tire pressure MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1039 of 1216

22-l-.

WHEELS

AND TIRES

CONTENTSNZZAA-

SERVICE ADJUSTMENT PROCEDURES.......4TROUBLESHOOTING......................................3

Tire

InflationPressureCheck......................4Bald Spots

TireWearCheck..........................................4Cracked Treads

Wheel

RunoutCheck...................................4Feathered Edge

SPECIFICATIONSRapid Wear at Center.............................................2

General

Specifications..................................2Rapid Wear at Shoulders

ServiceSpecificationsScalloped Wear...................................2Wear on One Side

7TorqueSpecifications...................................2

WHEEL AND TIRE..........................................5

Page 1040 of 1216

5 22-2WHEELS AND TIRES - Specifications

SPECIFICATIONS

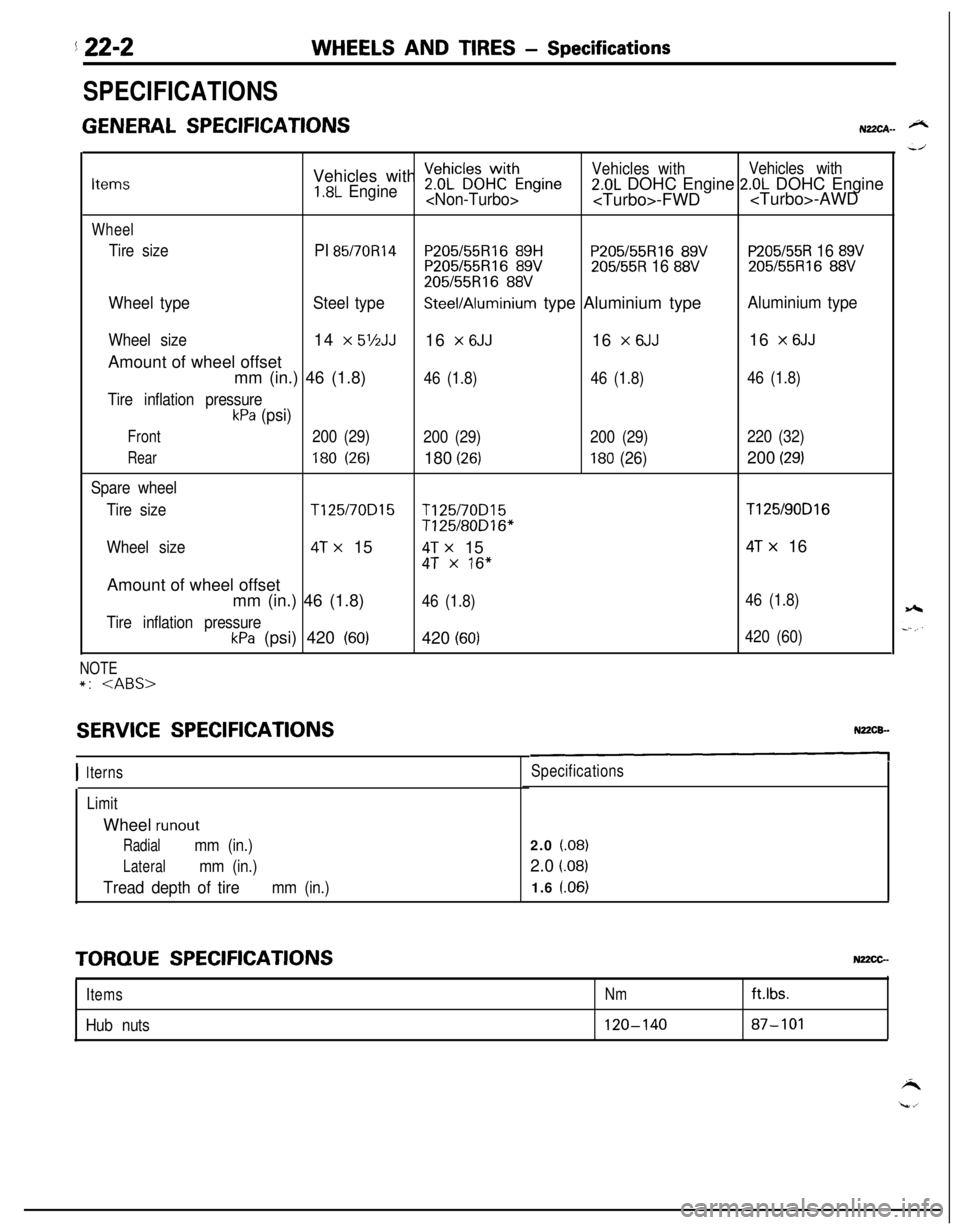

GENERAL SPECIFICATIONSN22CA- @NVehicles with

~eDhL”~~HWCthEngineVehicles withVehicles withItems1.8L Engine2.0L DOHC Engine 2.0L DOHC Engine

Wheel

Tire sizePI 85/70R14P205155Rl6 89HP205/55R16 89VP205/55R 16 89VP205155R16 89V205/55R 16 88V205/55R16 88V

205/55R16 88V

Wheel typeSteel typeSteel/Aluminium type Aluminium typeAluminium type

Wheel size14 x 5’/2JJ16 x 6JJ16 x 6JJ16 x 6JJAmount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi)

Front200 (29)

200 (29)200 (29)220 (32)

Rear180 (26)180 (26)180 (26)200 (29)

Spare wheel

Tire size

T125/70D15T125/70D15T125/90D16

T125/80D16*

Wheel size

4T x 154T x 154T x 16

4T x 16”Amount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi) 420 (60)420 (60)420 (60)

NOTE*:

SERVICE SPECIFICATIONS

I 1terns

LimitWheel

runout

Radialmm (in.)

Lateralmm (in.)

Tread depth of tiremm (in.)

Specifications2.0

(.08)2.0

i.08)1.6 l.06)

TORQUE SPECIFICATIONSNz2cG-

ItemsNm

Hub nuts120-140ftlbs.87-101

Page 1041 of 1216

WHEELS AND TIRES - Troubleshooting22-3

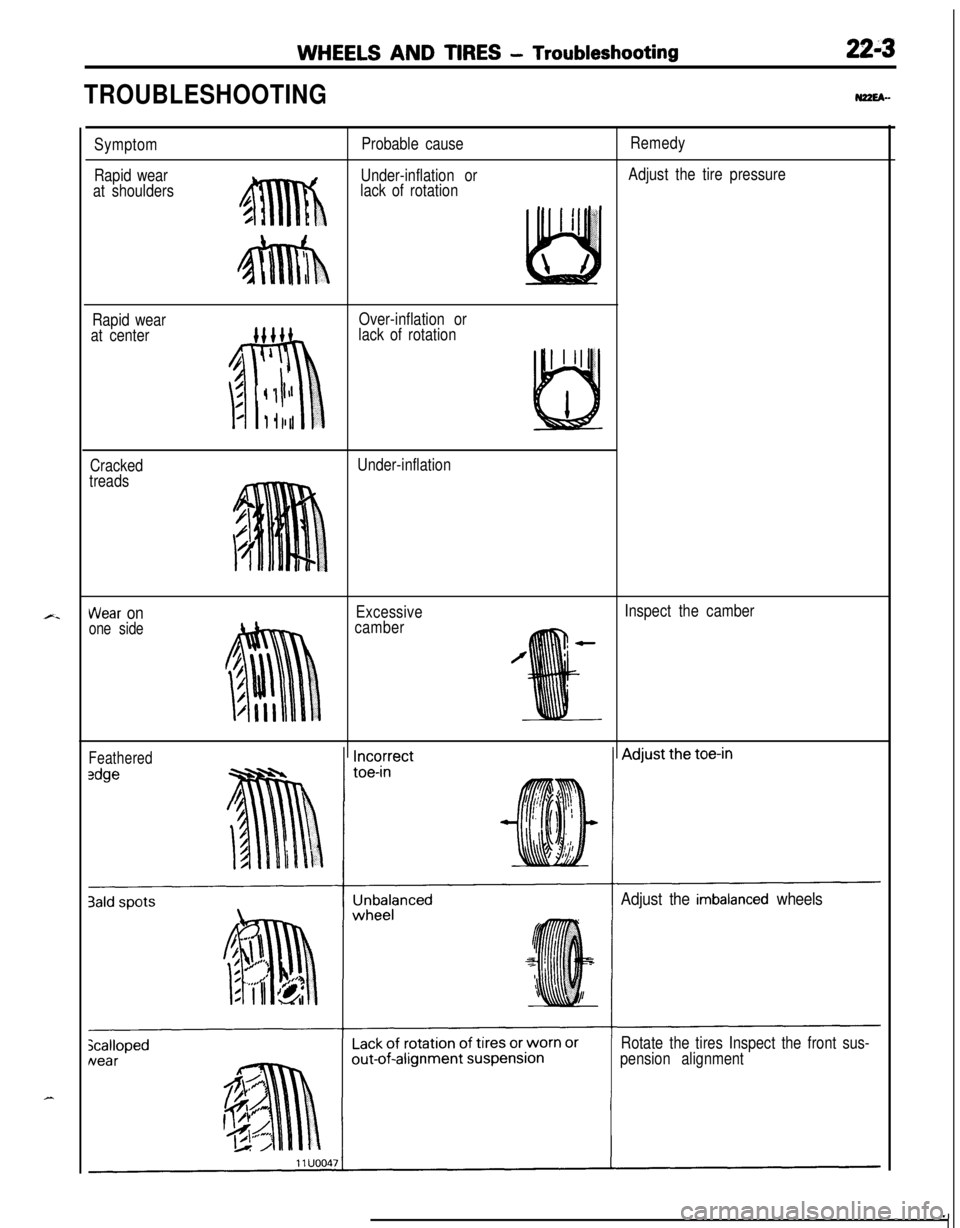

TROUBLESHOOTINGN22EA-

Symptom

Rapid wear

at shouldersProbable cause

Under-inflation or

lack of rotationRemedy

Adjust the tire pressure

Rapid wear

at centerOver-inflation or

lack of rotation

Cracked

treadsUnder-inflation

Wear onone side

Excessive

camberInspect the camber

Feathered

Adjust the imbalanced wheels

Rotate the tires Inspect the front sus-

pension alignment

Page 1042 of 1216

22-4WHEELS AND TIRES - Service Adjustment Procedures

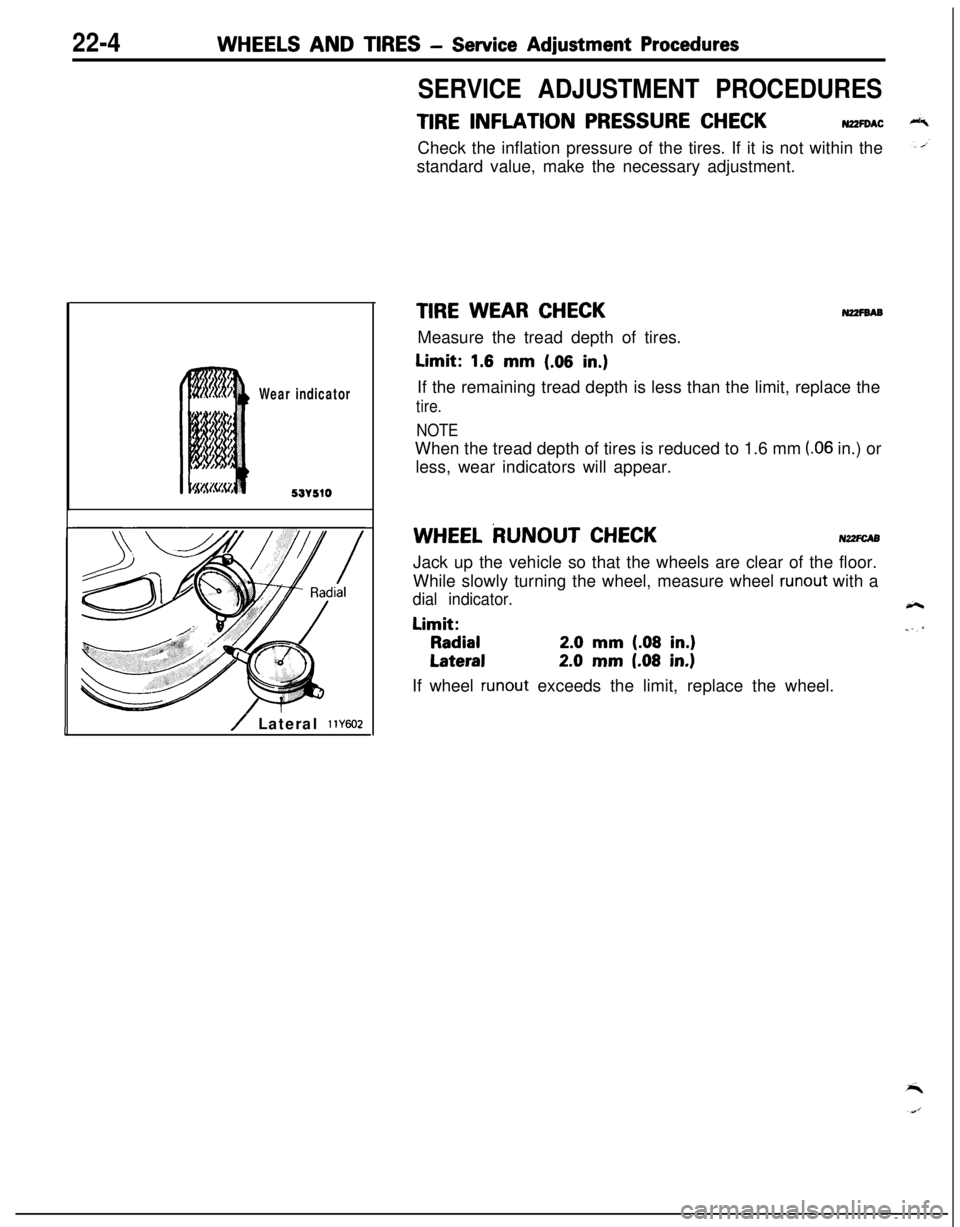

Wear indicator

53r510

/ Lateral 11Y602

SERVICE ADJUSTMENT PROCEDURES

TIRE INFLATION PRESSURE CHECKN2ZFOACCheck the inflation pressure of the tires. If it is not within the

standard value, make the necessary adjustment.

TIRE WEAR CHECKN2zFsABMeasure the tread depth of tires.Limit:

1.6 mm (.06 in,)If the remaining tread depth is less than the limit, replace the

tire.

NOTEWhen the tread depth of tires is reduced to 1.6 mm

(.06 in.) or

less, wear indicators will appear.

WHEEL RUNOUT CHECKNZ2FCA5Jack up the vehicle so that the wheels are clear of the floor.

While slowly turning the wheel, measure wheel

runout with a

dial indicator.Limit:

Radial2.0 mm (.08 in.)

Lateral2.0 mm (.08 in.)If wheel

runout exceeds the limit, replace the wheel.

Page 1044 of 1216

22-6WHEELS AND TIRES - Wheel and Tire

INSTRUCTIONS FOR ALUMINUM TYPE

WHEELSUzzGfM

1. Aluminum is vulnerable to alkalies. If a vehicle

washing detergent has been used, or salt from

sea water or road chemicals has adhered, washthe vehicle as soon as possible. After washing

the vehicle, apply body or wheel wax to the

aluminum type wheels to prevent corrosion.

2. When cleaning the vehicle with steam, do not

direct steam onto the aluminum type wheels.

When tightening nuts for aluminum type

wheels, particularly observe the following:

(1) Clean the hub surface of aluminum type

wheels.(2) After finger-tightening wheel nuts, tighten

them to specifications.

(3) Do not use an impact wrench or push the

wrench by foot to tighten the wheel nuts.

(4) Do not apply oil to the threaded portions.

INSTRUCTIONS FOR TIRE CHAINS AND

SNOW TIRESNZZGGAA

1.Use tire chains only on front wheels. Do not usetire chains on rear wheels.

2. When using snow tires, use them on all four

wheels for maneuverability and safety.

INSTRUCTIONS FOR COMPACT SPARE

TIRE;c.1. The compact spare tire is designed to. save

space in the luggage compartment, and its

L’lighter weight makes it easier to use if a fiat tire

occurs.

2.The following instructions for the compact sparetire should be observed.

(1) Check the inflation pressure after installing

the spare, and adjust to the specified pres-

sure.(2) Avoid driving through automatic car washes

and over obstacles that could possibly dam-

age the vehicle’s undercarriage. Because

the tire is smaller than the original tire, car

ground clearance is slightly reduced.

(3) The compact spare tire should not be used

on any other wheels, nor should standard

tires, snow tires, wheel covers or trim rings

be used with the compact spare wheel. If

such use is attempted, damage to these

items or other vehicle components may

occur.

Page 1094 of 1216

23-50BODY - Moulding

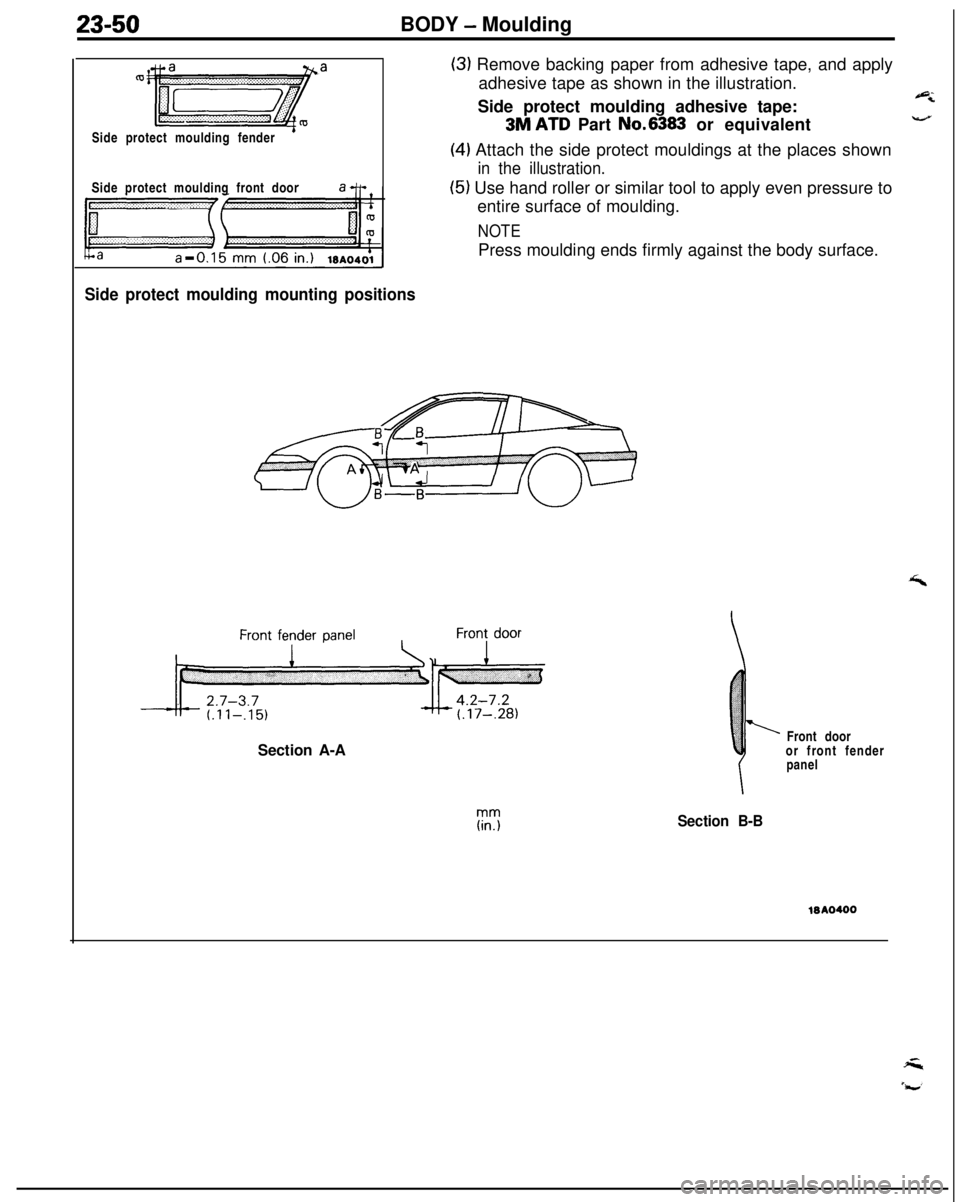

Side protect moulding fender

’Side protect moulding front door

Side protect moulding mounting positions

(3) Remove backing paper from adhesive tape, and apply

adhesive tape as shown in the illustration.

Side protect moulding adhesive tape:

6

3M ATD Part No.6383 or equivalentV

(4) Attach the side protect mouldings at the places shown

in the illustration.

(5) Use hand roller or similar tool to apply even pressure to

entire surface of moulding.

NOTEPress moulding ends firmly against the body surface.

Section A-AFront door

or front fender

ipanel

Section B-BWA0400

Page 1119 of 1216

BODY - Aero Parts23-75

\18A0245

16A0765

18A041618A041C

SERVICE POINTS OF REMOVAL

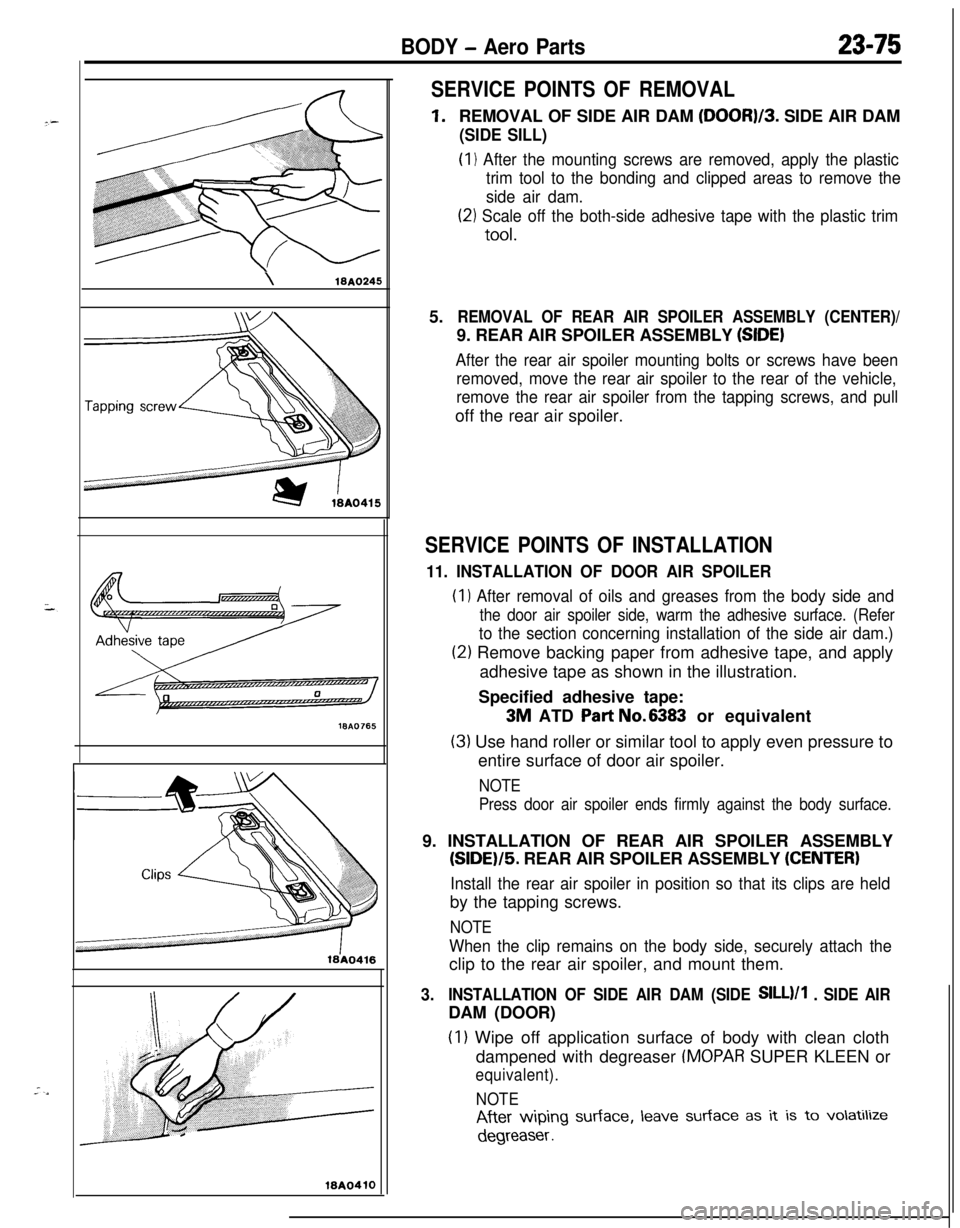

1.REMOVAL OF SIDE AIR DAM (DOOR)/3. SIDE AIR DAM

(SIDE SILL)(I

1 After the mounting screws are removed, apply the plastic

trim tool to the bonding and clipped areas to remove the

side air dam.

(21 Scale off the both-side adhesive tape with the plastic trim

tool.5.

REMOVAL OF REAR AIR SPOILER ASSEMBLY (CENTER)/9. REAR AIR SPOILER ASSEMBLY

(SIDE)

After the rear air spoiler mounting bolts or screws have been

removed, move the rear air spoiler to the rear of the vehicle,

remove the rear air spoiler from the tapping screws, and pulloff the rear air spoiler.

SERVICE POINTS OF INSTALLATION

11. INSTALLATION OF DOOR AIR SPOILER(I

1 After removal of oils and greases from the body side and

the door air spoiler side, warm the adhesive surface. (Refer

to the section concerning installation of the side air dam.)

(2) Remove backing paper from adhesive tape, and apply

adhesive tape as shown in the illustration.

Specified adhesive tape:

3M ATD Part No.6383 or equivalent

(3) Use hand roller or similar tool to apply even pressure to

entire surface of door air spoiler.

NOTE

Press door air spoiler ends firmly against the body surface.9. INSTALLATION OF REAR AIR SPOILER ASSEMBLY

(SIDE)/5. REAR AIR SPOILER ASSEMBLY (CENTER)

Install the rear air spoiler in position so that its clips are heldby the tapping screws.

NOTE

When the clip remains on the body side, securely attach theclip to the rear air spoiler, and mount them.

3.INSTALLATION OF SIDE AIR DAM (SIDE SILL)/1 . SIDE AIRDAM (DOOR)

(I 1 Wipe off application surface of body with clean cloth

dampened with degreaser

IMOPAR SUPER KLEEN or

equivalent).

NOTE

After wiping surface, leave surface as it is to volatilize

degreaser .

Page 1120 of 1216

23-76BODY - Aero Parts

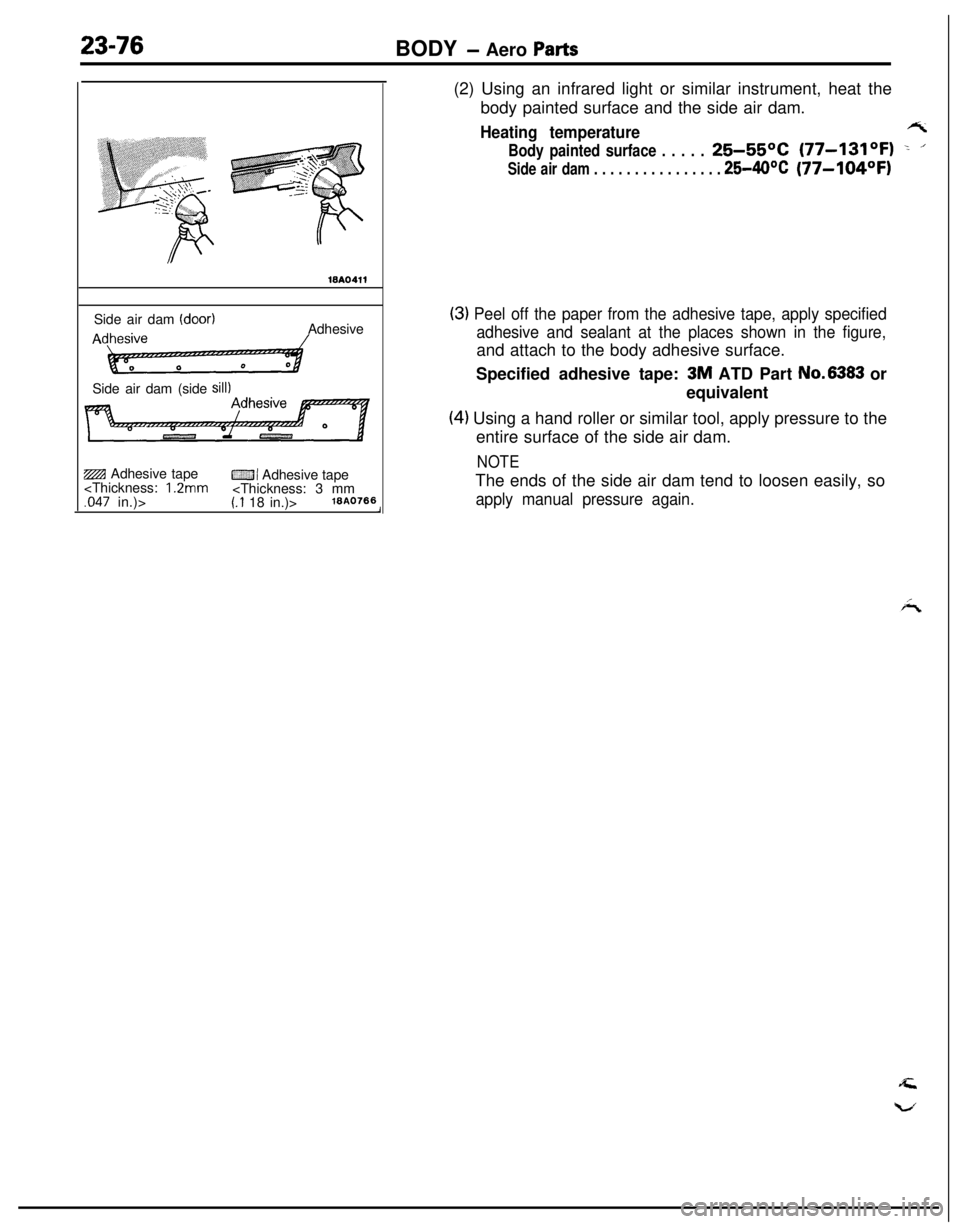

WA0411Side air dam

(door)AAdhesive

Side air dam (side

sill)ZBI Adhesive tape

CZJI Adhesive tape

body painted surface and the side air dam.

Heating temperaturert

Body painted surface . . . . .25-55OC (77-131OF) -. ’

Side air dam . . . . . . . . . . . . . . . . 25-40°C(77-104OFI

(3) Peel off the paper from the adhesive tape, apply specified

adhesive and sealant at the places shown in the figure,and attach to the body adhesive surface.

Specified adhesive tape:

3M ATD Part No.6383 or

equivalent

(4) Using a hand roller or similar tool, apply pressure to the

entire surface of the side air dam.

NOTEThe ends of the side air dam tend to loosen easily, so

apply manual pressure again.

Page 1163 of 1216

-.

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 241$19Oil collector can

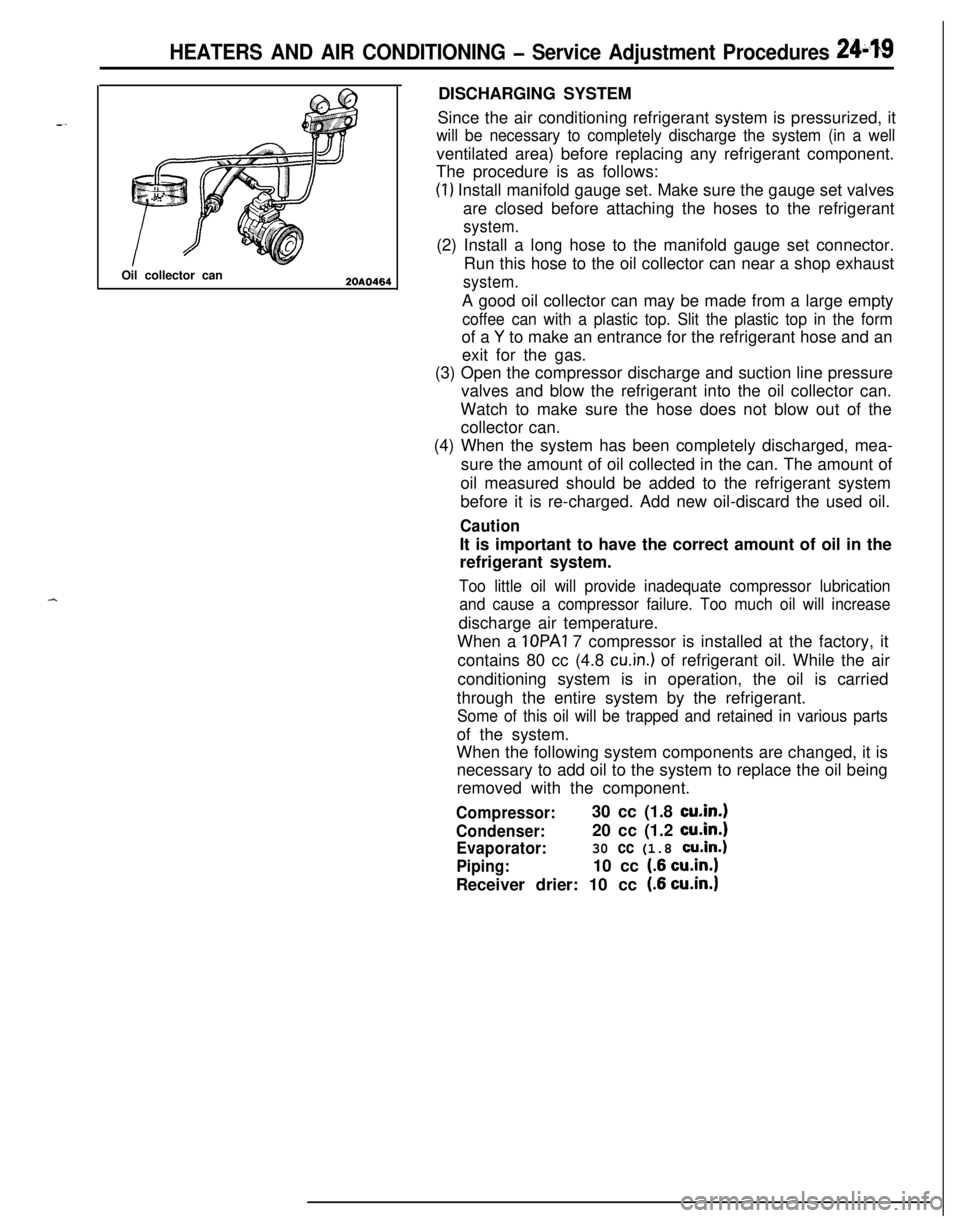

2OAO464DISCHARGING SYSTEM

Since the air conditioning refrigerant system is pressurized, it

will be necessary to completely discharge the system (in a wellventilated area) before replacing any refrigerant component.

The procedure is as follows:

(1) Install manifold gauge set. Make sure the gauge set valves

are closed before attaching the hoses to the refrigerant

system.(2) Install a long hose to the manifold gauge set connector.

Run this hose to the oil collector can near a shop exhaust

system.A good oil collector can may be made from a large empty

coffee can with a plastic top. Slit the plastic top in the formof a

Y to make an entrance for the refrigerant hose and an

exit for the gas.

(3) Open the compressor discharge and suction line pressure

valves and blow the refrigerant into the oil collector can.

Watch to make sure the hose does not blow out of the

collector can.

(4) When the system has been completely discharged, mea-

sure the amount of oil collected in the can. The amount of

oil measured should be added to the refrigerant system

before it is re-charged. Add new oil-discard the used oil.

CautionIt is important to have the correct amount of oil in the

refrigerant system.

Too little oil will provide inadequate compressor lubrication

and cause a compressor failure. Too much oil will increasedischarge air temperature.

When a IOPAI 7 compressor is installed at the factory, it

contains 80 cc (4.8

cu.in.) of refrigerant oil. While the air

conditioning system is in operation, the oil is carried

through the entire system by the refrigerant.

Some of this oil will be trapped and retained in various partsof the system.

When the following system components are changed, it is

necessary to add oil to the system to replace the oil being

removed with the component.

Compressor:30 cc (1.8 cu.in.1

Condenser:20 cc (1.2 cu.in.1

Evaporator:30 cc (1.8 cu.in.)

Piping:10 cc (.6 cu.in.1Receiver drier: 10 cc

(.6 cu.in.1

Page 1166 of 1216

24-22 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures(9) Charge through the suction side of the system by slowly

opening the suction manifold valve. Adjust the valve as

necessary so charging pressure does not exceed 345

kPa 6(50 psi). Maintain the temperature of the water in the pan w’

by adding warm water as necessary.

Note the weight of water added, to ensure accuracy when

determining amount of refrigerant added to system.

(lO)When specified refrigerant charge Max. 925

g (32 oz.) has

entered the system, close the gauge set manifold valves,

refrigerant manifold valves, and

reconnnect wiring. Each

can contains 397

g (14 oz.) of R-l 2. Use 2 l/2 cans.

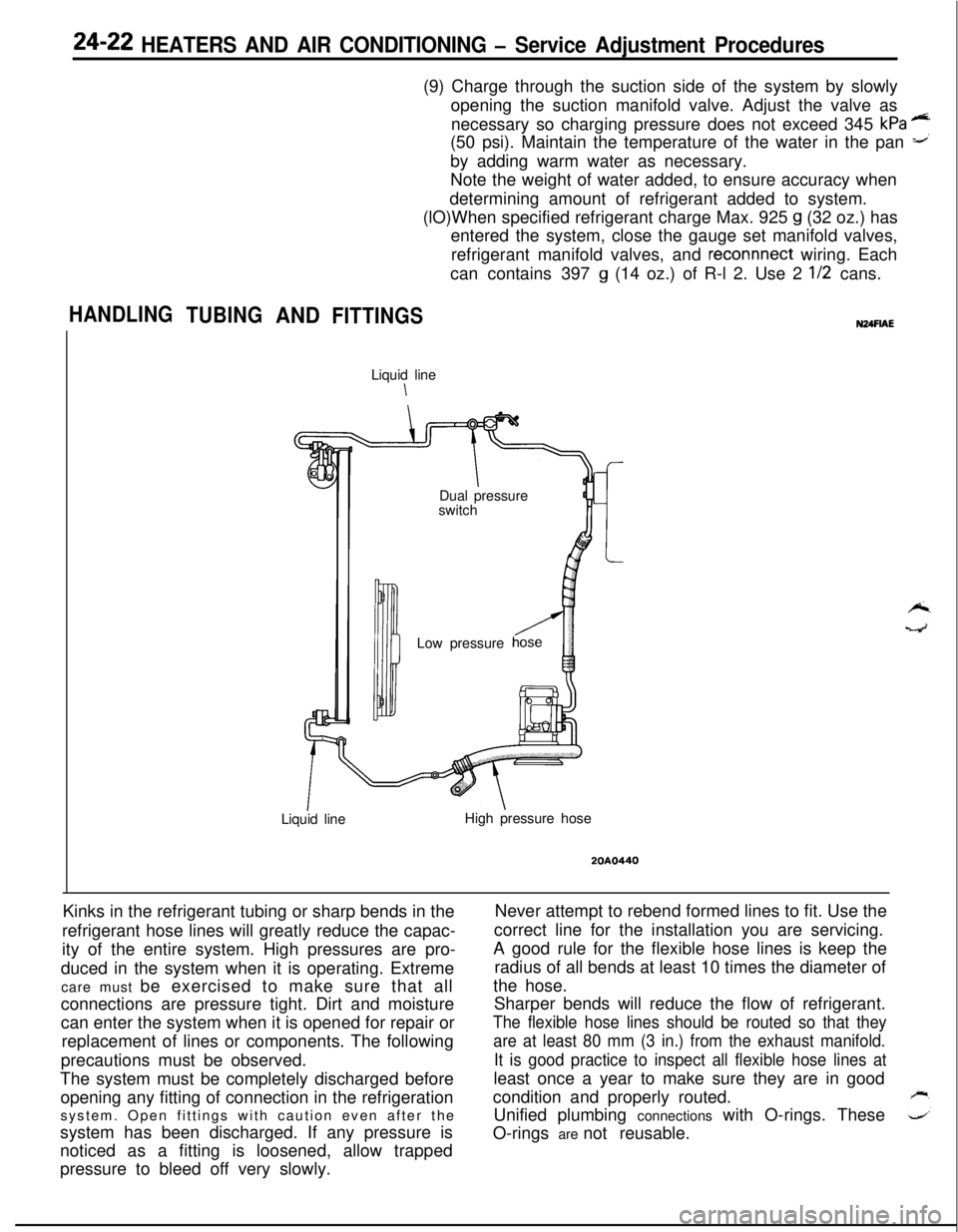

HANDLING

TUBINGANDFITTINGSLiquid line

\

IDual pressure

switch

Low pressure

Liquid lineHigh pressure hose

20A0440Kinks in the refrigerant tubing or sharp bends in the

refrigerant hose lines will greatly reduce the capac-

ity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all

connections are pressure tight. Dirt and moisture

can enter the system when it is opened for repair or

replacement of lines or components. The following

precautions must be observed.

The system must be completely discharged before

opening any fitting of connection in the refrigeration

system. Open fittings with caution even after the

system has been discharged. If any pressure is

noticed as a fitting is loosened, allow trapped

pressure to bleed off very slowly.Never attempt to rebend formed lines to fit. Use the

correct line for the installation you are servicing.

A good rule for the flexible hose lines is keep the

radius of all bends at least 10 times the diameter of

the hose.

Sharper bends will reduce the flow of refrigerant.

The flexible hose lines should be routed so that they

are at least 80 mm (3 in.) from the exhaust manifold.

It is good practice to inspect all flexible hose lines atleast once a year to make sure they are in good

condition and properly routed.

Unified plumbing connections with O-rings. These

O-rings are not reusable.