ESP MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 7 of 1273

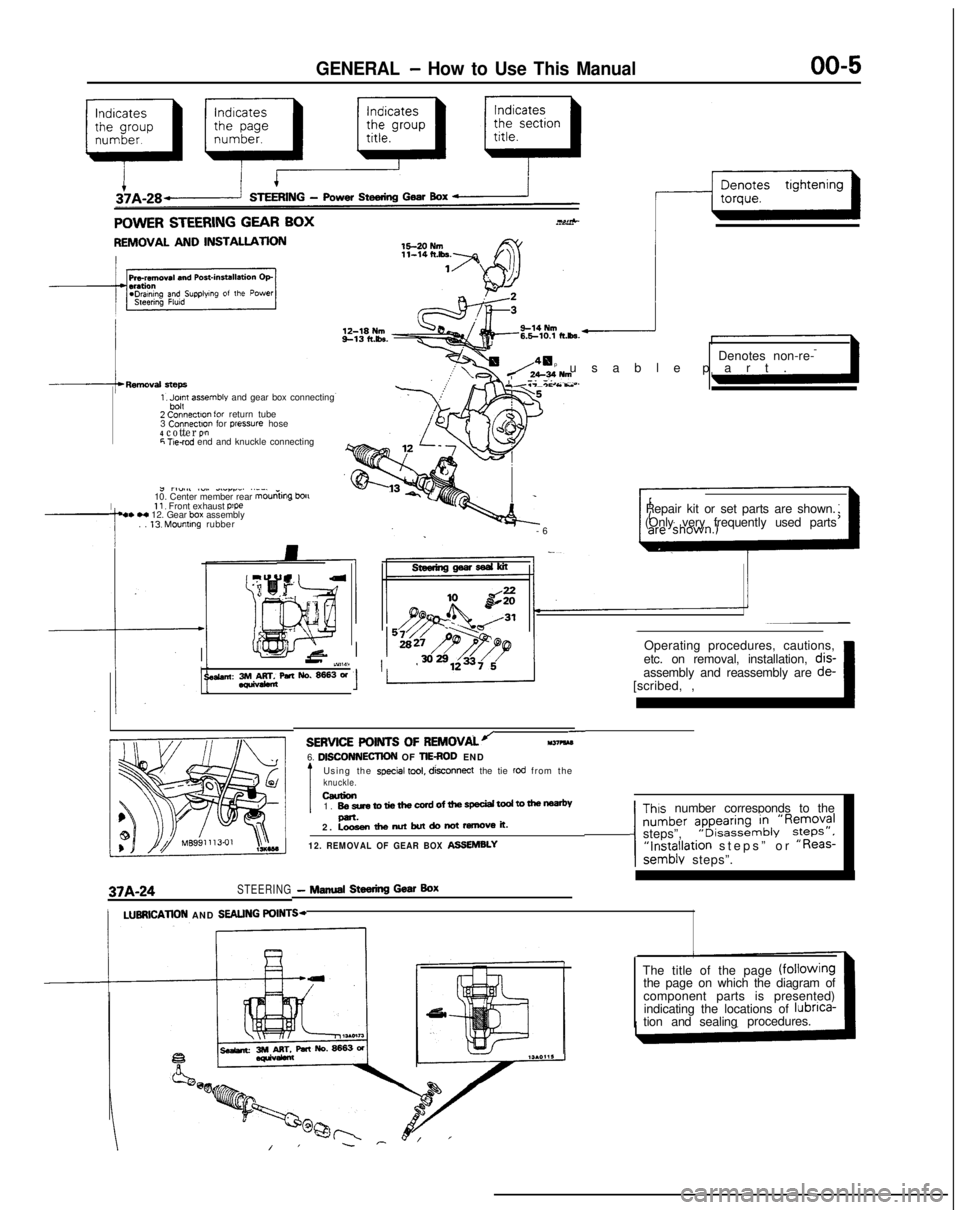

GENERAL - How to Use This Manual

QfitIIICQ CTEEQINC CFAR RnY..^-TV..&” Y.LLI.II.Y Y_.. w-1.

REMOVAL AND INSTALLATION

1, Jpn assemble and gear box connecting

2 Connectlo” for return tube

3 Connectm

for pressure hose4 cotter P!”6 T!e-rod end and knuckle connecting

I

J rl”.#l ~“,. dLlrr_. ..__

10. Center member rear mouniing

bou11, Front exhaust p’pe4. H 12. Gear box assembly

. . 13. Mounting rubber Denotes non-re-

p usable part

.

Y.T-*c As..

-

6

Repair kit or set parts are shown.

(Only very frequently used parts

Operating procedures, cautions,

II-’ iY,W11 ’etc. on removal, installation, dis-

se&an: 3rM&rr&paNo.~3W[scribed, ,~ 1assembly and reassembly are

de-

37A-24STEERING- NINA Steering Gear Box

-SERVICE POINTS OF

REMOVALJll37?kM6. DlSCONNECllON OF TIEROD END

Using the special tool, disconnect

the tie rod from theknuckle.ceurion1. BesretotiethewrdofthespeciaitodtomenP-.2. Loosenthenutbutdonotremoveit.

12. REMOVAL OF GEAR BOX ASSEMBLY

Thus number corresponds to the

number ?pyi:,“~&‘R~;;?Isteps”,“Installation steps” or “Reas-semblv steps”.

/LUBRlCATlON AND SEALING POINTS-

The title of the page (fOilOWingthe page on which the diagram of

component parts is presented)

indicating the locations of lubnca-

tion and sealingprocedures.

Page 8 of 1273

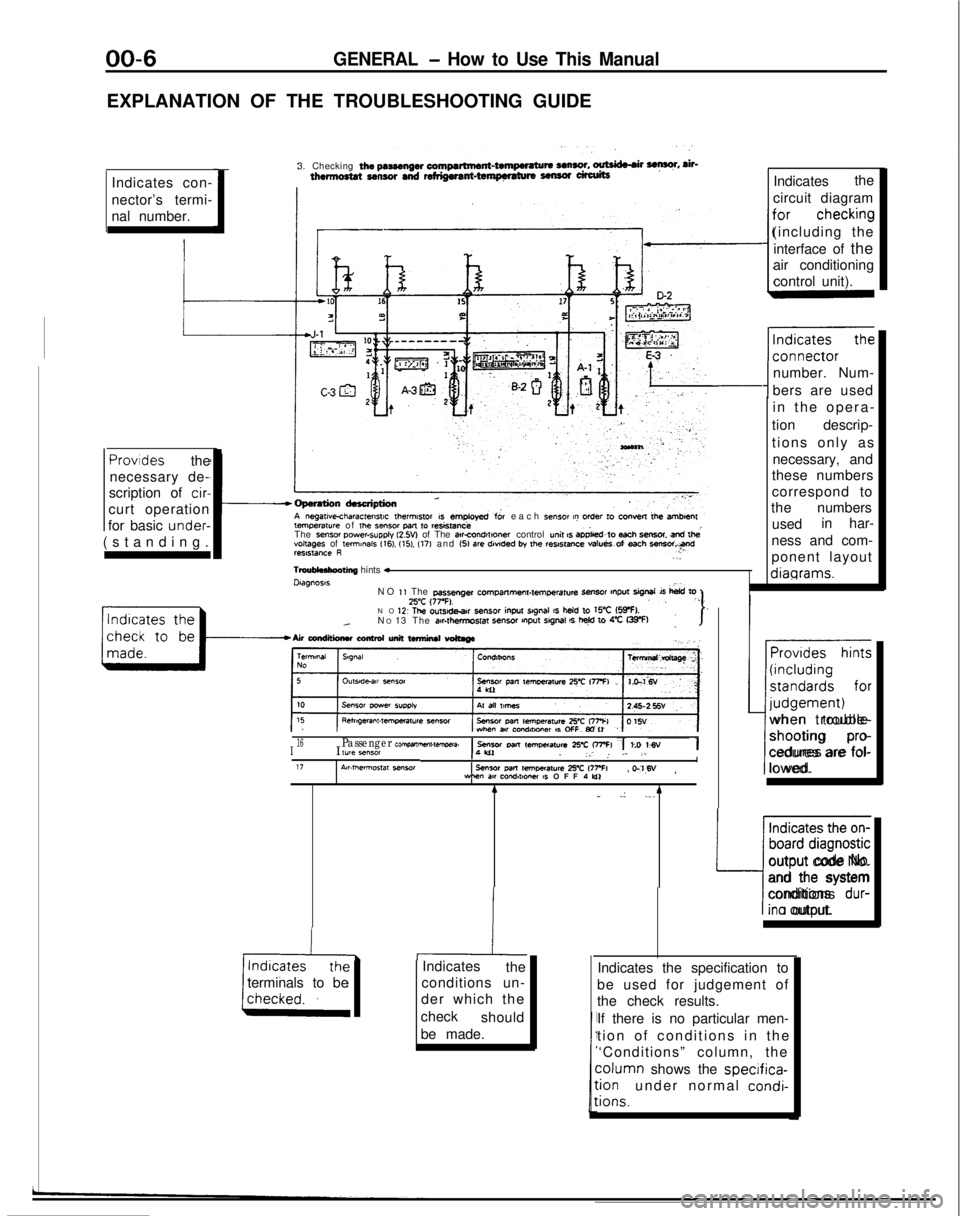

00-6GENERAL - How to Use This Manual

EXPLANATION OF THE TROUBLESHOOTING GUIDEIndicates con-

nector’s termi-

nal number. 3. Checking

the pasmngw compartment-twnpwatu* UnSO!. ~ F, ah-thermo8tat sensor and refdgwant-tempnaturs sensor ufalitsIndicates

the

circuit diagram

(including the interface of the

air conditioning

control unit).

number. Num-

bers are used temperawe

of

the Sensor pm

to resistanceeach sensor t? order to convest lb+ amben

The sense, power-supply l2.W of The atrcOnd,f,oner control unit s aD&d~to each SmSOt snd lhevoltages of te,mmaIs 116). (151. (17) and (51 are

dwded by the reslstme va!ueS.of each ““Freelstance R..

TmuMnhooting

hints *Dtagnoss

in the opera

-

tion descrip-

tions only as necessary, and

these numbers

correspond to

the numbers

used in har-

ness and com-

ponent layout diagrams.Provides

the

necessary de-

scription of

cir-

curt operation

for basic under-

(standing.

NO

1, The passenger cPrrlpmme”l-lemperatu4

-r tnput sigrml is

hid toZ’C (77-F).,, “”NO 1’2 The ou~sde.ar sensor

inpu

srgnal IS held to WC (5IpF).._N

O 13 The air#t,?,mpSf~ SenSO, VlPut SlgMl 6 t+ 10 4% G33-F):I-Airwndtlimluconhdunittwmirutwtmge

~~

I16I lYle *“MIPassenger com,wnme”t-tawa.1 sensor Parr lem,mat”r~ 25-c OFFI 7 to WV1,‘W. _: ,. L. .LI17A~r.,hermos,at seworsensor

Pm

remoeraure 2% 177% WM”

m cQndlt*Ow IS OFF 1 Lo, o-‘l,W

,

terminals to be 4

_

.: ._. 4

-hiIndicates

the

conditions un-

der which the

check should

be made. Provides hints

(including

standards for

I-- judgement)

when trouble-

shooting

pro-

cedures are fol-

lowed.

Indicates the on-

board diagnostic

L:

output code No.

and the system

conditions

dur-

ina output.

Indicates the specification to

be used for judgement of

the check results.

If there is no particular men-

tion of conditions in th

e

‘Conditions” column, the column

shows the

specifica-:ionunder normal condi-

:ions.

Page 36 of 1273

00-34GENERAL- Lubrication and Maintenance

LUBRICATION AND

MAINTE-

NANCEMOOPA-

Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum protection for the vehicle owner’s investment

against all reasonable types of driving conditions. Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by the Society of Automotive Engineers (SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute (NLGI).

MAINTENANCE SCHEDULES Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

The item numbers used in the “SCHEDULED MAINTENANCE TABLE” correspond to th

e

“MAINTENANCE SERVICE” section numbers.

SEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service. Component service information

isIncluded i

n

appropriate units for vehicles operating under one or

more of the following conditrons:

1.Trailer towing or police, taxi, or

commerciai

type

operation

2. Operation of Vehicle (1) Short-trip operation at freezing temperature(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city traffic during hot weather above

32°C (90°F)

(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual number, for example, SAE 1

OW-30, which Indicates

a multigrade oil.

The API classification system defines oil perform- ance in terms of engine usage. Only engine oil

designed “For Service SG” or “For Service

SGKD”,

when available, should be used. These oils contain

sufficient chemical additives to provide maximum

engine protection. Both the SAE grade and the API

designation can be found on the container.

Caution

Test results submitted to EPA have shown that

laboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-

dingly, the potential exists for humans to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be taken, therefore, when changing engine oil, to minimize the amount and length of

exposure time to used engine oil on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to remove

any used engine oil. Do not use gasoline,

thinners, or solvents.

GEAR LUBRICANTS

The SAE grade number also indicates the viscosity of Multi-Purpose Gear Lubricants.

The API classfication

system defines gear lubricants

in terms of usage. Typically gear lubricants conform-

ing to API

GL-4 or GL-5 with a viscosity of SAE 75W-85W

are recommended for manual transaxle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the

NLGI designation and

are further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified,

Multi-

Purpose Grease, NLGI grade 2 should be used.

FUEL USAGE STATEMENT

Your vehicle must use unleaded gasoline only.

This vehicle has a fuel filler tube especially designed

to accept only the smaller-diameter unleaded gaso- line

dispensrng nozzle.

Caution

Using leaded gasoline in your vehicle will damage

the catalytic converter, and affect the warranty

coverage validity.

All vehicles except those with DOHC engines

Your vehicle is designed to operate on unleaded

gasoline having a minimum octane rating of 87 or

91 RON (Research Octane Number).

Vehicles equipped with DOHC engines

Your vehicle is designed to operate on premiumunleaded gasoline having a minimum

octane rating

of 91 or 95 RON (Research Octane Number).

TSB Revision

Page 59 of 1273

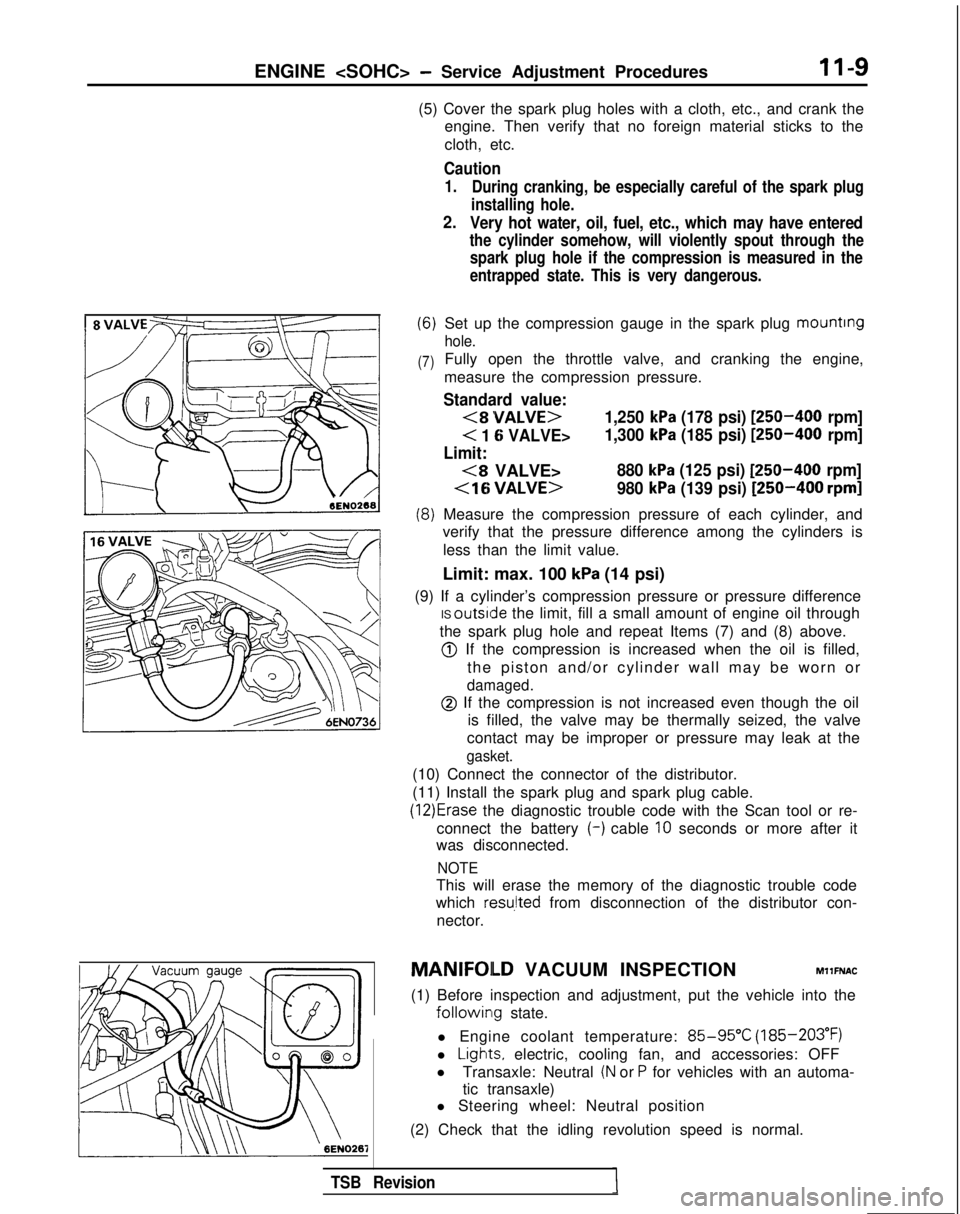

ENGINE

(5) Cover the spark plug holes with a cloth, etc., and crank the engine. Then verify that no foreign material sticks to the

cloth, etc.

Caution

1. During cranking, be especially careful of the spark plug

installing hole.

2.Very hot water, oil, fuel, etc., which may have entered

the cylinder somehow, will violently spout through the spark plug hole if the compression is measured in the

entrapped state. This is very dangerous.

MANIFOILD VACUUM INSPECTIONMllFNAC

(6)

(7)

(8)

Set up the compression gauge in the spark plug mounting

hole.

Fully open the throttle valve, and cranking the engine,

measure the compression pressure.

Standard value:

<8VALVE>1,250 kPa (178 psi) [250-400 rpm]

< 1 Ei VALVE>

1,300 kPa (185 psi) [250-400 rpm]

Limit:

(8 VALVE>880 kPa (125 psi) [250-400 rpm]

[250-400 rpm]

Measure the compression pressure of each cylinder, and

verify that the pressure difference among the cylinders is

less than the limit value.

Limit: max. 100

kPa (14 psi)

(9) If a cylinder’s compression pressure or pressure difference IS outside

the limit, fill a small amount of engine oil through

the spark plug hole and repeat Items (7) and (8) above.

@ If the compression is increased when the oil is filled, the piston and/or cylinder wall may be worn or

damaged.

@ If the compression is not increased even though the oil is filled, the valve may be thermally seized, the valve

contact may be improper or pressure may leak at the

gasket.

(10) Connect the connector of the distributor.

(11) Install the spark plug and spark plug cable.

(12)Erase the diagnostic trouble code with the Scan tool or re-

connect the battery (-)

cable

10 seconds or more after it

was disconnected.

NOTE

This will erase the memory of the diagnostic trouble code

which

resu,lted from disconnection of the distributor con-

nector.

(1) Before inspection and adjustment, put the vehicle into the

followin~g state.

l Engine coolant temperature:

85-95°C (185-203°F)

l

Ligt-Its, electric, cooling fan, and accessories: OFF

l Transaxle: Neutral

(N or P for vehicles with an automa-

tic transaxle)

l Steering wheel: Neutral position

(2) Check that the idling revolution speed is normal.

TSB Revision

Page 82 of 1273

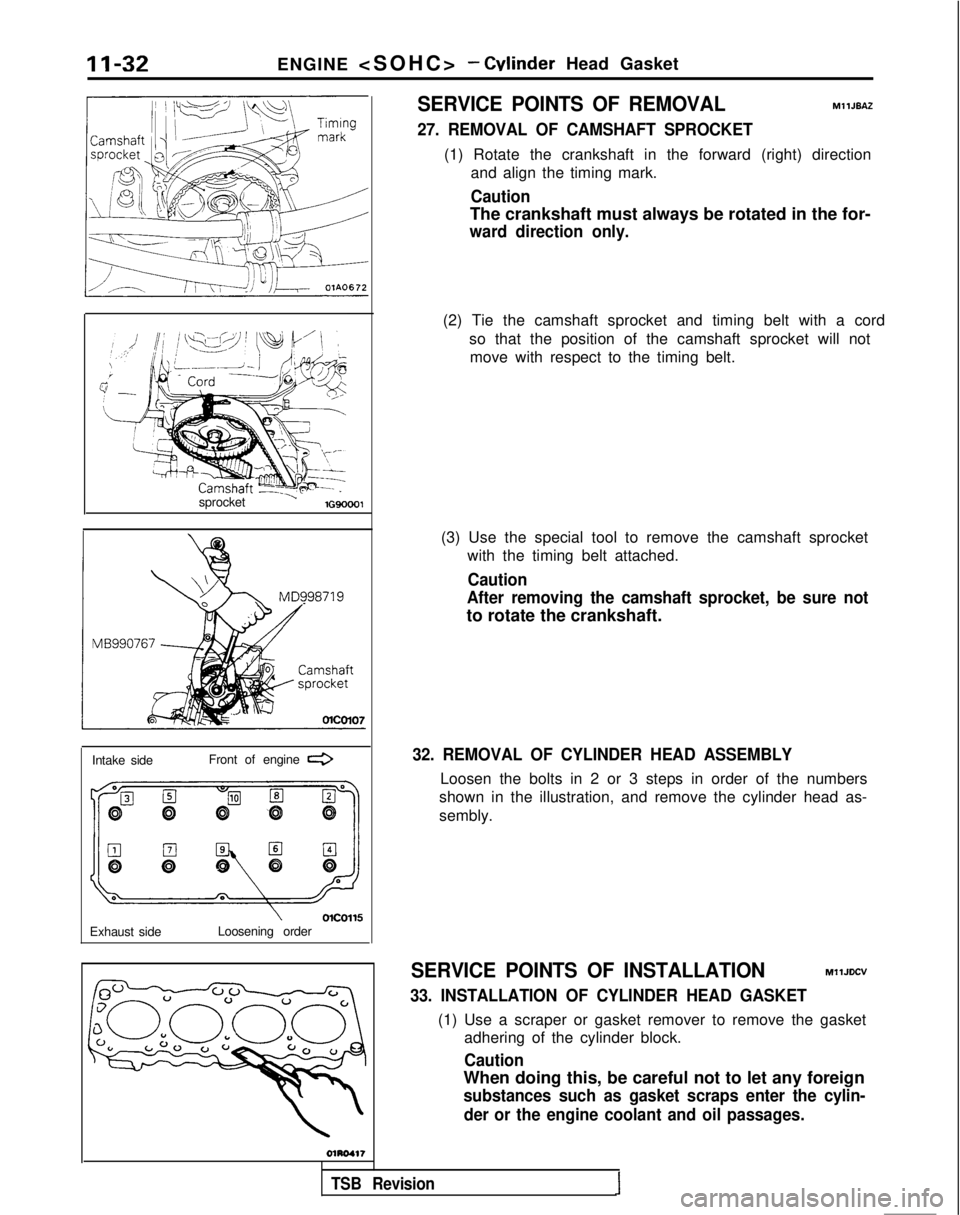

11-32ENGINE

- Winder Head Gasket

sprocket

’lG90001

Intake side Front of engine e

I

Exhaust side\olCOll!iLoosening order

SERVICE POINTS OF REMOVALMllJEAZ

27. REMOVAL OF CAMSHAFT SPROCKET

(1) Rotate the crankshaft in the forward (right) direction

and align the timing mark.

Caution

The crankshaft must always be rotated in the for-

ward direction only.

(3) Use the special tool to remove the camshaft sprocketwith the timing belt attached.

Caution

After removing the camshaft sprocket, be sure not

to rotate the crankshaft.

32. REMOVAL OF CYLINDER HEAD ASSEMBLY

Loosen the bolts in 2 or 3 steps in order of the numbers

shown in the illustration, and remove the cylinder head as-

sembly.

SERVICE POINTS OF INSTALLATIONMllJDCV

33. INSTALLATION OF CYLINDER HEAD GASKET

(1) Use a scraper or gasket remover to remove the gasket adhering of the cylinder block.

Caution

When doing this, be careful not to let any foreign

substances such as gasket scraps enter the cylin-

der or the engine coolant and oil passages.

(2) Tie the camshaft sprocket and timing belt with a cord

so that the position of the camshaft sprocket will notmove with respect to the timing belt.

TSB Revision1

Page 95 of 1273

ENGINE

11-45

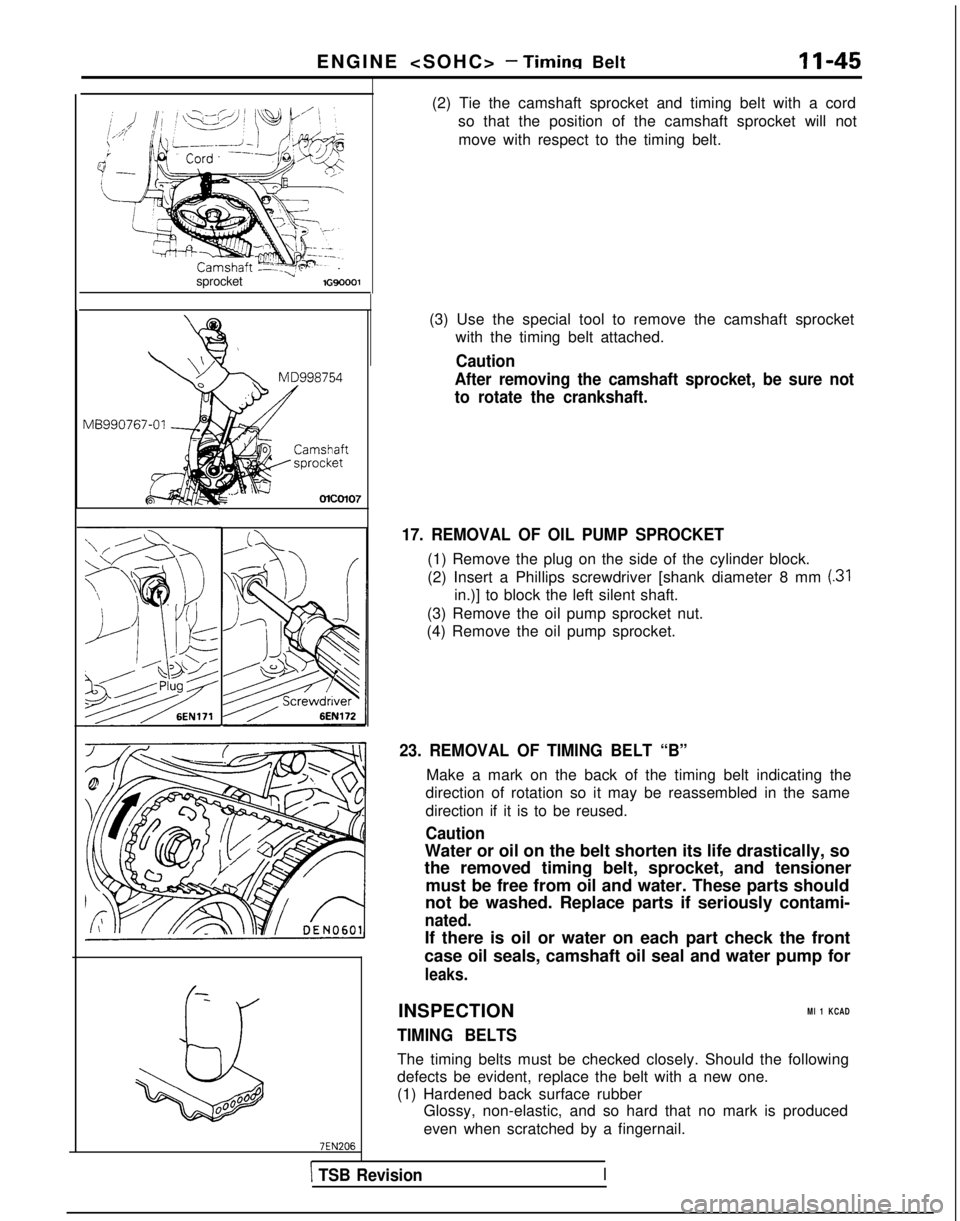

sprocket

vlGVO001 MD998754

vlB990767-01

-

&

00B00°

(2) Tie the camshaft sprocket and timing belt with a cord

so that the position of the camshaft sprocket will not

move with respect to the timing belt.

(3) Use the special tool to remove the camshaft sprocket with the timing belt attached.

Caution

After removing the camshaft sprocket, be sure not

to rotate the crankshaft.

17. REMOVAL OF OIL PUMP SPROCKET

(1) Remove the plug on the side of the cylinder block.

(2) Insert a Phillips screwdriver [shank diameter 8 mm

(31

in.)] to block the left silent shaft.

(3) Remove the oil pump sprocket nut.

(4) Remove the oil pump sprocket.

23. REMOVAL OF TIMING BELT “B”

Make a mark on the back of the timing belt indicating the

direction of rotation so it may be reassembled in the same

direction if it is to be reused.

Caution

Water or oil on the belt shorten its life drastically, so

the removed timing belt, sprocket, and tensioner

must be free from oil and water. These parts should

not be washed. Replace parts if seriously contami-

nated.

If there is oil or water on each part check the front

case oil seals, camshaft oil seal and water pump for

leaks.

INSPECTIONMl 1 KCAD

TIMING BELTS

The timing belts must be checked closely. Should the following

defects be evident, replace the belt with a new one.

(1) Hardened back surface rubber Glossy, non-elastic, and so hard that no mark is produced

even when scratched by a fingernail.

\ TSB RevisionI

Page 109 of 1273

ENGINE

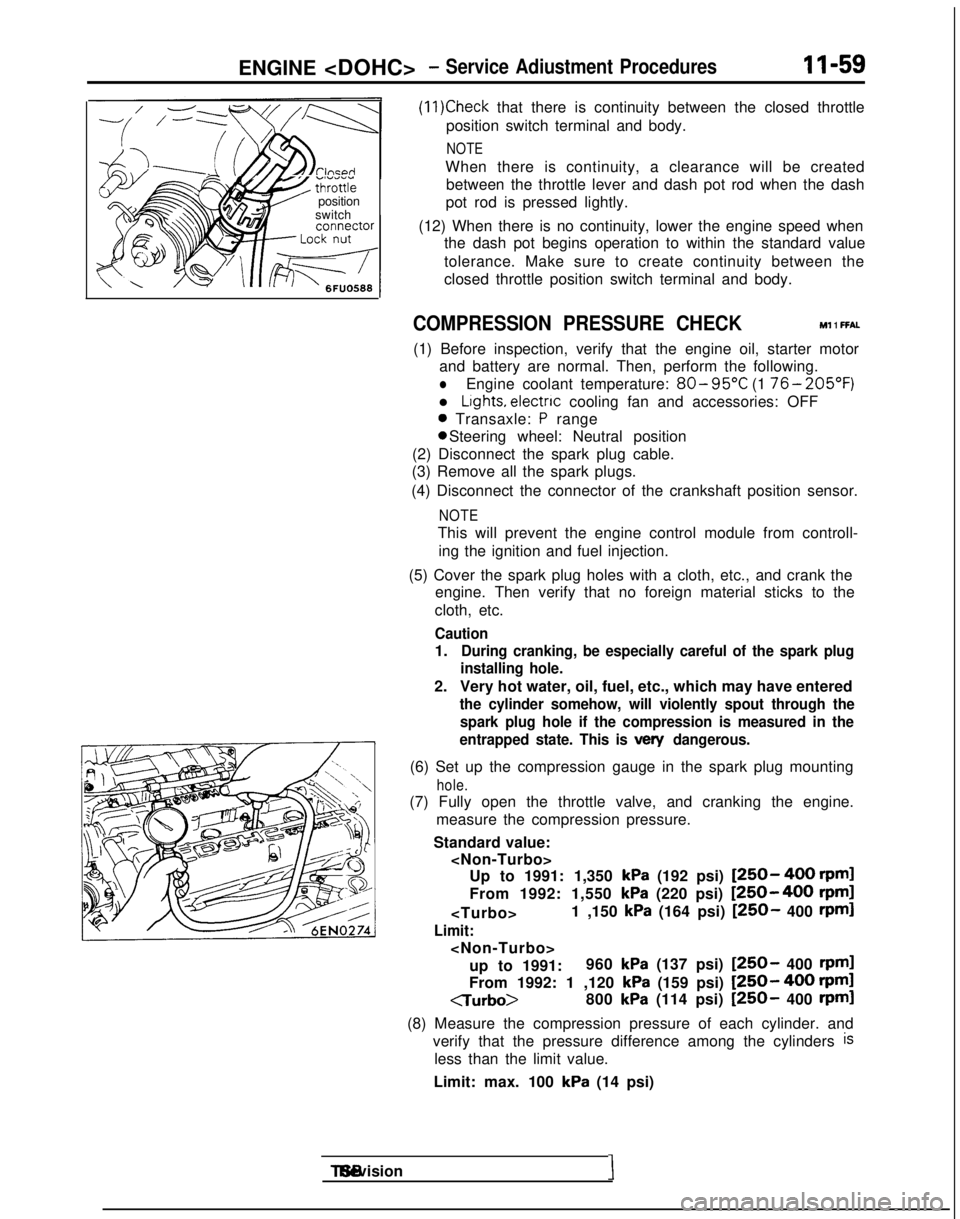

7 Go;;ikv position

switch

(11)Check that there is continuity between the closed throttle

position switch terminal and body.

NOTE

When there is continuity, a clearance will be created between the throttle lever and dash pot rod when the dash

pot rod is pressed lightly.

(12) When there is no continuity, lower the engine speed when the dash pot begins operation to within the standard value

tolerance. Make sure to create continuity between the

closed throttle position switch terminal and body.

COMPRESSION PRESSURE CHECK Ml 1 FFAL

(1) Before inspection, verify that the engine oil, starter motor

and battery are normal. Then, perform the following.

lEngine coolant temperature: 80- 95°C

(1 76- 205’F)

l Lights, electnc

cooling fan and accessories: OFF

0 Transaxle: P range 0 Steering wheel: Neutral position

(2) Disconnect the spark plug cable.

(3) Remove all the spark plugs.

(4) Disconnect the connector of the crankshaft position sensor.

NOTE

This will prevent the engine control module from controll- ing the ignition and fuel injection.

(5) Cover the spark plug holes with a cloth, etc., and crank the engine. Then verify that no foreign material sticks to the

cloth, etc.

Caution

1.During cranking, be especially careful of the spark plug

installing hole.

2. Very hot water, oil, fuel, etc., which may have entered

the cylinder somehow, will violently spout through the

spark plug hole if the compression is measured in the

entrapped state. This is

vex/ dangerous.

(6) Set up the compression gauge in the spark plug mounting

hole.

(7) Fully open the throttle valve, and cranking the engine.

measure the compression pressure.

Standard value:

kPa (192 psi) [250- 400 rpml

From 1992: 1,550

kPa (220 psi) [250-400 rpm]

Limit:

up to 1991: 960

kPa (137 psi) [250- 400 rpml

From 1992: 1 ,120 kPa (159 psi) [250- 400 rpml

CTurbo>

800

kPa (114 psi) [250- 400 rpml

(8) Measure the compression pressure of each cylinder. and verify that the pressure difference among the cylinders

is

less than the limit value.

Limit: max. 100

kPa (14 psi) TSB Revision

I

Page 161 of 1273

FUEL SYSTEM

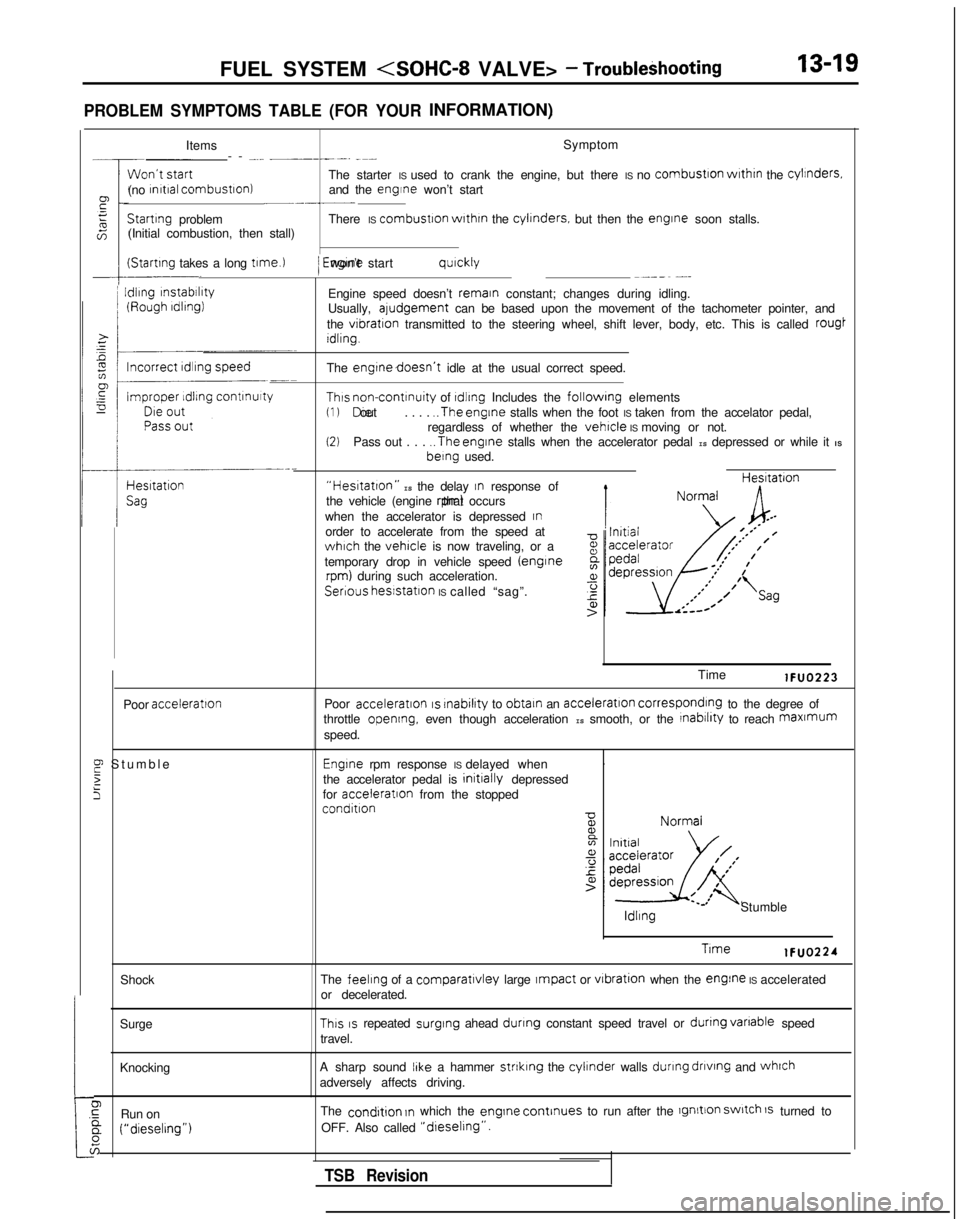

PROBLEM SYMPTOMS TABLE (FOR YOURINFORMATION)

:tShock

Surge

Knocking

0,GRun ona (“dieselrng”)

6

Items Symptom

-- -... __----. -~-

The starter IS used to crank the engine, but there IS no

combustron

wrthrn

the cylinders.

(no rnrtral combustron)

and the engine won’t start~-.-__Startrng

problem There IS combustron

wrthrn

the cylrnders.

but then the engrne

soon stalls.

(Initial combustion, then stall)

(Startrng takes a long t1me.l

I

Idling

rnstabrlrty

/ Engrne won’t start qurckly~--_~ -...

Engine speed doesn’t remain constant; changes during idling.

Usually, aludgement can be based upon the movement of the tachometer pointer, and

the

vibration transmitted to the steering wheel, shift lever, body, etc. This is call\

ed rougt

Idling.

The

engtnedoesn’t idle at the usual correct speed.

Thus non-contrnuity of rdlrng Includes the followrng elements(1) Die out

. . . . ..The

engine stalls when the foot IS taken from the accelator pedal,

regardless of whether the vehicle IS moving or not.(2)Pass out . . . ..The

engine stalls when the accelerator pedal IS depressed or while it IS berng

used.

“Hestatton” IS the delay In response of

the vehicle (engine rpm) that occurs

when the accelerator is depressed

Inorder to accelerate from the speed atwhich the vehicle is now traveling, or a

temporary drop in vehicle speed (enginerpm) during such acceleration. Hesltatron

Serious

hesstatlon IS called “sag”.

Poor

acceleration

E Stumbl

e

2

5

Time lFUO223

Poor

acceleration IS rnabilrty

to obtain an acceleration corresponding to the degree of

throttle opening, even though acceleration IS smooth, or the rnabrlrty to reach maxmum

speed.

Engrne rpm response IS delayed when .

the accelerator pedal is initrally

depressed

for acceleratron

from the stopped

condition ldllng

Stumble

Trme lFUO224

The

feeling of a comparatlvley large Impact or vrbration

when the engine IS accelerated

or decelerated.

This IS repeated surging

ahead dunng constant speed travel or dunng

vanable

speed

travel.

A sharp sound

IIke a hammer strtklng the cylinder walls during

dnvtng

and whrch

adversely affects driving.

The

condrtion In which the engrne

continues to run after the lgnltion switch 1s turned to

OFF. Also called

“dreselrng”.

TSB Revision

Page 247 of 1273

FUEL SYSTEM

fine probe7FU1264 1

(15) Reduce the internal pressure of the fuel pipes and hoses.

(Refer to

P.13-102.)

(16) Disconnect the fuel pressure gauge and the special toolsfrom the fuel rail.

Caution

Because there will be some residual pressure in the fuel

pipe line, use a shop towel to cover so that fuel doesn’t

splatter.

(17)Replace the O-ring at the end of the fuel high-pressure

hose with a new one. (18)After

connecting the fuel high-pressure hose to the fuel

rail, tighten the installation bolt.

(19)Check to be sure that there is no fuel leakage.

@ Apply battery voltage to the terminal for activation of the fuel pump so as to activate the fuel pump.

@ With fuel pressure applied, check for leakage of the fuel

line.

INSPECTION OF ENGINE CONTROL MODULE

TERMINAL VOLTAGEMl 3ZALBa

(1) Connect the extremely fine probe (paper clip, etc.) to the probe of the voltmeter.

(2) At each terminal of the engine control module connector,

insert the extremely fine probe from the wire side, and

measure the voltage referring to the check chart.

NOTE

1. In the state in which the connector of the engine

control module is connected, measure the voltage.

2. Measure the voltage across each terminal to the

terminal No. 106.

(ground terminal).

3. You may find it convenient to pull out the engine control module to make it easier to reach the connector

terminals.

4.Inspection need not be executed in the chart’s sequence.

Caution

Short-circuiting the positive

(+) probe between a con-

nector terminal and ground could damage the vehicle

wiring, the sensor, the engine control module, or all

there. Use care to prevent this!

(3) If voltmeter shows any deviation from standard value, check the corresponding sensor, actuator and related

electrical wiring, then repair or replace.

(4) After repair or replacement, recheck with the voltmeter to confirm that the repair has corrected the problem.

Page 257 of 1273

FUEL SYSTEM

Higt

fuel

&ring Oi’

FUEL FILTER

REMOVAL AND INSTALLATION

~zgz&i&r” 1@Release of Residual Pressure from High

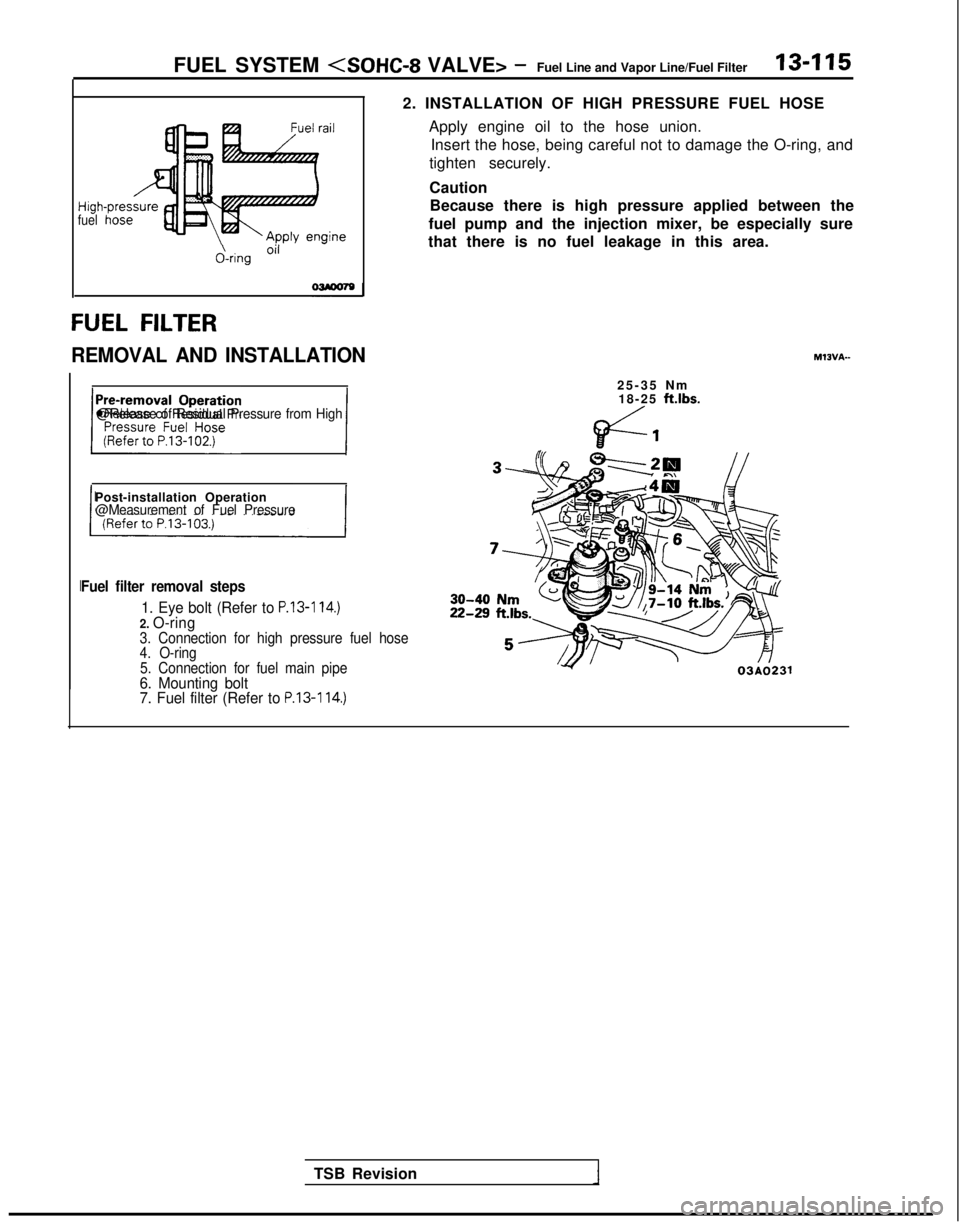

2. INSTALLATION OF HIGH PRESSURE FUEL HOSE

Apply engine oil to the hose union.Insert the hose, being careful not to damage the O-ring, and

tighten securely.

Caution Because there is high pressure applied between the

fuel pump and the injection mixer, be especially sure

that there is no fuel leakage in this area.

25-35 N

m

18-25

ft.lbs.

Post-installation Operation@Measurement of Fuel Pressure

Fuel filter removal steps

1. Eye bolt (Refer to P.13-114.)2. O-ring3. Connection for high pressure fuel hose

4. O-ring

5. Connection for fuel main pipe

6. Mounting bolt

7. Fuel filter (Refer to P.13-114.)

TSB Revision 03AO231