instrument panel MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1045 of 1216

23-lBODY

CONTENTSN23Ak-

AERO PARTS..........................................74

CENTRAL DOOR LOCKING SYSTEM...........70

DOOR ASSEMBLY....................................63

DOOR GLASS AND REGULATOR................66

DOORHANDLEANDLATCH.....................69

DOOR MIRROR........................................72

DOOR MOULDING AND

DRIP LINE WEATHERSTRIP........................72

....DOOR RUNCHANNEL...............................71

DOOR TRIM AND WATERPROOF FILM........65

ELECTRIC REMOTE CONTROLLED

MIRROR SWITCH.....................................73

FENDER..................................................51

FLOOR CONSOLE....................................84

FRONT BUMPER......................................39

FRONT SEAT..........................................90

FUEL TANKFILLERDOOR.........................38

GARNISHES............................................47

HEADLINING...........................................89

HOOD....................................................34

INSTRUMENT PANEL................................79

LIFTGATE...............................................36

LIFTGATE WINDOWGLASS......................62

LOOSE PANEL.........................................53

MOULDING.............................................48

POWER WINDOW....................................67

QUARTERWINDOWGLASS......................61

REAR BUMPER........................................43

REAR SEAT............................................93

SEAT BELT.............................................94

SERVICE ADJUSTMENT PROCEDURES........31

Door Adjustment....................................32

Door Glass Adjustment............................32Door Inside Handle Play Check..................

32

Door Outside Handle Play Check................32

Floor PanInspection...............................

33Fuel Filler Door Adjustment.......................

31

Hood Adjustment...................................31

Liftgate Adjustment.................................31

Water Test...........................................33

SPECIAL TOOLS......................................5

SPECIFICATIONS.....................................2

General Specifications..............................

2

Lubricants.............................................5

Sealants and Adhesives...........................5

Service Specifications..............................3

Torque Specifications..............................3

SUNROOF...............................................77TRIMS

....................................................85

TROUBLESHOOTING................................6WINDOW

GLASS.....................................54

WINDSHIELD...........................................58

Page 1123 of 1216

23-78BODY -Instrument Panel23-79

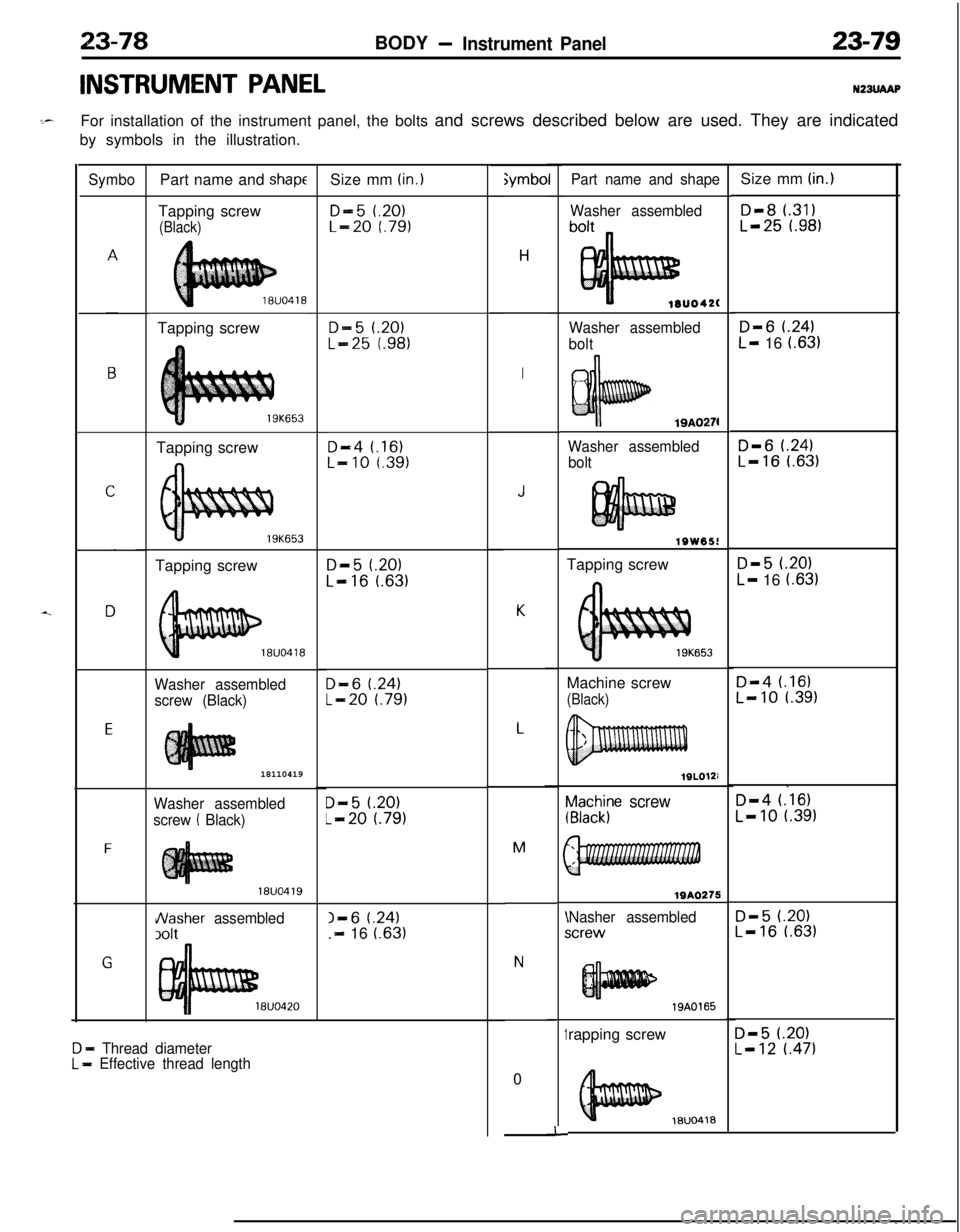

INSTRUMENT PANELNZBUAAPI_-

For installation of the instrument panel, the bolts and screws described below are used. They are indicated

by symbols in the illustration.

Symbo

E

F

GPart name and

shapeTapping screw

(Black)Tapping screw

Tapping screw

19K653Tapping screw

Washer assembled

screw (Black)18110419

Washer assembled

screw

! Black)

18UO419

Nasher assembled

3olt

8UO420

D - Thread diameterL = Effective thread lengthSize mm

(in.)

D-5 t.20)L-20 f.79)

D-5 1.20)

L-25 t.98)

D-4 t.16)L-10 r.391

D-5 f.20)

L-16 l.63)

D-6 t.24)

L-20 l.79)

D-5 t.20)

L-20 t.791

I-6 t.24)-=- 16 i.63);ymbo

H

I

J

K

L

M

N0

~a2h$e screw

WA0275

Nasher assembledicrew\I

1

-I-rapping screw

Part name and shape

Washer assembled

lOUO42(

Washer assembled

bolt

19A0274

Washer assembled

bolt

lSW65!Tapping screw

653Machine screw

(Black)

19A0165

18UO418Size mm

(in.)

D-8 l.31)L-25 t.98)

D-6 t.24)

L- 16 (.63)

D-6 f.24)L-16 l.63)

D-5 (.20)

L- 16 i.631

D-4 t.16)L-10 l.39)

D-4 (.‘16)

L-10 t.391

D-5 t.20)L-16 l.63)

D-5 l.20)L-12 t.471

Page 1124 of 1216

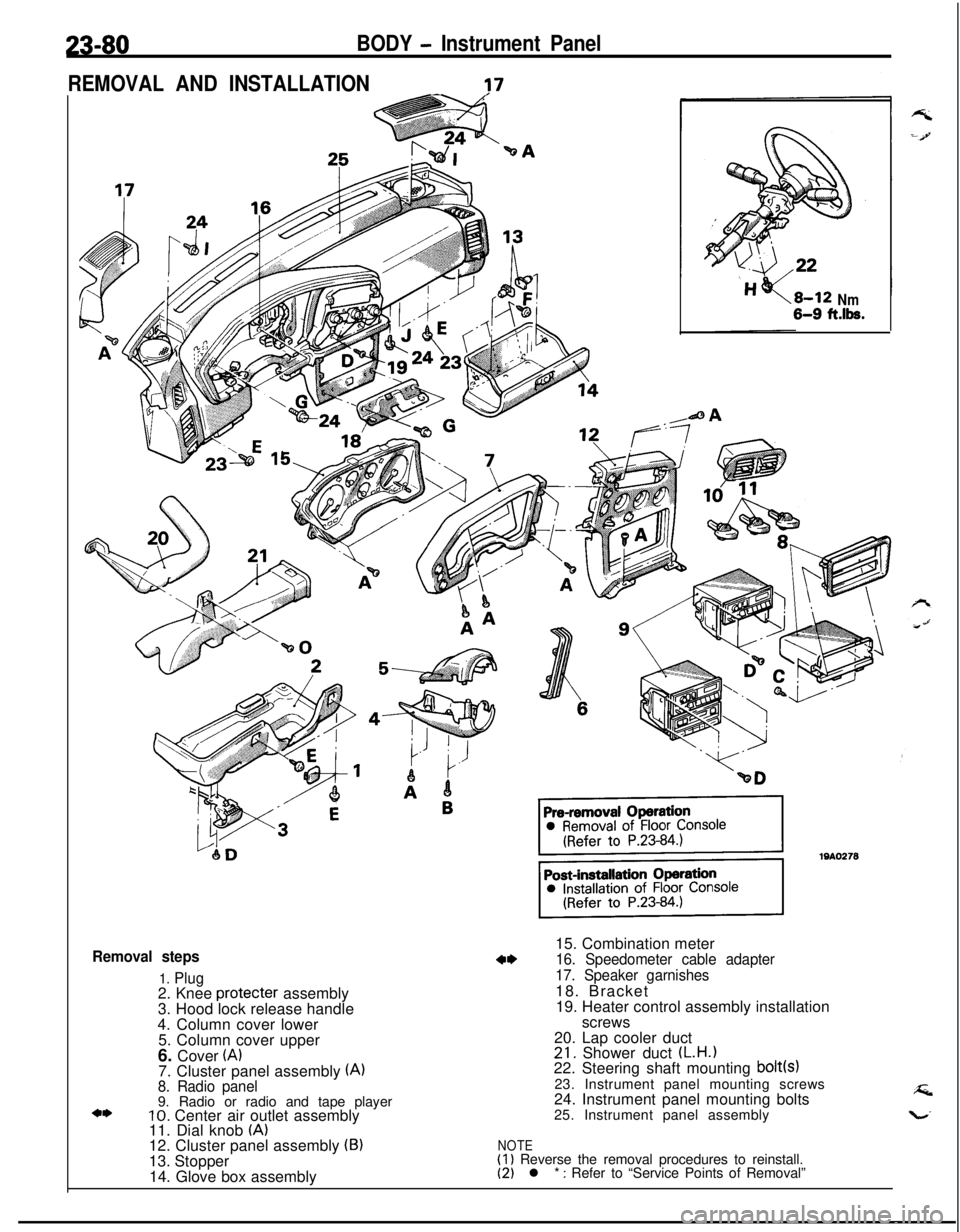

23-80BODY - Instrument Panel

REMOVAL AND INSTALLATION

-?7

Removal steps

1. Plug2. Knee protecter assembly

3. Hood lock release handle

4. Column cover lower

5. Column cover upper

6. Cover

(A)7. Cluster panel assembly (A)8. Radio panel9. Radio or radio and tape player

10. Center air outlet assembly

11. Dial knob (A)12. Cluster panel assembly (B)13. Stopper

14. Glove box assembly

Nm6-9 ft.lk.15. Combination meter

16. Speedometer cable adapter

17. Speaker garnishes18. Bracket

19. Heater control assembly installation

screws

20. Lap cooler duct

21. Shower duct (L.H.122. Steering shaft mounting bolt(s)23. Instrument panel mounting screws

24. Instrument panel mounting bolts

25. Instrument panel assembly

NOTE(1) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”

Page 1125 of 1216

BODY - Instrument Panel23-81

SECT. A-A

Flat-tip

( - ) screwdriver19A0274

1910267

SERVICE POINTS OF REMOVAL

10. REMOVAL OF CENTER AIR OUTLET ASSEMBLY

Removing the paw1 of the center air outlet assembly with aflat-tip

( - 1 screwdriver,remove the center air outlet

assembly with the plastic trim tool.

16. REMOVAL OF SPEEDOMETER CABLE ADAPTER

(1) Disconnect the speedometer cable at the transaxle endof the cable.

(2) Pull the speedometer cable slightly toward the vehicle

interior, release the lock by turning the adapter to the leftor right, and then remove the adapter.

Page 1126 of 1216

23-82BODY - Instrument Panel

9N23

Cluster panel (A) disassembly steps

1. Switch holder (A)2. Headlight pop-up switch

3. Plug

(A)4. Rheostat

5. Cluster panel

(A)

Cluster panel (B) disassembly steps6. Switch holder

(5)7. Hazard switch

8.

p;Fr window defogger switch or plug

9.

$far wiper and washer switch or plug10. Heater control panel assembly

II. Cluster panel (B)

Knee protector disassembly steps12. Lap cooler grill assembly

13. Knee protector

Glove box disassembly steps14. Glove box lock assembly

15. Glove box pad

16. Glove box hinge

17. Glove box

Instrument panel disassembly steps18. Glove box light switch

19. Lower frame

20. Corner pad21. Glove box striker

22. Glove box light bracket

23. Speakers

Page 1127 of 1216

BODY - Instrument Panel23-83

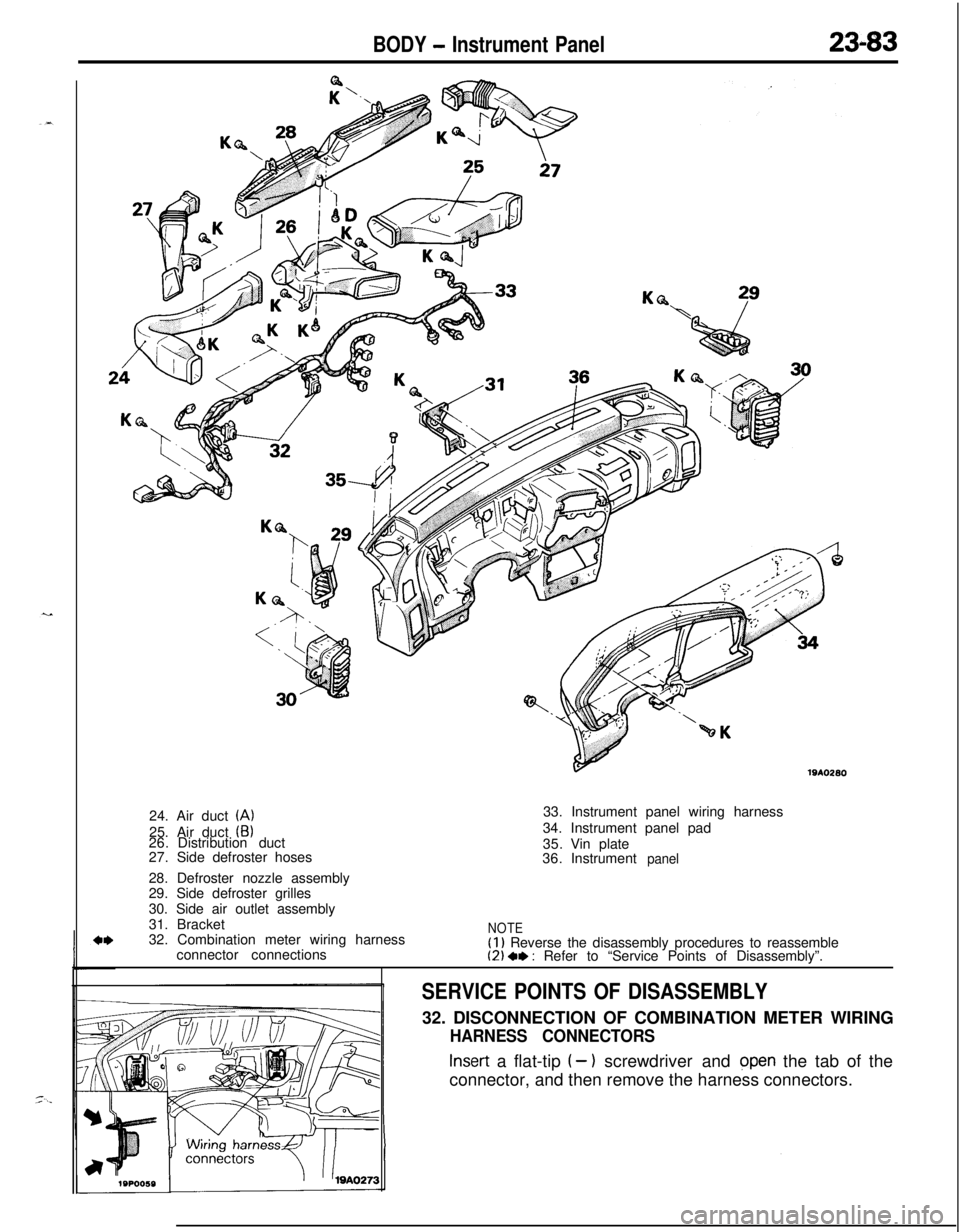

191026024. Air duct

(A)25. Air duct

(B)26.Distribution duct

27.Side defroster hoses

28. Defroster nozzle assembly

29. Side defroster grilles

30. Side air outlet assembly

31. Bracket

32. Combination meter wiring harness

connector connections33. Instrument panel wiring harness

34. Instrument panel pad

35.Vin plate

36.Instrument

panel

NOTE(I) Reverse the disassembly procedures to reassemble(2) 4, : Refer to “Service Points of Disassembly”.

SERVICE POINTS OF DISASSEMBLY32. DISCONNECTION OF COMBINATION METER WIRING

HARNESS CONNECTORS

Insert a flat-tip I- 1 screwdriver and open the tab of the

connector, and then remove the harness connectors.

Page 1131 of 1216

BODY - Trims23-871@Poo70

10P0081

Trim

Gro19P0000

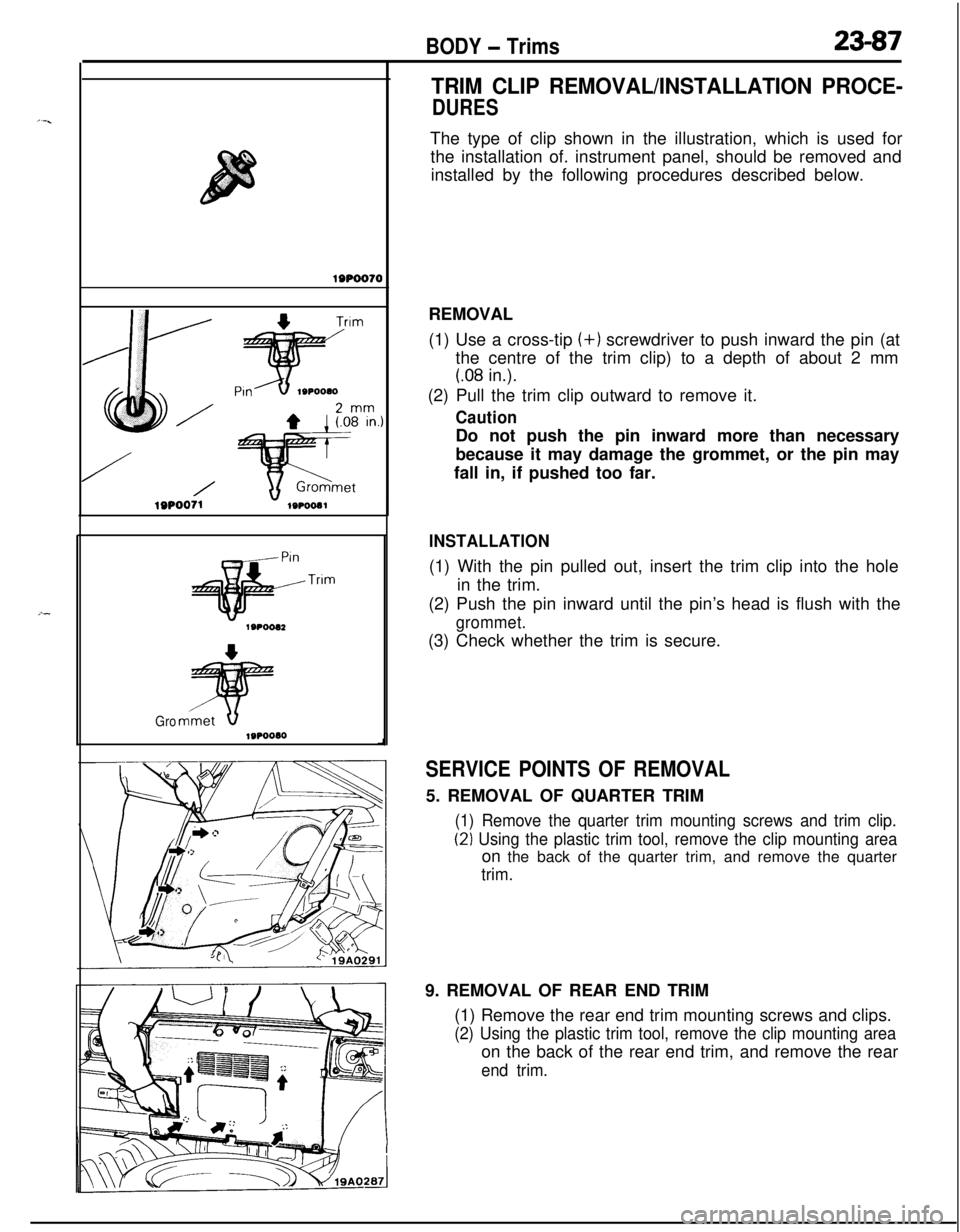

TRIM CLIP REMOVAL/INSTALLATION PROCE-

DURESThe type of clip shown in the illustration, which is used for

the installation of. instrument panel, should be removed and

installed by the following procedures described below.

REMOVAL

(1) Use a cross-tip (+) screwdriver to push inward the pin (at

the centre of the trim clip) to a depth of about 2 mm

(.08 in.).

(2) Pull the trim clip outward to remove it.

CautionDo not push the pin inward more than necessary

because it may damage the grommet, or the pin may

fall in, if pushed too far.

INSTALLATION(1) With the pin pulled out, insert the trim clip into the hole

in the trim.

(2) Push the pin inward until the pin’s head is flush with the

grommet.(3) Check whether the trim is secure.

SERVICE POINTS OF REMOVAL5. REMOVAL OF QUARTER TRIM

(1) Remove the quarter trim mounting screws and trim clip.

(2) Using the plastic trim tool, remove the clip mounting areaon the back of the quarter trim, and remove the quarter

trim.9. REMOVAL OF REAR END TRIM

(1) Remove the rear end trim mounting screws and clips.

(2) Using the plastic trim tool, remove the clip mounting areaon the back of the rear end trim, and remove the rear

end trim.

Page 1139 of 1216

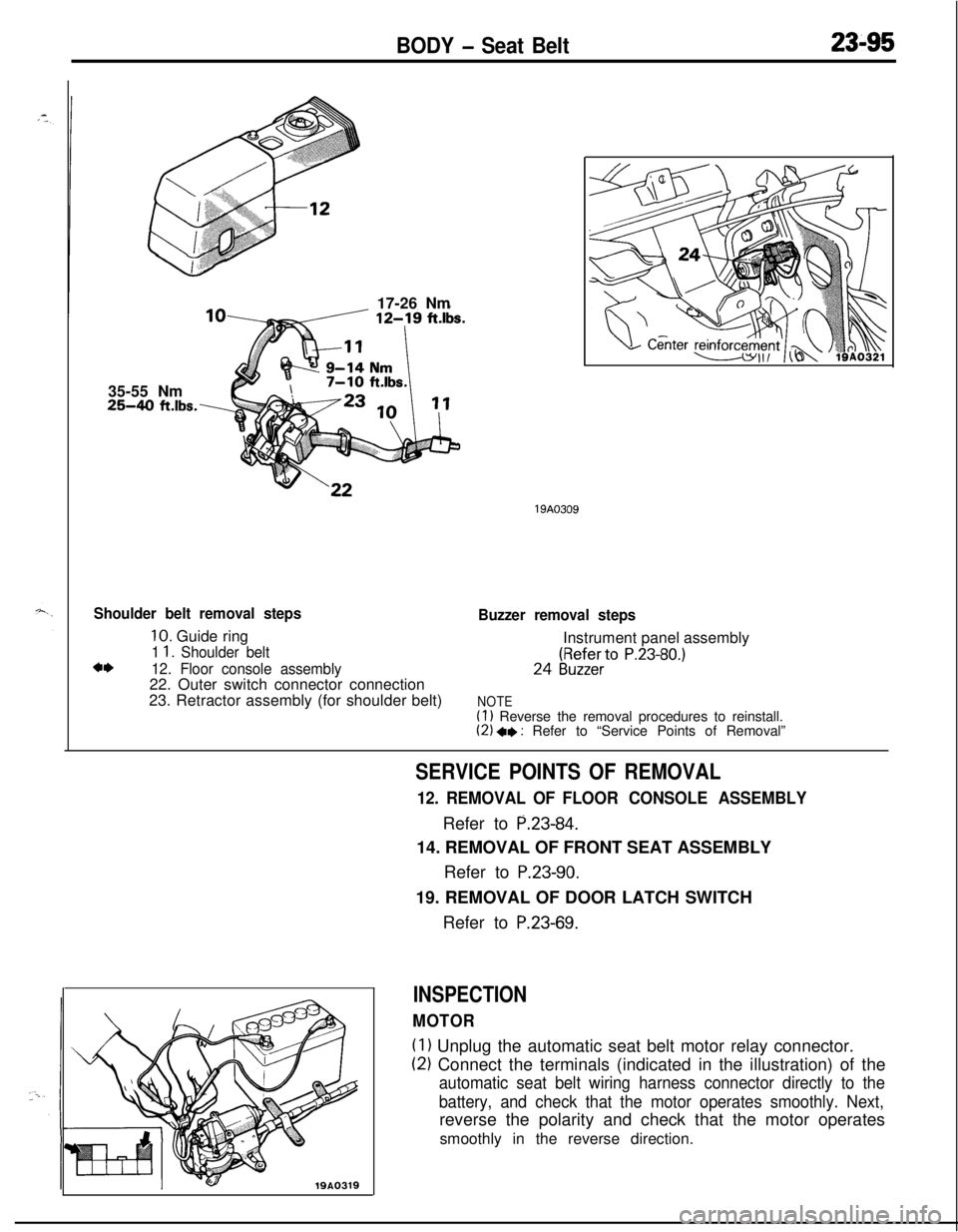

BODY - Seat Belt23-9535-55 Nm

25-40 ft.lbs.\17-26 Nm

Shoulder belt removal steps

10. Guide ring

1 1. Shoulder beltc*12. Floor console assembly22. Outer switch connector connection

23. Retractor assembly (for shoulder belt)

19A0309

Buzzer removal stepsInstrument panel assembly24

(gy;ZfieerrtO P.23-80.)

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”

19A0319

SERVICE POINTS OF REMOVAL

12. REMOVAL OF FLOOR CONSOLE ASSEMBLYRefer to

P.23-84.14. REMOVAL OF FRONT SEAT ASSEMBLY

Refer to

P.23-90.19. REMOVAL OF DOOR LATCH SWITCH

Refer to

P.23-69.

INSPECTION

MOTOR

(1) Unplug the automatic seat belt motor relay connector.

(2) Connect the terminals (indicated in the illustration) of the

automatic seat belt wiring harness connector directly to the

battery, and check that the motor operates smoothly. Next,reverse the polarity and check that the motor operates

smoothly in the reverse direction.

Page 1142 of 1216

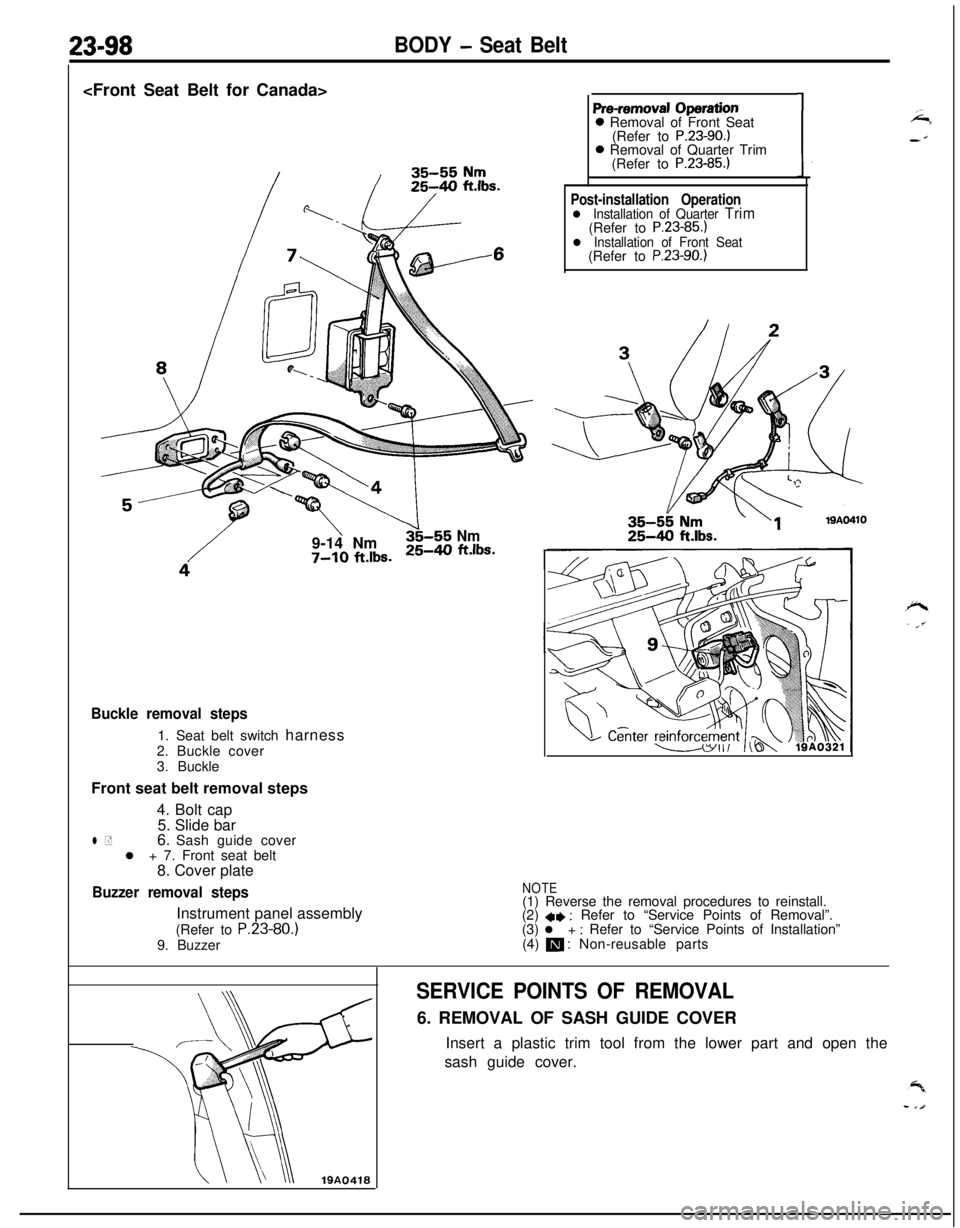

23-98BODY - Seat Belt

\9-14 Nms-55 Nm

7-10 ft.lbs.25-40 ft.lbs.

Pre-removal Operation0 Removal of Front Seat

(Refer to

P.23-90.)0 Removal of Quarter Trim

(Refer to

P.23-85.)

Post-installation Operationl Installation of Quarter Trim(Refer to P.23-85.)l Installation of Front Seat(Refer to P.23-90.)

Buckle removal steps1. Seat belt switch harness

2. Buckle cover

3. Buckle

Front seat belt removal steps

4. Bolt cap

5. Slide bar

l +6. Sash guide cover

l + 7. Front seat belt

8. Cover plate

Buzzer removal stepsInstrument panel assembly

(Refer to P.23-80.)

9. BuzzerNOTE(1) Reverse the removal procedures to reinstall.

(2)

+e : Refer to “Service Points of Removal”.

(3) l + : Refer to “Service Points of Installation”

(4) m : Non-reusable parts

SERVICE POINTS OF REMOVAL6. REMOVAL OF SASH GUIDE COVER

Insert a plastic trim tool from the lower part and open the

sash guide cover.

Page 1145 of 1216

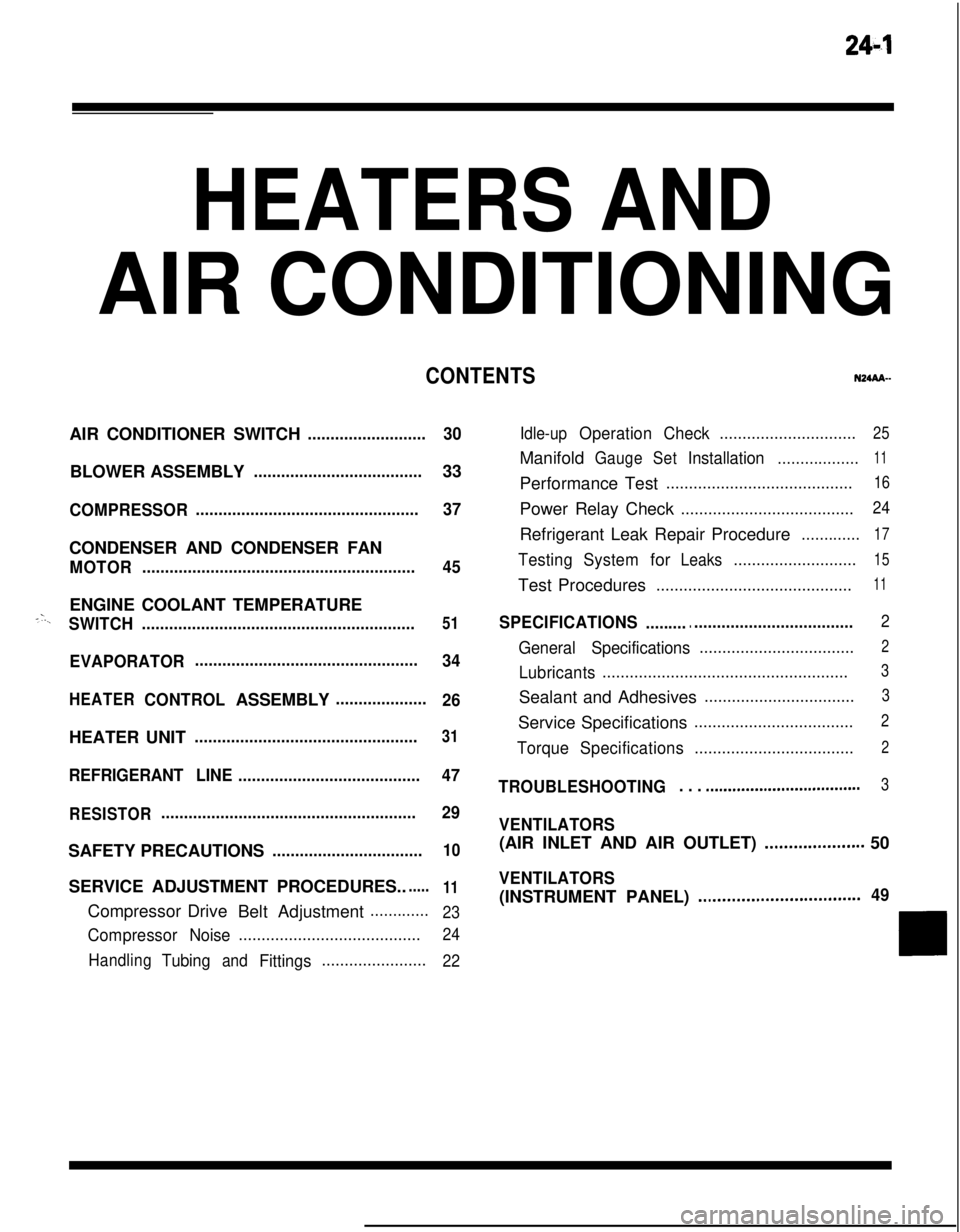

24-l

HEATERS ANDAIR CONDITIONING

CONTENTSN24M--AIR CONDITIONER SWITCH

..........................30BLOWER ASSEMBLY

.....................................33

COMPRESSOR.................................................37CONDENSER AND CONDENSER FAN

MOTOR............................................................45ENGINE COOLANT TEMPERATURE

-‘-.,SWITCH............................................................51

EVAPORATOR.................................................

34

HEATERCONTROLASSEMBLY....................

26HEATER UNIT

.................................................31

REFRIGERANTLINE........................................47

RESISTOR........................................................29SAFETY PRECAUTIONS

.................................10SERVICE ADJUSTMENT PROCEDURES..

.....11Compressor Drive

Belt Adjustment

.............

23

CompressorNoise........................................24

Handling

TubingandFittings.......................22Idle-up

OperationCheck..............................25Manifold

GaugeSetInstallation..................11Performance Test

.........................................16Power Relay Check

......................................24Refrigerant Leak Repair Procedure

.............17

TestingSystemforLeaks...........................15Test Procedures

...........................................11

SPECIFICATIONS.............................................2

General Specifications..................................2

Lubricants......................................................3Sealant and Adhesives

.................................3Service Specifications

...................................2

TorqueSpecifications...................................2

TROUBLESHOOTING. . . ..a................................3

VENTILATORS(AIR INLET AND AIR OUTLET)

..,....s............. 50

VENTILATORS(INSTRUMENT PANEL)

..,...................*...........49