oil level MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 110 of 1216

3-8REAR AXLE - Service Adjustment Procedures

09D031

llA0065SERVICE ADJUSTMENT PROCEDURES

REAR AXLE TOTAL BACKLASH CHECK

N03FAAF

If the vehicle vibrates and produces a booming sound due to animbalance of the driving system, measure the rear axle total

backlash by the following procedures to see if the differential

carrier assembly required removal.

(1) Place the gearshift lever in the neutral position, apply the

parking brake and jack up the vehicle.

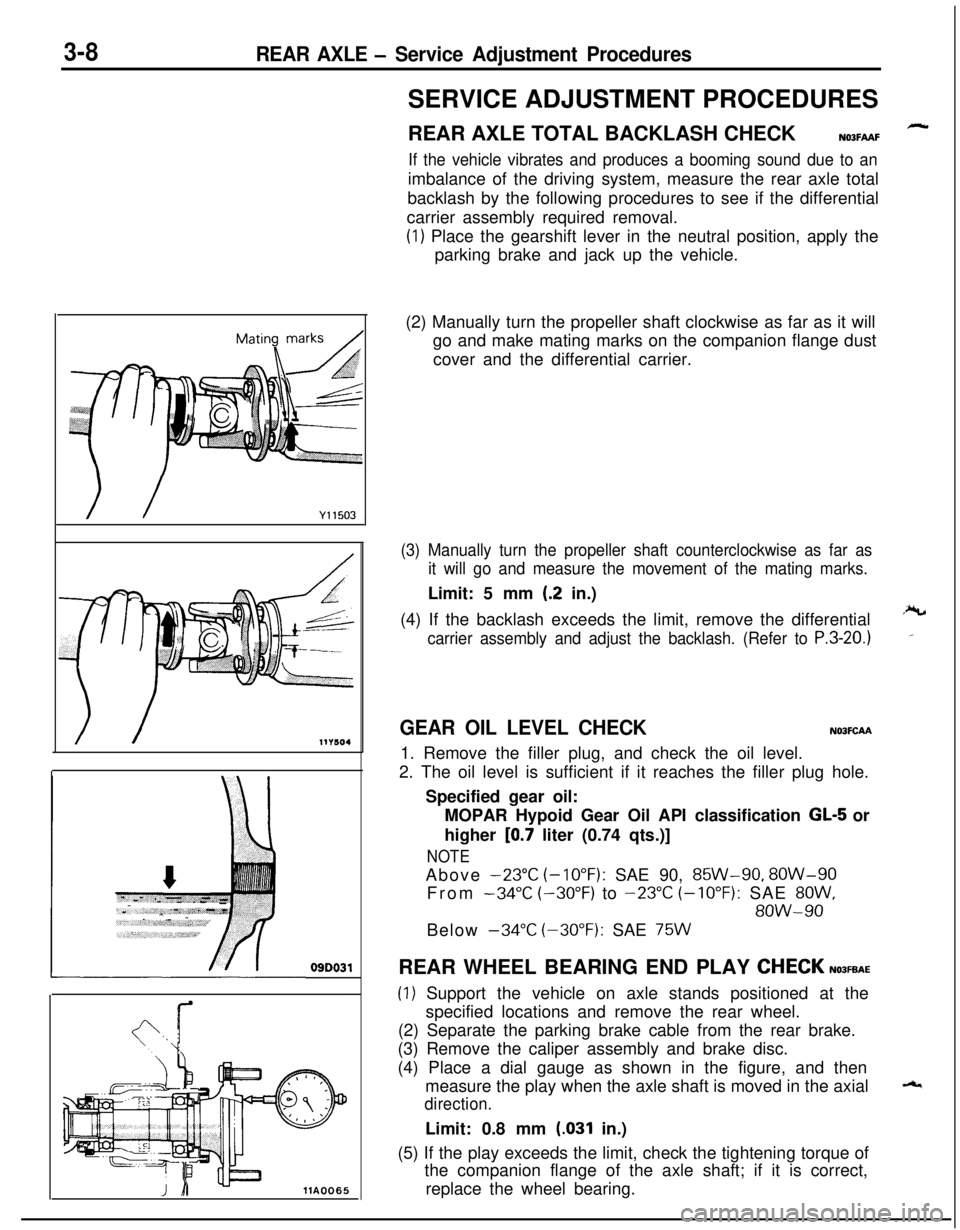

(2) Manually turn the propeller shaft clockwise as far as it will

go and make mating marks on the companion flange dust

cover and the differential carrier.

(3) Manually turn the propeller shaft counterclockwise as far as

it will go and measure the movement of the mating marks.Limit: 5 mm

(.2 in.)

(4) If the backlash exceeds the limit, remove the differential

carrier assembly and adjust the backlash. (Refer to P.3-20.)

GEAR OIL LEVEL CHECKN03FCAA1. Remove the filler plug, and check the oil level.

2. The oil level is sufficient if it reaches the filler plug hole.

Specified gear oil:

MOPAR Hypoid Gear Oil API classification

GL-5 or

higher

[0.7 liter (0.74 qts.)]

NOTEAbove

-23°C (-10°F): SAE 90, 85W-90, 8OW-90

From

-34°C (-30°F) to -23°C (-10°F): SAE 8OW,

8OW-90Below

-34°C (-30°F): SAE 75WREAR WHEEL BEARING END PLAY

CHECKN03FEAE

(1) Support the vehicle on axle stands positioned at the

specified locations and remove the rear wheel.

(2) Separate the parking brake cable from the rear brake.

(3) Remove the caliper assembly and brake disc.

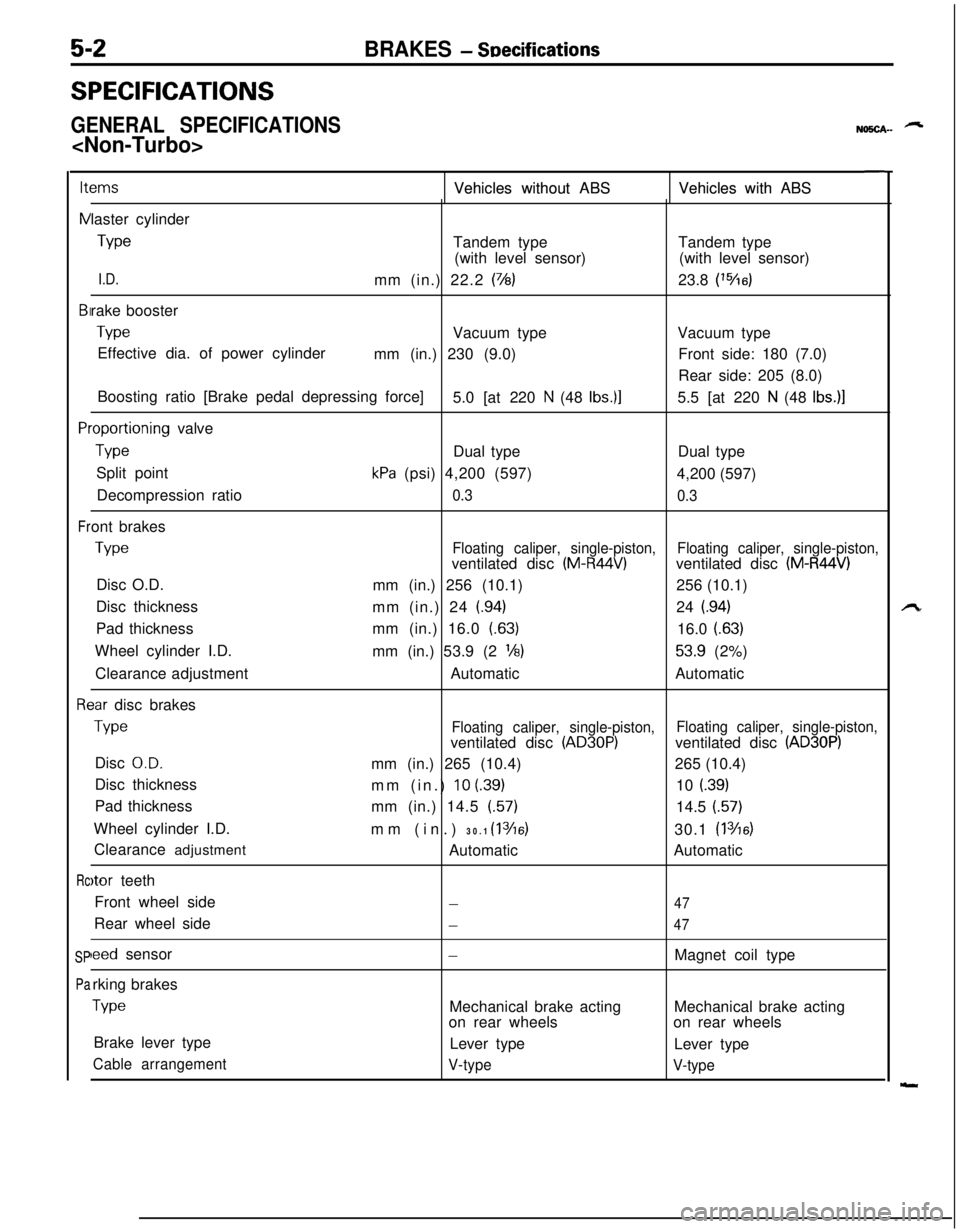

(4) Place a dial gauge as shown in the figure, and then

measure the play when the axle shaft is moved in the axial

direction.Limit: 0.8 mm

(.031 in.)

(5) If the play exceeds the limit, check the tightening torque of

the companion flange of the axle shaft; if it is correct,

replace the wheel bearing.

Page 142 of 1216

5-2BRAKES - SDecifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

NO!iCA-- -

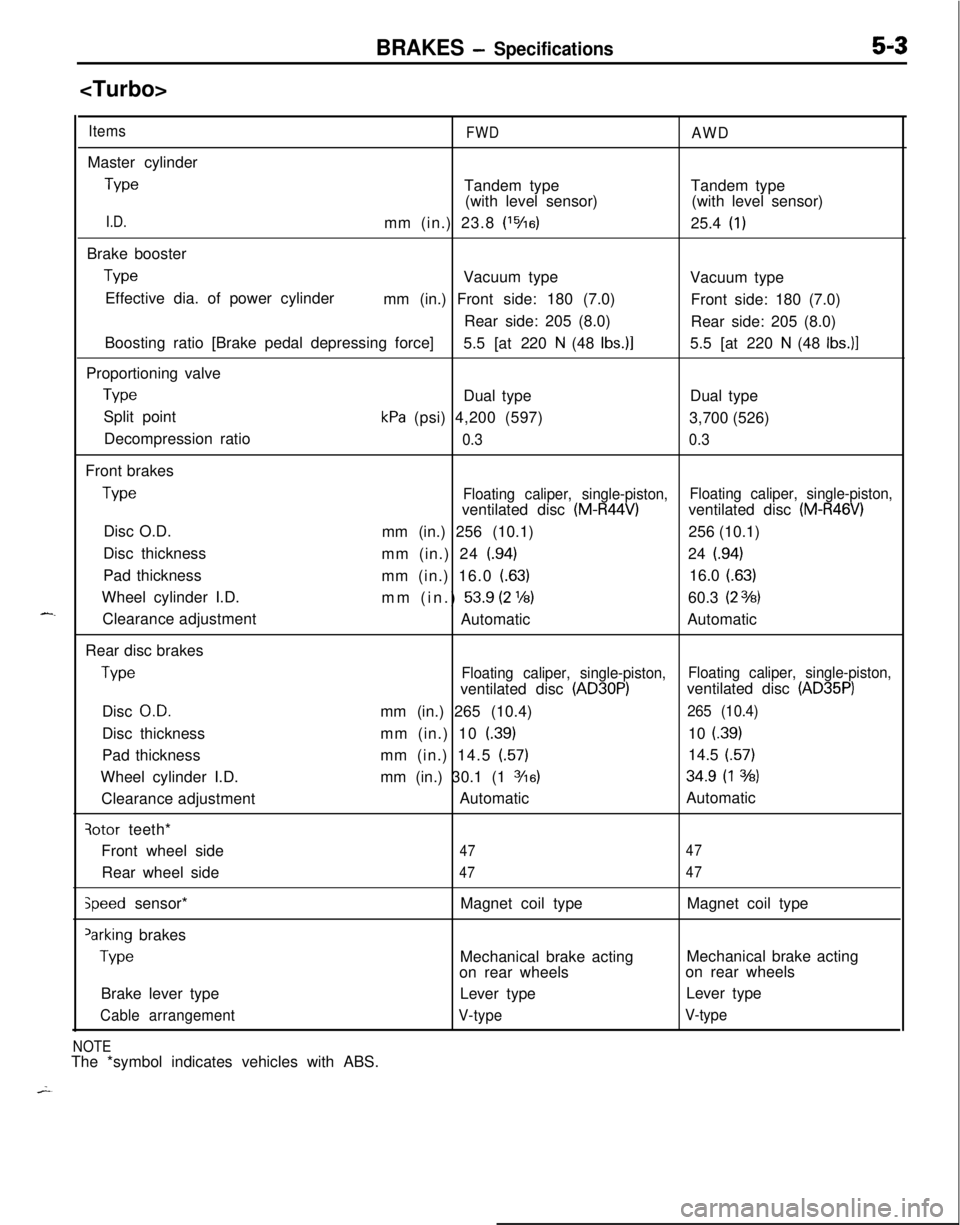

ItemsItems

NNVehicles without ABS Vehicles without ABSVehicles with ABS Vehicles with ABS

BIBI

PlPl

Fr Frlaster cylinder

TypeTandem typeTandem type

(with level sensor)(with level sensor)

I.D.mm (in.) 22.2 (7/8)23.8 (‘%6)rake booster

TypeVacuum typeVacuum type

Effective dia. of power cylinder

mm (in.) 230 (9.0)Front side: 180 (7.0)

Rear side: 205 (8.0)

Boosting ratio [Brake pedal depressing force]

5.0 [at 220

N (48 Ibs.)]5.5 [at 220 N (48 Ibs.)]

.oportioning valve

TypeDual typeDual type

Split point

kPa (psi) 4,200 (597)

4,200 (597)

Decompression ratio

0.3

0.3ont brakes

TypeFloating caliper, single-piston,ventilated disc (M-R44V)Floating caliper, single-piston,ventilated disc (M-R44V)Disc O.D.

mm (in.) 256 (10.1)256 (10.1)

Disc thickness

mm (in.) 24

(.94)24 (.94)Pad thicknessmm (in.) 16.0 (63)

16.0

(.63)Wheel cylinder I.D.

mm (in.) 53.9 (2

l/8)53.9 (2%)

Clearance adjustmentAutomaticAutomatic

3ar disc brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc (AD30P)ventilated disc (AD30P)Disc

O.D.mm (in.) 265 (10.4)265 (10.4)

Disc thickness

mm (in.)

10 (39)10 i.39)Pad thickness

mm (in.) 14.5 (57)

14.5 (57)

Wheel cylinder I.D.

mm (in.) 30.1

(1 3/16)30.1 (1 346)Clearance adjustment

AutomaticAutomatic

)tor teeth

Front wheel side

-47Rear wheel side

-47

leed sensor-Magnet coil type

rking brakes

TypeMechanical brake actingMechanical brake acting

on rear wheelson rear wheels

Brake lever type

Lever type

Lever type

Cable arrangement

V-type

V-type

Rc Rc

SP SP

Pa Pa

Page 143 of 1216

BRAKES - Specifications5-3

ItemsFWDAWDMaster cylinder

TypeTandem type

(with level sensor)Tandem type

(with level sensor)

I.D.mm (in.) 23.8 (‘%a)25.4 (1)Brake booster

TypeVacuum type

Vacuum type

Effective dia. of power cylinder

mm (in.) Front side: 180 (7.0)

Front side: 180 (7.0)

Rear side: 205 (8.0)

Rear side: 205 (8.0)

Boosting ratio [Brake pedal depressing force]

5.5 [at 220

N (48 Ibs.)]5.5 [at 220 N (48 Ibs.)]Proportioning valve

TypeDual typeDual type

Split point

kPa (psi) 4,200 (597)

3,700 (526)

Decompression ratio

0.30.3Front brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc (M-R44V)ventilated disc (M-R46V)Disc O.D.

mm (in.) 256 (10.1)256 (10.1)

Disc thickness

mm (in.) 24

(.94)24 (.94)Pad thickness

mm (in.) 16.0

(.63)16.0 (.63)Wheel cylinder I.D.

mm (in.)

53.9 (2 ‘16)60.3 (23%3)Clearance adjustment

AutomaticAutomatic

Rear disc brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc (AD30P)ventilated disc (AD35P)Disc

O.D.mm (in.) 265 (10.4)265 (10.4)Disc thicknessmm (in.) 10

(.39)10 f.39)Pad thicknessmm (in.) 14.5

(.57)14.5 (.57)Wheel cylinder I.D.mm (in.) 30.1 (1

3/16)34.9 (1 3h)Clearance adjustmentAutomaticAutomatic

qotor teeth*

Front wheel side

4747Rear wheel side

4747

speed sensor*Magnet coil typeMagnet coil type‘arking brakes

TypeMechanical brake actingMechanical brake acting

on rear wheelson rear wheels

Brake lever typeLever typeLever type

Cable arrangementV-typeV-type

NOTEThe *symbol indicates vehicles with ABS.

Page 185 of 1216

BRAKES - Service Adiustment Procedures5-45I

\\14A0416

2314A04.54

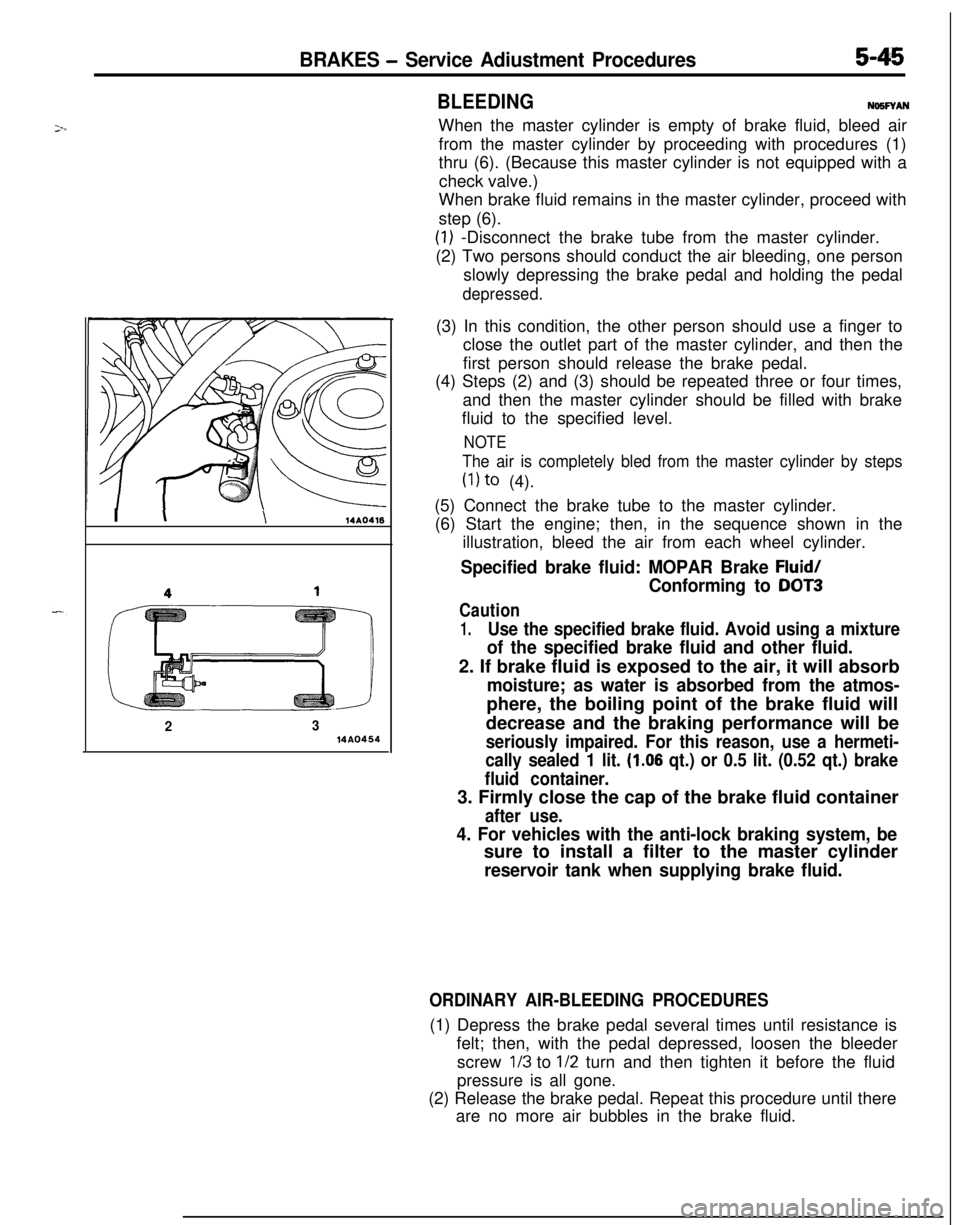

BLEEDINGN65FYAN

When the master cylinder is empty of brake fluid, bleed air

from the master cylinder by proceeding with procedures (1)

thru (6). (Because this master cylinder is not equipped with a

check valve.)

When brake fluid remains in the master cylinder, proceed with

step (6).

(1) -Disconnect the brake tube from the master cylinder.

(2) Two persons should conduct the air bleeding, one person

slowly depressing the brake pedal and holding the pedal

depressed.(3) In this condition, the other person should use a finger to

close the outlet part of the master cylinder, and then the

first person should release the brake pedal.

(4) Steps (2) and (3) should be repeated three or four times,

and then the master cylinder should be filled with brake

fluid to the specified level.

NOTE

The air is completely bled from the master cylinder by steps

(1) to (4).

(5) Connect the brake tube to the master cylinder.

(6) Start the engine; then, in the sequence shown in the

illustration, bleed the air from each wheel cylinder.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to DOT3

Caution

1.Use the specified brake fluid. Avoid using a mixture

of the specified brake fluid and other fluid.2. If brake fluid is exposed to the air, it will absorb

moisture; as water is absorbed from the atmos-phere, the boiling point of the brake fluid will

decrease and the braking performance will be

seriously impaired. For this reason, use a hermeti-

cally sealed 1 lit.

(1.06 qt.) or 0.5 lit. (0.52 qt.) brake

fluid container.3. Firmly close the cap of the brake fluid container

after use.

4. For vehicles with the anti-lock braking system, besure to install a filter to the master cylinder

reservoir tank when supplying brake fluid.

ORDINARY AIR-BLEEDING PROCEDURES(1) Depress the brake pedal several times until resistance is

felt; then, with the pedal depressed, loosen the bleeder

screw

l/3 to l/2 turn and then tighten it before the fluid

pressure is all gone.

(2) Release the brake pedal. Repeat this procedure until there

are no more air bubbles in the brake fluid.

Page 251 of 1216

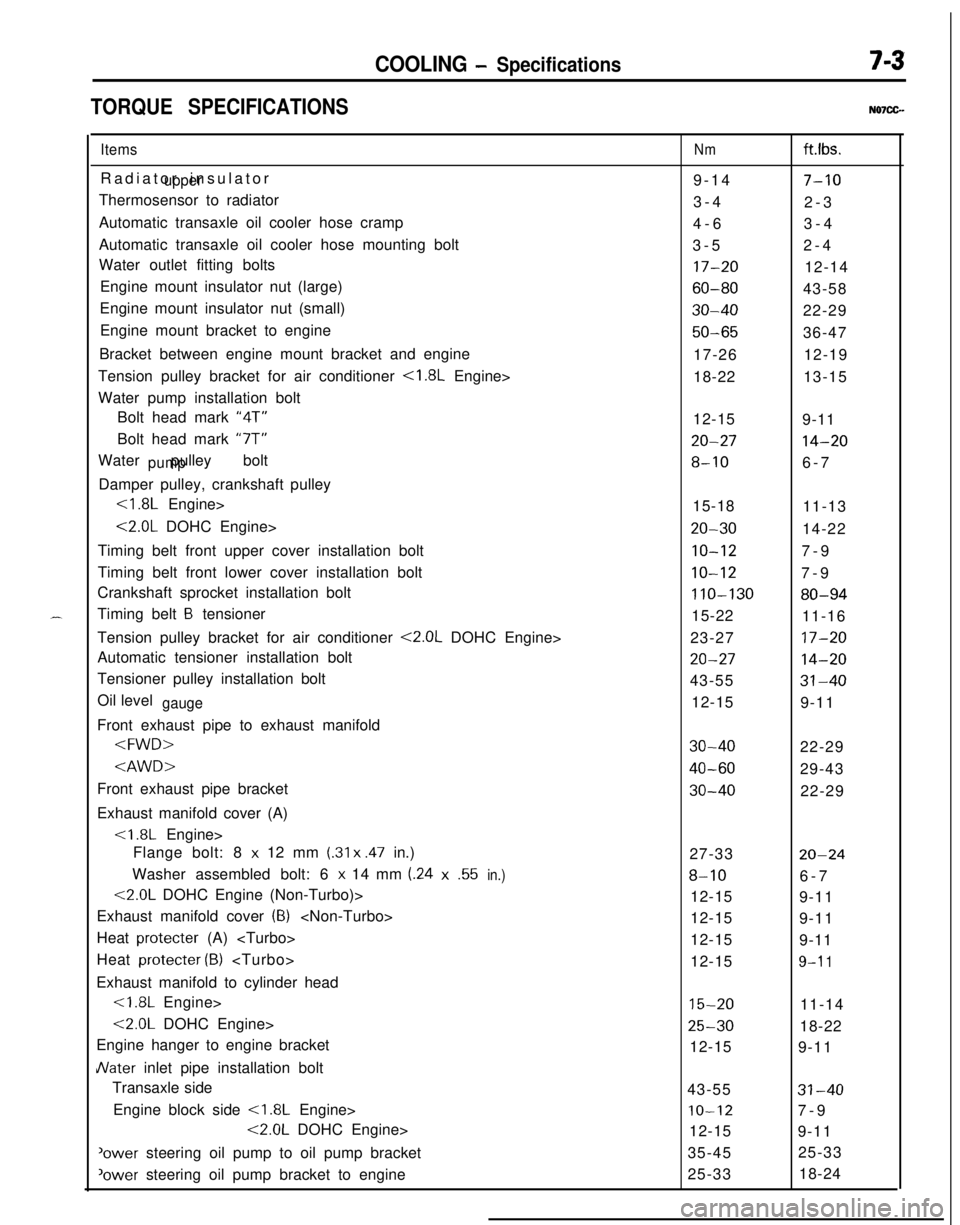

COOLING - Specifications7-3

TORQUE SPECIFICATIONSN07CG.

ItemsRadiator insulator

upperThermosensor to radiator

Automatic transaxle oil cooler hose cramp

Automatic transaxle oil cooler hose mounting bolt

Water outlet fitting bolts

Engine mount insulator nut (large)

Engine mount insulator nut (small)

Engine mount bracket to engine

Bracket between engine mount bracket and engine

Tension pulley bracket for air conditioner

<1.8L Engine>

Water pump installation bolt

Bolt head mark “4T”

Bolt head mark “7T”

Water pulley bolt

pumpDamper pulley, crankshaft pulley

<1.8L Engine>

<2.0L DOHC Engine>

Timing belt front upper cover installation bolt

Timing belt front lower cover installation bolt

Crankshaft sprocket installation bolt

Timing belt

B tensioner

Tension pulley bracket for air conditioner

<2.0L DOHC Engine>

Automatic tensioner installation bolt

Tensioner pulley installation bolt

Oil level

gaugeFront exhaust pipe to exhaust manifold

Exhaust manifold cover (A)

Flange bolt: 8

x 12 mm (.31 x .47 in.)

Washer assembled bolt: 6

x 14 mm (.24x.55in.)

<2.0L DOHC Engine (Non-Turbo)>

Exhaust manifold cover

(8)

Heat protecter (A)

Heat protecter

(B)

Exhaust manifold to cylinder head<1.8L Engine>

<2.0L DOHC Engine>

Engine hanger to engine bracket

JVater inlet pipe installation bolt

Transaxle side

Engine block side

<1.8L Engine>

<2.0L DOHC Engine>

'ower steering oil pump to oil pump bracket

‘ower steering oil pump bracket to engine

Nmft.lbs.

9-14

7-103-4

2-3

4-63-4

3-52-4

17-2012-14

60-8043-58

30-4022-29

50-6536-47

17-2612-19

18-2213-15

12-15

9-11

20-2714-20

8-106-7

15-18

11-13

20-3014-22

IO-127-9

10-127-9

110-13080-9415-22

11-16

23-27

17-20

20-2714-2043-55

31-4012-15

9-11

30-4022-29

40-6029-43

30-4022-29

27-33

20-24

8-106-7

12-15

9-11

12-15

9-11

12-15

9-11

12-15

9-l 1

15-2011-14

25-3018-22

12-15

9-11

43-55

31-40

IO-127-9

12-15

9-11

35-4525-33

25-3318-24

Page 260 of 1216

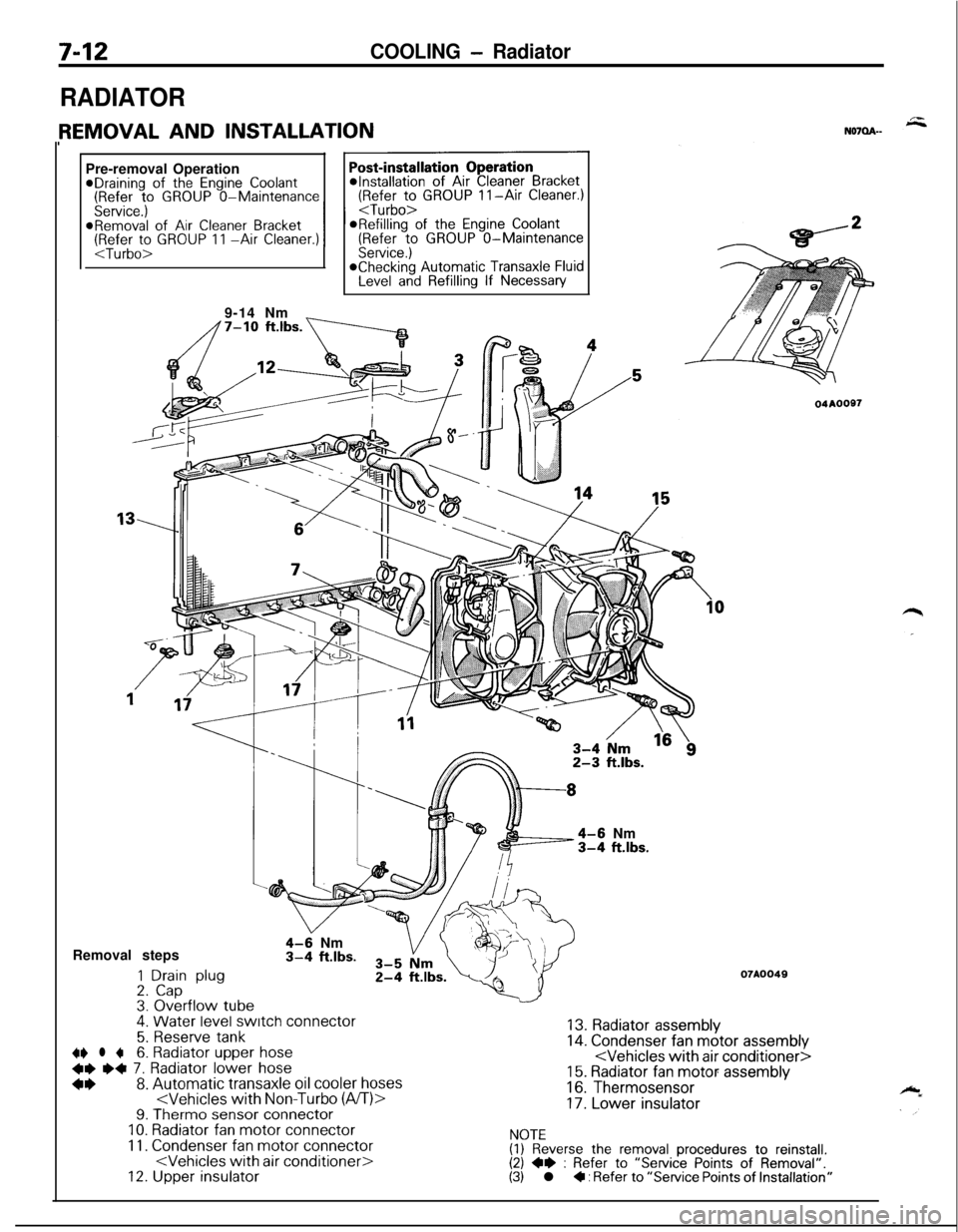

7-12COOLING - Radiator

RADIATORPre-removal Operation

@Draining of the Engine Coolant(Refer to GROUP O-Maintenance(Refer to GROUP II-Air Cleaner.)

Service.)

I I

9-14 Nm

_

4-6 Nm3-4 ft.lbs.Removal steps

1 Drain plug2. Cap3. Overflow tube.

4-9 Nm3-4 ft.lbs.

4. Water level switch connector

5. Reserve tank~~ l +6. Radiator upper hose

+e e+ 7. Radiator lower hose

*I)8. Automatic transaxle oil cooler hoses

11. Condenser fan motor connector

04AOOS7

07A0049

13. Radiator assembly14. Condenser fan motor assembly

16. Thermosensor

17. Lower insulator

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”

Page 273 of 1216

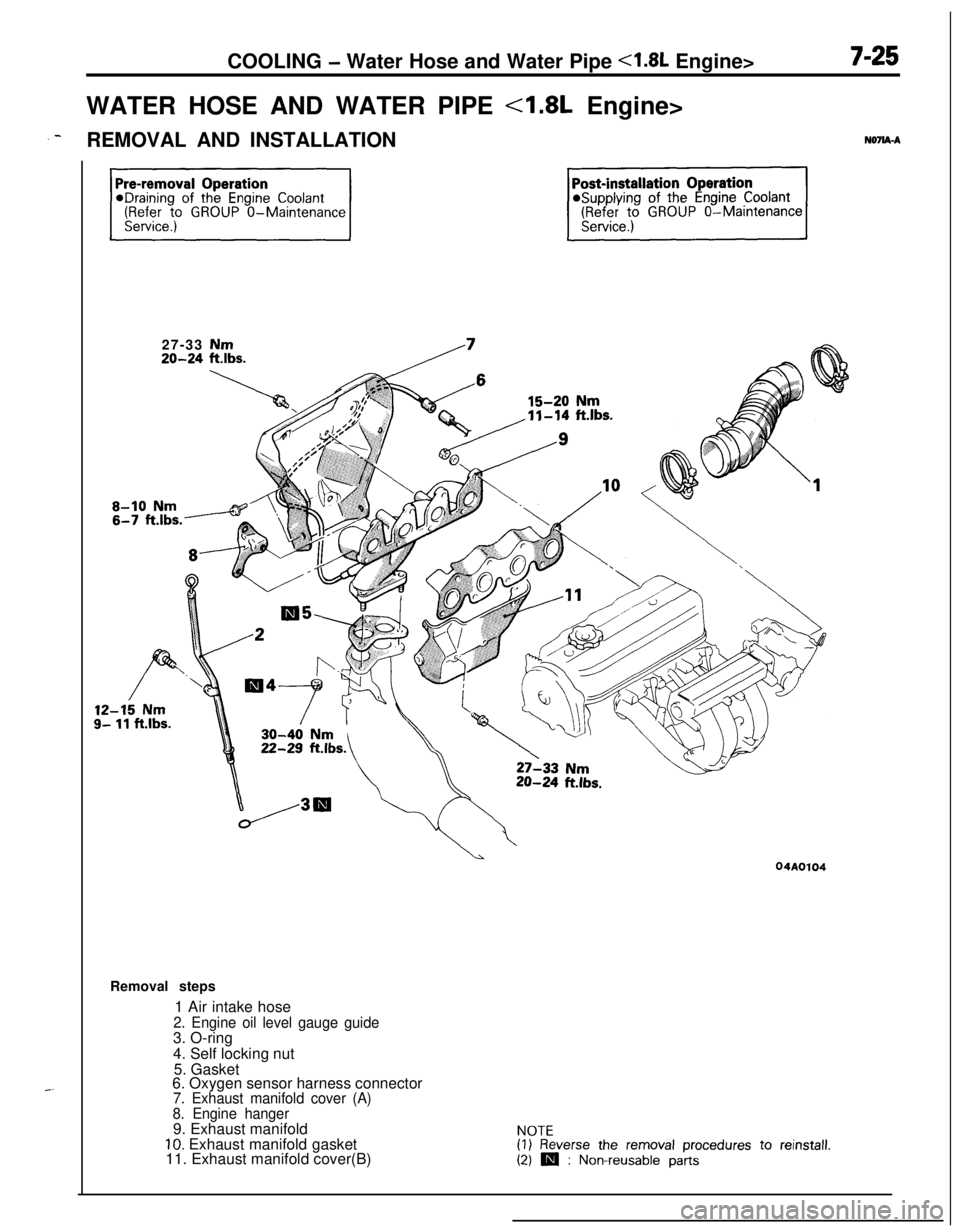

COOLING - Water Hose and Water Pipe <1.8L Engine>

WATER HOSE AND WATER PIPE

<1.8L Engine>

_-REMOVAL AND INSTALLATIONNO’IIA-A27-33 Nm

20-24 ftlbs.

12-15 Nms- 11 ft.lbs.Removal steps

1 Air intake hose

2. Engine oil level gauge guide3. O-ring

4. Self locking nut

5. Gasket

6. Oxygen sensor harness connector

7. Exhaust manifold cover (A)

8. Engine hanger9. Exhaust manifold

IO. Exhaust manifold gasket

11. Exhaust manifold cover(B)NOTE(1) Reverse the removal procedures to reinstall.(2) m : Non-reusable parts

Page 279 of 1216

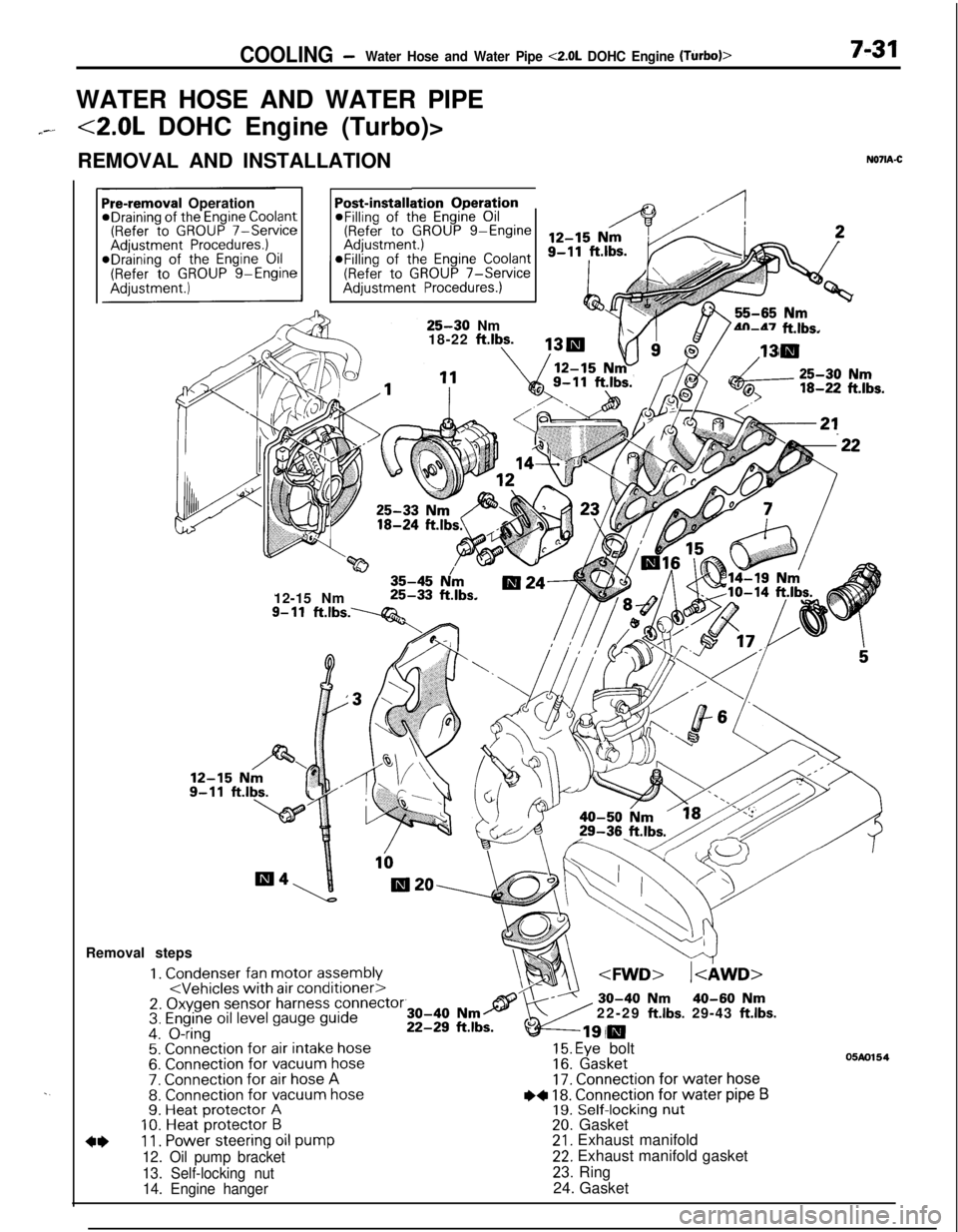

COOLING -Water Hose and Water Pipe <2.0L DOHC Engine (Turbo)>7-31WATER HOSE AND WATER PIPE

7--<2.0L DOHC Engine (Turbo)>

REMOVAL AND INSTALLATION

N071A-C

. .

ation OperationPost-installi@Filling of the Engine Oil(Refer to GROUP g-EngineaFilling of the

Engine Coolant(Refer to GROUP 7-ServiceAdjustment Procedures.)

Pre-removal OperationeDraining of the Engine Coolant(Refer to GROUP 7-ServiceAdjustment Procedures.)*Draining of the Engine Oil(Refer to GROUP g-Engine

25-30 Nm

18-22 ftlbs.4n-47 ft.lbs.

w35-45 N/m12-15 Nm25-33 ft.lbs.

9- 11ft.lbs.----Q&Removal steps

1. Condenser fan motor assembly

4*11. Power steering oil pump

12. Oil pump bracket

13. Self-locking nut

14. Engine hanger22-29

ft.lbs. 29-43 ft.lbs.

15. Eye bolt16. Gasket17. Connection for water hose

I)+ 18. Connection for water pipe B19. Self-locking nut20. Gasket21. Exhaust manifold22. Exhaust manifold gasket

23. Ring

24. Gasket

05m154

Page 307 of 1216

ENGINE - Troubleshooting9-23

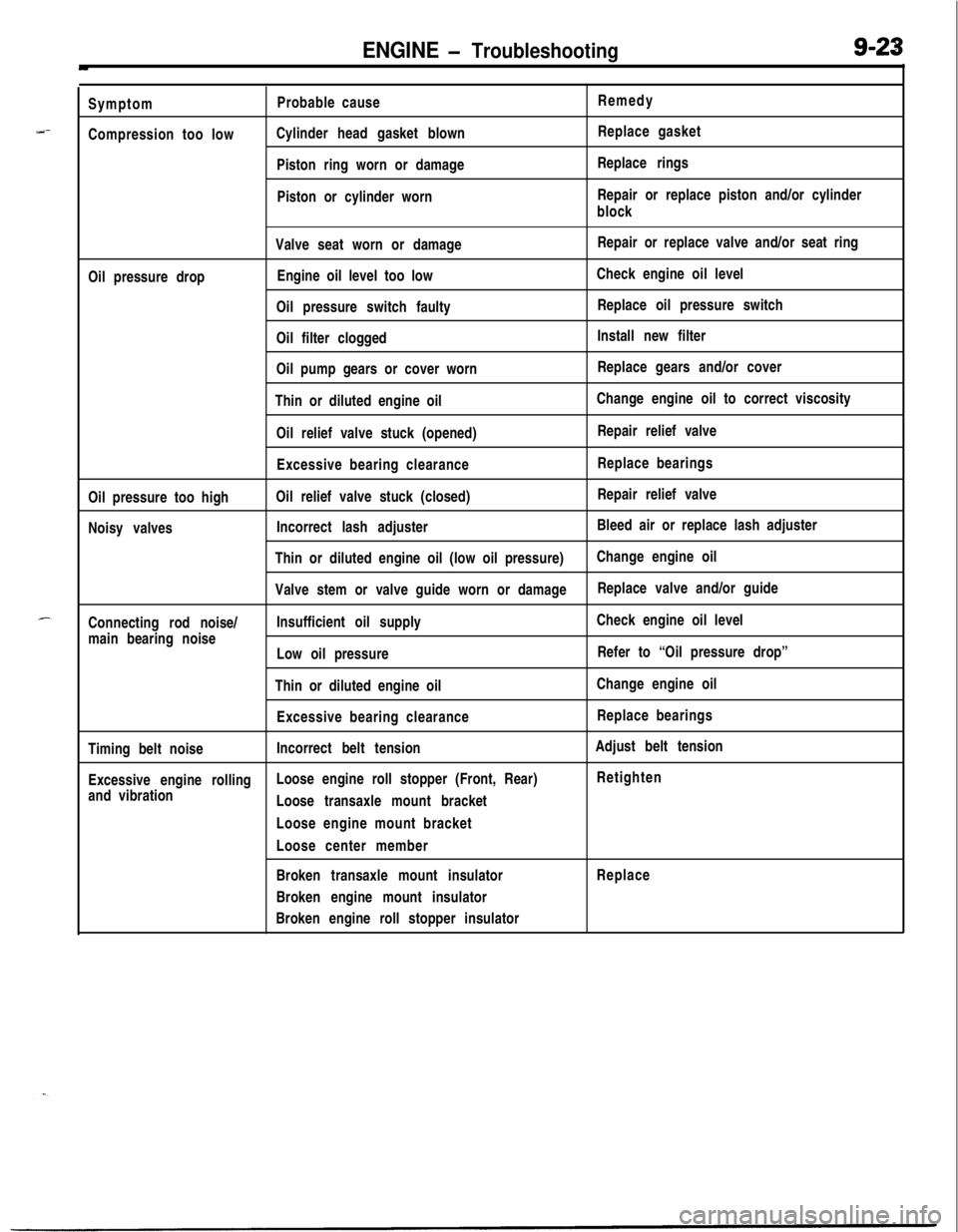

--Symptom

Compression too lowProbable cause

Cylinder head gasket blown

Piston ring worn or damage

Piston or cylinder wornRemedy

Replace gasket

Replace rings

Repair or replace piston and/or cylinder

block

Valve seat worn or damageRepair or replace valve and/or seat ring

Oil pressure dropEngine oil level too lowCheck engine oil level

Oil pressure switch faultyReplace oil pressure switch

Oil filter cloggedInstall new filter

Oil pump gears or cover wornReplace gears and/or cover

Thin or diluted engine oilChange engine oil to correct viscosity

Oil relief valve stuck (opened)Repair relief valve

Excessive bearing clearanceReplace bearings

Oil pressure too highOil relief valve stuck (closed)Repair relief valve

Noisy valvesIncorrect lash adjusterBleed air or replace lash adjuster

Thin or diluted engine oil (low oil pressure)Change engine oil

Valve stem or valve guide worn or damageReplace valve and/or guide

Connecting rod noise/Insufficient oil supplyCheck engine oil level

main bearing noise

Low oil pressureRefer to “Oil pressure drop”

Thin or diluted engine oilChange engine oil

Excessive bearing clearanceReplace bearings

Timing belt noiseIncorrect belt tensionAdjust belt tension

Excessive engine rollingLoose engine roll stopper (Front, Rear)Retighten

and vibration

Loose transaxle mount bracket

Loose engine mount bracket

Loose center member

Broken transaxle mount insulatorReplace

Broken engine mount insulator

Broken engine roll stopper insulator

Page 356 of 1216

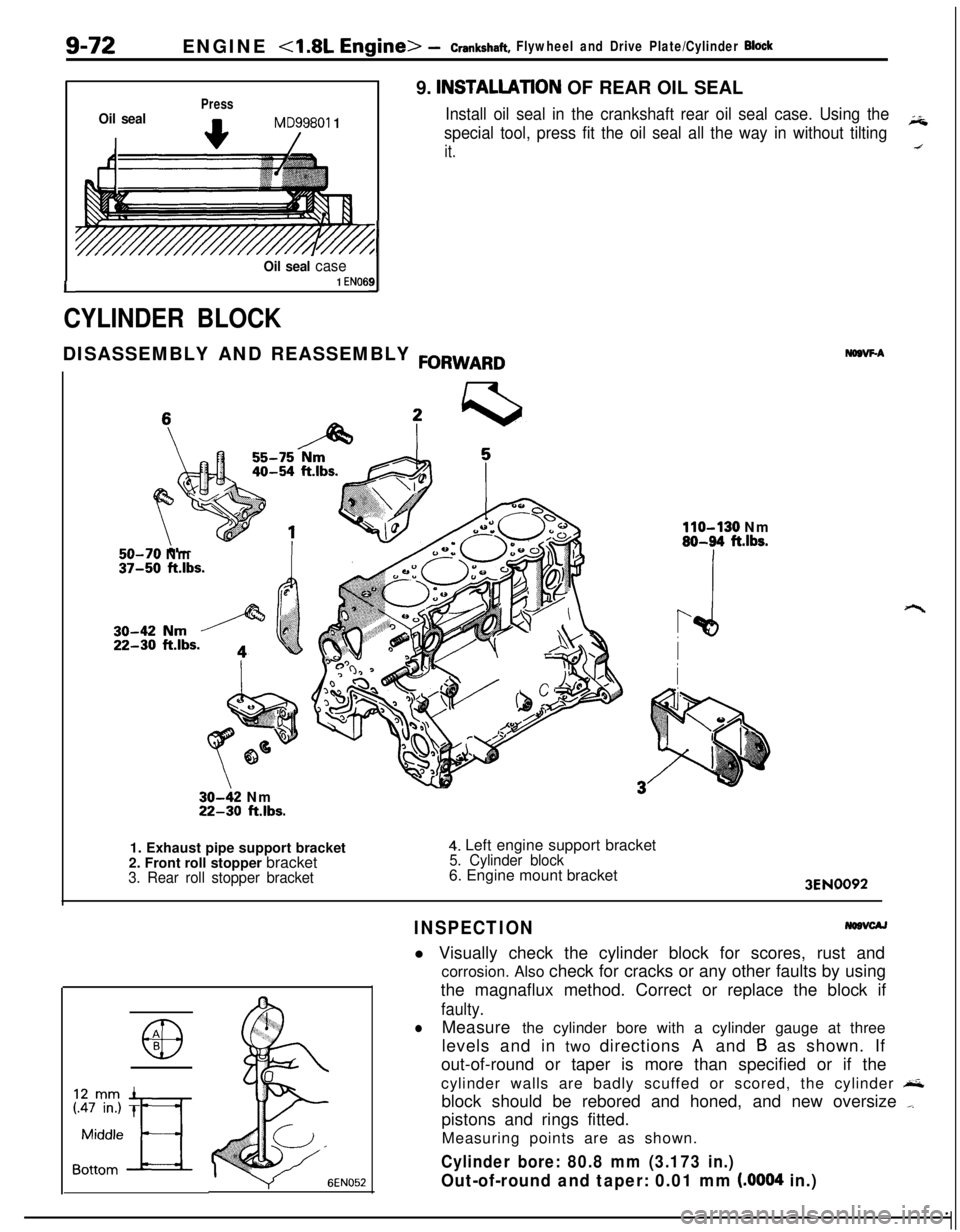

9-72ENGINE <1.8L Engine> -Crankshaft, Flywheel and Drive Plate/Cylinder Block

PressOil seal

I

MD99801 1

/

Oil seal case1 EN06L

CYLINDER BLOCK

i//

199.

INSTALLATlON OF REAR OIL SEAL

Install oil seal in the crankshaft rear oil seal case. Using the

special tool, press fit the oil seal all the way in without tiltingiii

it.DISASSEMBLY AND REASSEMBLY

FORWARD

50-70 Nm37-50 ft.lbs.

30-42 Nm22-30 ft.lbs.

NDBVF-A

110-130 Nm80-94 ft.lbs.1. Exhaust pipe support bracket

2. Front roll stopper bracket

3. Rear roll stopper bracket

4. Left engine support bracket5. Cylinder block6. Engine mount bracket

3EN0092

INSPECTIONl Visually check the cylinder block for scores, rust and

corrosion. Also check for cracks or any other faults by using

the magnaflux method. Correct or replace the block if

faulty.

lMeasure the cylinder bore with a cylinder gauge at three

levels and in two directions A and

B as shown. If

out-of-round or taper is more than specified or if the

cylinder walls are badly scuffed or scored, the cylinder

&block should be rebored and honed, and new oversize

_pistons and rings fitted.

Measuring points are as shown.

Cylinder bore: 80.8 mm (3.173 in.)

Out-of-round and taper: 0.01 mm (.0004 in.)