sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 390 of 1273

13-248FUEL SYSTEM

(8) Switch OFF the ignition switch.

(9) If the scan tool was not used, disconnect the jumper wire from the diagnostic test mode control terminal. (10)Disconnect

the jumper wire from the terminal for adjust-

ment of ignition timing, and return the connector to its

original condition.

(11

)Start the engine again and let it run at idle speed for about

ten minutes; check to be sure that the idling condition is

normal.

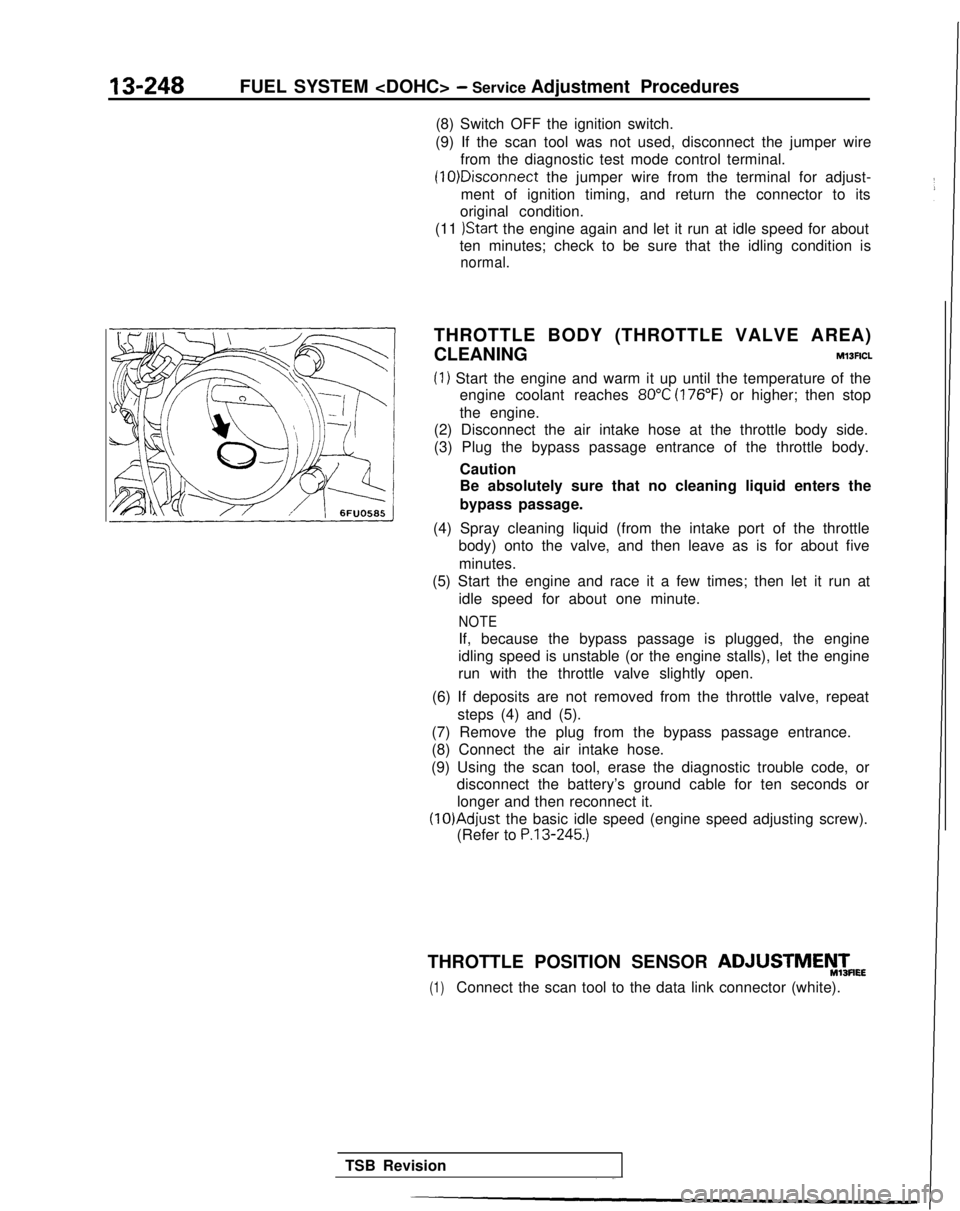

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

Ml3ACL

(1) Start the engine and warm it up until the temperature of the engine coolant reaches

80°C (176°F) or higher; then stop

the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Plug the bypass passage entrance of the throttle body.

Caution

Be absolutely sure that no cleaning liquid enters the

bypass passage.

(4) Spray cleaning liquid (from the intake port of the throttle body) onto the valve, and then leave as is for about five

minutes.

(5) Start the engine and race it a few times; then let it run at

idle speed for about one minute.

NOTE

If, because the bypass passage is plugged, the engine

idling speed is unstable (or the engine stalls), let the engine

run with the throttle valve slightly open.

(6) If deposits are not removed from the throttle valve, repeat steps (4) and (5).

(7) Remove the plug from the bypass passage entrance.

(8) Connect the air intake hose.

(9) Using the scan tool, erase the diagnostic trouble code, or disconnect the battery’s ground cable for ten seconds or

longer and then reconnect it. (lO)Adjust

the basic idle speed (engine speed adjusting screw).

(Refer to

P.13-245.)

THROTTLE POSITION SENSOR ADJUSTMEyTmEE

(1)Connect the scan tool to the data link connector (white).

TSB Revision

Page 391 of 1273

FUEL SYSTEM

13-249

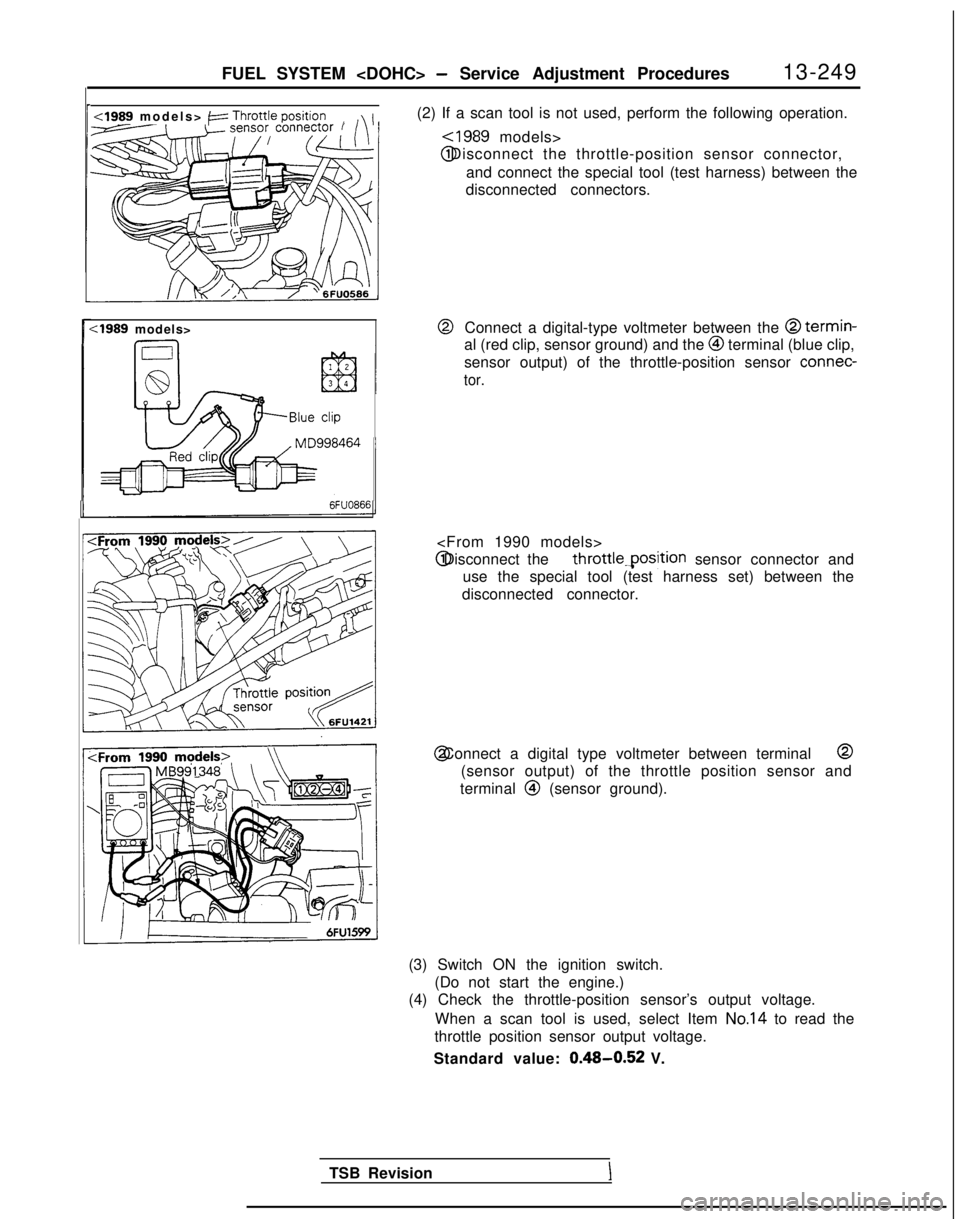

<1989 models> /zz Throttle position

(2) If a scan tool is not used, perform the following operation.,-

~1989 models> @ Disconnect the throttle-position sensor connector,

and connect the special tool (test harness) between the

disconnected connectors.

:1989 models>@Connect a digital-type voltmeter between the @ termin-

al (red clip, sensor ground) and the @I terminal (blue clip,

sensor output) of the throttle-position sensor connec-

tor.

Blue

clip

throttle.position sensor connector and

use the special tool (test harness set) between the

disconnected connector. @ Connect a digital type voltmeter between terminal @

(sensor output) of the throttle position sensor and

terminal

@ (sensor ground).

(3) Switch ON the ignition switch. (Do not start the engine.)

(4) Check the throttle-position sensor’s output voltage.

When a scan tool is used, select Item

No.14 to read the

throttle position sensor output voltage.

Standard value:

0.48-0.52 V.

TSB Revision

I

Page 393 of 1273

FUEL SYSTEM

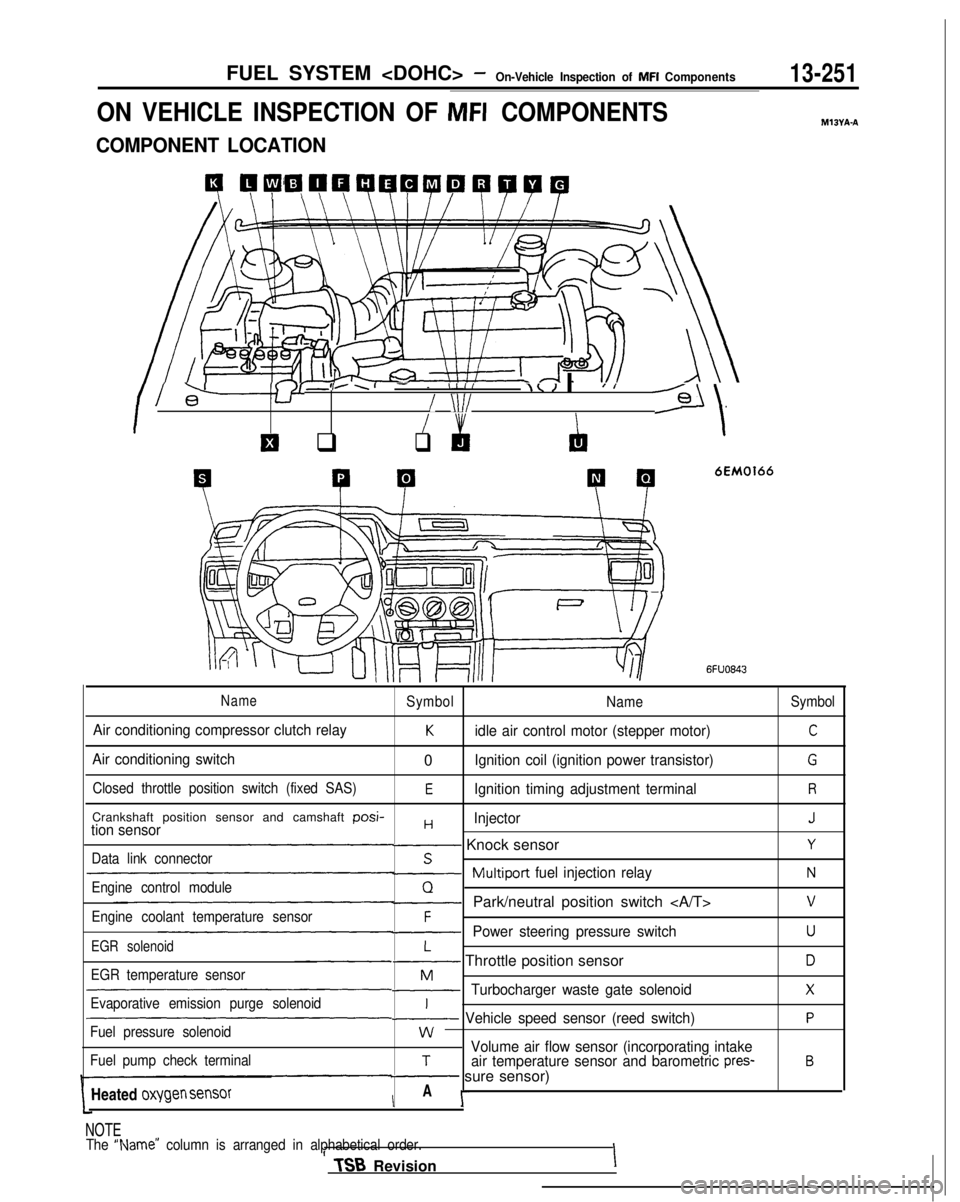

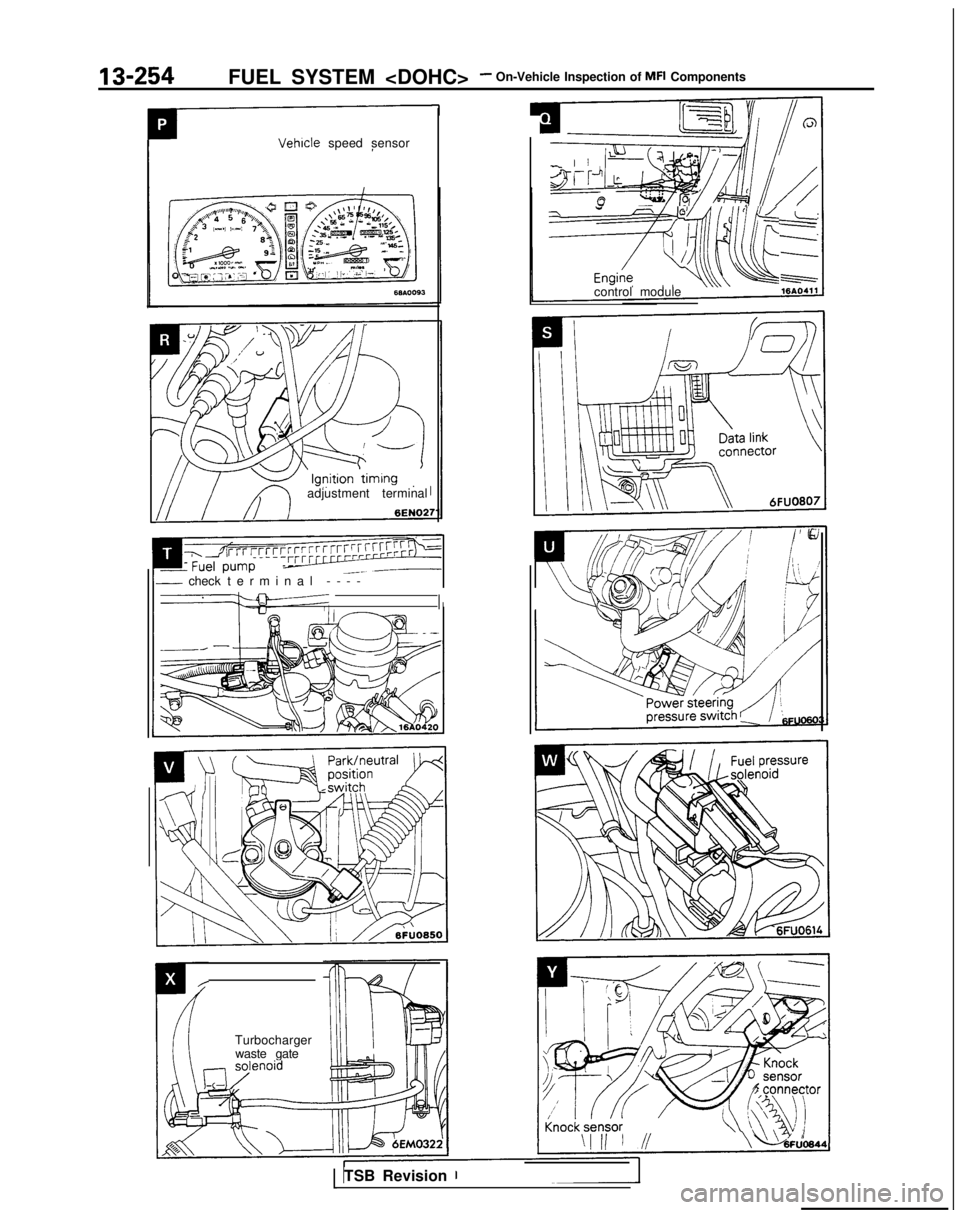

ON VEHICLE INSPECTION OF MFI COMPONENTS

COMPONENT LOCATION

4 QCiW41QQWPQWQ

I l-+-Y8’

-,..I- - IIII\< I IJ I

/ \lI/--Gl/

El q

I &

q

‘\

P P

6EM0166

MIBYA-A

6FUO843

NameSymbol

NameSymbol

Air conditioning compressor clutch relayKidle air control motor (stepper motor)C

Air conditioning switch0Ignition coil (ignition power transistor)G

Closed throttle position switch (fixed SAS)EIgnition timing adjustment terminalR

Crankshaft position sensor and camshaft posi-HInjectorJtion sensor- Knock sensorYData link connectorS~Multiport

fuel injection relayNEngine control moduleQ-Park/neutral position switch vEngine coolant temperature sensorF-Power steering pressure switchUEGR solenoidL- Throttle position sensorDEGR temperature sensorM-Turbocharger waste gate solenoidXEvaporative emission purge solenoidI~ Vehicle speed sensor (reed switch)PFuel pressure solenoidwVolume air flow sensor (incorporating intakeFuel pump check terminalTair temperature sensor and barometric pres-B- sure sensor)

Heated

oxygen sensorIA I-

NOTE

The “Name” column is arranged in alphabetical order.II TSB

RevisionI

Page 394 of 1273

13-252FUEL SYSTEM

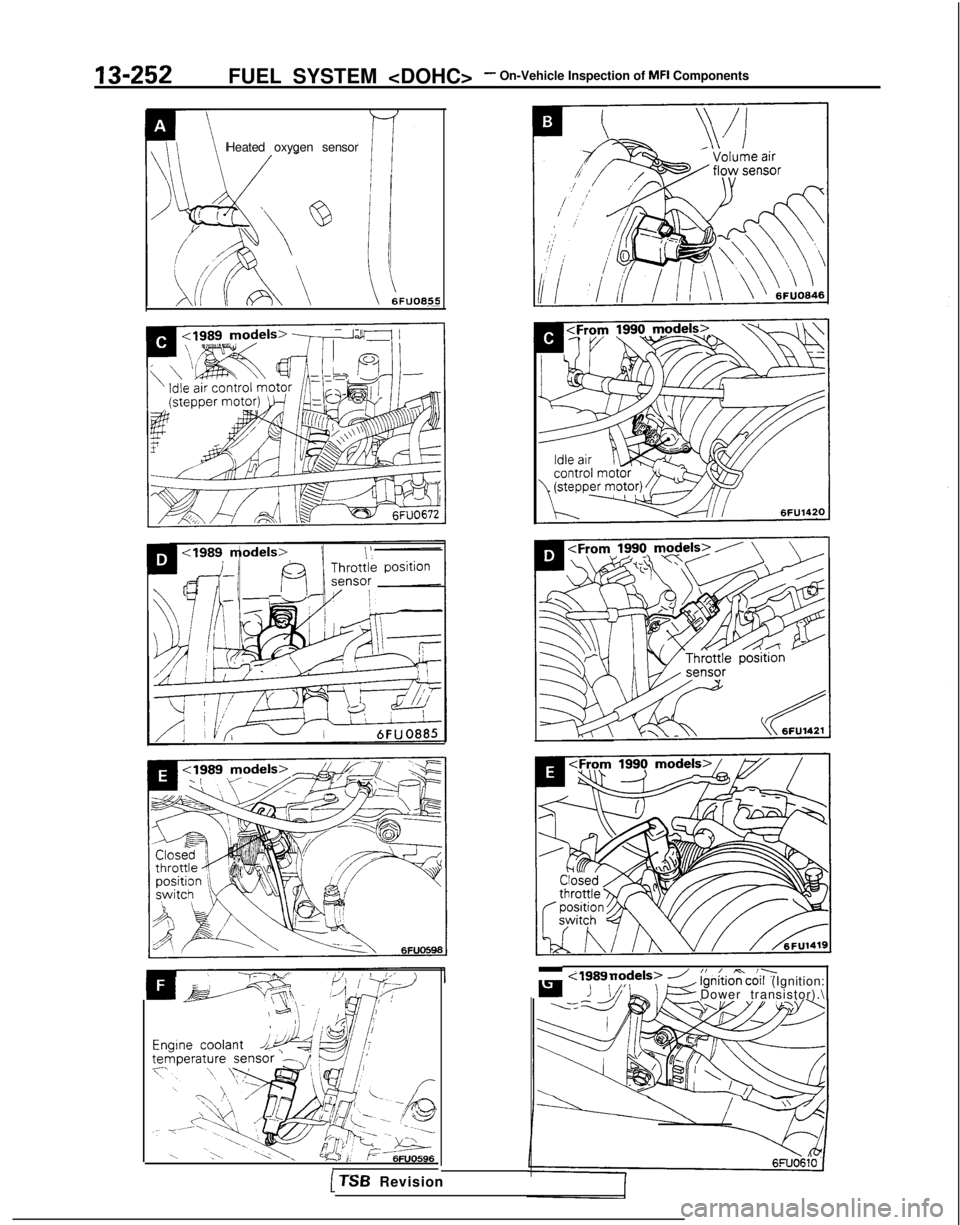

Heated oxygen sensor

la&/+$&,s ‘T*

1 \‘!;/ *- 7)lY-7

\ I--.P--&O596I ~~

- ~~~- ,,od&>/ ‘I.! m

”<1989 Ilgnltlon co11 (Ignition:

Dower transistor).\ [

TSB Revision

Page 396 of 1273

13-254FUEL SYSTEM

speed sensor

adjustment terminal

- check terminal ---

-

II

,

Turbocharger

waste gate

a,ylenoid

‘I K&h--

=yq@

control module

1 TSB Revision

Page 397 of 1273

FUEL SYSTEM

COMPONENTS INSPECTION PROCEDURE-

Using Scan ToolMlsYsAGa

Refer to P.13-41.

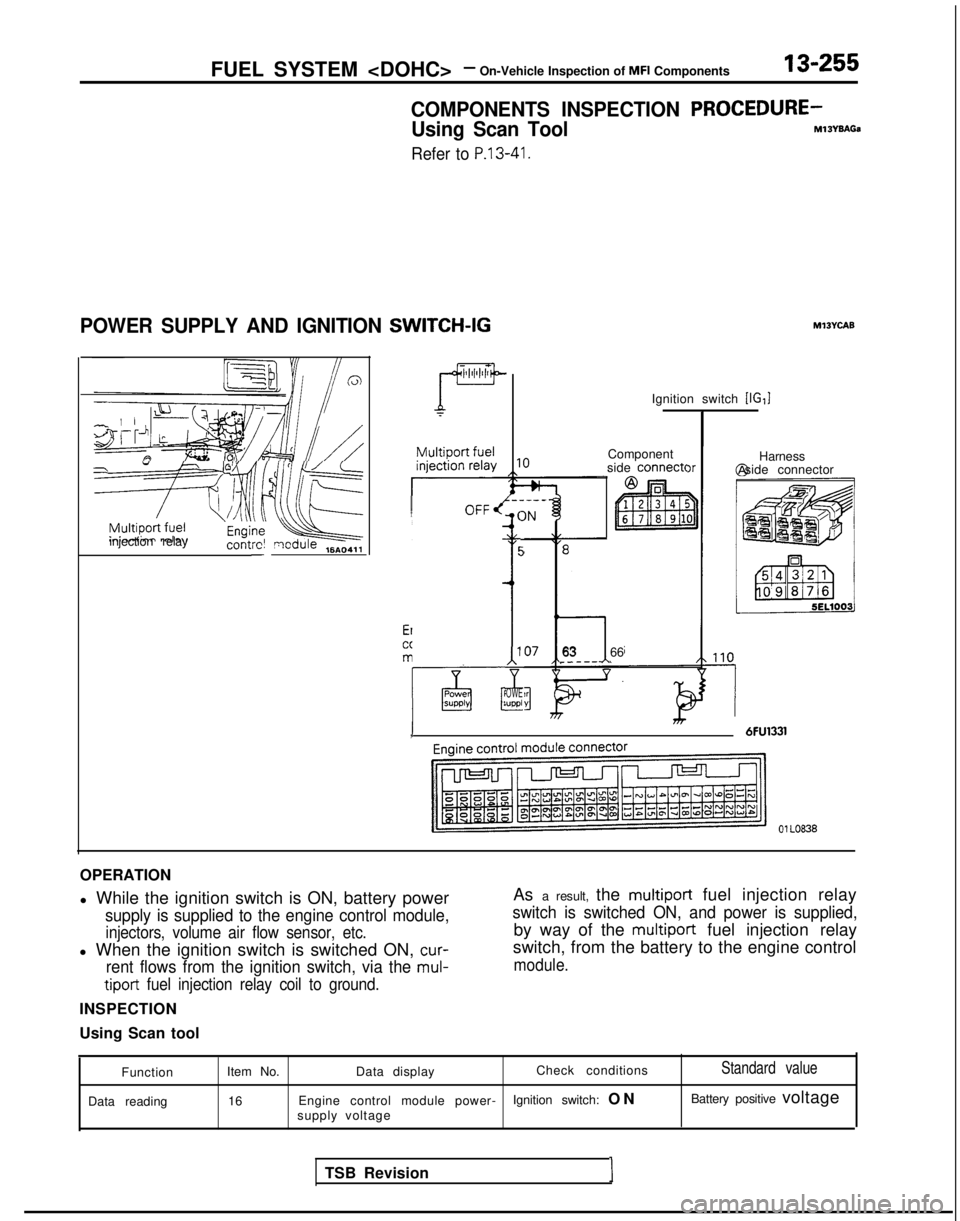

POWER SUPPLY AND IGNITION SWITCH-IG

zT=f?Qjkeinjection relay

contrc! qcdule ,6A04,,-

----_OFF/ (IN

t5

’ i

4

-

‘OWE;uppl-

Ignition switch [IG,]

Component

side

connect<

763 66.----

1 6FU1331, )r

Ml3YcAB

Harness

@ side connector

01 LO838

OPERATION

l While the ignition switch is ON, battery power

supply is supplied to the engine control module,

injectors, volume air flow sensor, etc.

l When the ignition switch is switched ON, cur-

rent flows from the ignition switch, via the mul-

tiport

fuel injection relay coil to ground.

INSPECTION

Using Scan tool As a result, the

multiport fuel injection relay

switch is switched ON, and power is supplied,

by way of the multiport fuel injection relay

switch, from the battery to the engine control

module.

Function

Data reading Item No.

Data display Check conditionsStandard value

16

Engine control module power- Ignition switch: O

N

Battery positive voltage

supply voltage

TSB Revision I

Page 403 of 1273

FUEL SYSTEM

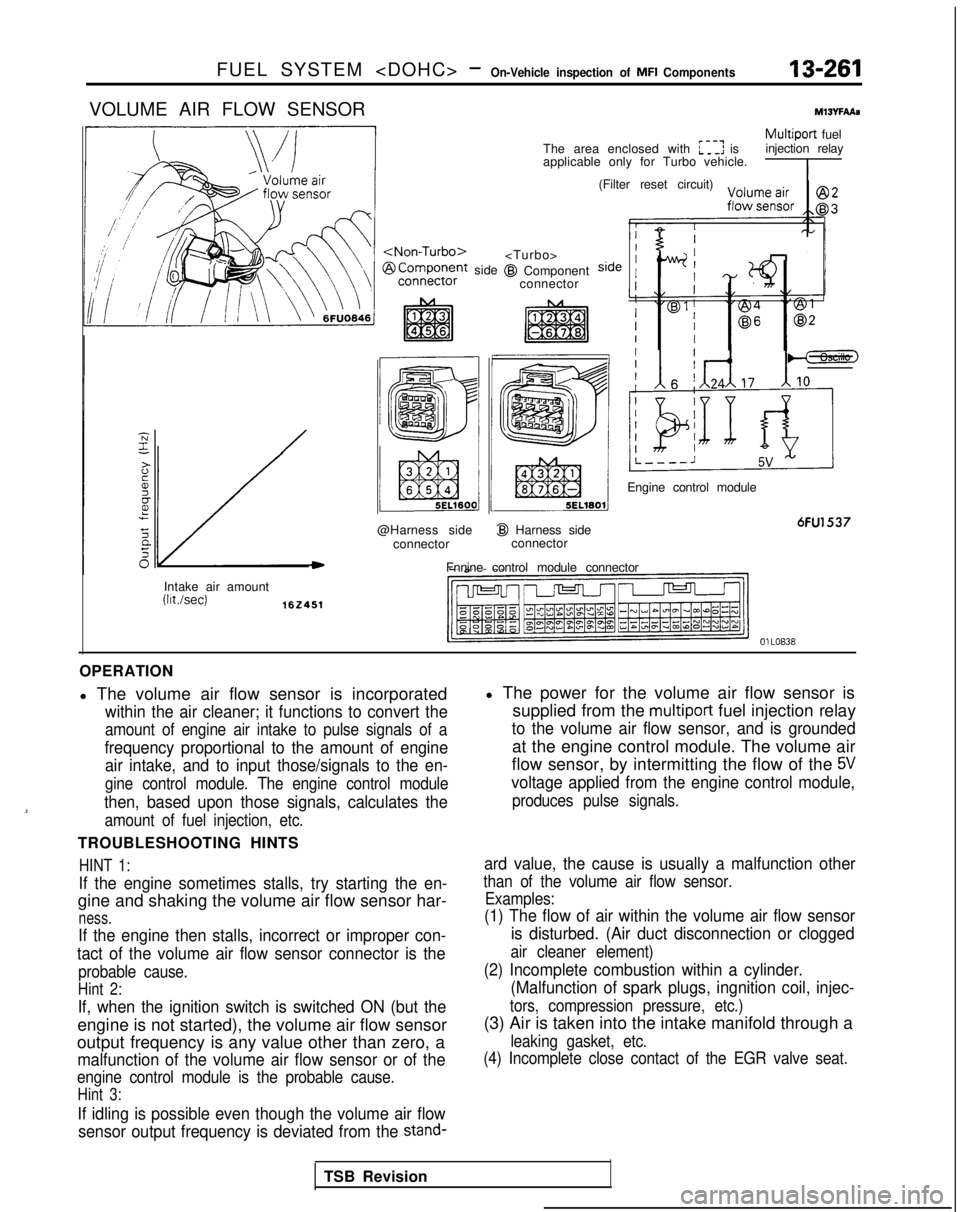

VOLUME AIR FLOW SENSORMlWFAAs

/

side

@Harness side connector

I@ Harness sideconnector

Fnnine control module connector

Multiport fuel

The area enclosed with :I: is injection relay

applicable only for Turbo vehicle.

I

@I Component connector (Filter reset circuit)

Engine control module

6FU1537

Intake air amount (Wsec)

162451

OlLO838

OPERATION

l The volume air flow sensor is incorporated

within the air cleaner; it functions to convert the

amount of engine air intake to pulse signals of a

frequency proportional to the amount of engine air intake, and to input those/signals to the en-

gine control module. The engine control module

then, based upon those signals, calculates the

amount of fuel injection, etc.

TROUBLESHOOTING HINTS

HINT 1:

If the engine sometimes stalls, try starting the en-

gine and shaking the volume air flow sensor har-

ness.

If the engine then stalls, incorrect or improper con-

tact of the volume air flow sensor connector is the

probable cause.

Hint 2:

If, when the ignition switch is switched ON (but the

engine is not started), the volume air flow sensor

output frequency is any value other than zero, a

malfunction of the volume air flow sensor or of the

engine control module is the probable cause.

Hint 3:

If idling is possible even though the volume air flow

sensor output frequency is deviated from the

stand-

l The power for the volume air flow sensor is supplied from the

multiport fuel injection relay

to the volume air flow sensor, and is grounded

at the engine control module. The volume air

flow sensor, by intermitting the flow of the

5V

voltage applied from the engine control module,

produces pulse signals.

ard value, the cause is usually a malfunction other

than of the volume air flow sensor. Examples:

(1) The flow of air within the volume air flow sensor

is disturbed. (Air duct disconnection or clogged

air cleaner element)

(2) Incomplete combustion within a cylinder.(Malfunction of spark plugs, ingnition coil, injec-

tors, compression pressure, etc.)

(3) Air is taken into the intake manifold through a

leaking gasket, etc.

(4) Incomplete close contact of the EGR valve seat.

TSB Revision

Page 404 of 1273

13-262FUEL SYSTEM

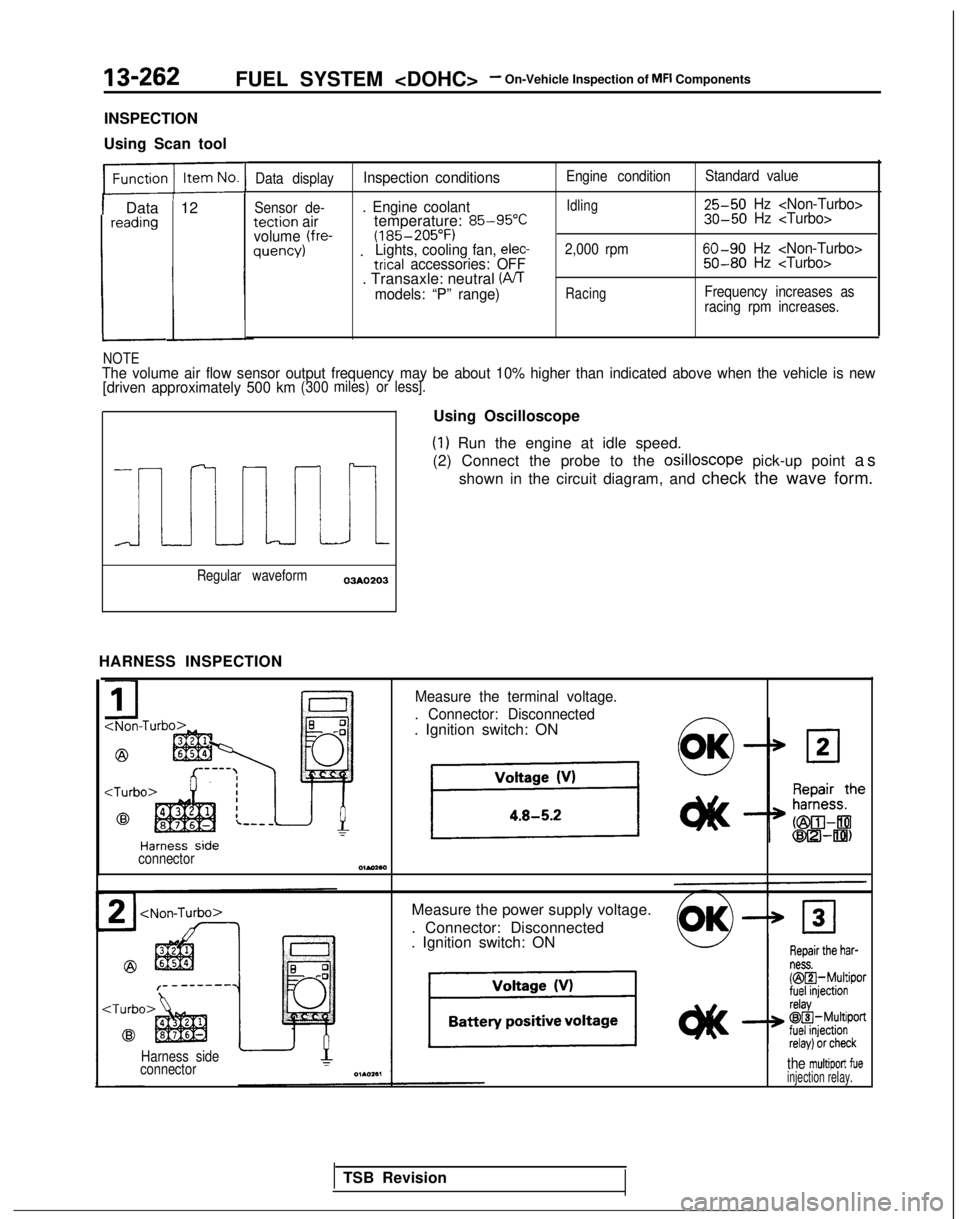

INSPECTION

Using Scan tool

1 Data 12reading

L

Data displayInspection conditions

Sensor de-. Engine coolanttection airtemperature: 85-95°Cvolume (fre-(185-205°F)quency) .Lights, cooling fan, elec-trical accessories: OFF. Transaxle: neutral (PJTmodels: “P” range)

Engine condition

Idling

2,000 rpm

Racing

Standard value 25-50

Hz

60-90 Hz

Frequency increases as

racing rpm increases.

NOTEThe volume air flow sensor output frequency may be about 10% higher than\

indicated above when the vehicle is new

[driven approximately 500 km(300 miles) or less].

i

Regular waveform03AO203

HARNESS INSPECTION Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the osilloscope

pick-up point as

shown in the circuit diagram, and check the wave form.

Measure the terminal voltage.

. Connector: Disconnected

. Ignition switch: ON

connectorOlMaa

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

Harness side

connectorthe multiport fueinjection relay.

TSB Revision

Page 405 of 1273

FUEL SYSTEM

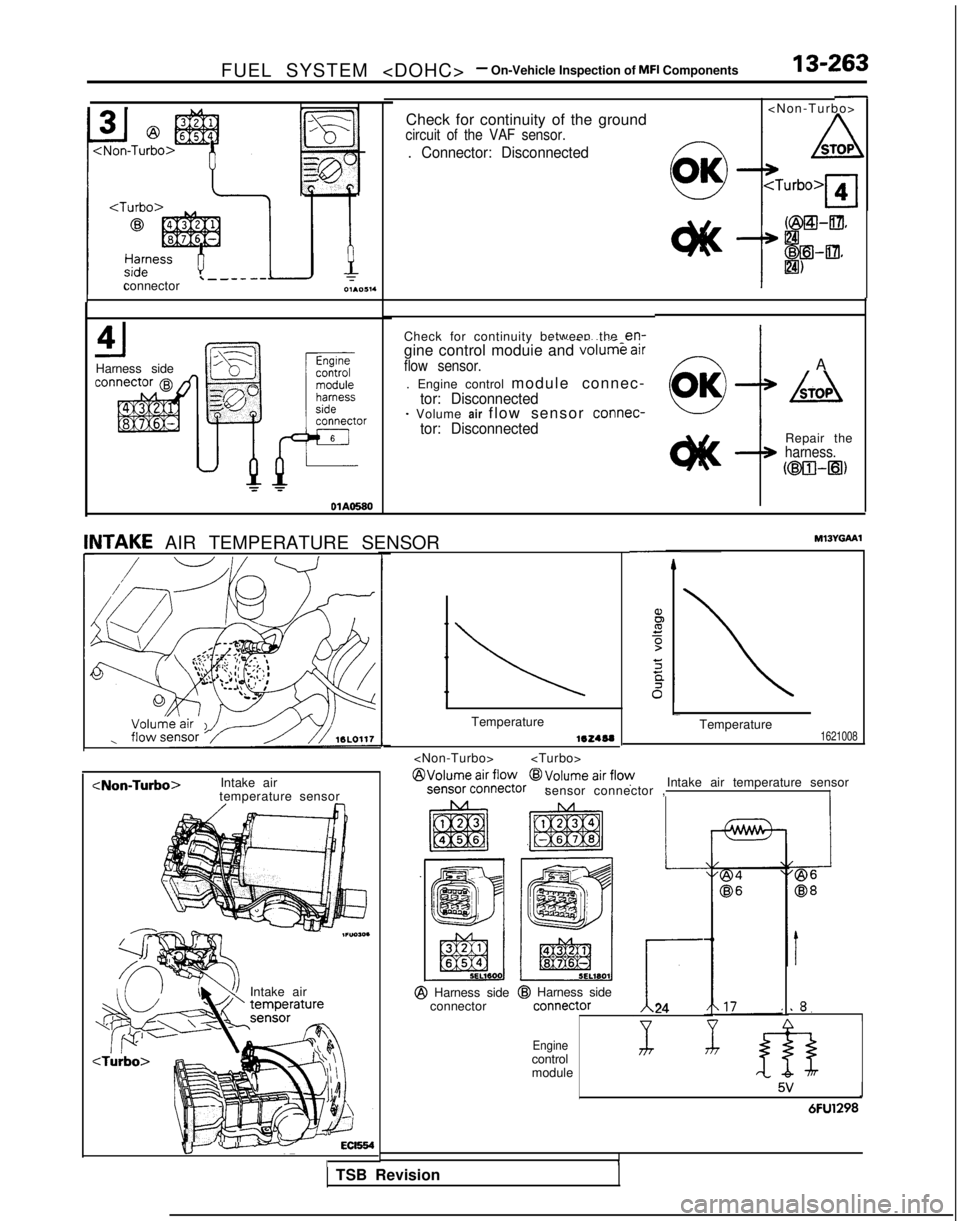

Check for continuity of the ground

circuit of the VAF sensor.

. Connector: Disconnected

\--connector

4Harness side Check for continuity between the

en-3 air__.. --.. ..-gine control moduie and volumt

UIIflow sensor.Y---L1 A

. Engine control module connec-

tor: Disconnected- Volume air flow sensor connec-tor: Disconnected

kTOA

Repair theharness.

NliwHBl)

DlAO!XO

MlJYGAAlUTAKE AIR TEMPERATURE SENSORI

I

Temperature-Temperature1621008

sensor connector , Intake air temperature sensor

temperature sensor

I24

Intake air

@I Harness side

connector@I Harness side

.8.I

4Enginecontrol

module 5V

I1

6FU1298

Iv---I1 TSB Revision

Page 406 of 1273

13-264FUEL SYSTEM

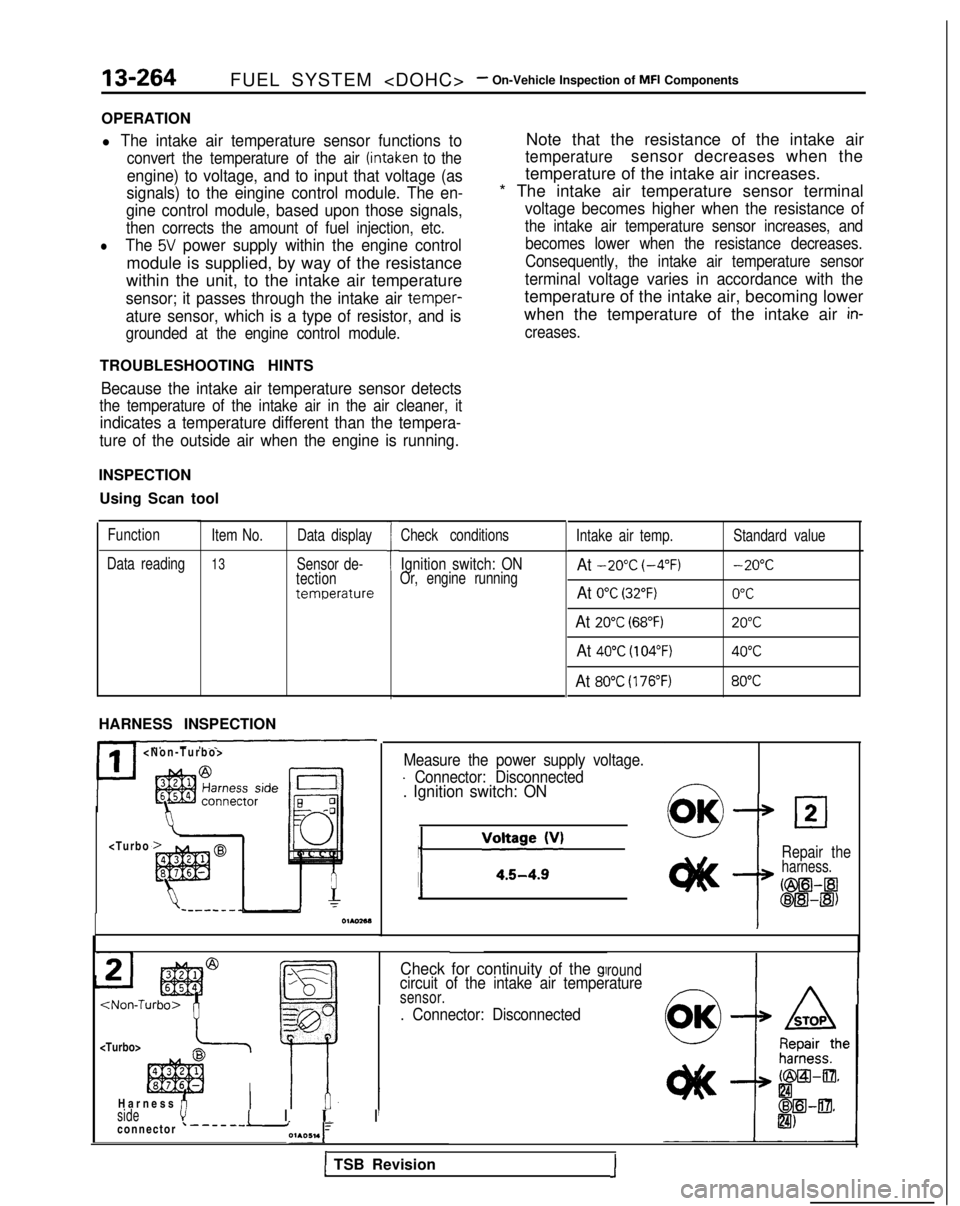

OPERATION

l The intake air temperature sensor functions to

convert the temperature of the air (intaken to the

engine) to voltage, and to input that voltage (as

signals) to the eingine control module. The en-

gine control module, based upon those signals,

then corrects the amount of fuel injection, etc.

lThe 5V power supply within the engine control

module is supplied, by way of the resistance

within the unit, to the intake air temperature

sensor; it passes through the intake air temper-

ature sensor, which is a type of resistor, and is

grounded at the engine control module.

Note that the resistance of the intake air

temperaturesensor decreases when the

temperature of the intake air increases.

* The intake air temperature sensor terminal

voltage becomes higher when the resistance of

the intake air temperature sensor increases, and becomes lower when the resistance decreases.

Consequently, the intake air temperature sensor

terminal voltage varies in accordance with the

temperature of the intake air, becoming lower

when the temperature of the intake air

in-

creases.

TROUBLESHOOTING HINTS

Because the intake air temperature sensor detects

the temperature of the intake air in the air cleaner, it

indicates a temperature different than the tempera-

ture of the outside air when the engine is running.

INSPECTION

Using Scan tool

Function

Data reading Item No.

13

Data display

Sensor de-

tection

temperature

HARNESS INSPECTION

II

I

Check conditions

Ignition switch: ONOr, engine running

Intake air temp.At -20°C (-4°F)

At 0°C (32°F)

At 20°C (68°F)

At 40°C (104°F)

At 80°C (176°F)

Standard value -20°C

0°C

20°C

40°C

80°C

Measure the power supply voltage.

- Connector: Disconnected. Ignition switch: ON

j

/‘“:;~~~v’0OKLl2

Repair theharness.

Cm--a

oE!l-@)

Check for continuity of the glroundcircuit of the intake air temperaturesensor.

. Connector: Disconnected

I

sidevI I 1~ I

I

Harness fi

connector ‘-------i01A051.1

1 TSB Revision1