ignition MITSUBISHI GALANT 1989 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 185 of 1273

FUEL SYSTEM

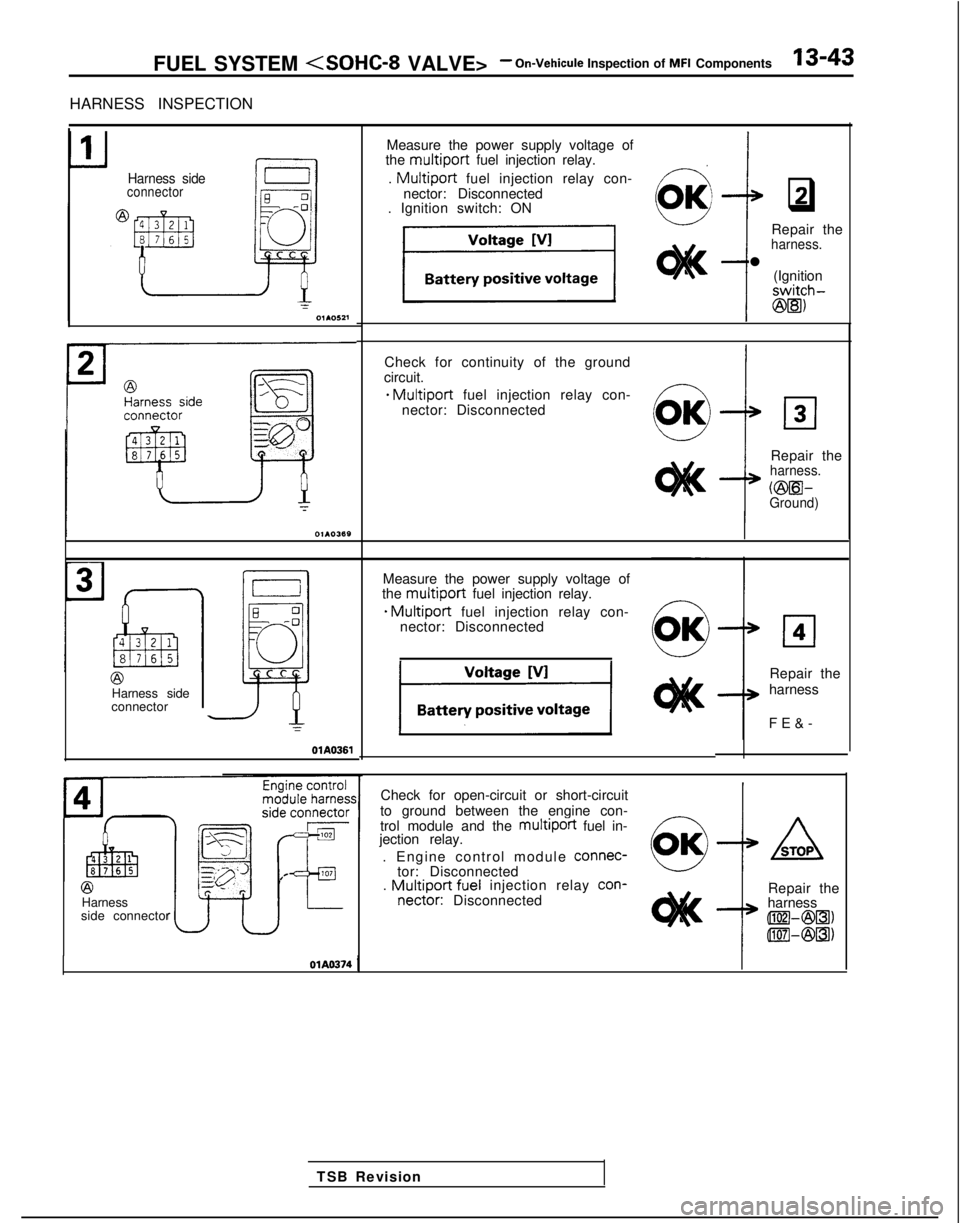

HARNESS INSPECTION

Harness sideconnector

Measure the power supply voltage of

the multiport fuel injection relay.

.

Multiport fuel injection relay con-

nector: Disconnected

. Ignition switch: ON

q2

Check for continuity of the groundIcircuit.

* Multiport fuel injection relay con-

nector: Disconnected

Repair the

harness.

VBEil-Ground)

J

TSB Revision

@Harness side

connector Repair the

harness.

l

(Ignition

switch-

@5)

OlA0361

Measure the power supply voltage of

the multiport fuel injection relay.

* Multiport fuel injection relay con-

nector: Disconnected

El4

Repair the

harness

FE&

-

@Harness

side connector Check for open-circuit or short-circuit

to ground between the engine con-

trol module and the

multiport fuel in-

jection relay.

. Engine control module connec-

tor: Disconnected

.

Multiport fuel injection relay con-

nectar:

Disconnected Repair the

harness

llEW&Bl)

llIEl-@5)

Page 189 of 1273

FUEL SYSTEM

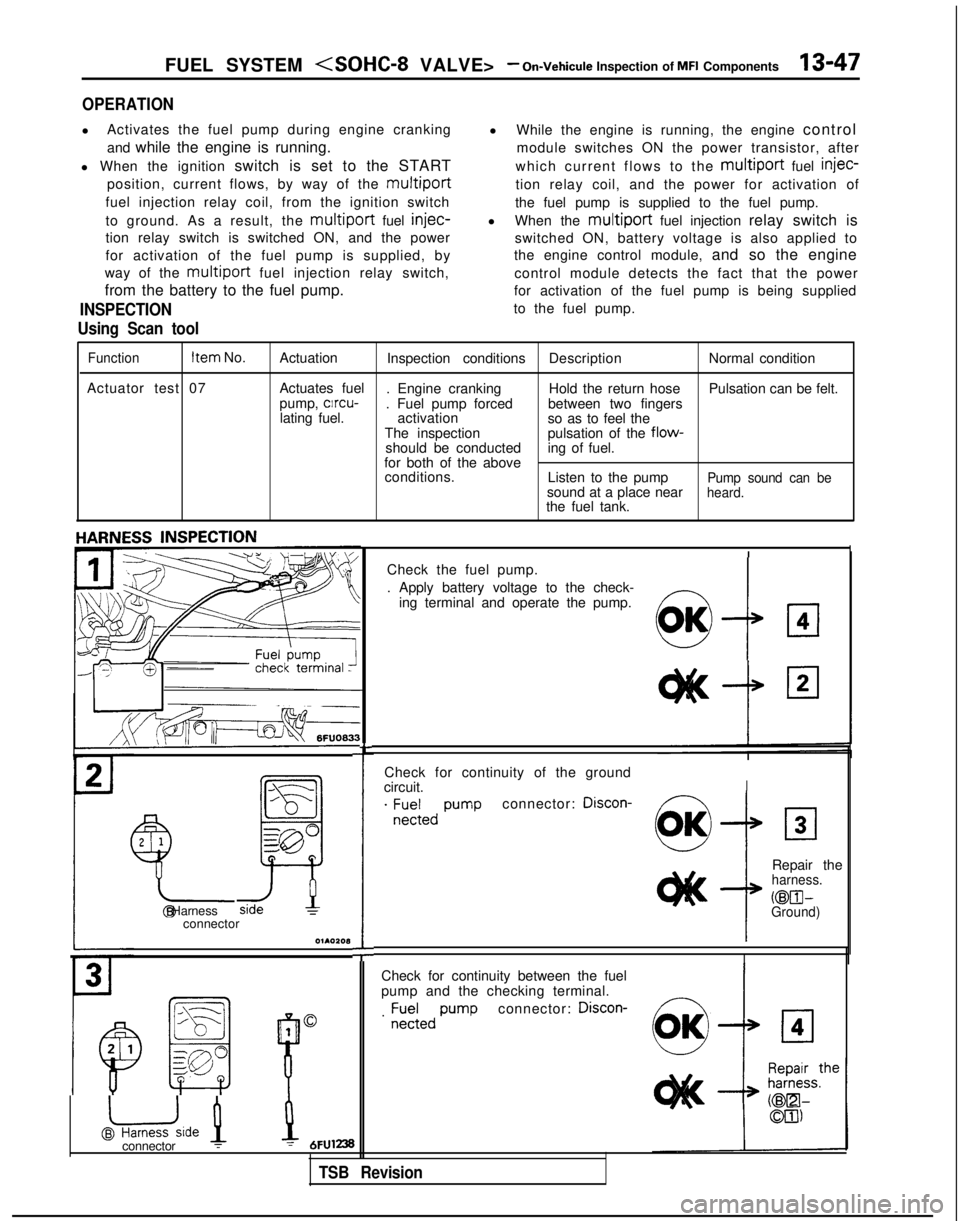

OPERATION

l

Activates the fuel pump during engine cranking

and while the engine is running.

l When the ignition switch is set to the START

position, current flows, by way of the

multiport

fuel injection relay coil, from the ignition switch

to ground. As a result, the

multiport fuel injec-

tion relay switch is switched ON, and the power

for activation of the fuel pump is supplied, by

way of the

multiport fuel injection relay switch,

from the battery to the fuel pump.

INSPECTION

Using Scan tool

l While the engine is running, the engine control

module switches ON the power transistor, after

which current flows to the

multiport fuel injec-

tion relay coil, and the power for activation of

the fuel pump is supplied to the fuel pump.

l When the

multiport fuel injection relay switch is

switched ON, battery voltage is also applied to

the engine control module, and so the engine

control module detects the fact that the power

for activation of the fuel pump is being supplied

to the fuel pump.

Function Item

No.

Actuation Inspection conditions DescriptionNormal condition

Actuator test 07 Actuates fuel

. Engine cranking Hold the return hosePulsation can be felt.

pump, clrcu-

. Fuel pump forced between two fingers

lating fuel. activation

so as to feel the

The inspection pulsation of the

flow-should be conducteding of fuel.

for both of the above conditions. Listen to the pump

Pump sound can besound at a place nearheard.the fuel tank.

Check for continuity of the ground

circuit.

I

. ;E;;,, pumpconnector: Discon-

2

1

Y-

!

Repair theharness.

@El- @ HarnessGround)connector

O~AOZOl3

I

Check for continuity between the fuel

pump and the checking terminal.

connector: Discon-

1

@uide 1

B

0. ;;;;,,

pump

L

Check the fuel pump.

. Apply battery voltage to the check-

ing terminal and operate the pump.

!I:7

OK

connector :1 = 6FUl238

TSB Revision

Page 191 of 1273

FUEL SYSTEM

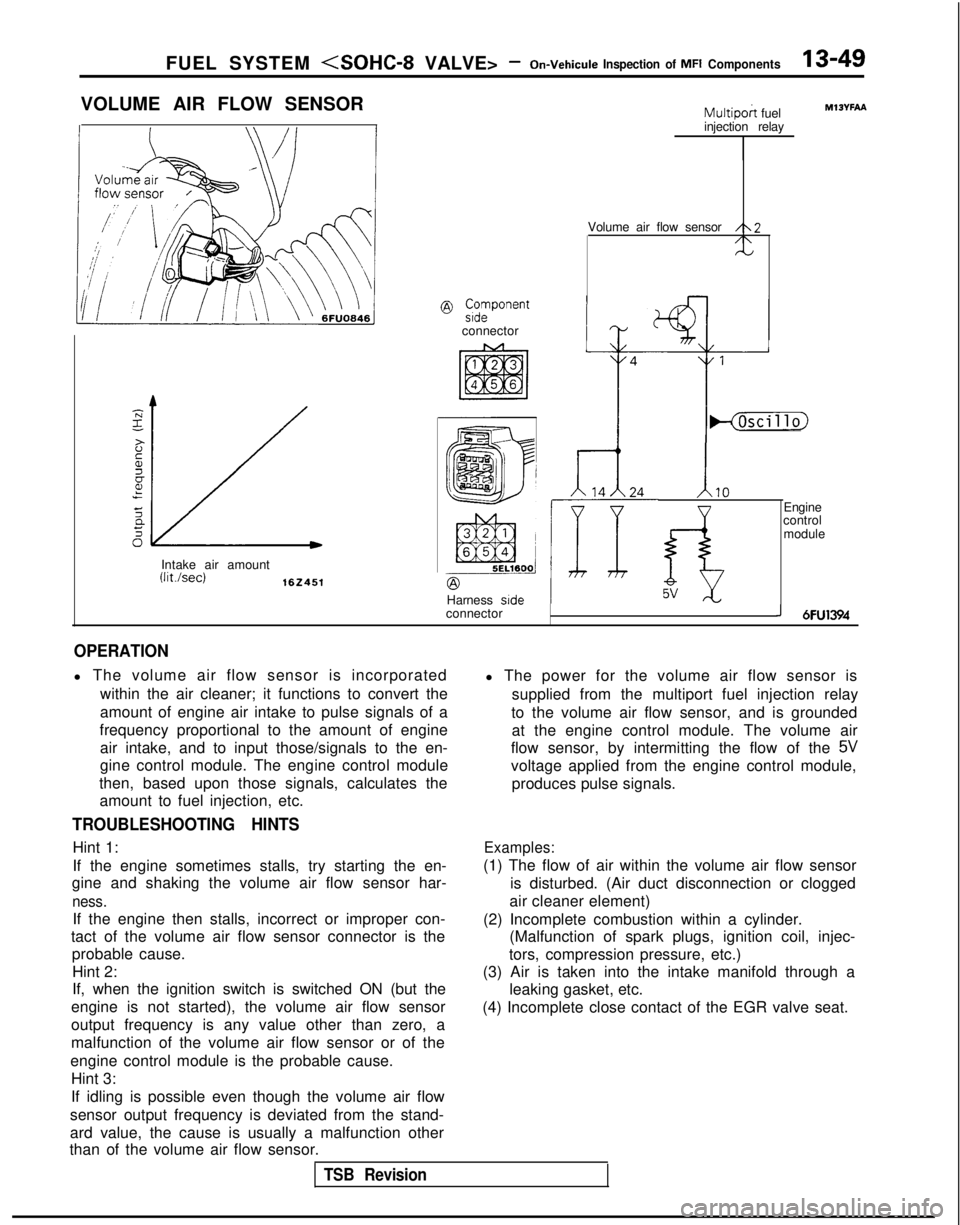

VOLUME AIR FLOW SENSOR

@ ;;vonent

connector

Intake air amount

(Wsec)162451

Multipoh fuel

injection relay

Volume air flow sensor

/\2/\N

Harness side

connector

IHjhcillo)

1.10

f-i5V

Engine

control

module

MlOYFAA

J 6FU1394

OPERATION

l The volume air flow sensor is incorporated

within the air cleaner; it functions to convert the

amount of engine air intake to pulse signals of a

frequency proportional to the amount of engine air intake, and to input those/signals to the en-

gine control module. The engine control module

then, based upon those signals, calculates the amount to fuel injection, etc.

TROUBLESHOOTING HINTS

Hint 1:

If the engine sometimes stalls, try starting the en-

gine and shaking the volume air flow sensor har-

ness.

If the engine then stalls, incorrect or improper con-

tact of the volume air flow sensor connector is the probable cause.

Hint 2:

If, when the ignition switch is switched ON (but the

engine is not started), the volume air flow sensor

output frequency is any value other than zero, a

malfunction of the volume air flow sensor or of the

engine control module is the probable cause. Hint 3:

If idling is possible even though the volume air flow

sensor output frequency is deviated from the stand-

ard value, the cause is usually a malfunction other

than of the volume air flow sensor. l The power for the volume air flow sensor is

supplied from the multiport fuel injection relay

to the volume air flow sensor, and is grounded at the engine control module. The volume air

flow sensor, by intermitting the flow of the

5V

voltage applied from the engine control module,

produces pulse signals.

Examples:

(1) The flow of air within the volume air flow sensor is disturbed. (Air duct disconnection or clogged

air cleaner element)

(2) Incomplete combustion within a cylinder. (Malfunction of spark plugs, ignition coil, injec-

tors, compression pressure, etc.)

(3) Air is taken into the intake manifold through a leaking gasket, etc.

(4) Incomplete close contact of the EGR valve seat.

TSB Revision

Page 192 of 1273

13-50 FUEL SYSTEM

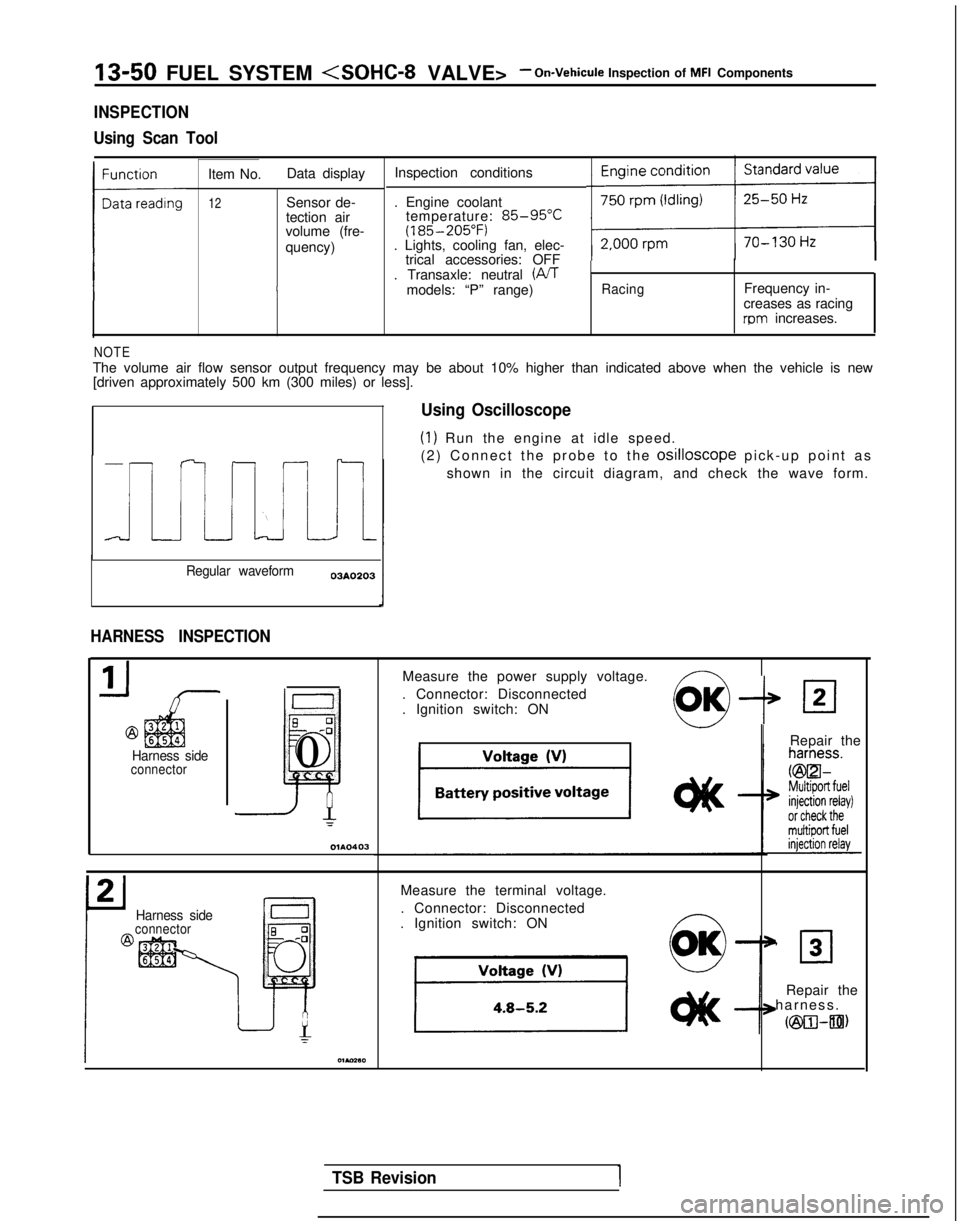

INSPECTION

Using Scan Tool

Item No. Data display Inspection conditions

12Sensor de-

tection air

volume (fre-

quency) . Engine coolant

temperature: 85-95°C(185-205°F). Lights, cooling fan, elec-

trical accessories: OFF

. Transaxle: neutral (iVT

models: “P” range)

RacingFrequency in-

creases as racing

rpm increases.

NOTEThe volume air flow sensor output frequency may be about 10% higher than\

indicated above when the vehicle is new [driven approximately 500 km (300 miles) or less].

Regular waveform 03A0203

HARNESS INSPECTION

@

Harness sideconnector

6

0-0

~

0

=

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the

osilloscope pick-up point a

s

shown in the circuit diagram, and check the wave form.

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

--P

IRepair the

Harness sideconnector

Measure the terminal voltage.

. Connector: Disconnected

. Ignition switch: ON ~

0

OK’ 30

Repair the

harness

.

cm-an)

TSB Revision1

Page 194 of 1273

13-52 FUEL SYSTEM

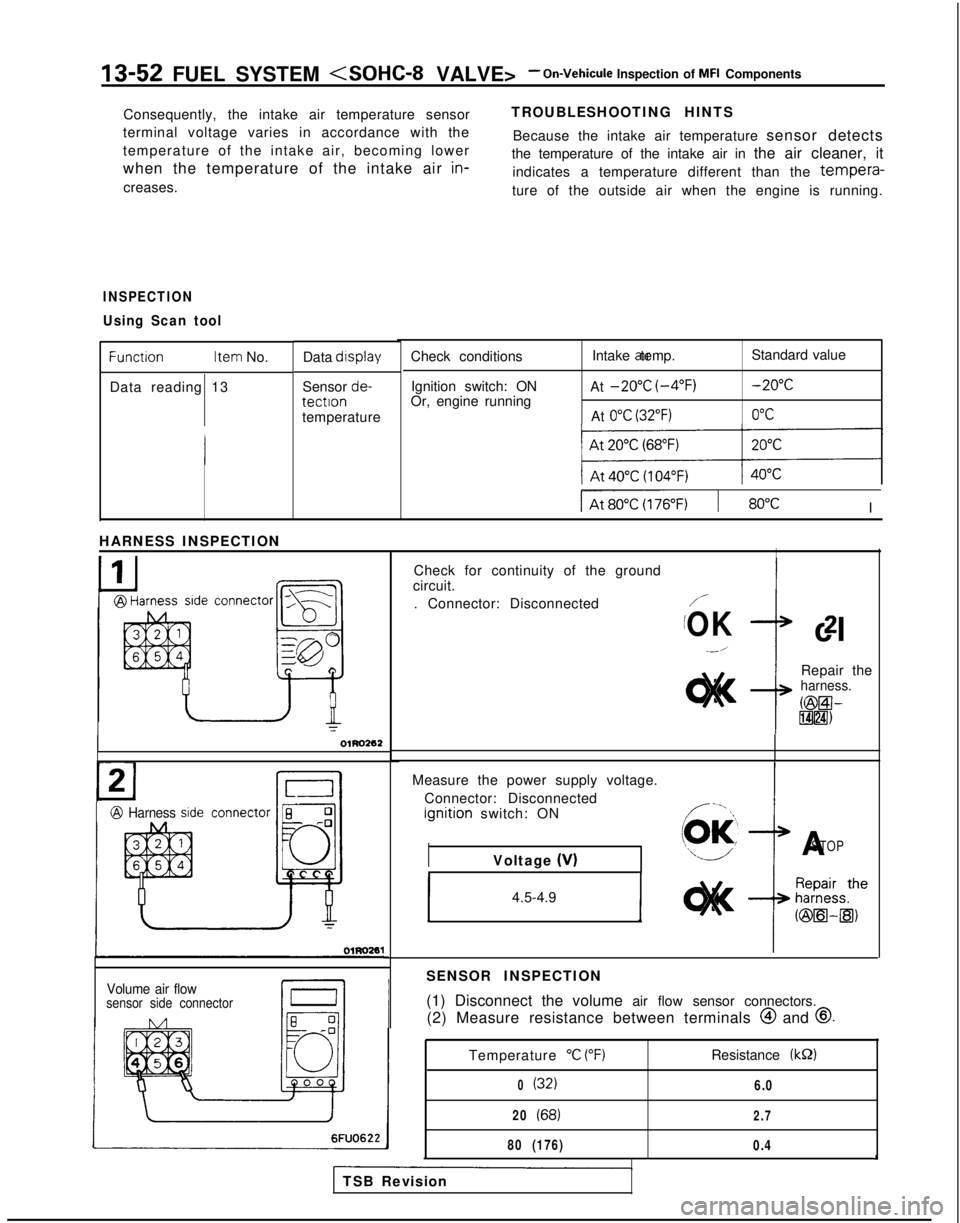

Consequently, the intake air temperature sensor

terminal voltage varies in accordance with the

temperature of the intake air, becoming lower

when the temperature of the intake air in-

creases. TROUBLESHOOTING HINTS

Because the intake air temperature sensor detects

the temperature of the intake air in the air cleaner, it

indicates a temperature different than the

tempera-

ture of the outside air when the engine is running.

INSPECTION

Using Scan tool

Function Item

No.

Data reading 13 Data display

Sensor de-tectlontemperature

connector

-,-S=

[

a

ry:

EQO

n

OlRO262

Check conditions

Ignition switch: ON

Or, engine running Intake air temp.

At

-20°C (-4°F)

At 0°C (32°F)

Standard value -20°C

0°C

IAt60~) I 80°CI

HARNESS INSPECTION

I

@ Harness sideconnector 8 0-0

Jill

I54

T

Volume air flowsensor side connector

Check for continuity of the ground

circuit.

. Connector: Disconnected

/-

/OKcl2

--/

Repair theharness.

@El-lT$lH)

IMeasure the power supply voltage.

Connector: Disconnected Ignition

switch: ON

IASTOPVoltage (V)

1 4.5-4.9 1

SENSOR INSPECTION

(1) Disconnect the volume air flow sensor connectors.

(2) Measure resistance between terminals @

and

@.

6FUO622

Temperature “C (“F)

0(32)

20(68)

80 (176)

Resistance (kS2)

6.0

2.7

0.4A

TSB Revision

Page 196 of 1273

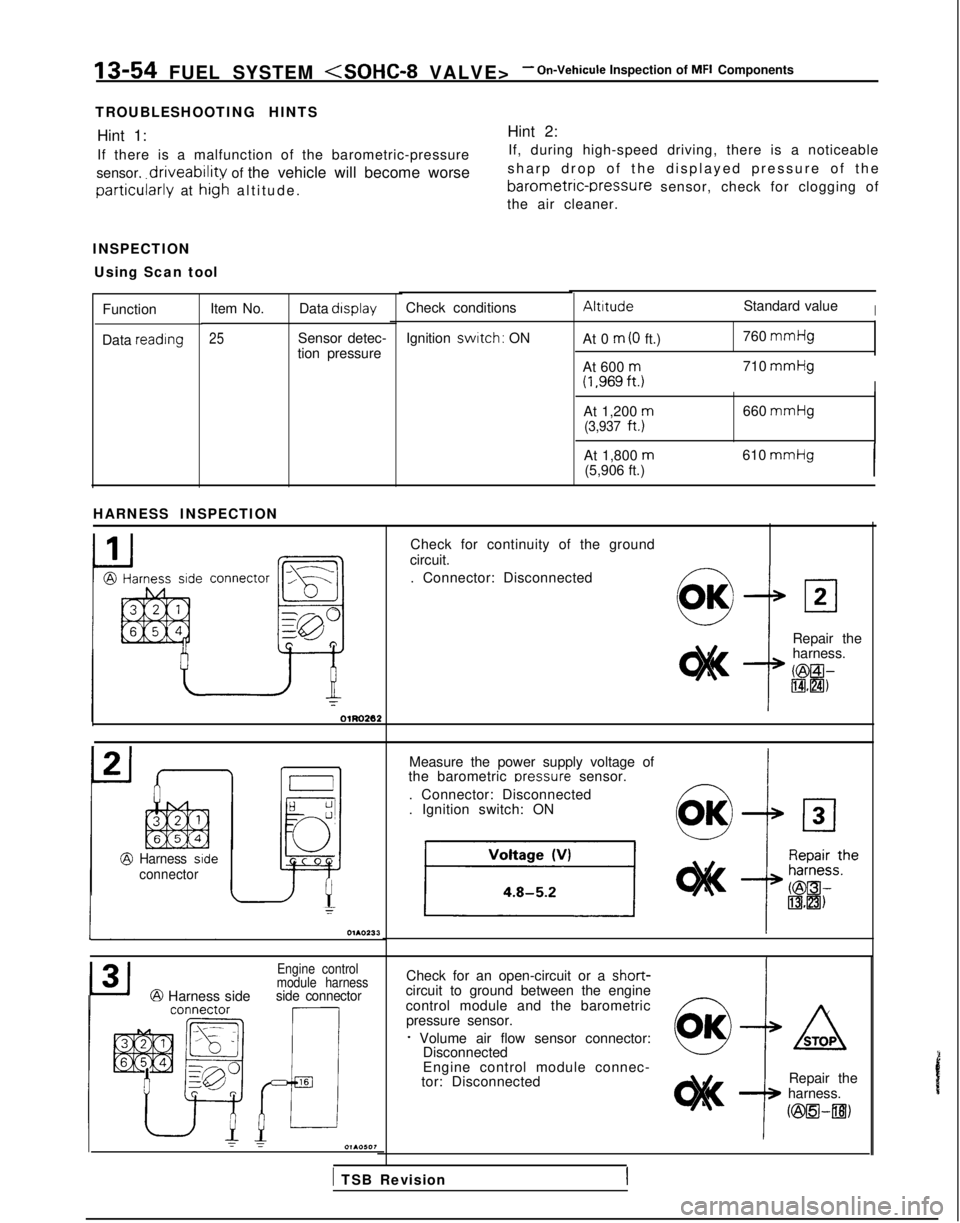

13-54 FUEL SYSTEM

TROUBLESHOOTING HINTS Hint 1: Hint 2:

If there is a malfunction of the barometric-pressure If, during high-speed driving, there is a noticeable

sensor,

driveability of the vehicle will become worse sharp drop of the displayed pressure of th

e

barometric-rxessure sensor, check for clogging ofparticularly at hig’h altitude

.

the air cleaner.

INSPECTION Using Scan tool

AltitudeStandard valueICheck conditions

Item No. Data display

25Sensor detec-

tion pressure

Function

Data reading

Ignition switch: ON

At 0 m (0 ft.) 760 mmHg

At 600

m(1,969ft.j710 mmHg

I

At 1,200 m660

mmHg(3,937

ft.)

At 1,800

m(5,906 ft.) 610 mmHgI

HARNESS INSPECTION

Check for continuity of the ground

circuit.

. Connector: Disconnected

connector

L,?

la

Fi

gg-CI

e

Repair the

harness.

KBEil-IBHZI)

Measure the power supply voltage of

the barometric oressure

sensor.

. Connector: Disconnected

. Ignition switch: ON

Harness side

connector

Check for an open-circuit or a short-circuit to ground between the engine

control module and the barometric pressure sensor.

f Volume air flow sensor connector: Disconnected

Engine control

module harness

@ Harness sideside connector

Engine control module connec-

tor: Disconnected Repair the

harness.

ozsEl-~)

1 TSB Revision

Page 198 of 1273

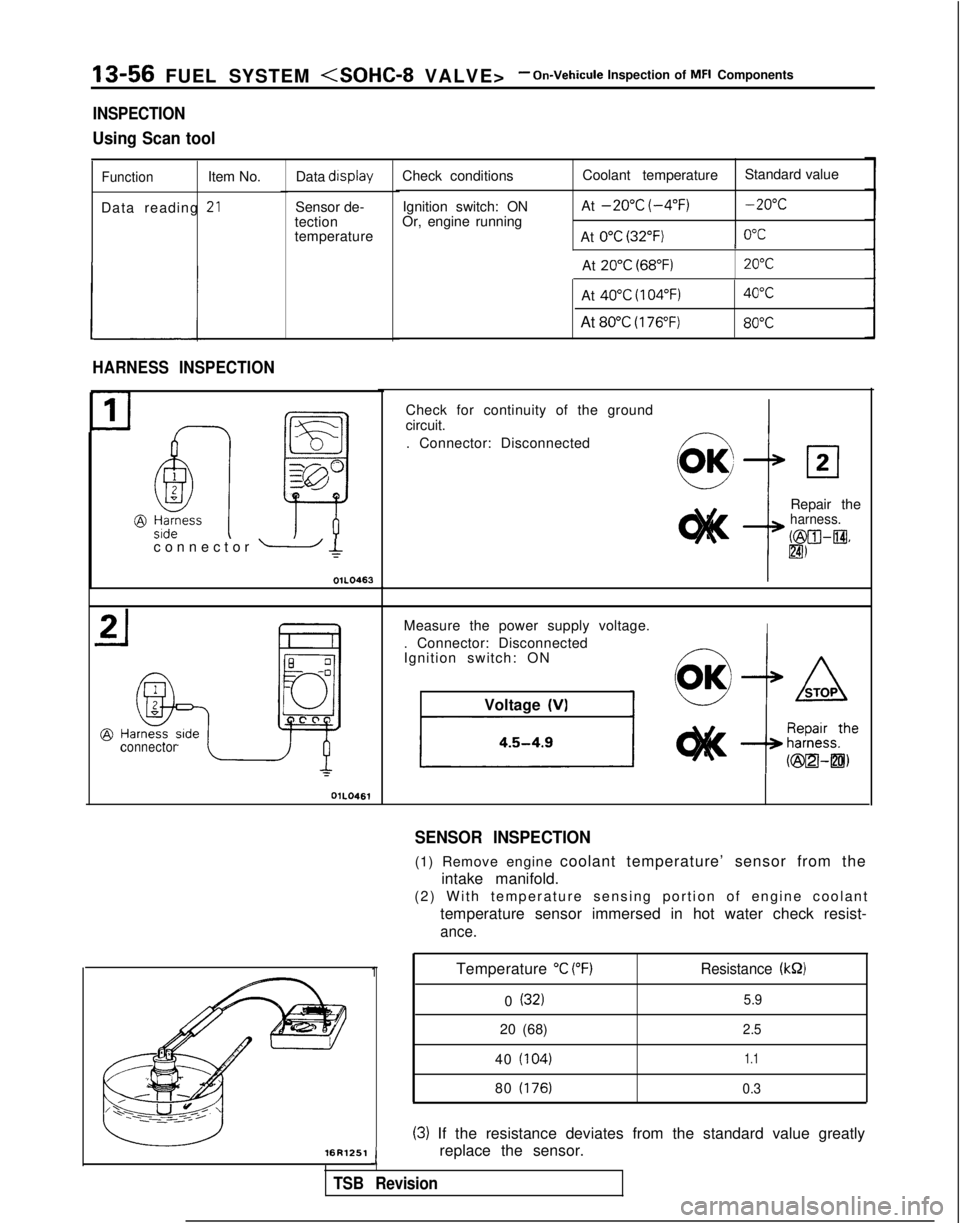

13-56 FUEL SYSTEM

INSPECTION

Using Scan tool

FunctionItem No.

Data reading

-*LI

Data display

Sensor de-

tection

temperature

HARNESS INSPECTION

connector OlLO461Check conditions

Ignition switch: ON

Or, engine running Coolant temperature

Standard value

At

-20°C (-4°F)-20°C

At 0°C (32°F)0°C I

At

20°C (68°F)20°C

connector - Ic

OIL0463L

-16R1251

Temperature “C (“F)Resistance (kS2)

0 (32)5.9

20 (68)2.5

40 (104)1.1

80 (176) 0.3

(3) If the resistance deviates from the standard value greatly

replace the sensor.

J

TSB Revision

At 40°C (104°F)40°C

At 80°C (176°F)80°C

1

Check for continuity of the ground

circuit.

. Connector: Disconnected

Repair the

harness.

b&XII-@.

lm

Measure the power supply voltage.I. Connector: Disconnected

Ignition switch: ONVoltage

(VI

SENSOR INSPECTION

(1) Remove engine coolant temperature’ sensor from the

intake manifold.

(2) With temperature sensing portion of engine coolan

t

temperature sensor immersed in hot water check resist-

ance.

Page 200 of 1273

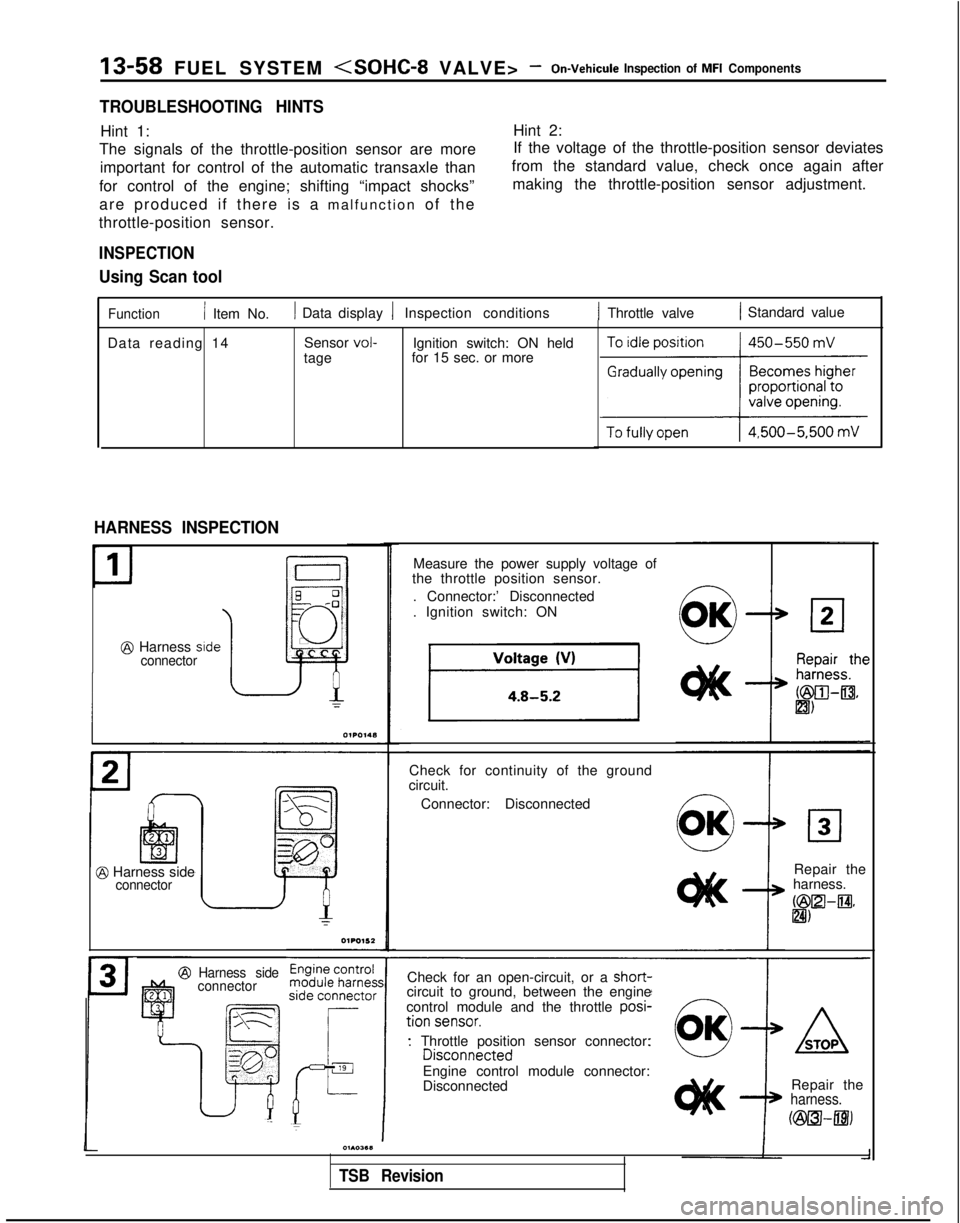

13-58 FUEL SYSTEM

TROUBLESHOOTING HINTS

Hint 1:Hint 2:

The signals of the throttle-position sensor are more If the voltage of the throttle-position sensor deviates

important for control of the automatic transaxle than from the standard value, check once again after

for control of the engine; shifting “impact shocks” making the throttle-position sensor adjustment.

are produced if there is a malfunction of the

throttle-position sensor.

INSPECTION

Using Scan tool

Function/ Item No.1 Data display 1 Inspection conditions1 Throttle valve1 Standard value

Data reading 14 Sensor

vol-tageIgnition switch: ON held

for 15 sec. or more

HARNESS INSPECTION

E q-0

JJ ~

@ Harness side0

connector

@ Harness sideconnector

Harness side

connector

Measure the power supply voltage of

the throttle position sensor.

. Connector:’ Disconnected

. Ignition switch: ON

Check for continuity of the ground

circuit.

Connector: Disconnected

Repair the

harness.

bZilZl-m* &I)

Check for an open-circuit, or a short-

circuit to ground, between the engine

control module and the throttle posi-

. Throttle position sensor connector: Engine control module connector:

Disconnected Repair the

harness.

Fi&TUI-mj

01103611

TSB Revision

Page 202 of 1273

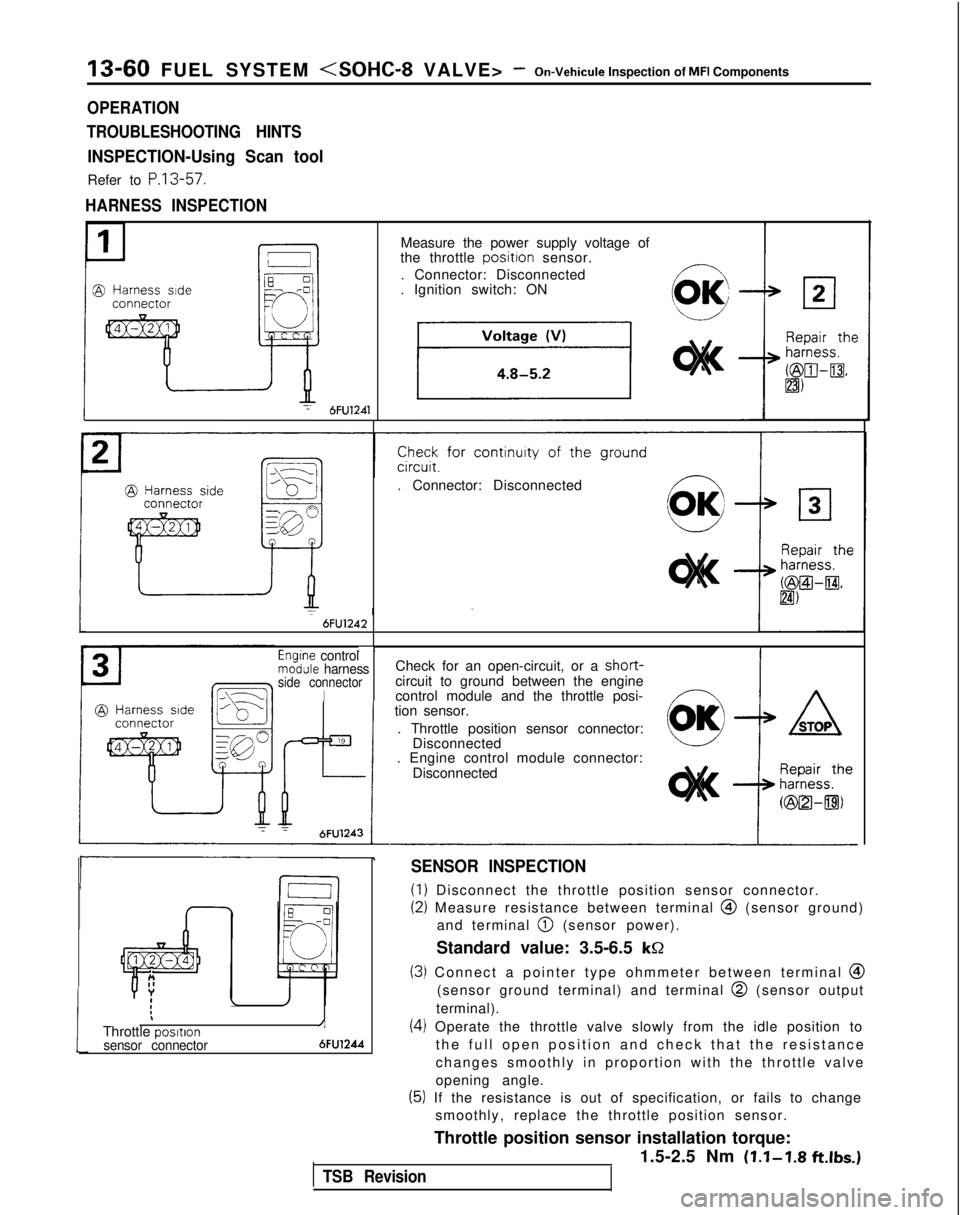

13-60 FUEL SYSTEM

OPERATION

TROUBLESHOOTING HINTS

INSPECTION-Using Scan tool

Refer to P.13-57.

HARNESS INSPECTION

Measure the power supply voltage of

the throttle positlon

sensor.

. Connector: Disconnected

. Ignition switch: ON

6FU1241

. Connector: Disconnected

6FU1242

Er’ ”I

miglne controlodule harnessCheck for an open-circuit, or a short-

side connectorcircuit to ground between the engineIcontrol module and the throttle posi-

tion sensor.

19

!!F!=6FU1243

. Throttle position sensor connector: Disconnected0

OK

. Engine control module connector:

Disconnectedr

ASTOP

L

I\:

Throttle posltlon/

sensor connector6FU1244

Repair the

harness.

i

K292Ha)

SENSOR INSPECTION

(1) Disconnect the throttle position sensor connector.

(2) Measure resistance between terminal @ (sensor ground)

and terminal

@ (sensor power).

Standard value: 3.5-6.5

kQ

(3) Connect a pointer type ohmmeter between terminal @

(sensor ground terminal) and terminal

@ (sensor output

terminal).

(4) Operate the throttle valve slowly from the idle position to the full open position and check that the resistanc

e

changes smoothly in proportion with the throttle valve

opening angle.

(5) If the resistance is out of specification, or fails to change smoothly, replace the throttle position sensor.

Throttle position sensor installation torque: 1.5-2.5 Nm (1.1-1.8

ft.lbs.)

TSB Revision

Page 204 of 1273

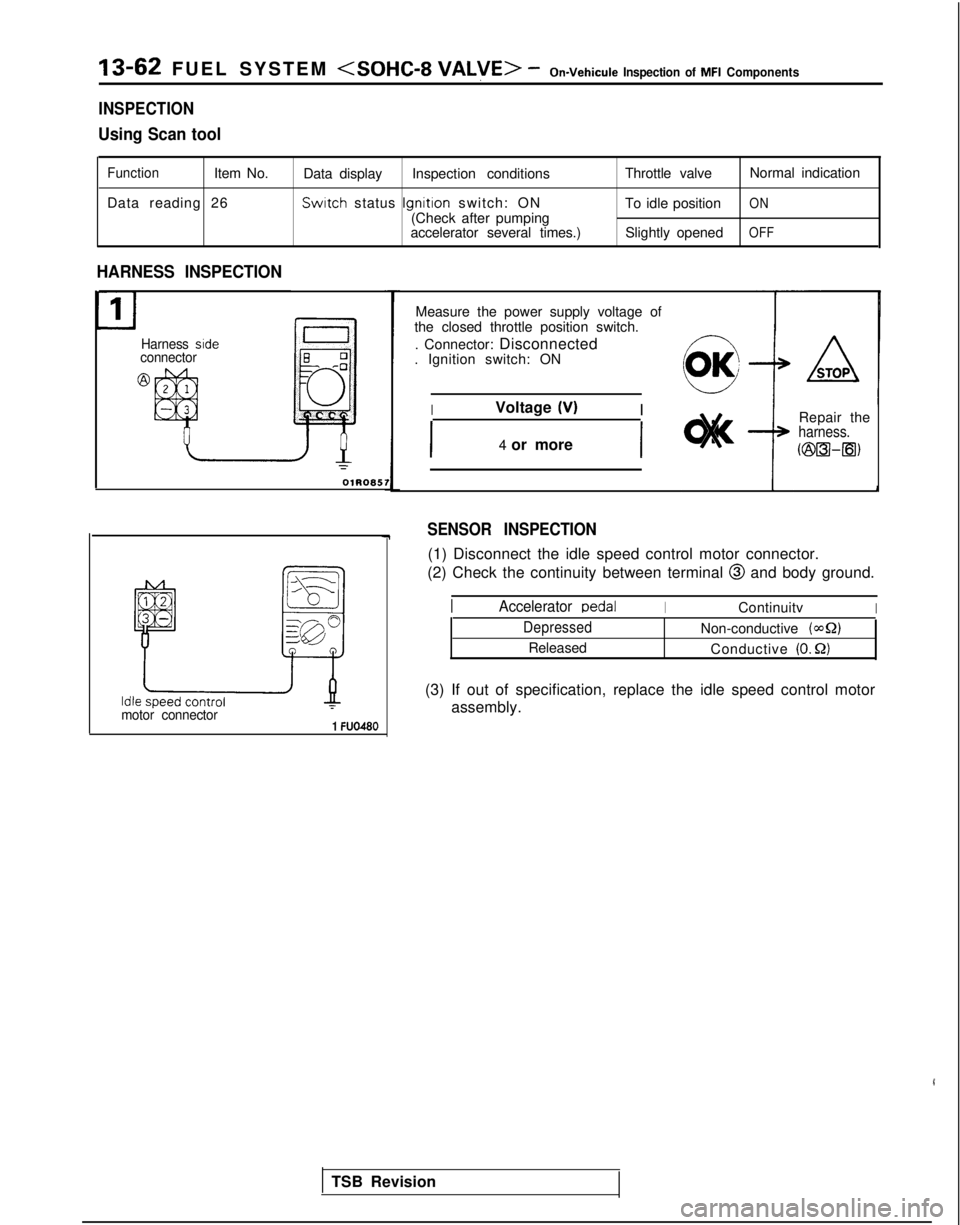

13-62 FUEL SYSTEM

INSPECTION

Using Scan tool

FunctionItem No.

Data reading 26 Data display

Inspection conditions Switch

status Ignition

switch: ON

(Check after pumping

accelerator several times.) Throttle valve

Normal indication

To idle position

ON

Slightly openedOFF

HARNESS INSPECTION

Harness sideconnector

Y

OlR085

motor connector1 FUO480

Measure the power supply voltage of

the closed throttle position switch.

. Connector: Disconnected

. Ignition switch: ON

IVoltage (V)I

I4 or moreI

Repair theharness.

c@a-m)

SENSOR INSPECTION

(1) Disconnect the idle speed control motor connector.

(2) Check the continuity between terminal

@ and body ground.

TSB Revision

IAccelerator DedalIContinuitvI

DepressedNon-conductive (42)

Released Conductive (0. Q)

(3) If out of specification, replace the idle speed control motor

assembly.