height MITSUBISHI ECLIPSE 1993 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 6 of 57

-

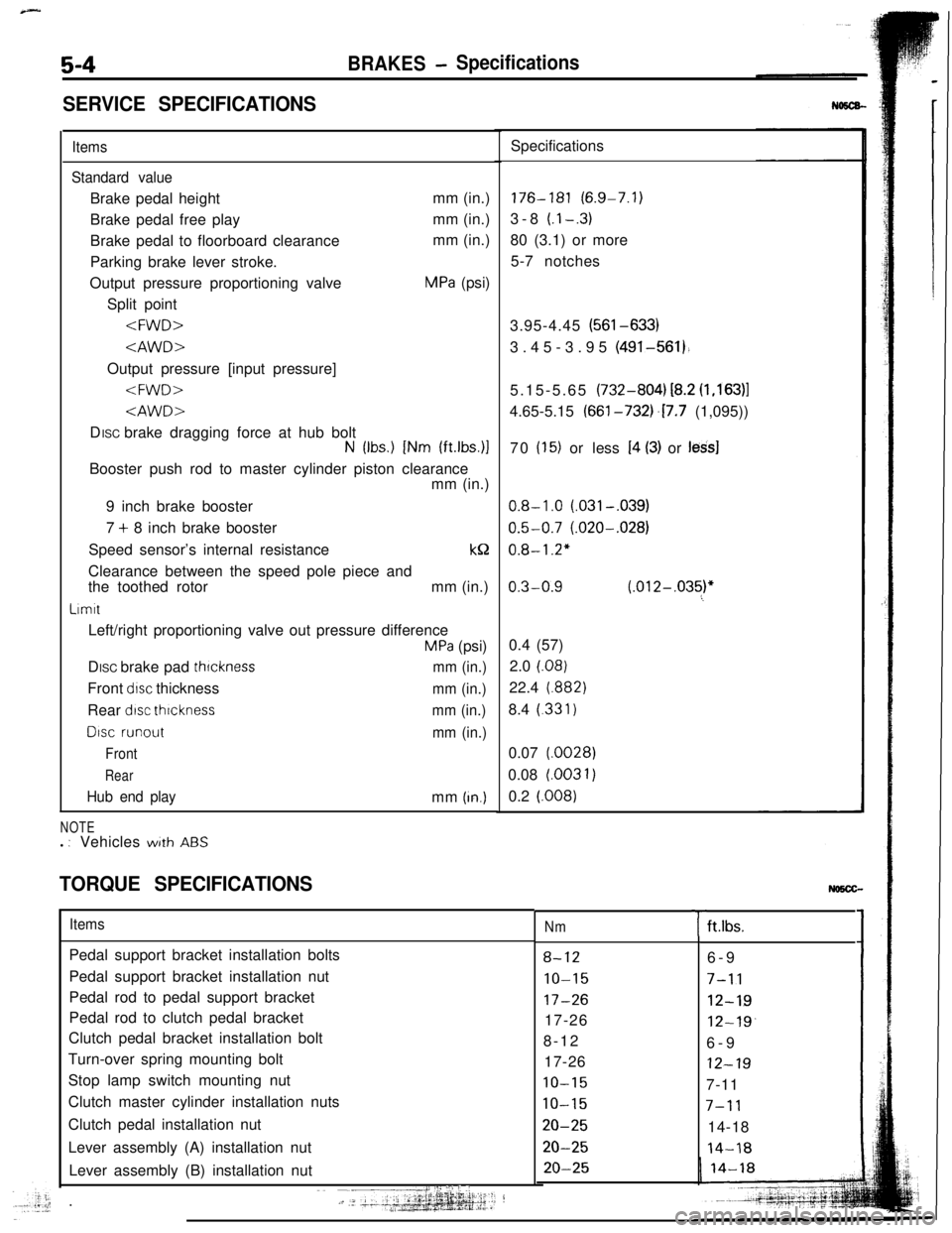

5-4BRAKES- Specifications

SERVICE SPECIFICATIONS

Items

Standard valueBrake pedal heightmm (in.)

Brake pedal free playmm (in.)

Brake pedal to floorboard clearancemm (in.)

Parking brake lever stroke.

Output pressure proportioning valve

MPa (psi)

Split point

N (Ibs.) [Nm (ft.lbs.)lBooster push rod to master cylinder piston clearance

mm (in.)

9 inch brake booster

7 + 8 inch brake booster

Speed sensor’s internal resistancek&

Clearance between the speed pole piece and

the toothed rotormm (in.)

LrmttLeft/right proportioning valve out pressure difference

MPa (psi)

DISC brake pad

thrcknessmm (in.)Front

drsc thicknessmm (in.)Rear

dtsc thrcknessmm (in.)

DISC runout

mm (in.)

Front

Rear

Hub end playmm (In.)

NOTEl : Vehicleswith ABS

TORQUE SPECIFICATIONSSpecifications176-181 (6.9-7.1)

3-8

(.l-.3)80 (3.1) or more

5-7 notches

3.95-4.45 (561-633)

3.45-3.95 (491-561).

5.15-5.65 (732-804) i8.2

(1,163)14.65-5.15 (661-732j.17.7 (1,095))

70

(15) or less I4 (3) or less]

0.8-1.0 (.031-,039)

0.5-0.7 (.020-.028)

0.8-1.2"

0.3-0.9 (.012-,035)"60.4 (57)

2.0

(.08)22.4

(.882)8.4

(.331)0.07

(.0028)0.08 l.0031)

0.2

(.008)

ItemsPedal support bracket installation bolts

Pedal support bracket installation nut

Pedal rod to pedal support bracket

Pedal rod to clutch pedal bracket

Clutch pedal bracket installation bolt

Turn-over spring mounting bolt

Stop lamp switch mounting nut

Clutch master cylinder installation nuts

Clutch pedal installation nut

Lever assembly (A) installation nut

Lever assembly (B) installation nut

I:: ::I .:‘i j ,:~~ -__j.-, .‘- ‘+‘+gg&p.~j:;.;1--?.+.k

Nm

8-12

IO-15

17-2617-26

8-12

17-26

10-15

10-15

20-25

20-25

20-25

Tft.lbs.

6-9

7-11

12-19

12-19.6-9

12-197-11

7-1114-18

14-18

Page 25 of 57

BRAKES 7 Front Disc Brake5-83

14AO55314A0552

\Piston seal\

14AO551

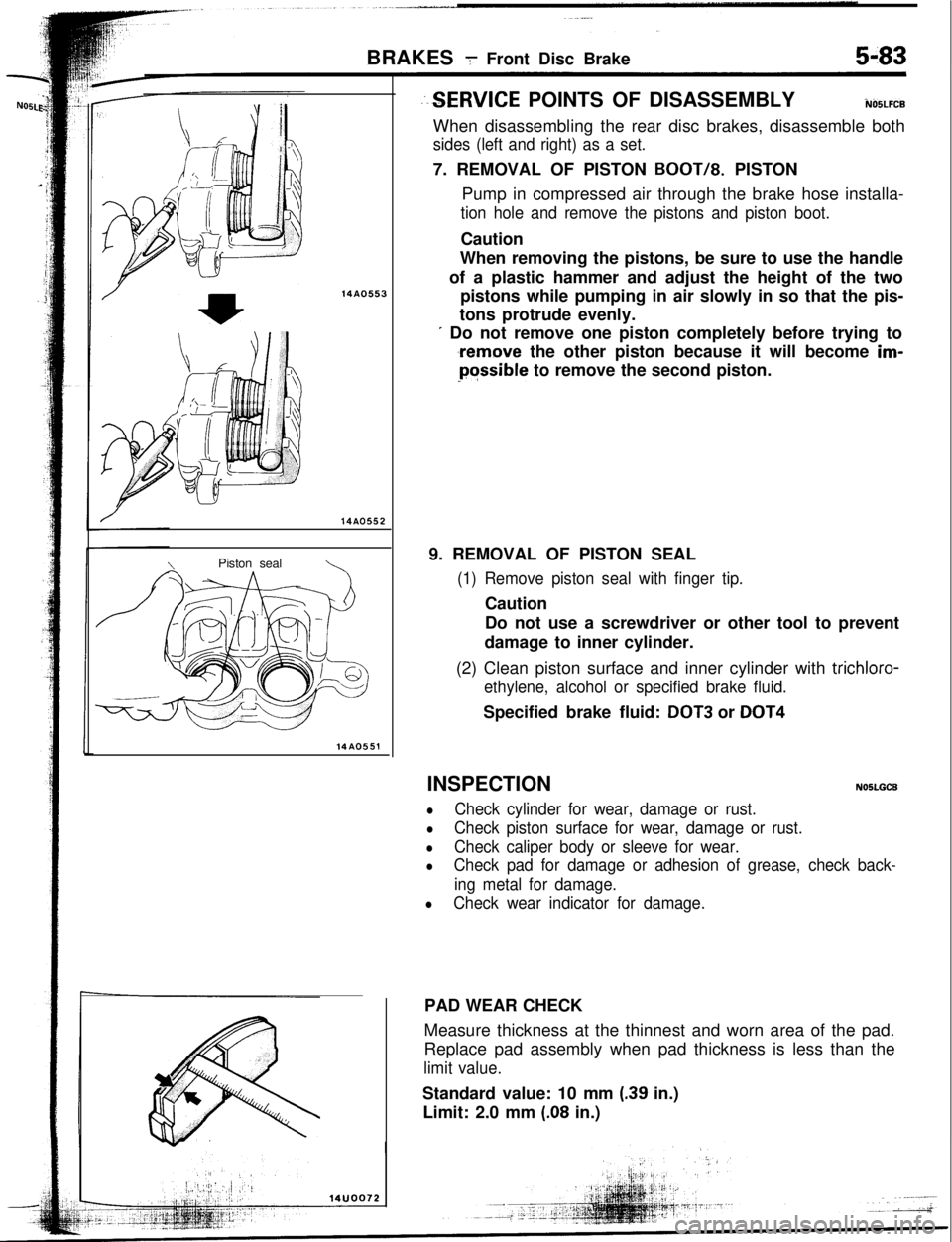

--SERVICE POINTS OF DISASSEMBLYiUO5LFCBWhen disassembling the rear disc brakes, disassemble both

sides (left and right) as a set.7. REMOVAL OF PISTON

BOOT/8. PISTON

Pump in compressed air through the brake hose installa-

tion hole and remove the pistons and piston boot.Caution

When removing the pistons, be sure to use the handle

of a plastic hammer and adjust the height of the two

pistons while pumping in air slowly in so that the pis-

tons protrude evenly.

I Do not remove one piston completely before trying to

,remove the other piston because it will become im-Possible to remove the second piston.

9. REMOVAL OF PISTON SEAL

(1) Remove piston seal with finger tip.Caution

Do not use a screwdriver or other tool to prevent

damage to inner cylinder.

(2) Clean piston surface and inner cylinder with trichloro-

ethylene, alcohol or specified brake fluid.Specified brake fluid:

DOT3 or DOT4INSPECTION

NOSLGCB

lCheck cylinder for wear, damage or rust.

lCheck piston surface for wear, damage or rust.

lCheck caliper body or sleeve for wear.

lCheck pad for damage or adhesion of grease, check back-

ing metal for damage.

lCheck wear indicator for damage.PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace pad assembly when pad thickness is less than the

limit value.Standard value: 10 mm

(.39 in.)

Limit: 2.0 mm

(.08 in.)