length MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 18 of 1216

18INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions b&ire Service

DOING SERVICE WORK IN GROUPS OF VO’bRMORE TECHNICIANS

.-I-7.IIf the service work is to be done by two or more technicians

working together, extra caution must be taken.

VoltagedistributionMaximum

voltage

NOTE ON INSTALLATION OF RADIO EQIJIPMEATeThe computers of the electronic control system has been

designed so that external radio waves will not interfere with

their operation.

However, if antenna or cable of amateur transceiver etc. is

routed near the computers, it may affect the operation of the

computers, even if the output of the transceiver is no more

than

25W.To protect each of the computers from interference by

transmitter (hum, transceiver, etc.), the following should be

observed.1. Install the antenna on the roof or rear bumper.

2.Because radio waves are emitted from the coaxial cable of

the antenna, keep it 200 mm (8 in.) away from the

computers and the wiring harness. If the cable must cross

hthe wiring harness, route it so that it runs at right angles to

the wiring harness.

3.The antenna and the cable should be well matched, and thestanding-wave ratio* should be kept low.

4.A transmitter having a large output should not be installed

in the vehicle.

5.After installation of transmitter, run the engine at idle, emit

radio waves from the transmitter and make sure that the

engine is not affected.

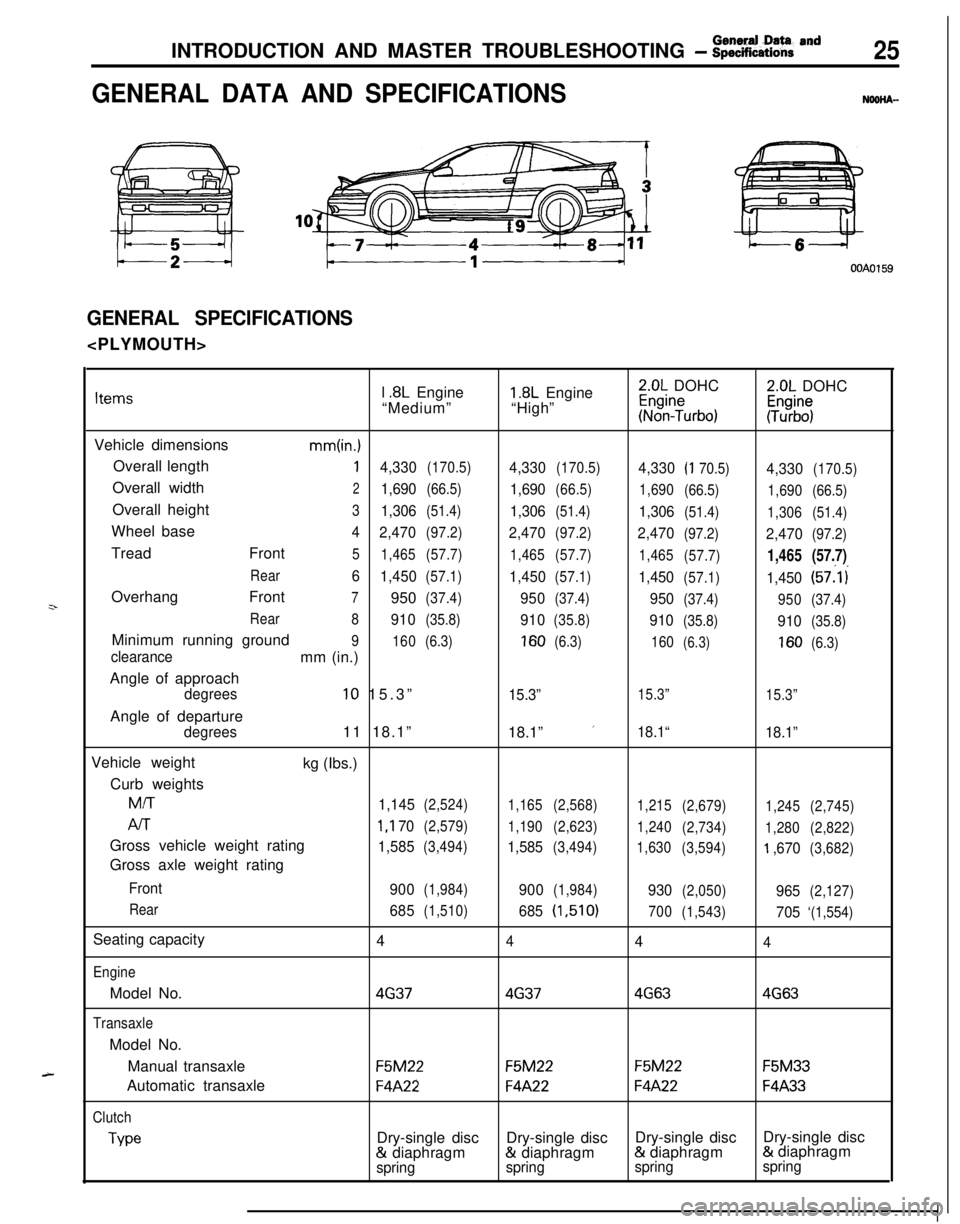

“STANDING-WAVE RATIO

If an antenna and a cable having different impedances are

connected, the input impedance Zi will vary in accordance with

the length of the cable and the frequency of the transmitter,

and the voltage distribution will also vary in accordance with

the location.

The ratio between this maximum voltage and minimum voltage

is called the standing-wave ratio. It can also be represented bythe ratio between the impedances of the antenna and the

cable.The amount of radio waves emitted from the cable increases

as the standing-wave ratio increases, and this increases the

possibility of the electronic components being adversely

affected.

Page 25 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - :;k%ii::& and25

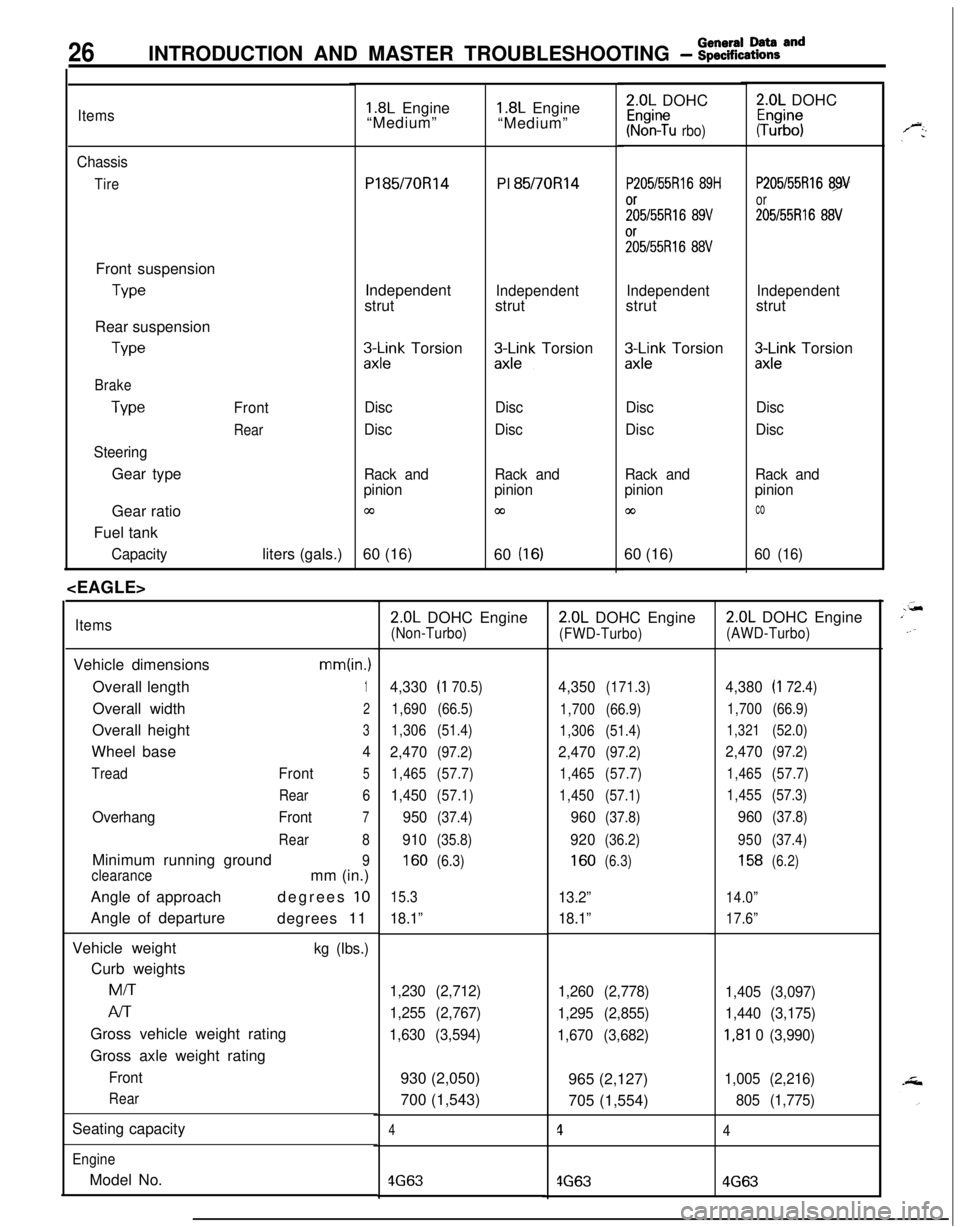

GENERAL DATA AND SPECIFICATIONSNOOHA-

OOAOl59

GENERAL SPECIFICATIONS

z-

A-l

.8L Engine1.8L Engine2.0L DOHC2.0L DOHCItems“Medium”“High”~%n?urbo):Tz%$

Vehicle dimensions

mm(in.)Overall length

14,330(170.5)4,330(170.5)4,330(I 70.5)4,330(170.5)Overall width

21,690(66.5)1,690(66.5)

1,690

(66.5)

1,690(66.5)Overall height

31,306(51.4)1,306(51.4)1,306(51.4)

1,306(51.4)Wheel base

4

2,470(97.2)2,470(97.2)2,470(97.2)2,470(97.2)Tread Front

5

1,465(57.7)

1,465(57.7)

1,465

(57.7)1,465(57.7)

Rear6

1,450(57.1)1,450(57.1)1,450(57.1)1,450(57:l i

Overhang Front

7950(37.4)950(37.4)950(37.4)

950(37.4)

Rear

8

910(35.8)910(35.8)910(35.8)910(35.8)Minimum running ground

9

160(6.3)160(6.3)

160(6.3)160(6.3)clearancemm (in.)

Angle of approach

degrees10 15.3”15.3”15.3”

15.3”Angle of departure

degrees11 18.1”

18.1” ’18.1“

18.1”Vehicle weight

kg (Ibs.)

Curb weights

M/T

1,145(2,524)

1,165(2,568)

1,215

(2,679)

1,245(2,745)

AIT1 ,I 70(2,579)

1,190(2,623)

1,240

(2,734)

1,280(2,822)Gross vehicle weight rating

1,585(3,494)1,585(3,494)

1,630

(3,594)‘I ,670(3,682)Gross axle weight rating

Front

900(1,984)900(1,984)930(2,050)965(2,127)

Rear

685(1,510)685(1,510)

700

(1,543)705‘(1,554)Seating capacity

4

444

EngineModel No.

4G3746374G634G63

TransaxleModel No.

Manual transaxle

F5M22F5M22F5M22F5M33Automatic transaxle

F4A22F4A22F4A22F4A33

Clutch

TypeDry-single discDry-single discDry-single discDry-single disc& diaphragm& diaphragm& diaphragm& diaphragm

springspringspringspring

Page 26 of 1216

26INTRODUCTION AND MASTER TROUBLESHOOTING - :;:%:a=and

Items

Chassis

TireFront suspension

TypeRear suspension

We

Brake

Type

SteeringGear typeFront

RearGear ratio

Fuel tank

Capacityliters (gals.)

1.8L Engine

“Medium”Pl85/70R14

PI 85/70Rl4

Independent

strut

Independentstrut

3l\Fk Torsion&k-k Torsion

Disc

DiscDisc

Disc

Rack and

pinion

03

Rack and

pinion

cn60 (16)

60

(16)

ItemsVehicle dimensions

mm(in.)Overall length

1Overall width

2Overall height

3Wheel base

4

TreadFront5

Rear6

OverhangFront7

Rear8Minimum running ground

9

clearancemm (in.)

Angle of approachdegrees

10Angle of departure

degrees 11

Vehicle weight

kg (Ibs.)Curb weightsMiT

Al-rGross vehicle weight rating

Gross axle weight rating

Front

RearSeating capacity

EngineModel No.

1.8L Engine

“Medium”2.0L DOHC

Kr%n?u rbo)

P205/55Rl6 89H

;;5/55R16 89V%55R16

88V

Independentstrut

zx;;k Torsion

Disc

Disc

Rack and

pinion

co60 (16)

2.0L DOHC

#b”;

P205/55Rl6 89

or

205155R16 88V

Independentstrut

3Lnk Torsion

Disc

Disc

Rack and

pinion

co

60 (16)

2.0L DOHC Engine(Non-Turbo)

4,330(I 70.5)

1,690(66.5)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

950(37.4)

910(35.8)

160(6.3)

15.3

18.1”

1,230 (2,712)

1,255 (2,767)

1,630 (3,594)930 (2,050)

700 (1,543)

4

4G63

2.0L DOHC Engine

(FWD-Turbo)

4,350(171.3)

1,700(66.9)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

960(37.8)

920(36.2)

160(6.3)

13.2”

18.1”

1,260 (2,778)

1,295 (2,855)

1,670 (3,682)965 (2,127)

705 (1,554)

1

4G63

2.0L DOHC Engine

(AWD-Turbo)

4,380(I 72.4)

1,700(66.9)

1,321(52.0)

2,470(97.2)

1,465(57.7)

1,455(57.3)

960(37.8)

950(37.4)

158(6.2)

14.0”

17.6”

1,405 (3,097)

1,440 (3,175)

I,81 0 (3,990)

1,005 (2,216)

805 (1,775)

4

4G63

Page 36 of 1216

o-2LUBRICATION AND MAINTENANCE - General Information

GENERAL INFORMATIONNGQPA--Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe

lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by theSociety of Automotive Engineers (SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute

(NLGI).MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item numbers in

the “MAINTENANCE SERVICE” section.

SEVERE SERVICEVehicles operating under severe service conditions

will require more frequent service.

Component service information is included in

appropriate units for vehicles operating under one ormore of the following conditions:

1.Trailer towing or police, taxi, or commercial type

operation2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city

traffic during hot weather above

32°C (90°F)(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of

engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual

number, for example, SAE

lOW-30, which indicates

a multigrade oil.

The API classification system defines oil perform-

ance in terms of engine usage. Only engine oil

designed “For Service SG” or “For Service

SGKD”,when available, should be used. These oils contain

sufficient chemical additives to provide maximum

engine protection. Both the SAE grade and the API

designation can be found on the container.Caution

Test results submitted to EPA have shown thatlaboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-

dingly, the potential exists for humans

to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be’ taken, therefore, when changingengine oil, to minimize the amount and length of

exposure time to used engine

pi! on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to removeany used engine oil. Do not use gasoline,

thinners, or solvents.

GEAR LUBRICANTSThe SAE grade number also indicates the viscosity

of Multi-Purpose Gear Lubricants.

The API classfication system defines gear lubricants

in terms of usage. Typically gear lubricants conform-ing to API

GL-4 or GL-5 with a viscosity of SAE

75W-85W are recommended for manual transaxle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the NLGI designation andare further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified, Multi-

Purpose Grease,

NLGI grade 2 should be used.

MOPAR Multi-Mileage Lubricant, P&t Number

2525035 or equivalent, meets these requirement

and is recommended.

FUEL USAGE STATEMENT

Use gasolines having a minimum anti-knock index

(Octane Value) of 87,

(R + M)/2. This designation is

comparable to a Research Octane Number of 91.

Unleaded gasolines only must be used in vehicles

equipped with catalyst emission control systems.

All vehicles, so equipped, have labels located on the

instrument panel and on the back of fuel filler lid that

state, “UNLEADED GASOLINE ONLY”. These vehi-

cles also have fuel filler tubes especially designed toaccept the smaller diameter unleaded gasoline

dispensing nozzles only.

MATERIALS ADDED

TO FUELIndiscriminate use of fuel system cleanng agents

should be avoided. Many of these materials in-

tended for gum and varnish removal may contain

highly active solvents or similar ingredients that can

be harmful to gasket and diaphragm materials usedin fuel system component parts.

Page 47 of 1216

LUBRICATION AND MAINTENANCE - Maintenance Serviceo-13

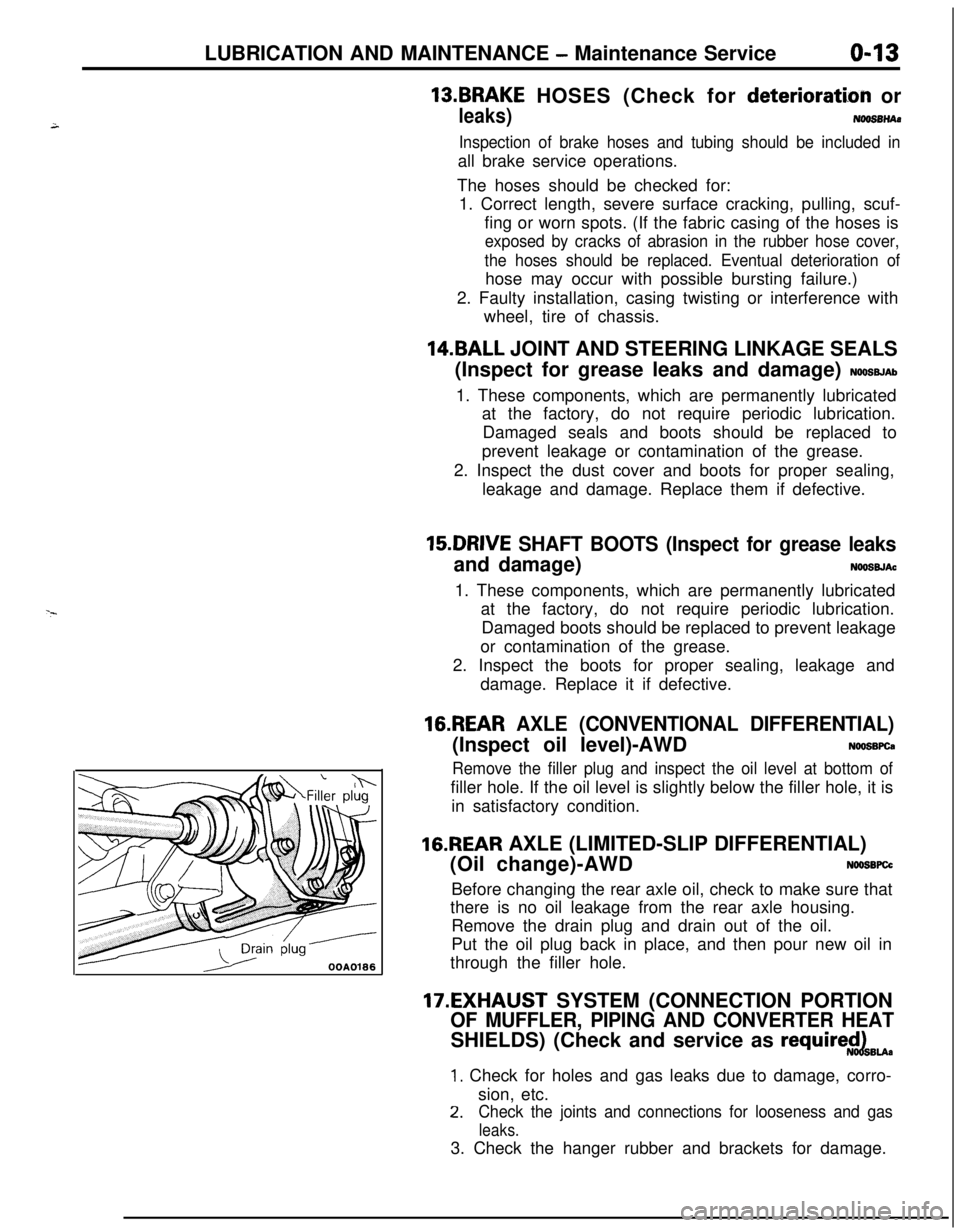

OOAOlB6

13.BRAKE HOSES (Check for deteriorati.on or

leaks)NwBBnAs

Inspection of brake hoses and tubing should be included inall brake service operations.

The hoses should be checked for:

1. Correct length, severe surface cracking, pulling, scuf-

fing or worn spots. (If the fabric casing of the hoses is

exposed by cracks of abrasion in the rubber hose cover,

the hoses should be replaced. Eventual deterioration ofhose may occur with possible bursting failure.)

2. Faulty installation, casing twisting or interference with

wheel, tire of chassis.

14.BALL JOINT AND STEERING LINKAGE SEALS

(Inspect for grease leaks and damage)

NWSBJAb1. These components, which are permanently lubricated

at the factory, do not require periodic lubrication.

Damaged seals and boots should be replaced to

prevent leakage or contamination of the grease.

2. Inspect the dust cover and boots for proper sealing,

leakage and damage. Replace them if defective.

15.DRIVE SHAFT BOOTS (Inspect for grease leaksand damage)

NWSBJAc1. These components, which are permanently lubricated

at the factory, do not require periodic lubrication.

Damaged boots should be replaced to prevent leakage

or contamination of the grease.

2. Inspect the boots for proper sealing, leakage and

damage. Replace it if defective.

16.REAR AXLE (CONVENTIONAL DIFFERENTIAL)(Inspect oil level)-AWD

NWSBFCa

Remove the filler plug and inspect the oil level at bottom offiller hole. If the oil level is slightly below the filler hole, it is

in satisfactory condition.

16.REAR AXLE (LIMITED-SLIP DIFFERENTIAL)

(Oil change)-AWD

N66SBFCcBefore changing the rear axle oil, check to make sure that

there is no oil leakage from the rear axle housing.

Remove the drain plug and drain out of the oil.

Put the oil plug back in place, and then pour new oil in

through the filler hole.

17.EXHAUST SYSTEM (CONNECTION PORTION

OF MUFFLER, PIPING AND CONVERTER HEATSHIELDS) (Check and service as

require$dBu.

1. Check for holes and gas leaks due to damage, corro-

sion, etc.

2.Check the joints and connections for looseness and gas

leaks.3. Check the hanger rubber and brackets for damage.

Page 50 of 1216

2-2FRONT SUSPENSION - Specifications

SPECIFICATIONS

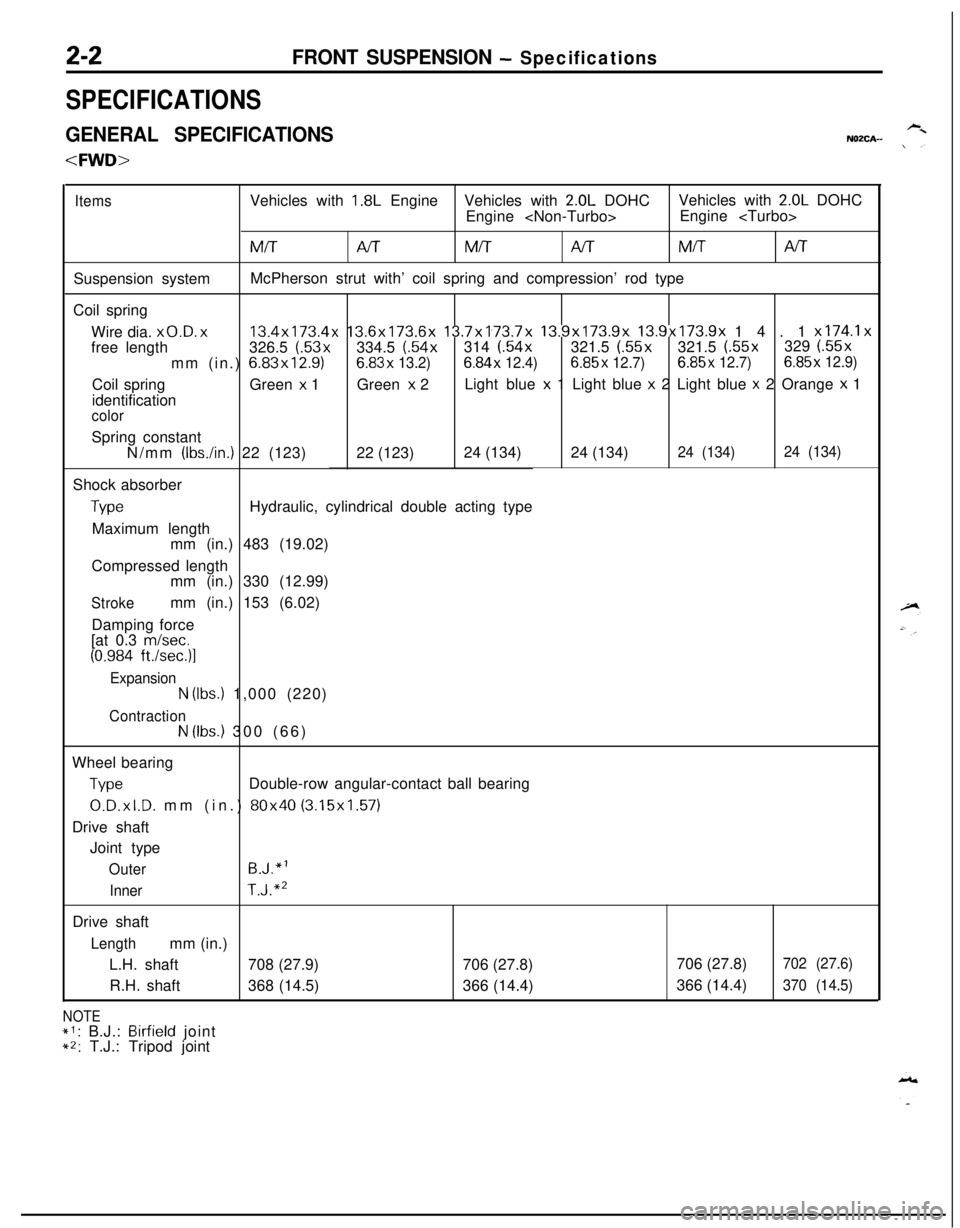

GENERAL SPECIFICATIONSNOZCA-

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHCVehicles with 2.0L DOHC

Engine

MM/TAITMITNTSuspension systemMcPherson strut with’ coil spring and compression’ rod type

Coil spring

Wire dia.

x0.D. x13.4x173.4x 13.6x173.6x 13.7x173.7x 13.9x173.9x 13.9x173.9x 14.1 x174.1xfree length326.5 (.53x334.5 (.54x314 (.54x321.5 (.55x321.5 (.55x329 (.55x

mm (in.) 6.83x12.9)6.83x

13.2)6.84x 12.4)6.85x 12.7)6.85x 12.7)6.85x 12.9)Coil springGreen

x 1Green x 2Light blue x 1 Light blue x 2 Light blue x 2 Orange x 1

identification

colorSpring constant

N/mm

(IbsAn.) 22 (123)22 (123)24 (134)24 (134)24 (134)24 (134)Shock absorber

TypeHydraulic, cylindrical double acting type

Maximum length

mm (in.) 483 (19.02)

Compressed length

mm (in.) 330 (12.99)

Strokemm (in.) 153 (6.02)

Damping force

[at 0.3

m/set.

(0.984 ft./sec.)l

Expansion

N (Ibs.) 1,000 (220)

ContractionN (Ibs.) 300 (66)

Wheel bearing

TypeDouble-row angular-contact ball bearing

0.D.xl.D. mm (in.) 80x40 (3.15x1.57)

Drive shaft

Joint type

OuterB.J.“l

InnerT.J.“’Drive shaft

Lengthmm (in.)

L.H. shaft708 (27.9)706 (27.8)

R.H. shaft368 (14.5)366 (14.4)

NOTE*1: B.J.: Birfield joint*2: T.J.: Tripod joint706 (27.8)

702 (27.6)366 (14.4)

370 (14.5)

Page 51 of 1216

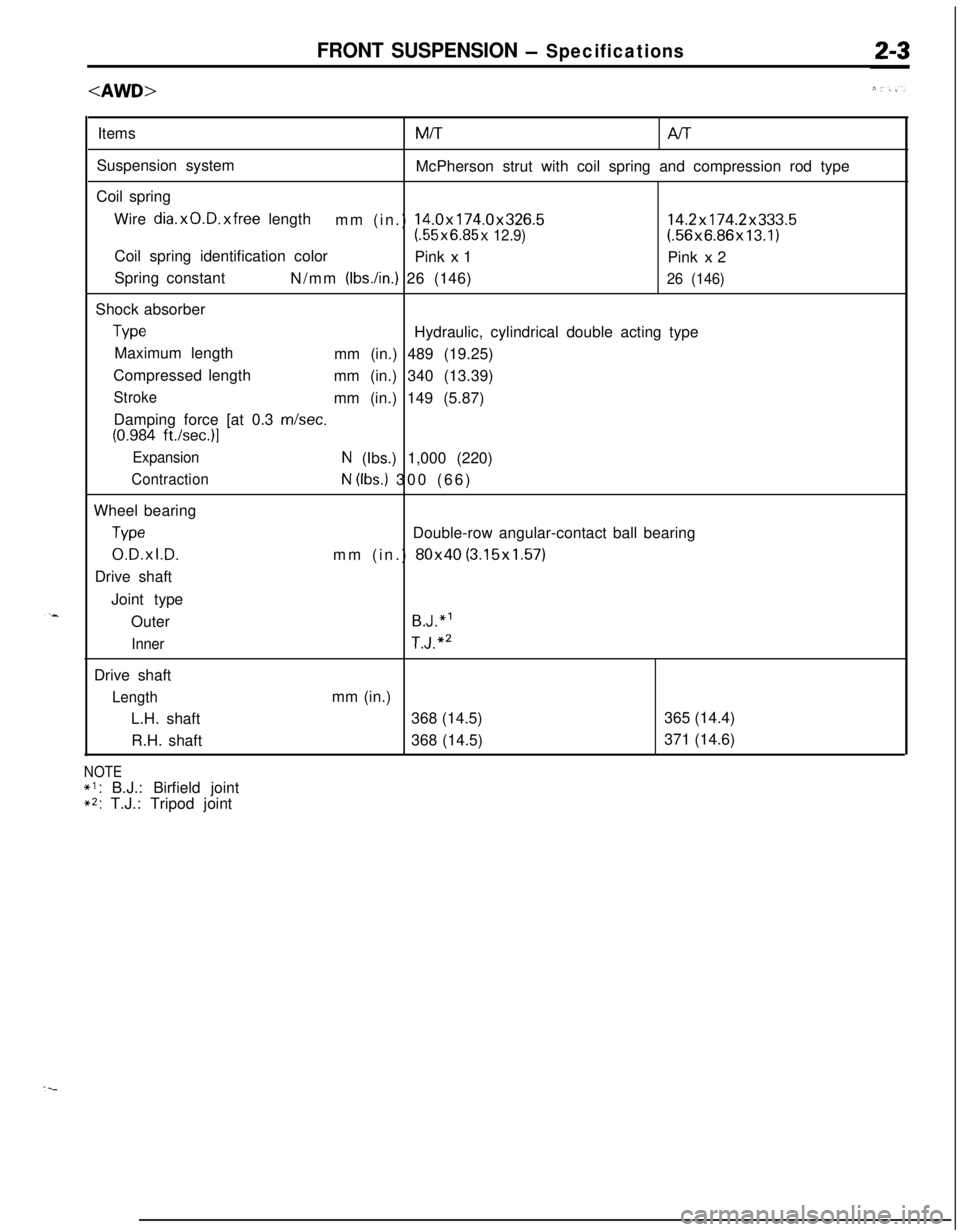

FRONT SUSPENSION - SpecificationsItemsMiT

Al-rSuspension system

McPherson strut with coil spring and compression rod type

Coil spring

Wire

dia.xO.D.xfree length

mm (in.) 14.0x174.0x326.514.2x174.2x333.5(.55x6.85x 12.9)(.56x6.86x13.1)

Coil spring identification color

Pink

x 1

Pink x 2

Spring constant

N/mm

(Ibs./in.) 26 (146)26 (146)Shock absorber

TypeHydraulic, cylindrical double acting type

Maximum length

mm (in.) 489 (19.25)

Compressed length

mm (in.) 340 (13.39)

Strokemm (in.) 149 (5.87)

Damping force [at 0.3 m/set.

(0.984 ft./set.)]

ExpansionN (Ibs.) 1,000 (220)

ContractionN (Ibs.) 300 (66)

Wheel bearing

TypeDouble-row angular-contact ball bearing

0.D.xl.D.mm (in.) 80x40 (3.15x1.57)

Drive shaft

Joint type

Outer

B.J.“’

InnerT.J.“’Drive shaft

Lengthmm (in.)

L.H. shaft368 (14.5)365 (14.4)

R.H. shaft368 (14.5)371 (14.6)

NOTE

*I: B.J.: Birfield joint**: T.J.: Tripod joint

Page 52 of 1216

2-4FRONT SUSPENSION - Specifications

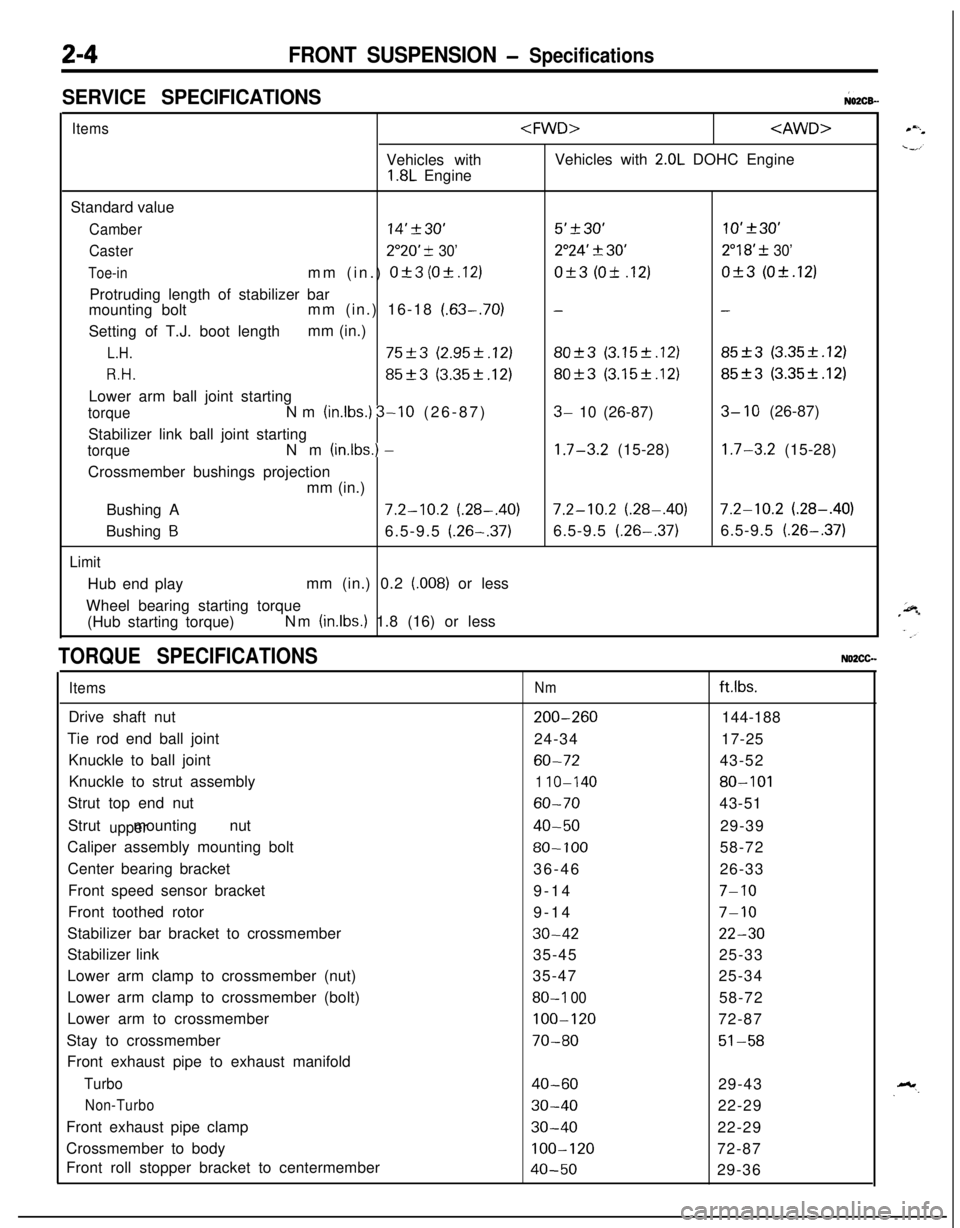

SERVICE SPECIFICATIONS;02CB-

ItemsVehicles with

1.8L Engine

2.0L DOHC Engine

Standard value

Camber14’230’5’+30’10’+30’

Caster2”20’ -t 30’2”24’ 3130’2”18’ f 30’

Toe-inmm (in.) Of3 (Ok.12)Of3 (Ok .12)Of3 (Ok.12)

Protruding length of stabilizer bar

mounting boltmm (in.) 16-18

(.63-.70)--Setting of T.J. boot lengthmm (in.)

L.H.75+3 (2.95f.12)80-+3 (3.15f.12)85_+3 (3.35k.12)

R.H.85f3 (3.35k.12)80+3 (3.15k.12)85f3 (3.35f.12)Lower arm ball joint starting

torqueNm (in.lbs.) 3-10 (26-87)3- 10 (26-87)3- 10 (26-87)

Stabilizer link ball joint starting

torqueNm (inlbs.) -1.7-3.2 (15-28)1.7-3.2 (15-28)

Crossmember bushings projection

mm (in.)

Bushing A

7.2-10.2 (.28-.40)7.2-10.2 (.28-.40)7.2-10.2 (.28-.40)

Bushing

B6.5-9.5 (.26-.37)6.5-9.5 (.26-.37)6.5-9.5 (.26-.37)

LimitHub end playmm (in.) 0.2

(.008) or less

Wheel bearing starting torque

(Hub starting torque)Nm

(in.lbs.) 1.8 (16) or less

TORQUE SPECIFICATIONSNO2CG.

ItemsDrive shaft nut

Tie rod end ball joint

Knuckle to ball joint

Knuckle to strut assembly

Strut top end nut

Strut mounting nut

upperCaliper assembly mounting bolt

Center bearing bracket

Front speed sensor bracket

Front toothed rotor

Stabilizer bar bracket to crossmember

Stabilizer link

Lower arm clamp to crossmember (nut)

Lower arm clamp to crossmember (bolt)

Lower arm to crossmember

Stay to crossmember

Front exhaust pipe to exhaust manifold

Turbo

Non-TurboFront exhaust pipe clamp

Crossmember to body

Front roll stopper bracket to centermember

Nmftlbs.

200-260144-188

24-3417-25

60-7243-52

1 IO-14080-101

60-7043-51

40-5029-39

80-10058-72

36-4626-33

9-14

7-109-14

7-10

30-4222-3035-4525-33

35-4725-34

80-I 0058-72

100-12072-87

70-8051-58

40-6029-43

30-4022-29

30-4022-29

100-12072-87

40-5029-36

Page 69 of 1216

FRONT SUSPENSION - Drive Shaft

DRIVE SHAFT

T.J.-B.J. type drive shaft is used. The left side drive

shaft has an inner shaft and center bearing so that

the left and right side drive shafts are same length.

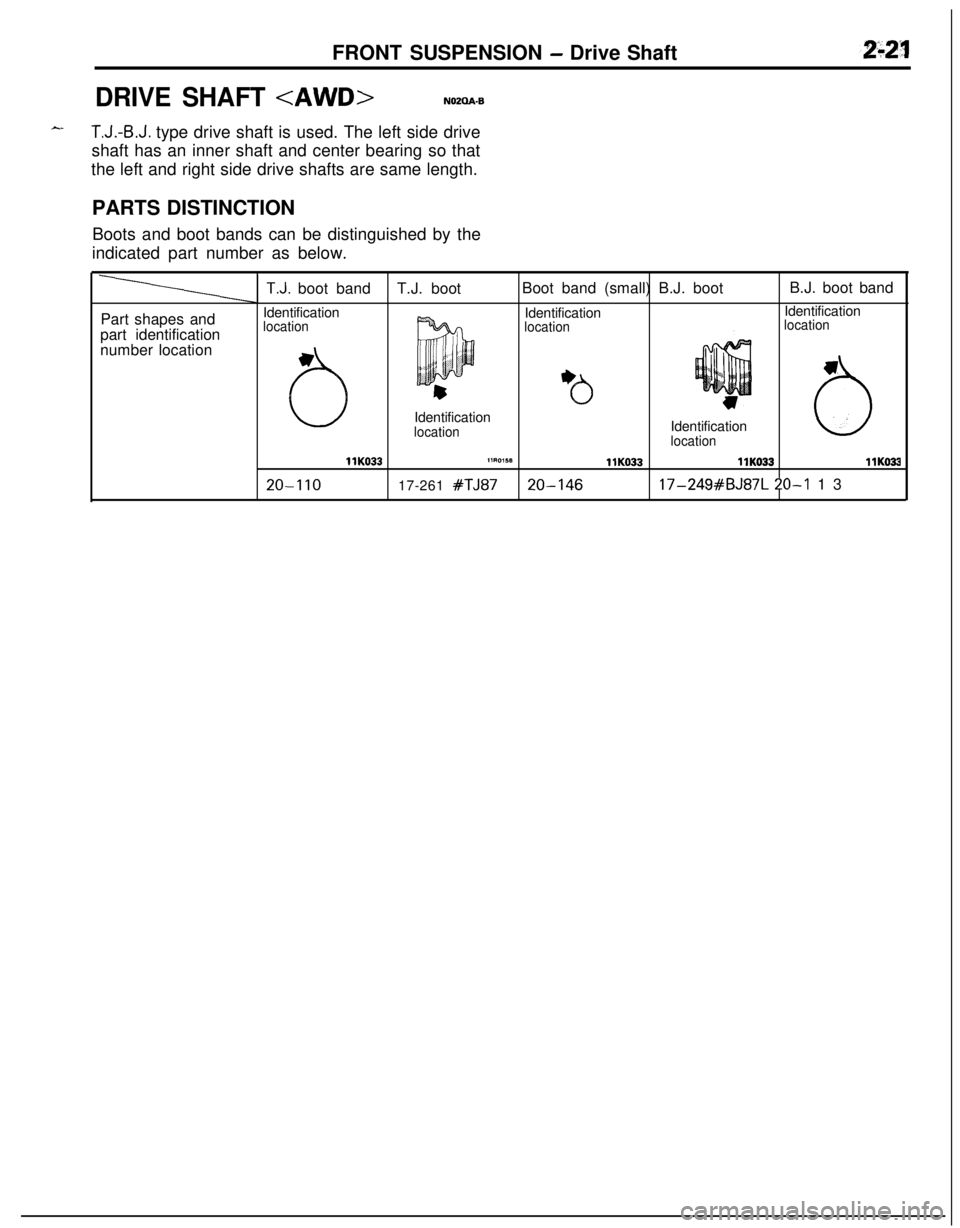

PARTS DISTINCTION

Boots and boot bands can be distinguished by the

indicated part number as below.

Part shapes and

part identification

number location

T.J. boot bandT.J. bootBoot band (small) B.J. bootB.J. boot band

Identification

IdentificationIdentification

location

locationlocation

uIdentification

locationIdentificationlocation6

llK033llRO,SBllK033llK033llKO33

20-I 1017-261 #TJ8720-14617-249#BJ87L 20-I 13

Page 79 of 1216

FRONT SUSPENSION - Strut Assembly

MB991237 -12l.0254

Strut insulator bearing12A0523

Bu’mp rubber

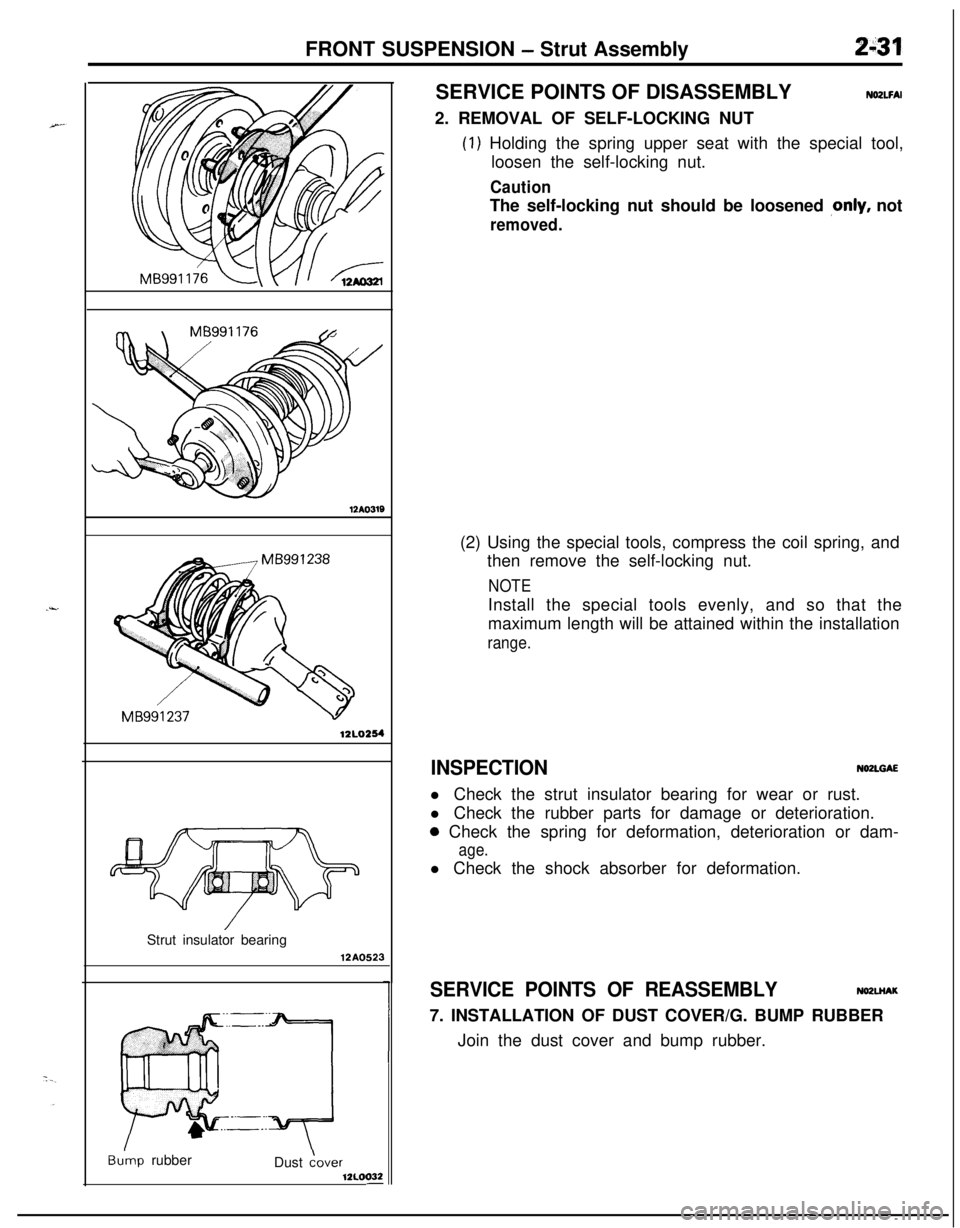

Dust Gover12LOO32-SERVICE POINTS OF DISASSEMBLY

NO2LFAI2. REMOVAL OF SELF-LOCKING NUT

(1) Holding the spring upper seat with the special tool,

loosen the self-locking nut.

CautionThe self-locking nut should be loosened

,only, not

removed.(2) Using the special tools, compress the coil spring, and

then remove the self-locking nut.

NOTEInstall the special tools evenly, and so that the

maximum length will be attained within the installation

range.

INSPECTIONNOZLGAEl Check the strut insulator bearing for wear or rust.

l Check the rubber parts for damage or deterioration.

0 Check the spring for deformation, deterioration or dam-

age.l Check the shock absorber for deformation.

SERVICE POINTS OF REASSEMBLYNO2LHAK7. INSTALLATION OF DUST COVER/G. BUMP RUBBER

Join the dust cover and bump rubber.