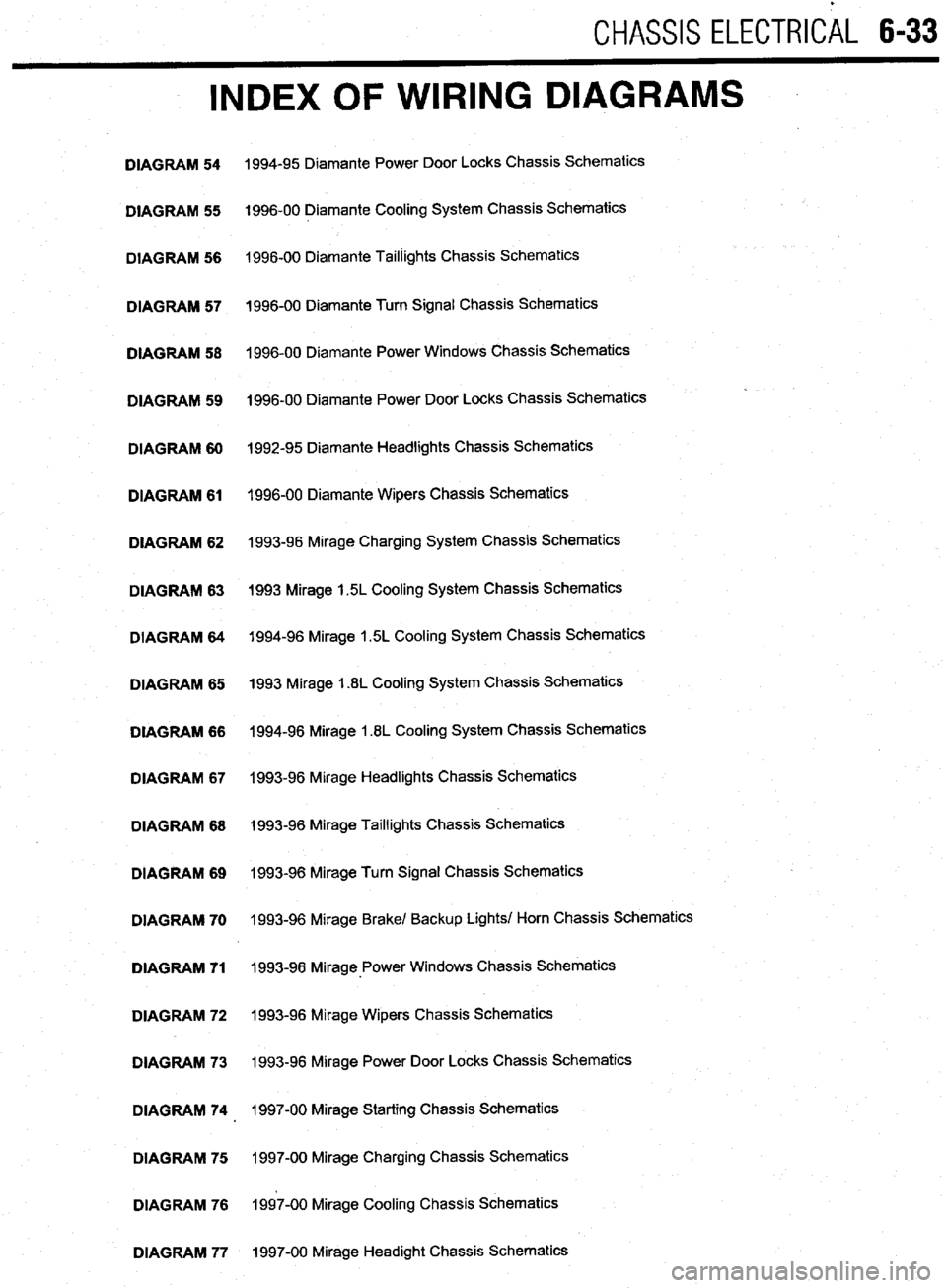

CHASSIS ELECTRlCiL 6-33

INDEX OF WIRING DIAGRAMS

DIAGRAM 54

DIAGRAM 55

DIAGRAM 56

DIAGRAM 57

DIAGRAM 58

DIAGRAM 59

DIAGRAM 60

DIAGRAM 61

DIAGRAM 62

DIAGRAM 63

DIAGRAM 64

DIAGRAM 65

DIAGRAM 66

DIAGRAM 67

DIAGRAM 68

DIAGRAM 69

DIAGRAM 70

DIAGRAM 71

DIAGRAM 72

DIAGRAM 73

DIAGRAM 74

DIAGRAM 75

DIAGRAM 76

DIAGRAM 77 1994-95 Diamante Power Door Locks Chassis Schematics

1996-00 Diamante Cooling System Chassis Schematics

1996-00 Diamante Taillights Chassis Schematics

1996-00 Diamante Turn Signal Chassis Schematics

1996-00 Diamante Power Windows Chassis Schematics

1996-00 Diamante Power Door Locks Chassis Schematics

1992-95 Diamante Headlights Chassis Schematics

1996-00 Diamante Wipers Chassis Schematics

1993-96 Mirage Charging System Chassis Schematics

1993 Mirage 1.5L Cooling System Chassis Schematics

1994-96 Mirage 1.5L Cooling System Chassis Schematics

1993 Mirage 1.8L Cooling System Chassis Schematics

1994-96 Mirage 1.8L Cooling System Chassis Schematics

1993-96 Mirage Headlights Chassis Schematics

1993-96 Mirage Taillights Chassis Schematics

1993-96 Mirage Turn Signal Chassis Schematics

1993-96 Mirage Brake/ Backup Lights/ Horn Chassis Schematics

1993-98 Mirage-Power Windows Chassis Schematics

1993-96 Mirage Wipers Chassis Schematics

1993-96 Mirage Power Door Locks Chassis Schematics

1997-00 Mirage Starting Chassis Schematics

1997-00 Mirage Charging Chassis Schematics

1997-00 Mirage Cooling Chassis Schematics

1997-00 Mirage Headight Chassis Schematics

Page 237 of 408

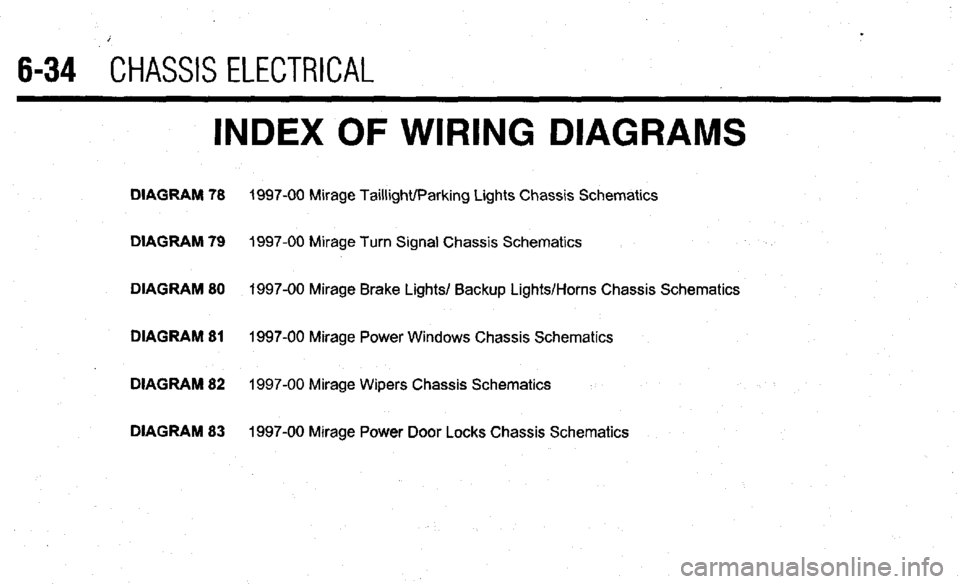

6-34 CHASSIS ELECTRICAL

INDEX OF WIRING DIAGRAMS

DIAGRAM 78 1997-00 Mirage Taillight/Parking Lights Chassis Schematics

DIAGRAM 79

1997-00 Mirage Turn Signal Chassis Schematics

DIAGRAM 80 1997-00 Mirage Brake Lights/ Backup Lights/Horns Chassis Schematics

DIAGRAM 81

1997-00 Mirage Power Windows Chassis Schematics

DIAGRAM 82 1997-00 Mirage Wipers Chassis Schematics

DIAGRAM 83 1997-00 Mirage Power Door Locks Chassis Schematics