Figure 49 MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 523 of 3870

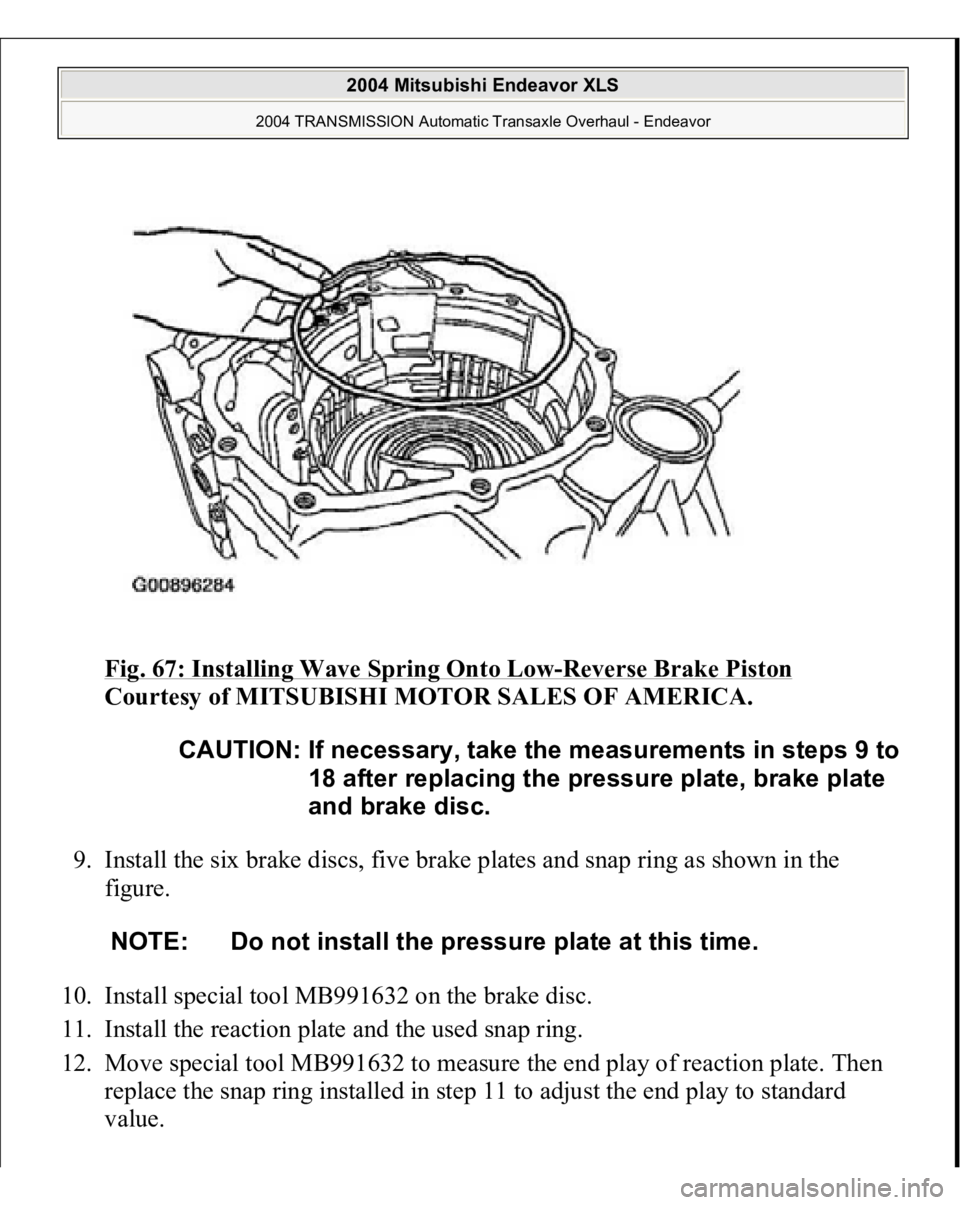

Fig. 67: Installing Wave Spring Onto Low

-Reverse Brake Piston

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

9. Install the six brake discs, five brake plates and snap ring as shown in the

figure.

10. Install special tool MB991632 on the brake disc.

11. Install the reaction plate and the used snap ring.

12. Move special tool MB991632 to measure the end play of reaction plate. Then

replace the snap ring installed in step 11 to adjust the end play to standard

value.

CAUTION: If necessary, take the measurements in steps 9 to

18 after replacing the pressure plate, brake plate

and brake disc.

NOTE: Do not install the pressure plate at this time.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 524 of 3870

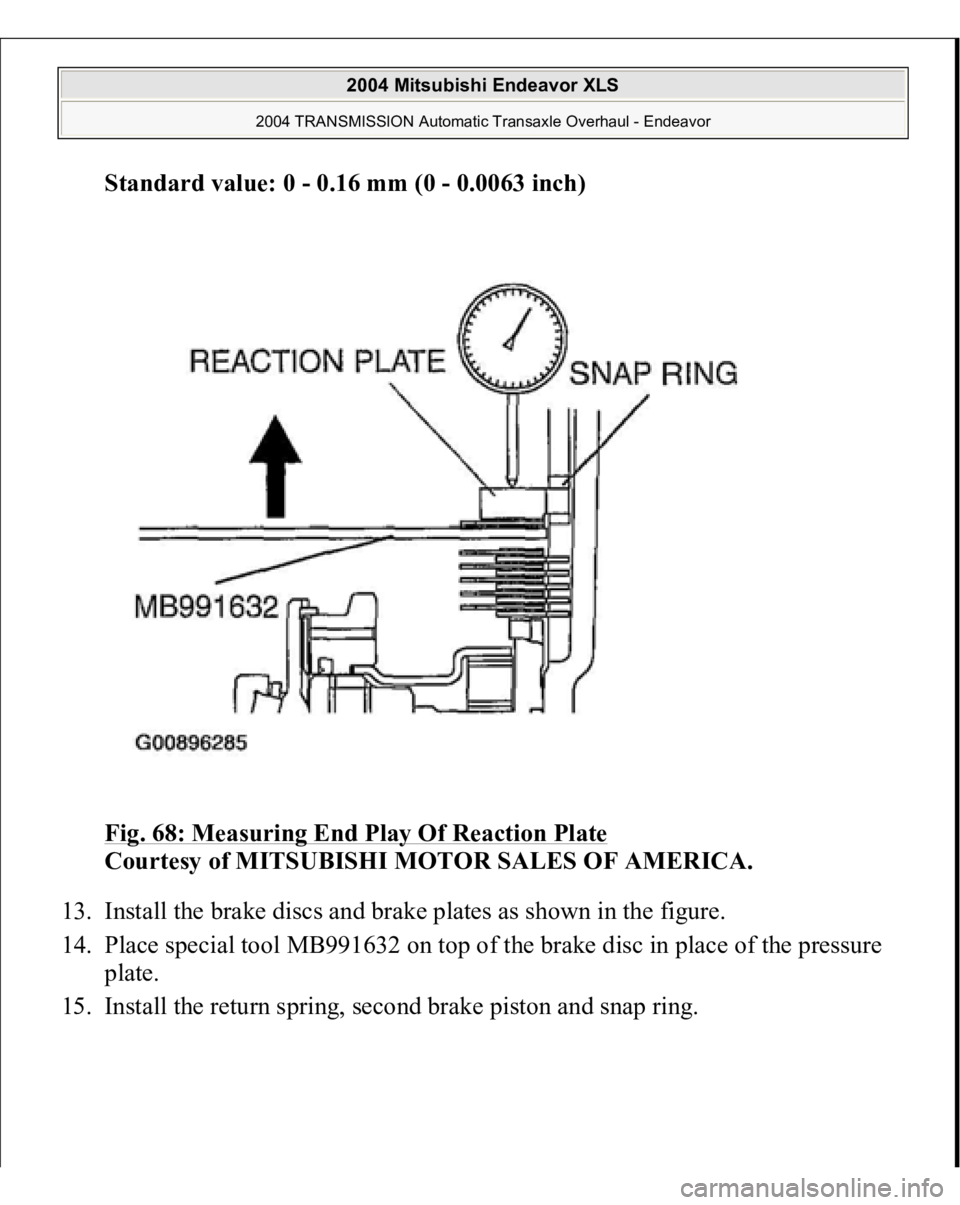

Standard value: 0 - 0.16 mm (0 - 0.0063 inch)

Fig. 68: Measuring End Play Of Reaction Plate

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

13. Install the brake discs and brake plates as shown in the figure.

14. Place special tool MB991632 on top of the brake disc in place of the pressure

plate.

15. Install the return s

prin

g, second brake

piston and sna

p rin

g.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 695 of 3870

2004 ELECTRICAL

Battery - Endeavor

BATTERY ON-VEHICLE SERVICE BATTERY CHECK

BATTERY VISUAL INSPECTION (1) 1. Ensure that the battery electrolyte level is between A and B shown in the

figure. Add if the level is lower than the specified range.

2. Use a hydrometer and temperature gauge to check the specific gravity of the

electrolyte.

Standard value:

1.220 - 1.290 [at 20°C (68°F)]

The specific gravity of electrolyte depends on its temperature. Use the formula

below to determine the proper value.

Conversion on centigrade

D20 =(t - 20) x 0.0007 + Dt

Conversion on Fahrenheit

D20 =(t - 68) x 0.0007 + Dt

D20 : Specific gravity as if electrolyte temperature is 20°C (68°F)

WARNING:Battery posts, terminals and related accessories

contain lead and lead compounds. WASH HANDS

AFTER HANDLING.

2004 Mitsubishi Endeavor Limited 2004 ELECTRICAL Battery - Endeavor

2004 Mitsubishi Endeavor Limited 2004 ELECTRICAL Battery - Endeavor

Page 1113 of 3870

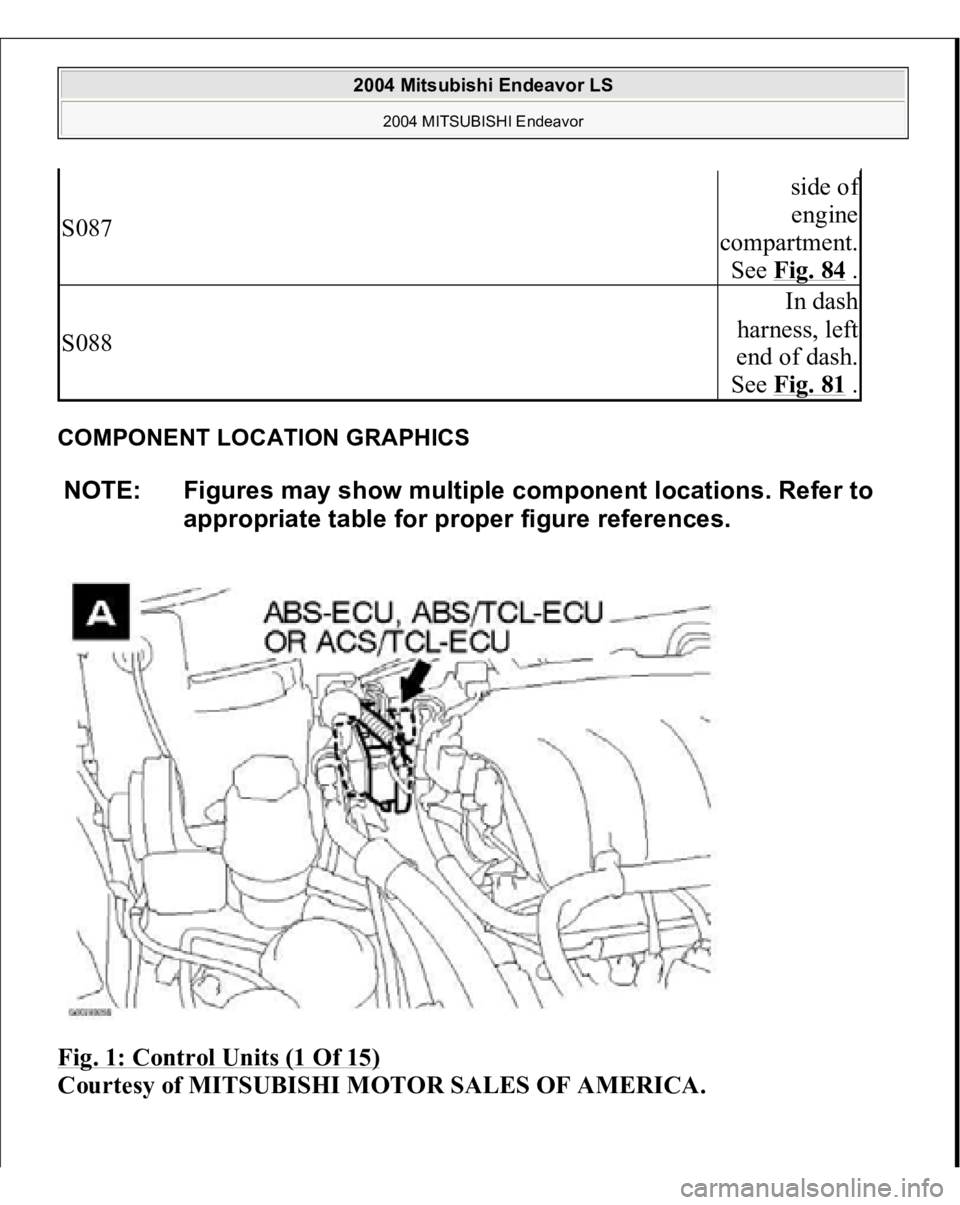

COMPONENT LOCATION GRAPHICS Fig. 1: Control Units (1 Of 15)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

S087

side o

f

engine

compartment.

See Fig. 84 .

S088

In dash

harness, left

end of dash.

See Fig. 81

.

NOTE: Figures may show multiple component locations. Refer to

appropriate table for proper figure references.

2004 Mitsubishi Endeavor LS

2004 MITSUBISHI Endeavor

Page 1402 of 3870

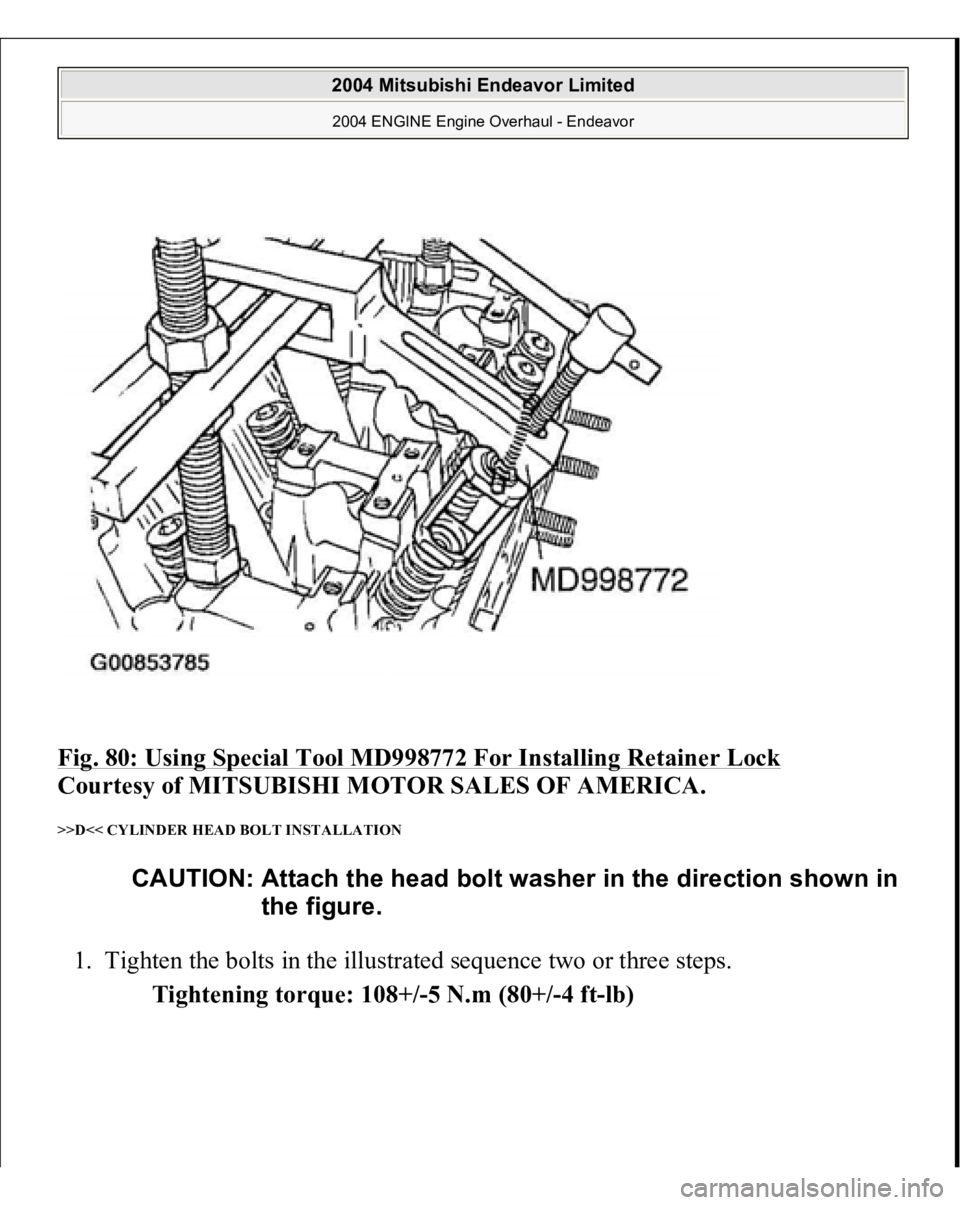

Fig. 80: Using Special Tool MD998772 For Installing Retainer Lock

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>D<< CYLINDER HEAD BOLT INSTALLATION 1. Tighten the bolts in the illustrated sequence two or three steps.

Tightening torque: 108+/-5 N.m (80+/-4 ft-lb)

CAUTION: Attach the head bolt washer in the direction shown in

the figure.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1534 of 3870

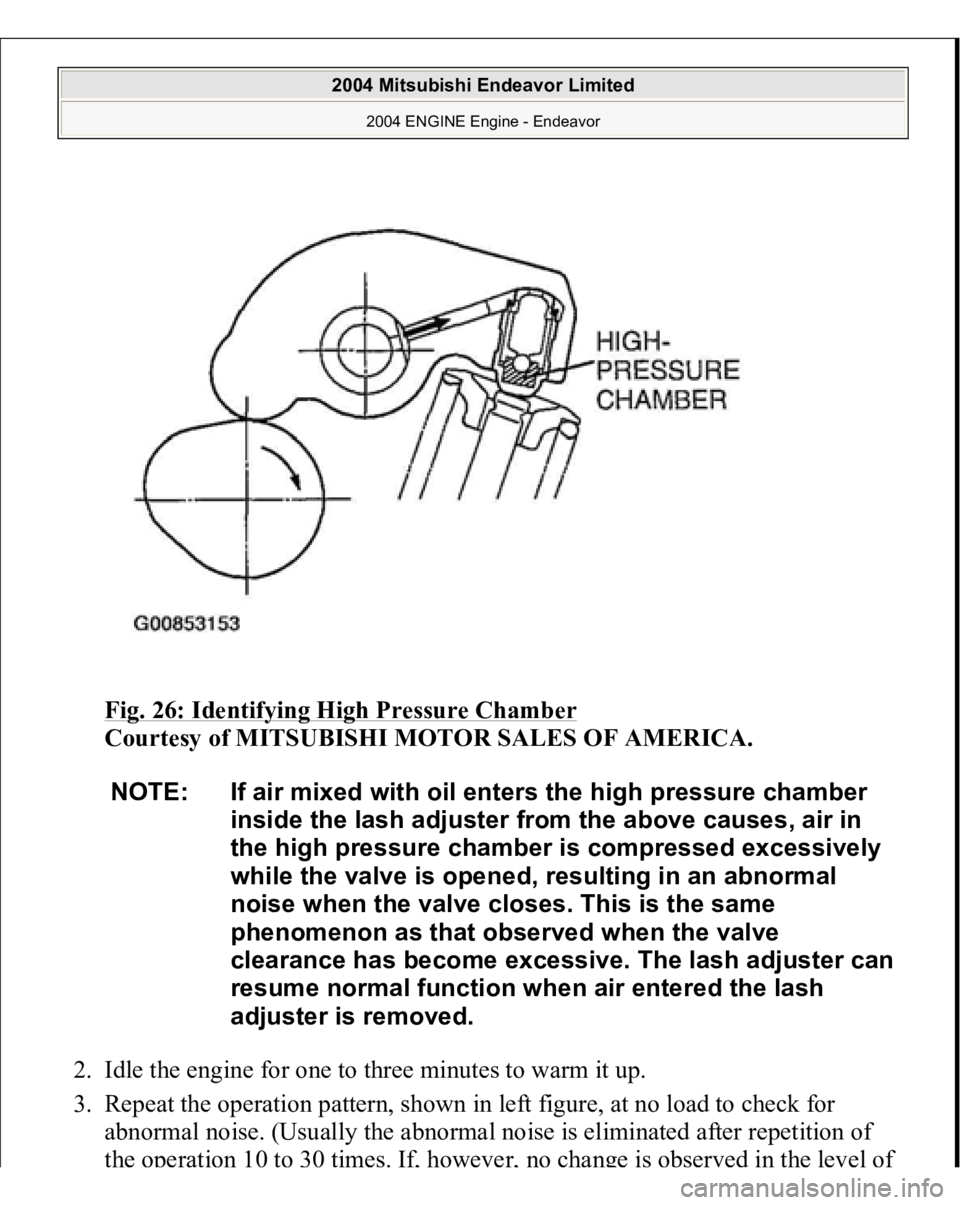

Fig. 26: Identifying High Pressure Chamber

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

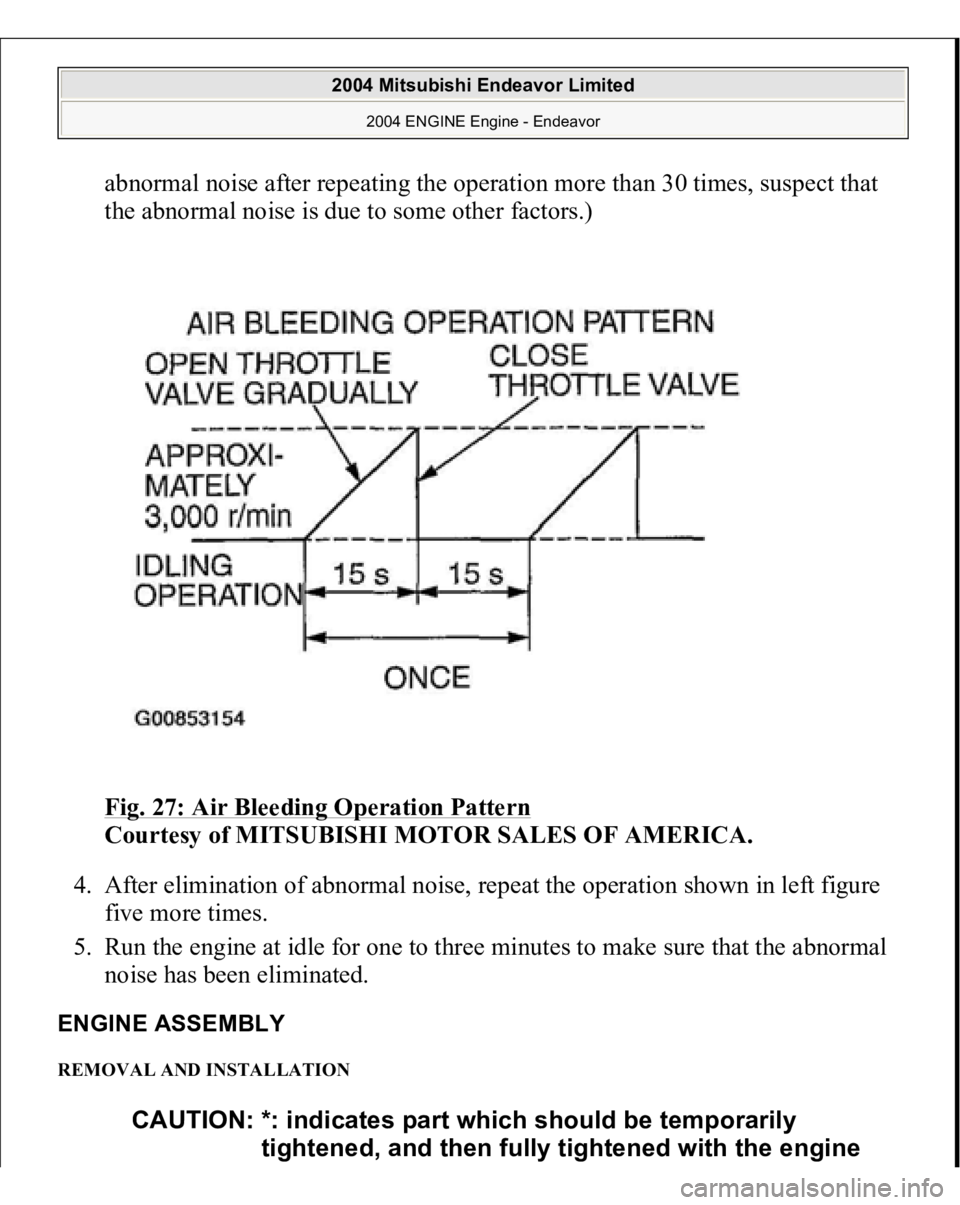

2. Idle the engine for one to three minutes to warm it up.

3. Repeat the operation pattern, shown in left figure, at no load to check for

abnormal noise. (Usually the abnormal noise is eliminated after repetition of

the ope

ration 1

0 to 30 tim

es.

If, howeve

r, no change is obse

rved

in

the leve

l of

NOTE: If air mixed with oil enters the high pressure chamber

inside the lash adjuster from the above causes, air in

the high pressure chamber is compressed excessively

while the valve is opened, resulting in an abnormal

noise when the valve closes. This is the same

phenomenon as that observed when the valve

clearance has become excessive. The lash adjuster can

resume normal function when air entered the lash

adjuster is removed.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1535 of 3870

abnormal noise after repeating the operation more than 30 times, suspect that

the abnormal noise is due to some other factors.)

Fig. 27: Air Bleeding Operation Pattern

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. After elimination of abnormal noise, repeat the operation shown in left figure

five more times.

5. Run the engine at idle for one to three minutes to make sure that the abnormal

noise has been eliminated.

ENGINE ASSEMBLY REMOVAL AND INSTALLATION

CAUTION: *: indicates part which should be temporarily

tightened, and then fully tightened with the engine

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1856 of 3870

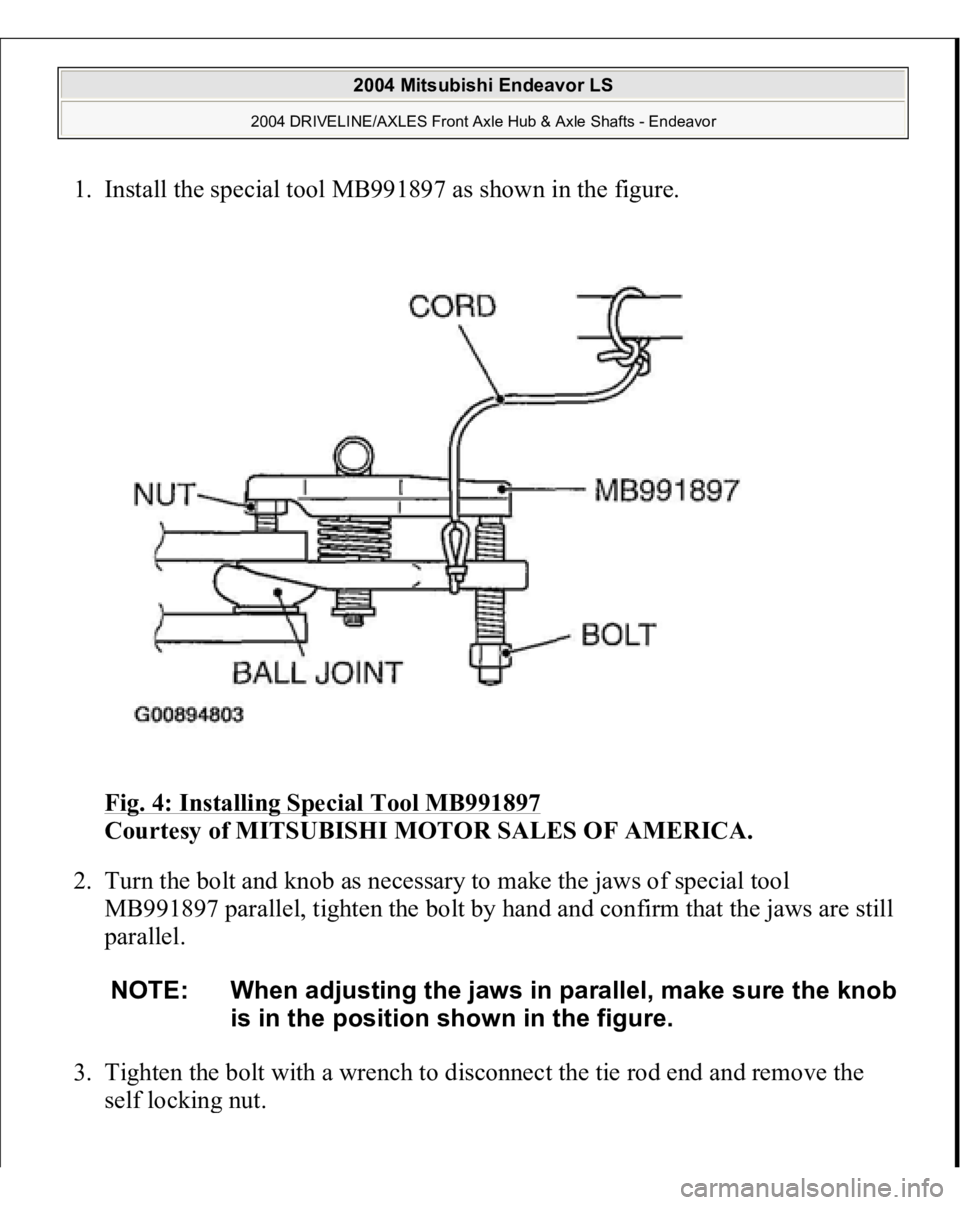

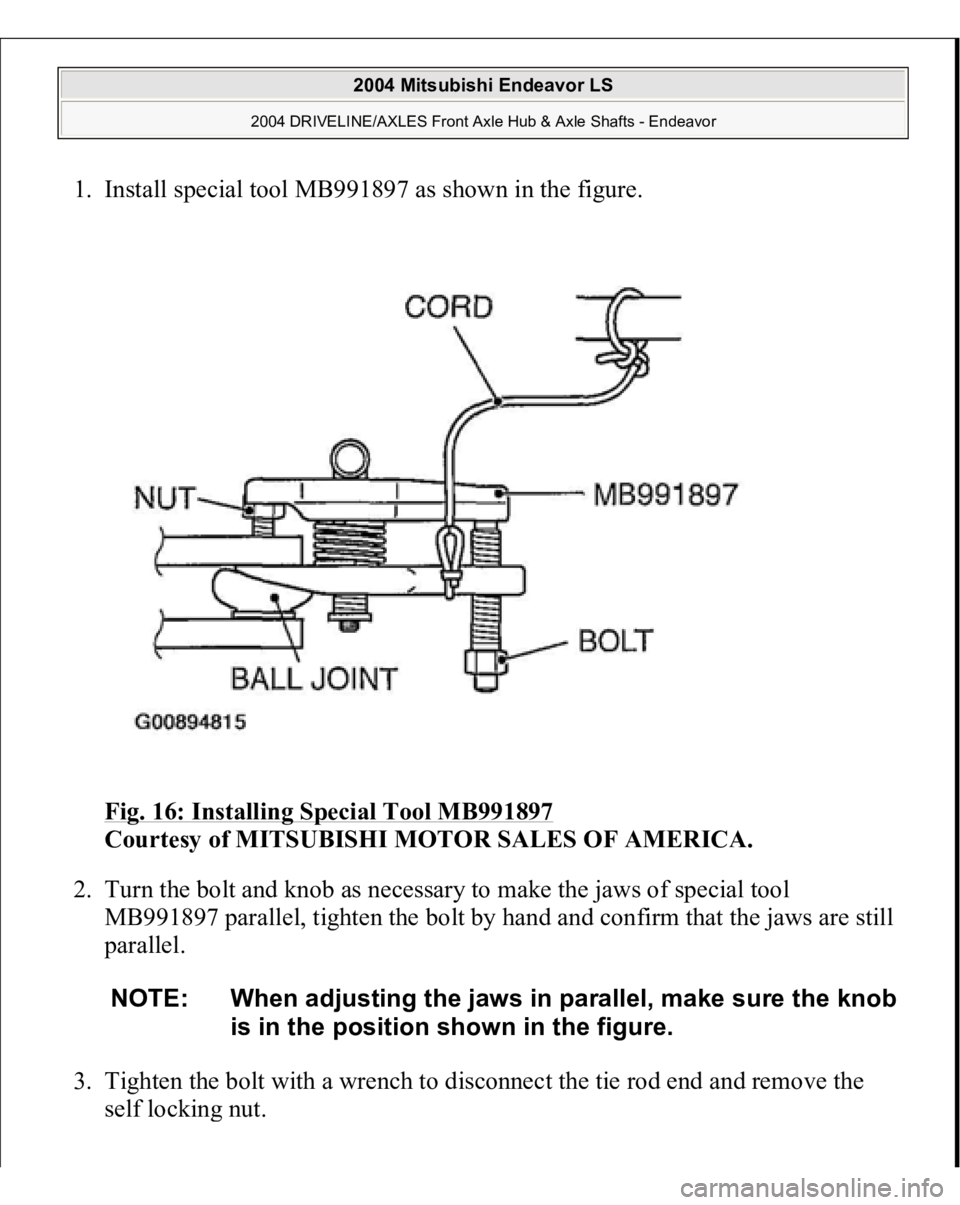

1. Install the special tool MB991897 as shown in the figure.

Fig. 4: Installing Special Tool MB991897

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Turn the bolt and knob as necessary to make the jaws of special tool

MB991897 parallel, tighten the bolt by hand and confirm that the jaws are still

parallel.

3. Tighten the bolt with a wrench to disconnect the tie rod end and remove the

self lockin

g nut.

NOTE: When adjusting the jaws in parallel, make sure the knob

is in the position shown in the figure.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1867 of 3870

1. Install special tool MB991897 as shown in the figure.

Fig. 16: Installing Special Tool MB991897

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Turn the bolt and knob as necessary to make the jaws of special tool

MB991897 parallel, tighten the bolt by hand and confirm that the jaws are still

parallel.

3. Tighten the bolt with a wrench to disconnect the tie rod end and remove the

self lockin

g nut.

NOTE: When adjusting the jaws in parallel, make sure the knob

is in the position shown in the figure.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1974 of 3870

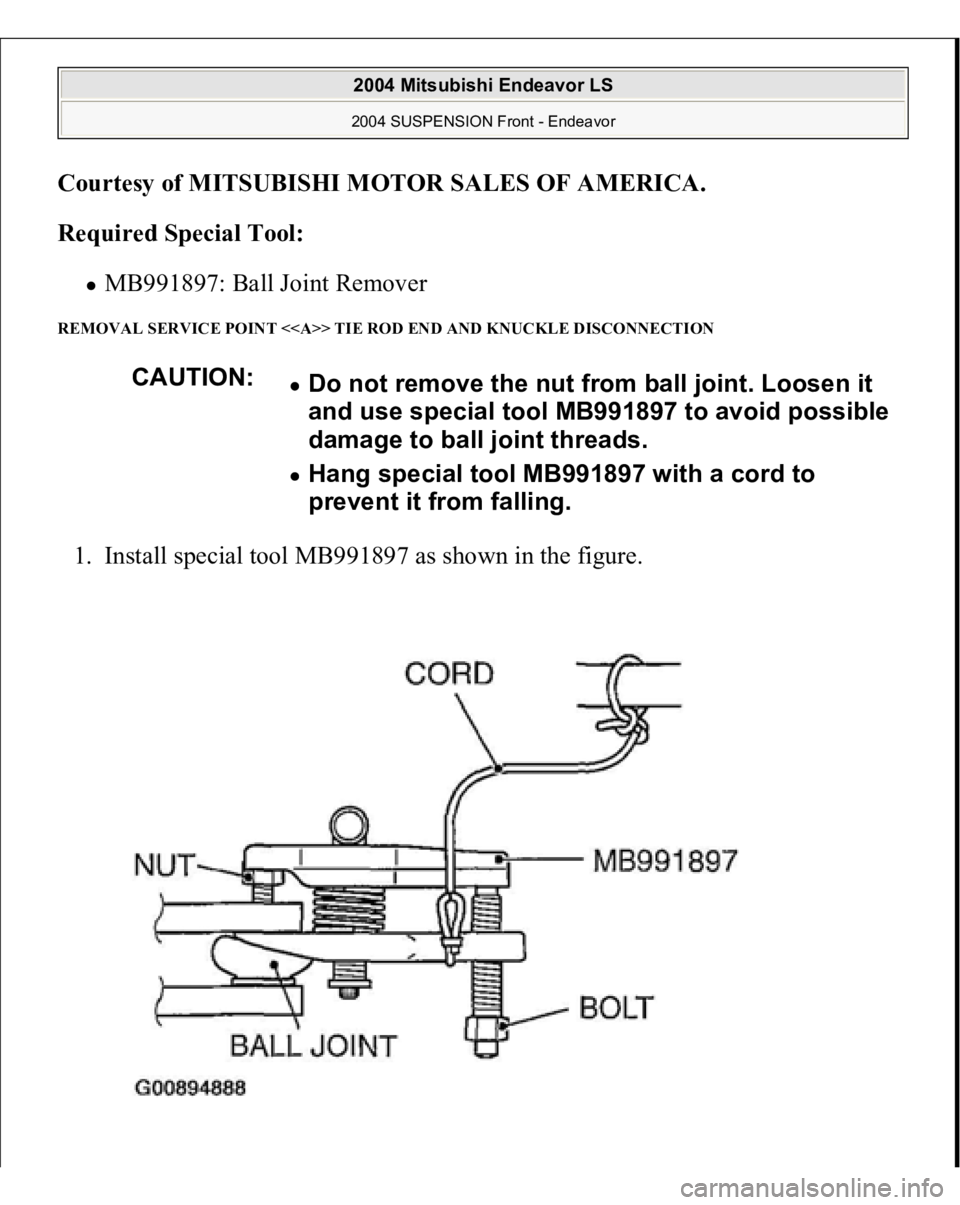

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

Required Special Tool:

MB991897: Ball Joint Remover

REMOVAL SERVICE POINT <> TIE ROD END AND KNUCKLE DISCONNECTION 1. Install special tool MB991897 as shown in the figure.

CAUTION:

Do not remove the nut from ball joint. Loosen it

and use special tool MB991897 to avoid possible

damage to ball joint threads. Hang special tool MB991897 with a cord to

prevent it from falling.

2004 Mitsubishi Endeavor LS 2004 SUSPENSION Front - Endeavor