MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Page 691 of 3870

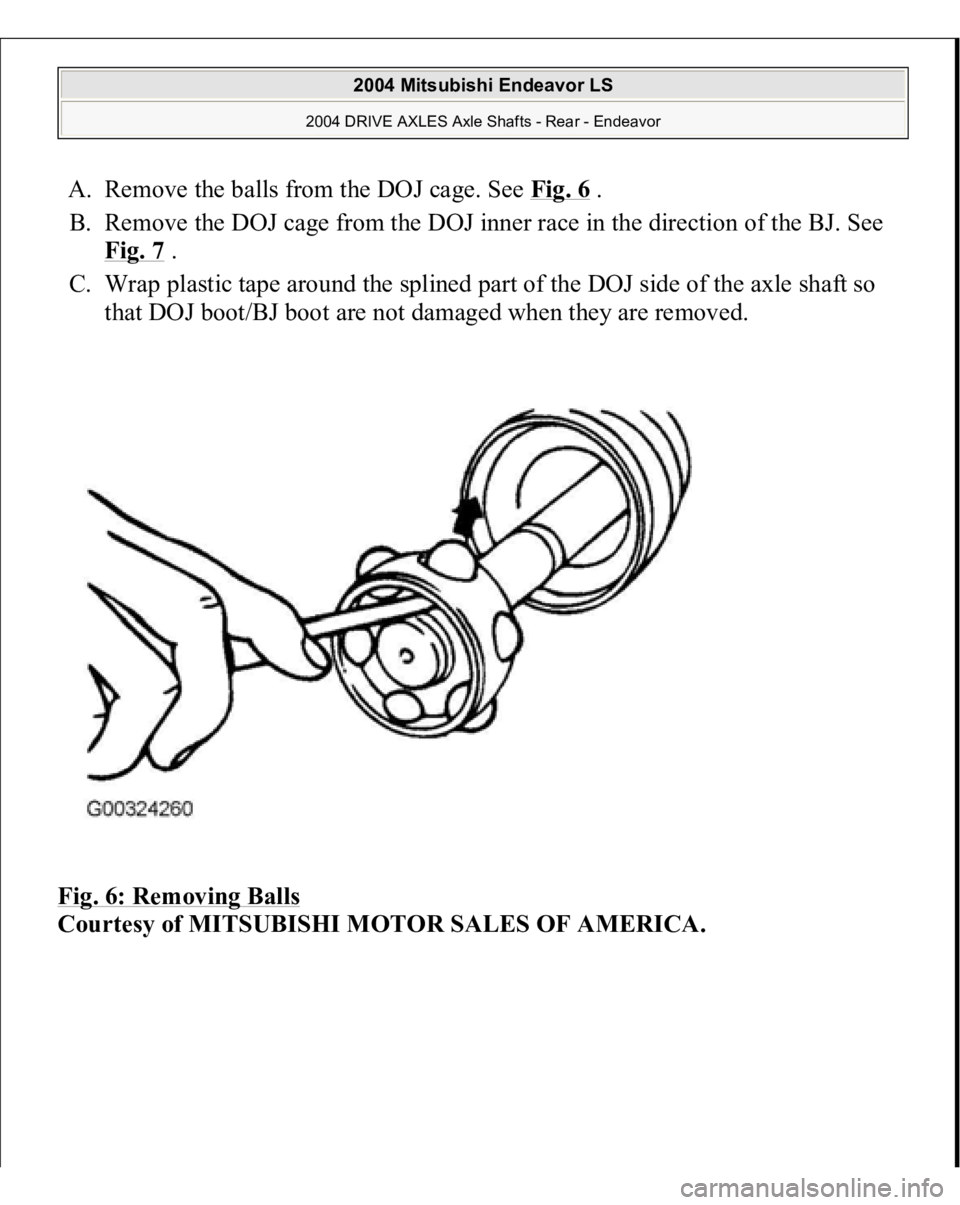

A. Remove the balls from the DOJ cage. See Fig. 6

.

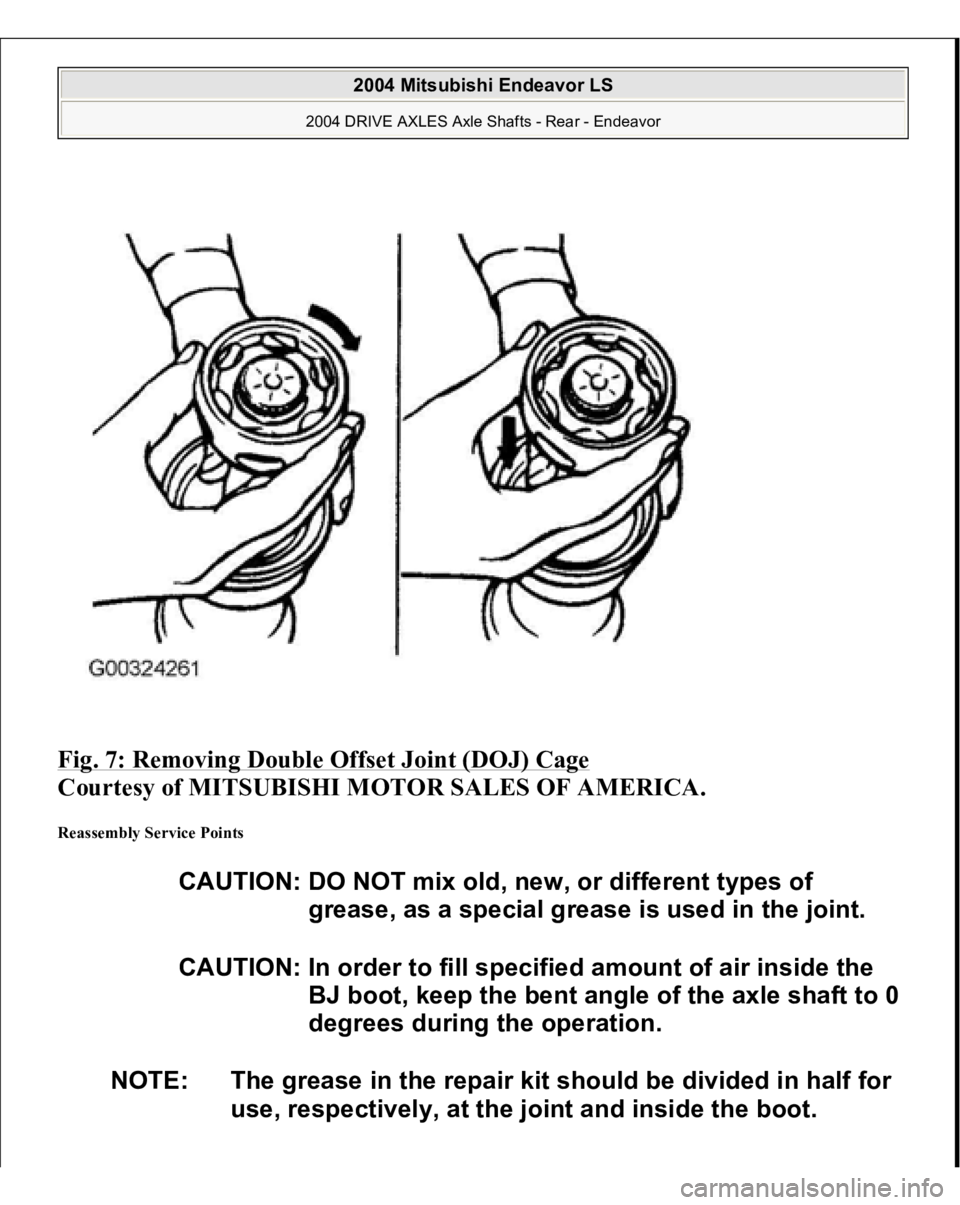

B. Remove the DOJ cage from the DOJ inner race in the direction of the BJ. See

Fig. 7

.

C. Wrap plastic tape around the splined part of the DOJ side of the axle shaft so

that DOJ boot/BJ boot are not damaged when they are removed.

Fig. 6: Removing Balls

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Rear - Endeavor

Page 692 of 3870

Fig. 7: Removing Double Offset Joint (DOJ) Cage

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Reassembly Service Points

CAUTION: DO NOT mix old, new, or different types of

grease, as a special grease is used in the joint.

CAUTION: In order to fill specified amount of air inside the

BJ boot, keep the bent angle of the axle shaft to 0

degrees during the operation.

NOTE: The grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Rear - Endeavor

Page 693 of 3870

A. Wrap tape around the spline part of the shaft, then install BJ boot and DOJ

boot. Fill the inside of the BJ and BJ boot with specified grease. Tighten the

boot band.

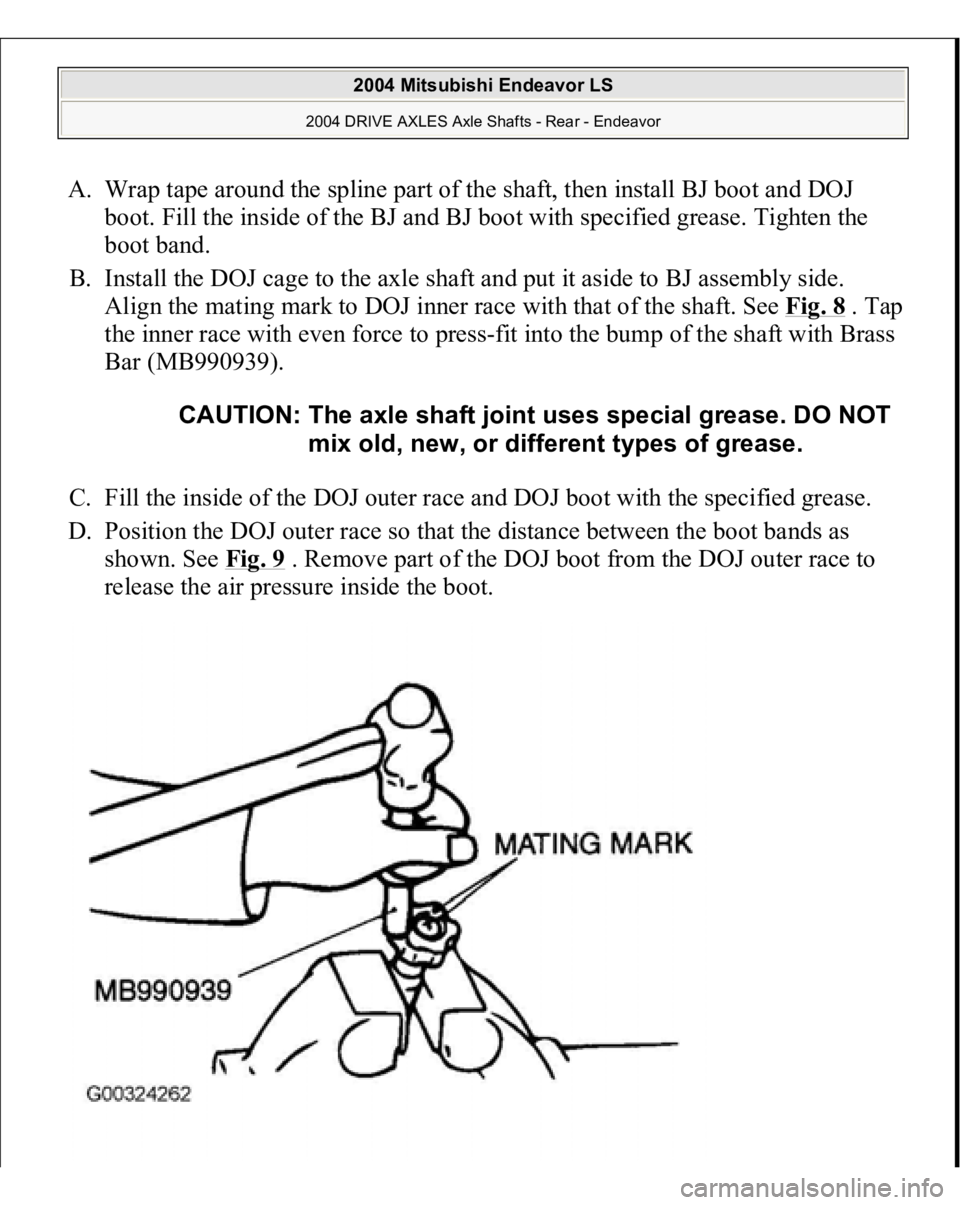

B. Install the DOJ cage to the axle shaft and put it aside to BJ assembly side.

Align the mating mark to DOJ inner race with that of the shaft. See Fig. 8

. Tap

the inner race with even force to press-fit into the bump of the shaft with Brass

Bar (MB990939).

C. Fill the inside of the DOJ outer race and DOJ boot with the specified grease.

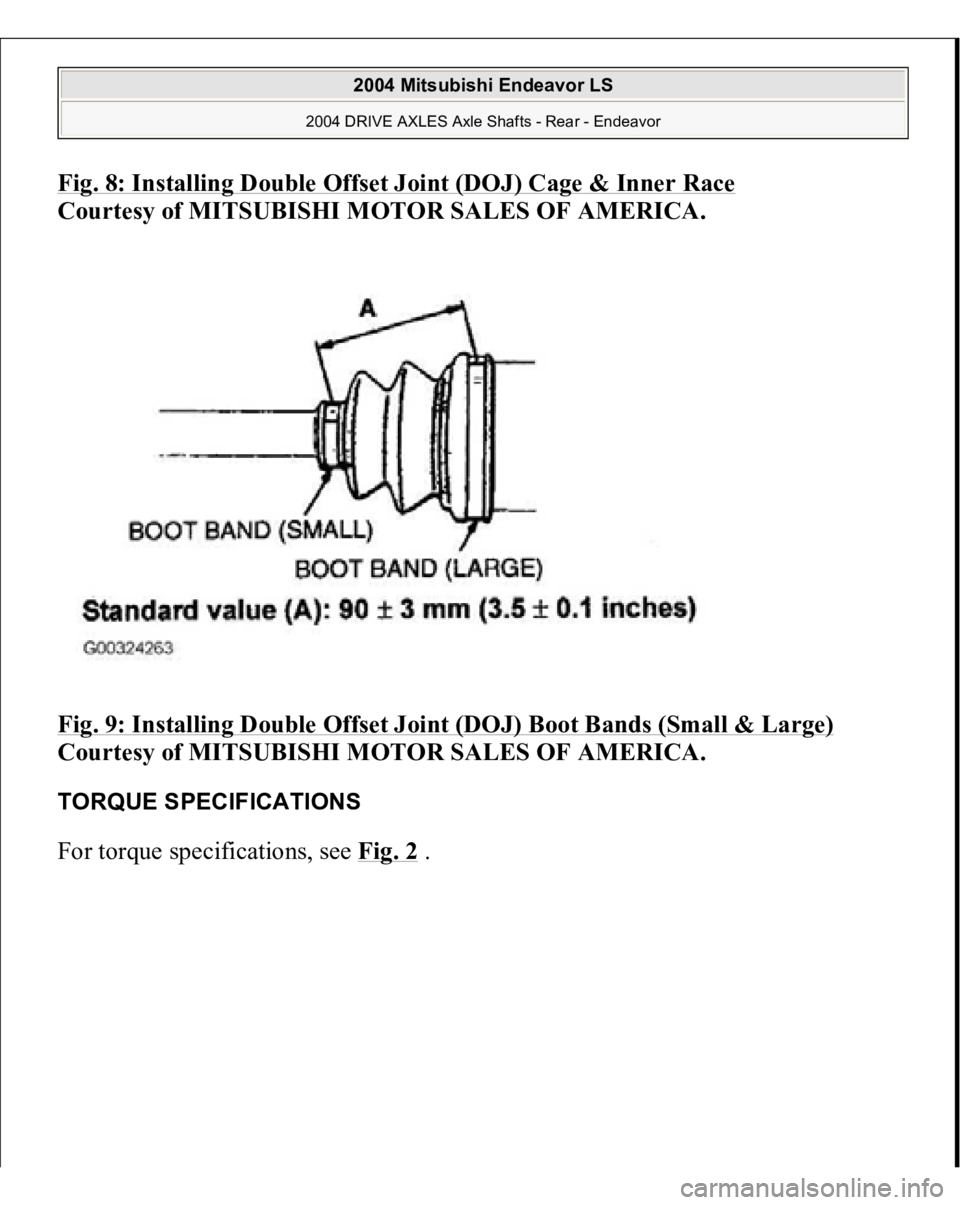

D. Position the DOJ outer race so that the distance between the boot bands as

shown. See Fig. 9

. Remove part of the DOJ boot from the DOJ outer race to

release the air pressure inside the boot.

CAUTION: The axle shaft joint uses special grease. DO NOT

mix old, new, or different types of grease.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Rear - Endeavor

Page 694 of 3870

Fig. 8: Installing Double Offset Joint (DOJ) Cage & Inner Race

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Fig. 9: Installing Double Offset Joint (DOJ) Boot Bands (Small & Large)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

TORQUE SPECIFICATIONS For tor

que s

pecifications, see Fi

g. 2

.

2004 Mitsubishi Endeavor LS

2004 DRIVE AXLES Axle Shafts - Rear - Endeavor

Page 775 of 3870

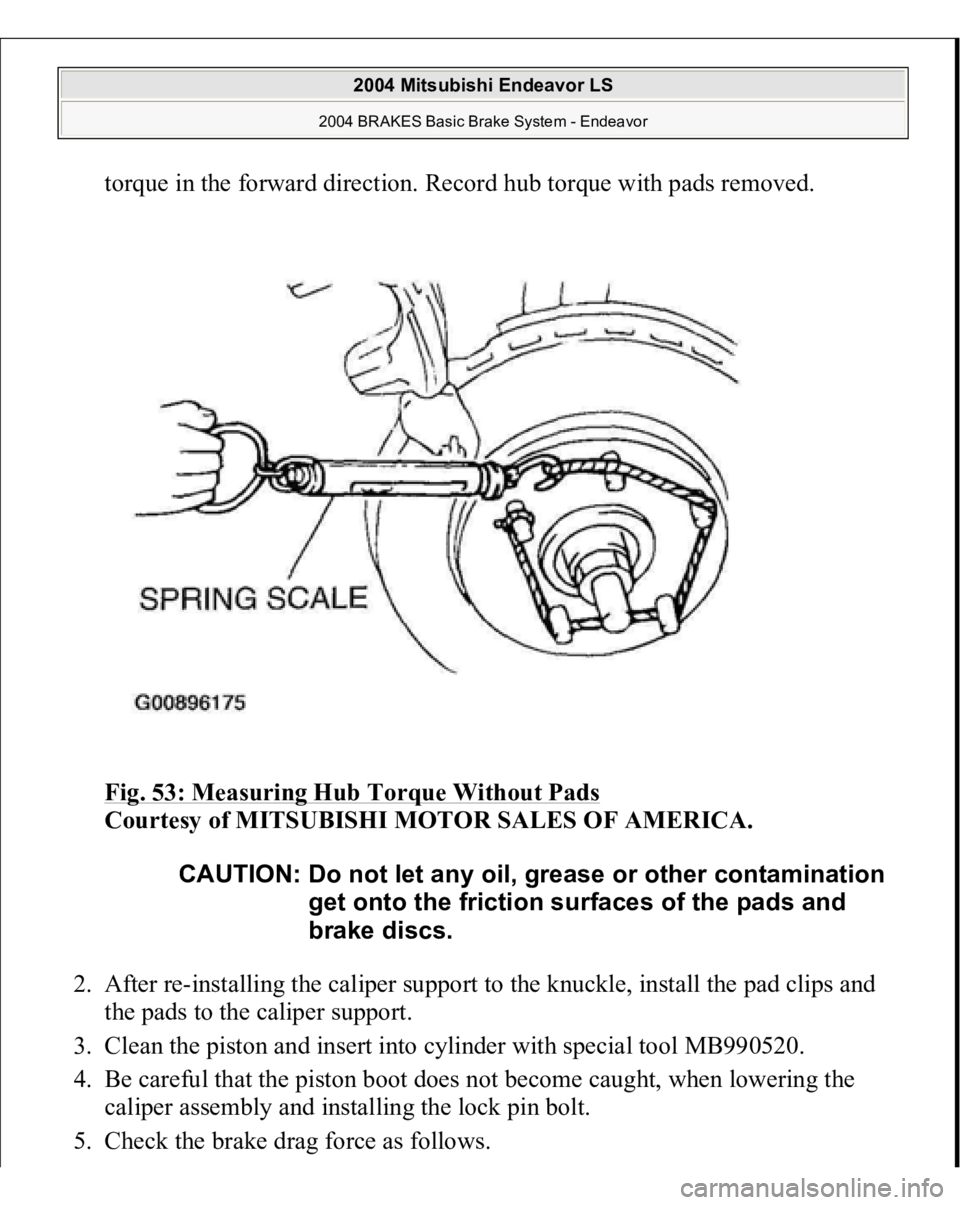

torque in the forward direction. Record hub torque with pads removed.

Fig. 53: Measuring Hub Torque Without Pads

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. After re-installing the caliper support to the knuckle, install the pad clips and

the pads to the caliper support.

3. Clean the piston and insert into cylinder with special tool MB990520.

4. Be careful that the piston boot does not become caught, when lowering the

caliper assembly and installing the lock pin bolt.

5. Check the brake drag force as follows.

CAUTION: Do not let any oil, grease or other contamination

get onto the friction surfaces of the pads and

brake discs.

2004 Mitsubishi Endeavor LS

2004 BRAKES Basic Brake System - Endeavor

Page 779 of 3870

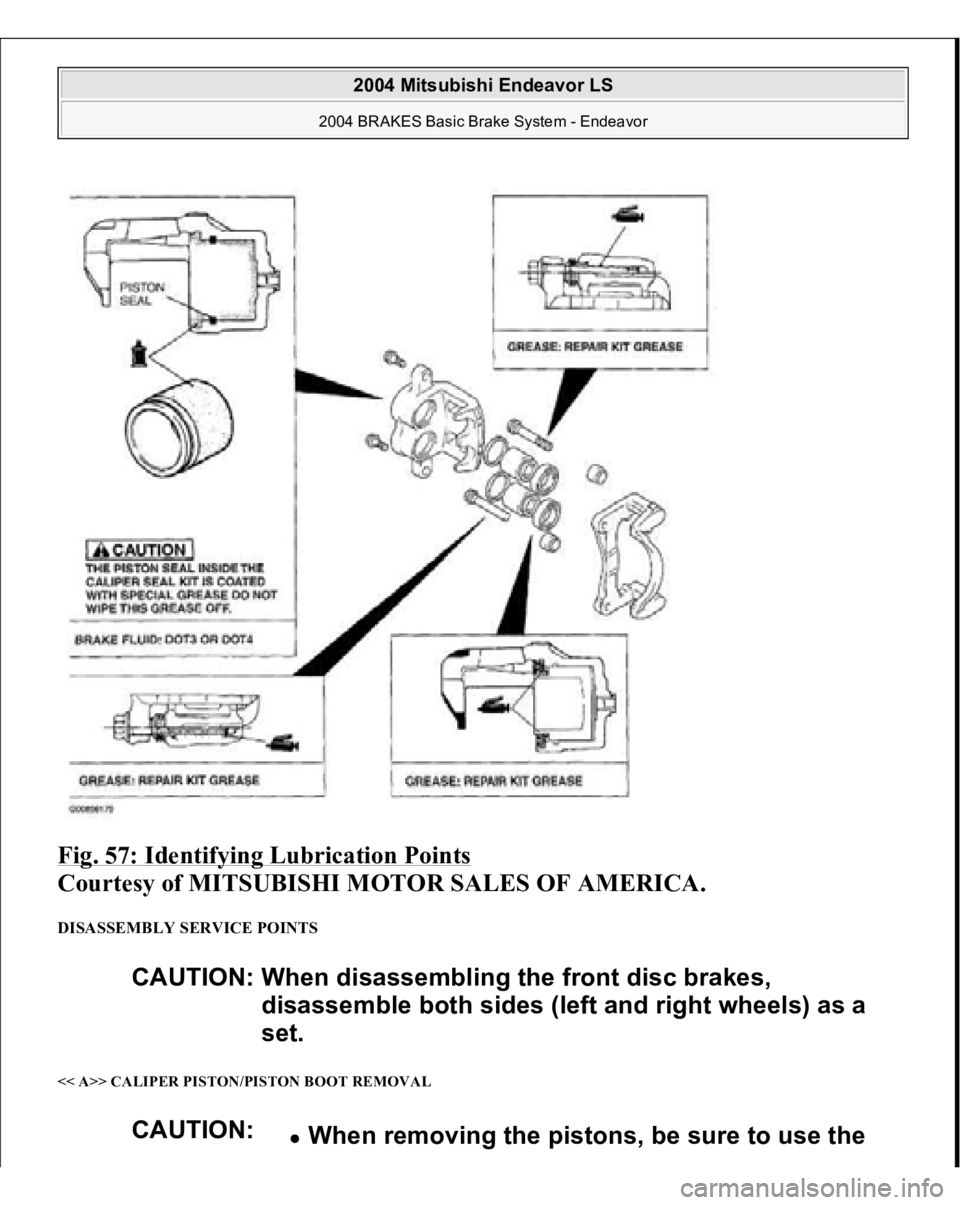

Fig. 57: Identifying Lubrication Points

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

DISASSEMBLY SERVICE POINTS << A>> CALIPER PISTON/PISTON BOOT REMOVAL

CAUTION: When disassembling the front disc brakes,

disassemble both sides (left and right wheels) as a

set.

CAUTION:

When removing the pistons, be sure to use the

2004 Mitsubishi Endeavor LS

2004 BRAKES Basic Brake System - Endeavor

Page 780 of 3870

Blow compressed air slowly from the connecting portion of the brake hose to pull

out the

piston and the

piston boots.handle of a plastic hammer and adjust the height

of the two pistons while pumping in air slowly so

that the pistons protrude evenly. Do not remove one piston completely before

trying to remove the other piston, because it will

become impossible to remove the second piston. Blow air little by little to remove the piston. The

piston will pop out if a force of air is applied

suddenly.

2004 Mitsubishi Endeavor LS

2004 BRAKES Basic Brake System - Endeavor

Page 784 of 3870

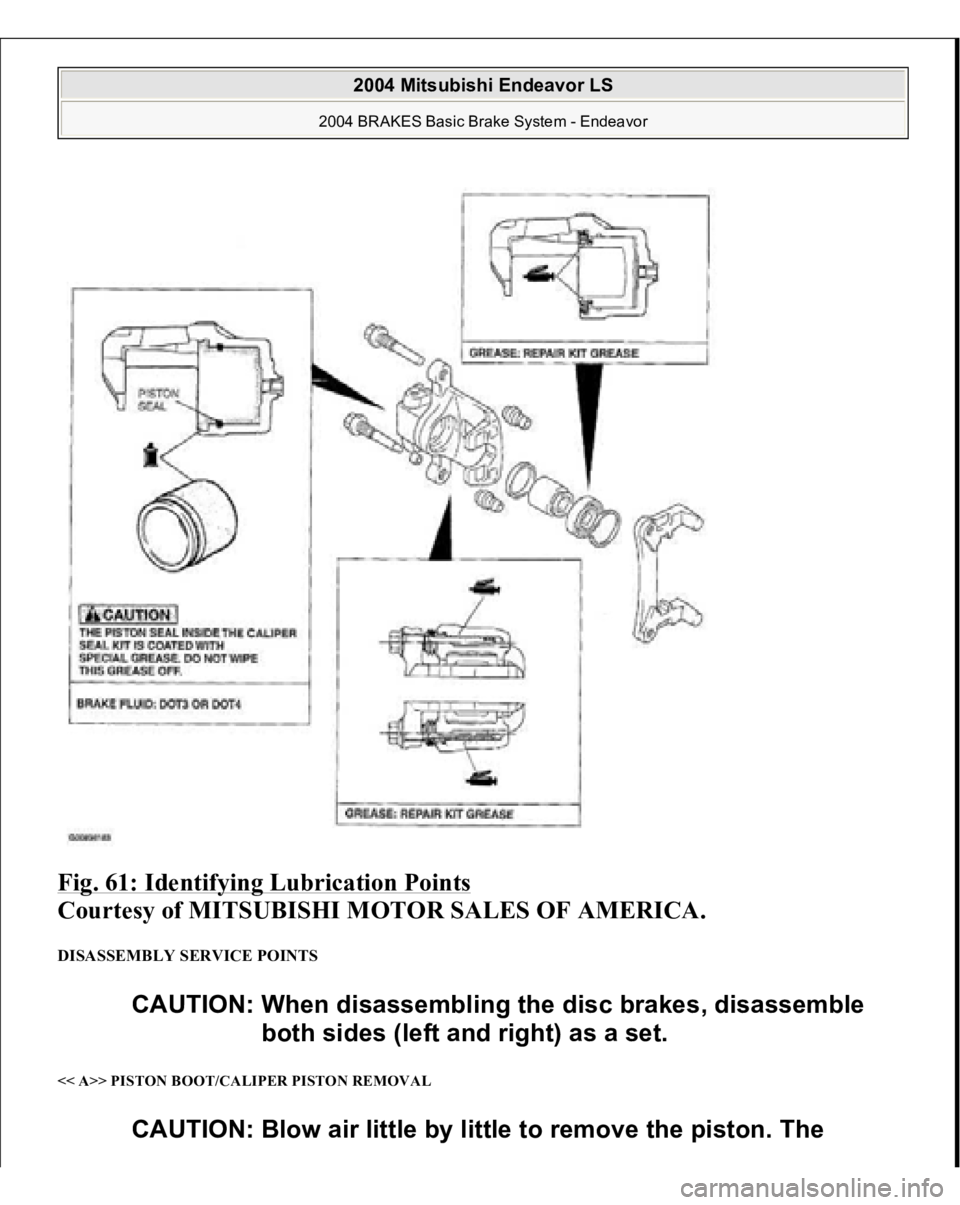

Fig. 61: Identifying Lubrication Points

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

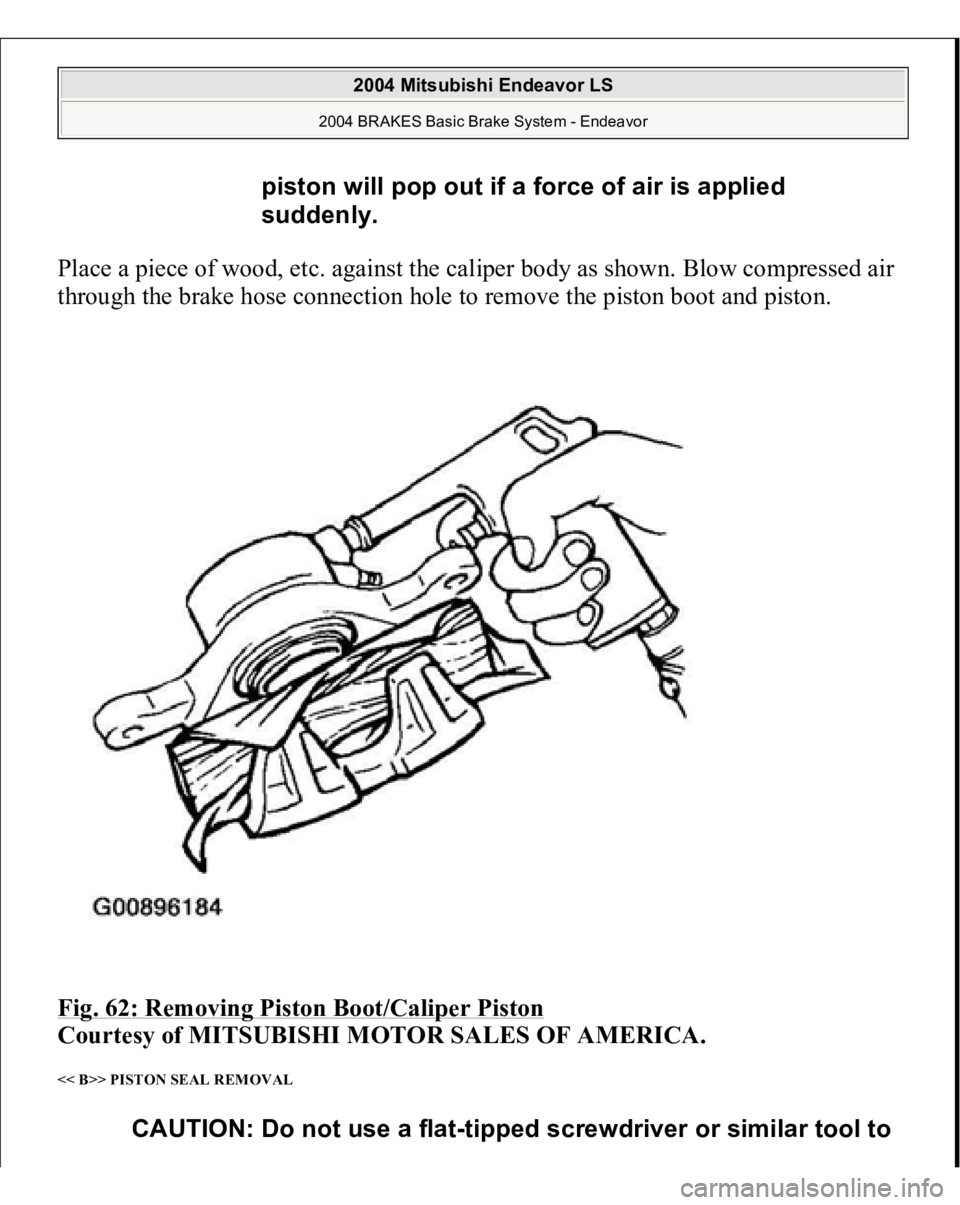

DISASSEMBLY SERVICE POINTS << A>> PISTON BOOT/CALIPER PISTON REMOVAL

CAUTION: When disassembling the disc brakes, disassemble

both sides (left and right) as a set.

CAUTION: Blow air little by little to remove the piston. The

2004 Mitsubishi Endeavor LS

2004 BRAKES Basic Brake System - Endeavor

Page 785 of 3870

Place a piece of wood, etc. against the caliper body as shown. Blow compressed air

through the brake hose connection hole to remove the piston boot and piston.

Fig. 62: Removing Piston Boot/Caliper Piston

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

<< B>> PISTON SEAL REMOVAL

piston will pop out if a force of air is applied

suddenly.

CAUTION: Do not use a flat-tipped screwdriver or similar tool to

2004 Mitsubishi Endeavor LS

2004 BRAKES Basic Brake System - Endeavor

Page 1087 of 3870

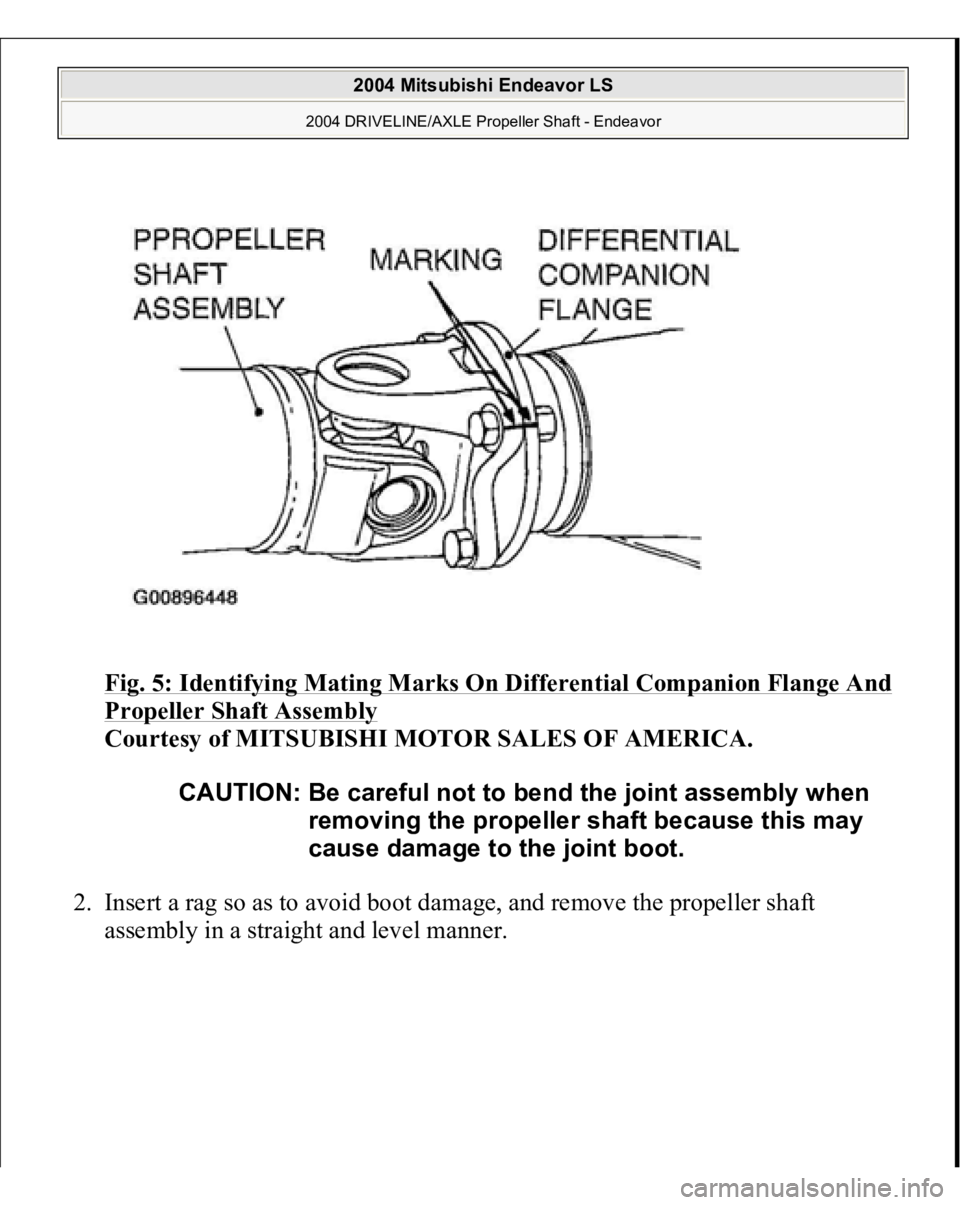

Fig. 5: Identifying Mating Marks On Differential Companion Flange And Propeller Shaft Assembly

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Insert a rag so as to avoid boot damage, and remove the propeller shaft

assembly in a straight and level manner.

CAUTION: Be careful not to bend the joint assembly when

removing the propeller shaft because this may

cause damage to the joint boot.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLE Propeller Shaft - Endeavor