weight MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 371 of 1216

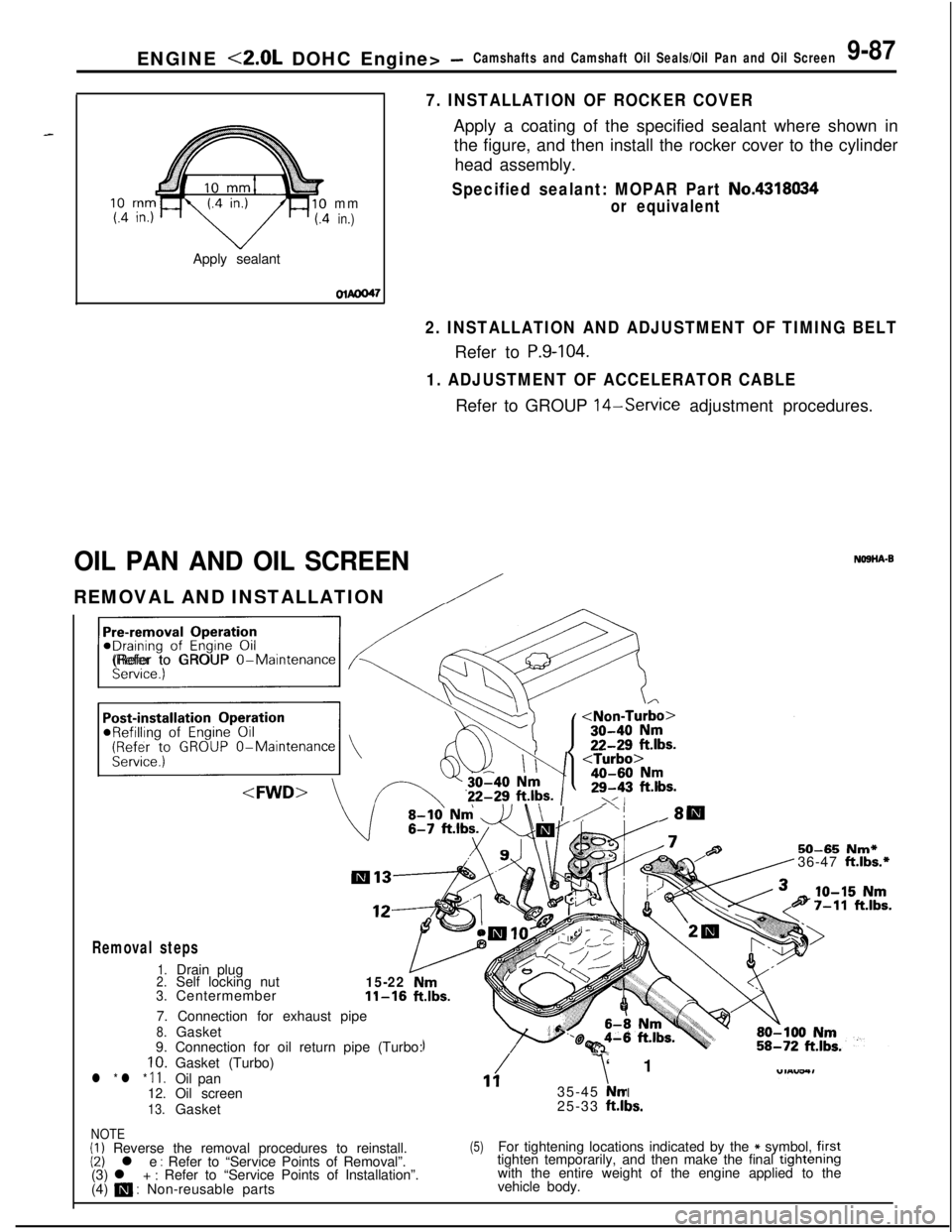

ENGINE <2.0L DOHC Engine> -Camshafts and Camshaft Oil Seals/Oil Pan and Oil Screen9-87

7. INSTALLATION OF ROCKER COVERApply a coating of the specified sealant where shown in

the figure, and then install the rocker cover to the cylinder

head assembly.

Apply sealant

mmin.)

Specified sealant: MOPAR Part No.4318034

or equivalent

olmO47

2. INSTALLATION AND ADJUSTMENT OF TIMING BELTRefer to

P.9-104.

1. ADJUSTMENT OF ACCELERATOR CABLERefer to GROUP 14-Service adjustment procedures.

OIL PAN AND OIL SCREENNO9HA-BREMOVAL AND INSTALLATION

/

/j<&(Refer to GROUP O-Maintenance

\ I/“!18

III13

12-

Removal steps

1.Drain plug2.Self locking nut15-22Nm3.Centermember11-16ft.lbs.7. Connection for exhaust pipe

8.Gasket

9. Connection for oil return pipe (Turbo:IO. Gasket (Turbo)

l * l * 11.Oil pan12.Oil screen

13.Gasket

50-65 Nm*36-47 ft.lbs.*

/117‘1

35-45 NmI25-33 ft.ll3s.

NOTE(I) Reverse the removal procedures to reinstall.(2) l e : Refer to “Service Points of Removal”.

(3) l + : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

(5)For tightening locations indicated by the * symbol, firsttighten temporarily, and then make the final trghtenrngwith the entire weight of the engine applied to the

vehicle body.

Page 634 of 1216

17-24REAR SUSPENSION

1

II

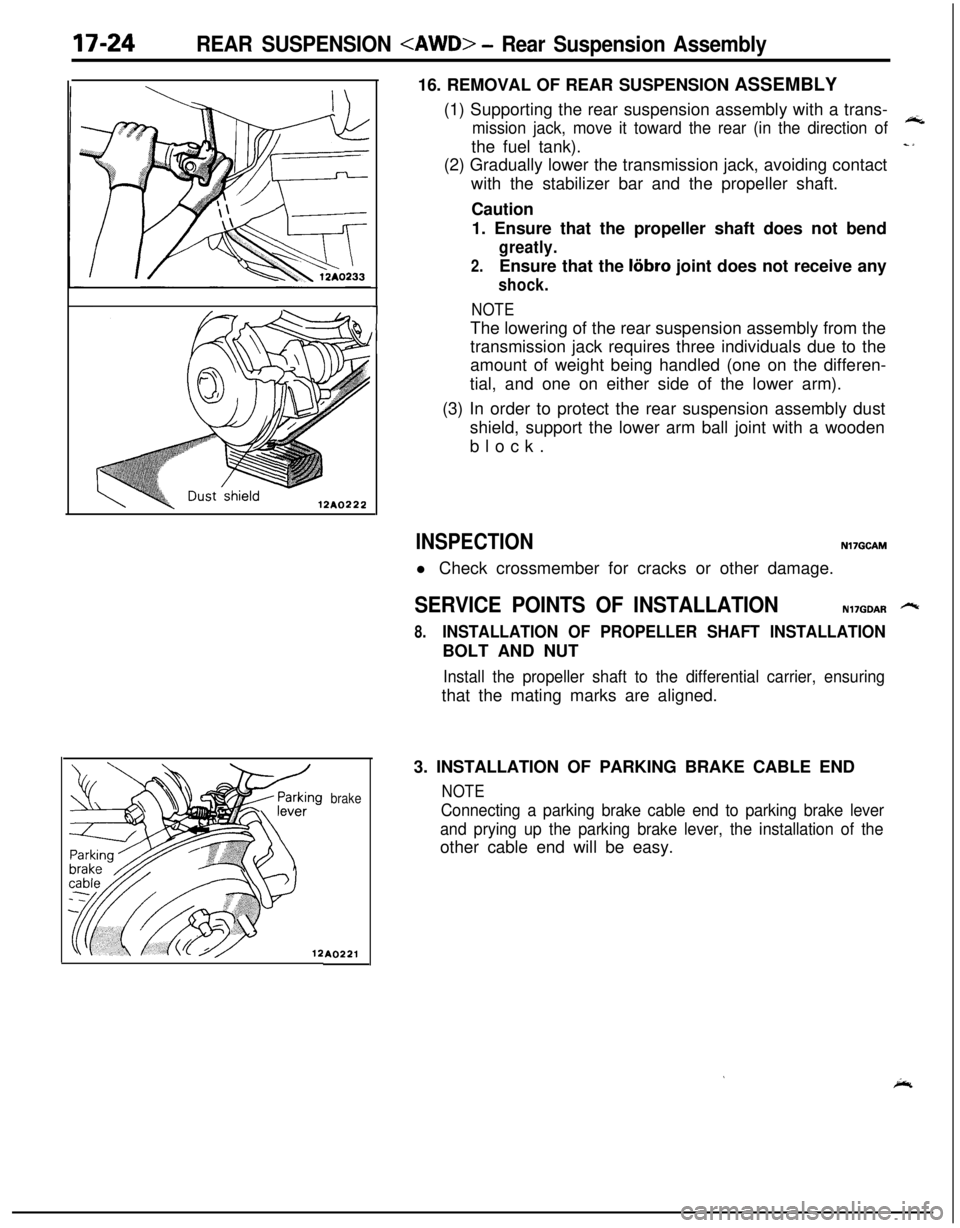

brakeA022116. REMOVAL OF REAR SUSPENSION ASSEMBLY

(1) Supporting the rear suspension assembly with a trans-

mission jack, move it toward the rear (in the direction of

wtthe fuel tank).

c1(2) Gradually lower the transmission jack, avoiding contact

with the stabilizer bar and the propeller shaft.

Caution

1. Ensure that the propeller shaft does not bend

greatly.

2.Ensure that the liibro joint does not receive any

shock.

NOTEThe lowering of the rear suspension assembly from the

transmission jack requires three individuals due to the

amount of weight being handled (one on the differen-

tial, and one on either side of the lower arm).

(3) In order to protect the rear suspension assembly dust

shield, support the lower arm ball joint with a wooden

block.

INSPECTIONNl7GCAMl Check crossmember for cracks or other damage.

SERVICE POINTS OF INSTALLATIONN17GOAR -

8.INSTALLATION OF PROPELLER SHAFT INSTALLATIONBOLT AND NUT

Install the propeller shaft to the differential carrier, ensuringthat the mating marks are aligned.

3. INSTALLATION OF PARKING BRAKE CABLE END

NOTE

Connecting a parking brake cable end to parking brake lever

and prying up the parking brake lever, the installation of theother cable end will be easy.

’ice,

Page 713 of 1216

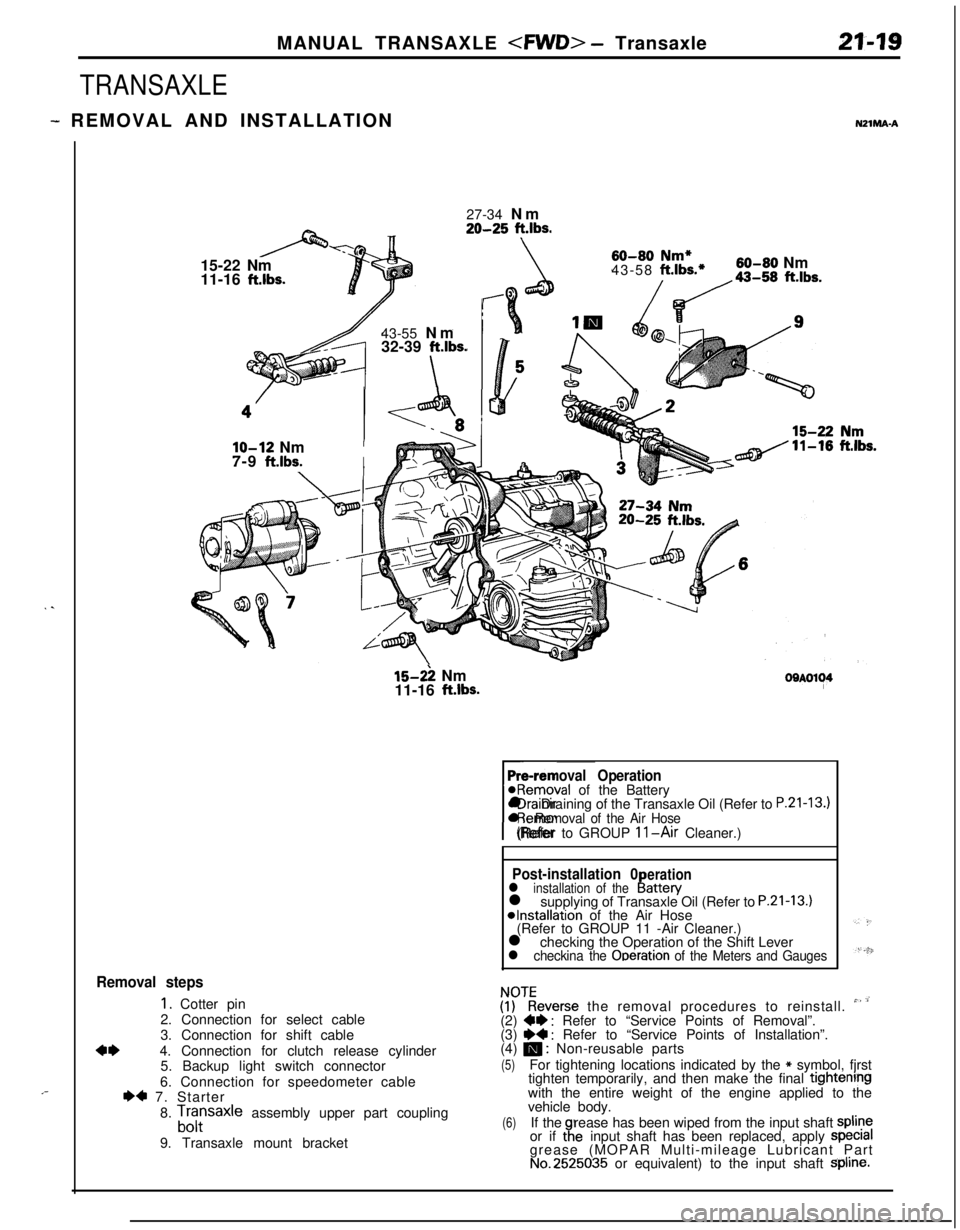

MANUAL TRANSAXLE

TRANSAXLE

- REMOVAL AND INSTALLATIONNZlMA-A

. .

,-27-34 Nm

20-25 ft.lbs.15-22 Nm

11-16

ft.lbs.43-55 Nm

32-39

ft.lbs.

\

60-80 Nm*43-58 ft.lbs.*60-80 Nm

/da-,, ft.lbs.

lo-12 NmI7-9

ft.lbs.I

15-2: Nm

11-16 ft.lbs.OOAOl~4

Pre-removal Operation@Removal of the Battery

rl Draining of the Transaxle Oil (Refer to

P.21-13.)l Removal of the Air Hose(Refer to GROUP 11-Air Cleaner.)

Post-installation 0erationl installation of theI!attery

l supplying of Transaxle Oil (Refer to P.21-13.)*Installation of the Air Hose

(Refer to GROUP 11 -Air Cleaner.)

l checking the Operation of the Shift Lever

l checkina the Ooeration of the Meters and Gauges

Removal steps

1. Cotter pin

2. Connection for select cable

3. Connection for shift cable

4*4. Connection for clutch release cylinder

5. Backup light switch connector

6. Connection for speedometer cable

I)* 7. Starter

8.

Lfrsaxle assembly upper part coupling

9. Transaxle mount bracket

ZKeverse the removal procedures to reinstall. ” ’(2) W : Refer to “Service Points of Removal”.

(3) ~~ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

(5)For tightening locations indicated by the * symbol, fjrst

tighten temporarily, and then make the final tightenrngwith the entire weight of the engine applied to the

vehicle body.

(6)If therease has been wiped from the input shaft spline

or if taeinput shaft has been replaced, apply specralgrease (MOPAR Multi-mileage Lubricant Part

No.2525035 or equivalent) to the input shaft Spline.

Page 776 of 1216

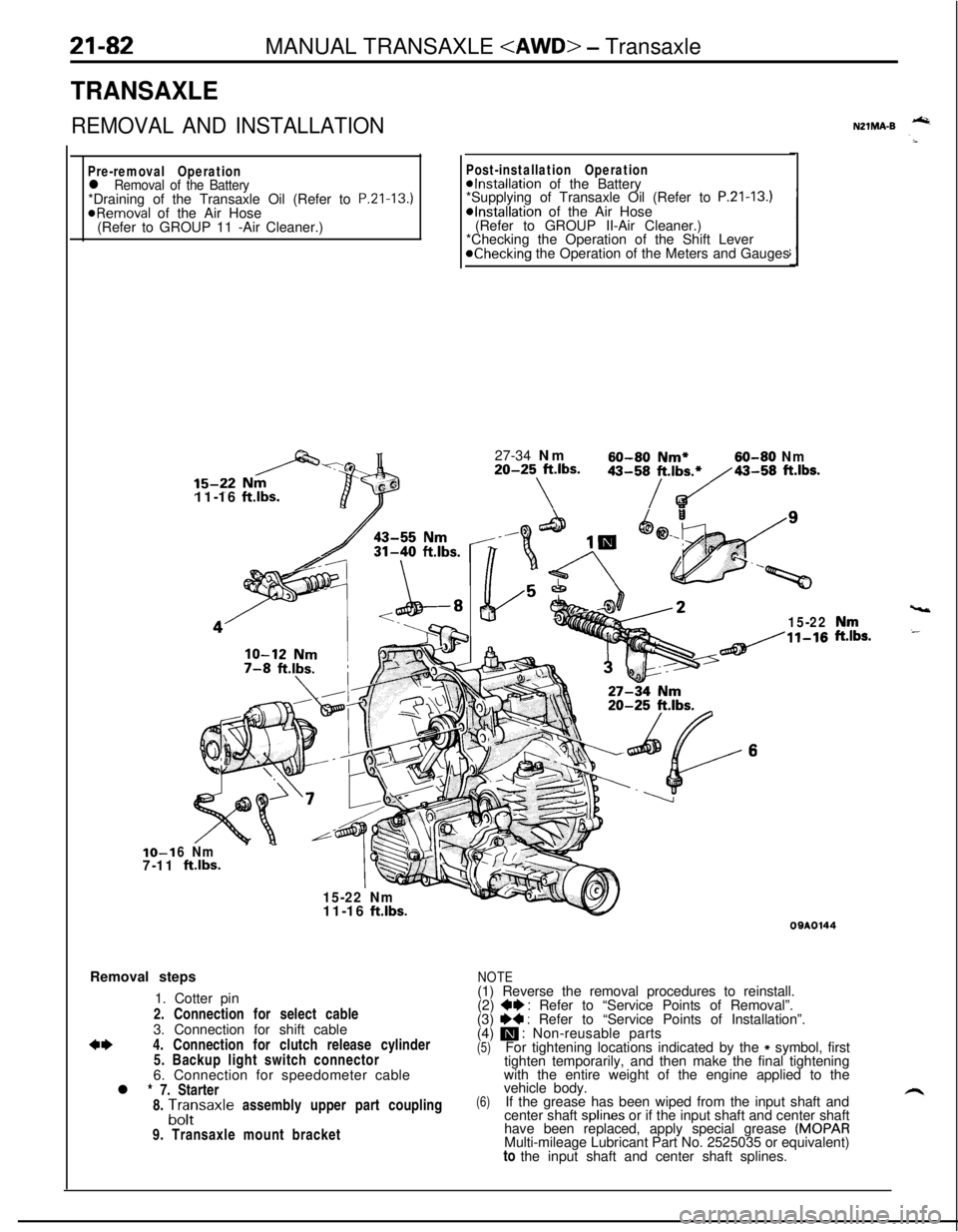

21-82MANUAL TRANSAXLE

TRANSAXLE

REMOVAL AND INSTALLATION

Pre-removal Operationl Removal of the Battery*Draining of the Transaxle Oil (Refer to P.Zl-13.)

@Removal of the Air Hose

(Refer to GROUP 11 -Air Cleaner.)IO-1

7-1111-16

ftlbs.

Post-installation Operation@Installation of the Battery

*Supplying of Transaxle Oil (Refer to P.21-13.)*Installation of the Air Hose

(Refer to GROUP II-Air Cleaner.)

*Checking the Operation of the Shift Lever

@Checking the Operation of the Meters and Gauges

27-34 Nm

60-60 Nm*60-80 Nm20-25 ft.lbs.

\

43-58/t.,b~43-58 ft.lbs.

15-22

6 Nm

ftlbs.

15-22 Nm

vt11-16

ft.lbs.Removal steps

1. Cotter pin

2. Connection for select cable

3. Connection for shift cable

*I)4. Connection for clutch release cylinder

5. Backup light switch connector

6. Connection for speedometer cable

l * 7. Starter

8.

A;;saxle assembly upper part coupling

9. Transaxle mount bracket

NZlMA-B -

,“rr,s.

09AOl44

NOTE(1) Reverse the removal procedures to reinstall.

(2)

+e : Refer to “Service Points of Removal”.

(3) I)+ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts(5)For tightening locations indicated by the * symbol, first

tighten temporarily, and then make the final tightening

with the entire weight of the engine applied to the

(6)vehicle body.

If the grease has been wiped from the input shaft and

center shaft splines or if the input shaft and center shaft

have been replaced, apply special grease

(MOPARMulti-mileage Lubricant Part No. 2525035 or equivalent)

to the input shaft and center shaft splines.

Page 1043 of 1216

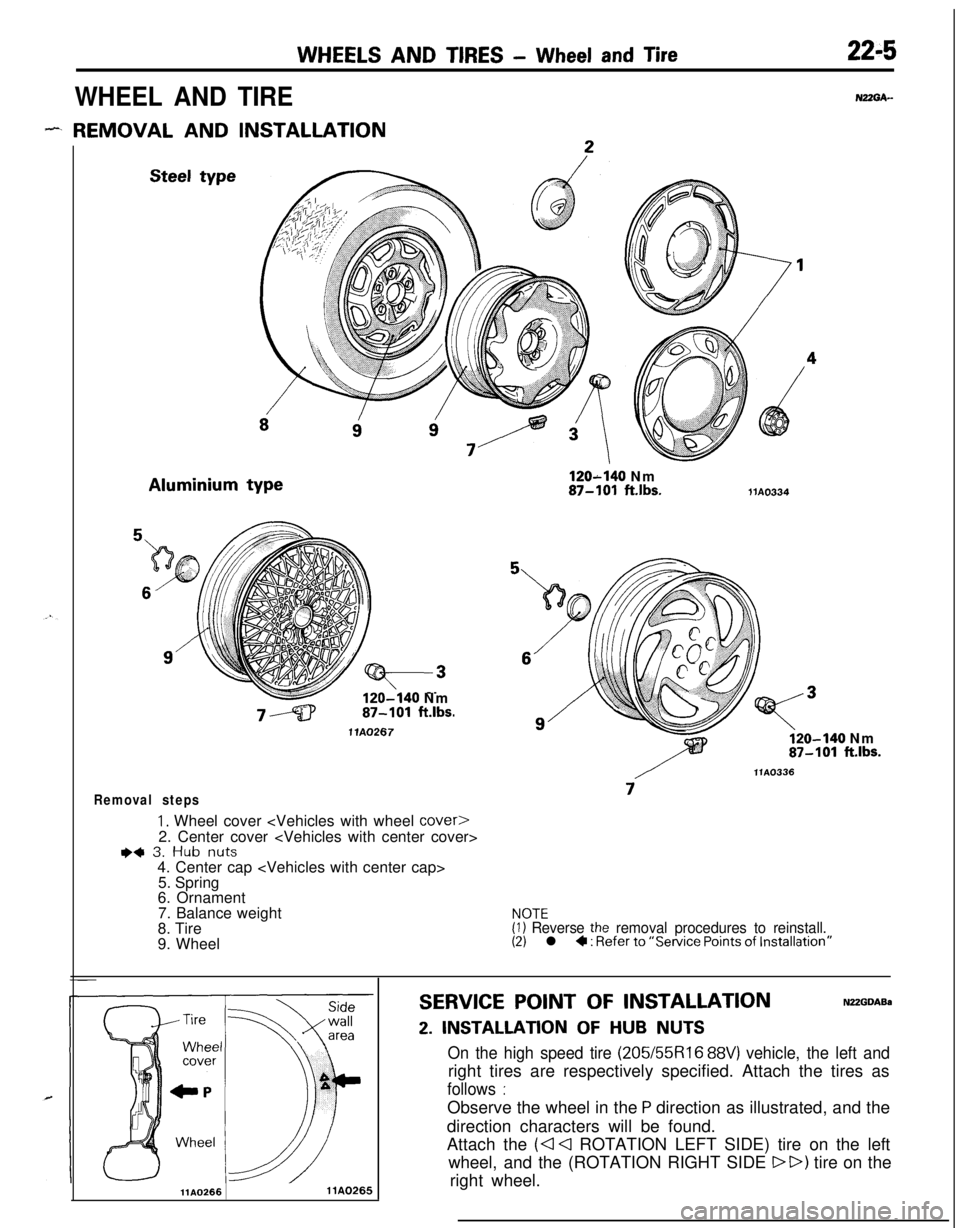

WHEELS AND TIRES - Wheel and Tire22-5

WHEEL AND TIRE

- REMOVAL AND INSTALLATIONSteel typeAluminium type

120-140 Nm87-101 ft.lbs.

1 lA0267

Removal steps

1. Wheel cover

I)+ 3. Hub nuts4. Center cap

5. Spring

6. Ornament

7. Balance weight

8. Tire

9. WheelNUGA-

120-140 Nm87-101 ftlbs.liA0334

o-140 Nm87-101 ft.lbs.

/llA0336

7

NOTE(1) Reverse the removal procedures to reinstall.(2) l 4 : Refer to “Service Points of Installation”

llAO2661 lAO265

SERVICE POINT OF INSTALLATIONNUGDABa

2. INSTALLATION OF HUB NUTS

On the high speed tire (205/55R16 88V) vehicle, the left andright tires are respectively specified. Attach the tires as

follows :Observe the wheel in the

P direction as illustrated, and the

direction characters will be found.

Attach the

(a Cl ROTATION LEFT SIDE) tire on the left

wheel, and the (ROTATION RIGHT SIDE

DD) tire on the

right wheel.

Page 1044 of 1216

22-6WHEELS AND TIRES - Wheel and Tire

INSTRUCTIONS FOR ALUMINUM TYPE

WHEELSUzzGfM

1. Aluminum is vulnerable to alkalies. If a vehicle

washing detergent has been used, or salt from

sea water or road chemicals has adhered, washthe vehicle as soon as possible. After washing

the vehicle, apply body or wheel wax to the

aluminum type wheels to prevent corrosion.

2. When cleaning the vehicle with steam, do not

direct steam onto the aluminum type wheels.

When tightening nuts for aluminum type

wheels, particularly observe the following:

(1) Clean the hub surface of aluminum type

wheels.(2) After finger-tightening wheel nuts, tighten

them to specifications.

(3) Do not use an impact wrench or push the

wrench by foot to tighten the wheel nuts.

(4) Do not apply oil to the threaded portions.

INSTRUCTIONS FOR TIRE CHAINS AND

SNOW TIRESNZZGGAA

1.Use tire chains only on front wheels. Do not usetire chains on rear wheels.

2. When using snow tires, use them on all four

wheels for maneuverability and safety.

INSTRUCTIONS FOR COMPACT SPARE

TIRE;c.1. The compact spare tire is designed to. save

space in the luggage compartment, and its

L’lighter weight makes it easier to use if a fiat tire

occurs.

2.The following instructions for the compact sparetire should be observed.

(1) Check the inflation pressure after installing

the spare, and adjust to the specified pres-

sure.(2) Avoid driving through automatic car washes

and over obstacles that could possibly dam-

age the vehicle’s undercarriage. Because

the tire is smaller than the original tire, car

ground clearance is slightly reduced.

(3) The compact spare tire should not be used

on any other wheels, nor should standard

tires, snow tires, wheel covers or trim rings

be used with the compact spare wheel. If

such use is attempted, damage to these

items or other vehicle components may

occur.

Page 1165 of 1216

i

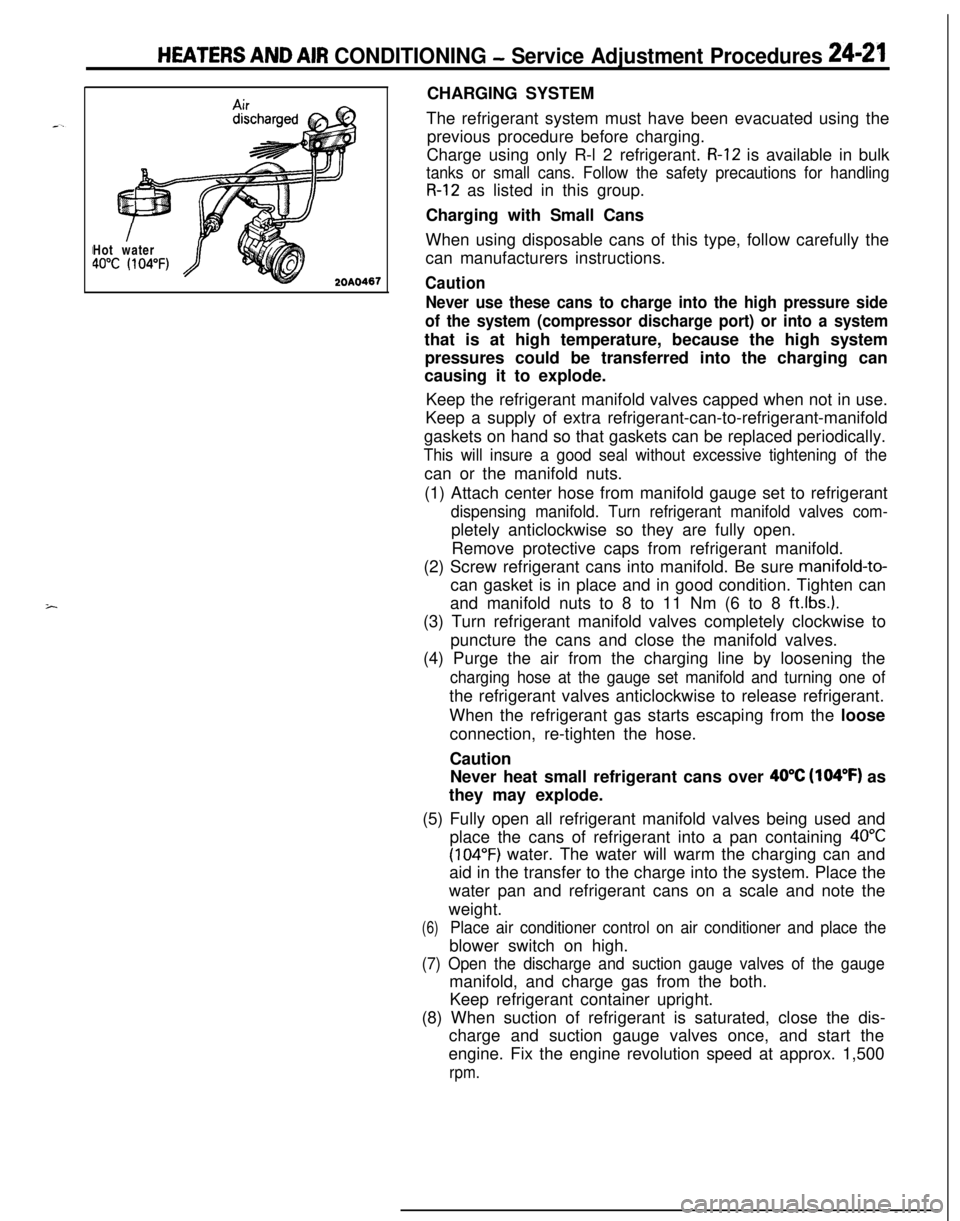

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-21Hot water40°C (104°F)

1467CHARGING SYSTEM

The refrigerant system must have been evacuated using the

previous procedure before charging.

Charge using only R-l 2 refrigerant.

R-12 is available in bulk

tanks or small cans. Follow the safety precautions for handling

R-12 as listed in this group.

Charging with Small Cans

When using disposable cans of this type, follow carefully the

can manufacturers instructions.

Caution

Never use these cans to charge into the high pressure side

of the system (compressor discharge port) or into a systemthat is at high temperature, because the high system

pressures could be transferred into the charging can

causing it to explode.

Keep the refrigerant manifold valves capped when not in use.

Keep a supply of extra refrigerant-can-to-refrigerant-manifold

gaskets on hand so that gaskets can be replaced periodically.

This will insure a good seal without excessive tightening of thecan or the manifold nuts.

(1) Attach center hose from manifold gauge set to refrigerant

dispensing manifold. Turn refrigerant manifold valves com-pletely anticlockwise so they are fully open.

Remove protective caps from refrigerant manifold.

(2) Screw refrigerant cans into manifold. Be sure

manifold-to-can gasket is in place and in good condition. Tighten can

and manifold nuts to 8 to 11 Nm (6 to 8

ft.lbs.).(3) Turn refrigerant manifold valves completely clockwise to

puncture the cans and close the manifold valves.

(4) Purge the air from the charging line by loosening the

charging hose at the gauge set manifold and turning one ofthe refrigerant valves anticlockwise to release refrigerant.

When the refrigerant gas starts escaping from the loose

connection, re-tighten the hose.

Caution

Never heat small refrigerant cans over

40°C (104°F) as

they may explode.

(5) Fully open all refrigerant manifold valves being used and

place the cans of refrigerant into a pan containing

40°C

(104°F) water. The water will warm the charging can and

aid in the transfer to the charge into the system. Place the

water pan and refrigerant cans on a scale and note the

weight.

(6)Place air conditioner control on air conditioner and place theblower switch on high.

(7) Open the discharge and suction gauge valves of the gaugemanifold, and charge gas from the both.

Keep refrigerant container upright.

(8) When suction of refrigerant is saturated, close the dis-

charge and suction gauge valves once, and start the

engine. Fix the engine revolution speed at approx. 1,500

rpm.

Page 1166 of 1216

24-22 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures(9) Charge through the suction side of the system by slowly

opening the suction manifold valve. Adjust the valve as

necessary so charging pressure does not exceed 345

kPa 6(50 psi). Maintain the temperature of the water in the pan w’

by adding warm water as necessary.

Note the weight of water added, to ensure accuracy when

determining amount of refrigerant added to system.

(lO)When specified refrigerant charge Max. 925

g (32 oz.) has

entered the system, close the gauge set manifold valves,

refrigerant manifold valves, and

reconnnect wiring. Each

can contains 397

g (14 oz.) of R-l 2. Use 2 l/2 cans.

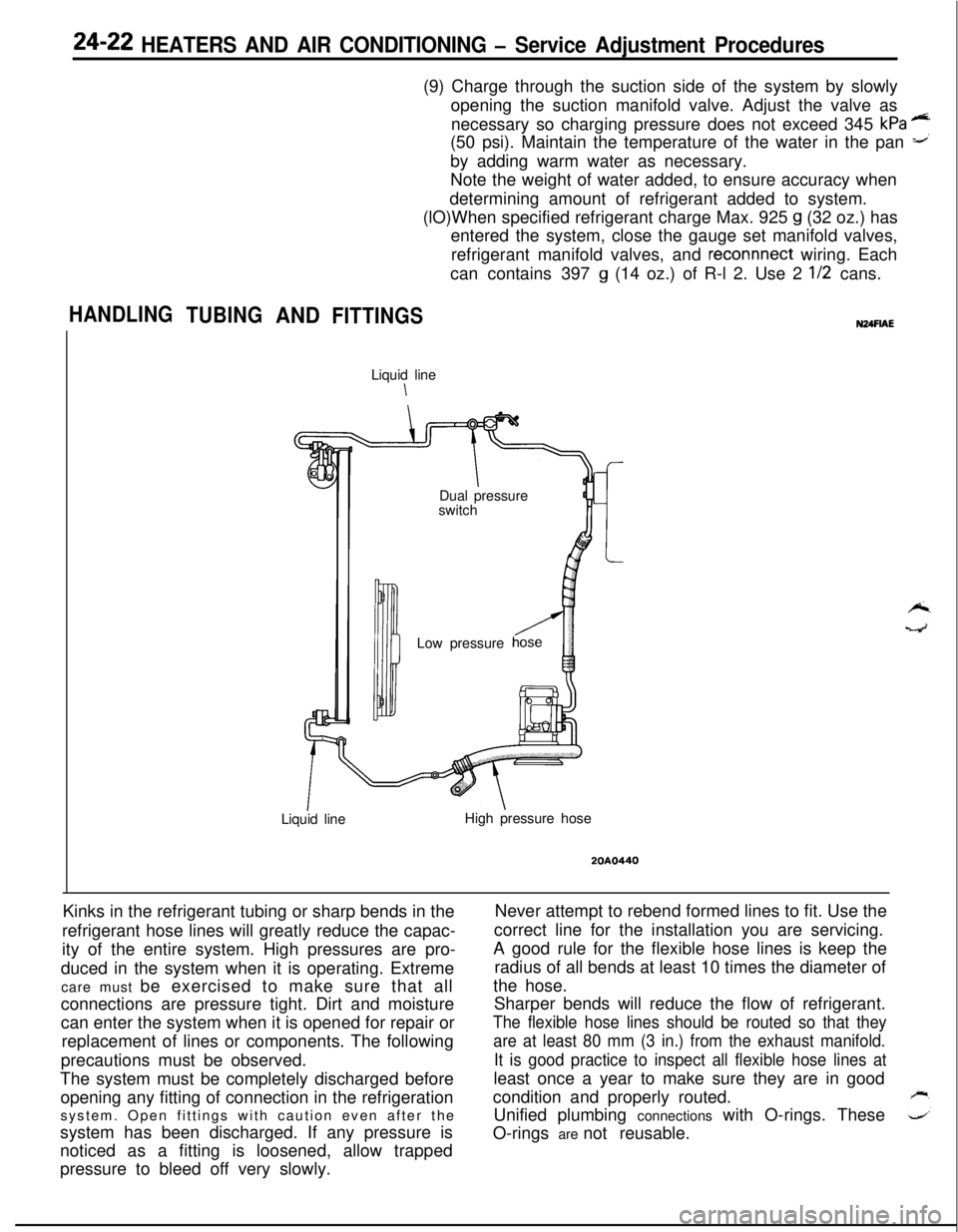

HANDLING

TUBINGANDFITTINGSLiquid line

\

IDual pressure

switch

Low pressure

Liquid lineHigh pressure hose

20A0440Kinks in the refrigerant tubing or sharp bends in the

refrigerant hose lines will greatly reduce the capac-

ity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all

connections are pressure tight. Dirt and moisture

can enter the system when it is opened for repair or

replacement of lines or components. The following

precautions must be observed.

The system must be completely discharged before

opening any fitting of connection in the refrigeration

system. Open fittings with caution even after the

system has been discharged. If any pressure is

noticed as a fitting is loosened, allow trapped

pressure to bleed off very slowly.Never attempt to rebend formed lines to fit. Use the

correct line for the installation you are servicing.

A good rule for the flexible hose lines is keep the

radius of all bends at least 10 times the diameter of

the hose.

Sharper bends will reduce the flow of refrigerant.

The flexible hose lines should be routed so that they

are at least 80 mm (3 in.) from the exhaust manifold.

It is good practice to inspect all flexible hose lines atleast once a year to make sure they are in good

condition and properly routed.

Unified plumbing connections with O-rings. These

O-rings are not reusable.