ESP MITSUBISHI GALANT 1989 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 351 of 1273

FUEL SYSTEM

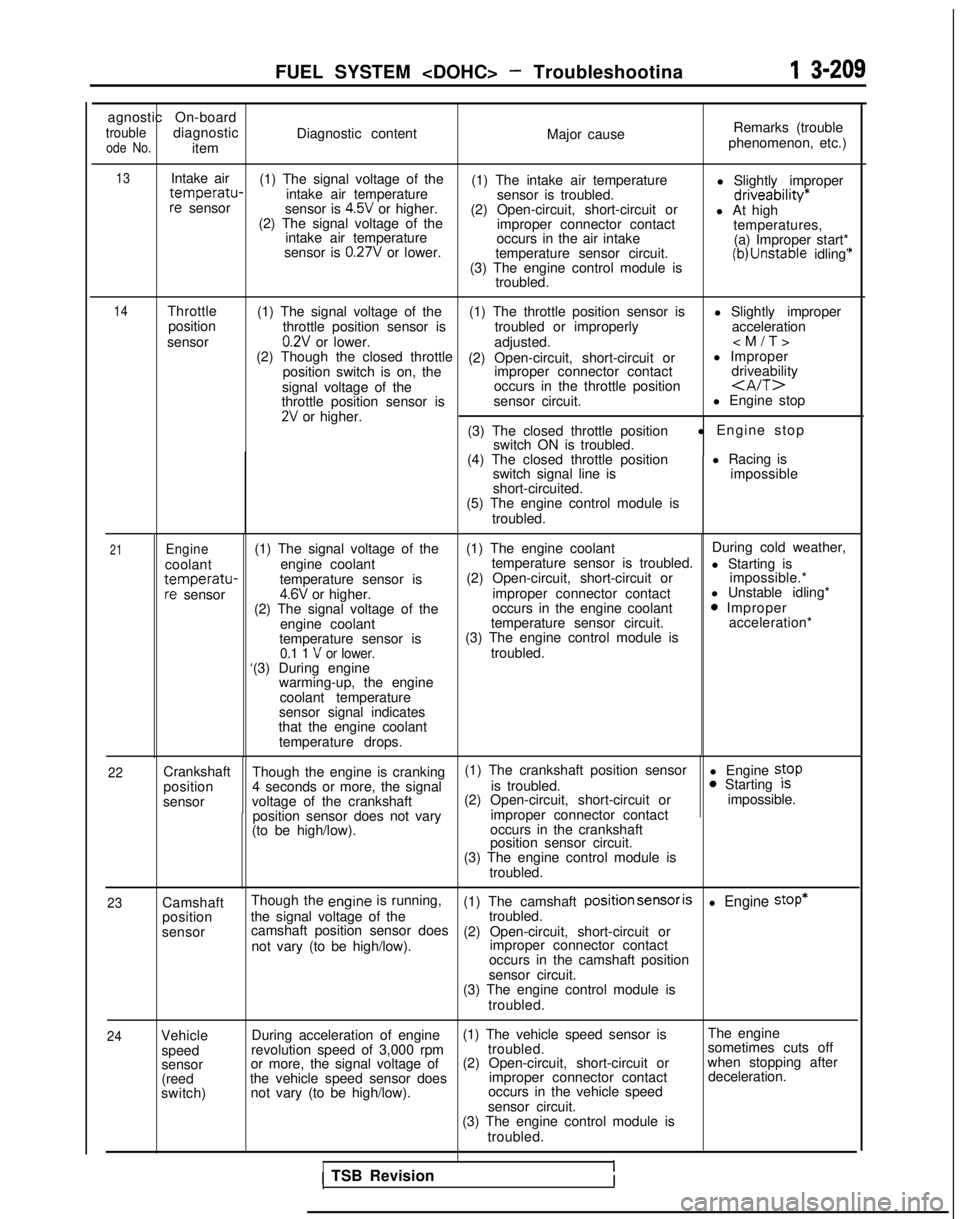

agnostic On-boardtroublediagnosticode No.item

Diagnostic content

Major causeRemarks (trouble

phenomenon, etc.)

13Intake air (1) The signal voltage of the

(1) The intake air temperature l Slightly impropertemperatu-intake air temperature

sensor is troubled.driveability*re sensorsensor is 4.5V or higher.(2) Open-circuit, short-circuit or l At high

(2) The signal voltage of the improper connector contacttemperatures,

intake air temperature occurs in the air intake

(a) Improper start*

sensor is

0.27V or lower. temperature sensor circuit. (b)Unstable

idling’

(3) The engine control module is

troubled.

14Throttle

position

sensor (1) The signal voltage of the

(1) The throttle position sensor is l Slightly improper

throttle position sensor is troubled or improperly acceleration

0.2V or lower.adjusted.

(2) Though the closed throttle (2) Open-circuit, short-circuit or l Improper

position switch is on, the improper connector contact driveability

signal voltage of the occurs in the throttle position

throttle position sensor is

sensor circuit. l Engine stop2V or higher.

(3) The closed throttle position l Engine stop

switch ON is troubled.

(4) The closed throttle position l Racing is

switch signal line is impossible

short-circuited.

(5) The engine control module is

troubled.

21Engine(1) The signal voltage of the (1) The engine coolant During cold weather,

coolant engine coolant temperature sensor is troubled.

l Starting is

temperatu-temperature sensor is(2) Open-circuit, short-circuit or

impossible.*re sensor4.6V or higher.improper connector contact l Unstable idling*

(2) The signal voltage of the occurs in the engine coolant0 Improper

engine coolant temperature sensor circuit.

acceleration*

temperature sensor is (3) The engine control module is

0.1 1 V or lower.troubled.

‘(3) During engine warming-up, the engine

coolant temperature

sensor signal indicates

that the engine coolant

temperature drops.

22Crankshaft Though the engine is cranking (1) The crankshaft position sensor

l Engine s,tOp

position4 seconds or more, the signal is troubled.0 Starting Is

sensor

voltage of the crankshaft (2) Open-circuit, short-circuit or

impossible.

position sensor does not vary improper connector contact

(to be high/low). occurs in the crankshaft

position sensor circuit.

(3) The engine control module is

troubled.

23Camshaft Though the engine is running,

(1) The camshaft pOSitiOn

Sensor iSl Engine stoP*position the signal voltage of the troubled.

sensor camshaft position sensor does

(2) Open-circuit, short-circuit or

not vary (to be high/low). improper connector contact

occurs in the camshaft position

sensor circuit.

(3) The engine control module is

troubled.

24Vehiclespeed

sensor

(reed

switch) During acceleration of engine

(1) The vehicle speed sensor is The engine

revolution speed of 3,000 rpm troubled.sometimes cuts off

or more, the signal voltage of (2) Open-circuit, short-circuit or when stopping after

the vehicle speed sensor does improper connector contact

deceleration.

not vary (to be high/low). occurs in the vehicle speed

sensor circuit.

(3) The engine control module is

troubled.

II1 TSB RevisionI

c

Page 355 of 1273

FUEL SYSTEM

PROBLEM SYMPTOMS TABLE(FORYOUR

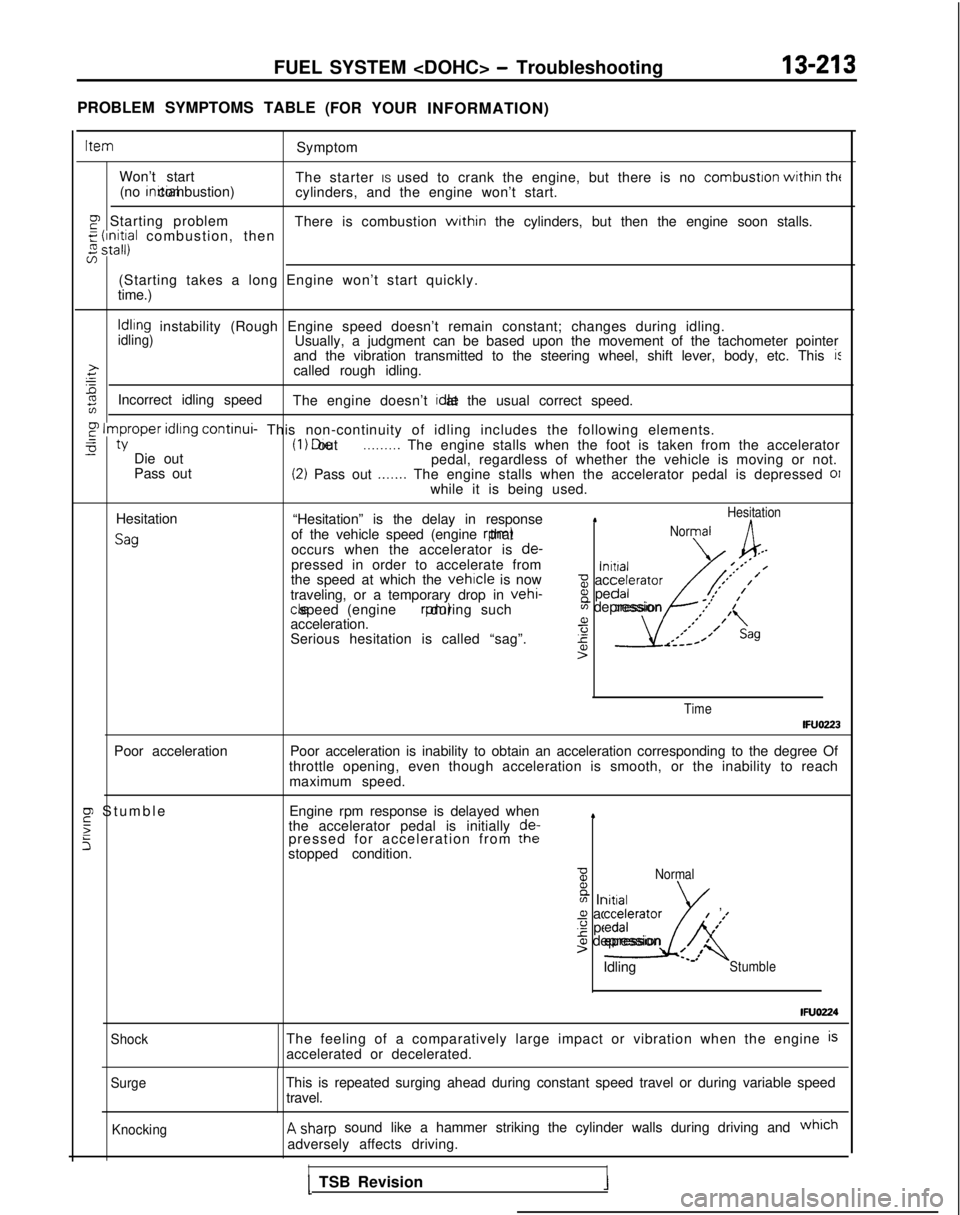

INFORMATION) Item

Symptom

Won’t start The starter IS used to crank the engine, but there is no combustron

withrn

tht(no inrtial combustion)

cylinders, and the engine won’t start.

p Starting problem There is combustion within the cylinders, but then the engine soon stalls.g

$$a combustion, then

5

(Starting takes a long Engine won’t start quickly.

time.)

Idling instability (Rough Engine speed doesn’t remain constant; changes du\

ring idling.idling)Usually, a judgment can be based upon the movement of the tachometer poi\

nter

and the vibration transmitted to the steering wheel, shift lever, body, \

etc. This i:>.ccalled rough idling.=

%zIncorrect idling speed The engine doesn’t Idle at the usual correct speed.

F

Improper

idling continui-

This non-continuity of idling includes the following elements.-0tY (I 1 Die out .._.__... The engine stalls when the foot is taken from the accelerator-Die out

pedal, regardless of whether the vehicle is moving or not.

Pass out(2) Pass out .._.... The engine stalls when the accelerator pedal is depressed 01while it is being used.

Hesitation

Sag

“Hesitation” is the delay in response1Hesitation

of the vehicle speed (engine rpm) thatNormal

occurs when the accelerator is

de-,--pressed in order to accelerate from\alnrtral-’‘** /the speed at which the vehicle is nowz accelerator,’ ’

traveling, or a temporary drop in vehi-8 pedal/*’

,’ ,’

cle speed (engine rpm) during such

acceleration. a

Serious hesitation is called “sag”.

4sAK

m depression .I’

1’

,’*;’ I(,

r-----

4’>

Time

IFUOZ23

Poor acceleration Poor acceleration is inability to obtain an acceleration corresponding t\

o the degree Of

throttle opening, even though acceleration is smooth, or the inability t\

o reach maximum speed.

F Stumbl

e

5

5

Engine rpm response is delayed when

the accelerator pedal is initially de-

pressed for acceleration from the

stopped condition.4

BNormal B

m Initiala acceleratorg pedal

I

’

-2

/#’

01 depression4t’>’ /Idling L’Stumble

IFUO224

ShockThe feeling of a comparatively large impact or vibration when the engine\

isaccelerated or decelerated.

SurgeThis is repeated surging ahead during constant speed travel or during va\

riable speed

travel.

KnockingA sharp sound like a hammer striking the cylinder walls during driving and which

adversely affects driving.

II1 TSB Revision1

Page 432 of 1273

13-290FUEL SYSTEM

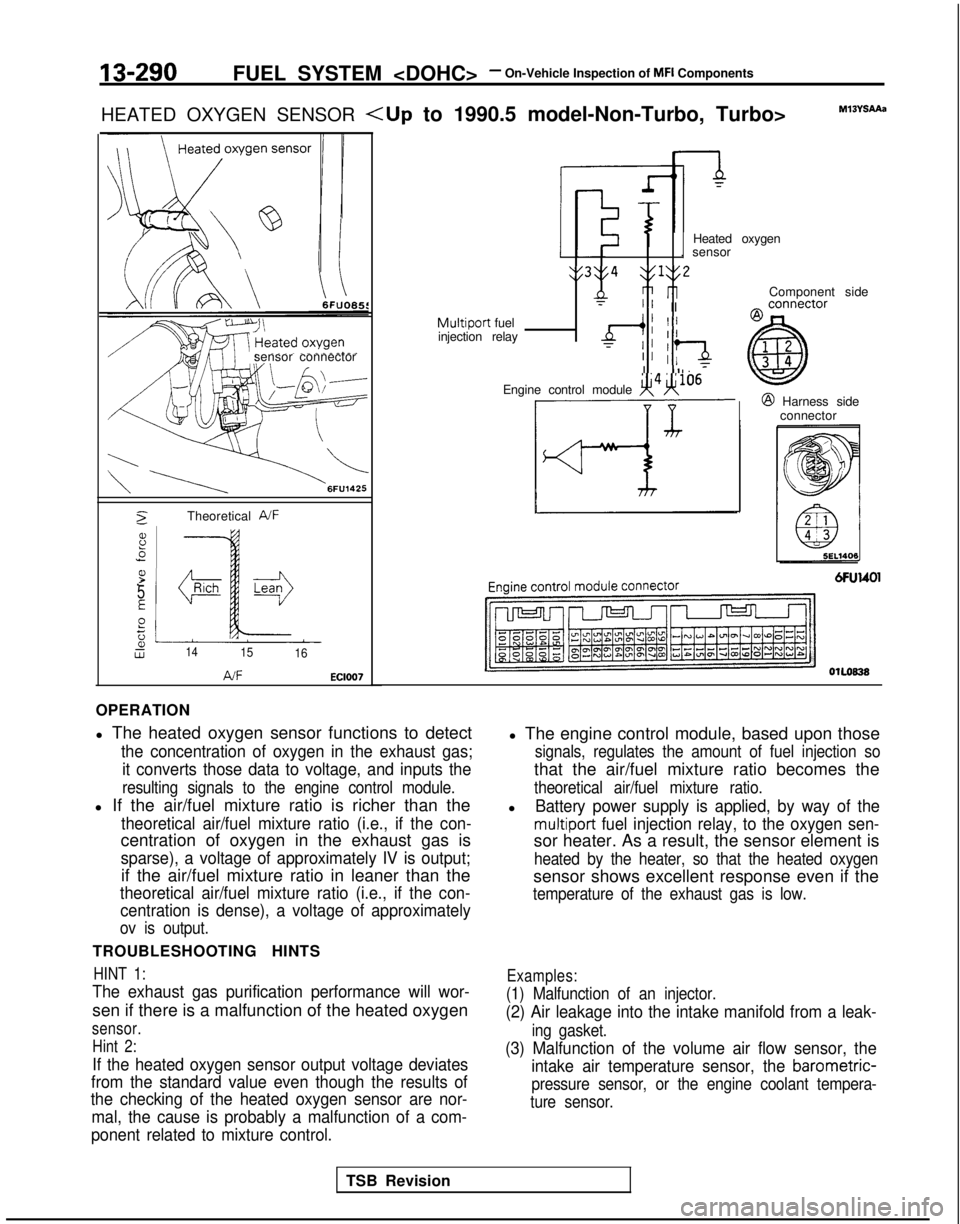

HEATED OXYGEN SENSOR

sensor connector

2Theoretical A/F

8.5

P.-

5

E

Pt;2Lw1415 16

AJFEC1007

Component side

Heated oxygen

. sensor

y3y4 $1y2

nri rlT” IIMultiport fuel

injection relayd; II

TII :‘aII Il. 7

Engine control module x4H106@ Harness side

connector

OlLoB38

OPERATION

l The heated oxygen sensor functions to detect

the concentration of oxygen in the exhaust gas;

it converts those data to voltage, and inputs the

resulting signals to the engine control module.

l If the air/fuel mixture ratio is richer than the

theoretical air/fuel mixture ratio (i.e., if the con-

centration of oxygen in the exhaust gas is

sparse), a voltage of approximately IV is output;

if the air/fuel mixture ratio in leaner than the

theoretical air/fuel mixture ratio (i.e., if the con-centration is dense), a voltage of approximately

ov is output.

TROUBLESHOOTING HINTS

HINT 1:

The exhaust gas purification performance will wor-

sen if there is a malfunction of the heated oxygen

sensor.

Hint 2:

If the heated oxygen sensor output voltage deviates

from the standard value even though the results of

the checking of the heated oxygen sensor are nor-

mal, the cause is probably a malfunction of a com-

ponent related to mixture control.

l The engine control module, based upon those

signals, regulates the amount of fuel injection so

that the air/fuel mixture ratio becomes the

theoretical air/fuel mixture ratio.

lBattery power supply is applied, by way of the

multiport fuel injection relay, to the oxygen sen-

sor heater. As a result, the sensor element is

heated by the heater, so that the heated oxygen

sensor shows excellent response even if the

temperature of the exhaust gas is low.

Examples:

(1) Malfunction of an injector.

(2) Air leakage into the intake manifold from a leak-

ing gasket.

(3) Malfunction of the volume air flow sensor, the intake air temperature sensor, the

barometric-

pressure sensor, or the engine coolant tempera-

ture sensor.

TSB Revision

Page 467 of 1273

FUEL SYSTEM

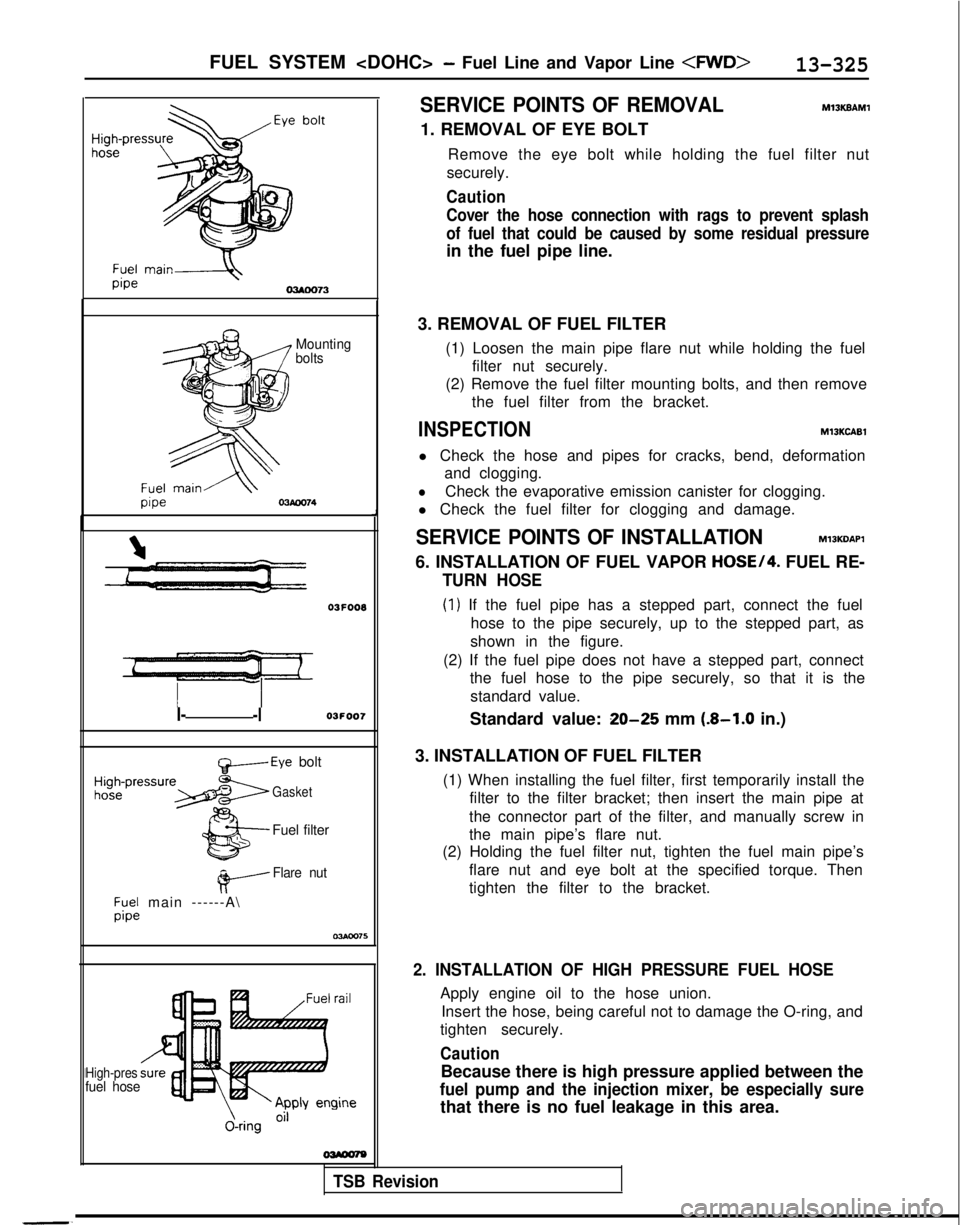

Mounting

bolts 03F008

I--l03FOO7Standard value: 20-25 mm (8-1.0 in.)

t&-----Eye bolt

Gasket

Fuel filter

#-----

Flare nut

;y;; main ------A\

J

I

-.

High-presfuel hose

J-ring

O”

SERVICE POINTS OF REMOVALMlSKBAMl

1. REMOVAL OF EYE BOLT

Remove the eye bolt while holding the fuel filter nut

securely.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

3. REMOVAL OF FUEL FILTER (1) Loosen the main pipe flare nut while holding the fuelfilter nut securely.

(2) Remove the fuel filter mounting bolts, and then remove the fuel filter from the bracket.

INSPECTIONMlOKCABl

l Check the hose and pipes for cracks, bend, deformationand clogging.

lCheck the evaporative emission canister for clogging.

l Check the fuel filter for clogging and damage.

SERVICE POINTS OF INSTALLATIONMlJKDAPl

6. INSTALLATION OF FUEL VAPOR HOSE/4. FUEL RE-

TURN HOSE

(1) If the fuel pipe has a stepped part, connect the fuel

hose to the pipe securely, up to the stepped part, as

shown in the figure.

(2) If the fuel pipe does not have a stepped part, connect the fuel hose to the pipe securely, so that it is the

standard value.

3. INSTALLATION OF FUEL FILTER (1) When installing the fuel filter, first temporarily install thefilter to the filter bracket; then insert the main pipe at

the connector part of the filter, and manually screw in

the main pipe’s flare nut.

(2) Holding the fuel filter nut, tighten the fuel main pipe’s

flare nut and eye bolt at the specified torque. Then

tighten the filter to the bracket.

TSB Revision 2. INSTALLATION OF HIGH PRESSURE FUEL HOSE

Apply engine oil to the hose union.

Insert the hose, being careful not to damage the O-ring, and

tighten securely.

Caution

Because there is high pressure applied between the

fuel pump and the injection mixer, be especially sure

that there is no fuel leakage in this area.

Page 468 of 1273

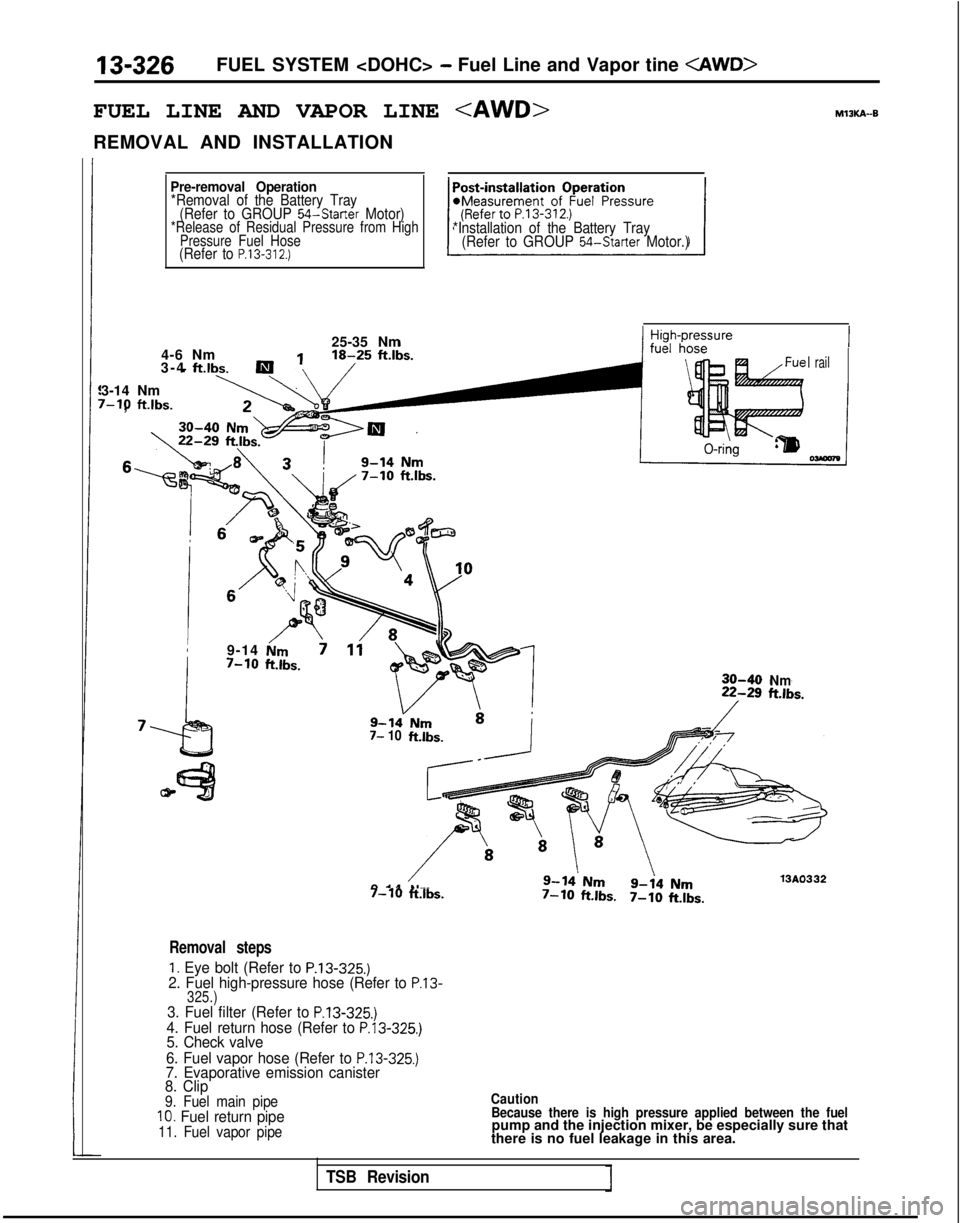

13-326FUEL SYSTEM

FUEL LINE AND VAPOR LINE

REMOVAL AND INSTALLATION

Pre-removal Operation*Removal of the Battery Tray(Refer to GROUP 54-Starter Motor)*Release of Residual Pressure from High Pressure Fuel Hose

(Refer to P.13-312.)

*Installation of the Battery Tray(Refer to GROUP 54-Starter Motor.)

25-35 Nm

4-6 Nm

3-4

ft.lbs.i

3-14 Nm v-10

ftlbs.

,

I rail

9-14rGm7-10ft.lbs.30-40Nm

7- 10 ftlbs.

13AO3329-14Nm7-10ft.lbs.7-10ft.lbs.7-10

ftlbs.

Removal steps

1. Eye bolt (Refer to P.13-325.)2. Fuel high-pressure hose (Refer to P.13-325.)3. Fuel filter (Refer to P.13-325.)4. Fuel return hose (Refer to P.13-325.)5. Check valve

6. Fuel vapor hose (Refer to

P.13-325.)7. Evaporative emission canister

8. Clip

9. Fuel main pipe10. Fuel return pipe11. Fuel vapor pipe Caution

Because there is high pressure applied between the fuelpump and the injection mixer, be especially sure that

there is no fuel leakage in this area.

TSB Revision

Page 495 of 1273

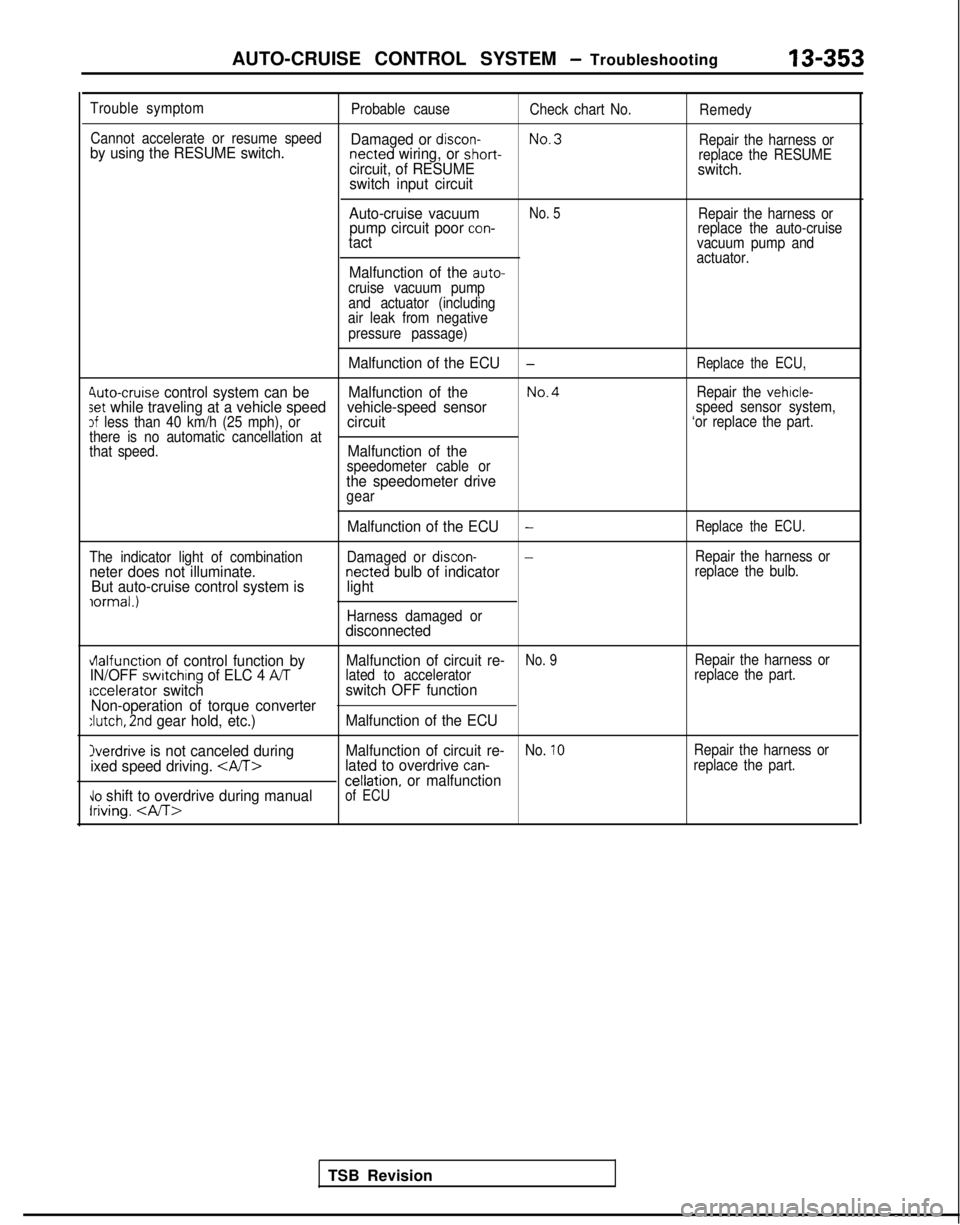

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting13-353

Trouble symptom

Probable causeCheck chart No.Remedy

Cannot accelerate or resume speed

No.3

by using the RESUME switch. Damaged or discon- netted wiring, or short-

Repair the harness orcircuit, of RESUMEreplace the RESUMEswitch.

switch input circuit

Auto-cruise vacuum

No. 5Repair the harness orpump circuit poor con-replace the auto-cruisetactvacuum pump and

actuator.

Malfunction of the auto-cruise vacuum pump

and actuator (including

air leak from negative

pressure passage)

Malfunction of the ECU-Replace the ECU,

4uto-cruise control system can be Malfunction of theNo.4Repair the vehicle-set while traveling at a vehicle speed vehicle-speed sensorspeed sensor system,3f less than 40 km/h (25 mph), orcircuit‘or replace the part.

there is no automatic cancellation at

that speed.

Malfunction of thespeedometer cable orthe speedometer drivegear

The indicator light of combination

neter does not illuminate. But auto-cruise control system is

iormal.)

Malfunction of the ECU-Replace the ECU.

Damaged or discon--Repair the harness ornetted bulb of indicatorreplace the bulb.light

Harness damaged ordisconnected

vlalfunction of control function by Malfunction of circuit re-No. 9Repair the harness orIN/OFF switchrng of ELC 4 ATlated to accelerator

replace the part.accelerator switchswitch OFF function

Non-operation of torque converter

:lutch, 2nd gear hold, etc.) Malfunction of the ECU

Overdrive is not canceled during Malfunction of circuit re-No. 10Repair the harness or

ixed speed driving. lated to overdrive can-replace the part.cellation, or malfunction\lo shift to overdrive during manualIriving.

of ECU

TSB Revision

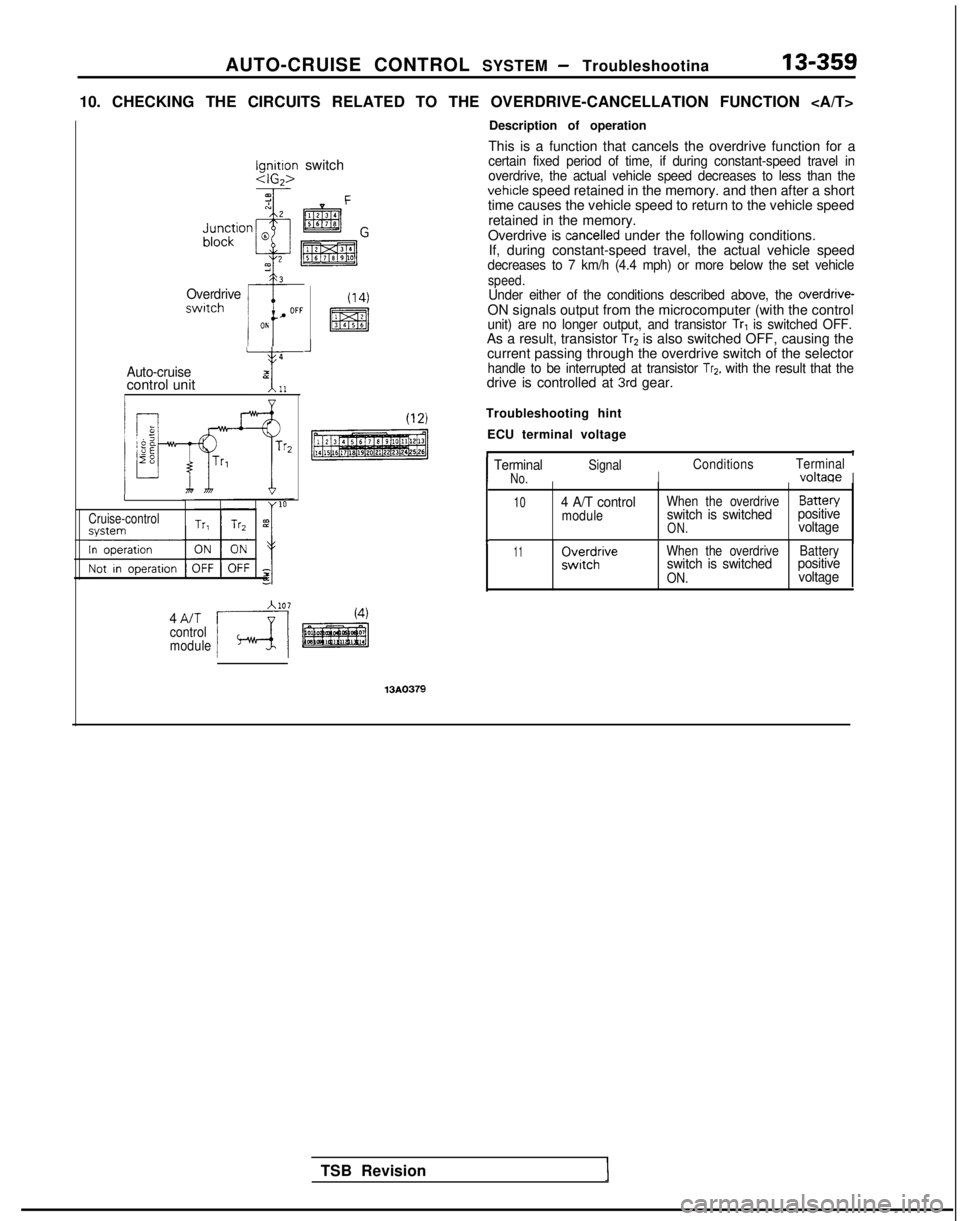

Page 501 of 1273

Page 553 of 1273

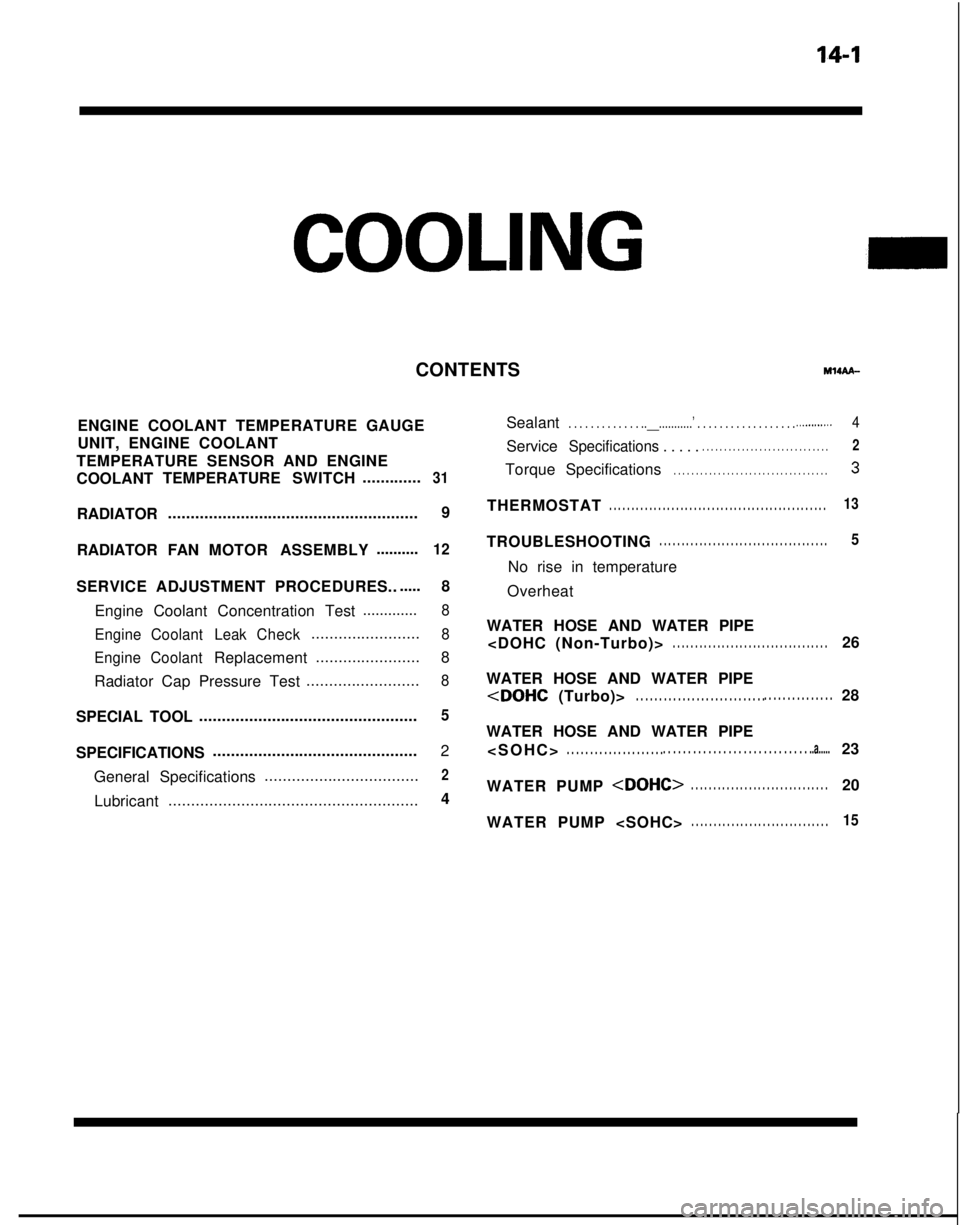

14-1

COOLING

ENGINE COOLANT TEMPERATURE GAUGE

UNIT, ENGINE COOLANT

TEMPERATURE SENSOR AND ENGINE

COOLANT TEMPERATURE

SWITCH.............

31

RADIATOR ....................................................... 9

RADIATOR FAN MOTOR ASSEMBLY ..........

12

SERVICE ADJUSTMENT PROCEDURES..

.....

8

Engine Coolant Concentration Test .............

8

Engine Coolant LeakCheck

........................8

Engine Coolant

Replacement .......................

8

Radiator Cap Pressure Test .........................

8

SPECIAL TOOL................................................5

SPECIFICATIONS .............................................

2

General Specifications ..................................

2

Lubricant

....................................................... 4

CONTENTS

IM14AA-

Sealant. . . . . . . . . . . . . ..__...........’ . . . . . . . . . . . . . \

. . . . . .._.........4

ServiceSpecifications . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Torque

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

THERMOSTAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . .13

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. .5

No rise in temperature

Overheat

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

WATER HOSE AND WATER PIPE

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..a.....23

WATER PUMP

WATER PUMP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Page 651 of 1273

21-1

CLUTCH

CONTENTS

CLUTCH CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . .10SPECIFICATIONS. . . . . . . . . . . . . . . ..*...........................2

CLUTCHMASTER CYLINDER. . . . . . . . . . . . . . . . . . . . . . . .12GeneralSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CLUTCH PEDALLubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . .3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . .7

ServiceSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CLUTCHRELEASECYLINDER. . . . . . . . . . . . . . . . . . . . . . .13Torque Specifications . . . . . . . . . .._.......................3

SERVICE ADJUSTMENT PROCEDURES . . . . . . . 5TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. .4

Bleeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6Clutch chatters

Clutch Pedal Inspection and Adjustment . . . .

5Clutch noise

Clutch pedal feels “heavy”

Clutch slips

Gear shift malfunction

CAUTION When

servicing clutch assemblies or com-

ponents for vehicles with SOHC engine

(Up to 1991 models), do NOT create dust

by sanding or by cleaning clutch parts

with a dry brush or with compressed air.

(A water dampened cloth should be used).

The clutch disc contains “Asbestos Fibers”

which can become airborne if dust is

created during service operations. Breath-

ing dust containing “Asbestos Fibers”

may cause serious bodily harm.

Page 749 of 1273

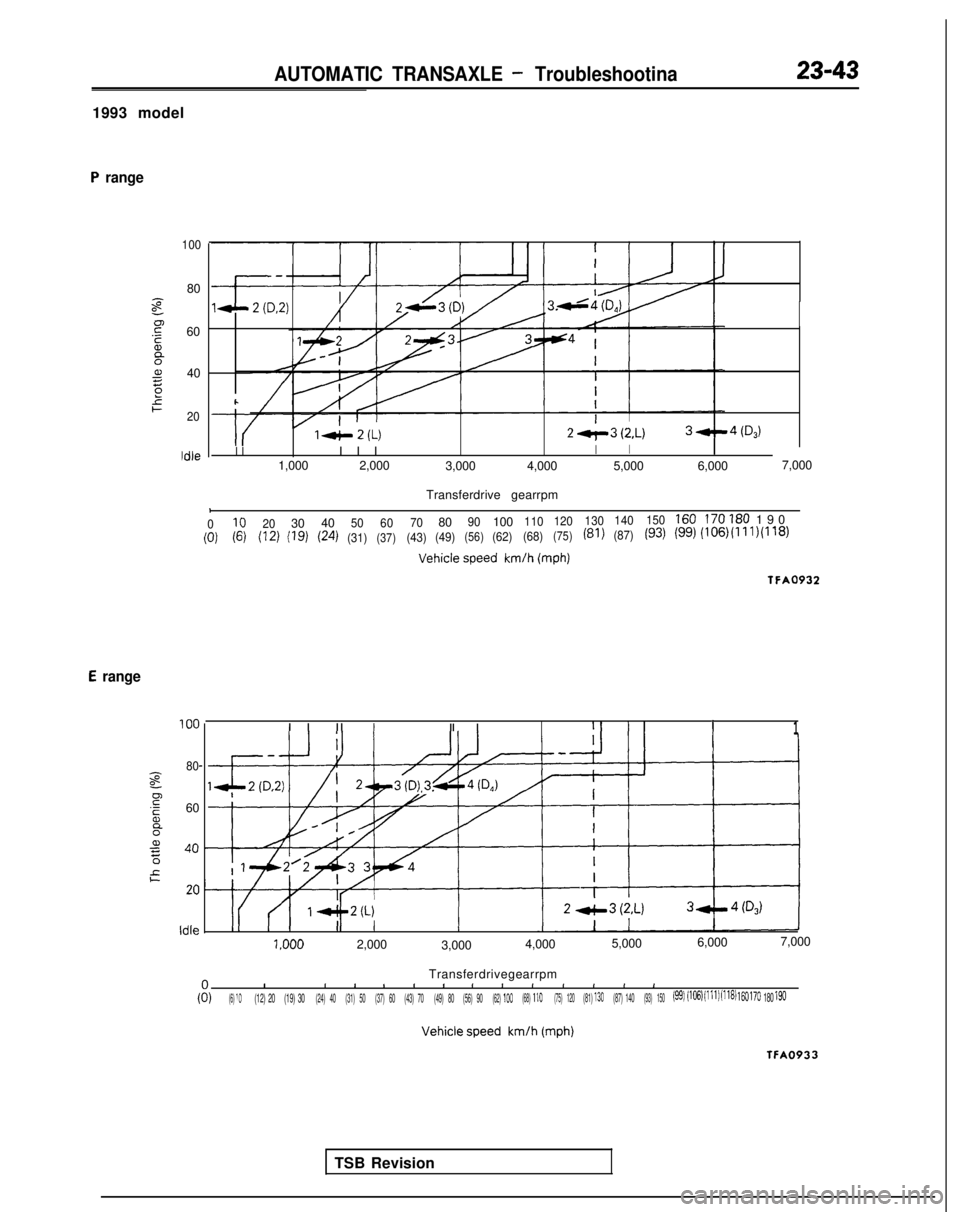

AUTOMATIC TRANSAXLE - Troubleshootina

1993 model

P range

100

80

60 40

20

Idle

1-1 2 (D.2)

c

tfI* 2(L)2-13 (2,L)3--4(b)

I II I III

1,000 2,000 3,000 4,000 5,000 6,000 7,000

Transferdrive gearrpm

1

0102030 4050 60 708090100110120 130140 150160170 180 19

0

(0)(6)(12)119)(24)(31)(37)(43)

(49)(56)(62) (68)(75)(81)(87)(93)(99) (106)(111)(118)

Vehiclespeed km/h(mph)

TFA0932

E range

31

F.-c

ti

a,

5:‘5

if

100

80

-

60 Idle

I I

II

III II1

1,0002,000

3,0004,000

5,0006,000

7,000

Transferdrivegearrpm ,

III

tIIII , , , tI(00)(6) 10(12) 20 (19) 30(24) 40 (31) 50 (37) 60

(43) 70(49) 80(56) 90(62) 100(68) 110

(75) 120(81) 130(87) 140(93) 150(99)(106)(111)(118) 160 170 180 190

Vehiclespeed km/h(mph)

TFA0933

TSB Revision