alarm MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 571 of 1216

i-._AUTO-CRUISE CONTROL SYSTEM

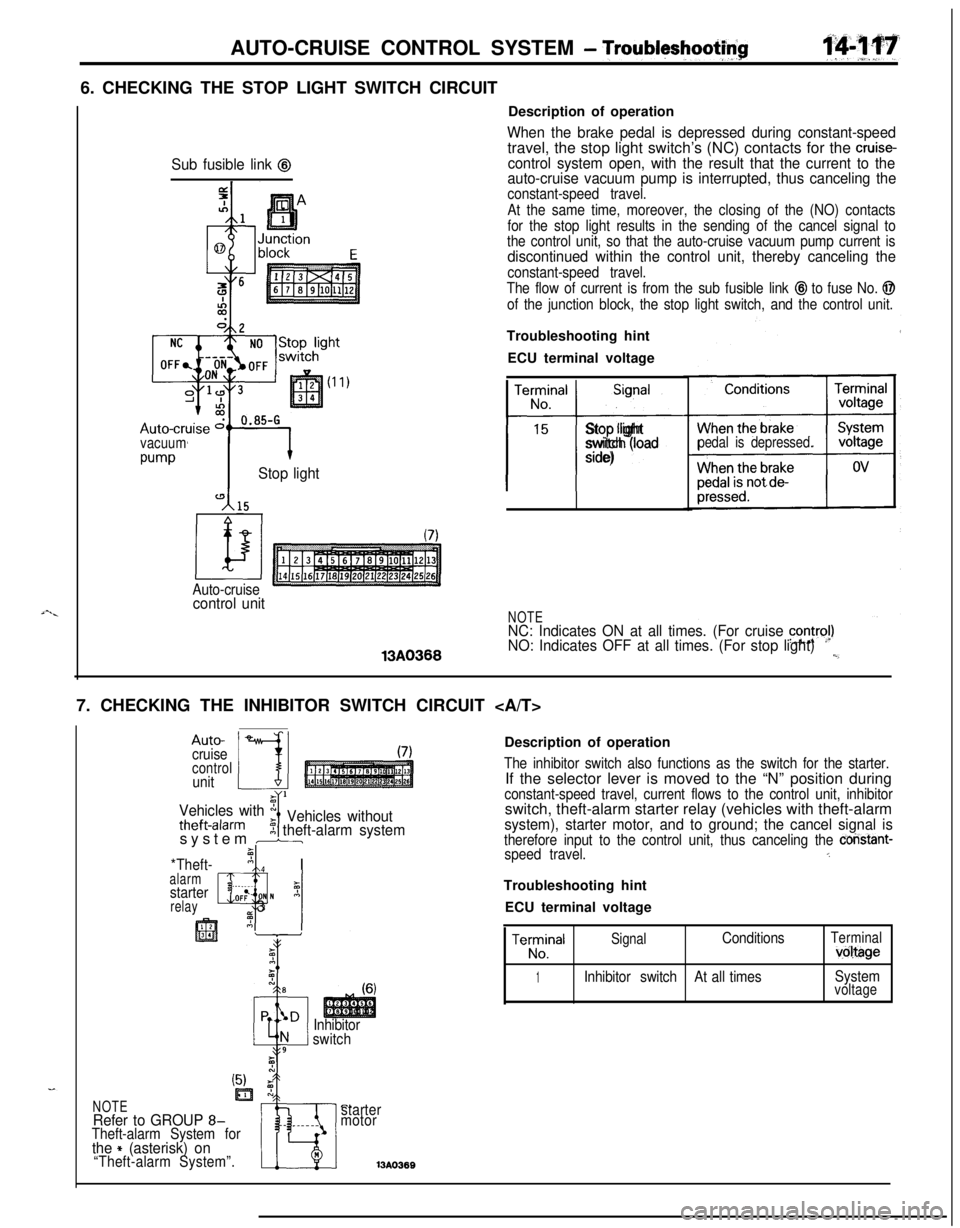

- Troubltyshootf$6. CHECKING THE STOP LIGHT SWITCH CIRCUIT

Sub fusible link @

vacuum

w-vStop light

Auto-cruisecontrol unit13A0366Description of operation

When the brake pedal is depressed during constant-speedtravel, the stop light switch’s (NC) contacts for the cruise-control system open, with the result that the current to the

auto-cruise vacuum pump is interrupted, thus canceling the

constant-speed travel.

At the same time, moreover, the closing of the (NO) contacts

for the stop light results in the sending of the cancel signal to

the control unit, so that the auto-cruise vacuum pump current is

discontinued within the control unit, thereby canceling the

constant-speed travel.

The flow of current is from the sub fusible link

@I to fuse No. @

of the junction block, the stop light switch, and the control unit.Troubleshooting hint

ECU terminal voltage

TerminalSignal

No.

15

t-i-

Stop light

switch (load

side)pedal is depressed.

NOTENC: Indicates ON at all times. (For cruise contra!)NO: Indicates OFF at all times. (For stop light)l,_7. CHECKING THE INHIBITOR SWITCH CIRCUIT

Auto-

cruise

controlunit

Vehicles with x

theft-alarmIVehicles without5 theft-alarm systemsystem br

*Theft-’ nI Ialarm, ._I

starterz

relayQlOF: N A_ 3

Inhibitor

switchDescription of operation

The inhibitor switch also functions as the switch for the starter.If the selector lever is moved to the “N” position during

constant-speed travel, current flows to the control unit, inhibitorswitch, theft-alarm starter relay (vehicles with theft-alarm

system), starter motor, and to ground; the cancel signal istherefore input to the control unit, thus canceling the constant-speed travel.5Troubleshooting hint

ECU terminal voltage

TeE!alSignalConditionsTerminalvoltage

1Inhibitor switchAt all timesSystemvoltage

C.starter

motor13A036BNOTERefer to GROUP 8-Theft-alarm System forthe + (asterisk) on“Theft-alarm System”.

Page 585 of 1216

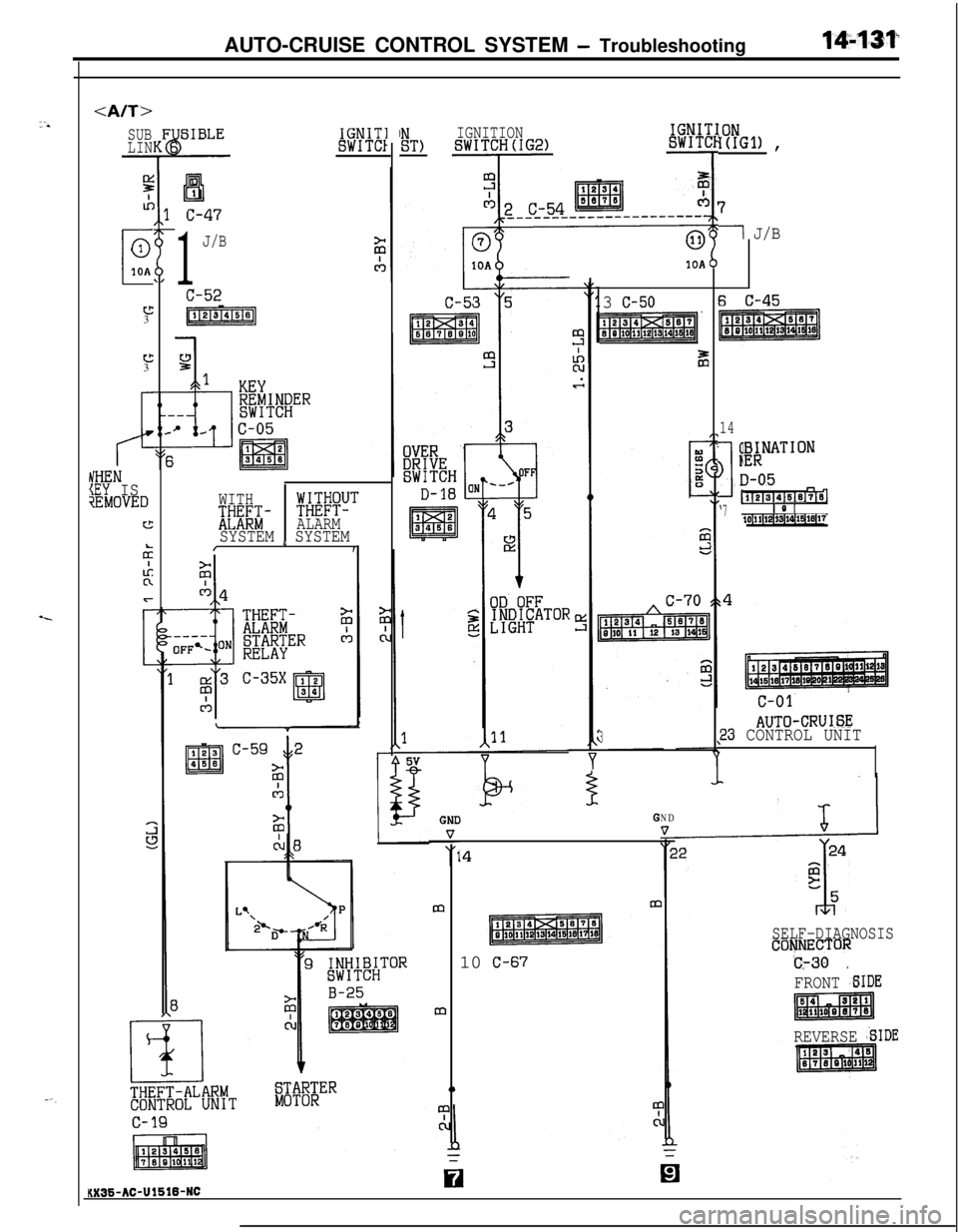

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting14L’1.31”

-=cA/T>

SUB

LIN

!z

A

c

0

10A

c3

c3

h'HEN{EY IS?EMOVED

c

2Iu-zn

r

:ONI(IG1) ,INIGNITIONST)SWITCH(IG2)

-1

SIBLE

4

raII31

c-47

1

J/B

C-52

(liIals14r51sl]

IGNITISWITCI

1 J/B10A

3 c-50

7Flimsq’

z

6 c-45

14

LW$NATION

9

I, ,D-05

‘71(2~3~41516~715“‘I0 1lo~llll~l3ll4pm7

WITH

iEK;Si-

#gpT

ALARMSYSTEM I SYSTEMI,

AUTO-CRUI6E,23 CONTROL UNIT

73

i

GND

14

m10

C-67

m

0

KX35-AC-Ul516-NCn

SELF-DIAGNOSISCOt$NECTOR

c-30 :

FRONT 'SIDE

piELRq

REVERSE ,-SIDE

Page 897 of 1216

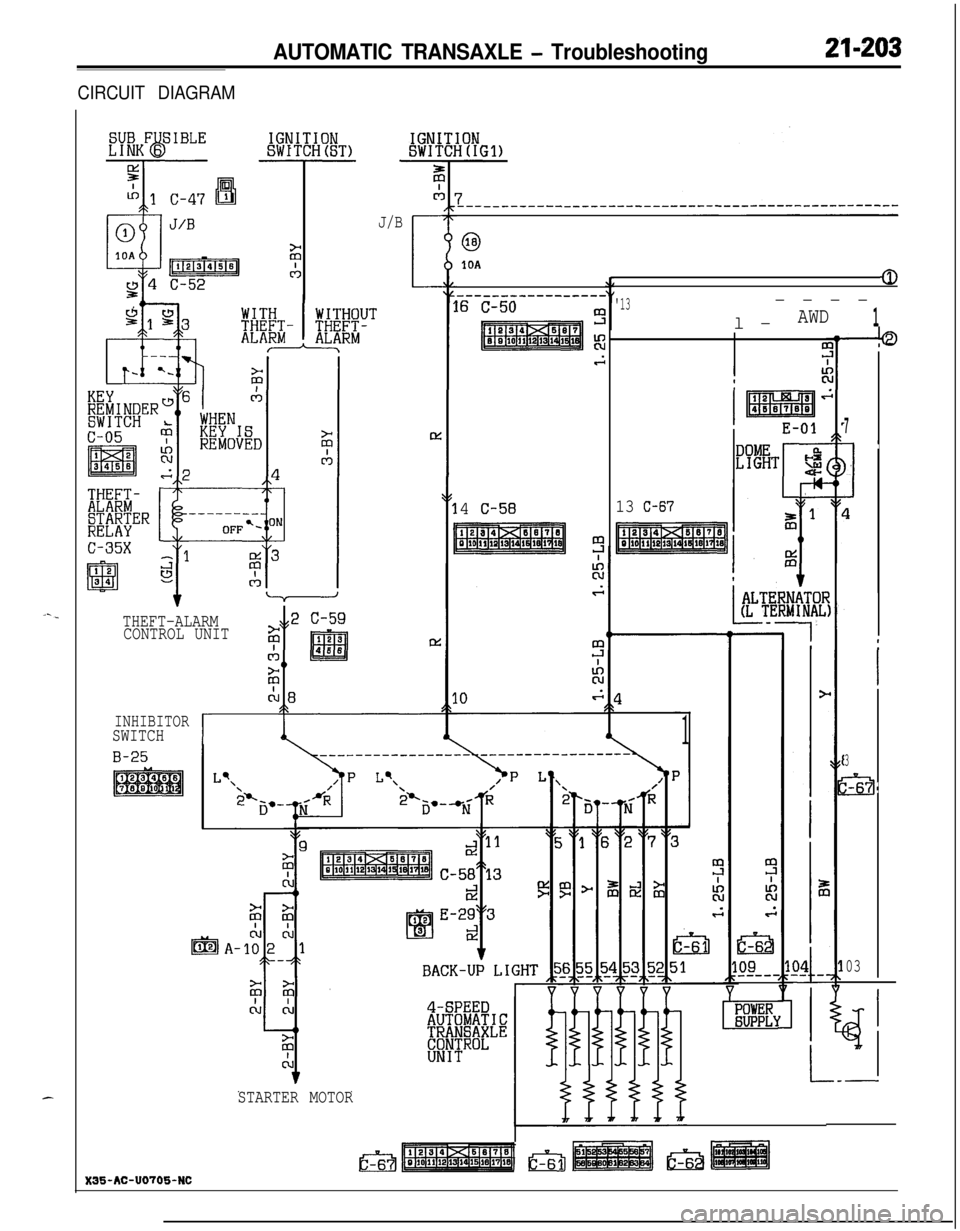

AUTOMATIC TRANSAXLE - Troubleshooting21-203

CIRCUIT DIAGRAM

J/B

63IOA

0

'13l-----AWD1

cL

13 C-67

1

'OU'EiRaPPLl

--b

7

1'

I

I

3

xl:- 71

03

4

I

L--

-----------------16 C-502zs

4

C-58

El

THEFT-ALARM

CONTROL UNIT

INHIBITORSWITCH

B-25

r

STARTER MOTOR

X35-AC-U0705-NC

Page 1055 of 1216

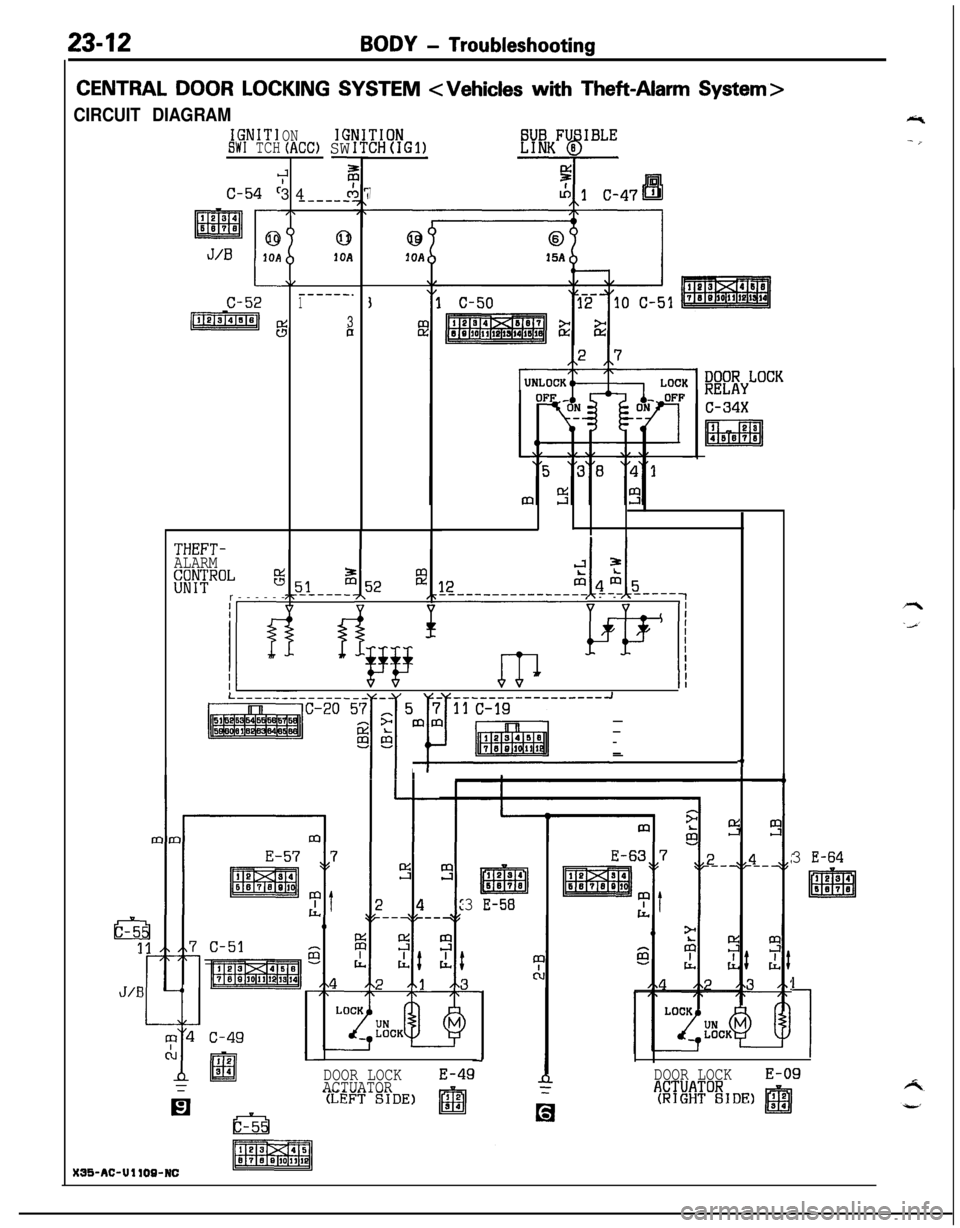

BODY - Troubleshooting234'1

CENTRAL DOOR LOCKING SYSTEM

CIRCUIT DIAGRAM..-

,-.

SUB FU0IBLELINK 8

g

J/Bk 1 c-47 'B

@

L

10A

L

is411

J/B

L

4c

c-51

c-49

12

al34

3 E-64

DOOR LOCKE-49DOOR LOCKE-09

KX3b-AC-WIOB-Xi:

Page 1056 of 1216

2342BODY - Troubleshooting

CENTRAL DOOR LOCKING SYSTEM

CIRCUIT DIAGRAM

IGNITISW1 TCH

c

c-54 c

ONIGI(ACC) SW-

r'334

9P------.IX

0

10A

\/------.1

43bC-52-:

THEFT-ALARMg$;ROL $jr------51z------.

I

CH(IG1)

7

431OA

1

fl

fiie;yLOCK

c-34x

f!iiGqII

?

$4m5--- -----1!2---w---w---: (II

IL-++;I

II

j2s9

L--------------- _

C-20 5~7f.f5,8m~ii-~,i;----'

I1

3 E-50

3 E-64

1

1

X95-AC-Ull00-NC

DOOR LOCKE-09%%8°iIDE,

m

DOOR LOCKE-49

ACTUATOR

Page 1057 of 1216

BODY - Troubleshooting23-13

OPERATION

TROUBLESHOOTING HINTS

-.l If the inside lock knobs of the doors are placedin the LOCK (or UNLOCK) position, the switch inthe door lock actuator will be “OFF” (or “ON”),

and the output transistor will be “ON” for 0.5

second according to the timer function in the

door lock control unit (or theft-alarm control unit).As a result, the LOCK side (or UNLOCK side) of

the door lock relay will be “ON”, operating the

actuators of all of the doors.

NOTE

The door lock actuator contains a PTC thermistor

to prevent damage caused by overheating of the

motor. If the central door lock is frequently used,the actuator may temporarily fail to operate. If it

returns to normal in a few minutes, it is not

defective.

1.

2.One of the door lock actuators fails to operate.

l Check the door actuator which fails to

operate.Cannot be placed in the LOCK or UNLOCK

position by the inside lock knob on either driver’s

or front passenger’s seat side.0 Check the switch in the actuator.0 Check the door lock control unit (or

theft-alarm control unit).

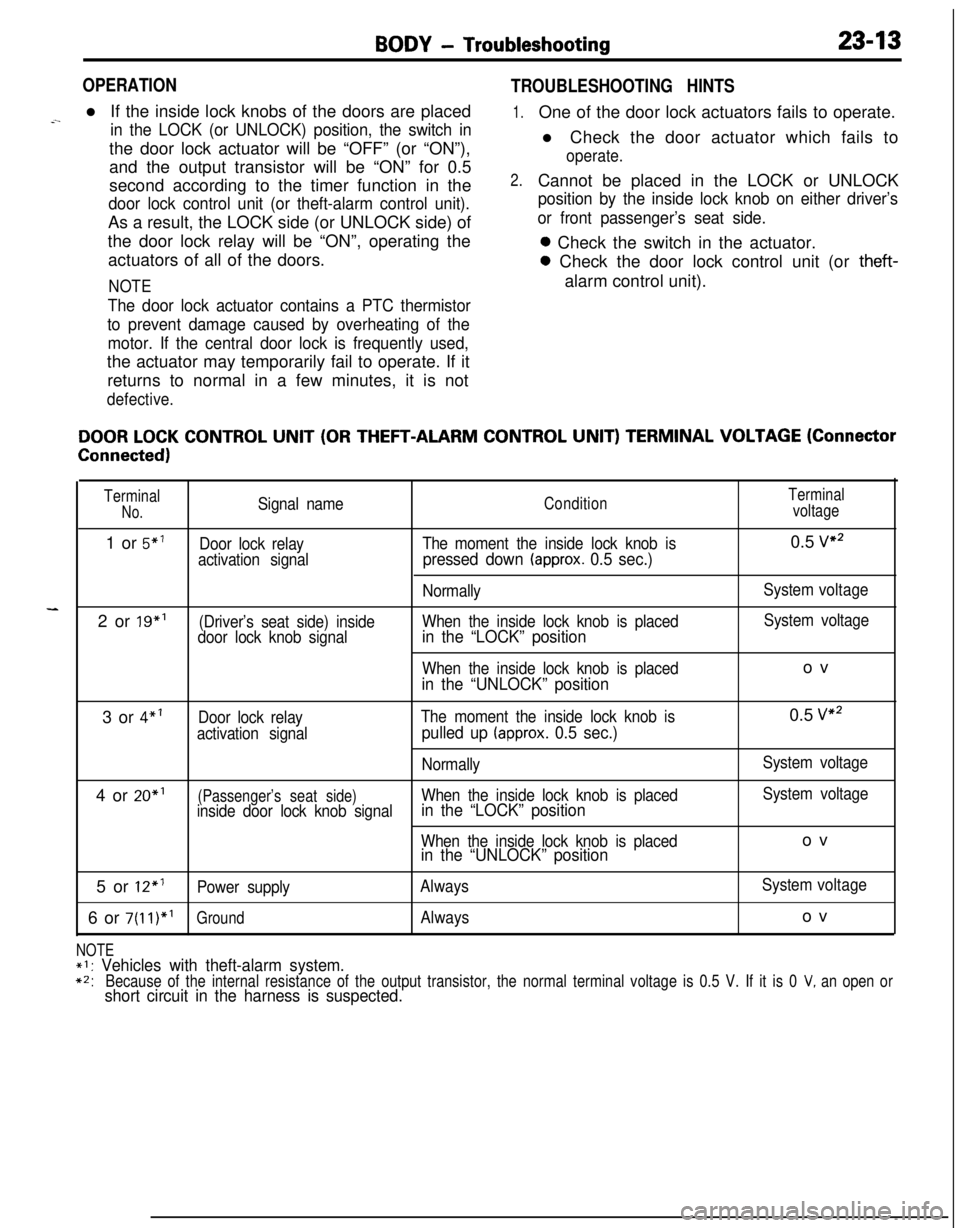

DOOR LOCK CONTROL UNIT (OR THEFT-ALARM CONTROL UNIT) TERMINAL VOLTAGE (Connector

Connected)

TerminalSignal nameConditionTerminalNo.voltage1 or

5”’Door lock relayThe moment the inside lock knob is0.5 vs2

activation signal

pressed down (approx. 0.5 sec.)

NormallySystem voltage2 or 19”’

(Driver’s seat side) insideWhen the inside lock knob is placedSystem voltage

door lock knob signalin the “LOCK” position

When the inside lock knob is placedov

in the “UNLOCK” position3 or

4”’Door lock relayThe moment the inside lock knob is0.5 v2

activation signalpulled up (approx. 0.5 sec.)

NormallySystem voltage4 or 20”’

(Passenger’s seat side)When the inside lock knob is placedSystem voltage

inside door lock knob signalin the “LOCK” position

When the inside lock knob is placedovin the “UNLOCK” position5 or

12*’Power supplyAlwaysSystem voltage6 or

7(11)*’GroundAlwaysov

NOTE*I: Vehicles with theft-alarm system.

*2:Because of the internal resistance of the output transistor, the normal terminal voltage is 0.5 V. If it is 0 V, an open orshort circuit in the harness is suspected.

Page 1078 of 1216

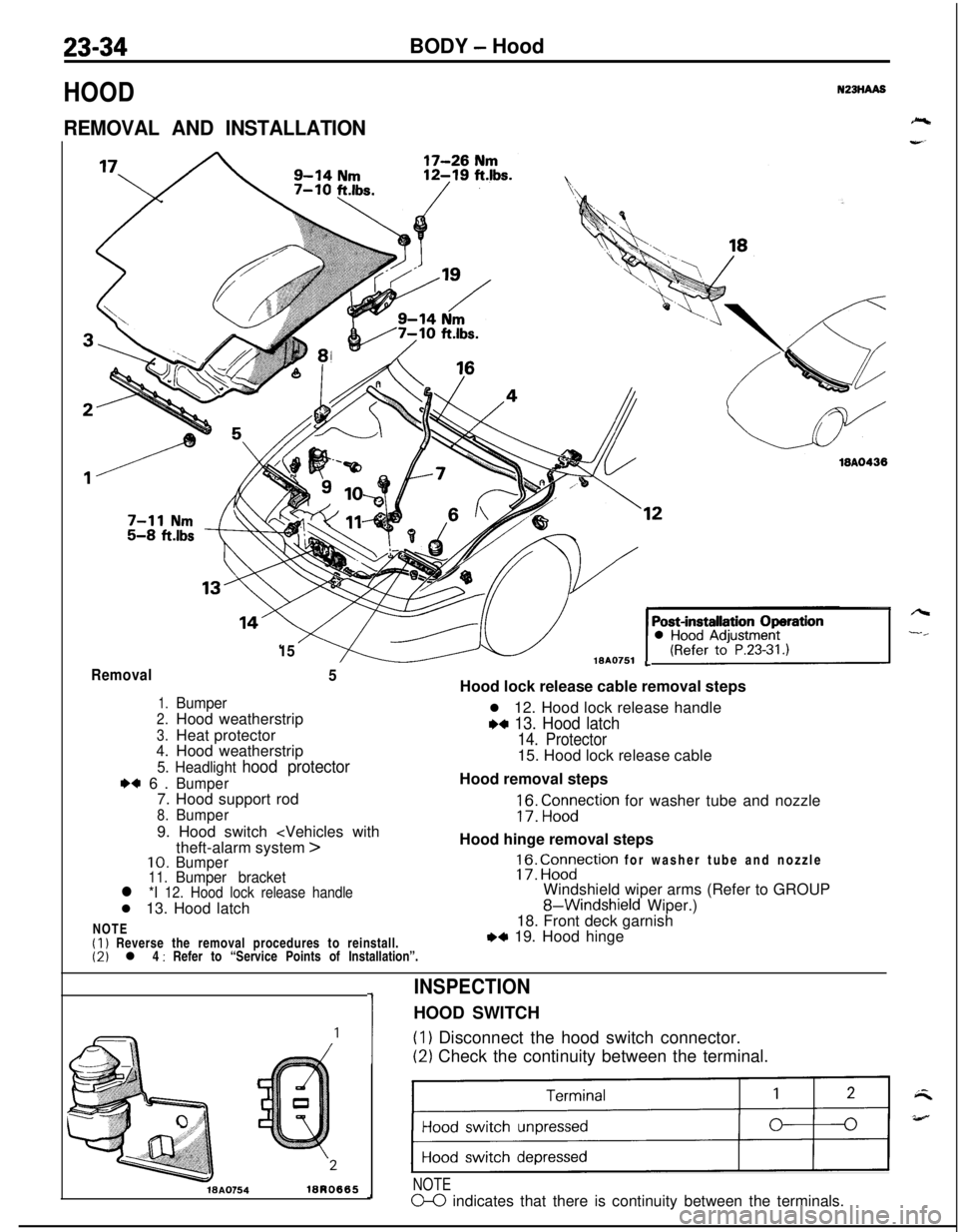

23-34BODY - Hood

HOOD

REMOVAL AND INSTALLATION

N23HAA8

1518AO751

18A0438

LRemoval5

1.Bumper

2.Hood weatherstrip

3.Heat protector4.Hood weatherstrip

5. Headlight hood protector

I)+ 6.Bumper7. Hood support rod

8.Bumper9. Hood switch

>10.Bumper11.Bumper bracketl *I 12. Hood lock release handlel 13. Hood latch

NOTE

(1) Reverse the removal procedures to reinstall.(2) l 4 : Refer to “Service Points of Installation”.Hood lock release cable removal steps

l 12. Hood lock release handle

w 13. Hood latch

14. Protector15. Hood lock release cable

Hood removal steps

;f3: “,;n,yction for washer tube and nozzle

Hood hinge removal steps

17: ig?ction for washer tube and nozzle

Windshield wiper arms (Refer to GROUP

8-Windshield Wiper.)

18. Front deck garnish

,*I 19. Hood hinge

1

INSPECTIONHOOD SWITCH(I

1 Disconnect the hood switch connector.

(2) Check the continuity between the terminal.

WA0754lBRO665

)

NOTE

m indicates that there is continuity between the terminals.

Page 1080 of 1216

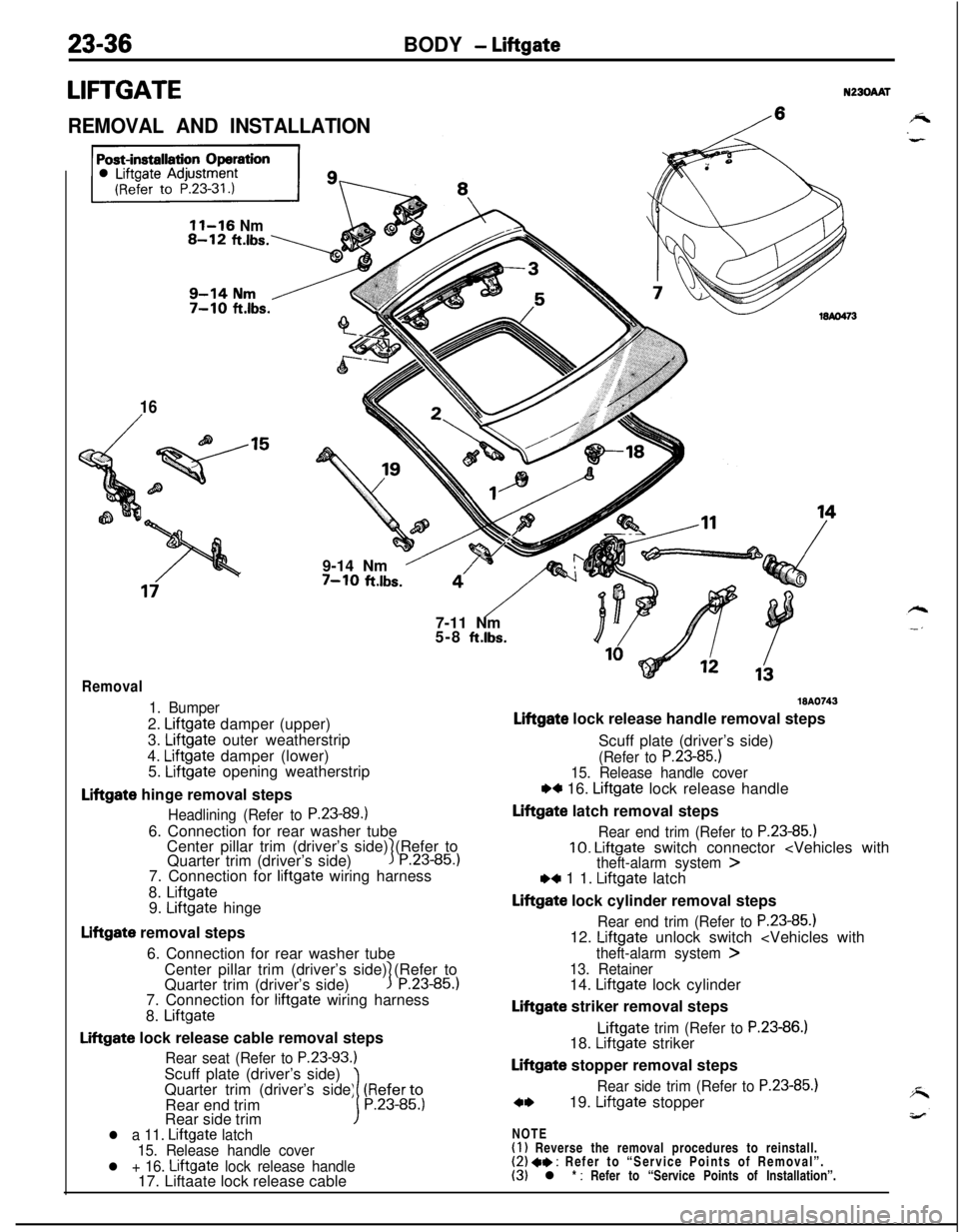

23-36BODY - Liftgate

LIFTGATEN230AAT

REMOVAL AND INSTALLATION/

11-16 Nm

16

/9-14 Nm

’7-10 ft.lbs.

“‘/- -$j7-11 Nm

5-8

ft.lbs.

Removal

1. Bumper2.

Liftgate damper (upper)

3.

Liftgate outer weatherstrip

4.

Liftgate damper (lower)

5. Liftgate opening weatherstrip

Liftgate hinge removal steps

Headlining (Refer to P.23-89.16. Connection for rear washer tube

Center pillar trim (driver’s side) (Refer to

Quarter trim (driver’s side)

3P.23-85.)7. Connection for

liftgate wiring harness

8.

Liftgate9. Liftgate hinge

Liftgate removal steps

6. Connection for rear washer tube

Center pillar trim (driver’s side) (Refer to

Quarter trim (driver’s side)

1P.23-85.)7. Connection for

liftgate wiring harness

8.

Liftgate

Liftgate lock release cable removal steps

Rear seat (Refer to P.23-93.)Scuff plate (driver’s side)

Quarter trim (driver’s side) (Referto

Rear end trim

1P.23-85.)Rear side trim

l a 11. Liftgate latch

15. Release handle cover

l + 16. Liftgate lock release handle17. Liftaate lock release cable

WA0743

Liftgate lock release handle removal steps

Scuff plate (driver’s side)

(Refer to P.23-85.)15. Release handle cover

w 16. Liftgate lock release handle

Liftgate latch removal steps

Rear end trim (Refer to P.23-85.)10. Liftgate switch connector

Liftgate lock cylinder removal steps

Rear end trim (Refer to P.23-85.112. Liftgate unlock switch

13. Retainer14. Liftgate lock cylinder

Liftgate striker removal stepsLiftgate

trim (Refer to P.23-86.)18. Liftgate striker

Liftgate stopper removal steps

Rear side trim (Refer to P.23-85.)

c*19. Liftgate stopper

NOTE

(1) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.

Page 1113 of 1216

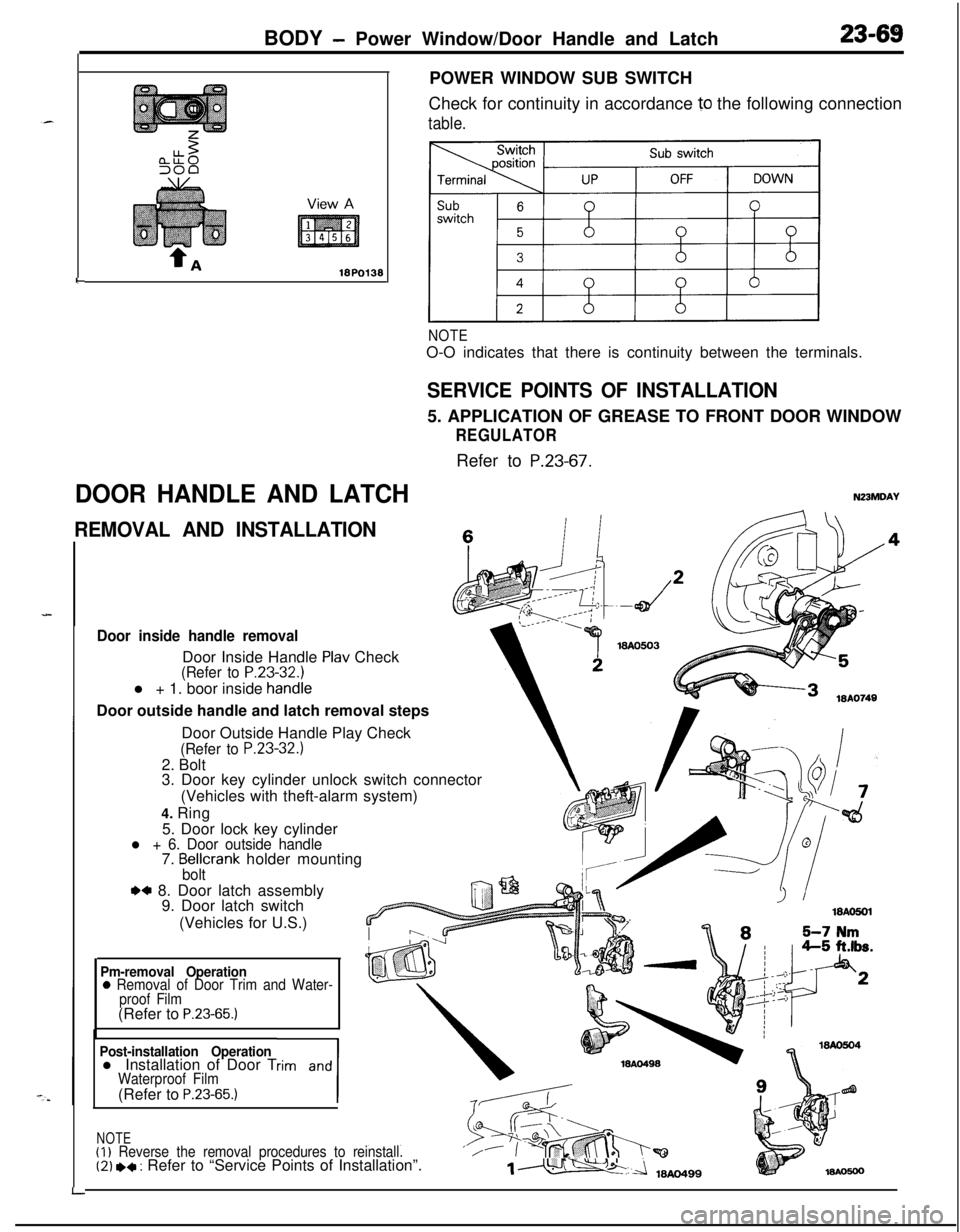

BODY - Power Window/Door Handle and Latch23-69

I-

DOOR HANDLE AND LATCHPOWER WINDOW SUB SWITCH

Check for continuity in accordance

10 the following connection

table.

NOTEO-O indicates that there is continuity between the terminals.

SERVICE POINTS OF INSTALLATION5. APPLICATION OF GREASE TO FRONT DOOR WINDOW

REGULATORRefer to

P.23-67.

N23MDAY

REMOVAL AND INSTALLATIONc

Door inside handle removalDoor Inside Handle

Plav Check(Refer to P.23-32.1l + 1. boor inside

handieDoor outside handle and latch removal steps

LDoor Outside Handle Play Check

(Refer to P.23-32.)2. Bolt

3. Door key cylinder unlock switch connector

(Vehicles with theft-alarm system)

4. Ring

5. Door lock key cylinder

l + 6. Door outside handle7. Bellcrank holder mountingbolt

.a 8. Door latch assembly

9. Door latch switch

(Vehicles for U.S.)

Pm-removal Operation0 Removal of Door Trim and Water-

proof Film(Refer to

P.23-65.)

Post-installation Operationl Installation of Door Trim and

1

Waterproof Film(Refer to P.23-65.)

NOTE(I)

Reverse the removal procedures to reinstall.‘/(2) *+ : Refer to “Service Points of Installation”.1m

Page 1114 of 1216

23-70BODY- Door Handle and Latch/Central Door Lockina Svstem

I18AO750 1lBY3611 I.- .--,

!-

II

T!3123

18PO39i

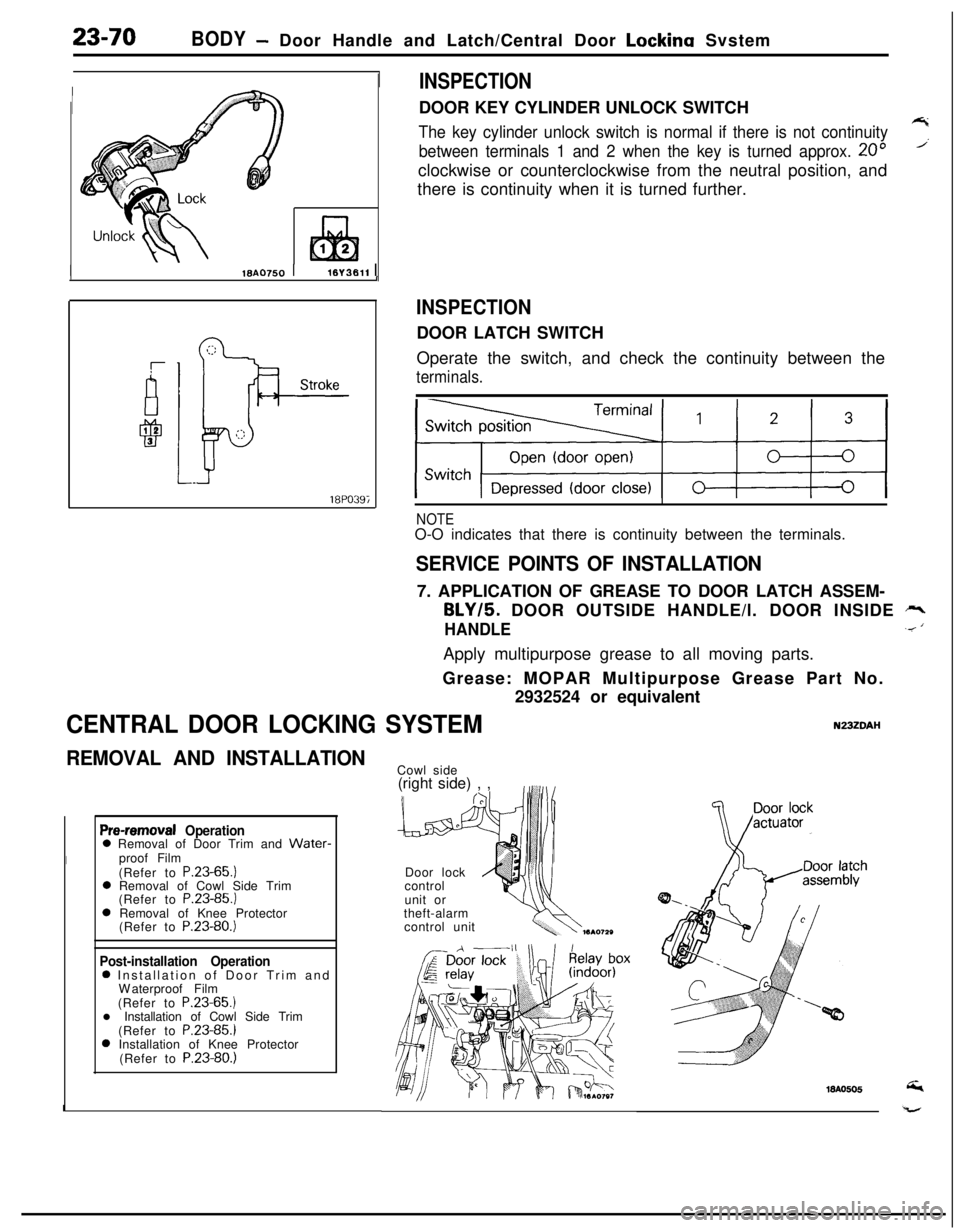

INSPECTIONDOOR KEY CYLINDER UNLOCK SWITCH

The key cylinder unlock switch is normal if there is not continuity7

between terminals 1 and 2 when the key is turned approx. 20”’clockwise or counterclockwise from the neutral position, and

there is continuity when it is turned further.

INSPECTIONDOOR LATCH SWITCH

Operate the switch, and check the continuity between the

terminals.

NOTEO-O indicates that there is continuity between the terminals.

SERVICE POINTS OF INSTALLATION7. APPLICATION OF GREASE TO DOOR LATCH ASSEM-

BLY/5. DOOR OUTSIDE HANDLE/l. DOOR INSIDE rr,

HANDLE.< ‘Apply multipurpose grease to all moving parts.

Grease: MOPAR Multipurpose Grease Part No.

2932524 or equivalent

CENTRAL DOOR LOCKING SYSTEMN23ZDAI-I

REMOVAL AND INSTALLATION

Pre-removal Operation0 Removal of Door Trim and Water-

Iproof Film

(Refer to P.23-65.)

0 Removal of Cowl Side Trim

(Refer to P.23-85.)

0 Removal of Knee Protector

(Refer to P.23-80.)

Post-installation Operation0 Installation of Door Trim and

Waterproof Film

(Refer to P.23-65.)

l Installation of Cowl Side Trim

(Refer to P.23-85.)

0 Installation of Knee Protector

(Refer to P.23-80.)

ICowl side

(right side) , ,

Door lock

control

unit or

theft-alarm

control unit