power steering fluid MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 662 of 1216

19-14STEERING - Service Adjustment Procedures < Power Steering >Shut-off valv

Pressure gauge

(FW close)

(C-3309-E)I

Temperature

gauge

\e’\

Pressure hoses

Re(Mti990994)

\Oil pump

713AO145Shut-off valve

Pressure gauge(FullY ?penl

Pressure hoses

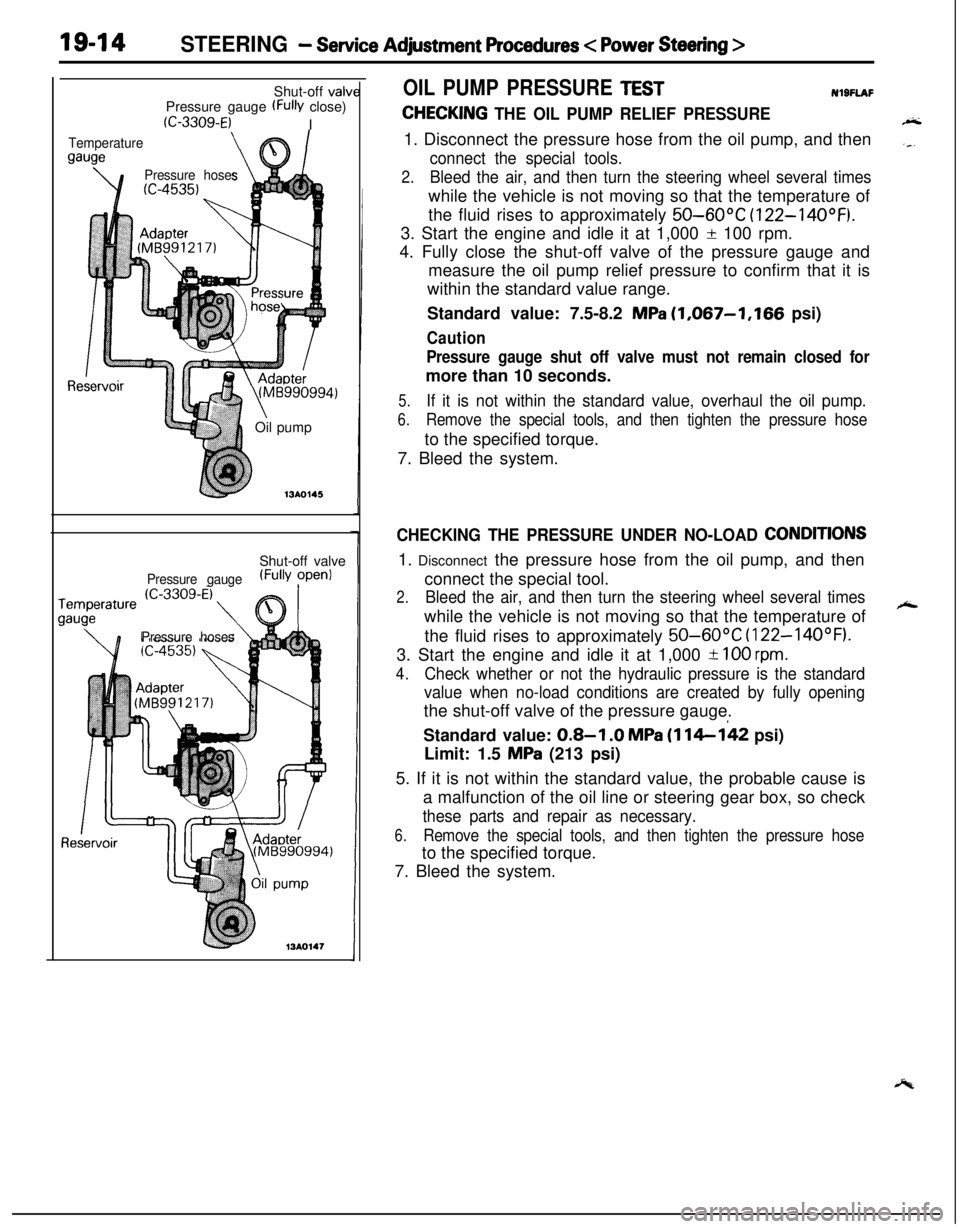

OIL PUMP PRESSURE TESTNl9FlAF

CHECKING THE OIL PUMP RELIEF PRESSURE1. Disconnect the pressure hose from the oil pump, and then

connect the special tools.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50-60°C (122-14OOF).3. Start the engine and idle it at 1,000

f 100 rpm.

4. Fully close the shut-off valve of the pressure gauge and

measure the oil pump relief pressure to confirm that it is

within the standard value range.

Standard value: 7.5-8.2

MPa (1,067-1,166 psi)

Caution

Pressure gauge shut off valve must not remain closed formore than 10 seconds.

5.If it is not within the standard value, overhaul the oil pump.

6.Remove the special tools, and then tighten the pressure hoseto the specified torque.

7. Bleed the system.

CHECKING THE PRESSURE UNDER NO-LOAD CONDITIONS1. Disconnect the pressure hose from the oil pump, and then

connect the special tool.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50-60°C (122-14OOF).3. Start the engine and idle it at 1,000

-t 100 rpm.

4.

Check whether or not the hydraulic pressure is the standard

value when no-load conditions are created by fully openingthe shut-off valve of the pressure gauge.

Standard value:

0.8-I .O MPa (114-142 psi)

Limit: 1.5

MPa (213 psi)

5. If it is not within the standard value, the probable cause is

a malfunction of the oil line or steering gear box, so check

these parts and repair as necessary.

6.Remove the special tools, and then tighten the pressure hoseto the specified torque.

7. Bleed the system.

Page 663 of 1216

-

c. .

STEERING - Service Adiustment Procedures

Shut-off valve

Pressure gauge

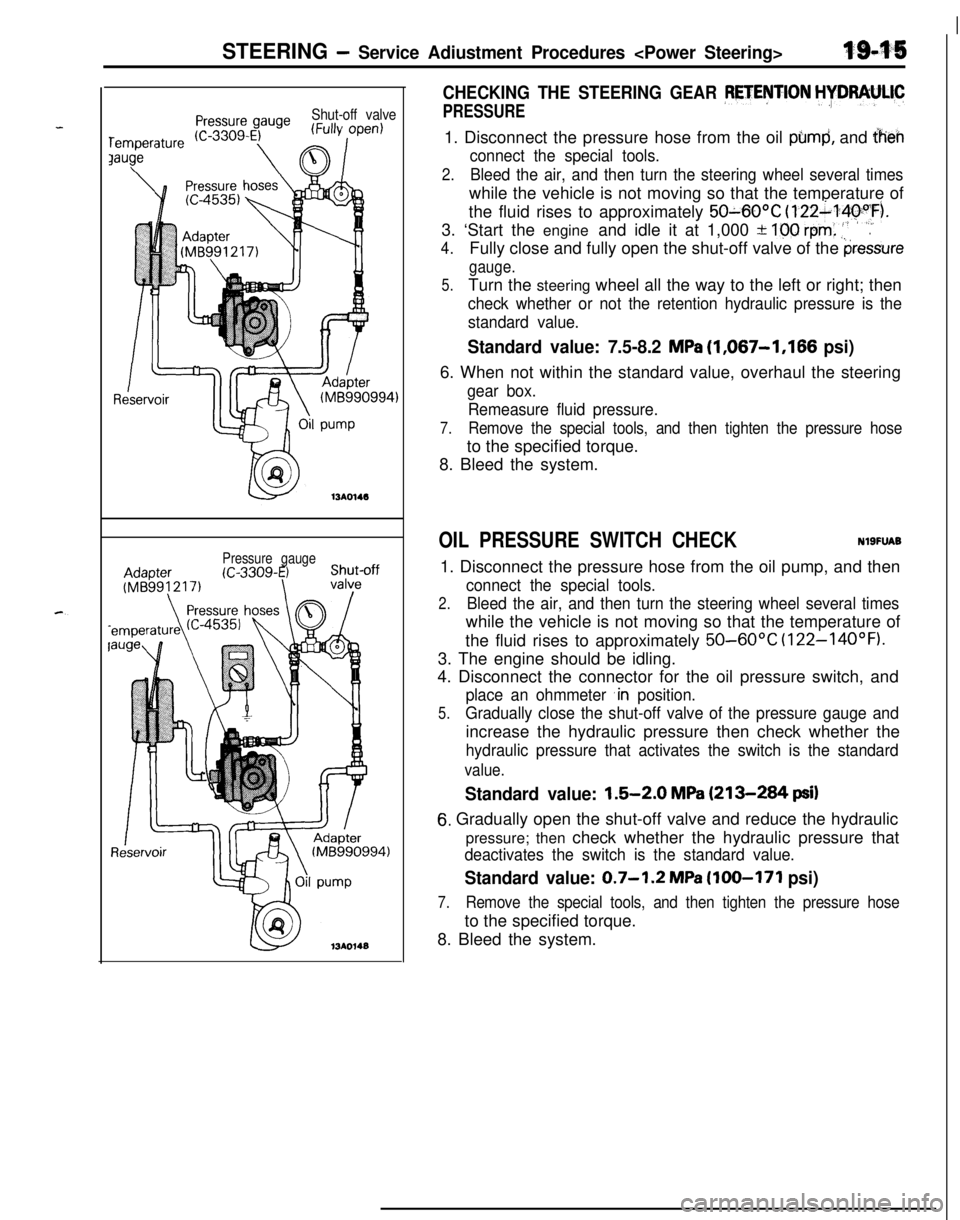

CHECKING THE STEERING GEAR PETENTION HYDRAULIC

PRESSURE1. Disconnect the pressure hose from the oil

pbmd, and iheh

connect the special tools.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50~60OC (122~14pyF).

3. ‘Start the engine and idle it at 1,000 +

100 rem: .‘,’.

4.Fully close and fully open the shut-off valve of the pressure

gauge.

5.Turn the steering wheel all the way to the left or right; then

check whether or not the retention hydraulic pressure is the

standard value.

Standard value: 7.5-8.2 MPa (1,067-1,166 psi)6. When not within the standard value, overhaul the steering

gear box.

Remeasure fluid pressure.

7.Remove the special tools, and then tighten the pressure hoseto the specified torque.

8. Bleed the system.

OIL PRESSURE SWITCH CHECKNlSFUAB1. Disconnect the pressure hose from the oil pump, and then

connect the special tools.

2.Bleed the air, and then turn the steering wheel several timeswhile the vehicle is not moving so that the temperature of

the fluid rises to approximately

50-60°C (122-14OOF).3. The engine should be idling.

4. Disconnect the connector for the oil pressure switch, and

place an ohmmeter ,in position.

5.Gradually close the shut-off valve of the pressure gauge andincrease the hydraulic pressure then check whether the

hydraulic pressure that activates the switch is the standard

value.

Standard value: 1.5-2.0 MPa (213-284 psi)

6. Gradually open the shut-off valve and reduce the hydraulic

pressure; then check whether the hydraulic pressure that

deactivates the switch is the standard value.

Standard value: 0.7-1.2 MPa (100-171 psi)

7.Remove the special tools, and then tighten the pressure hoseto the specified torque.

8. Bleed the system.

Page 676 of 1216

19-28STEERING - Power Steering Gear Box

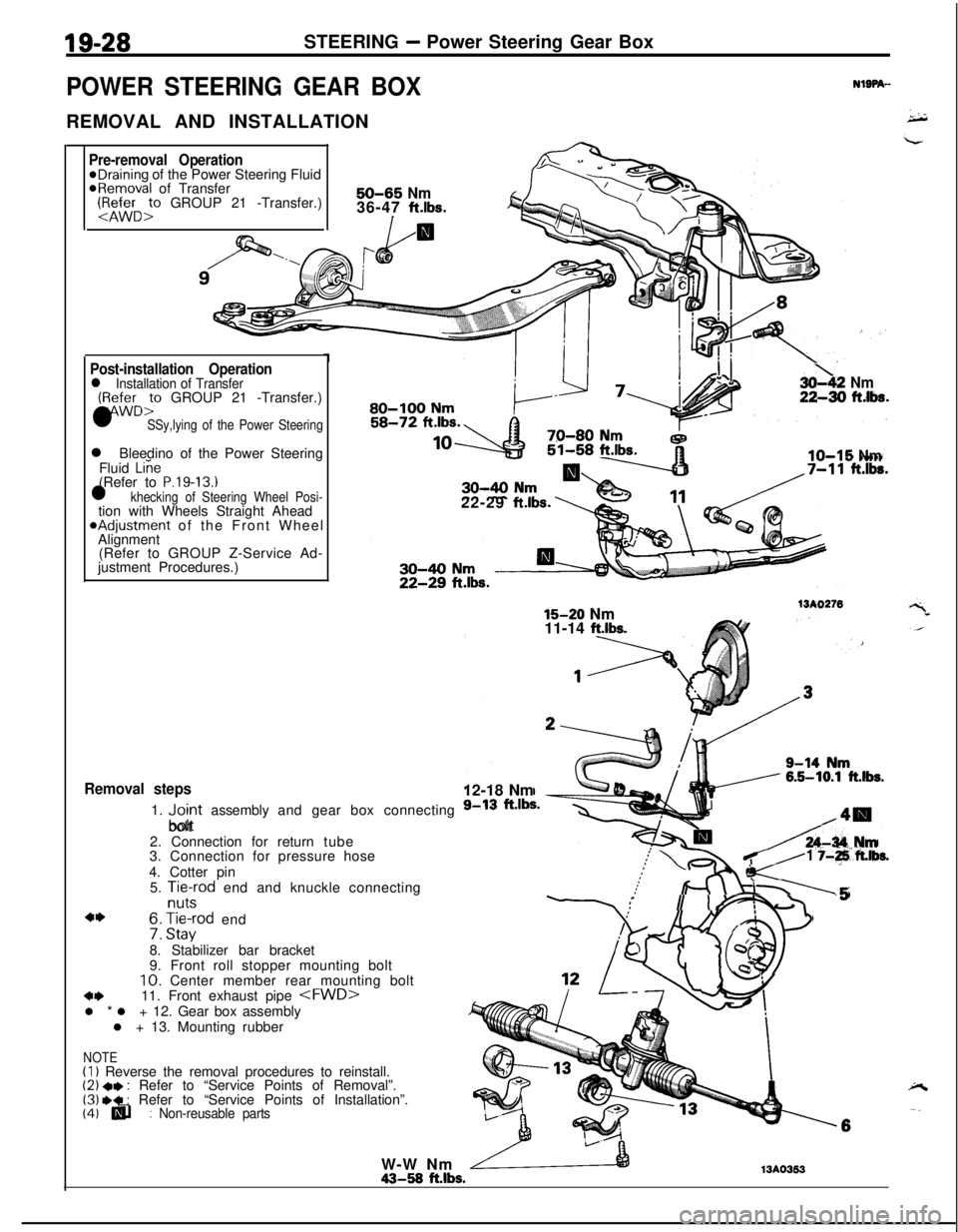

POWER STEERING GEAR BOXREMOVAL AND INSTALLATION

-

NlSPA--

Pre-removal Operation@Draining of the Power Steering Fluid@Removal of Transfer:1&&r:, GROUP 21 -Transfer.)50-65 Nm36-47 ft.lbs.

I/a

Post-installation Operationl Installation of Transfer(:zD:” GROUP 21 -Transfer.)

l SSy,lying of the Power Steeringl Bleedino of the Power Steering

Fluid

Liie(Refer to P.19-13.1l khecking of Steering Wheel Posi-tion with Wheels Straight Ahead*Adjustment of the Front Wheel

Alignment

(Refer to GROUP Z-Service Ad-

justment Procedures.)

Removal steps1.

“,;;rt assembly and gear box connecting

bolt

2. Connection for return tube

3. Connection for pressure hose

4. Cotter pin

5.

Aft-cd end and knuckle connecting

4I)f3: H,“a:od end

8. Stabilizer bar bracket

9. Front roll stopper mounting bolt10. Center member rear mounting bolt

4411. Front exhaust pipe

l + 13. Mounting rubber

(I) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) .* : Refer to “Service Points of Installation”.(4) q : Non-reusable parts(4) lli

3oh2 Nm22-30 ftlba.^a-aa I.au-IUU NrnI

IO-15 Nm22-29

ft.lbs.

15-20 Nm15-20 Nm

11-14 ft.lbs.

13A027612-18 Nm

A-34 IUm

K-

1 j-+ft.lbs.

:II I-.5

/ .2!

i!!1

NOTEW-W Nm43-58

ft.lbs.13A0353

Page 682 of 1216

19-34STEERING - Power Steering Gear Box

Guide

/Oil seal

Back-up washer13A0181

roller

13R0380

O-ring

13R037E

V&t hole

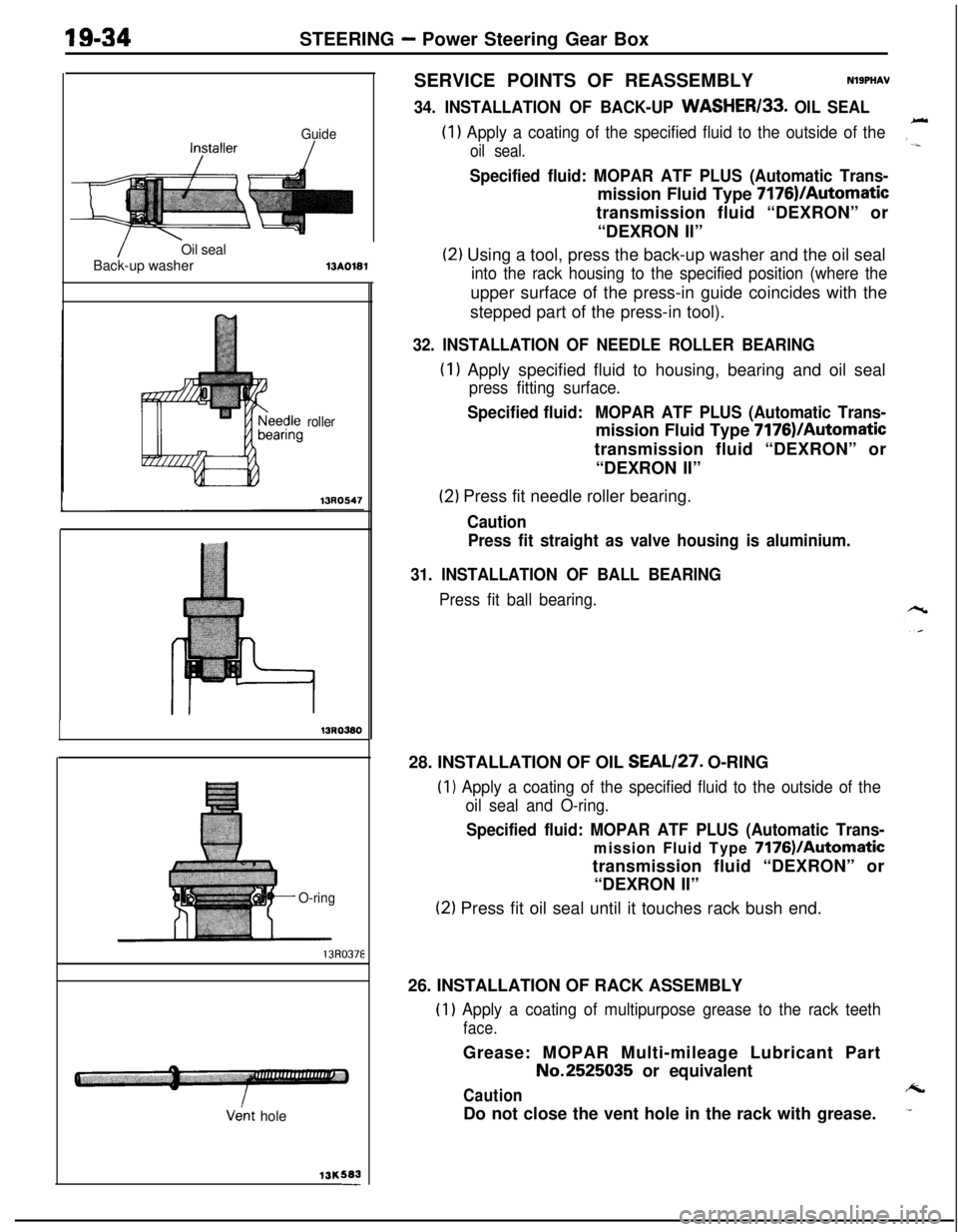

13K583-SERVICE POINTS OF REASSEMBLY

NlSPHAV

34. INSTALLATION OF BACK-UP WASHER133. OIL SEAL

(1) Apply a coating of the specified fluid to the outside of the

oil seal.

Specified fluid: MOPAR ATF PLUS (Automatic Trans-mission Fluid Type 7176)/Automatic

transmission fluid “DEXRON” or

“DEXRON II”

(2) Using a tool, press the back-up washer and the oil seal

into the rack housing to the specified position (where theupper surface of the press-in guide coincides with the

stepped part of the press-in tool).

32. INSTALLATION OF NEEDLE ROLLER BEARING

(1) Apply specified fluid to housing, bearing and oil seal

press fitting surface.

Specified fluid:MOPAR ATF PLUS (Automatic Trans-mission Fluid Type 7176)/Automatic

transmission fluid “DEXRON” or

“DEXRON II”

(2) Press fit needle roller bearing.

Caution

Press fit straight as valve housing is aluminium.

31. INSTALLATION OF BALL BEARING

Press fit ball bearing.28. INSTALLATION OF OIL SEAL/27. O-RING(I

1 Apply a coating of the specified fluid to the outside of the

oil seal and O-ring.

Specified fluid: MOPAR ATF PLUS (Automatic Trans-

mission Fluid Type 7176VAutomatictransmission fluid “DEXRON” or

“DEXRON II”

(2) Press fit oil seal until it touches rack bush end.

26. INSTALLATION OF RACK ASSEMBLY

(1) Apply a coating of multipurpose grease to the rack teeth

face.Grease: MOPAR Multi-mileage Lubricant PartNo.2525035 or equivalent

CautionDo not close the vent hole in the rack with grease.

Page 683 of 1216

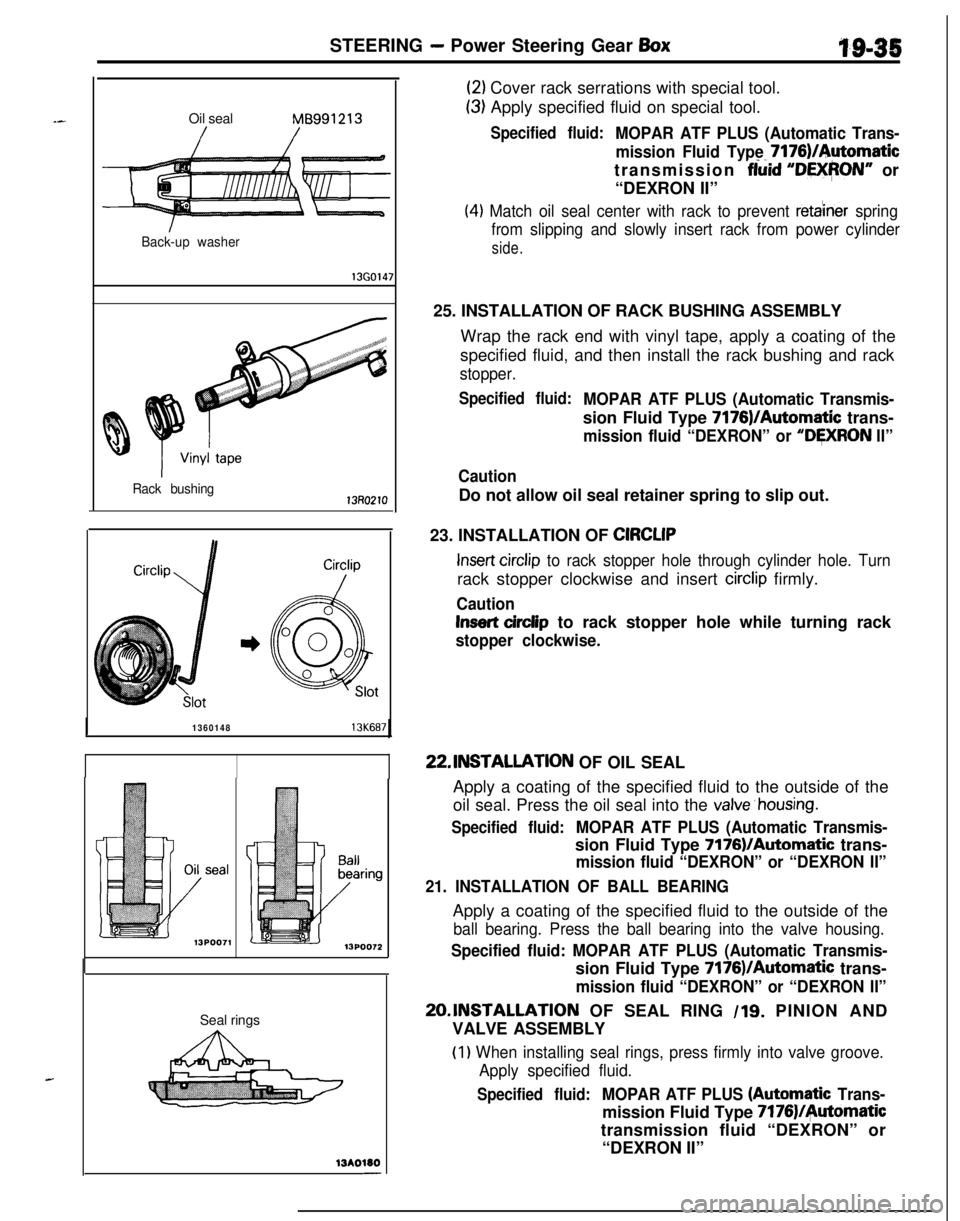

STEERING - Power Steering Gear BoxOil sealMB991213

Back-up washer

13G014;

Rack bushing

7

136014813K687Seal rings

13A0110-

(2) Cover rack serrations with special tool.

(3) Apply specified fluid on special tool.

Specified fluid:MOPAR ATF PLUS (Automatic Trans-

mission Fluid Type 7176)/Automatic

transmission

fiiid “DEXPON” or

“DEXRON II”

(4) Match oil seal center with rack to prevent reta’iner spring

from slipping and slowly insert rack from power cylinder

side.25. INSTALLATION OF RACK BUSHING ASSEMBLY

Wrap the rack end with vinyl tape, apply a coating of the

specified fluid, and then install the rack bushing and rack

stopper.

Specified fluid:MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

mission fluid “DEXRON” or “DWRON II”

CautionDo not allow oil seal retainer spring to slip out.

23. INSTALLATION OF

CIRCLIP

Insert circlip to rack stopper hole through cylinder hole. Turnrack stopper clockwise and insert

circlip firmly.

Caution

Insert cirdip to rack stopper hole while turning rack

stopper clockwise.22.lNSTALLATlON OF OIL SEAL

Apply a coating of the specified fluid to the outside of the

oil seal. Press the oil seal into the

valve’housing.

Specified fluid:MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type

7176VAutomatic trans-

mission fluid “DEXRON” or “DEXRON II”

21. INSTALLATION OF BALL BEARINGApply a coating of the specified fluid to the outside of the

ball bearing. Press the ball bearing into the valve housing.

Specified fluid: MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

mission fluid “DEXRON” or “DEXRON II”

20,lNSTALLATlON OF SEAL RING /lg. PINION AND

VALVE ASSEMBLY

(1) When installing seal rings, press firmly into valve groove.

Apply specified fluid.

Specified fluid:MOPAR ATF PLUS (Autombtic Trans-mission Fluid Type

7176)/+tomatictransmission fluid “DEXRON” or

“DEXRON II”

Page 684 of 1216

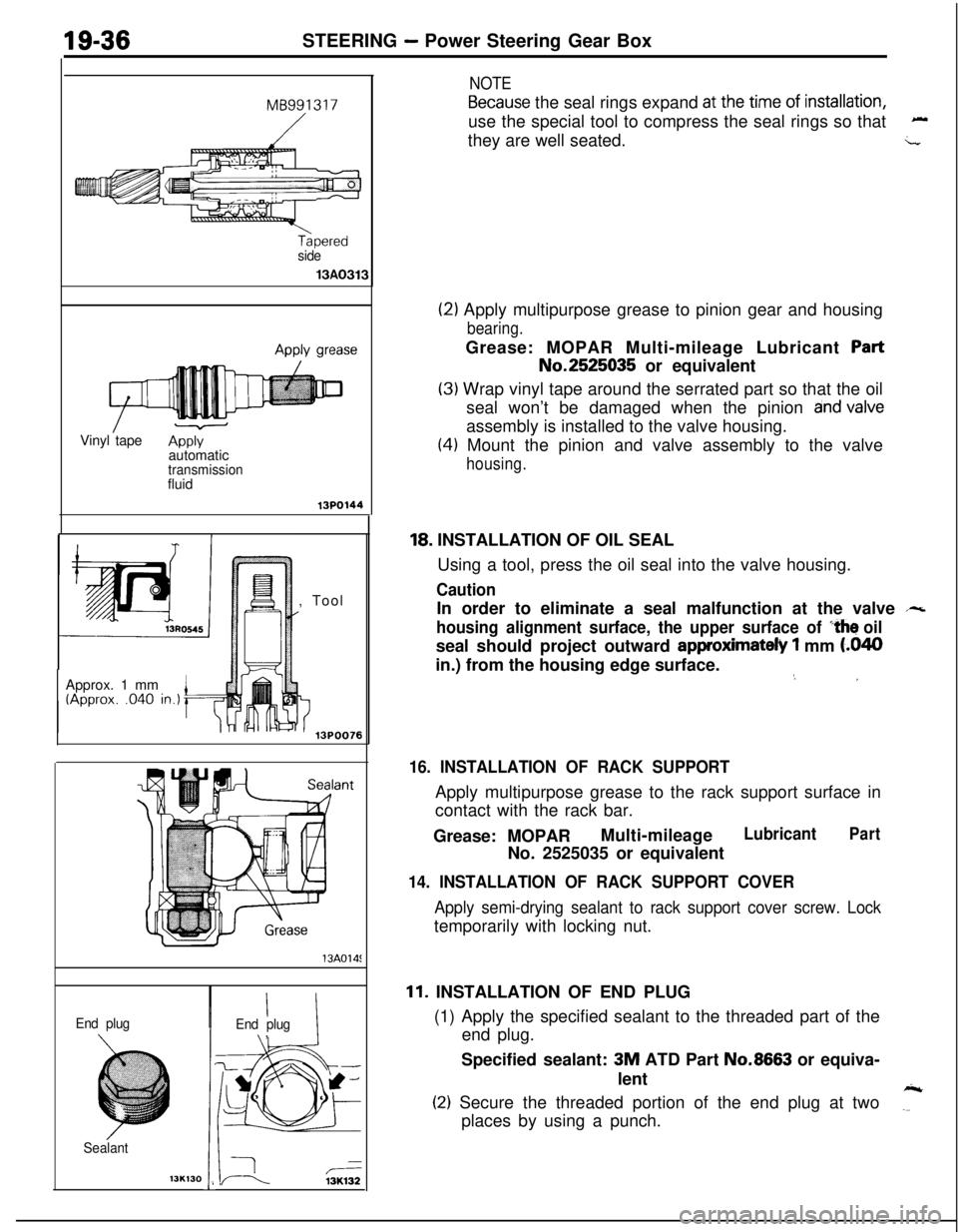

19-36STEERING - Power Steering Gear BoxMB991317

side

13A031fVinyl tape

APP~automatic

transmissionfluid

13POl44

IApprox. 1 mm

(Approx. ,040 in.)i, Tool

’ 13POO76

13A014:

End plug

Sealant

13K,30II

I

IEnd plug\ ,I

NOTE

Because the seal rings expand at the time of installation,use the special tool to compress the seal rings so that

-they are well seated.

L

(2) Apply multipurpose grease to pinion gear and housing

bearing.Grease: MOPAR Multi-mileage Lubricant

PartNo.2525035 or equivalent

(3) Wrap vinyl tape around the serrated part so that the oil

seal won’t be damaged when the pinion

and valveassembly is installed to the valve housing.

(4) Mount the pinion and valve assembly to the valve

housing.

18. INSTALLATION OF OIL SEAL

Using a tool, press the oil seal into the valve housing.

CautionIn order to eliminate a seal malfunction at the valve

-

housing alignment surface, the upper surface of -the oilseal should project outward

approximatelv 1 mm t.040in.) from the housing edge surface.

‘, I

16. INSTALLATION OF RACK SUPPORTApply multipurpose grease to the rack support surface in

contact with the rack bar.

Grease: MOPARMulti-mileage

LubricantPartNo. 2525035 or equivalent

14. INSTALLATION OF RACK SUPPORT COVER

Apply semi-drying sealant to rack support cover screw. Locktemporarily with locking nut.

11. INSTALLATION OF END PLUG

(1) Apply the specified sealant to the threaded part of the

end plug.

Specified sealant:

3M ATD Part No.6663 or equiva-

lent

rL-

(2) Secure the threaded portion of the end plug at two._places by using a punch.

Page 687 of 1216

STEERING - Power Steering Oil Pump1849

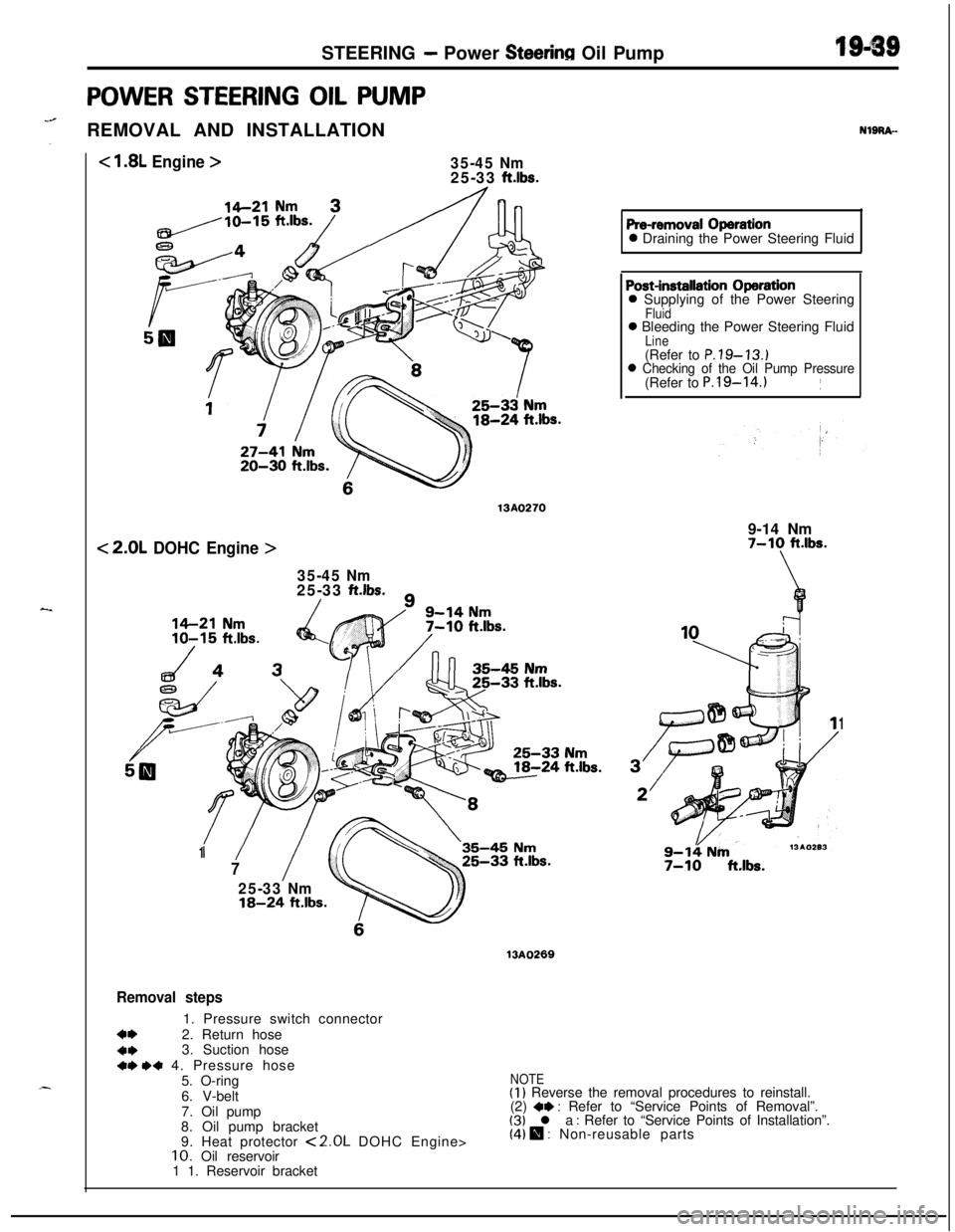

POWER STEERING OIL PUMP

“@REMOVAL AND INSTALLATION

< 1.8L Engine >35-45 Nm25-33 ft.lbs.

20-30 ft.lbs.

13A0270

< 2.0L DOHC Engine >

35-45 Nm25-33 ft.lbs./

NlgRA-

Pre-removal Operation0 Draining the Power Steering Fluid

‘/1

7

25-33 Nm18-24 ft.lbs.

35-45 Nm

Post-installation Operation0 Supplying of the Power Steering

Fluid0 Bleeding the Power Steering Fluid

Line(Refer to P.79-13.)0 Checking of the Oil Pump Pressure(Refer to P.l9-14.)~

9-14 Nm

7-10 ft.lbs.

\

1

9-14 Nm7-10 ft.lbs.

13AO269

Removal steps1. Pressure switch connector

a*2. Return hose

4*3. Suction hose+r) .+ 4. Pressure hose

5. O-ring

6. V-belt

7. Oil pump

8. Oil pump bracket

9. Heat protector

<2.0L DOHC Engine>10. Oil reservoir

1 1. Reservoir bracket

NOTE(I) Reverse the removal procedures to reinstall.

(2) *I) : Refer to “Service Points of Removal”.(3) l a : Refer to “Service Points of Installation”.(4) 0 : Non-reusable parts

Page 688 of 1216

1 S-40STEERING - Power Steering Oil Pump

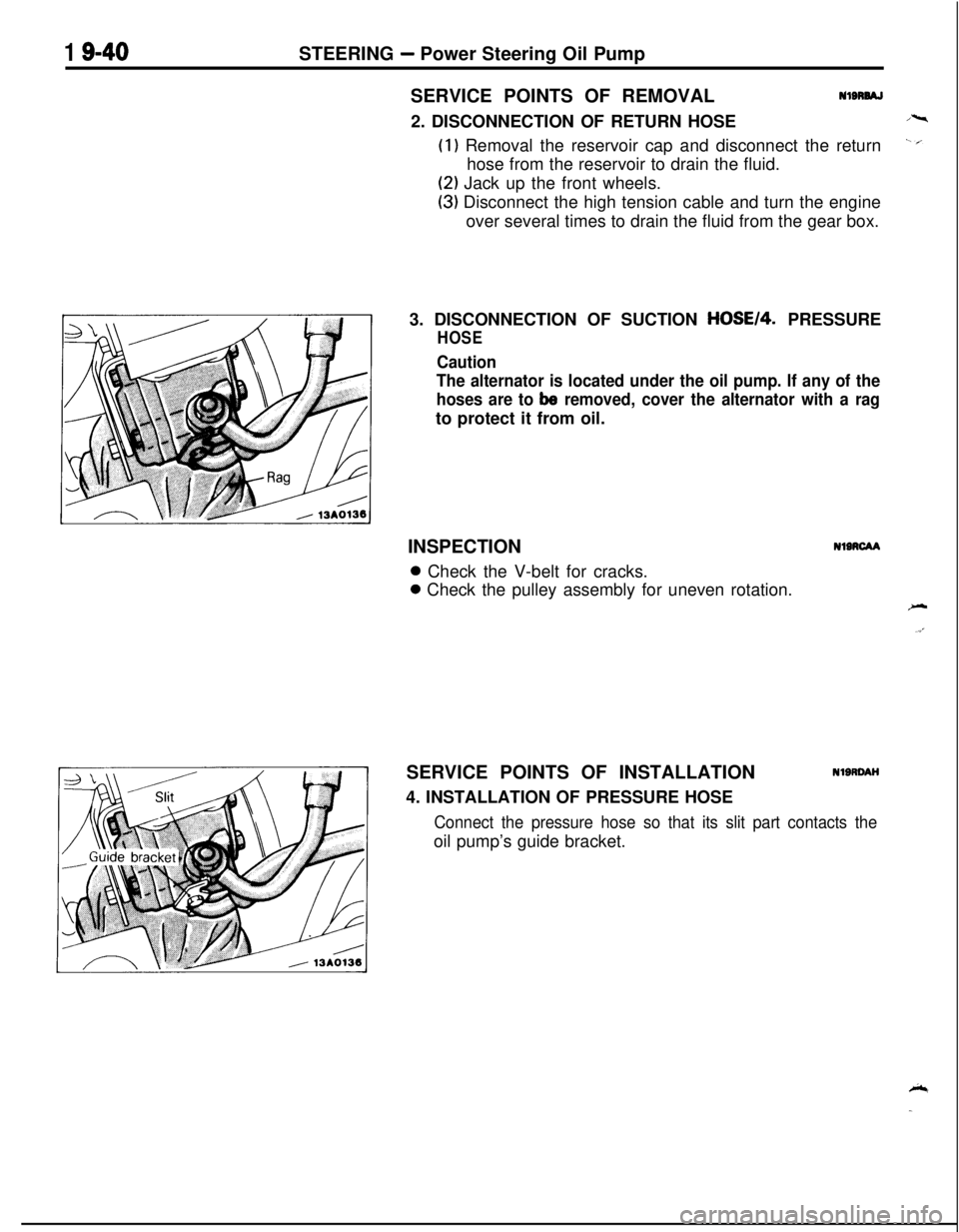

SERVICE POINTS OF REMOVAL

Nl8RW2. DISCONNECTION OF RETURN HOSE

(1) Removal the reservoir cap and disconnect the return

hose from the reservoir to drain the fluid.

(2) Jack up the front wheels.

(3) Disconnect the high tension cable and turn the engine

over several times to drain the fluid from the gear box.

3. DISCONNECTION OF SUCTION

HOSE14. PRESSURE

HOSE

Caution

The alternator is located under the oil pump. If any of the

hoses are to

be removed, cover the alternator with a ragto protect it from oil.

INSPECTION

NIRCAA0 Check the V-belt for cracks.0 Check the pulley assembly for uneven rotation.

SERVICE POINTS OF INSTALLATION

4. INSTALLATION OF PRESSURE HOSE

NlSRDAH

Connect the pressure hose so that its slit part contacts theoil pump’s guide bracket.

Page 691 of 1216

STEERING - Power Steering Oil Pump

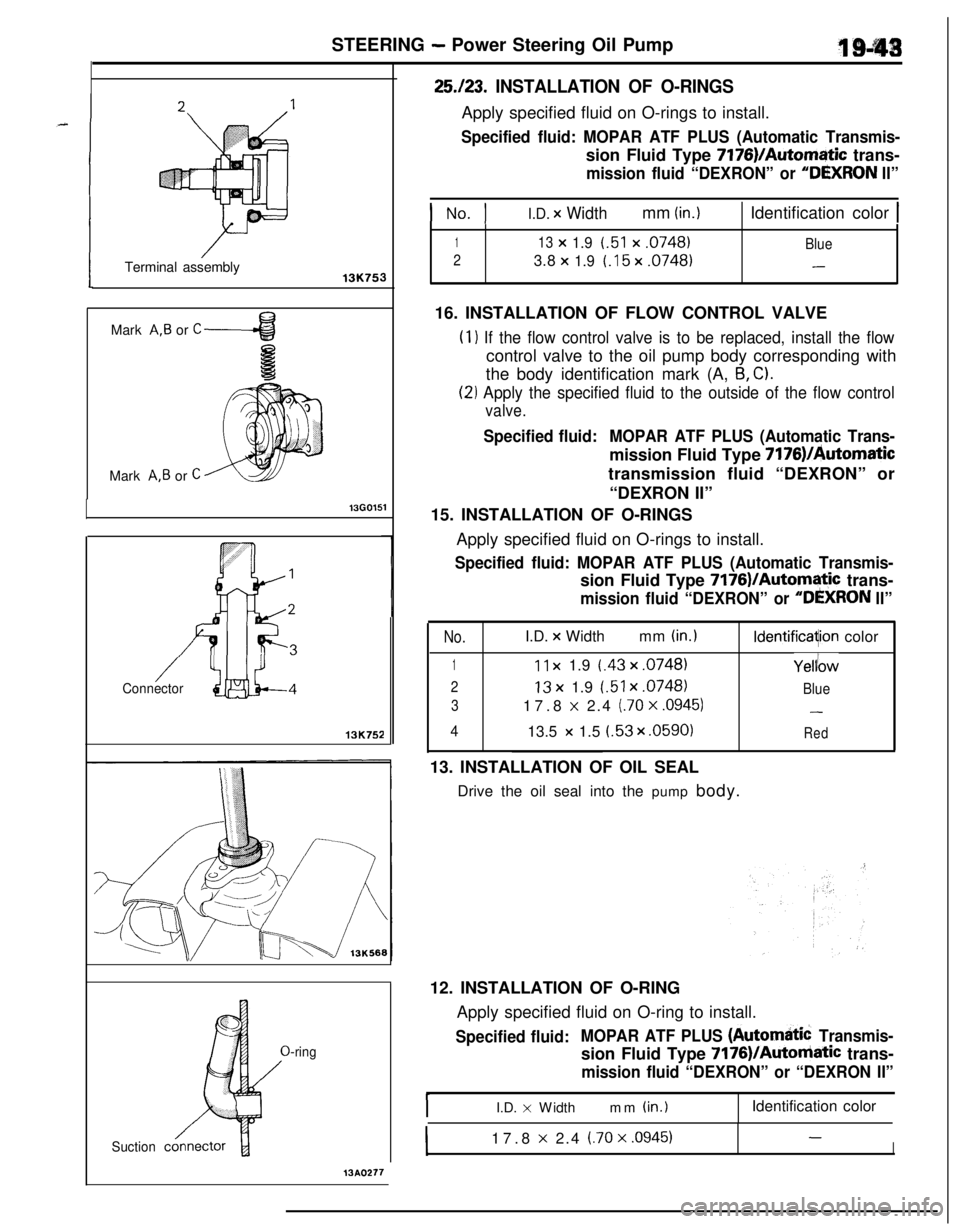

Terminal assembly

13K753Mark

A,B or C-43Mark

A,B or C

13G0151

/Connector13K752

Suction-ring

25.123. INSTALLATION OF O-RINGSApply specified fluid on O-rings to install.

Specified fluid: MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

mission fluid “DEXRON” or “DGXRON II”

I No. II.D. x Widthmm (in.)1 Identification color 1

113x1.9t.51x.0748)Blue

23.8

x1.9l.15x.0748)-16. INSTALLATION OF FLOW CONTROL VALVE

(1) If the flow control valve is to be replaced, install the flowcontrol valve to the oil pump body corresponding with

the body identification mark (A,

6, C).

(2) Apply the specified fluid to the outside of the flow control

valve.

Specified fluid:MOPAR ATF PLUS (Automatic Trans-mission Fluid Type

7176)/htomatictransmission fluid “DEXRON” or

“DEXRON II”

15. INSTALLATION OF O-RINGS

Apply specified fluid on O-rings to install.

Specified fluid: MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

mission fluid “DEXRON” or “DlkXRON II”

No.I.D. x Widthmm (in.)

1I 1 x 1.9 t.43 x .0748)

213x 1.9 l.51 x .0748)

317.8 x 2.4 j.70 X .0945)

413.5 x 1.5 t.53 x .0590)

ldentificaqion color

Yelllow

Blue

-

Red13. INSTALLATION OF OIL SEAL

Drive the oil seal into the pump body.

12. INSTALLATION OF O-RING

Apply specified fluid on O-ring to install.

Specified fluid:MOPAR ATF PLUS (Automatib Transmis-sion Fluid Type 7176)/Autoniatic trans-

mission fluid “DEXRON” or “DEXRON II”I.D.

x Widthmm (in.)Identification color

I17.8 x 2.4 (.70 x .0945)-I

13A0277

Page 692 of 1216

19-44STEERING - Power Steering Oil Pump

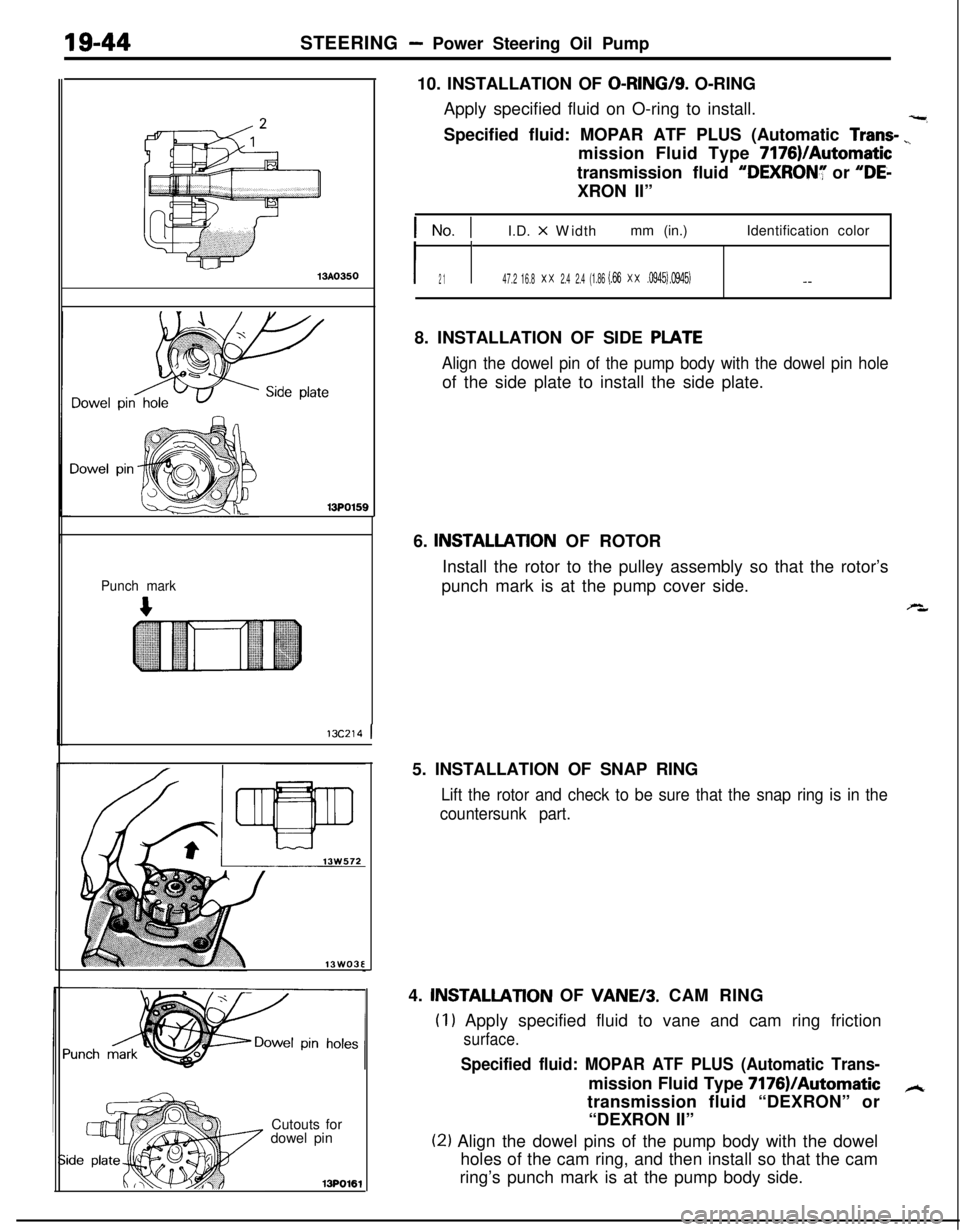

13AO350

13PO159

Punch mark

13c214 I

13W03ECutouts for

dowel pin

13PO16110. INSTALLATION OF

O-RING/S. O-RING

Apply specified fluid on O-ring to install.

-,Specified fluid: MOPAR ATF PLUS (Automatic

Trans- ”mission Fluid Type 7176)/Automatic

transmission fluid

“DEXRONY or “DE-XRON II”

1 No. 1I.D. x Widthmm (in.)Identification color

I2 1I47.2 16.8x x2.4 2.4(1.86 (.66x x.0945) .0945)- -8. INSTALLATION OF SIDE

PLATE

Align the dowel pin of the pump body with the dowel pin holeof the side plate to install the side plate.

6.

INSTALLATlON OF ROTOR

Install the rotor to the pulley assembly so that the rotor’s

punch mark is at the pump cover side.

s,5. INSTALLATION OF SNAP RING

Lift the rotor and check to be sure that the snap ring is in the

countersunk part.4.

INSTALLATlON OF VANE/3. CAM RING

(I1 Apply specified fluid to vane and cam ring friction

surface.

Specified fluid: MOPAR ATF PLUS (Automatic Trans-mission Fluid Type 7176)IAutomatic

Atransmission fluid “DEXRON” or

“DEXRON II”

(21 Align the dowel pins of the pump body with the dowel

holes of the cam ring, and then install so that the cam

ring’s punch mark is at the pump body side.