MITSUBISHI ECLIPSE 1993 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 1 of 57

Page 2 of 57

Partial BACKUPService Manual

.i’

GROUP INDEXNOSAl

LASER

TALON

1993

Volume-l

Engine, Chassis& Body

FOREWORDThis Service Manual has been prepared with the

latest service information available at the time of

publication. It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any

servicrng necessary to maintain or

restore the high levels of performance and reliabilitydesigned into these outstanding vehicles.

This BACKUP DSM manual IS to be used ONLY as a BACKUP. Please DO NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed OWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your orlglnalmanual was lost or destroyed.)Please See

README.N or README.HTML for additional Information.

Thank you. G~mm~emymanual@hotma~l.com

CHRYSLER

CORPORATION

Chrysler Corporation reserves the right to make changes in design or tomake additions to or improvements in its products without imposingany obligations upon itself to install them on its products previouslymanufactured.Introduction and

Master

Troubleshooting.-I. . . . . . . . . . . . . . . . . . i

Lubrication and Maintenance . . . . . . . .El

Front Suspension. . . . . . . . . . . . . . . . . . . . . . . . . . . ..A..tiRear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~...

Service’ Brakes- Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~.....

Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~.....~~..

Engine. . . . . . . . . . . . . . . . . . . . . . . . ..*..............................Intake and Exhaust

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fuel System

‘,,, .*. . . . . . . . . . . . . . . . . . ..*........................4Propeller Shaft

..,.....,....,.................m.......

Rear Suspension.*........s........................

ManualSteering-po,er.h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..$\

ManualiTransaxle-Automatic:. . . . . , . . . . . . . . . . . . . . r+:,

Wheels and Tires_. .;,:.;*&i. . . . . . . . . . . . . . . . . . . . . . ..&......

j 8 .A$: >

Body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*...**...

Heater & Air CondjtJoning ..,.. ,.,. . . ...’

EmissionControlSystems1. . . . . . . . . . . . . .

0 1992 Mitsubishi)L-.”:

Printed in U.S.A.

Page 3 of 57

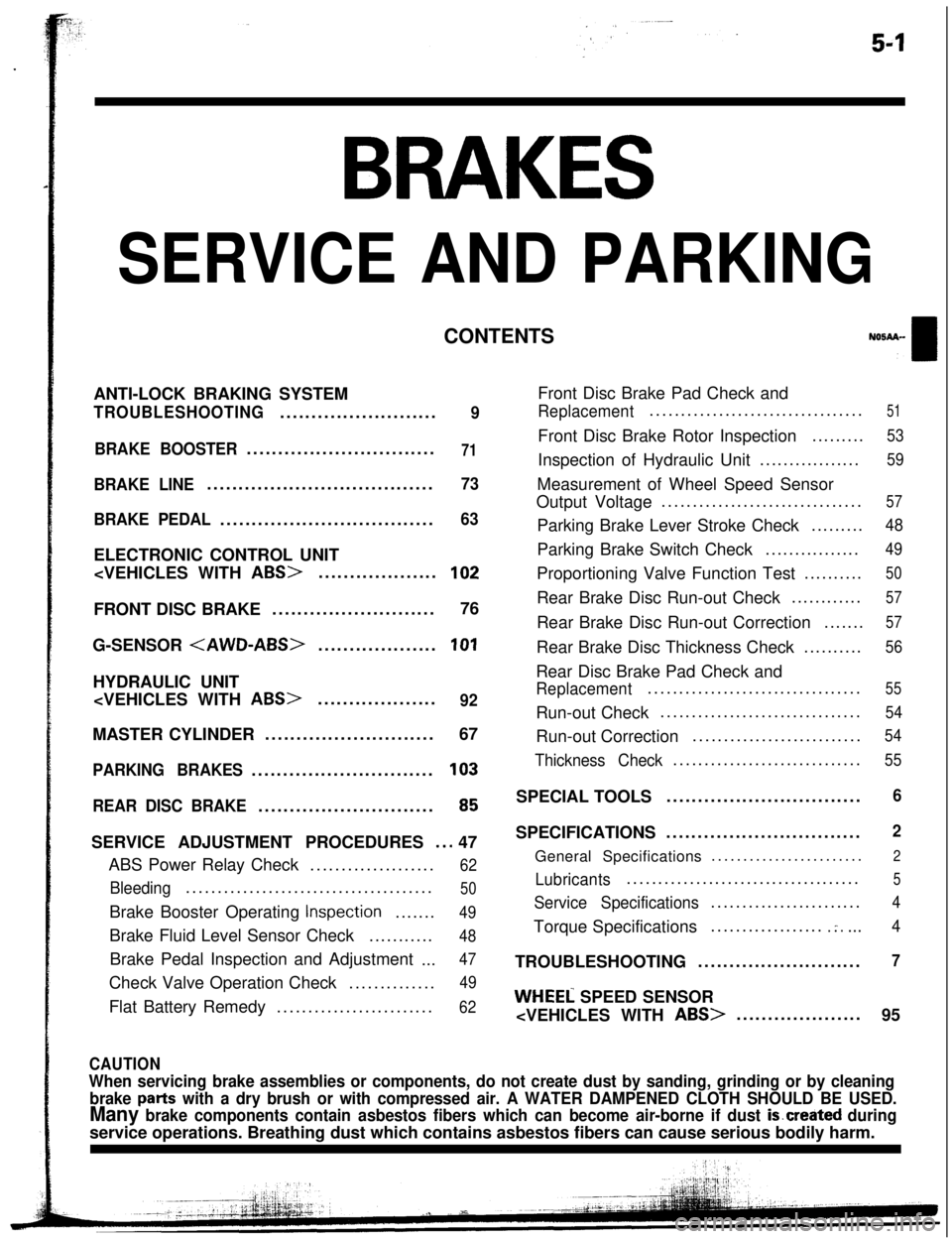

BRAKES

SERVICE AND PARKINGCONTENTS

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTING.........................9

BRAKE BOOSTER..............................

71

BRAKE LINE....................................73

BRAKE PEDAL..................................

63ELECTRONIC CONTROL UNIT

G-SENSOR

PARKING BRAKES.............................103

REAR DISC BRAKE............................

65SERVICE ADJUSTMENT PROCEDURES

..a 47

ABS Power Relay Check....................

62

Bleeding.......................................50Brake Booster Operating

Inspection.......49Brake Fluid Level Sensor Check...........

48Brake Pedal Inspection and Adjustment

...

47Check Valve Operation Check..............

49Flat Battery Remedy.........................

62Front Disc Brake Pad Check and

Replacement..................................51Front Disc Brake Rotor Inspection.........

53Inspection of Hydraulic Unit.................

59Measurement of Wheel Speed Sensor

Output Voltage................................

57Parking Brake Lever Stroke Check.........

48Parking Brake Switch Check................

49Proportioning Valve Function Test..........

50Rear Brake Disc Run-out Check............

57Rear Brake Disc Run-out Correction.......

57Rear Brake Disc Thickness Check..........

56Rear Disc Brake Pad Check and

Replacement..................................55Run-out Check................................

54Run-out Correction...........................

54

Thickness Check..............................55SPECIAL TOOLS...............................

6SPECIFICATIONS...............................

2General Specifications........................

2

Lubricants.....................................5

Service Specifications........................4Torque Specifications..................

.:....4TROUBLESHOOTING..........................

7

WHEEL SPEED SENSOR

95

CAUTION

When servicing brake assemblies or components, do not create dust by sanding, grinding or by cleaning

brake

parts with a dry brush or with compressed air. A WATER DAMPENED CLOTH SHOULD BE USED.

Many brake components contain asbestos fibers which can become air-borne if dust is.created duringservice operations. Breathing dust which contains asbestos fibers can cause serious bodily harm.

Page 4 of 57

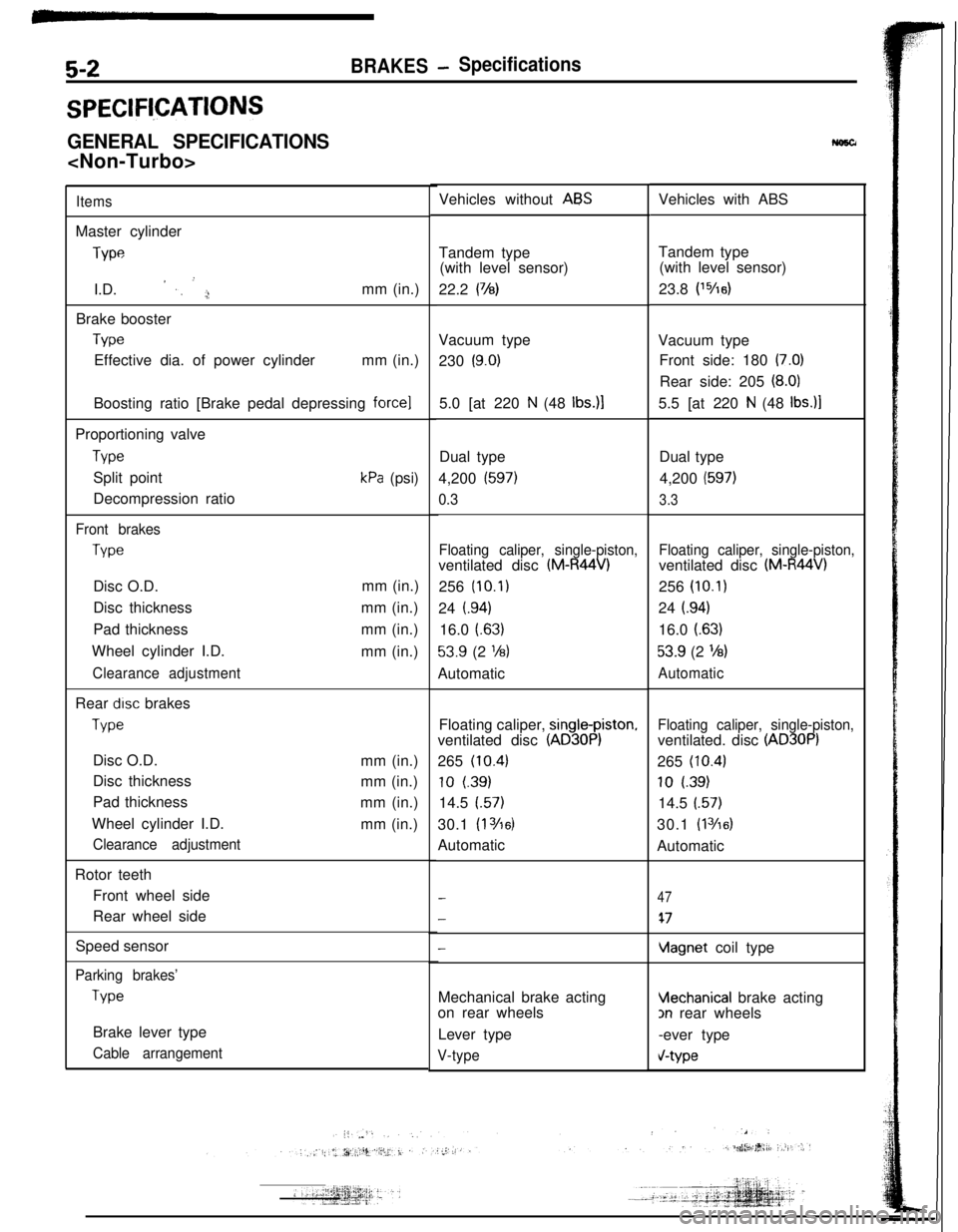

5-2BRAKES- Specifications

SPECIFl,CATIONS

GENERAL SPECIFICATIONS

ItemsMaster cylinder

J-wI.D.

’ ,, ’ ,;!mm (in.)

Brake booster

TvwEffective dia. of power cylindermm (in.)

Boosting ratio [Brake pedal depressing

force]5.0 [at 220 N (48 Ibs.)lProportioning valve

TypeSplit point

Decompression ratio

kPa (psi)

Front brakes

TypeDisc O.D.

Disc thickness

Pad thickness

Wheel cylinder I.D.

Clearance adjustmentmm (in.)

mm (in.)

mm (in.)

mm (in.)

Rear

drsc brakes

TypeDisc O.D.

Disc thickness

Pad thickness

Wheel cylinder I.D.

Clearance adjustmentmm (in.)

mm (in.)

mm (in.)

mm (in.)

Rotor teeth

Front wheel side

Rear wheel side

Speed sensor

-

Parking brakes’

TvwBrake lever type

Cable arrangementVehicles without

ABSVehicles with ABS

Tandem type

(with level sensor)

22.2

(78)Tandem type

(with level sensor)

23.8 P5/1dVacuum type

230

(9.0)Vacuum type

Front side: 180 (7.0)Rear side: 205

(8.0)5.5 [at 220

N (48 Ibs.)lDual type

4,200

(597)

0.3Dual type

4,200

(597)

3.3

Floating caliper, single-piston,ventilated disc

(M-R44V)256

(10.1)24

i.94)16.0

(.63)

53.9 (2 l/8)Automatic

Floating caliper, single-piston,ventilated disc

(M-R44V)256

(10.1)24

i.94)16.0

(.63)

53.9 (2 %)

AutomaticFloating caliper,

single-piston,ventilated disc

(AD30P)265

(10.43

10 (39)

14.5

(.57)30.1

(1 Yl6)Automatic

Floating caliper, single-piston,ventilated. disc

(AD30P)265

(10.4)

10 l.39)14.5

(.57)30.1

(1 3/6)Automatic

-

-

47

47

vlagnet coil type

Mechanical brake acting

Vlechanical brake acting

on rear wheels

3n rear wheels

Lever type

-ever type

V-typeV-type

Page 5 of 57

! y+

fr. .

‘iBR&gES - Specifications513

-

ItemsFWDAWD

Master cylinder

TypeTandem type

Tandem type

(with level sensor)(with level sensor)

I.D.mm (in.) 25.4 (1)25.4 (1)Brake booster

TypeVacuum typeVacuum type

Effective dia. of power cylinder

mm (in.) Front side: 188 (7.4)

Front side: 188 (7.4)

Rear side: 215 (8.5)Rear side: 215 (8.5)Boosting ratio [Brake pedal depressing force]

6.0 [at 220

N (48 Ibs.)]6.0 [at 220 N (48 Ibs.)]

‘.Proportioning valve

TypeDual typeDual type

Split point

kPa (psi) 2,500 (363)3,500 (508)Decompression ratio

0.250.25

Front brakes,,’ I

TypeFloating caliper, single-piston,

Floating caliper, double-pistonventilated disc

(M-R46V)ventilated disc (M-R56W)Disc O.D.

mm (in.)

256(10.1)276 (10.9)

Disc thickness

mm (in.) 24

(94)

24 (.94)Pad thickness

mm (in.) 16.0

(63)

16.0 (63)Wheel cylinder I.D.

mm (in.) 60.3

(2?,)41.3 (l”/*) x 2

Clearance adjustmentAutomatic

Automatic

?ear disc brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc

(AD30P)ventilated disc (AD35P)Disc

O.D.mm (in.) 265 (10.4)265 (10.4)Disc thickness

mm (in.) 10 (39)

10

f.39)Pad thickness

mm (in.) 14.5

(.57)14.5 (.57)Wheel cylinder I.D.

mm (in.)

30.1 (1 3/16)34.9 (1 3h)

Clearance adjustmentAutomaticAutomatic

3otor teeth*

Front wheel side

47

47Rear wheel side

47

47

speed sensor*

Magnet coil typeMagnet coil type

‘arking brakes

WeMechanical brake actingMechanical brake acting

on rear wheels

on rear wheels

Brake lever type

Lever type

Lever type

Cable arrangement

V-type

V-type

k ,.-YT--NultThe *symbol

indicates vehicles with ABS.

Page 6 of 57

-

5-4BRAKES- Specifications

SERVICE SPECIFICATIONS

Items

Standard valueBrake pedal heightmm (in.)

Brake pedal free playmm (in.)

Brake pedal to floorboard clearancemm (in.)

Parking brake lever stroke.

Output pressure proportioning valve

MPa (psi)

Split point

N (Ibs.) [Nm (ft.lbs.)lBooster push rod to master cylinder piston clearance

mm (in.)

9 inch brake booster

7 + 8 inch brake booster

Speed sensor’s internal resistancek&

Clearance between the speed pole piece and

the toothed rotormm (in.)

LrmttLeft/right proportioning valve out pressure difference

MPa (psi)

DISC brake pad

thrcknessmm (in.)Front

drsc thicknessmm (in.)Rear

dtsc thrcknessmm (in.)

DISC runout

mm (in.)

Front

Rear

Hub end playmm (In.)

NOTEl : Vehicleswith ABS

TORQUE SPECIFICATIONSSpecifications176-181 (6.9-7.1)

3-8

(.l-.3)80 (3.1) or more

5-7 notches

3.95-4.45 (561-633)

3.45-3.95 (491-561).

5.15-5.65 (732-804) i8.2

(1,163)14.65-5.15 (661-732j.17.7 (1,095))

70

(15) or less I4 (3) or less]

0.8-1.0 (.031-,039)

0.5-0.7 (.020-.028)

0.8-1.2"

0.3-0.9 (.012-,035)"60.4 (57)

2.0

(.08)22.4

(.882)8.4

(.331)0.07

(.0028)0.08 l.0031)

0.2

(.008)

ItemsPedal support bracket installation bolts

Pedal support bracket installation nut

Pedal rod to pedal support bracket

Pedal rod to clutch pedal bracket

Clutch pedal bracket installation bolt

Turn-over spring mounting bolt

Stop lamp switch mounting nut

Clutch master cylinder installation nuts

Clutch pedal installation nut

Lever assembly (A) installation nut

Lever assembly (B) installation nut

I:: ::I .:‘i j ,:~~ -__j.-, .‘- ‘+‘+gg&p.~j:;.;1--?.+.k

Nm

8-12

IO-15

17-2617-26

8-12

17-26

10-15

10-15

20-25

20-25

20-25

Tft.lbs.

6-9

7-11

12-19

12-19.6-9

12-197-11

7-1114-18

14-18

Page 7 of 57

-

BRAKES - Specifications

ItemsMaster cylinder to brake booster

Piston stopper bolt

Nipple installation screw

Brake booster installation nuts

Fitting

Flared brake line nuts

Brake hose bracket installation bolts

Front disc brake assembly installation bolts

Lock pin (front)

Guide pin (front)

Bleeder screw

Wheel bearing nut

Dust shield to axle beam

Rear disc brake assembly installation bolts

Drive shaft to companion flange

Companion flange to rear axle shaft

Brake hose to caliper body (rear)

Lock pin (rear)

Guide pin (rear)Spindle lever to parking brake lever

Rear speed sensor installation bolt

Speed sensor bracket installation bolt

Rotor to front hub

Rotor to rear hub

Nm8-12

1.5-3.0

1.5-3.0

11-17

15-18

13-1717-26

80-10064-86

64-86

7-9

200-2609-14

50-6055-65

160-20025-35

22-32

22-32

40-559-14

9-14

7-l 1

9-14

ft.lbs.6-9

l-2

l-2

8-12

11-13

9-1212-19

58-72

46-62

46-62

5-7

144-188”

7-1036-43

39-47

116-159

18-25

16-23

16-23

29-40

7-10

7-10

5-a

7-10

LUBRICANTSNo!xD-

Items

Brake fluidSpecified lubricant

MOPAR Brake Fluid/

Conforming to

DOT3 or DOT4Brake pedal bushing inner surface

Clevls pin and washer

Parking brake lever sliding parts

Bushing inner surfaceMOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

Page 8 of 57

5-50BRAKES - Service Adjustment Proi?edur&

Brakebooster

sideSpring

’

/

Valve

Pressure

gaugePressure

PropGtioning valve14LO181input pressure

14uoo55

2.Check the operation of the check valve by using a vacuul

pump.Vacuum pump connection Accept/reject criteria

Connection at the brake A negative pressure (vacuum)

is

booster side @created and held.Connection at the -intake

manifold side @A negative pressure (vacuum) is notcreated.

CautionIf the check valve is defective, replace it as an

assemb!unit together with the vacuum hose.

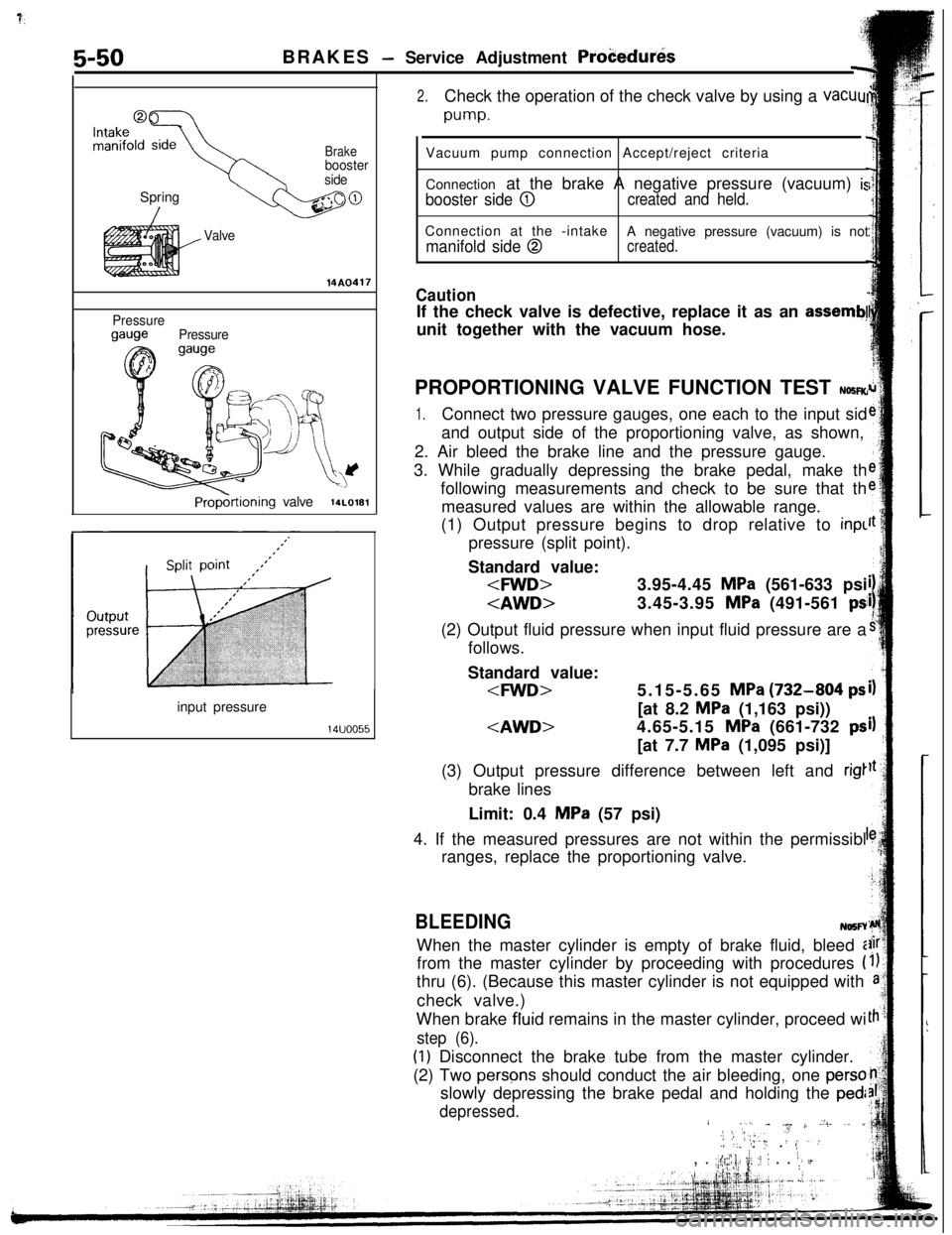

PROPORTIONING VALVE FUNCTION TEST

NO!iR(r

1.Connect two pressure gauges, one each to the input sid

and output side of the proportioning valve, as shown,

2. Air bleed the brake line and the pressure gauge.

3. While gradually depressing the brake pedal, make th

following measurements and check to be sure that th

measured values are within the allowable range.

(1) Output pressure begins to drop relative to inpl

pressure (split point).

Standard value:

follows.

Standard value:

MPa (1,163 psi))

MPa (1,095 psi)]

(3) Output pressure difference between left and

rig1brake lines

Limit: 0.4

MPa (57 psi)

4. If the measured pressures are not within the permissibl

ranges, replace the proportioning valve.

BLEEDINGNo5FYWhen the master cylinder is empty of brake fluid, bleed i

from the master cylinder by proceeding with procedures

(thru (6). (Because this master cylinder is not equipped with

check valve.)

When brake fluid remains in the master cylinder, proceed wi

step (6).

(1) Disconnect the brake tube from the master cylinder.

(2) Two

persqs should conduct the air bleeding, one persoslowly depressing the brake pedal and holding the

ped:

depressed.i .I..[ j,‘I- .~ j, Z’:. ~. jl2;:‘,.Y .‘.:./ ‘:” ‘: ,, . 8,, .

.;$y; ii; :: 1 . . i;, d

Page 9 of 57

BRAKES - Service Adjustment Procedures5-51

2314A0454When new

When worn14G0017

1

14 LO169check the sliding coWsTm~3..“.W% ,Y :sleeve and guide pin-~I ._. ;;:i ‘.(3) In this condition, the other person should use a finger to

close the outlet part of the, master cylinder, and then the

first person should release the brake pedal.

(4) Steps (2) and (3) should be repeated three or four times,

and then the master cylinder should be filled with brake

fluid to the specified level.

NOTE

The air is completely bled from the master cylinder by steps

(1) to (4).

(5) Connect the brake tube to the master cylinder.

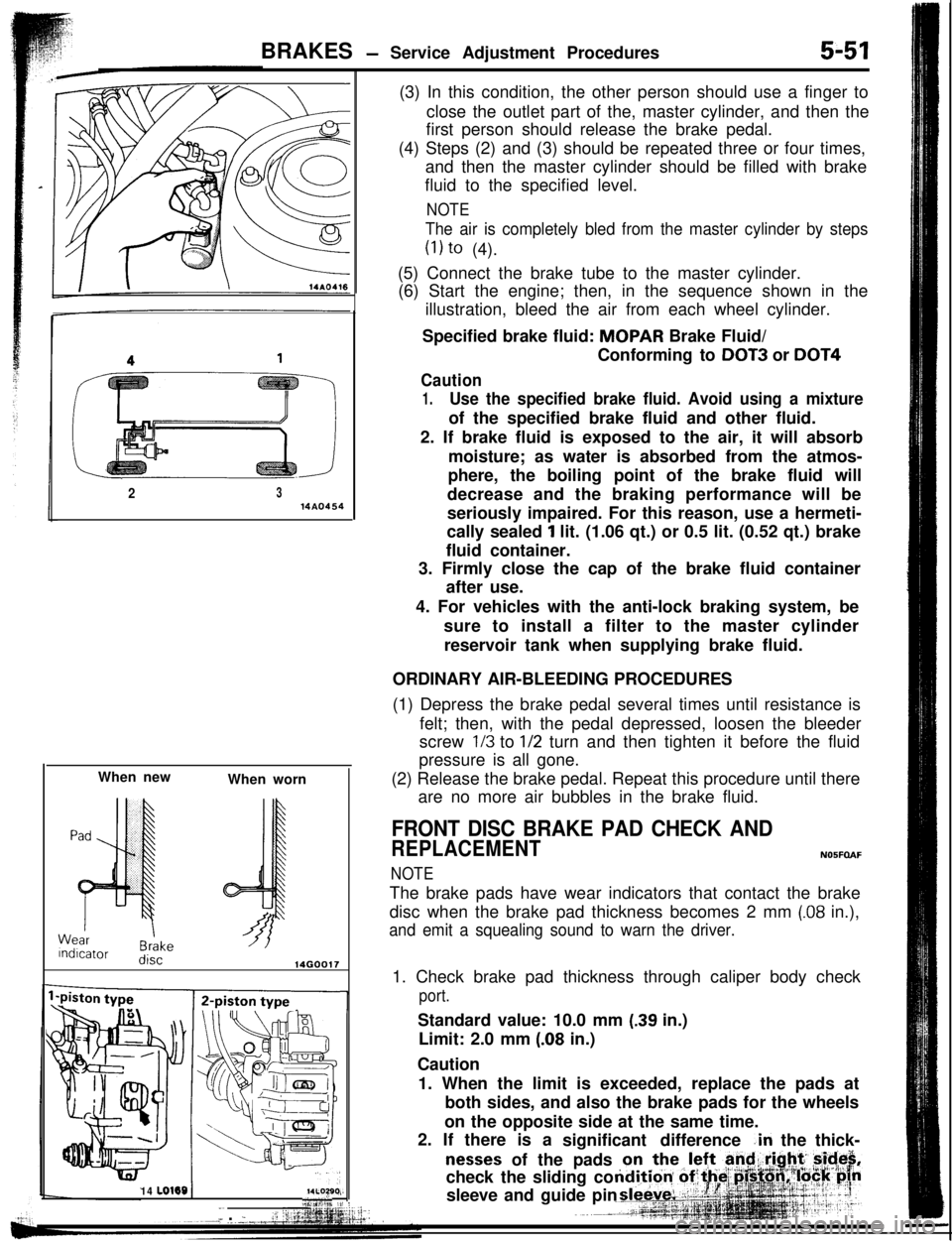

(6) Start the engine; then, in the sequence shown in the

illustration, bleed the air from each wheel cylinder.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to

DOT3 or DOT4

Caution

1.Use the specified brake fluid. Avoid using a mixtureof the specified brake fluid and other fluid.

2. If brake fluid is exposed to the air, it will absorb

moisture; as water is absorbed from the atmos-

phere, the boiling point of the brake fluid will

decrease and the braking performance will be

seriously impaired. For this reason, use a hermeti-

cally sealed

1 lit. (1.06 qt.) or 0.5 lit. (0.52 qt.) brake

fluid container.

3. Firmly close the cap of the brake fluid container

after use.

4. For vehicles with the anti-lock braking system, be

sure to install a filter to the master cylinder

reservoir tank when supplying brake fluid.

ORDINARY AIR-BLEEDING PROCEDURES

(1) Depress the brake pedal several times until resistance is

felt; then, with the pedal depressed, loosen the bleeder

screw

l/3 to l/2 turn and then tighten it before the fluid

pressure is all gone.

(2) Release the brake pedal. Repeat this procedure until there

are no more air bubbles in the brake fluid.

FRONT DISC BRAKE PAD CHECK AND

REPLACEMENTN05FOAF

NOTEThe brake pads have wear indicators that contact the brake

disc when the brake pad thickness becomes 2 mm

(.08 in.),

and emit a squealing sound to warn the driver.1. Check brake pad thickness through caliper body check

port.Standard value: 10.0 mm

(.39 in.)

Limit: 2.0 mm

(.08 in.)

Caution

1. When the limit is exceeded, replace the pads at

both sides, and also the brake pads for the wheels

on the opposite side at the same time.

2. If there is a

significant difference

.in the thick-

nesses of the pads

Page 10 of 57

5-52

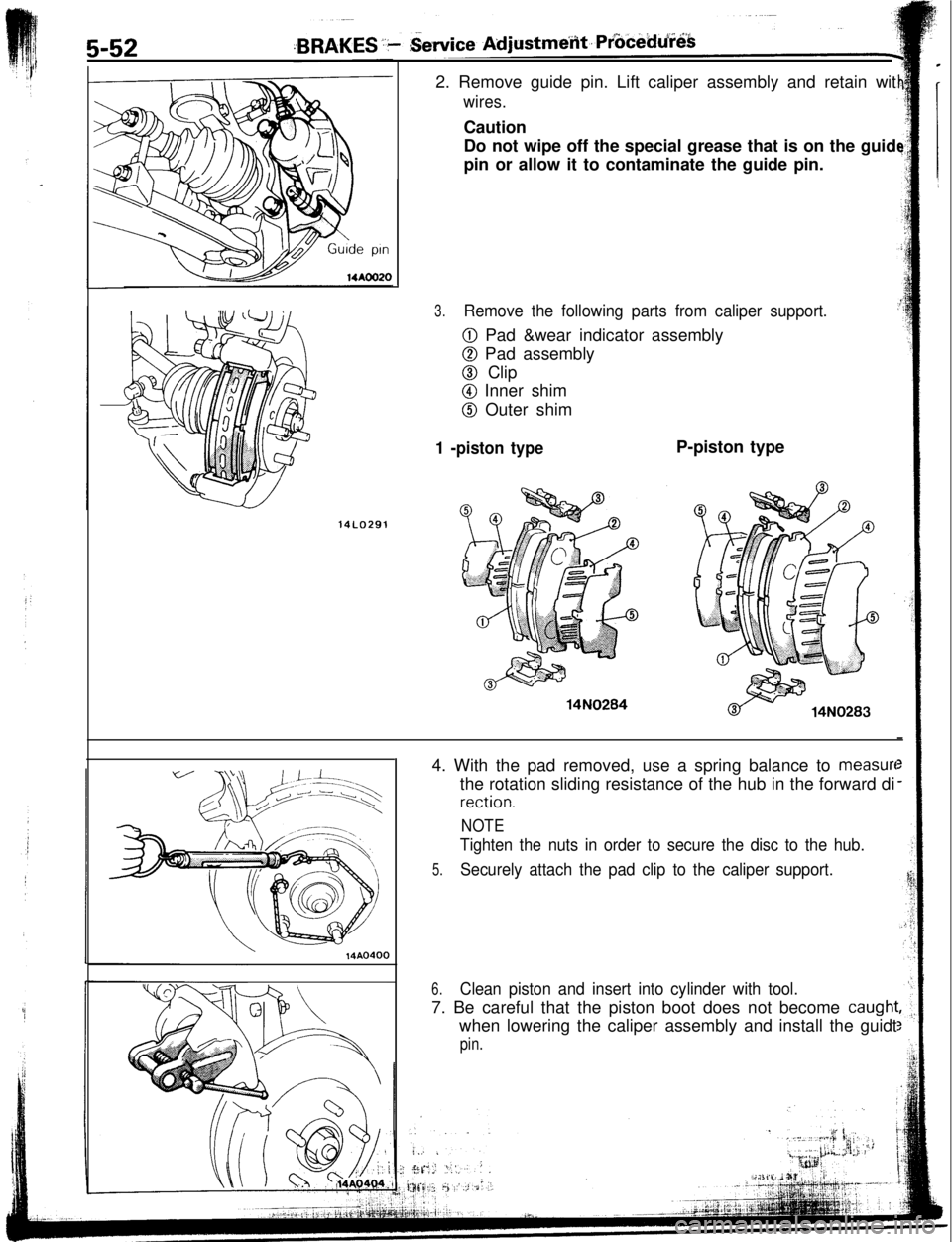

14LO2912. Remove guide pin. Lift caliper assembly and retain wit

wires.Caution

Do not wipe off the special grease that is on the guid

pin or allow it to contaminate the guide pin.

3.Remove the following parts from caliper support.

0 Pad &wear indicator assembly

0 Pad assembly

@ Clip

@I Inner shim

@ Outer shim

1 -piston type14N0284P-piston type

\14AO4004. With the pad removed, use a spring balance to

measurethe rotation sliding resistance of the hub in the forward di

rection.

NOTE

Tighten the nuts in order to secure the disc to the hub.

5.Securely attach the pad clip to the caliper support.

6.Clean piston and insert into cylinder with tool.7. Be careful that the piston boot does not become

caughlwhen lowering the caliper assembly and install the guidt

pin.