sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 417 of 1273

FUEL SYSTEM

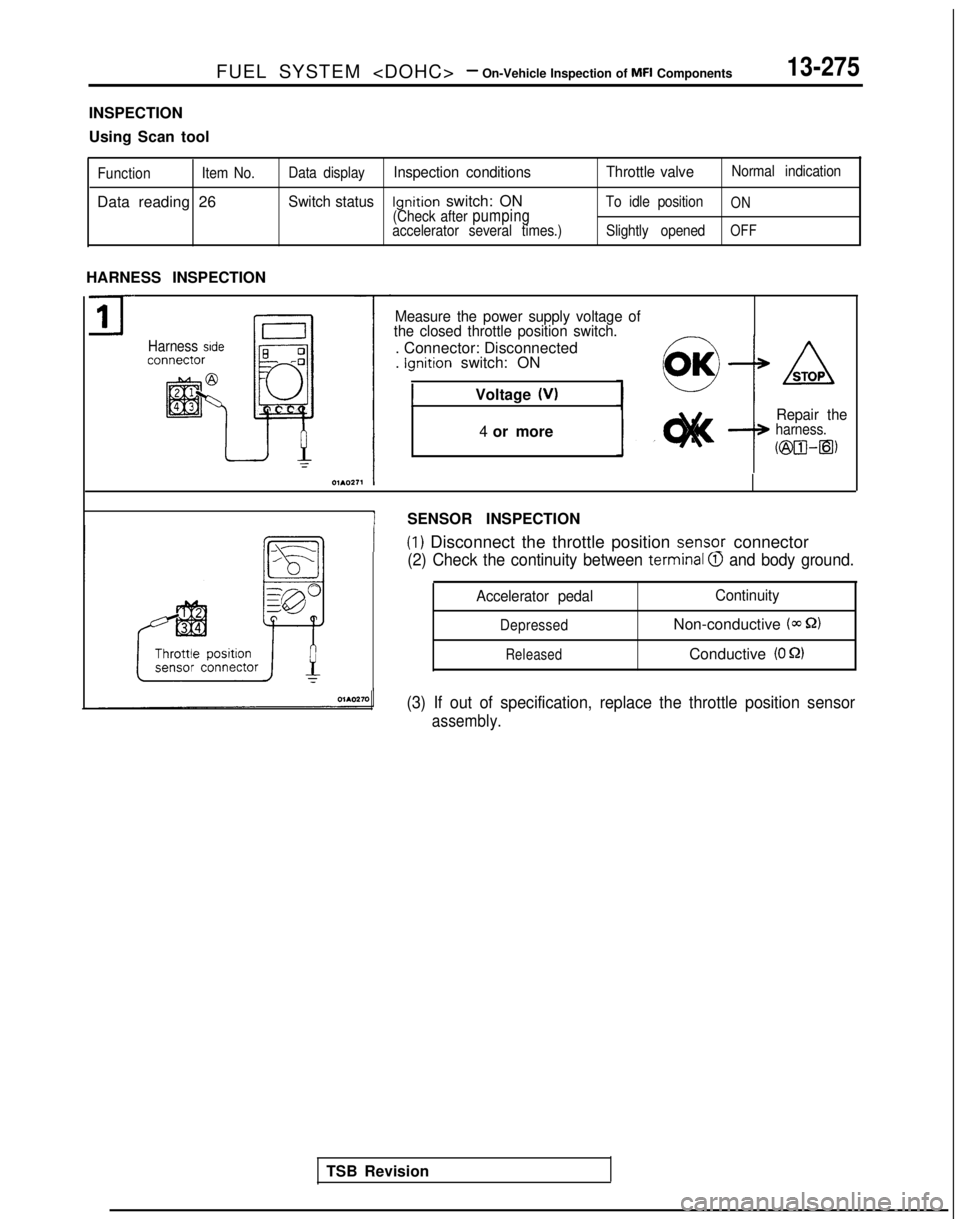

INSPECTION

Using Scan tool

Function

Item No.

Data reading 26

Data displayInspection conditions Throttle valveNormal indication

Switch statusIgnition switch: ONTo idle positionON(Check after pumpingaccelerator several times.)

Slightly openedOFF

HARNESS INSPECTION

71

-

Harness side

Measure the power supply voltage of

the closed throttle position switch.

-. Connector: Disconnected

. Ignition switch: ON

1Voltage (VI

4 or more

ASTOP

Repair theharness.

~@a-Q)

ISENSOR INSPECTION

I(1) Disconnect the throttle position senso_r connector

(2) Check the continuity between terminal QI and body ground.

TSB Revision

Accelerator pedal Continuity

DepressedNon-conductive (m S2)

ReleasedConductive (0 52)

(3) If out of specification, replace the throttle position sensor

assembly.

Page 418 of 1273

13-276FUEL SYSTEM

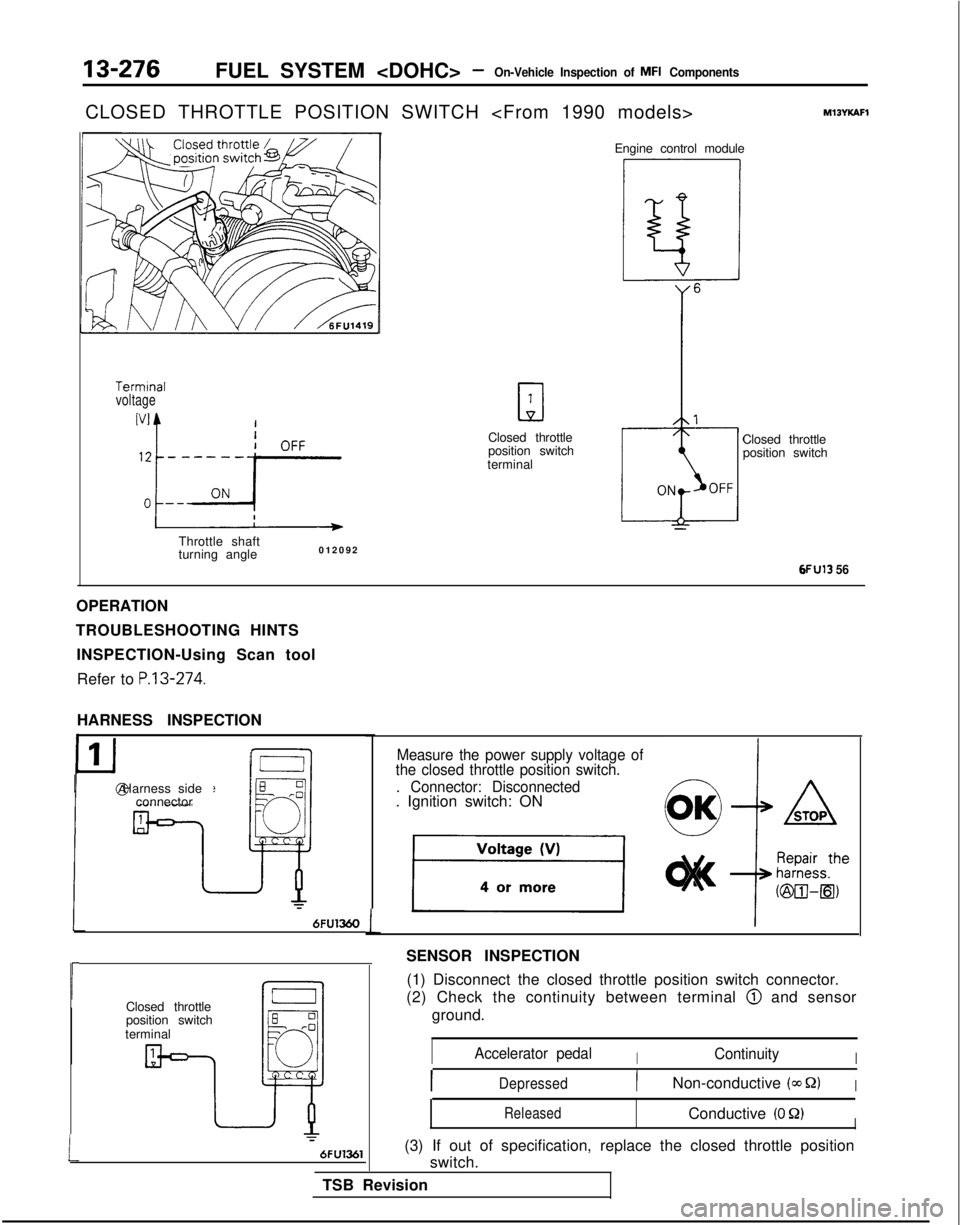

CLOSED THROTTLE POSITION SWITCH

Termrnalvoltage

Throttle shaft

turning angle012092

a

1

Closed throttle

position switch

terminal Engine control module

ci

Closed throttle

position switch

6FU13 56

OPERATION

TROUBLESHOOTING HINTS INSPECTION-Using Scan toolRefer to

P.13-274.

HARNESS INSPECTIONL

P

1

I

:

I @ Harness side

connector

Closed throttle

position switch

terminal

L

Measure the power supply voltage of

the closed throttle position switch.

. Connector: Disconnected

. Ignition switch: ON

SENSOR INSPECTION(1) Disconnect the closed throttle position switch connector.

(2) Check the continuity between terminal

@I and sensor

ground.

IAccelerator pedalIContinuityI

IDepressedINon-conductive (a Q)I

ReleasedConductive (0 S2)I

(3) If out of specification, replace the closed throttle position

switch.

TSB Revision

Page 419 of 1273

FUEL SYSTEM

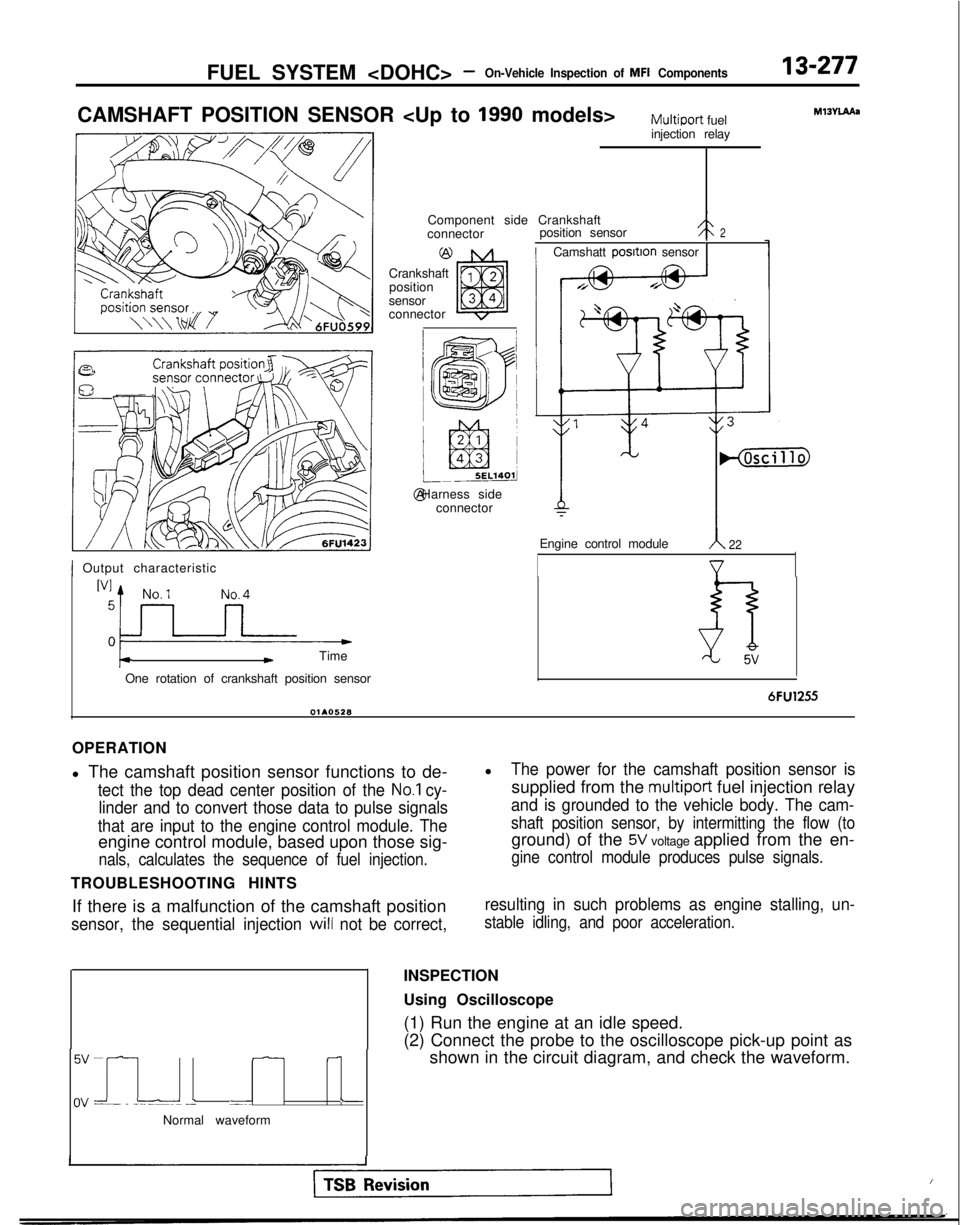

CAMSHAFT POSITION SENSOR

1 Output characteristic

I-cTime

One rotation of crankshaft position sensor injection relay

Component side Crankshaft

connector position sensor

2I14,

Crankshaft

position

sensor

connector

I_ /

i7; !

~\==, ’60,Giiz!! @ Harness side

connector Camshatt posItIon

sensor

Engine control module

A22

Q

6FU1255

OPERATION

l The camshaft position sensor functions to de-

tect the top dead center position of the No.1 cy-

linder and to convert those data to pulse signals

that are input to the engine control module. The

engine control module, based upon those sig-

nals, calculates the sequence of fuel injection.

TROUBLESHOOTING HINTS

If there is a malfunction of the camshaft position

sensor, the sequential injection will not be correct,

lThe power for the camshaft position sensor is

supplied from the multiport fuel injection relay

and is grounded to the vehicle body. The cam-

shaft position sensor, by intermitting the flow (to

ground) of the 5V voltage applied from the en-

gine control module produces pulse signals.

resulting in such problems as engine stalling, un-

stable idling, and poor acceleration.

5v---r-

ovL_--..---I2 --

Normal waveform INSPECTION

Using Oscilloscope

(1) Run the engine at an idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform.

Page 421 of 1273

FUEL SYSTEM

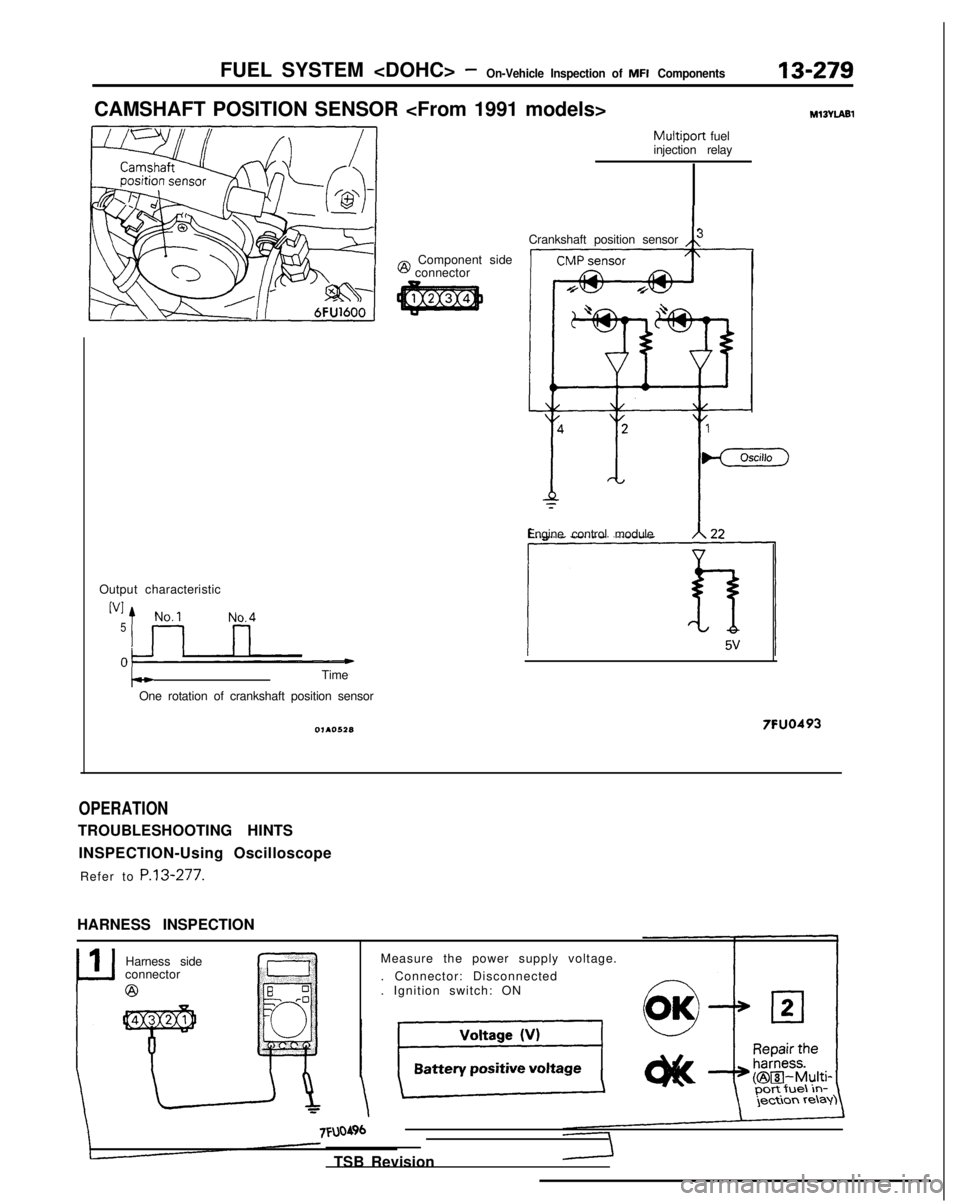

CAMSHAFT POSITION SENSOR

@

Component side

connector

Output characteristic

WINo.45

) Time

One rotation of crankshaft position sensor

Multiport fuel

injection relay

Crankshaft position sensor

I3

Engine control module

7FUO493

OPERATION

TROUBLESHOOTING HINTS INSPECTION-Using Oscilloscope Refer to

P.13-277.

HARNESS INSPECTION

Harness side

connector Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

7FUO496

TSB Revision

Page 422 of 1273

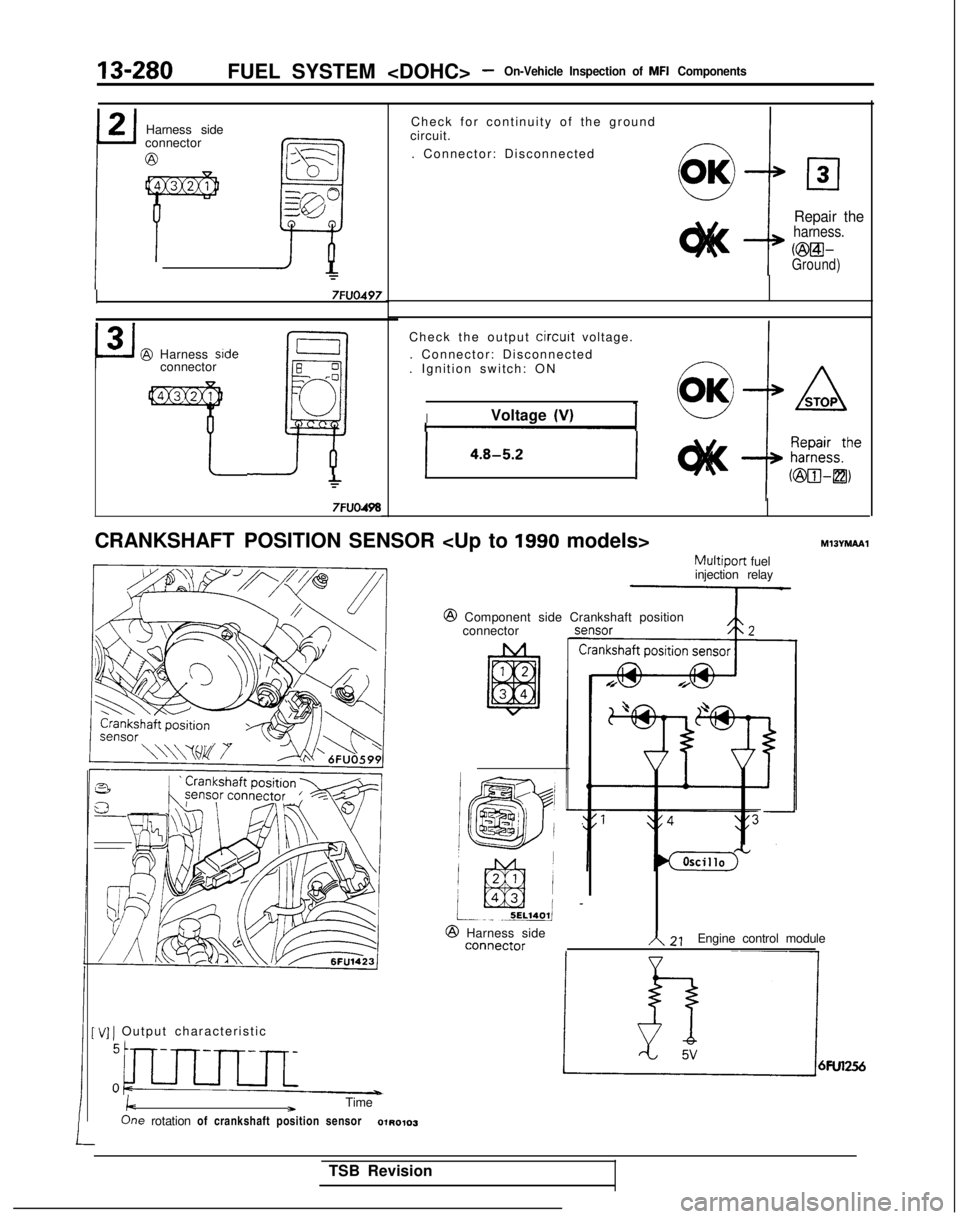

13-280FUEL SYSTEM

2

rHarness side

connector @

-----.

m

l----L

=s- 0

H

z/Q

=

7FVO497

P

3@ Harness srdeconnectorE 0

-0

4

0

c

7FVO498

Check for continuity of the ground

circuit.

. Connector: Disconnected

Repair theharness.

@WGround)

Check the output circuit voltage.

. Connector: Disconnected

. Ignition switch: ON

IVoltage (V)

1 4.8-5.2 (

CRANKSHAFT POSITION SENSOR

v] ) Output characteristic

LIaTime - One

rotation of crankshaft position sensor

OlROlO3

Multiport fuel

injection relay @

Component side Crankshaft position

connector @

Harness side

), 27Engine control module

MIOYYAAI

TSB Revision

Page 423 of 1273

FUEL SYSTEM

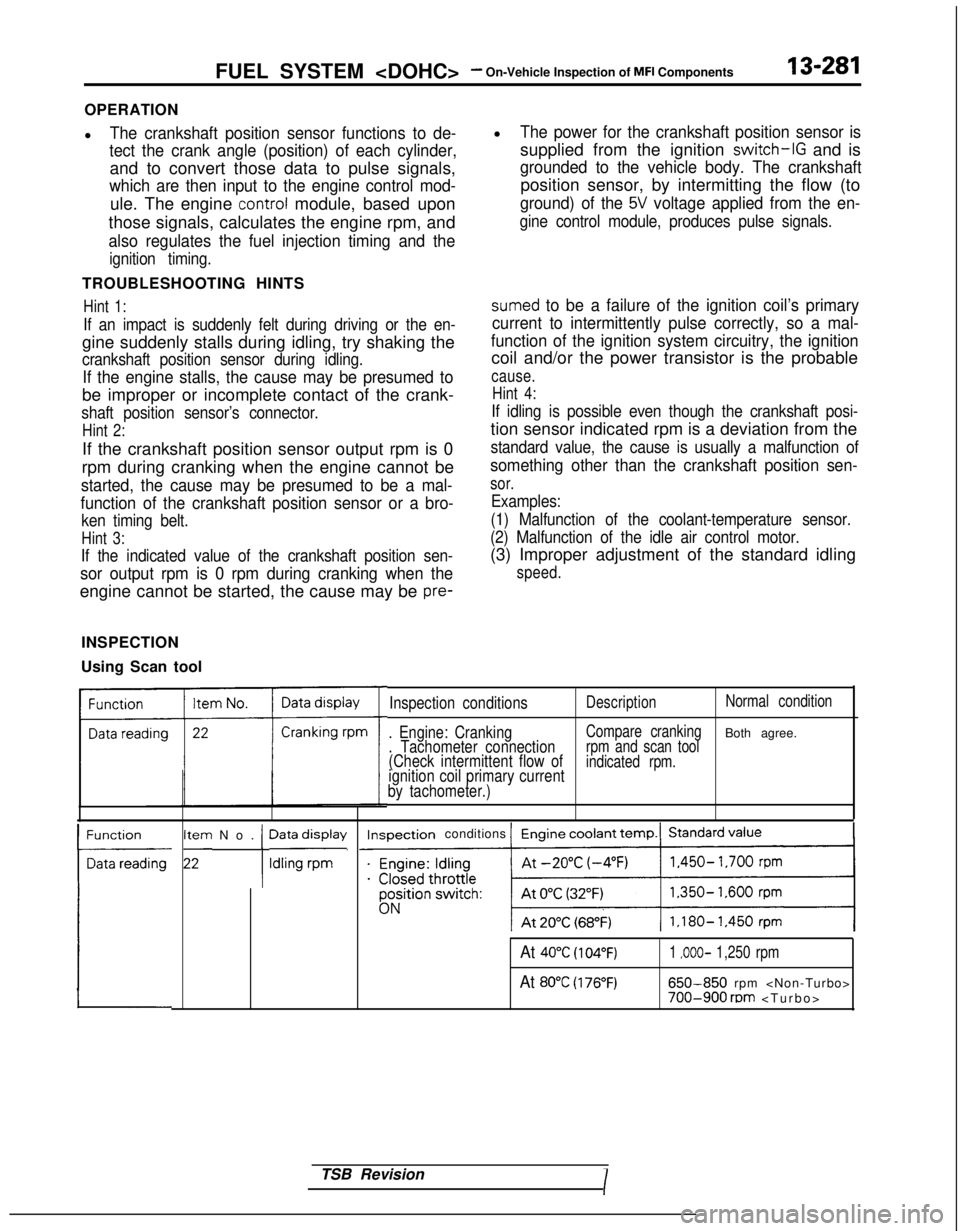

OPERATION

l

The crankshaft position sensor functions to de-

tect the crank angle (position) of each cylinder,

and to convert those data to pulse signals,

which are then input to the engine control mod-

ule. The engine control module, based upon

those signals, calculates the engine rpm, and

also regulates the fuel injection timing and the

ignition timing.

TROUBLESHOOTING HINTS

Hint 1:

If an impact is suddenly felt during driving or the en-

gine suddenly stalls during idling, try shaking the

crankshaft position sensor during idling.

If the engine stalls, the cause may be presumed to

be improper or incomplete contact of the crank-

shaft position sensor’s connector.

Hint 2:

If the crankshaft position sensor output rpm is 0

rpm during cranking when the engine cannot be

started, the cause may be presumed to be a mal-

function of the crankshaft position sensor or a bro-

ken timing belt.

Hint 3:

If the indicated value of the crankshaft position sen-

sor output rpm is 0 rpm during cranking when the

engine cannot be started, the cause may be pre-

INSPECTION

Using Scan tool l

The power for the crankshaft position sensor is

supplied from the ignition switch-IG

and is

grounded to the vehicle body. The crankshaft

position sensor, by intermitting the flow (to

ground) of the 5V voltage applied from the en-

gine control module, produces pulse signals.

sumed to be a failure of the ignition coil’s primary

current to intermittently pulse correctly, so a mal-

function of the ignition system circuitry, the ignition

coil and/or the power transistor is the probable

cause. Hint 4:

If idling is possible even though the crankshaft posi-

tion sensor indicated rpm is a deviation from the

standard value, the cause is usually a malfunction of

something other than the crankshaft position sen-

sor.

Examples:

(1) Malfunction of the coolant-temperature sensor.

(2) Malfunction of the idle air control motor.

(3) Improper adjustment of the standard idling

speed.

Inspection conditions

Description Normal condition

. Engine: CrankingCompare crankingBoth agree.. Tachometer connectionrpm and scan tool(Check intermittent flow ofindicated rpm.ignition coil primary current

by tachometer.)

burn No. / ~i~~~~,,Inspection conditions

At 40°C (104°F)

At 80°C (176°F)

1 ,OOO- 1,250 rpm

650-850 rpm

TSB Revision

I

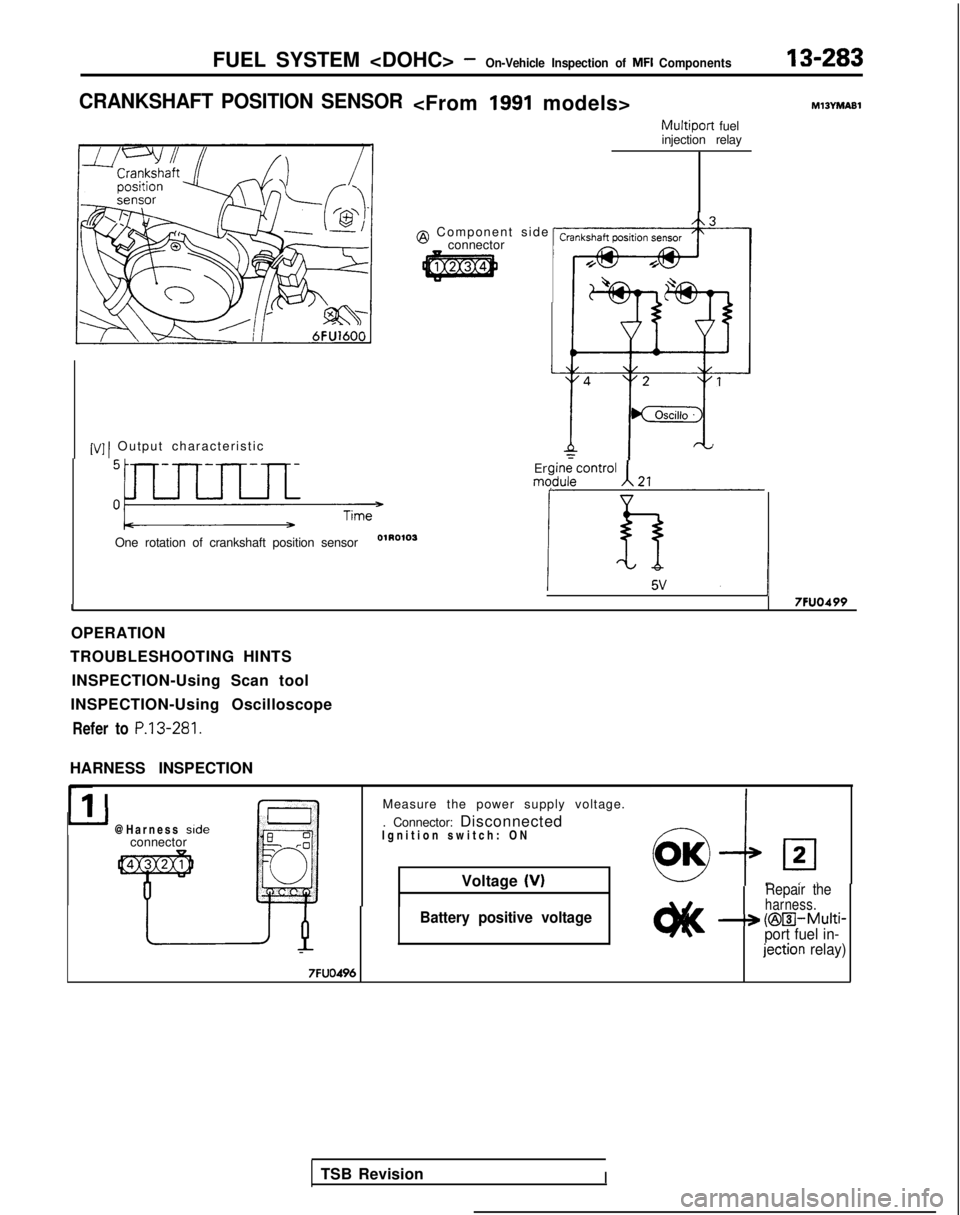

Page 425 of 1273

FUEL SYSTEM

CRANKSHAFT POSITION SENSOR

[VI 1 Output characteristic

One rotation of crankshaft position sensor

01R0’03

Engine controlmqdule21

R5VJ7FUO499I

Multiport fuel

injection relay

@ Component sid

e

connector

MlBYhlABl

OPERATION

TROUBLESHOOTING HINTS

INSPECTION-Using Scan tool

INSPECTION-Using Oscilloscope

Refer to

P.13-281.

HARNESS INSPECTION

11 I

1’1

Measure the power supply voltage.

@Harness

side. Connector: Disconnected

connector Ignition switch: O

N

Voltage (VI

Battery positive voltage

-

7FUO496

Repair theharness.-+ (@a-Multi-port fuel in-jection relay)

TSB RevisionI

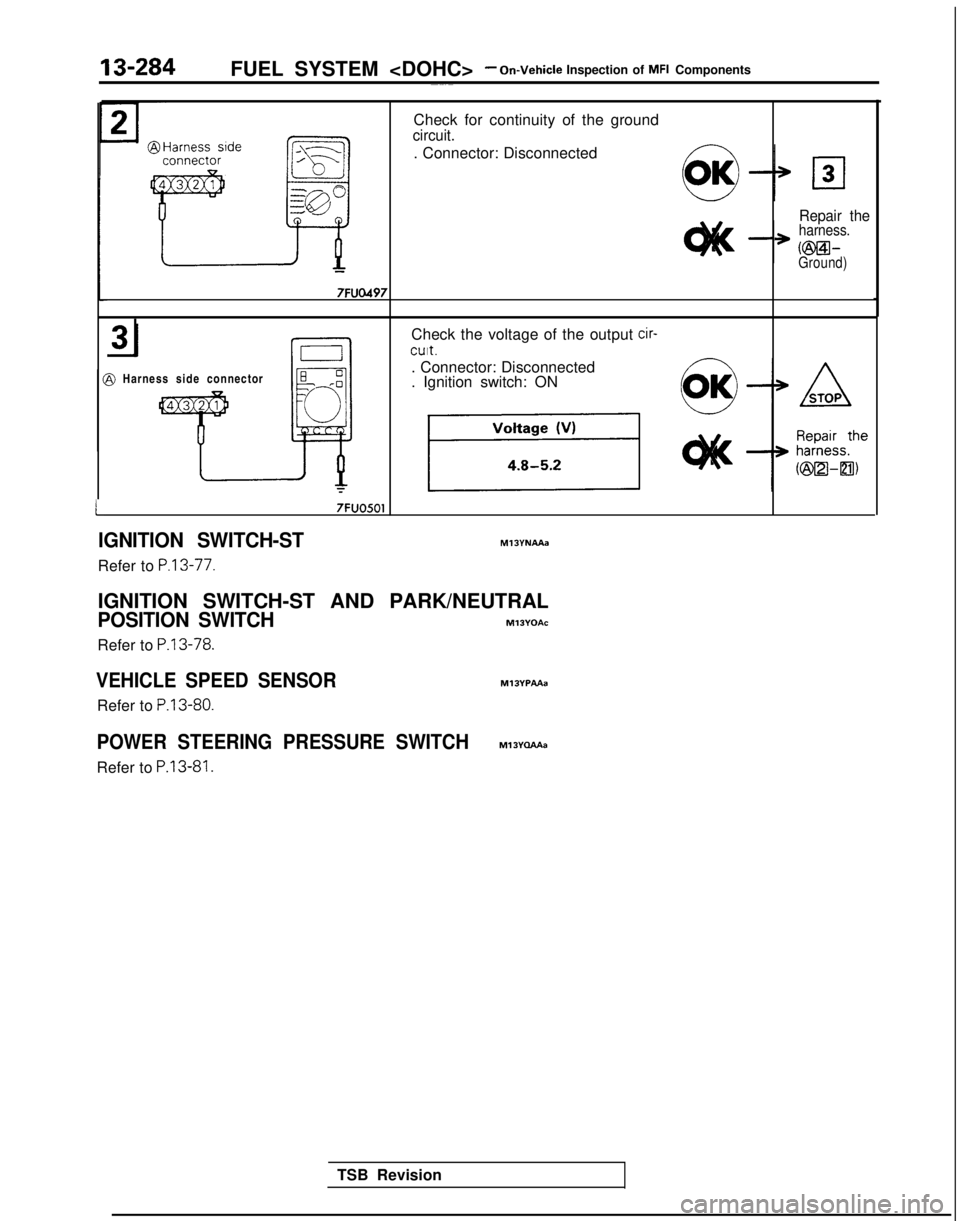

Page 426 of 1273

13-284FUEL SYSTEM

(

Check for continuity of the groundcircuit.

. Connector: Disconnected

7FUO497

Repair theharness.

* cm-Ground)

a Harness side connectorCheck the voltage of the output

cir- cut.

. Connector: Disconnected

. Ignition switch: ON

7FUOSOlL

IGNITION SWITCH-ST

Refer to P.13-77.

M13VNAAa

IGNITION SWITCH-ST AND PARK/NEUTRAL

POSITION SWITCHM13YOAc

Refer to P.13-78.

VEHICLE SPEED SENSOR

Refer to P.13-80.

M13YPAAa

POWER STEERING PRESSURE SWITCHM13VQAAa

Refer to P.13-81.

TSB Revision

Page 429 of 1273

FUEL SYSTEM

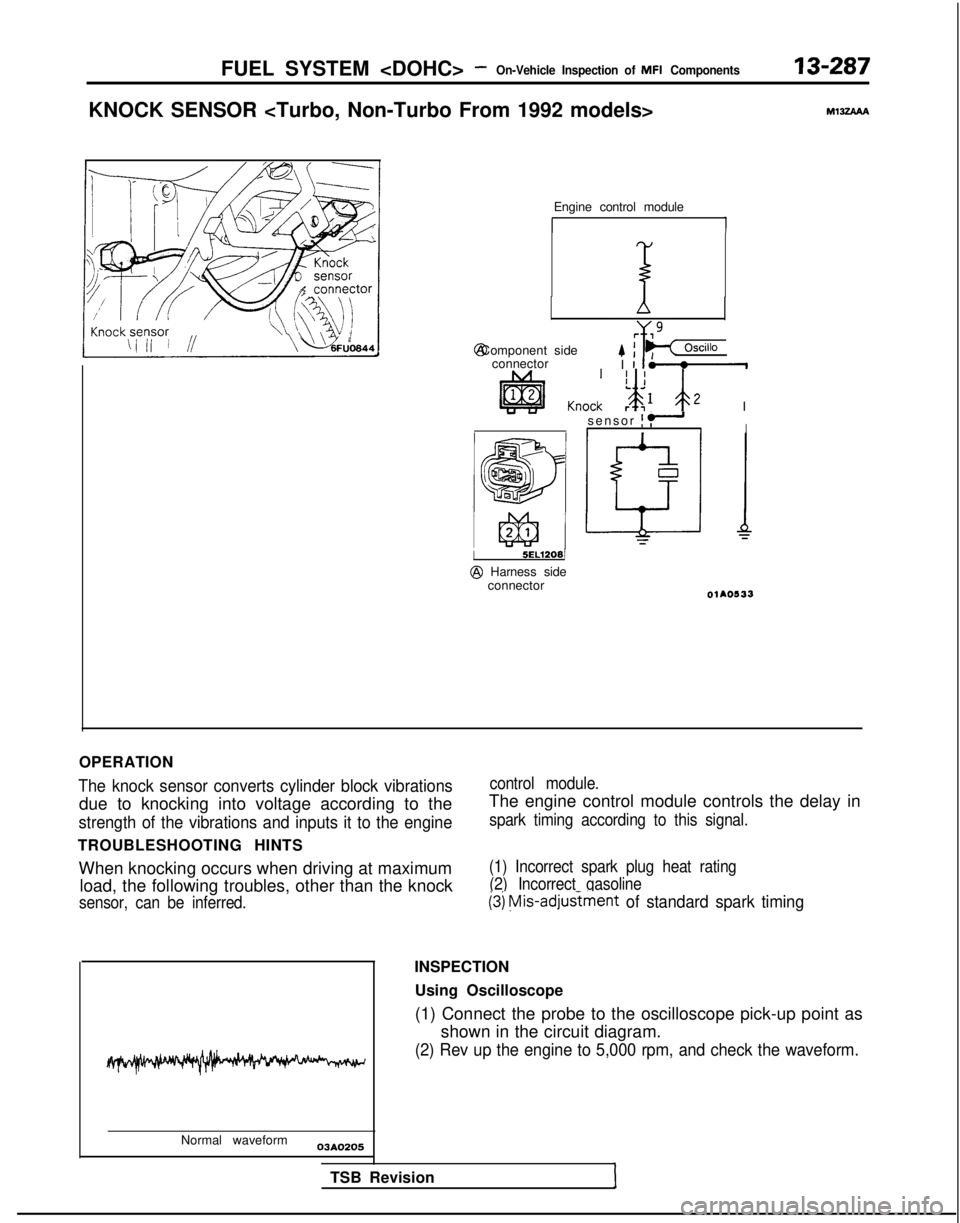

KNOCK SENSOR

M13zAAA

Engine control module

1 @ Component side

Oscillo

connector

I it’

ti hoc: !A!’ A2 II Isensor ! T1II

ISEL12081

@ Harness side

connector

OPERATION

The knock sensor converts cylinder block vibrations

due to knocking into voltage according to the

strength of the vibrations and inputs it to the engine

TROUBLESHOOTING HINTS When knocking occurs when driving at maximum load, the following troubles, other than the knock

control module.

The engine control module controls the delay in

spark timing according to this signal.

sensor, can be inferred. (1) Incorrect spark plug heat rating

(2) Incorrect gasoline

(3) Mis-adjustment of standard spark timing

Normal waveform 03A0205INSPECTION

Using Oscilloscope

(1) Connect the probe to the oscilloscope pick-up point as shown in the circuit diagram.

(2) Rev up the engine to 5,000 rpm, and check the waveform.

TSB Revision

Page 430 of 1273

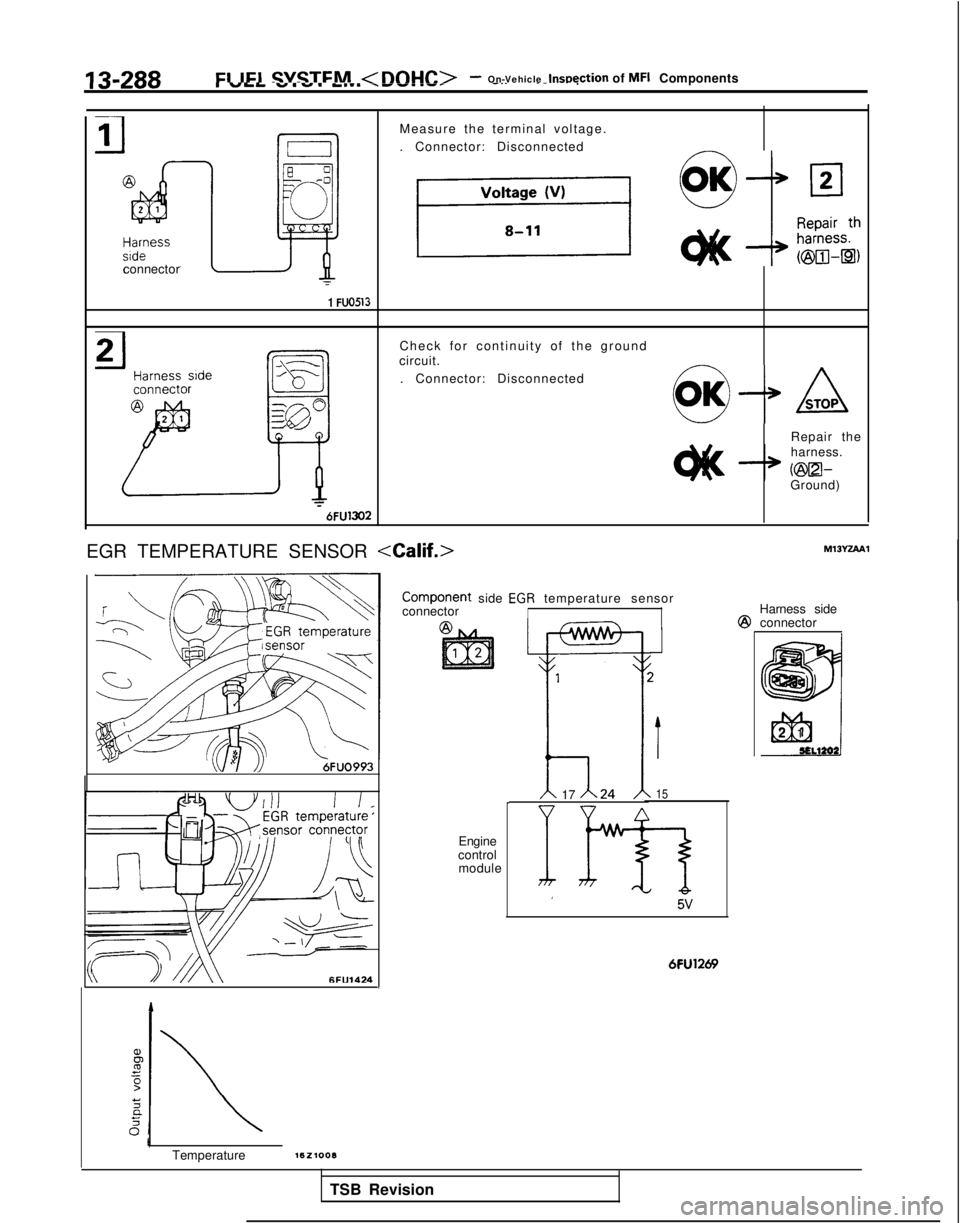

12,7QQFI IFI GVSXFM

of MFI ComponentsId-LuvI “Lh V.V. h.1. .--..v-_.. .- .

connector Measure the terminal voltage.

. Connector: Disconnected

pf?q f$!?;

1 FU0513

Check for continuity of the ground

circuit.

. Connector: Disconnected

@p/LA

Repair the

harness.

KBB-Ground)

76FU1302

EGR TEMPERATURE SENSOR

fiFU1424

Component side EGR temperature sensor

connectorI

1

. /

r

t-lA 17 A24 J

I

;

t

\15

Engine

control module

lrn5v

6FU1269

Harness side @

connector

!?ll

@lfiii

t?rl2 1 KL1202

ITemperature1521005

TSB Revision