169 MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 29 of 1216

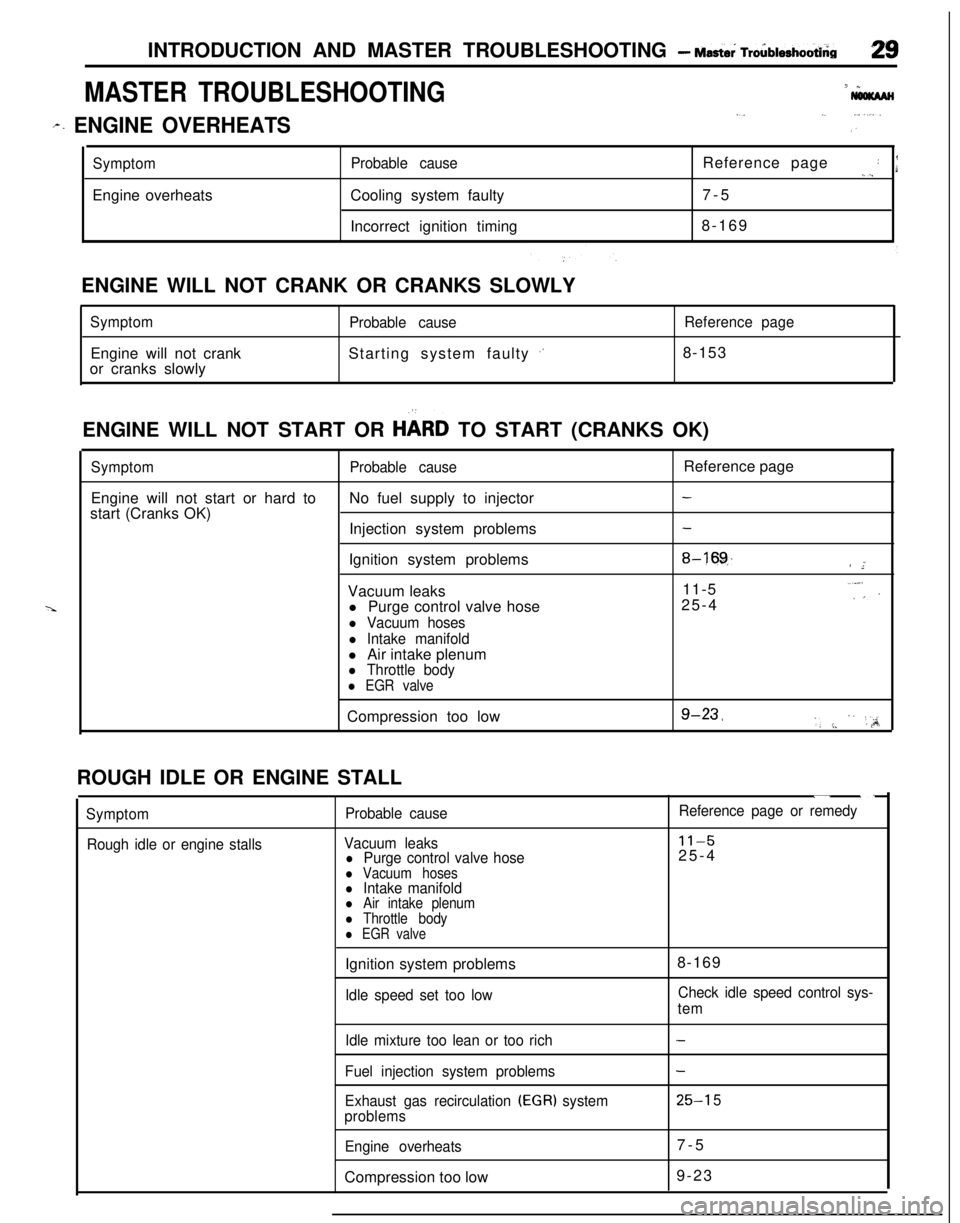

INTRODUCTION AND MASTER TROUBLESHOOTING - Mast& Tro6blerhootbia

MASTER TROUBLESHOOTING7 *

I,._ ,...

r. ENGINE OVERHEATSi ”

SymptomEngine overheatsProbable causeCooling system faulty

Incorrect ignition timingReference page: I._),7-5

8-169

ENGINE WILL NOT CRANK OR CRANKS SLOWLY

SymptomEngine will not crank

or cranks slowlyProbable causeStarting system faulty

,’

Reference page8-153

ENGINE WILL NOT START OR

HbRD TO START (CRANKS OK)

SymptomProbable causeReference page

Engine will not start or hard toNo fuel supply to injector

-start (Cranks OK)

Injection system problems

-Ignition system problems

8-16!$/ ”;Vacuum leaks11-5..“,:’l Purge control valve hose25-4

l Vacuum hoses

l Intake manifoldl Air intake plenum

l Throttle body

l EGR valveCompression too low

g-23,‘, :. ” ‘,;A;ROUGH IDLE OR ENGINE STALL

Symptom

Rough idle or engine stallsProbable cause

Vacuum leaks

l Purge control valve hosel Vacuum hosesl Intake manifoldl Air intake plenuml Throttle bodyl EGR valve

“. ._

Reference page or remedy

11-525-4

Ignition system problems

Idle speed set too low8-169Check idle speed control sys-

tem

Idle mixture too lean or too rich

Fuel injection system problems

Exhaust gas recirculation

(EGR) system

problems

Engine overheatsCompression too low

-

-

25-l 57-5

9-23

Page 30 of 1216

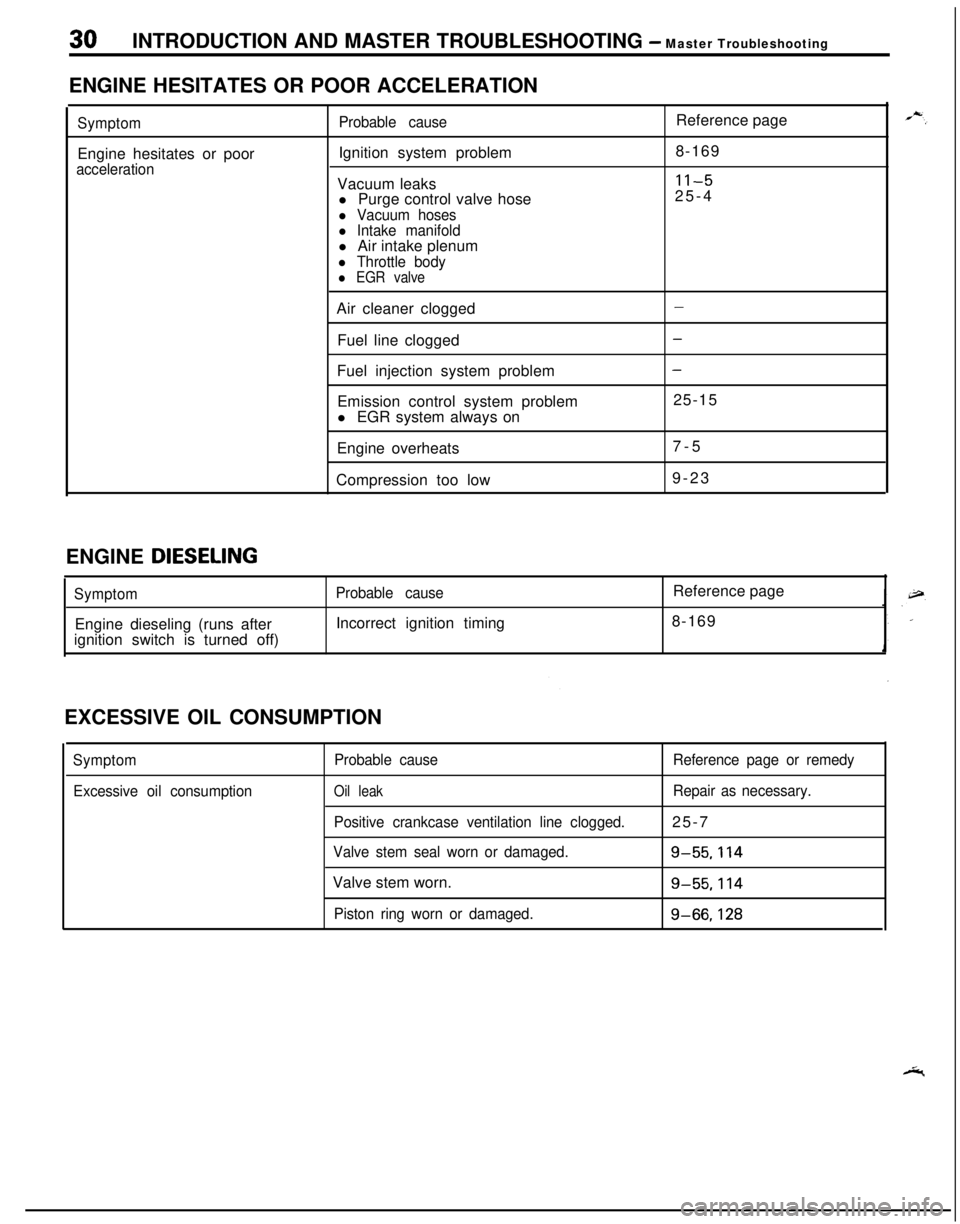

30INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting

ENGINE HESITATES OR POOR ACCELERATION

SymptomEngine hesitates or poor

accelerationProbable causeIgnition system problem

Vacuum leaks

l Purge control valve hose

l Vacuum hosesl Intake manifoldl Air intake plenum

l Throttle bodyl EGR valveReference page

8-169

11-525-4

Air cleaner clogged

Fuel line clogged

Fuel injection system problem

Emission control system problem

l EGR system always on

Engine overheats

Compression too low

-

-

-25-15

7-5

9-23

ENGINE

DIESELING

SymptomEngine dieseling (runs after

ignition switch is turned off)Probable causeIncorrect ignition timingReference page

8-169

EXCESSIVE OIL CONSUMPTION

Symptom

Excessive oil consumptionProbable cause

Oil leak

Positive crankcase ventilation line clogged.

Valve stem seal worn or damaged.Valve stem worn.

Piston ring worn or damaged.Reference page or remedy

Repair as necessary.25-7

g-55.114

g-55.114

g-66,128

Page 31 of 1216

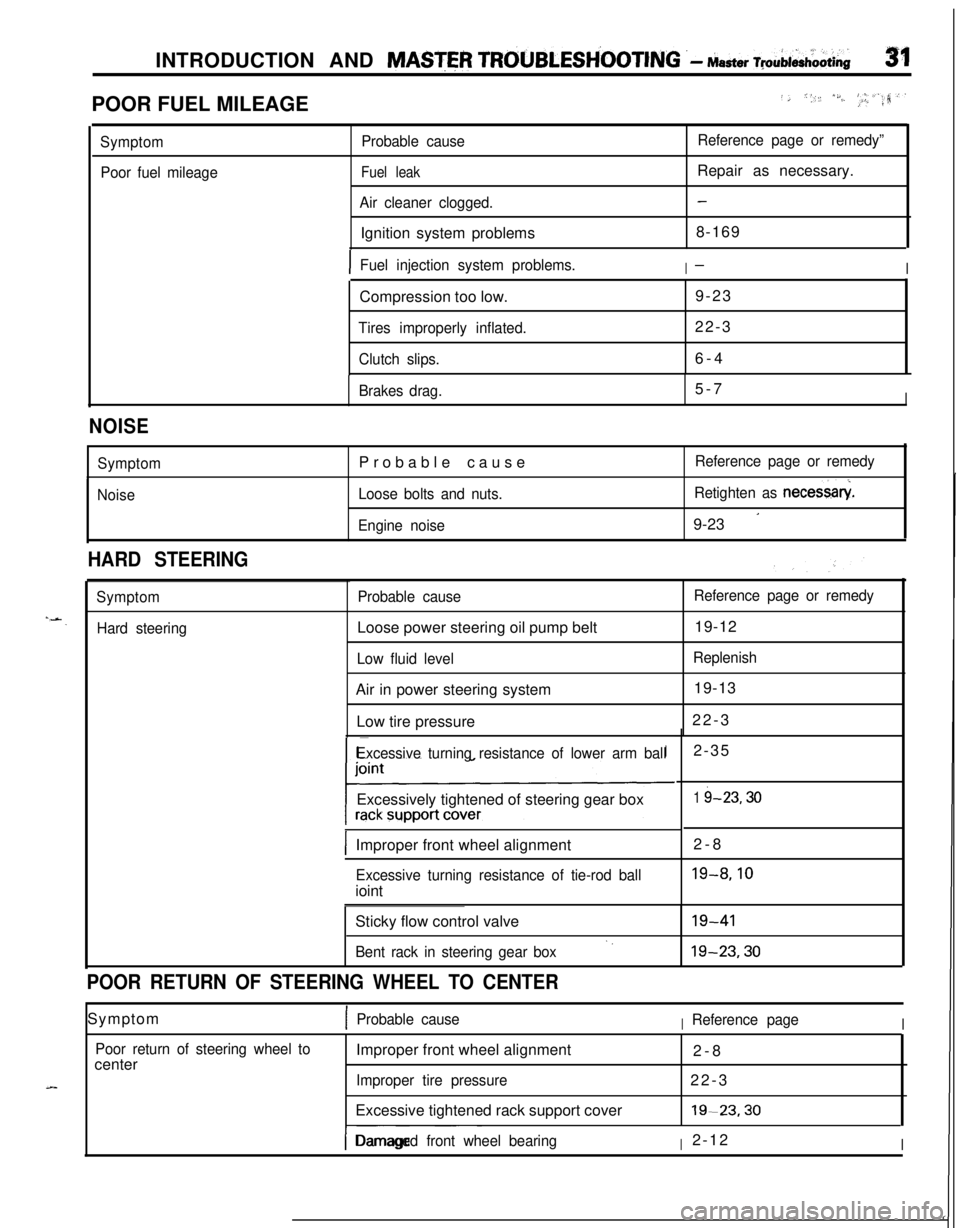

INTRODUCTION AND MASTER TROUBLESH’OOTING .- Master ~pAi&oOti~31POOR FUEL MILEAGE

../, *,, /S./..‘, _I, #_.a,‘.rr?

Symptom

Poor fuel mileageProbable cause

Fuel leak

Air cleaner clogged.Ignition system problems

Reference page or remedy”Repair as necessary.

-8-169

IFuel injection system problems.I-ICompression too low.9-23

Tires improperly inflated.22-3

Clutch slips.6-4

Brakes drag.5-7I

NOISE

Symptom

NoiseProbable cause

Loose bolts and nuts.

Engine noiseReference page or remedy

Retighten as necessary

9-23

’

HARD STEERING

Symptom

Hard steeringProbable causeLoose power steering oil pump belt

Low fluid levelAir in power steering system

Low tire pressure

Reference page or remedy19-12

Replenish19-13

22-3

Excessive turning resistance of lower arm ballExcessively tightened of steering gear box

IImproper front wheel alignment2-8

Excessive turning resistance of tie-rod ballioint2-35

1 i-23.30

19-8.10Sticky flow control valve

Bent rack in steering gear box‘.19-4119-23.30

POOR RETURN OF STEERING WHEEL TO CENTERSymptom

1Probable causeIReference pageI

Poor return of steering wheel tocenterImproper front wheel alignment

2-8

Improper tire pressure22-3

Excessive tightened rack support cover19-23.30

I-- ~~~Damaged front wheel bearingI2-12I

Page 66 of 1216

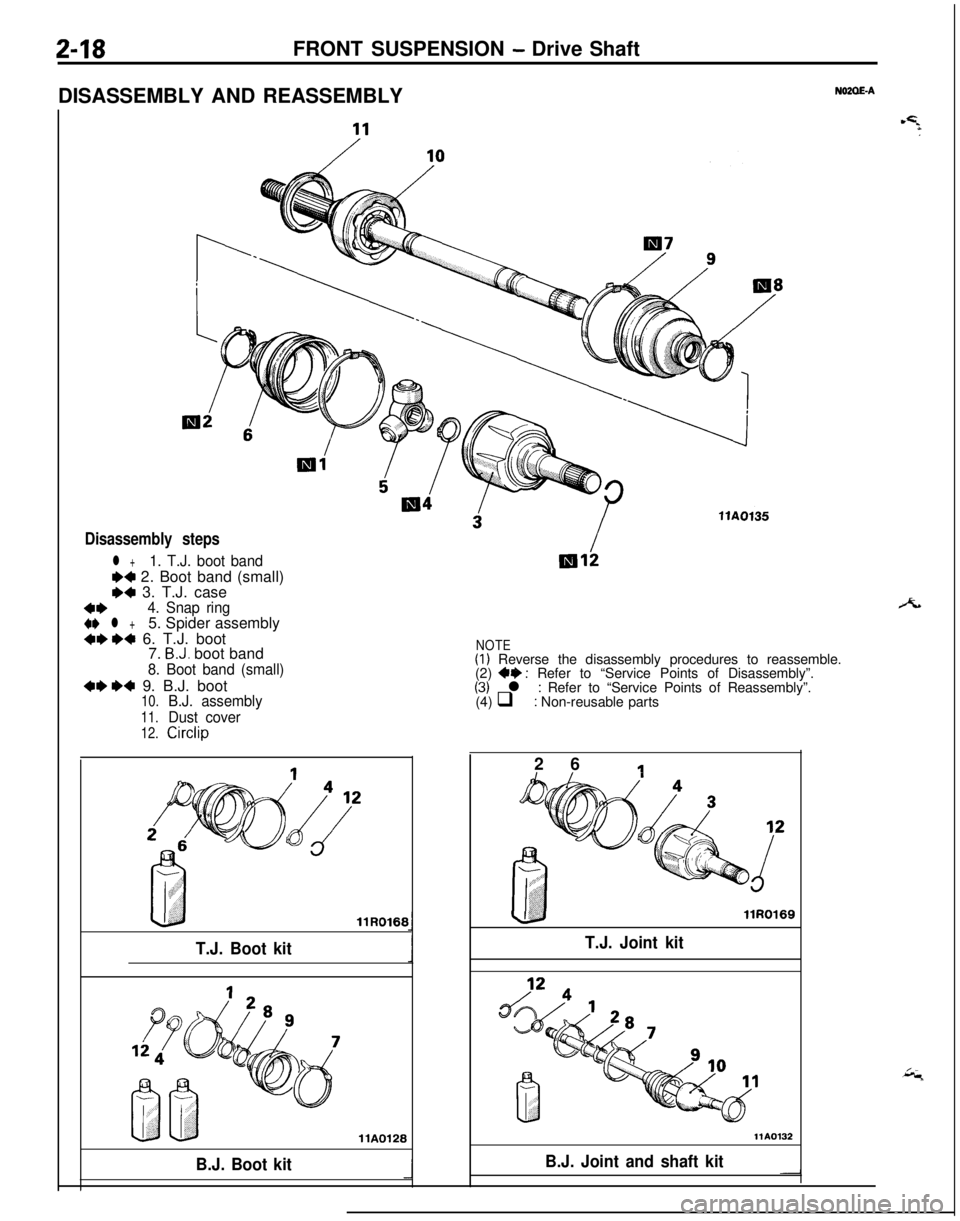

Z-18FRONT SUSPENSION - Drive Shaft

DISASSEMBLY AND REASSEMBLY

NOZOE-A

Disassembly steps

l +1. T.J. boot band

W 2. Boot band (small)e4 3. T.J. case

4*4. Snap ring

4I) l +5. Spider assembly4ee4 6. T.J. boot

7. B.J. boot band

8. Boot band (small)

4ee4 9. B.J. boot10.B.J. assembly

11.Dust cover

12.Circlip

T.J. Boot kitllR0166

llA0128

B.J. Boot kitllAOf35

NOTE(I) Reverse the disassembly procedures to reassemble.

(2) 4+ : Refer to “Service Points of Disassembly”.(3) l : Refer to “Service Points of Reassembly”.

(4) q : Non-reusable parts

2 6

1

llR0169

T.J. Joint kit

-IB.J. Joint and shaft kit

Page 98 of 1216

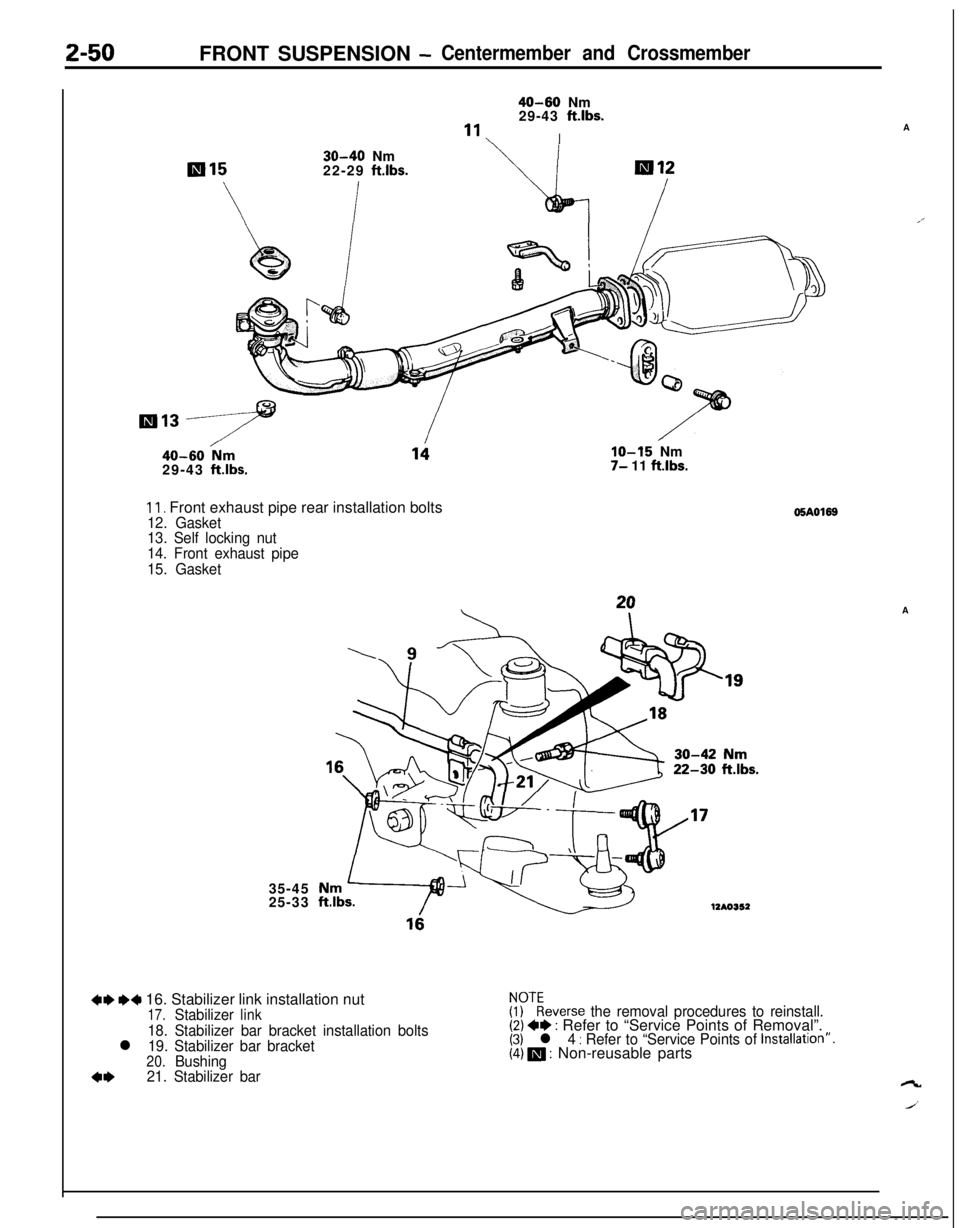

2-50FRONT SUSPENSION -Centermember and Crossmember

40-60 Nm

29-43 ftlbs.

“1I

30-40 Nm

22-29 ftlbs.

40-60 /Nm29-43 ftlbs.

11. Front exhaust pipe rear installation bolts12. Gasket

13. Self locking nut

14. Front exhaust pipe

15. Gasket35-45

25-33

IO-15 Nm7- 11 ftlbs.

22-30 ftlbs.

12AO352

+e MI 16. Stabilizer link installation nut17.Stabilizerlink

18. Stabilizer bar bracket installation boltsl 19. Stabilizer bar bracket20.Bushing

4*21. Stabilizer bar

05AO169

$?everse the removal procedures to reinstall.(2) +* : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installatron”.(4) m : Non-reusable partsA

A’A

ct

J’

Page 186 of 1216

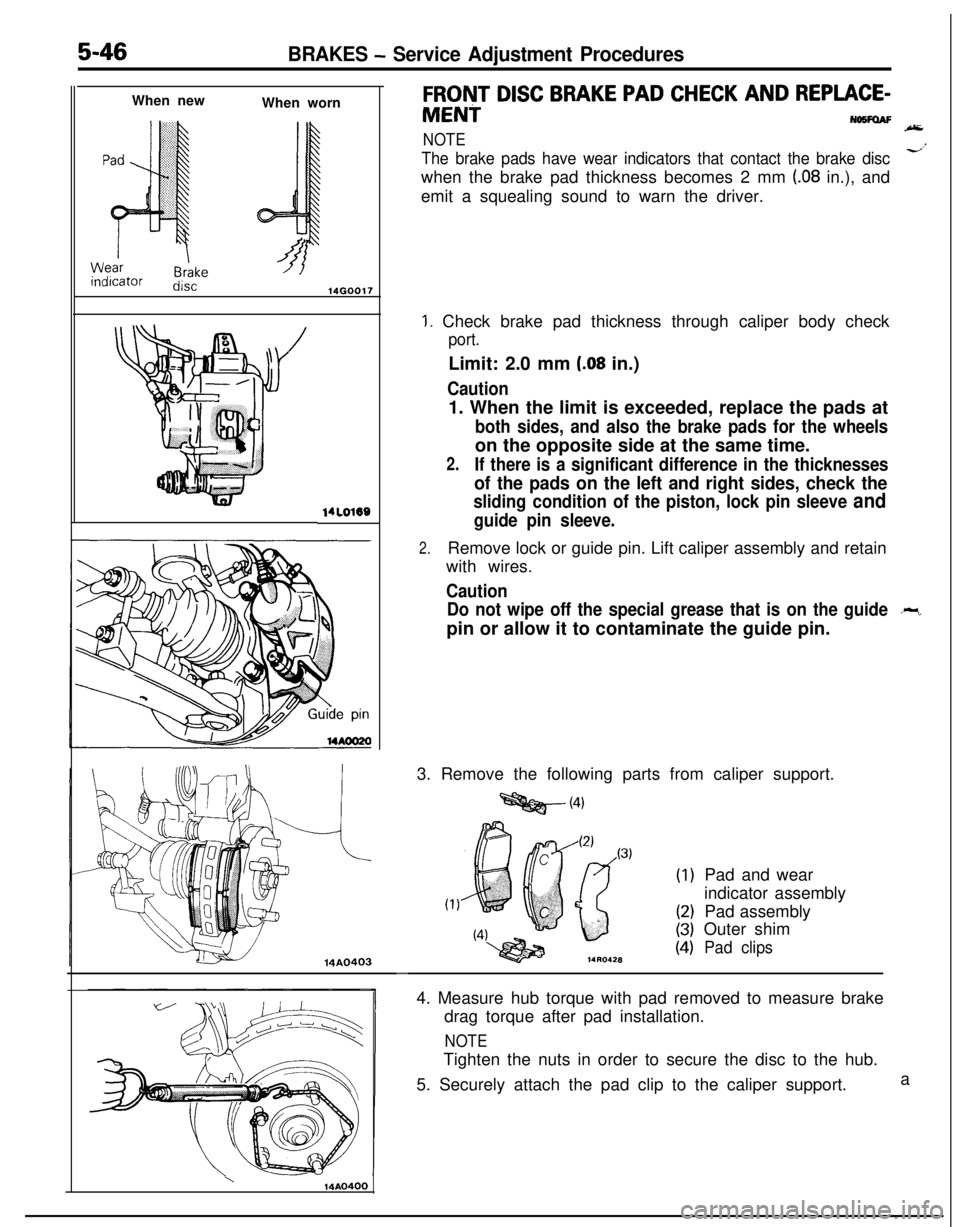

5-46BRAKES - Service Adjustment ProceduresWhen new

When worn

14G0017

14LO169

14A0403

\14AO400

FRONT DISC BRAKE PAD CHECK AND REPLACE-

MENiNWFOAF

NOTE

The brake pads have wear indicators that contact the brake discd’when the brake pad thickness becomes 2 mm

(.08 in.), and

emit a squealing sound to warn the driver.

1. Check brake pad thickness through caliper body check

port.Limit: 2.0 mm

(.08 in.)

Caution1. When the limit is exceeded, replace the pads at

both sides, and also the brake pads for the wheelson the opposite side at the same time.

2.If there is a significant difference in the thicknesses

of the pads on the left and right sides, check the

sliding condition of the piston, lock pin sleeve and

guide pin sleeve.

2.Remove lock or guide pin. Lift caliper assembly and retain

with wires.

Caution

Do not wipe off the special grease that is on the guide

-pin or allow it to contaminate the guide pin.

3. Remove the following parts from caliper support.

=Qg@-(4)

(1)

(2)

(3)

(4)Pad and wear

indicator assembly

Pad assembly

Outer shimPad clips

-4. Measure hub torque with pad removed to measure brake

drag torque after pad installation.

NOTETighten the nuts in order to secure the disc to the hub.

5. Securely attach the pad clip to the caliper support.a

Page 768 of 1216

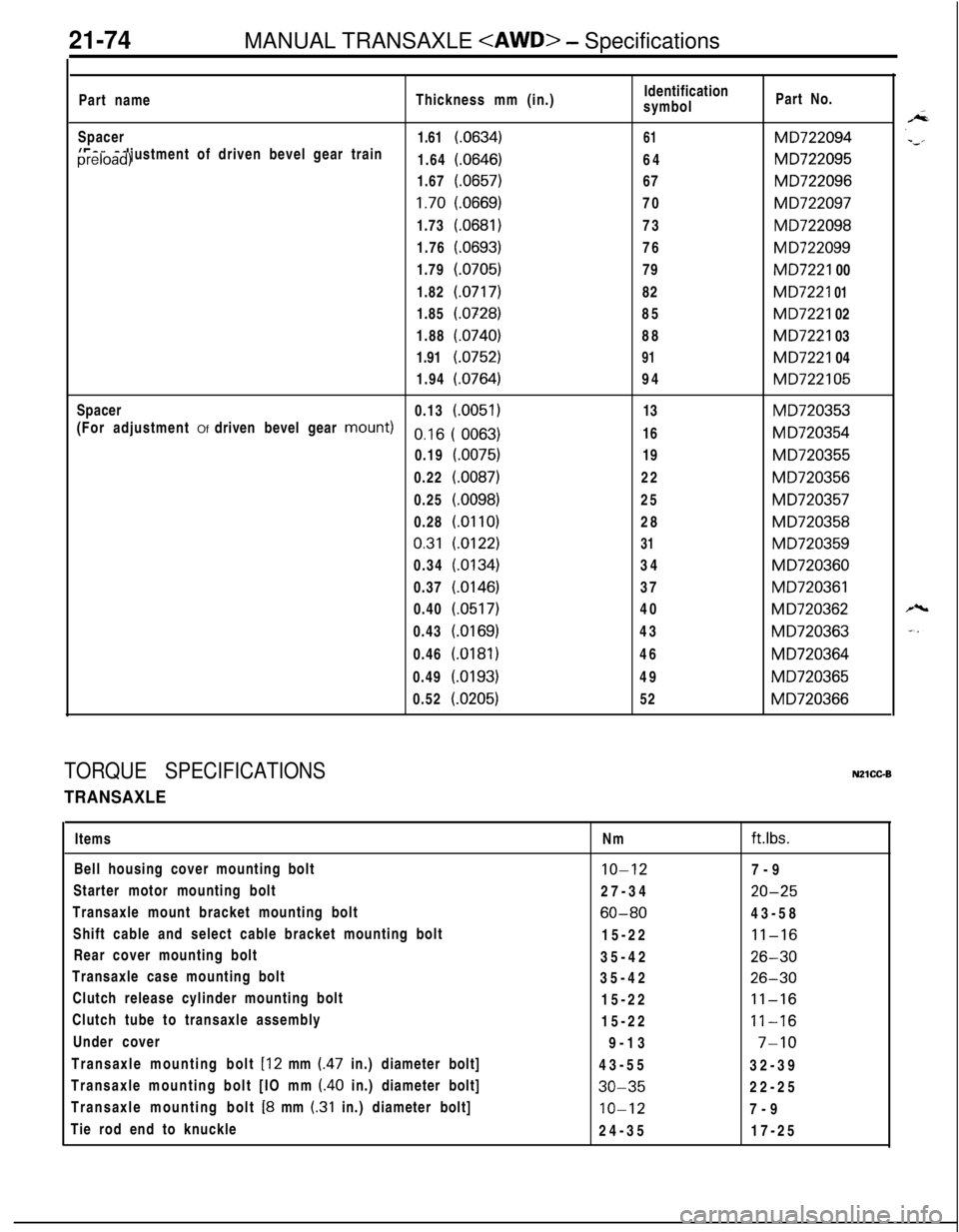

21-74MANUAL TRANSAXLE

Part nameThickness mm (in.)Identification

symbolPart No.

Spacer

1.61

(.0634)61MD722094(For adjustment of driven bevel gear trainpreload)

1.64

(.0646)64MD7220951.67

(0657)67MD722096

1.70(.0669)70MD7220971.73

(0681)73MD7220981.76

(.0693)76M D7220991.79

(0705)79MD7221 00

1.82

(0717)82MD7221 011.85

(.0328)85MD7221 02

1.88

(.0740)88MD7221 03

1.91

(.0752)91MD7221 04

1.94

(0764)94MD722105Spacer

0.13

(0051)13MD720353(For adjustment Of driven bevel gear

mOWIt)o,16 ( 0063)16M D7203540.19

(0075)19MD7203550.22

(.0087)22MD7203560.25

(.0098)25MD7203570.28(.Ol

IO)28MD7203580.31

(0122)31MD7203590.34

(0134)34MD7203600.37

(0146)37MD7203610.40

(0517)40M D7203620.43

(.0169)43MD7203630.46

(0181)46MD7203640.49

(.0193)49MD7203650.52

(0205)52MD720366

TORQUE SPECIFICATIONSNZlCC-B

TRANSAXLEItems

Bell housing cover mounting bolt

Starter motor mounting bolt

Transaxle mount bracket mounting bolt

Shift cable and select cable bracket mounting bolt

Rear cover mounting bolt

Transaxle case mounting bolt

Clutch release cylinder mounting bolt

Clutch tube to transaxle assembly

Under cover

Transaxle mounting bolt

[I2 mm (47 in.) diameter bolt]

Transaxle mounting bolt [IO mm

(40 in.) diameter bolt]

Transaxle mounting bolt [8 mm (.31 in.) diameter bolt]

Tie rod end to knuckleNm

ft.lbs.

IO-127-9

27-34

20-25

60-8043-58

15-22

11-1635-42

26-3035-42

26-3015-22

11-1615-22

11-169-13

7-1043-55

32-39

30-3522-25

IO-127-9

24-3517-25

Page 855 of 1216

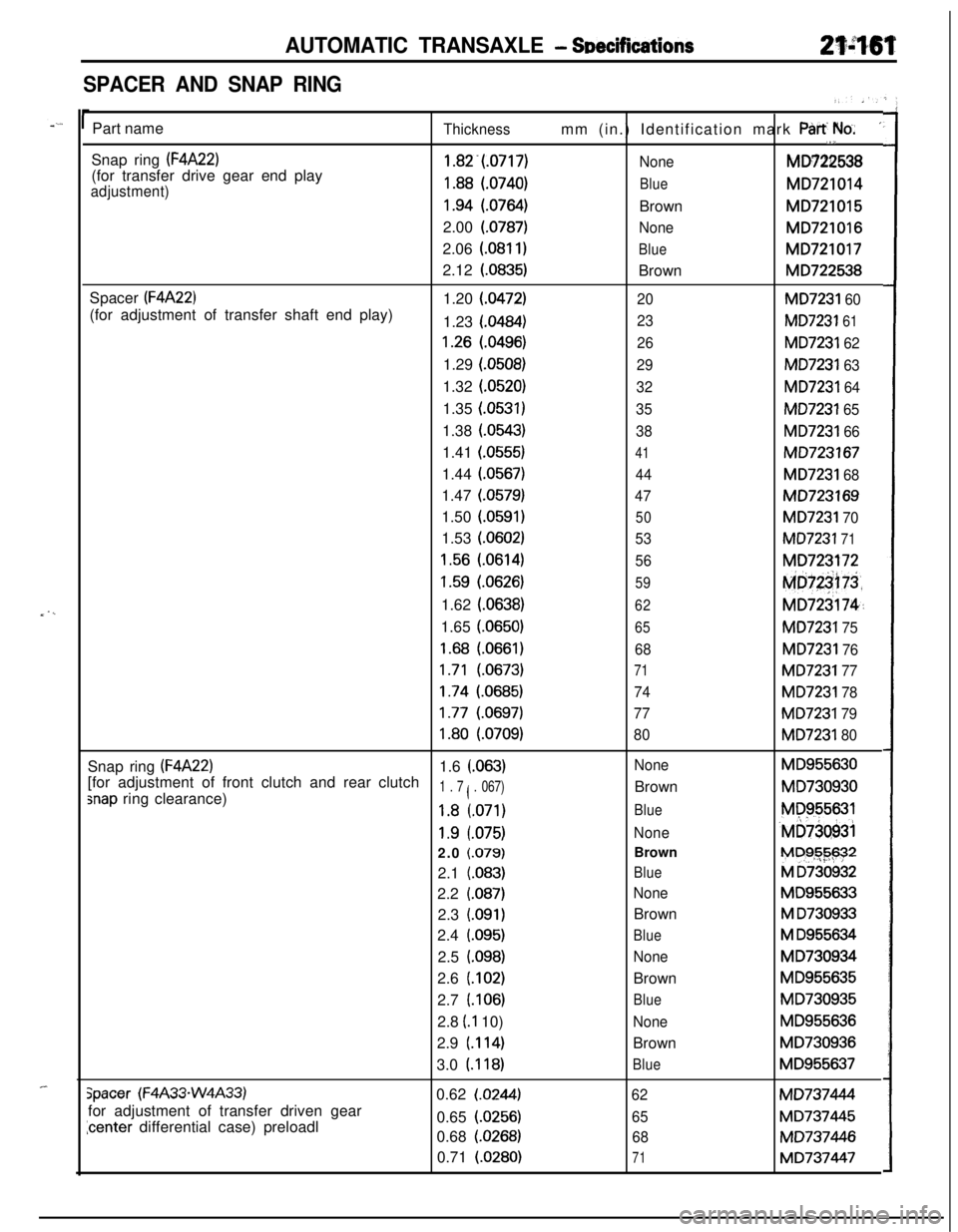

AUTOMATIC TRANSAXLE - SDecifications

SPACER AND SNAP RING

_ . ,_

_-Part name

Thicknessmm (in.) Identification mark Part We.’,1,Snap ring

(F4A22)1.82.(.0717)

NoneMD722538

(for transfer drive gear end play

adjustment)1.88 (.0740)BlueMD721014

1.94 (.0764)BrownMD721015

2.00 (0787)

NoneMD721016

2.06

(.081 I)BlueMD7210172.12

(.0835)BrownMD722538

Spacer

(F4A22)1.20 (0472)20MD7231 60(for adjustment of transfer shaft end play)

1.23 (0484)

23MD7231 61

1.26 (.0496)26MD7231 621.29 (0508)

29MD7231 631.32 (0520)

32MD7231 641.35 (0531)

35MD7231 651.38 (0543)

38MD7231 661.41 (0555)

41MD7231671.44

(.0567)44MD7231 681.47

(.0579)47MD723169

1.50

(.0591)

50MD7231 701.53 (0602)

53MD7231 71

1.56 (.0614)56MD723172

1.59 (0626)59Md@75,1.62

(.0638)

62MD723174~:1.65 (0650)

65MD7231 75

1.68 (.0661)68MD7231 76

1.71 (.0673)71MD7231 77

1.74 (.0685)74MD7231 78

1.77 (.0697)77MD7231 79

1.80 (.0709)80MD7231 80Snap ring

(F4A22)1.6 (.063)NoneMD955630[for adjustment of front clutch and rear clutch

snap ring clearance)1 . 7 ( . 067)BrownMD730930

1.8 (.071)BlueMP955631

1.9 l.075)None‘MD73Q93i2.0 f.079)BrownM~$G-$$?*

2.1

(.083)BlueM D7309322.2

(.087)NoneMD955633

2.3

(.091)BrownM D7309332.4

(.095)BlueM D9556342.5

i.098)NoneMD730934

2.6

(.102)BrownMD955635

2.7 (106)

BlueMD730935

2.8 (.I 10)

NoneMD9556362.9

(.114)BrownMD730936

3.0 (118)

BlueMD955637

Spacer (F4A33-W4A33)0.62 (.0244)62MD737444

for adjustment of transfer driven gear

icenter differential case) preloadl0.65 (0256)65MD7374450.68

(.0268)68MD737446

0.71 (0280)

71MD737447

Page 859 of 1216

AUTOMATIC TRANSAXLE - Specifi6atiorisPart name

Spacer

(W4A33)(for adjustment of drive bevel gear train

preload)Spacer

(W4A33)(for adjustment of driven bevel gear train

preload)

Spacer (W4A33)

~for adjustment of driven bevel gear trainxeload)

spacer (W4A33)for adjustment of driven bevel gear mount)

Thickness1.64

(.0646)1.67

(.0657)1.70

(.0669)1.73 (0681)

1.76 l.0693)1.79

(.0705)

1.82(0717)

1.85

(.0728)

1.19

(.0469)

1.22(0480)

1.25(.0492)

1.28(0504)

1.31(0516)

1.34(0528)

1.37(.0539)

1.40(0551)

1.43(.0563)

1.46(0575)

1.49(.0587)

1.52(0598)

1.55(0610)

1.58(0622)

1.61(0634)

1.64(0646)

1.67(.0657)

1.70(.0669)

1.73(0681)

1.76(.0693)

1.79

(.0705)

1.82(0717)

1.85(0728)

1.88(.0740)

1.91(.0752)

1.94

(.0764)

0.13(0051)

0.16

(.0063)0.19 (0075)

0.22(0087)

0.25(.0098)0.28

(.Ol 10)0.31(0122)

0.34(0134)

0.37(0146)

0.40(.0517)

0.43(.0169)

0.46(0181)

0.49(.0193)

0.52(0205)mm (in.) Identification mark ‘Part

‘);ilb. I”

B64MD724335

B67MD724336

B70MD724337

B73M~724338

B76MD724339

B79MD724340882

MD724341

B85MD724342

19MD7261 72

22

MD722081

25MD722082

28MD722683

31MD722084

34MD722085

37MD722086

40MD722087

43MD722088

46MD722089

49MD7228090

52

.MD722091

55MD722092

58MD722093

61MD722694

64MD722095

67MD722096

70MD722097

73MD722098

76MD722099

79MD7221 00

82MD7221 01’

85MD7221 02

88

MD7221 03

91MD7221 04

94

MD7221 05

13MD720353

16MD720354

j19MD72035522M~$,gjg~~

25,:!,MD’ly&““$28””

“’ti&2&58

e>I3 1hbf,&$&

34,‘IMbf2tiyo

37MD720361

40

MD720362

43

MD726363

46MD720364

49MD720365

52MD720366

Page 912 of 1216

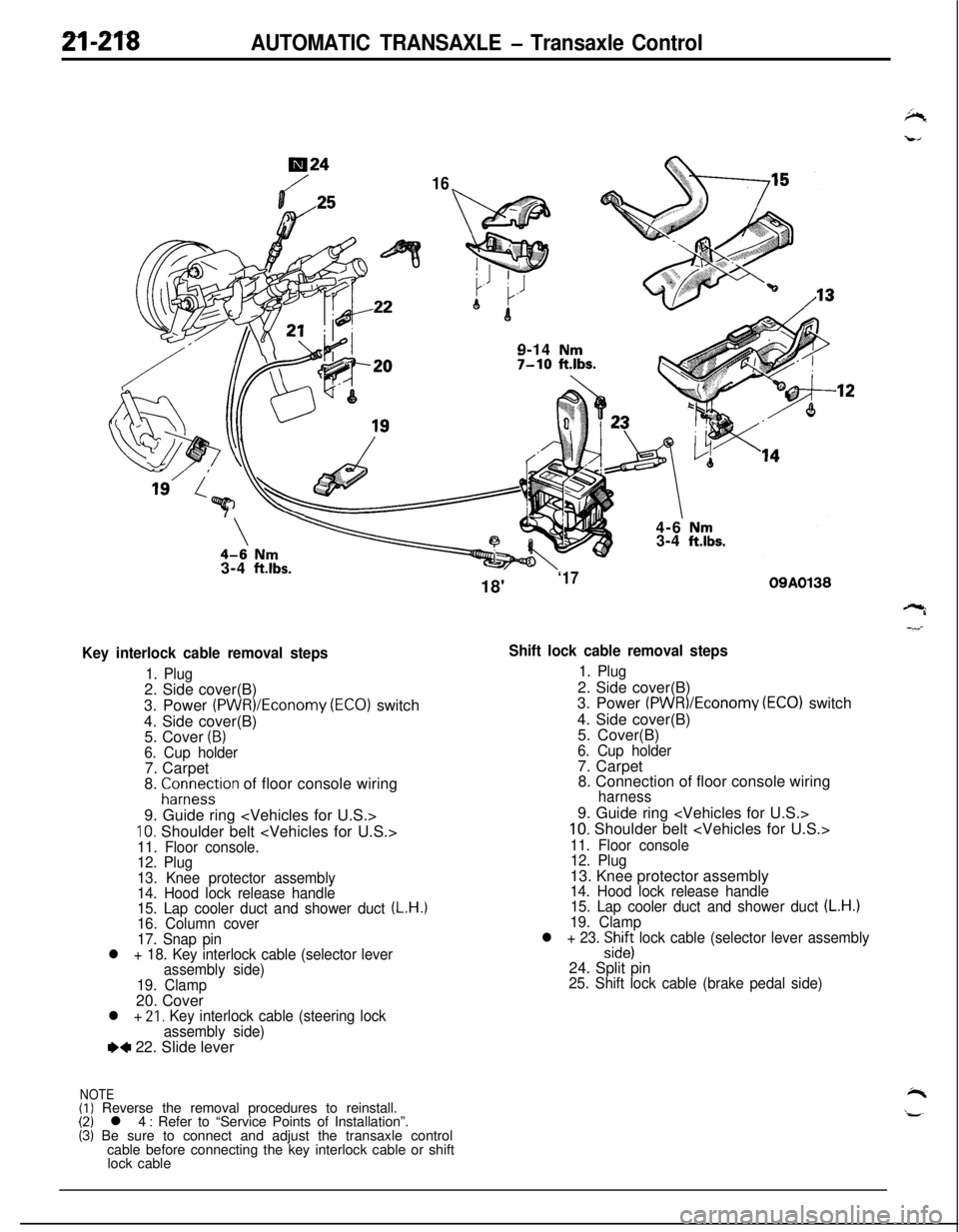

2l-218AUTOMATIC TRANSAXLE - Transaxle Control

724

169-14

Nm7-10 ftlbs.7

\\4-6 Nm3-4 ft.lbs.3-4

ft.lbs.

Key interlock cable removal steps

1. Plug2. Side cover(B)

3. Power

(PWR)/Economy (ECO) switch

4. Side cover(B)

5. Cover

(B)6. Cup holder7. Carpet

8.

;ir;eystion of floor console wiring

9. Guide ring

10. Shoulder belt

12. Plug

13. Knee protector assembly

14. Hood lock release handle

15. Lap cooler duct and shower duct

(L.H.)16. Column cover

17. Snap pin

l + 18. Key interlock cable (selector lever

assembly side)

19. Clamp20. Cover

l + 21, Key interlock cable (steering lock

assembly side)

e+ 22. Slide lever

NOTE(I) Reverse the removal procedures to reinstall.(2) l 4 : Refer to “Service Points of Installation”.(3) Be sure to connect and adjust the transaxle control

cable before connecting the key interlock cable or shift

lock cable18'

‘1709A0138

Shift lock cable removal steps

1. Plug2. Side cover(B)

3. Power

(PWR)/Economv (EC01 switch

4. Side cover(B)

’5. Cover(B)

6. Cup holder7. Carpet

8. Connection of floor console wiring

harness9. Guide ring

10. Shoulder belt

11. Floor console

12. Plug13. Knee protector assembly

14. Hood lock release handle

15. Lap cooler duct and shower duct (L.H.)19. Clamp

l + 23. :izs lock cable (selector lever assembly24. Split pin

25. Shift lock cable (brake pedal side)