relay MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 11 of 408

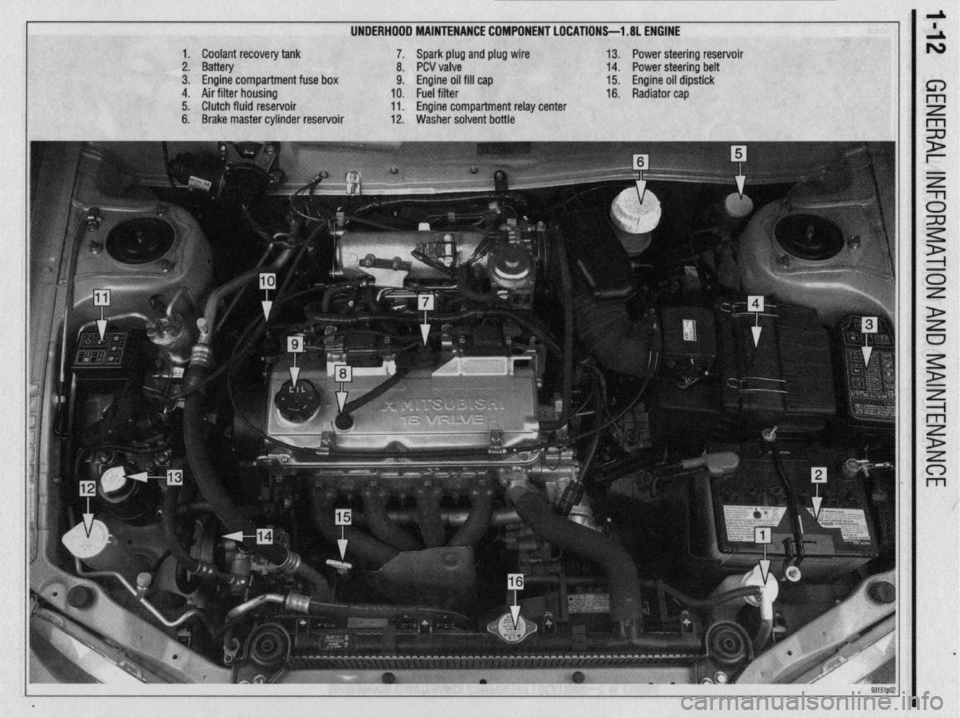

UNDERHOOD MAINTENANCE COMPONENT LOCATIONS-l .8L ENGINE

1. Coolant recovery tank

2. Battery

3. Engine compartment fuse box

4. Air filter housing

5. Clutch fluid reservoir

6. Brake master cylinder reservoir 7. Spark plug and plug wire

8. PCV valve

9. Engine oil fill cap

10. Fuel filter

11. Engine compartment relay center

12. Washer solvent bottle 13. Power steering reservoir

14. Power steering belt

15. Engine oil dipstick

16. Radiator cap

Page 161 of 408

.

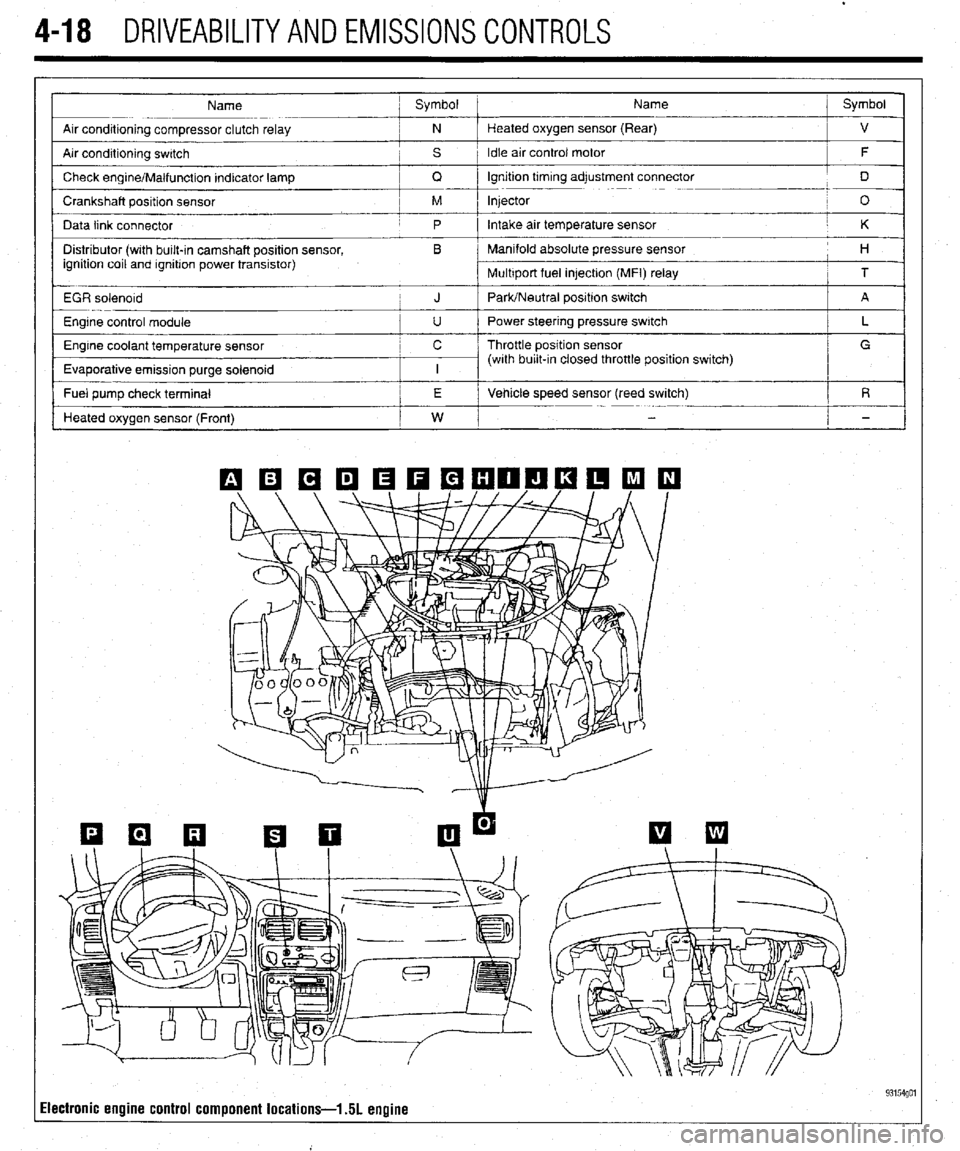

4-18 DRIVEABILITYAND EMISSIONS CONTROLS

Name ; Symbol Name j Symbol

I

Arr conditioning compressor clutch relay ; N Heated oxygen sensor (Rear)

j ”

Air condrtioning swatch , s 1 Idle air control motor

/ F

/

Check engrne/Malfunction Indicator lamp

/ Q lgnrtion trmrng adjustment connector

j D

Crankshaft position sensor / M Injector

! O

Data link connector

j p Intake air temperature sensor / K

Distributor (wrth bulk-in camshaft position sensor, , B Manifold absolute pressure sensor

ignition coil and rgnrtron power transistor) I 1 H

Multrport fuel in]ectron (MFI) relay

i T

EGR solenord

i J PaWNeutral positron switch j A

Engine control module

I u I Power steering pressure switch

Engine coolant temperature sensor c / Throttle position sensor

Evaporative emission purge solenoid

I I I (with burl&In closed throttle position switch) / L _

/ G

I

I

- Fuel pump check terminal /

I j E i Vehicle speed sensor (reed switch)

/ R

Heated oxygen sensor (Front)

I w I

i -

Ilectronic engine control component locations-l 51 engine 93154go1

Page 162 of 408

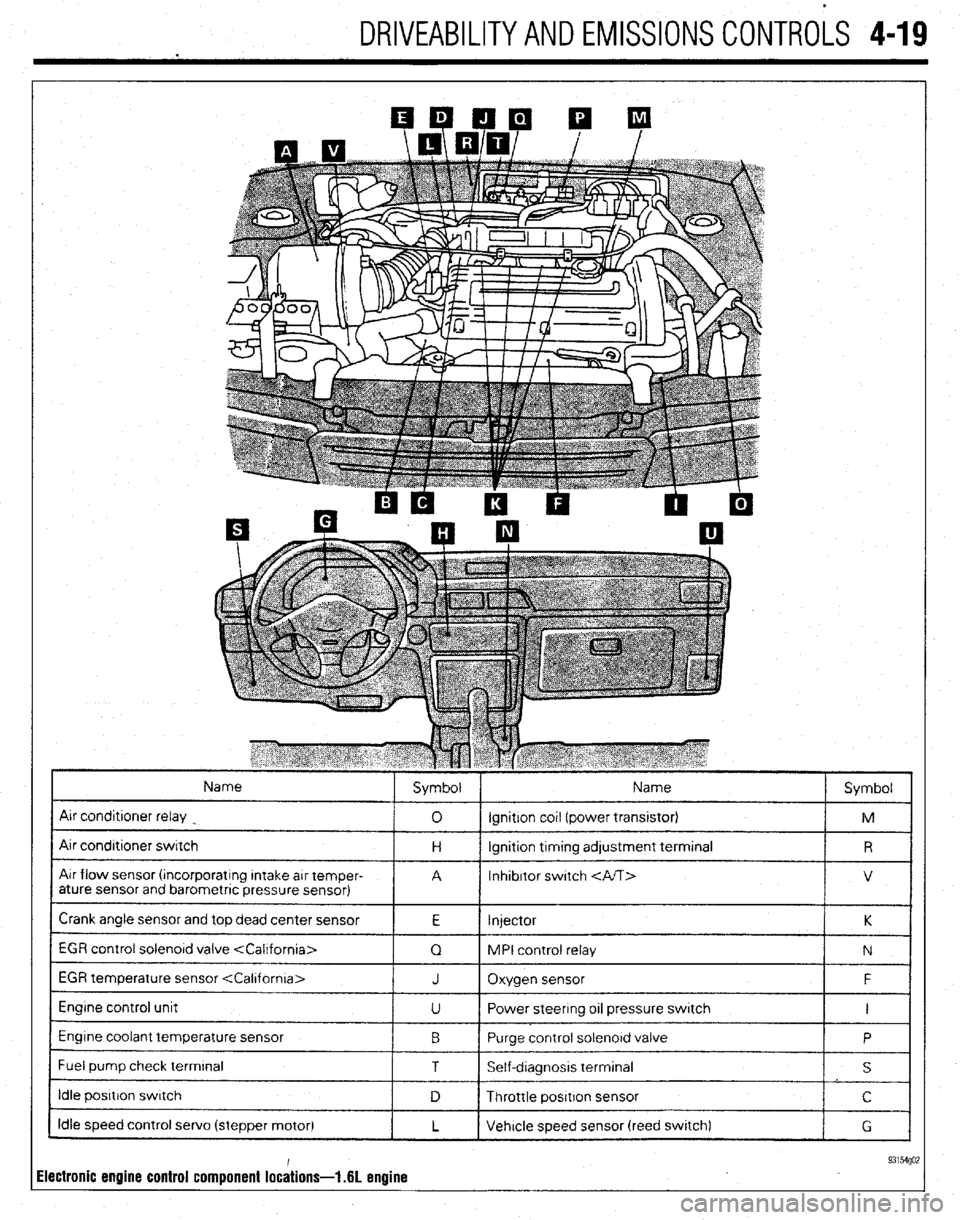

DRIVEABILITYAND EMISSIONS CONTROLS 4-19

Name

Air conditroner relay

Air condrtroner switch

Air flow sensor (rncorporatrng Intake arr temper-

ature sensor and barometric pressure sensor) Symbol Name

Symbol

0 ignition cot1 (power transrstor)

M

H lgnrtion trmtng adjustment terminal

R

A Inhibitor switch

V

Crank angle sensor and top dead center sensor

E Injector K

1 EGR control solenord valve

1 Q 1 MPI control relay

1 N 1

EGR temperature sensor

Engine control unit

Engine coolant temperature sensor

I Fuel pump check terminal J Oxygen sensor F

U Power steering 011 pressure switch I

0 Purge control solenord valve

P

1 T I Self-dragnosis terminal

I s I

I idle posrtron swatch

1 D 1 Throttle positron sensor I c I

Idle speed control servo (stepper motor)

L Vehicle speed sensor (reed swatch)

G

ilectronic engine control component lochions- .6L enuine 93154go;

Page 163 of 408

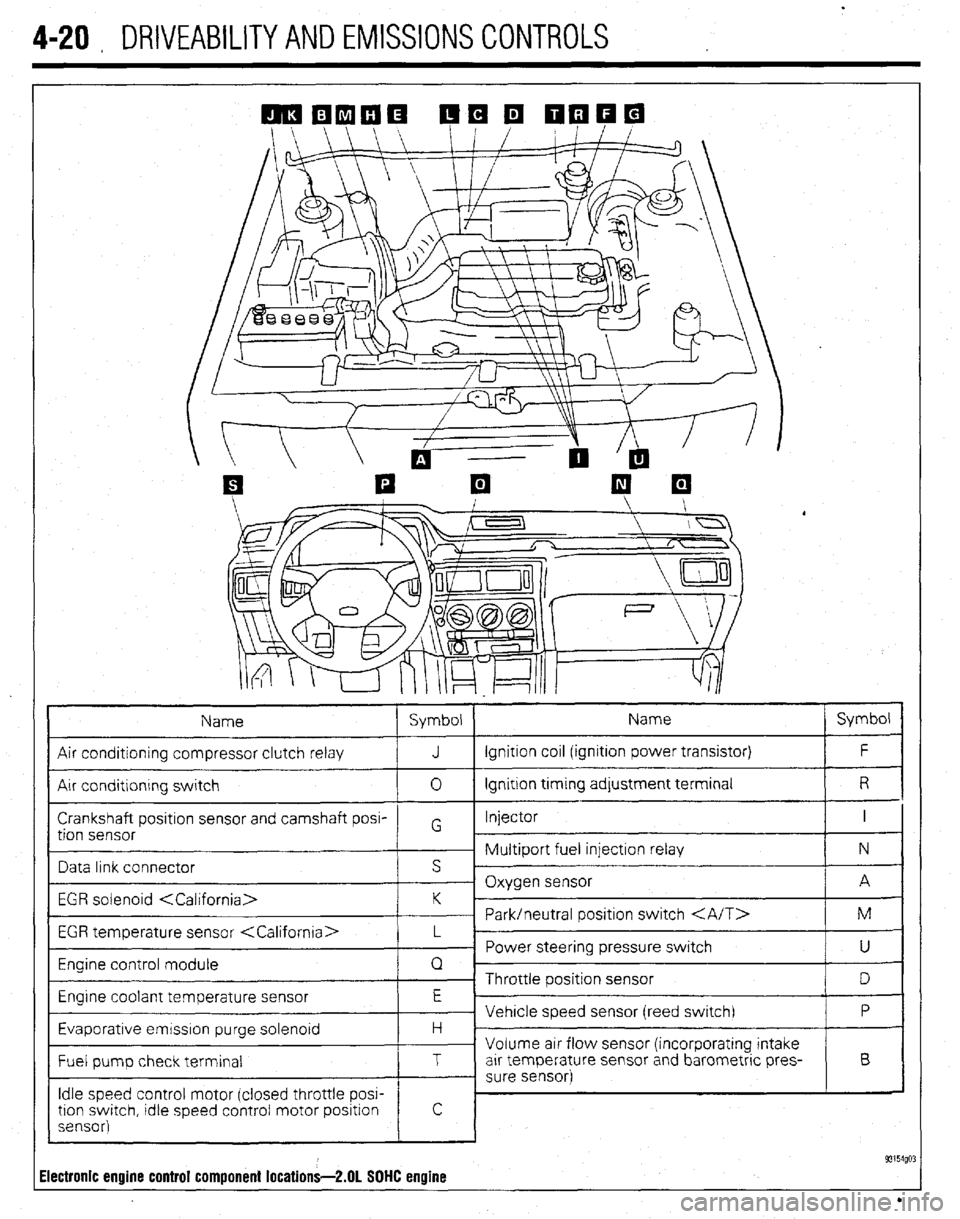

4-20 , DRIVEABILITYAND EMISSIONS CONTROLS

Name Symbol Name Symbol

Air conditioning compressor clutch relay J Ignition coil (ignition power transistor) F

Air conditlonrng switch 0 Ignition trming adjustment terminal R

Crankshaft positron sensor and camshaft posi- Injector I

tion sensor G

~ Multiport fuel injection relay N

Data link connector s ’

- Oxygen sensor A

EGR solenoid

~ Park/neutral positron switch M

EGR temperature sensor

_ Power steering pressure switch

U

Engine control module Q

~ Throttle position sensor

D

Engrne coolant temperature sensor E

Vehicle speed sensor (reed switch) P

Evaporative emrsslon purge solenoid H -

Volume air flow sensor (incorporating intake

Fuel pump check terminal T arr temperature sensor and barometric pres- B

- sure sensor)

Idle speed control motor (closed throttle POW

tron swatch, tdle speed control motor positron

sensor)

! c

93154go: Electronic engine control component locations-2.01 SOHC engine

Page 165 of 408

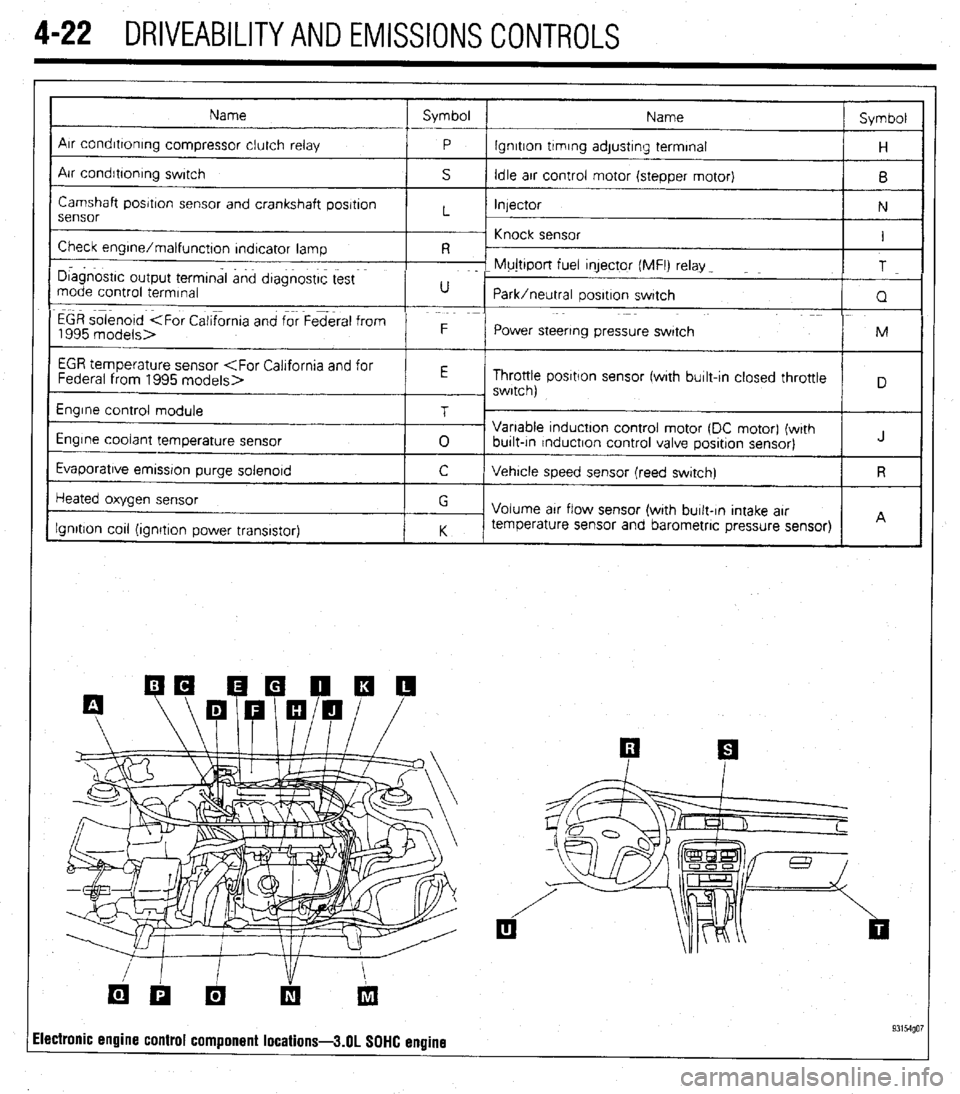

4-22 DRIVEABILITYAND EMISSIONS CONTROLS

Name Symbol

Name Symbol

I

Arr condrttontng compressor clutch relay

P lgnrtton trmrng adjustrng terminal

H

Air condrbonrng swrtch

S Idle arr control motor (stepper motor)

B

Camshaft posrtron sensor and crankshaft posrtron

Injector

N

sensor L

~ Knock sensor

Check engrne/malfunctton rndtcator lamp I

R -

I D~agnostrc output termtnal and dtagnostrc test F- Mujttport fuel qector (MFI) relay _

T

mode control termrnal U

Park/neutral oosrtron swatch

Q

EGR solenoid

1995 models> F

Power steering pressure swatch M

I

EGR temperature sensor

Throttle posrtlon sensor fwrth burlt-In closed throttle

, swrtch)

Engrne control module

Engine coolant temperature sensor

Evaporatrve emrssron purge solenord T

0 Variable tnductton control motor (DC motor) (wrth

burlt-tn rnductron control valve posrtron sensor) J

C Vehrcle speed sensor (reed swatch) R

Heated oxygen sensor

Ignition cot1 (ionrtron Dower transistor) G

Volume arr flow sensor (with burlt-In Intake arr

K temperature sensor and barometric pressure sensor)

I I A

ilectronic engine control component locations-3.01 SOHC engine 93154go7

Page 167 of 408

.

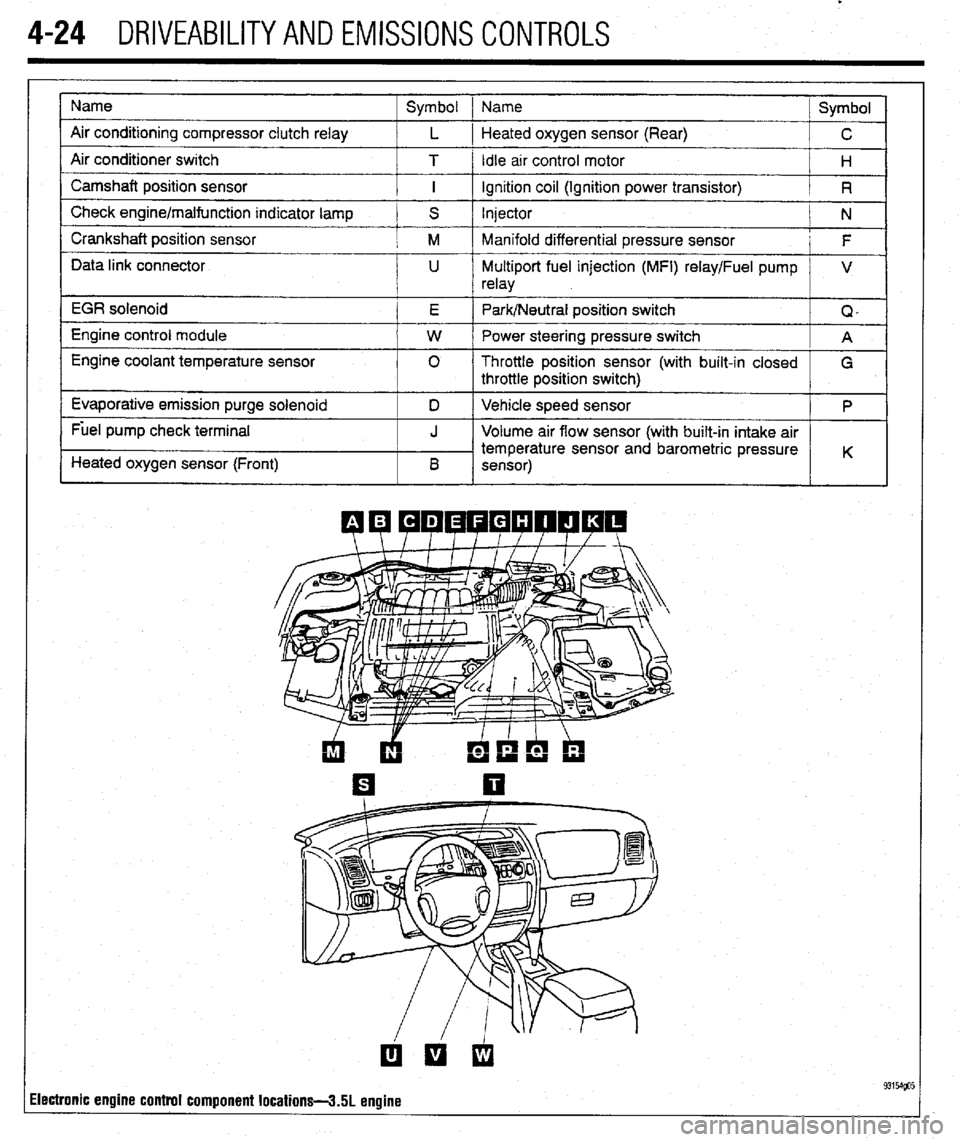

4-24 DRIVEABILITYAND EMISSIONS CONTROLS

Name

Air conditioning compressor clutch relay

Air conditioner switch

Camshaft position sensor

Check engine/malfunction indicator lamp

Crankshaft position sensor

Data link connector

EGR solenoid

Engine control module

Engine coolant temperature sensor

Evaporative emission purge solenoid

Fuel pump check terminal

Heated oxygen sensor (Front) Symbol 1 Name

Symbol

L 1 Heated oxygen sensor (Rear)

C

T / Idle arr control motor

H

I ignition coil (Ignition power transistor)

R

S Injector

N

M Manifold differential pressure sensor

F

U Multiport fuel injection (MFI) relay/Fuel pump V

relay

E Park/Neutral position switch

Q,

W Power steering pressure switch

A

0 Throttle position sensor (with built-in closed

G

throttle position switch)

D Vehicle speed sensor

P

J Volume air flow sensor (with built-in intake air

temperature sensor and barometric pressure

B K

sensor)

ilectronic engine control component locations-3.51 engine

Page 168 of 408

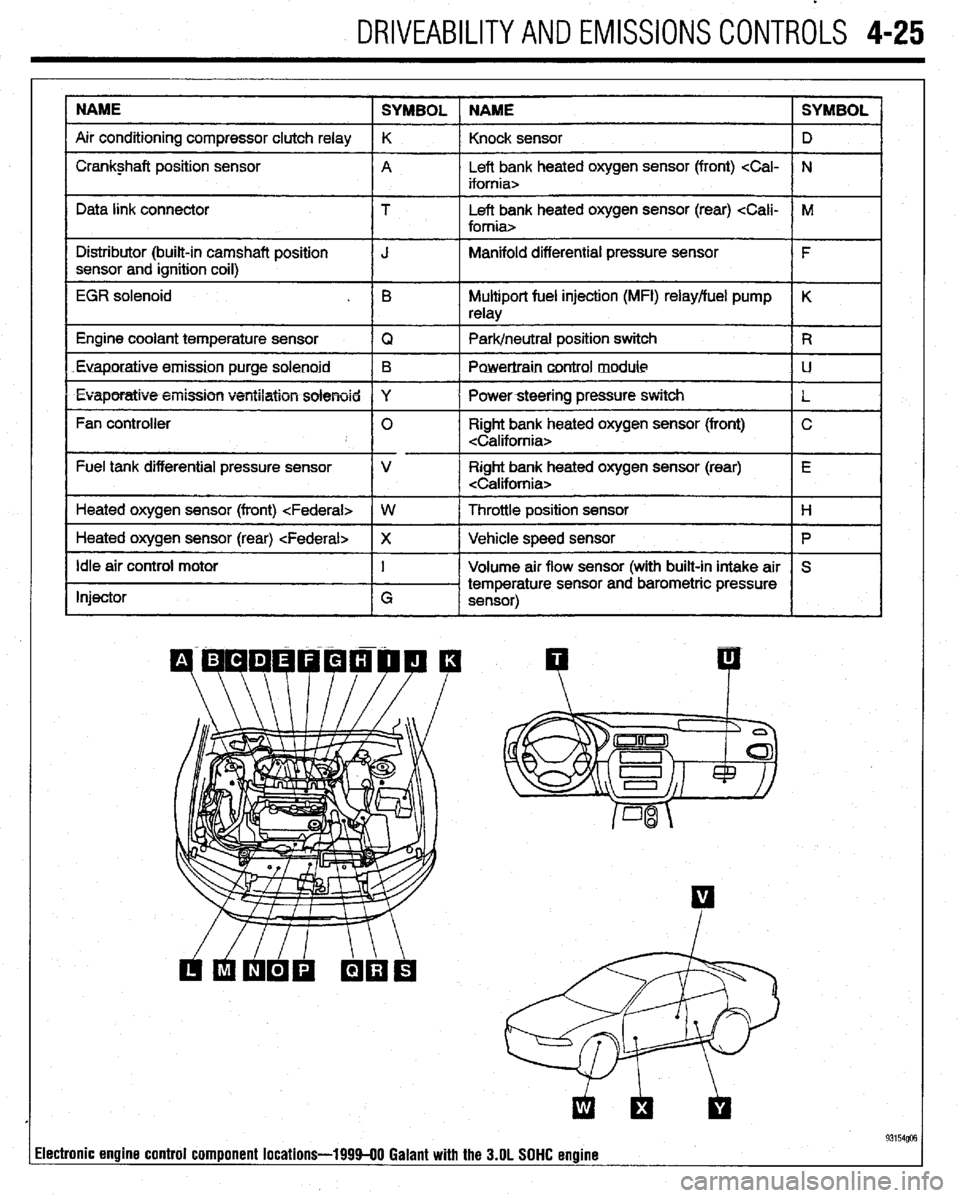

DRIVEABILITYAND EMISSIONS CONTROLS 4-25

NAME

SYMBOL NAME SYMBOL

Air conditioning compressor clutch relay K

Knock sensor D

I Crankshaft position sensor

A Left bank heated oxygen sensor (front)

I I

Data link connector T Left bank heated oxygen sensor (rear)

I Distributor (built-in camshaft position

I J Manifold differential pressure sensor

I F

sensor and ignition coil)

I

EGR solenoid . B Multiport fuel injection (MFI) relay/fuel pump K

relay

1 Engine coolant temperature sensor

IQ 1 Park/neutral position switch IR

Euaporatiue.emission purge solenoid B

Powertraincontrol module LJ

l Evaporatiw5+eiiission ventilation solenoid Y

I Powersteering pressure switch

L

Fan controller 0 Right bank heated oxygen sensor (front) C

Fuel tank differential pressure sensor V Right bank heated oxygen sensor (rear) E

Heated oxygen sensor (front)

I

1 Heated oxygen sensor (rear)

Ip I

Idle air control motor

Injector I

G Volume air flow sensor (with built-in intake air S

temperature sensor and barometric pressure

sensor)

I I

93154@3 lectronic engine control component locations-199940 Galant with the 3.OL SOHC engine

Page 170 of 408

DRIVEABILITYAND EMISSIONS CONTROLS 4-27

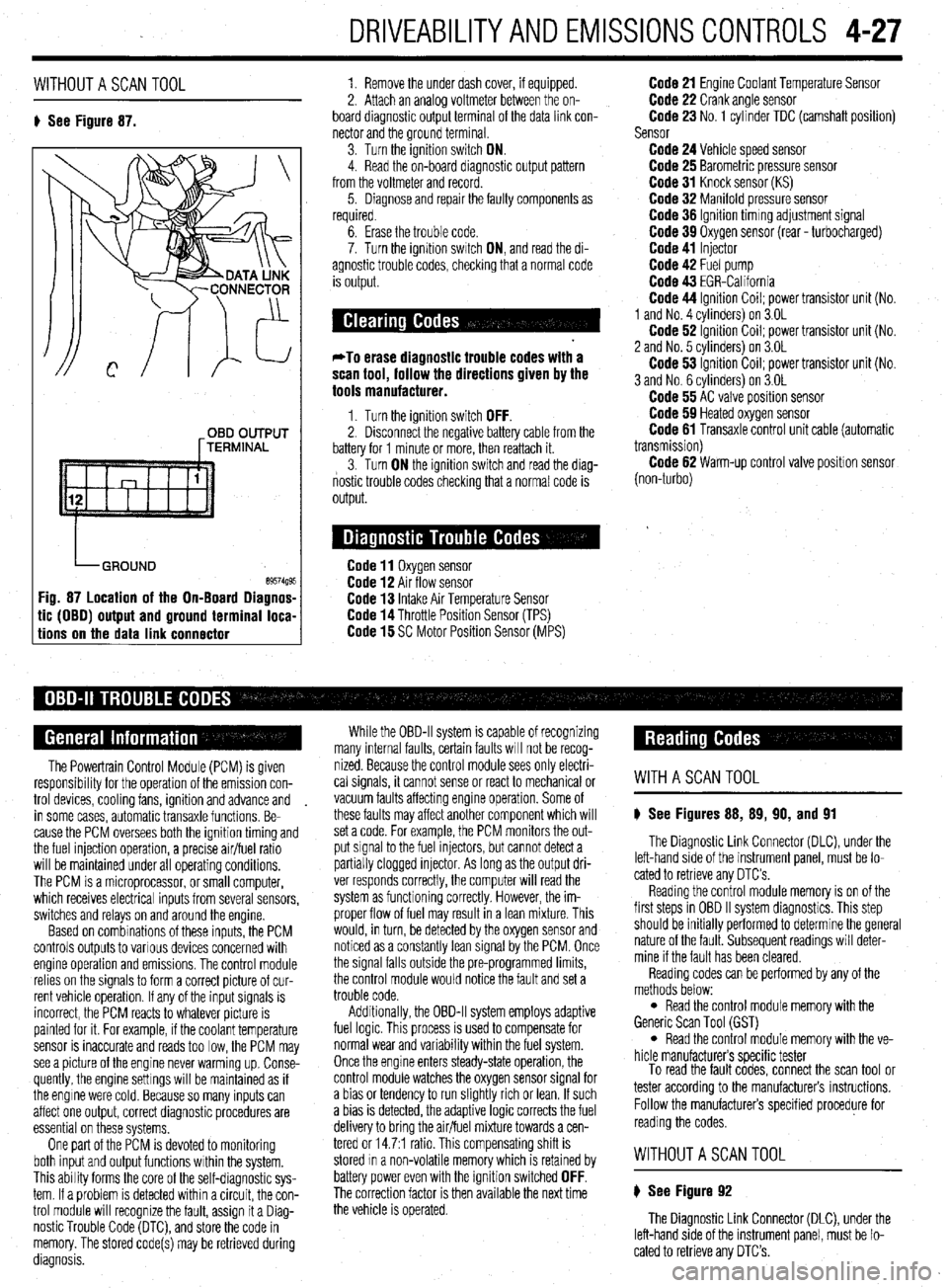

WITHOUTASCANTOOL

8 See Figure 87. 1. Remove the under dash cover, if equipped.

2. Attach an analoa voltmeter between the on-

board diagnostic outpit terminal of the data link con-

nector and the ground terminal

3. Turn the ignition switch ON.

4. Read the on-board diagnostic output pattern

from the voltmeter and record.

5. Diagnose and repair the faulty components as

required.

OBD OUTPUT

[TERMINAL

tic (OBO) output and ground terminal loca-

tions on the data link connector

6. Erase the trouble code.

7. Turn the ignition swatch ON, and read the di-

agnostic trouble codes, checking that a normal code

is output.

*To erase diagnostic trouble codes with a

scan tool, follow the directions given by the

tools manufacturer.

1. Turn the ignition switch OFF. 2. Disconnect the negative battery cable from the

battery for 1 minute or more, then reattach it.

3. Turn ON the ignition switch and read the diag-

nostic trouble codes checking that a normal code is

output.

Code 11 Oxygen sensor Code 12 Air flow sensor Code 13 Intake Air Temperature Sensor Code 14 Throttle Position Sensor (TPS) Code 15 SC Motor Position Sensor (MPS)

Code 21 Engine Coolant Temperature Sensor Code 22 Crank angle sensor Code 23 No. 1 cylinder TDC (camshaft position)

Sensor

Code 24 Vehicle speed sensor Code 25 Barometric pressure sensor Code 31 Knock sensor (KS) Code 32 Manifold pressure sensor Code 36 Ignition timmg adjustment signal Code 39 Oxygen sensor (rear - turbocharged) Code 41 Injector Code 42 Fuel pump Code 43 EGR-California Code 44 Ignition Coil; power transistor unit (No.

1 and No. 4 cvlinders) on 3.OL

Code 62 ignition Coil; power transistor unit (No.

2 and No. 5 cvlinders) on 3.OL

Code 53 ignition Coil; power transistor unit (No.

3 and No. 6 cylinders) on 3.OL

Code 55 AC valve position sensor Code 59 Heated oxygen sensor Code 61 Transaxle control unit cable (automatic

transmission)

Code 62 Warm-up control valve position sensor

(non-turbo)

The Powertrain Control Module (PCM) is given

responsibrlity for the operation of the emission con-

trol devices, cooling fans, ignition and advance and

in some cases, automatic transaxle functions. Be-

cause the PCM oversees both the ignition timing and

the fuel injection operation, a precise air/fuel ratio

will be maintained under all operating conditions,

The PCM is a microprocessor, or small computer,

which receives electrical inputs from several sensors,

switches and relays on and around the engine.

Based on combinations of these inputs, the PCM

controls outputs to various devices concerned with

engine operation and emissions. The control module

relies on the signals to form a correct picture of cur-

rent vehicle operation. If any of the input signals is

incorrect, the PCM reacts to whatever picture is

painted for it. For example, if the coolant temperature

sensor is inaccurate and reads too low, the PCM may

see a picture of the engine never warming up. Conse-

quently, the engine settings will be maintained as if

the engine were cold. Because so many inputs can

affect one output, correct diagnostic procedures are

essential on these systems,

One part of the PCM is devoted to monitoring

both input and output functions within the system.

This ability forms the core of the self-diagnostic sys-

tem. If a problem is detected within a circuit, the con-

trol module will recognize the fault, assign it a Diag-

nostic Trouble Code (DTC), and store the code in

memory. The stored code(s) may be retrieved during

diagnosis. While the OBD-II system is capable of recognizing

many internal faults, certain faults WIII not be recog-

nized. Because the control module sees only electri-

cal signals, it cannot sense or react to mechanical or

vacuum faults affecting engine operation. Some of

these faults may affect another component which will

set a code. For example, the PCM monitors the out-

put signal to the fuel injectors, but cannot detect a

partially clogged injector. As long as the output dri-

ver responds correctly, the computer will read the

system as functioning correctly. However, the im-

proper flow of fuel may result in a lean mixture. This

would, in turn, be detected by the oxygen sensor and

noticed as a constantly lean signal by the PCM. Once

the signal falls outside the pre-programmed limits,

the control module would notice the fault and set a

trouble code.

Additionally, the OBD-II system employs adaptive

fuel logic. This process is used to compensate for

normal wear and variability within the fuel system.

Once the engine enters steady-state operation, the

control module watches the oxygen sensor signal for

a bias or tendency to run slightly rich or lean. If such

a bias is detected, the adaptive logic corrects the fuel

delivery to bring the air/fuel mixture towards a cen-

tered or 14.7:1 ratio. This compensating shift is

stored In a non-volatile memory which is retained by

battery power even with the ignition switched

OFF. The correction factor is then available the next time

the vehicle is operated.

WITHASCANTOOL

8 See Figures 88, 89, 90, and 91

The Diagnostic Link Connector (DLC), under the

left-hand side of the instrument panel, must be lo-

cated to retrieve any OTC’s

Reading the control module memory is on of the

first steps in OBD II system diagnostics. This step

should be initially performed to determine the general

nature of the fault. Subsequent readings will deter-

mine if the fault has been cleared.

Reading codes can be performed by any of the

methods below:

l Read the control module memory with the

Generic Scan Tool (GST)

l Read the control module memory with the ve-

hicle manufacturers specific tester

To read the fault codes, connect the scan tool or

tester according to the manufacturers instructions.

Follow the manufacturers specified procedure for

reading the codes.

WITHOUTASCANTOOL

8 See Figure 92

The Diagnostic Link Connector (DLC), under the

left-hand side of the instrument panel, must be lo-

cated to retrieve any DTC’s.

Page 173 of 408

.

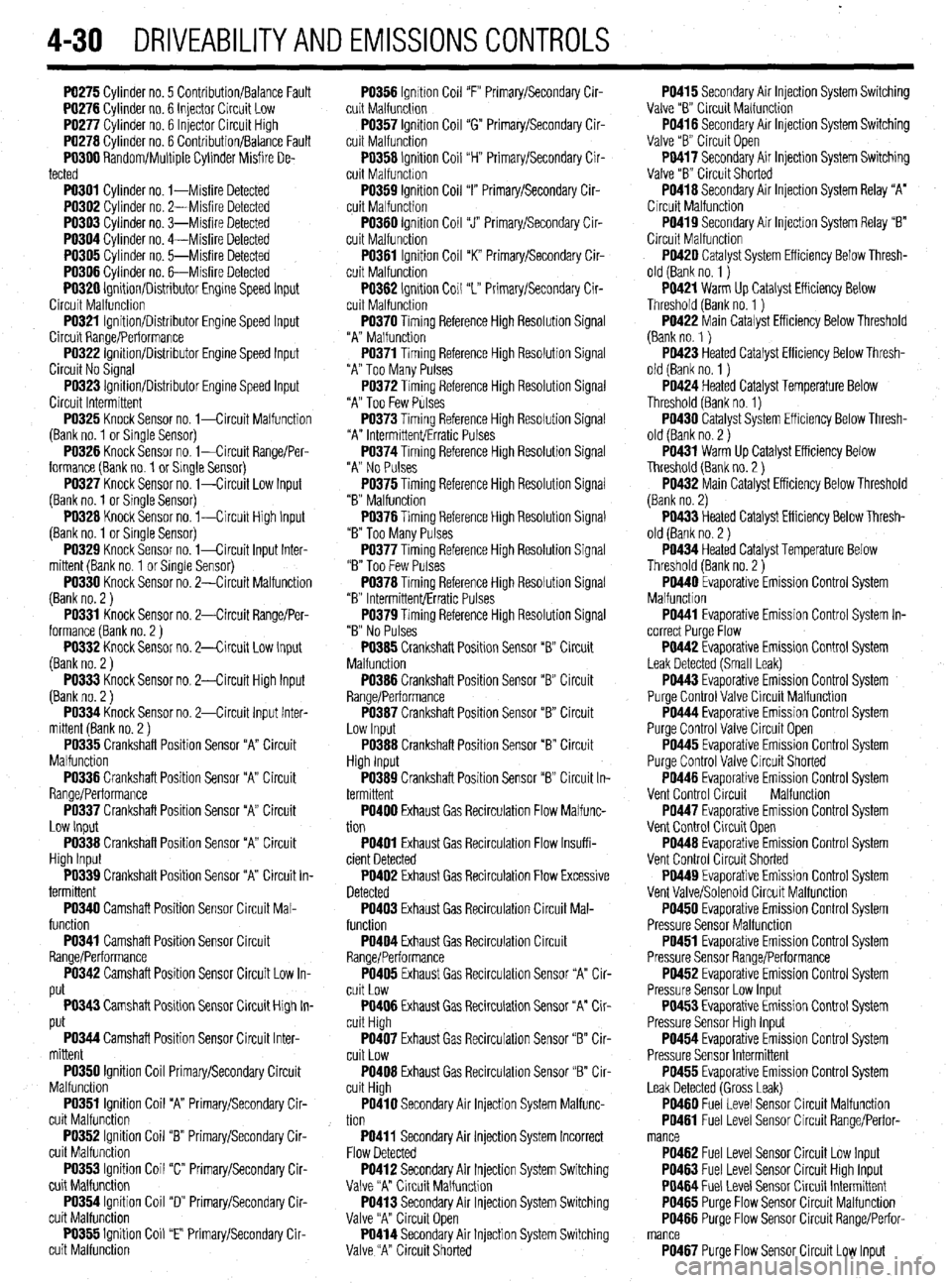

4-30 DRIVEABILITYAND EMISSIONS CONTROLS

PO275 Cvlinder no. 5 Contribution/Balance Fault

PO276 Cylinder no. 6 Injector Circuit Low

PO277 Cylinder no. 6 lniector Circuit High

PO278 Cylinder no. 6 Contribution/Balance Fault

PO300 Random/Multiple Cylinder Misfire De-

tected

PO301 Cylinder no. l-Misfire Detected

PO302 Cvlinder no 2-Misfire Detected

PO303 Cylinder no. 3-Misfire Detected

PO304 Cylinder no. 4-Misfire Detected

PO305 Cylinder no. +-Misfire Detected

PO306 Cylinder no. &-Misfire Detected

PO320 Ignition/Distributor Engine Speed Input

Circuit Malfunction

PO321 Ignition/Distributor Engine Speed Input

Circuit Range/Performance

PO322 Ignibon/Distributor Engine Speed Input

Circuit No Signal

PO323 Ignition/Distributor Engine Speed Input

Circuit Intermittent

PO325 Knock Sensor no. l-Circuit Malfunction

(Bank no. 1 or Single Sensor)

PO326 Knock Sensor no. l-Circuit Range/Per-

formance (Bank no. 1 or Srngle Sensor)

PO327 Knock Sensor no. l-Circuit Low Input

(Bank no. 1 or Single Sensor)

PO328 Knock Sensor no. l-Circuit High Input

(Bank no. 1 or Single Sensor)

PO329 Knock Sensor no. l-Circuit Input Inter-

mittent (Bank no. 1 or Smgle Sensor)

PO330 Knock Sensor no. 2-Circuit Malfunction

(Bank no. 2 )

PO331 Knock Sensor no. 2-Circuit Range/Per-

formance (Bank no. 2 )

PO332 Knock Sensor no. 2-Circuit Low Input

(Bank no. 2 )

PO333 Knock Sensor no. 2-Circuit High Input

(Bank no. 2 )

PO334 Knock Sensor no. 2-Circuit Input Inter-

mittent (Bank no. 2)

PO335 Crankshaft Position Sensor “A” Circuit

Malfunction

PO336 Crankshaft Position Sensor “A” Circuit

Range/Performance

PO337 Crankshaft Position Sensor “A” Circuit

Low Input

PO338 Crankshaft Position Sensor “A” Circuit

High Input

PO339 Crankshaft Position Sensor “A” Circuit In-

termittent

PO340 Camshaft Position Sensor Circuit Mal-

function

PO341 Camshaft Position Sensor Circuit

Range/Performance

PO342 Camshaft Position Sensor Circuit Low In-

put

PO343 Camshaft Position Sensor Circuit High In-

put

PO344 Camshaft Position Sensor Circuit Inter-

mittent

PO350 Ignition Coil Primary/Secondary Circuit

Malfunction

PO351 Ignition Coil “A” Primary/Secondary Cir-

cuit Malfunction

PO352 Ignition Coil “B” Primary/Secondary Cir-

cuit Malfunction

PO353 Ignition Coil “C” Primary/Secondary Cir-

cuit Malfunction

PO354 Ignition Coil “D” Primary/Secondary Cir-

cuit Malfunction

PO355 Ignition Coil “E” Primary/Secondary Cir-

cuit Malfunction PO356 Ignition Coil “F” Primary/Secondary Cir-

cuit Malfunction

PO357 Ignition Coil “G” Primary/Secondary Cir-

cuit Malfunction

PO358 Ignition Coil ‘Y-l” Primary/Secondary Cir-

cuit Malfunctron

PO359 Ignition Coil “I” Primary/Secondary Cir-

cuit Malfunction

PO360 Ignition Coil “J” Primary/Secondary Cir-

cuit Malfunction

PO361 Ignition Coil “K” Primary/Secondary Cir-

cuit Malfunction

PO362 Ignition Coil “L” Primary/Secondary Cir-

cuit Malfunction

PO370 Timing Reference High Resolution Signal

“A” Malfunction

PO371 Timing Reference High Resolution Signal

“A” Too Many Pulses

PO372 Timing Reference High Resolution Signal

“A” Too Few Pulses

PO373 Timing Reference High Resolution Signal

“A” Intermittent/Erratic Pulses

PO374 Timing Reference High Resolution Signal

“A” No Pulses

PO375 Timing Reference High Resolution Signal

“B” Malfunction

PO376 Timing Reference High Resolution Signal

“B” Too Many Pulses

PO377 Timing Reference High Resolution Signal

9” Too Few Pulses

PO378 Timing Reference High Resolution Signal

“B” Intermittent/Erratic Pulses

PO379 Timing Reference High Resolution Signal

“B” No Pulses

PO385 Crankshaft Position Sensor 9” Circuit

Malfunction

PO386 Crankshaft Position Sensor “B” Circuit

Range/Performance

PO387 Crankshaft Position Sensor ‘9” Circuit

Low Input

PO388 Crankshaft Position Sensor “B” Circuit

High Input

PO389 Crankshaft Position Sensor “B” Circuit In-

termittent

PO400 Exhaust Gas Recirculation Flow Malfunc-

tion

PO401 Exhaust Gas Recirculation Flow Insuffi-

cient Detected

PO402 Exhaust Gas Recirculation Flow Excessive

Detected

PO403 Exhaust Gas Recirculation Circuit Mal-

function

PO404 Exhaust Gas Recirculation Circuit

Range/Performance

PO405 Exhaust Gas Recirculation Sensor “A” Cir-

cuit Low

PO406 Exhaust Gas Recirculation Sensor “A” Cir-

cuit High

PO407 Exhaust Gas Recirculation Sensor “B” Cir-

cuit Low

PO408 Exhaust Gas Recirculation Sensor “B” Cir-

cuit High

PO410 Secondary Air Injection System Malfunc-

tion

PO411 Secondary Air Injection System Incorrect

Flow Detected

PO412 Secondary Air Injection System Switching

Valve “A” Circuit Malfunction

PO413 Secondary Air Injection System Switching

Valve “A” Circuit Open

PO414 Secondary Air Injection System Switching

Valve “A” Circuit Shorted PO415 Secondary Air Injection System Switching

Valve “B” Circuit Malfunction

PO416 Secondary Air Injection System Switching

Valve “B” Circuit Open

PO417 Secondary Air Injection System Switching

Valve “B” Circuit Shorted

PO418 Secondary Air Injection System Relay “A

Circuit Malfunction

PO419 Secondary Air Injection System Relay “B”

Circuit Malfunction

PO420 Catalyst System Efficiency Below Thresh-

old (Bank no. 1 )

PO421 Warm Up Catalyst Efficiency Below

Threshold (Bank no. 1 )

PO422 Main Catalyst Efficiency Below Threshold

(Bank no. 1 )

PO423 Heated Catalyst Efficiency Below Thresh-

old (Bank no. 1 )

PO424 Heated Catalyst Temperature Below

Threshold (Bank no. 1)

PO430 Catalyst System Efficiency Below Thresh-

old (Bank no. 2 )

PO431 Warm Up Catalyst Efficiency Below

Threshold (Bank no. 2 )

PO432 Main Catalyst Efficiency Below Threshold

(Bank no. 2)

PO433 Heated Catalyst Efficiency Below Thresh-

old (Bank no. 2 )

PO434 Heated Catalvst Temoerature Below

Threshold (Bank no. 2

j ’

PO440 Evaporative Emission Control System

Malfunction

PO441 Evaporative Emission Control System In-

correct Purge Flow

PO442 Evaporative Emission Control System

Leak Detected (Small Leak)

PO443 Evaporative Emission Control System

Purge Control Valve Circuit Malfunction

PO444 Evaporative Emission Control System

Purge Control Valve Circuit Open

PO445 Evaporative Emission Control System

Purge Control Valve Circuit Shorted

PO446 Evaporative Emission Control System

Vent Control Circuit Malfunction

PO447 Evaporative Emission Control System

Vent Control Circuit Open

PO448 Evaporative Emission Control System

Vent Control Circuit Shorted

PO449 Evaporative Emission Control System

Vent Valve/Solenoid Circuit Malfunction

PO450 Evaporative Emission Control System

Pressure Sensor Malfunction

PO451 Evaporative Emission Control System

Pressure Sensor Range/Performance

PO452 Evaporative Emission Control System

Pressure Sensor Low Input

PO453 Evaporative Emission Control System

Pressure Sensor High Input

PO454 Evaporative Emission Control System

Pressure Sensor Intermittent

PO455 Evaporative Emission Control System

Leak Detected (Gross Leak)

PO460 Fuel Level Sensor Circuit Malfunction

PO461 Fuel Level Sensor Circuit Range/Perfor-

mance

PO462 Fuel Level Sensor Circuit Low Input

PO463 Fuel Level Sensor Circuit High Input

PO464 Fuel Level Sensor Circuit Intermittent

PO465 Purge Flow Sensor Circuit Malfunction

PO466 Purge Flow Sensor Circuit Range/Perfor-

mance

PO467 Purge Flow Sensor Circuit Low Input

Page 175 of 408

4-32 DRIVEABILITYAND EMISSIONS CONTROLS

PO785 Shift/Timing Solenoid Malfunction

PO786 Shift/Timing Solenoid Range/Performance

PO787 Shift/Timing Solenoid Low

PO788 Shift/Timing Solenord High

PO789 Shift/Timing Solenoid Intermittent

PO790 Normal/Performance Switch Circuit Mal-

function

PO801 Reverse Inhibit Control Circuit Malfunc-

tion

PO803 l-4 Upshift (Skip Shift) Solenoid Control

Circuit Malfunction

PO804 l-4 Upshift (Skip Shift) Lamp Control

Circuit Malfunction

PllOO Induction Control Motor Position Sensor

Fault

PI101 Traction Control Vacuum Solenoid Circuit

Fault

Pl102 Traction Control Ventilation Solenoid Cir-

cuit Fault P1294 Target Idle Speed Not Reached

P1295 No 5-Volt Supply To TP Sensor

P1296 No 5-Volt Supply To MAP Sensor

P1297 No Change In MAP From Start To Run

PI300 Ignition Timing Adjustment Circuit

Pl390 Timing Belt Skipped One Tooth Or More

Pl391 Intermittent Loss Of CMP Or CKP Sensor

Signals P1495 EVAP Ventilation Solenoid Circurt Fault

P1496 5-Volt Supply Output Too Low

Pl500 Generator FR Terminal Circuit Fault

Pl600 PCM-TCM Serial Communication Link

Circuit Fault

Pl400 Manifold Differential Pressure Sensor

Fault P1696 PCM Failure- EEPROM Write Denied

Pl715 No CCD Messages From TCM

Pl750 TCM Pulse Generator Circuit Fault

Pl791 Pressure Control, Shift Control, TCC So-

lenoid Fault

P1443 EVAP Purge Control Solenoid “2” Circuit

Fault P1899 PCM ECT Level Signal to TCM Circuit

Fault

P1486 EVAP Leak Monitor Pinched Hose De-

tected

P1989 High Speed Condenser Fan Control Relay

Fault

P1487 High Speed Radiator Fan Control Relay

Circuit Fault

Pl490 Low Speed Fan Control Relay Fault

P1492 Battery Temperature Sensor High Voltage

P1494 EVAP Ventilation Switch Or Mechanical

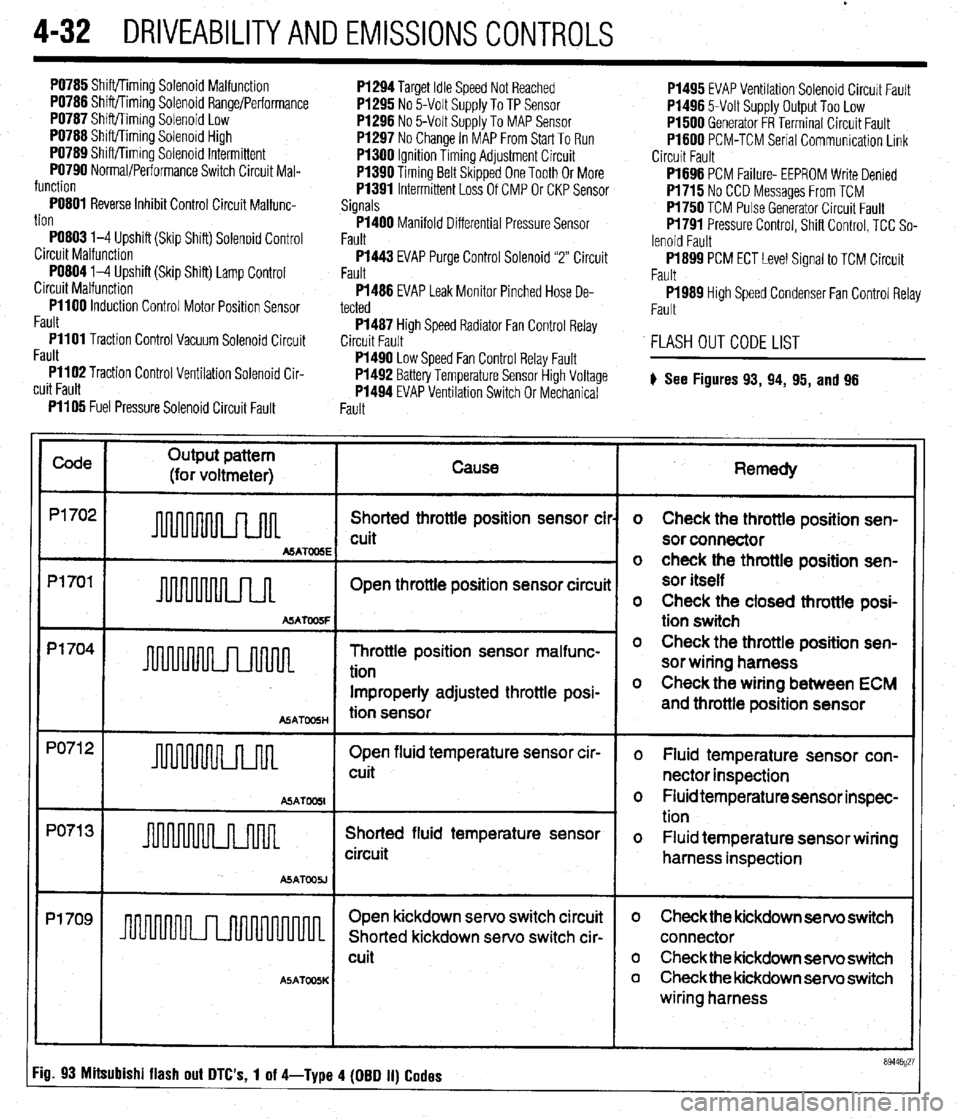

FLASH OUT CODE LIST

# See Figures

93, 94, 95, and 96

Fault PI105 Fuel Pressure Solenoid Circuit Fault

Code

Output pattern

(for voltmeter) Cause

P1702

Shorted throttle position sensor cil

cuit

MATOOSE

Pl701

Open throttle position sensor circuii

A!iATW5F

p1704 -

Throttle position sensor malfunc-

tion

Improperly adjusted throttle posi-

ASATmH tion sensor

PO71 2

Open fluid temperature sensor cir-

u 1 cuit

ASAT

PO71 3

Shorted fluid temperature sensor

circuit

ASATOOU

Pl709

I I Open kickdown servo switch circuit

Shorted kickdown servo switch cir-

cuit

A5ATOOSK

Remedy

o Check the throttle position sen-

sor connector

o check the throttle position sen-

sor itself

o Check the closed throttle posi-

tion switch

o Check the throttle position sen-

sor wiring harness

o Check the wiring between ECM

and throttle position sensor

o Fluid temperature sensor con-

nector inspection

o Fluid temperature sensor inspec-

tion

o Fluid temperature sensor wiring

harness inspection

o Check the kickdown servo switch

connector

o Check the kickdown servo switch

o Checkthe kickdown servo switch

wiring harness

Fig. 93 Mitsubishi flash out DTC's, 1 of 4-Type 4 (DBD II) Codes