light MITSUBISHI ECLIPSE 1993 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 32 of 57

INSTRUCTIONS FOR ALUMINUM TYPE

WHEELSN2zGFM

1. Aluminum is vulnerable to alkalies. If a vehicle

washing detergent has been used, or salt from

sea water or road chemicals has adhered, washthe vehicle as soon as possible. After washing

the vehicle, apply body or wheel wax to the

aluminum type wheels to prevent corrosion.

2. When cleaning the vehicle with steam, do not

direct steam onto the aluminum type wheels.

When tightening nuts for aluminum type

wheels, particularly observe the following:

(1) Cl;Zl;lsthe hub surface of aluminum type

(2) After finger-tightening wheel nuts, tighten

them to specifications.

(3) Do not use an impact wrench or push the

wrench by foot to tighten the wheel nuts.

(4) Do not apply oil to the threaded portions.

INSTRUCTIONS FOR TIRE CHAINS AND

SNOW TIRES

1.Use tire chains only on front wheels. Do not usetire chains on rear wheels.

2. When using snow tires, use them on all four

wheels for maneuverability and safety.

INSTRUCTIONS FOR COMPACT

TIRE

1. The compact spare tire is designed

space in the luggage compartment,

lighter weight makes it easier to use if

occurs.g

2.-- IThe following instructions for the compact spare .,z,tire should be observed.

i/(1) Check the inflation pressure after installing ii,the spare, and adjust to the specified

pres-..$i

sure.t’

(2) Avoid driving through automatic car washes

and over obstacles that could possiblyage the vehicle’s undercarriage. Because

the tire is smaller than the

original tire,

ground clearance is slightly reduced,

(3) The compact spare tire should not be

used: i5iS:on any other wheels, nor should standard

i;:?tires, snow tires, wheel covers or trim rings

Ibe used with the compact spare wheel. If.

1.;such use is attempted, damage to these

items or other vehicle components may

’

occur.

,i

Page 38 of 57

-- .__.,_...__

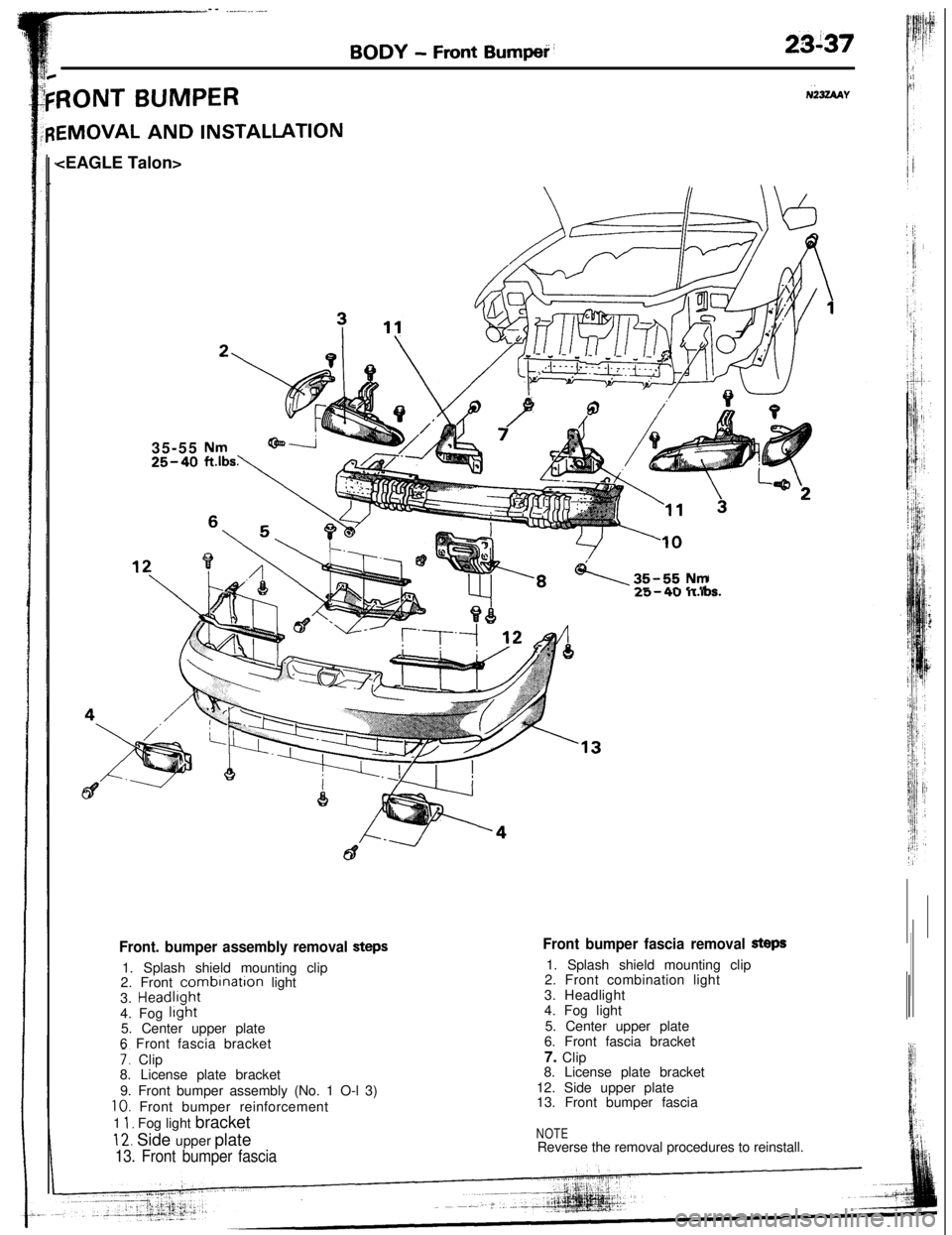

BODY - Front Bumped’23i37

RONT BUMPERNk4AY

EMOVAL AND INSTALLATION

35-55

25-40

\35-55Nma.-11 ._ II

Front bumper fascia removal Steps1. Splash shield mounting clip

2. Front combination light

3. Headlight

4. Fog light

5. Center upper plate

6. Front fascia bracket

7. Clip

8. License plate bracket

12. Side upper plate

13. Front bumper fasciaFront. bumper assembly removal steps1. Splash shield mounting clip

2. Front

combrnation light

3. Headlrght

4. Fog

light5. Center upper plate

6 Front fascia bracket

7. Clip

8. License plate bracket

9. Front bumper assembly (No. 1 O-l 3)

10. Front bumper reinforcement

1

1, Fog light bracket

12. Side upper plate

13. Front bumper fascia

NOTEReverse the removal procedures to reinstall.

Page 39 of 57

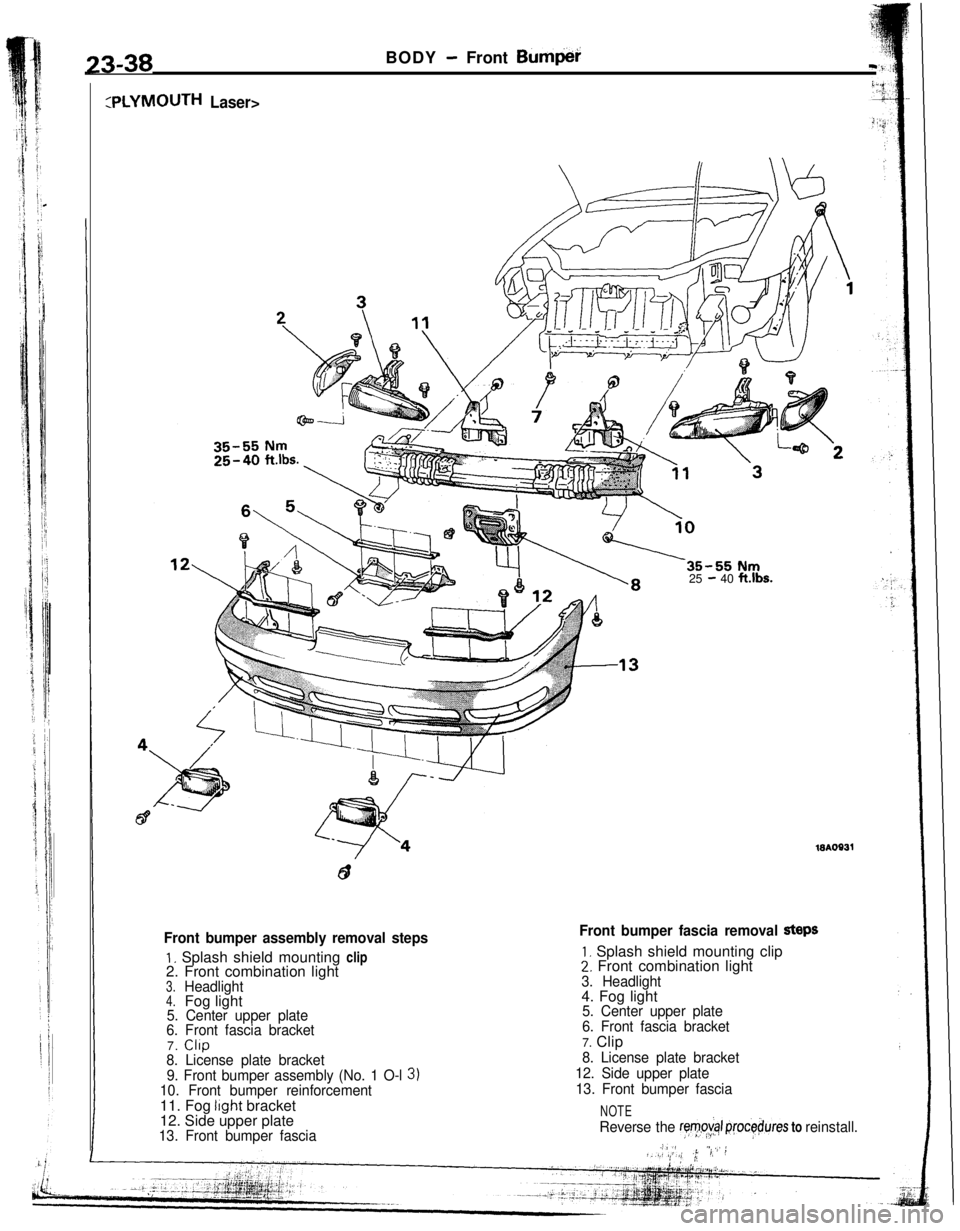

:PLYMOUTH Laser>25

- 40 ft.lbs.

23-38BODY - Front Bum$i

Front bumper assembly removal steps

1. Splash shield mounting clip

2. Front combination light

3.Headlight4.Fog light5. Center upper plate

6. Front fascia bracket7.

CllP8. License plate bracket

9. Front bumper assembly (No. 1 O-l

3)10. Front bumper reinforcement11. Fog light bracket

12. Side upper plate

13. Front bumper fascia

Front bumper fascia removal StePS

1, Splash shield mounting clip2. Front combination light

3. Headlight4. Fog light

5. Center upper plate

6. Front fascia bracket7. Clip

8. License plate bracket

12. Side upper plate

13. Front bumper fascia

NOTE

Reverse the ryv,o&+ ,rjrocebures to reinstall.,.,ir ,’.!,I,(1 ,(, /.; 1, !

Page 42 of 57

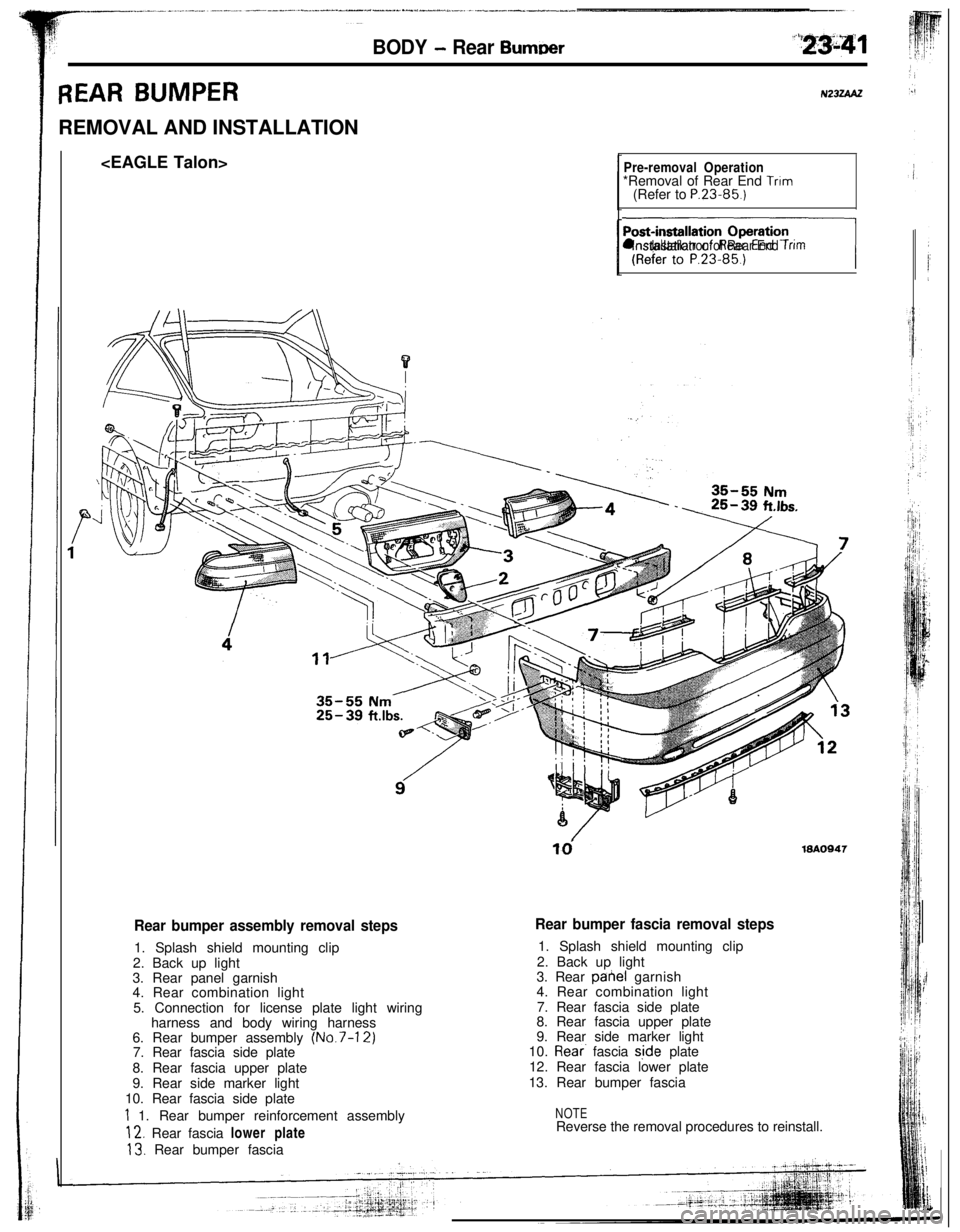

BODY - Rear Burn-r

REAR BUMPERREMOVAL AND INSTALLATION

Pre-removal Operation*Removal of Rear End Trim(Refer to P.23.85.)

nl lnstallatron of Rear End Trim

td19AO947

Rear bumper assembly removal steps1. Splash shield mounting clip

2. Back up light

3. Rear panel garnish

4. Rear combination light

5. Connection for license plate light wiring

harness and body wiring harness

6. Rear bumper assembly

(No.7-12)7. Rear fascia side plate

8. Rear fascia upper plate

9. Rear side marker light

10. Rear fascia side plate

1 1. Rear bumper reinforcement assembly

12. Rear fascia lower plate

13. Rear bumper fascia

Rear bumper fascia removal steps1. Splash shield mounting clip

2. Back up light

3. Rear pahel garnish

4. Rear combination light

7. Rear fascia side plate

8. Rear fascia upper plate

9. Rear side marker light

10.

Rear. fascia s,ide plate

12. Rear fascia lower plate

13. Rear bumper fascia

NOTEReverse the removal procedures to reinstall.

Page 43 of 57

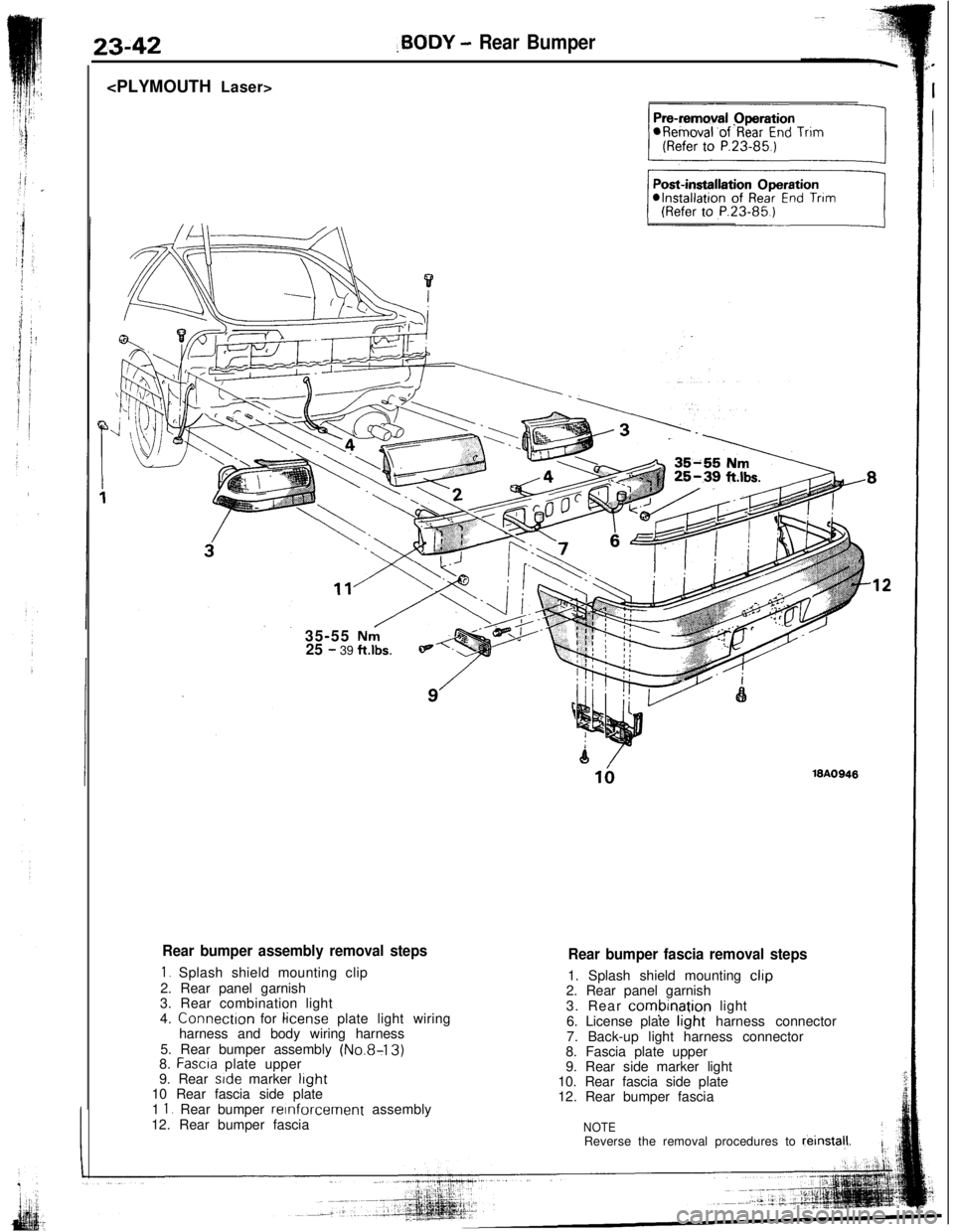

23-42,BODY - Rear Bumper

35-55

Nni25 - 39 ft.lbs.

Rear bumper assembly removal steps

1. Splash shield mounting clip

2. Rear panel garnish

3. Rear combination light

4. Connectron for

license plate light wiring

harness and body wiring harness

5. Rear bumper assembly

(No.8-13)8. Fascra plate upper

9. Rear side marker light10 Rear fascia side plate

1

1. Rear bumper reinforcement assembly

12. Rear bumper fascia

18A0948

Rear bumper fascia removal steps1. Splash shield mounting

clip2. Rear panel garnish

3. Rear

combinatjon light

6. License plate light harness connector

7. Back-up light harness connector

8. Fascia plate upper

9. Rear side marker light

10. Rear fascia side plate

12. Rear bumper fascia

NOTEReverse the removal procedures to reinstal,l.

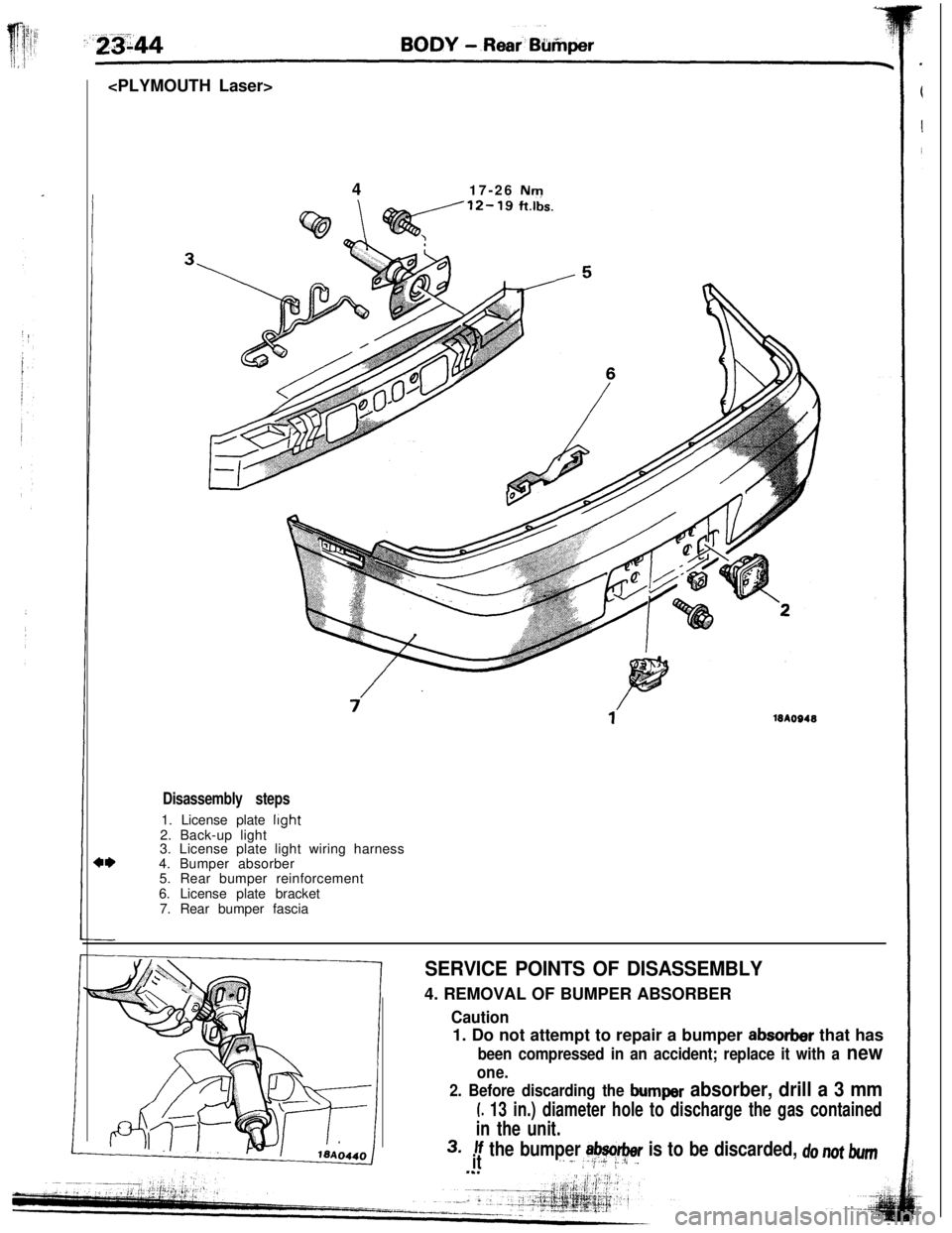

Page 45 of 57

417-26 Nm

18AO948

Disassembly steps1. License plate

light2. Back-up light

3. License plate light wiring harness

4. Bumper absorber

5. Rear bumper reinforcement

6. License plate bracket

7. Rear bumper fascia

SERVICE POINTS OF DISASSEMBLY4. REMOVAL OF BUMPER ABSORBER

2. Before discarding the bumper absorber, drill a 3 mm

L 13 in.) diameter hole to discharge the gas contained

in the unit.

3.If the bumper absorber is to be discarded, do not bumit,. _..2;+ i_.I/~.L I

Caution1. Do not attempt to repair a bumper

absorber that has

been compressed in an accident; replace it with a new

one.

Page 46 of 57

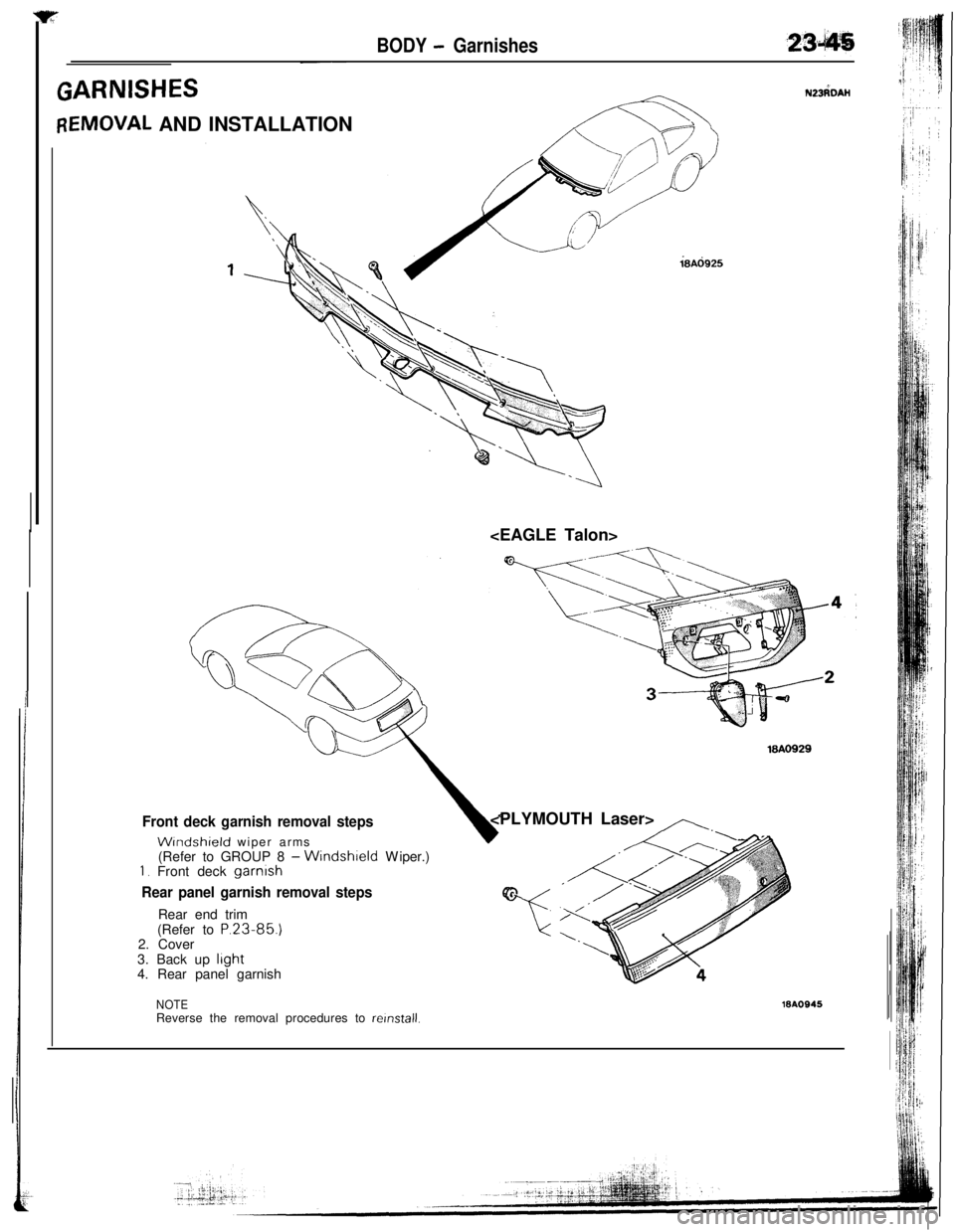

BODY - Garnishes-~

ZARNISHESN23dDAH

IEMOVAL AND INSTALLATION

18Ad925

18AO929

Front deck garnish removal steps

WIndshield wiper arms

(Refer to GROUP 8 -Windshield Wiper.)1. Front deck garnish

Rear panel garnish removal stepsRear end trim

(Refer to

P.23-85.)2. Cover

3. Back up

light4. Rear panel garnish

,,-..,.,-

E

“c

NOTEReverse the removal procedures to relnstall.16AOS45

Page 48 of 57

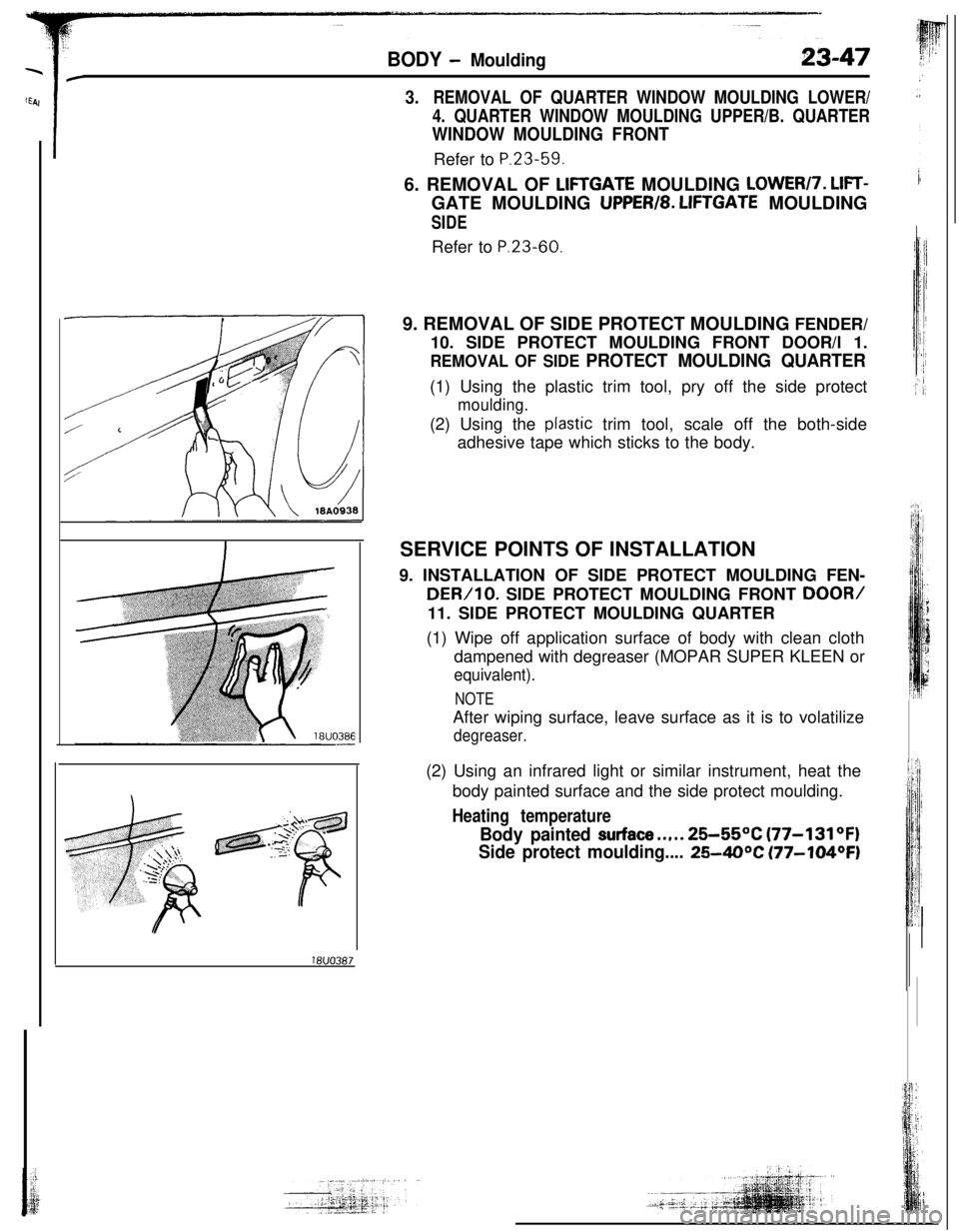

BODY - Moulding23-47

?8UO387

3.REMOVAL OF QUARTER WINDOW MOULDING LOWER/

4. QUARTER WINDOW MOULDING UPPER/B. QUARTER

WINDOW MOULDING FRONTRefer to P.23-59.

6. REMOVAL OF

LIFTGATE MOULDING LOWER17. LIFT-GATE MOULDING

UPPER/8. LIFTGATE MOULDING

SIDERefer to P.23-60.

9. REMOVAL OF SIDE PROTECT MOULDING FENDER/

10. SIDE PROTECT MOULDING FRONT DOOR/l 1.

REMOVAL OF SIDE PROTECT MOULDING QUARTER(1) Using the plastic trim tool, pry off the side protect

moulding.(2) Using the

ptastic trim tool, scale off the both-side

adhesive tape which sticks to the body.

SERVICE POINTS OF INSTALLATION

9. INSTALLATION OF SIDE PROTECT MOULDING FEN-

DER/10. SIDE PROTECT MOULDING FRONT DOOR/11. SIDE PROTECT MOULDING QUARTER

(1) Wipe off application surface of body with clean cloth

dampened with degreaser (MOPAR SUPER KLEEN or

equivalent).

NOTEAfter wiping surface, leave surface as it is to volatilize

degreaser.(2) Using an infrared light or similar instrument, heat the

body painted surface and the side protect moulding.

Heating temperature

Body painted surface..,.. 25-55OC (77-131OF)

Side protect moulding....

25-40°C (77-104OF)

Page 50 of 57

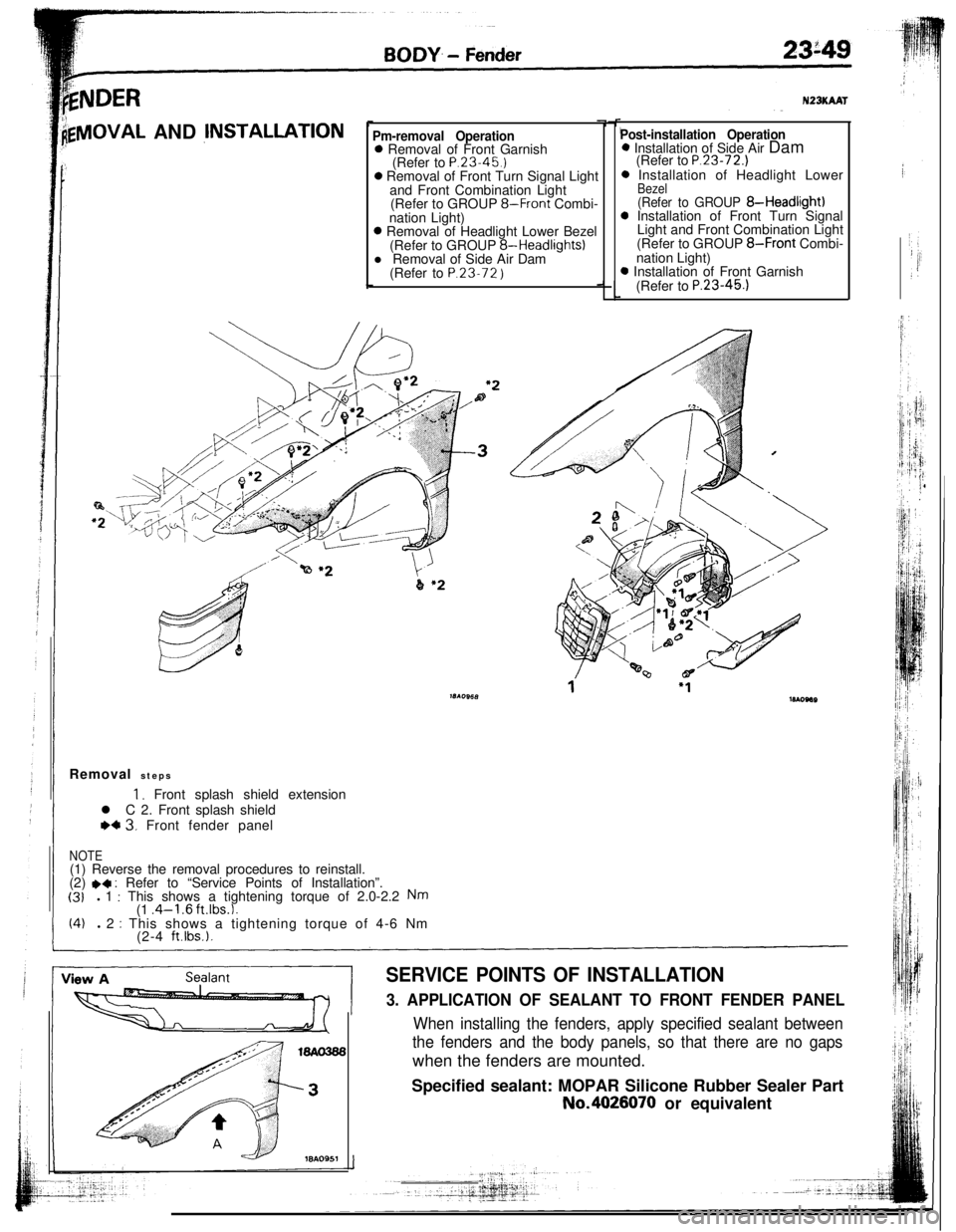

kNDER

lgVlOVAL AND jNSTALLATIONPm-removal Operation0 Removal of Front Garnish

(Refer to P.23.45.)0 Removal of Front Turn Signal Light

and Front Combination Light

(Refer to GROUP

8-Front Combi-

nation Light)0 Removal of Headlight Lower Bezel

(Refer to GROUP 8-Headlights)

l Removal of Side Air Dam

(Refer to P.23.72

)

N23KAAT

Post-installation Operation0 Installation of Side Air Dam

(Refer to

P.23-72.)0 Installation of Headlight Lower

Bezel(Refer to GROUP 8-Headlight)0 Installation of Front Turn Signal

Light and Front Combination Light

(Refer to GROUP

8-Front Combi-

nation Light)0 Installation of Front Garnish

(Refer to

P.23-45.1Removal steps

1, Front splash shield extension

l C 2. Front splash shield

WC 3. Front fender panel

NOTE(1) Reverse the removal procedures to reinstall.

(2)

.4 : Refer to “Service Points of Installation”.(31l 1 : This shows a tightening torque of 2.0-2.2 Nm(1 .4-l .6 ft.lbs.1.(4)l 2 : This shows a tightening torque of 4-6 Nm

(2-4 ft.lbs.).

SERVICE POINTS OF INSTALLATION

3. APPLICATION OF SEALANT TO FRONT FENDER PANEL

When installing the fenders, apply specified sealant between

the fenders and the body panels, so that there are no gapswhen the fenders are mounted.

Specified sealant: MOPAR Silicone Rubber Sealer PartNo.4026070 or equivalent

Page 52 of 57

*,i

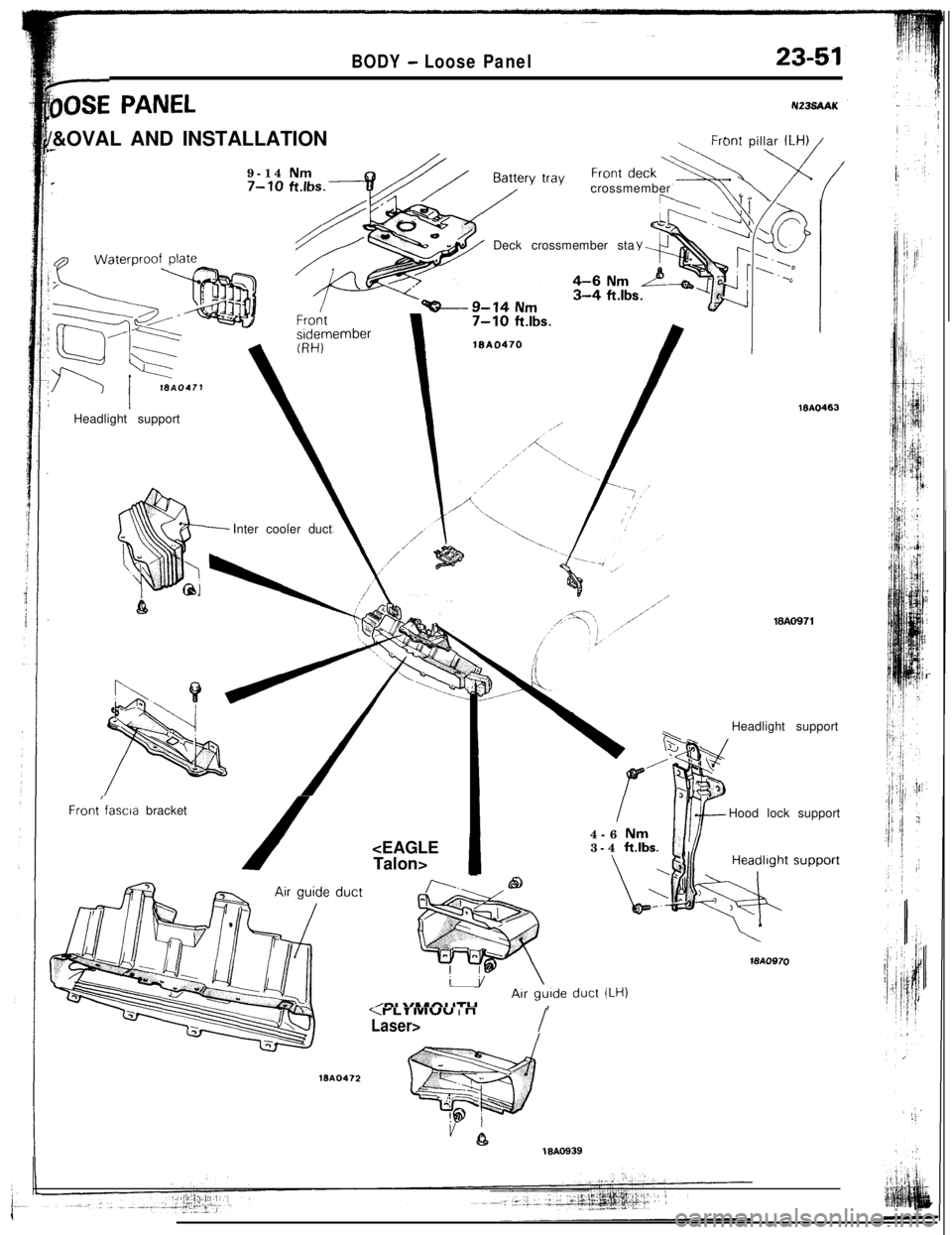

bSE PANEL

BODY - Loose Panel23-51

N23sAAK/&OVAL AND INSTALLATION

.-9-14

Nm.7-10 ft.k

Front pillar ILH) /Headlight support

Inter cooler duct

Front/fascia bracket

/crossmember

Deck crossmember sta

lSA0463

18AO971Headlight support

Nm3-4 ft.lbs.Hood lock support

WA0970

ISA0472

LT IVIUUIn

Laser>I

18AO939