belt MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 3 of 1273

00-l

GENERAL

CONTENTS

GENERAL DATA AND SPECIFICATIONS.....23

HOWTOUSETHISMANUAL......................

3

Definition of Terms ......................................3

ExplanationofCircuitDiagrams..................7

Explanation of

ManualContents .................4

Explanation of the Troubleshooting

Guide .............................................................

6

Model

Indications .........................................3

Scope of Maintenance, Repair and

Servicing Explanations

..................................

3

Troubleshooting .............................................3

LUBRICATIONANDMAINTENANCE............

34

MAINTENANCE SERVICE............................... 39

AirCleanerElement

.....................................39

Automatic

Transaxle

.....................................43

Ball Joint and Steering Linkage Seals ........45

Brake Hoses................................................. 45

Disc Brake Pads ........................................... 44

Drive Belt (For Water Pump and

Generator) .......................................................

41

Drive

Shaft Boots .........................................45

Engine Coolant

............................................. 44

Engine Oil .....................................................

41

Engine Oil Filter ...........................................41

Exhaust System

............................................ 45

FuelHoses

...................................................39

Fuel System

.................................................39

Manual Transaxle ..........................................42

RearAxle......................................................45

Rear Drum Brake Linings and

RearWheel Cylinders

..................................44

Spark

Plugs...................................................40

Timing Belt...................................................40

MASTER

TROUBLESHOOTING.....................28

PRECAUTIONS

BEFORESERVICE................15

RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIESTABLE..................35

SCHEDULED

MAINTENANCETABLE ...........38

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS

.......................................20

TABLE OF MAIN SEALANTS

AND

ADHESIVES ............................................46

TIGHTENING TORQUE

................................... 27

TOWING

ANDHOISTING ..............................17

VEHICLE

IDENTIFICATION .............................8

Chassis Number ...........................................

11

EngineModel

Stamping

...............................12

Theft Protection ............................................12

Vehicle Identification Code Chart Plate.......

8

Vehicle Identification Number List

..............8

Vehicle Identification Number Location .......

8

Vehicle Information

CodePlate...................1 1

Vehicle SafetyCertificationLabel................12

Page 10 of 1273

00-8GENERAL - Vehicle Identification

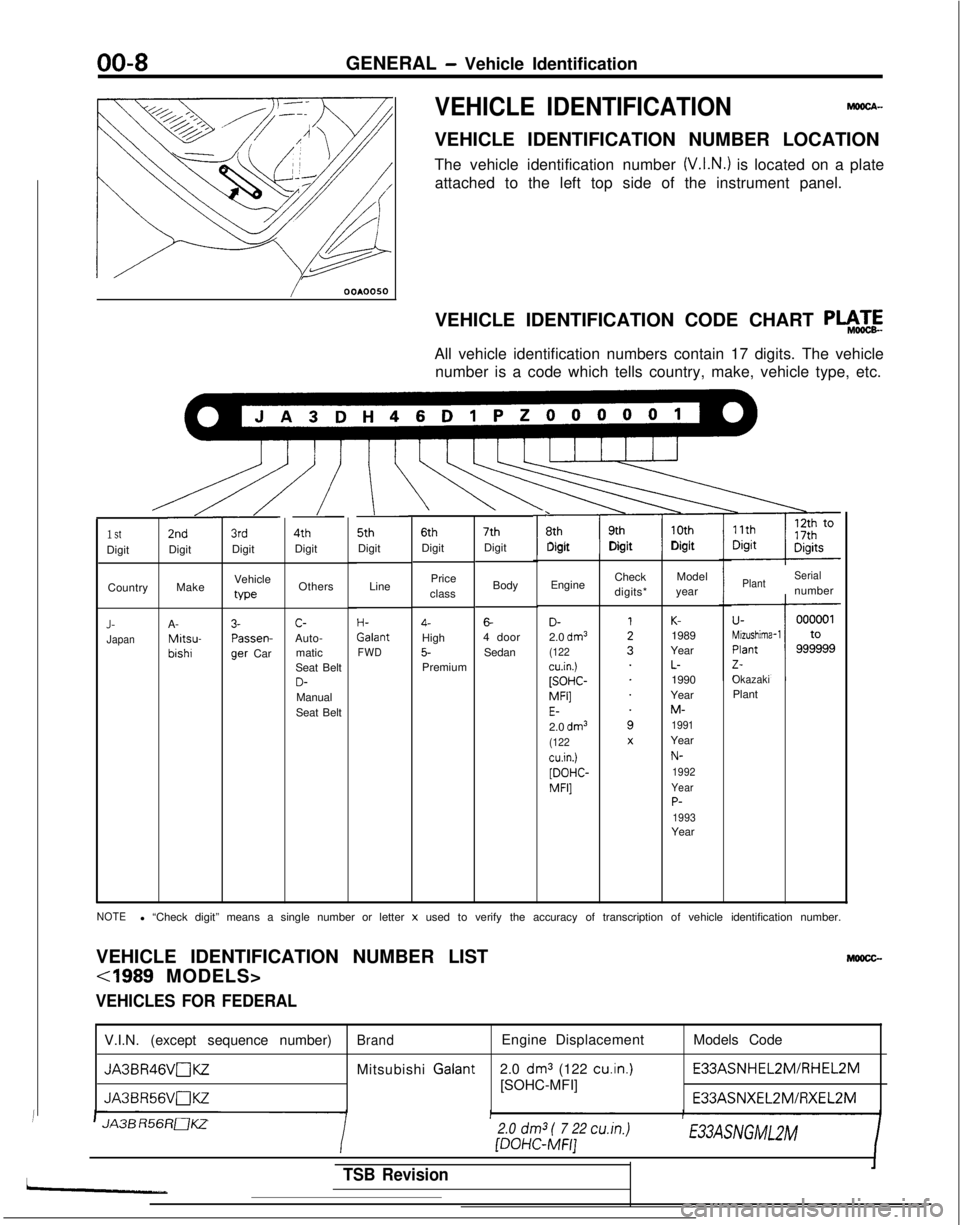

VEHICLE IDENTIFICATIONMOOCA-

VEHICLE IDENTIFICATION NUMBER LOCATION

The vehicle identification number

(V.I.N.) is located on a plate

attached to the left top side of the instrument panel.

/ OOAOOSO

VEHICLE IDENTIFICATION CODE CHART

P+zE

All vehicle identification numbers contain 17 digits. The vehiclenumber is a code which tells country, make, vehicle type, etc.

\ \\L\.u 5th 6th 7th

r\ 8th 9th 10th

Digit DigitDigitDigit Digit

Digit

I

3rdDigit

/

4thDigit

/ 2nd

Digit

Line

H- Galant

FWD

1 StDigit

Body

6-4 doorSedan

Price

class4-High5-Premium Engine

Check

digits*Model

year

Make Vehicle

typeOthersPlantSerialnumber

Country

OkazakiPlant

D-2.0 dm3(122cu.in.)[SOHC- MFI]

E-2.0 dm3(122cu.in.)[DOHC-

MFI]

K-1989

Year

L-1990

Year

M-1991Year

N-

1992

Year

P-1993Year

J-JapanA- Mitsu-

bishr

3- Passen-

9er

Car c-

Auto- matic

Seat Belt

D-Manual

Seat Belt

NOTEl “Check digit” means a single number or letter x used to verify the accuracy of transcription of vehicle identification \

number.

VEHICLE IDENTIFICATION NUMBER LIST

Mlmcc-

VEHICLES FOR FEDERAL

V.I.N. (except sequence number)BrandEngine Displacement Models Code

JA3BR46VnKZMitsubishi Galant

2.0 dm3 (122 cu.in.) E33ASNHEL2M/RHEL2M

JA3BR56VaKZ[SOHC-MFI]

E33ASNXEL2MlFiXEL2M

JA3B R56RaKZ

/

2.0

dm3

( 7 22 cu.in.) [DOHC-MFI]E33ASNGMLZM

TSB Revision

Page 32 of 1273

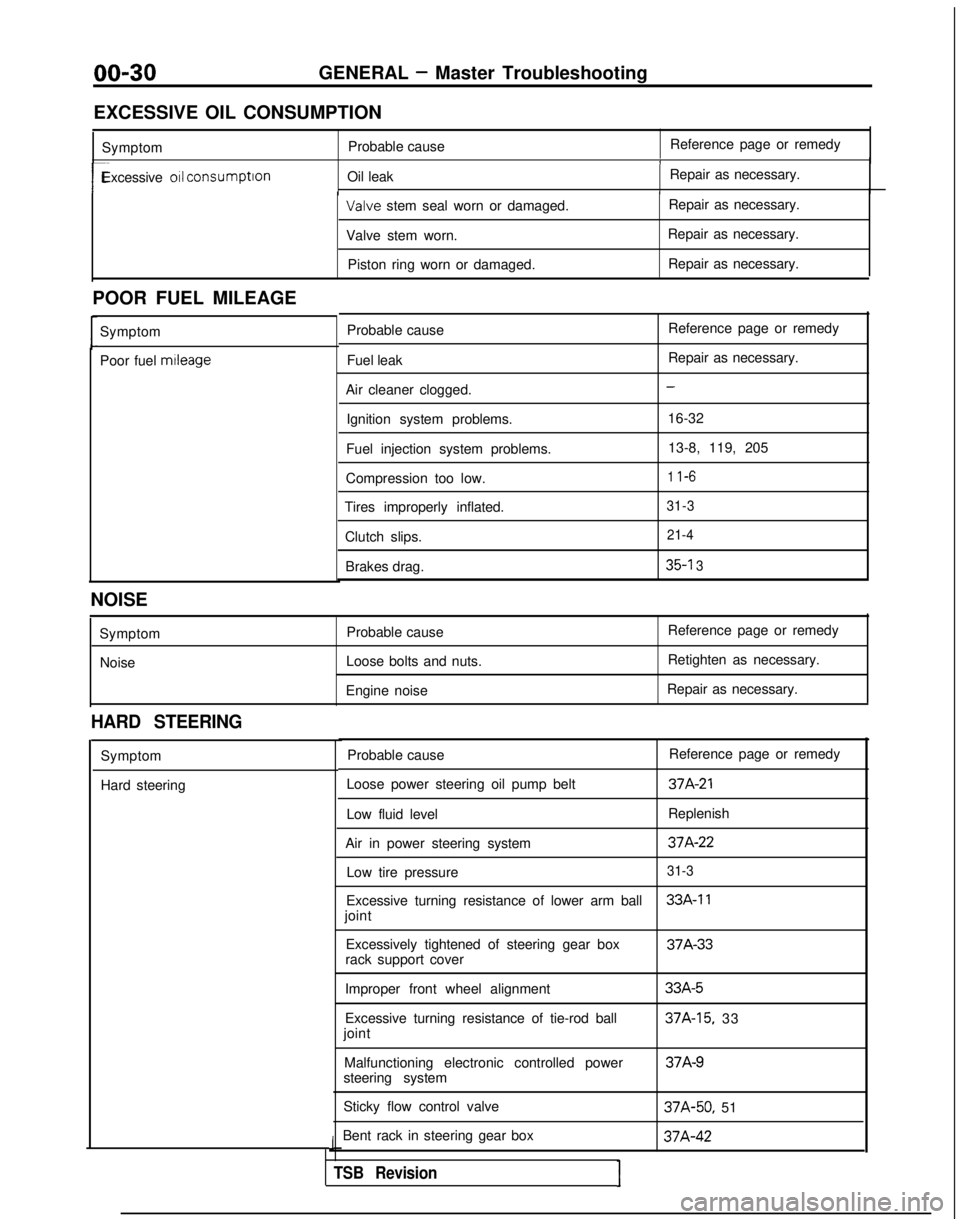

00-30GENERAL - Master Troubleshooting

EXCESSIVE OIL CONSUMPTION Symptom Probable cause Reference page or remedy

1

r-Excessive 011 consumption

Oil leak Repair as necessary.I Valve

stem seal worn or damaged. Repair as necessary.

Valve stem worn. Repair as necessary.

Piston ring worn or damaged. Repair as necessary.

POOR FUEL MILEAGE Symptom

Poor fuel mtleage

Probable cause

Fuel leak

Air cleaner clogged. Ignition system problems.

Fuel injection system problems.

Compression too low.

Tires improperly inflated.

Clutch slips.Brakes drag. Reference page or remedy

Repair as necessary.

-

16-32

13-8, 119, 205

1 l-6

31-3 21-4

35-l 3

NOISE

SymptomNoise Probable cause

Loose bolts and nuts.

Engine noise Reference page or remedy

Retighten as necessary.

Repair as necessary.

HARD STEERING

Symptom

Hard steering Probable cause

Reference page or remedy

Loose power steering oil pump belt

37A-21

Low fluid level Replenish

Air in power steering system

37A-22

Low tire pressure31-3

Excessive turning resistance of lower arm ball33A-11

joint Excessively tightened of steering gear box 37A-33

rack support cover

Improper front wheel alignment

Excessive turning resistance of tie-rod ball

joint

Malfunctioning electronic controlled power

steering system

Sticky flow control valve

Bent rack in steering gear box

J

TSB RevisionI

33A-5

37A-15, 33 37A-9

37A-50,

51 37A-42

Page 40 of 1273

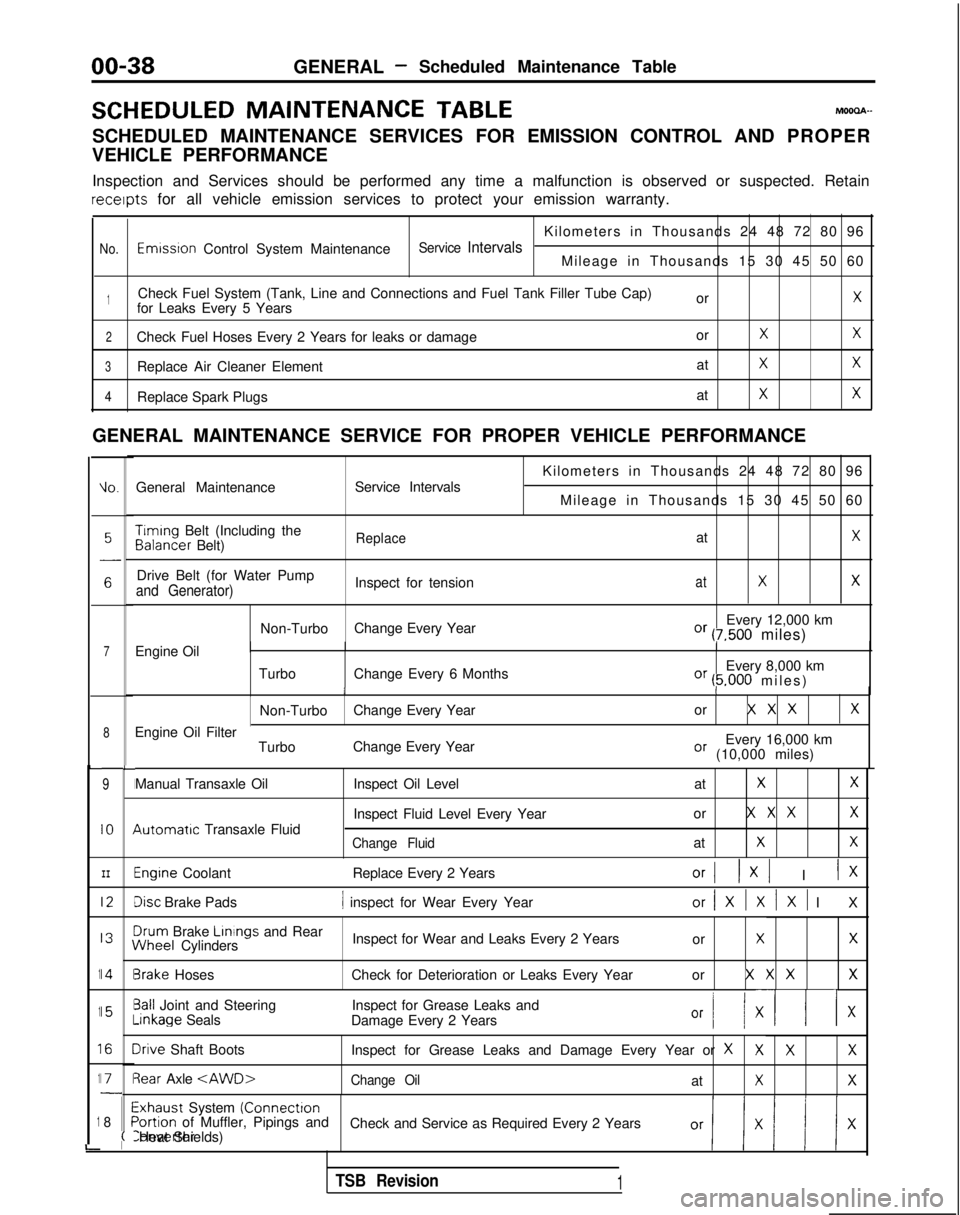

00-38GENERAL- Scheduled Maintenance Table

SCHEDULED MAINTENANCE

TABLEMOOOA-

SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PROPER

VEHICLE PERFORMANCE

Inspection and Services should be performed any time a malfunction is ob\

served or suspected. Retain receipts

for all vehicle emission services to protect your emission warranty.

Kilometers in Thousands 24 48 72 80 96

No.Emwsron Control System MaintenanceService IntervalsMileage in Thousands 15 30 45 50 60

1Check Fuel System (Tank, Line and Connections and Fuel Tank Filler Tube\

Cap) orXfor Leaks Every 5 Years

2Check Fuel Hoses Every 2 Years for leaks or damage orXX

3Replace Air Cleaner ElementatXX

4Replace Spark PlugsatXX

GENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

L

1

1

1

1

1

i

IO.General Maintenance

Service Intervals

7Engine Oil

8

9

IO

III2

I3

14

15

I6

I71

8

L

I

I

I

I

I\

I

II

I

I

;(

Kilometers in Thousands 24 48 72 80 96

Mileage in Thousands 15 30 45 50 60 Timing

Belt (Including the Balancer

Belt)

ReplaceatX

Drive Belt (for Water Pump

Inspect for tensionatXXand Generator)

Non-TurboChange Every Year Every 12,000 kmOr (7,500 miles)

Turbo Change Every 6 Months Every 8,000 km

Or (5.000 miles

)

II

Non-Turbo

Change Every Year or X X XX

Every 16,000 kmOr (10,000 miles)

Engine Oil Filter

TurboChange Every Year

Manual Transaxle Oil 4utomatrc

Transaxle Fluid Inspect Oil Level

at

XX

Inspect Fluid Level Every Yearor X X XX

Change FluidatXX

Engine Coolant

Replace Every 2 YearsOrI 1x1 I IX

Disc Brake Pads1 inspect for Wear Every Yearor/XlXlXl I

X

3rum

Brake Linings

and Rear iNheel

Cylinders Inspect for Wear and Leaks Every 2 Years

or

XX

3rake HosesCheck for Deterioration or Leaks Every Year or X X XX

3all Joint and SteeringInspect for Grease Leaks and-inkage

Seals

Damage Every 2 Years

Or I/ XII x

Irive Shaft Boots Inspect for Grease Leaks and Damage Every Year or XXXX

3ear Axle

Exhaust System (Connectron>ortion of Muffler, Pipings and

Check and Service as Required Every 2 YearsConverter Heat Shields)

TSB Revision1

Page 42 of 1273

00-40GENERAL- Maintenance Service

Caution

The air cleaner cover should be removed carefully,

because it includes the volume air flow sensor.

/

(5) Remove the air cleaner element.(6) Set a new air cleaner element and install the air cleaner cover.

I hose,I

Plug gapgauge

Measurementrection01

If

0110182

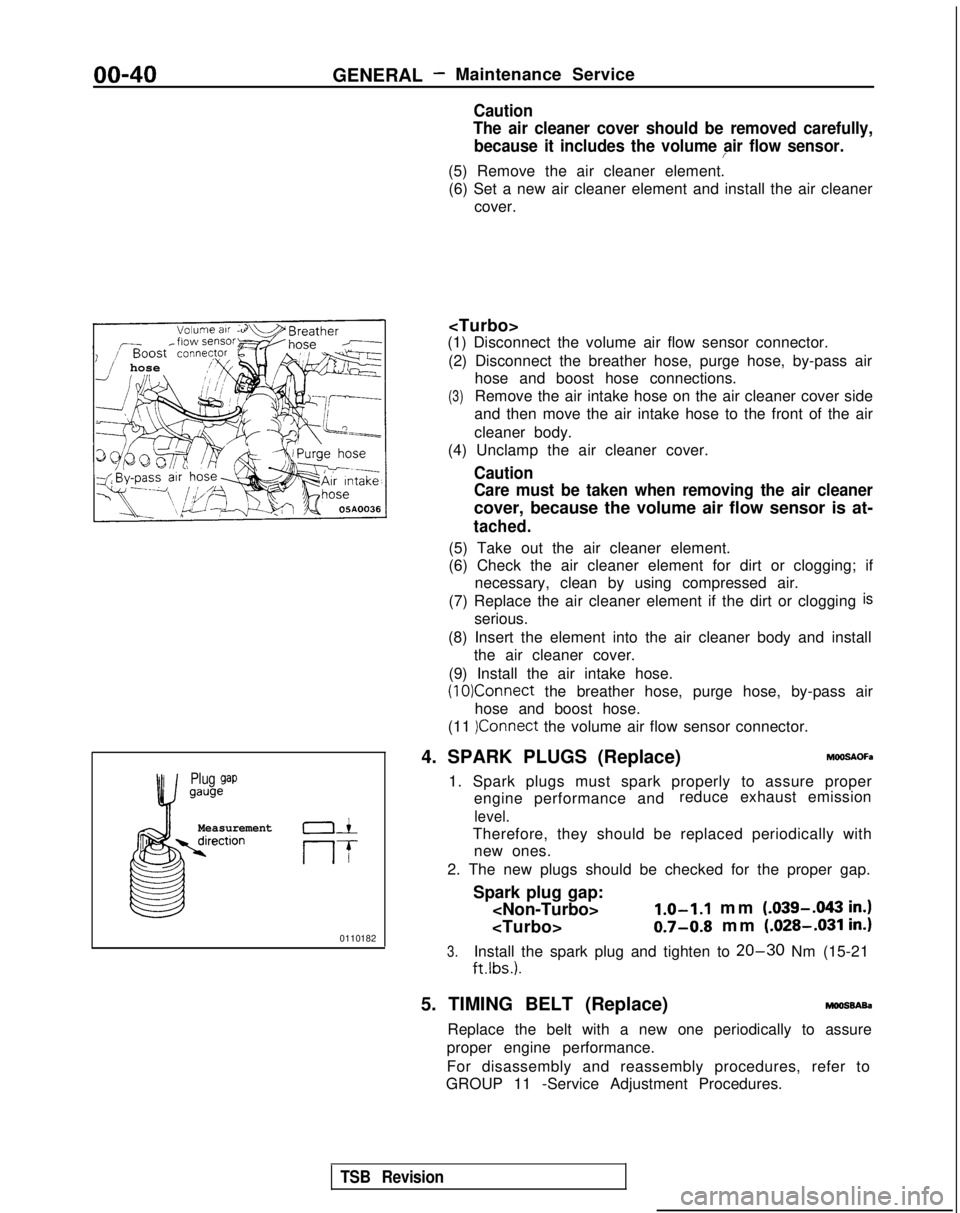

(1) Disconnect the volume air flow sensor connector.

(2) Disconnect the breather hose, purge hose, by-pass air hose and boost hose connections.

(3)Remove the air intake hose on the air cleaner cover side

and then move the air intake hose to the front of the air

cleaner body.

(4) Unclamp the air cleaner cover.

Caution

Care must be taken when removing the air cleaner

cover, because the volume air flow sensor is at-

tached.

(5) Take out the air cleaner element.

(6) Check the air cleaner element for dirt or clogging; if necessary, clean by using compressed air.

(7) Replace the air cleaner element if the dirt or clogging

is

serious.

(8) Insert the element into the air cleaner body and install the air cleaner cover.

(9) Install the air intake hose.

(10)Connect the breather hose, purge hose, by-pass air

hose and boost hose.

(11

)Connect the volume air flow sensor connector.

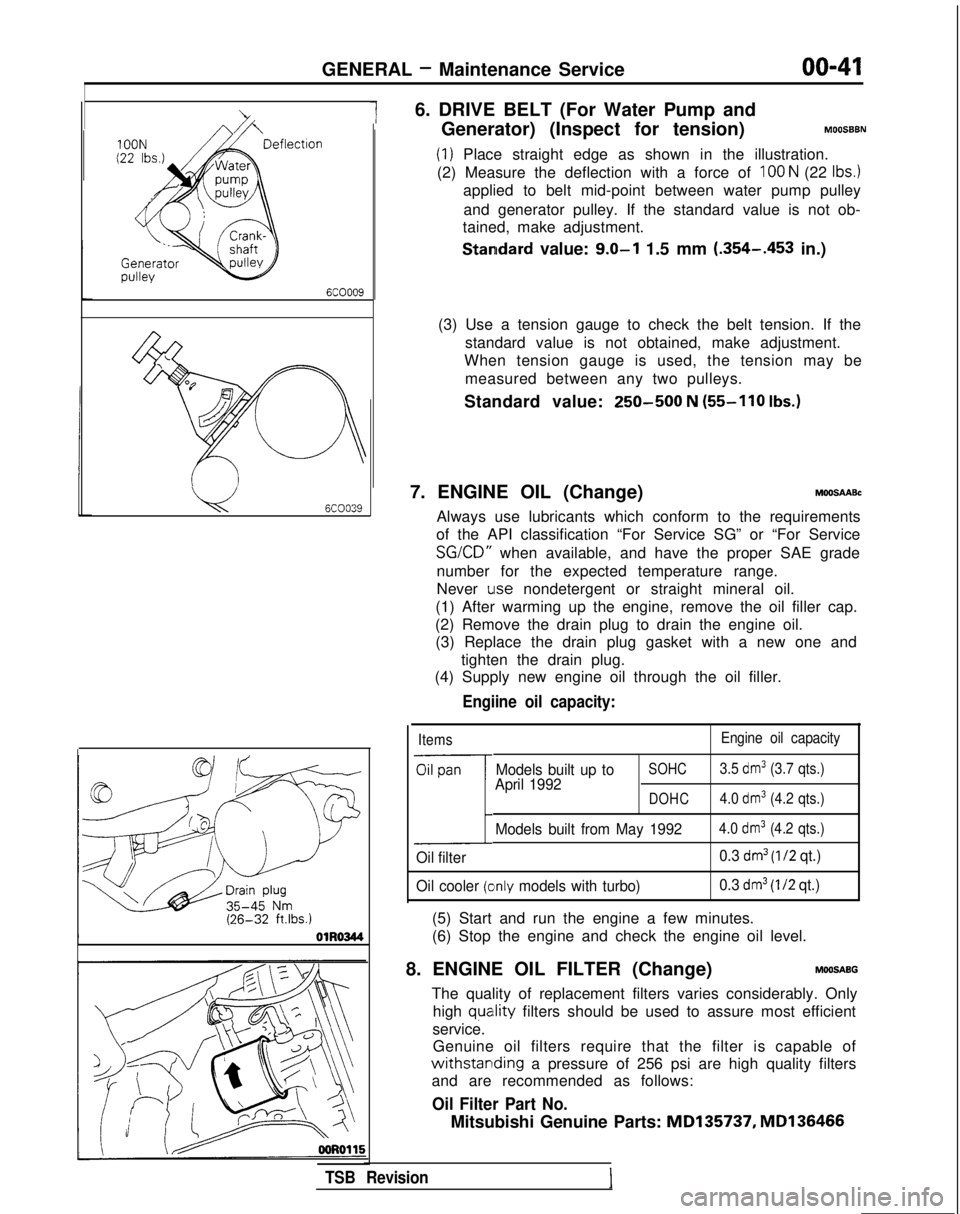

4. SPARK PLUGS (Replace)

h%OSAOFa

1. Spark plugs must spark properly to assure proper engine performance and reduce exhaust emission

level.

Therefore, they should be replaced periodically with

new ones.

2. The new plugs should be checked for the proper gap.

Spark plug gap:

mm (.039-.043

in.)

0.7-0.8 mm (.028-.031 in.)

3.Install the spark plug and tighten to 20-30 Nm (15-21

ftlbs.).

5. TIMING BELT (Replace)moossAsa

Replace the belt with a new one periodically to assure

proper engine performance.

For disassembly and reassembly procedures, refer to

GROUP 11 -Service Adjustment Procedures.

TSB Revision

Page 43 of 1273

GENERAL - Maintenance Service00-41

-1

6COOO9

L!6COO39

OlR0344

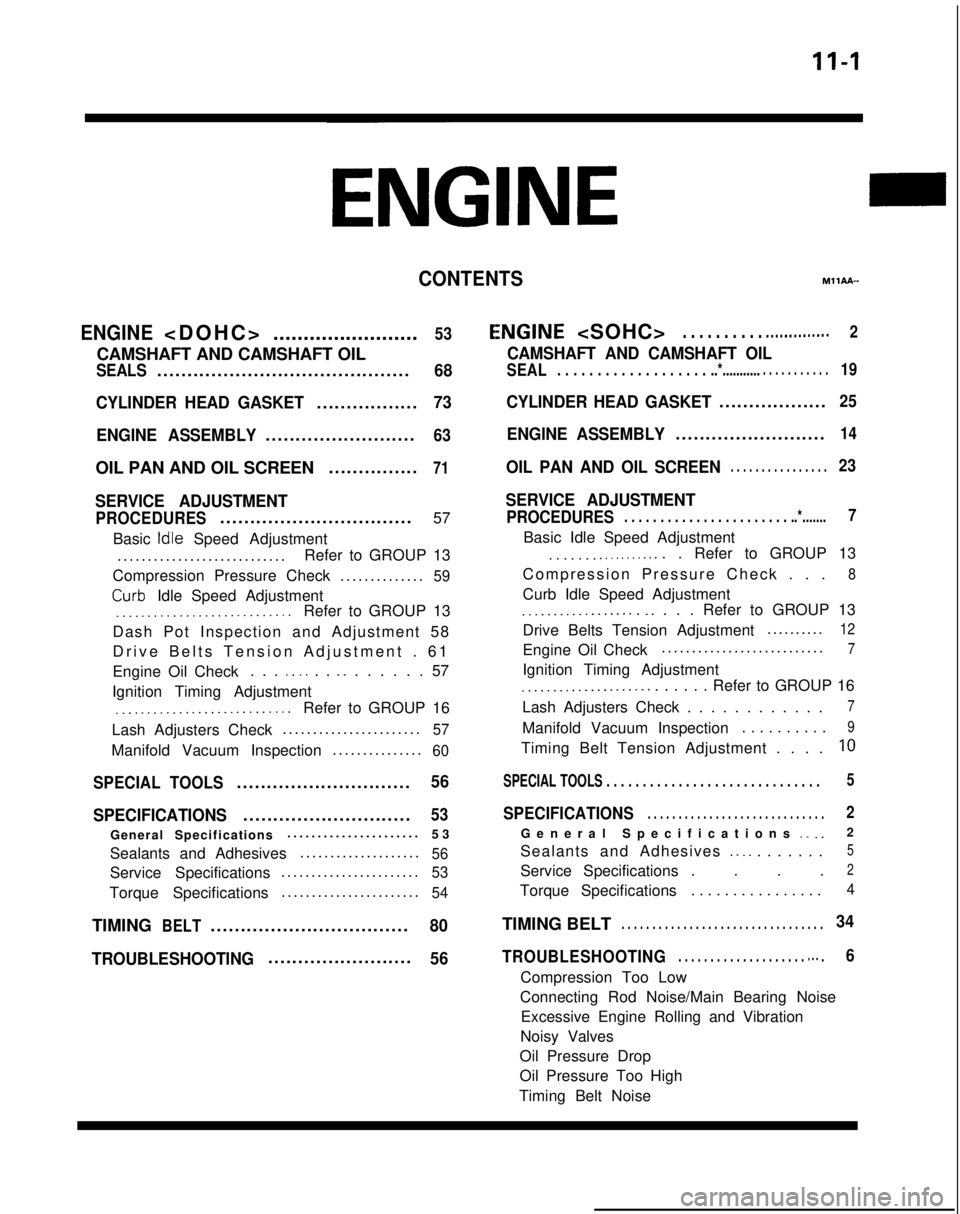

6. DRIVE BELT (For Water Pump and

Generator) (Inspect for tension)

MOOSBBN

(1) Place straight edge as shown in the illustration.

(2) Measure the deflection with a force of

100 N (22 Ibs.)

applied to belt mid-point between water pump pulley

and generator pulley. If the standard value is not ob-

tained, make adjustment.

Standard value: 9.0-l 1.5 mm (.354-.453

in.)

(3) Use a tension gauge to check the belt tension. If the standard value is not obtained, make adjustment.

When tension gauge is used, the tension may be

measured between any two pulleys.

Standard value:

250-500 N (55-110

Ibs.)

7. ENGINE OIL (Change)MOOSAABc

Always use lubricants which conform to the requirements

of the API classification “For Service SG” or “For Service SG/CD”

when available, and have the proper SAE grade

number for the expected temperature range.

Never

Lose nondetergent or straight mineral oil.

(1) After warming up the engine, remove the oil filler cap.

(2) Remove the drain plug to drain the engine oil. (3) Replace the drain plug gasket with a new one and

tighten the drain plug.

(4) Supply new engine oil through the oil filler.

Engiine oil capacity:

Items Engine oil capacity

Oil pan

1

Models built up toSOHC3.5 dm3 (3.7 qts.)

April 1992DOHC4.0 dm3 (4.2 qts.)

Models built from May 19924.0 dm3 (4.2 qts.)

Oil filter 0.3 dm3 (l/2 qt.)

Oil cooler

(clnly models with turbo) 0.3 dm3 (I/2 qt.)

(5) Start and run the engine a few minutes.

(6) Stop the engine and check the engine oil level.

8. ENGINE OIL FILTER (Change)

MOOSABG

The quality of replacement filters varies considerably. Only high

quatlity filters should be used to assure most efficient

service. Genuine oil filters require that the filter is capable of

withstarlding a pressure of 256 psi are high quality filters

and are recommended as follows:

Oil Filter Part No.

Mitsubishi Genuine Parts: MD135737,

MD136466

TSB Revision

Page 51 of 1273

11-I

CONTENTSM11AA-

ENGINE

........................

53

CAMSHAFT AND CAMSHAFT OIL

SEALS..........................................68

CYLINDER HEAD GASKET

.................73

ENGINE ASSEMBLY

.........................63

OIL PAN AND OIL SCREEN ...............71

SERVICE ADJUSTMENT

PROCEDURES................................

57

Basic

Idle Speed Adjustment

...........................

.

Refer to GROUP 13

Compression Pressure Check ..............

59

Curb- Idle Speed Adjustment_.___..__._____....___._....Refer to GROUP 13

Dash Pot Inspection and Adjustment 58

Drive Belts Tension Adjustment . 6

1

Engine Oil Check . . .

_. _. . . _. . . . . . . 57

Ignition Timing Adjustment

__..._.__...................Refer to GROUP 16

Lash Adjusters Check ......................

.

57

Manifold Vacuum Inspection

..............

.

60

SPECIAL TOOLS.............................56

SPECIFICATIONS

............................53

General Specifications .....................

.

53

Sealants and Adhesives ....................

56

Service Specifications......................

.

53

Torque Specifications

......................

.

54

TIMINGBELT.................................80

TROUBLESHOOTING

........................56

E,NGINE

CAMSHAFT AND CAMSHAFT OIL

SEAL. . . . . . . . . . . . . . . . . . . ..*............ . . . . . . . . . .19

CYLINDER HEAD GASKET..................25

ENGINE ASSEMBLY.........................14

OIL PAN AND OIL SCREEN. . . . . . . . . . . . . . . .23

SERVICE ADJUSTMENT

PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . ..*.......7

Basic Idle Speed Adjustment

. . . . . . . .._......... . Refer to GROUP 13

Compression Pressure Check . .

.

8

Curb Idle Speed Adjustment

.__................ _. . . . Refer to GROUP 13

Drive Belts Tension Adjustment .........

.

12

Engine Oil Check

..........................

.

7

Ignition Timing Adjustment

_...___............... . . . . . Refer to GROUP 16

Lash Adjusters Check . . . . . . . . . . . .

7

Manifold Vacuum Inspection . . . . . . . . . .9

Timing Belt Tension Adjustment . . . .10

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

.5

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Specifications _. _.2

Sealants and Adhesives

._ _. . . . . . . .5

Service Specifications . . . .2

Torque Specifications . . . . . . . . . . . . . . . .4

TIMING BELT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . m.. .6

Compression Too Low

Connecting Rod Noise/Main Bearing Noise Excessive Engine Rolling and Vibration

Noisy Valves

Oil Pressure Drop

Oil Pressure Too High

Timing Belt Noise

Page 52 of 1273

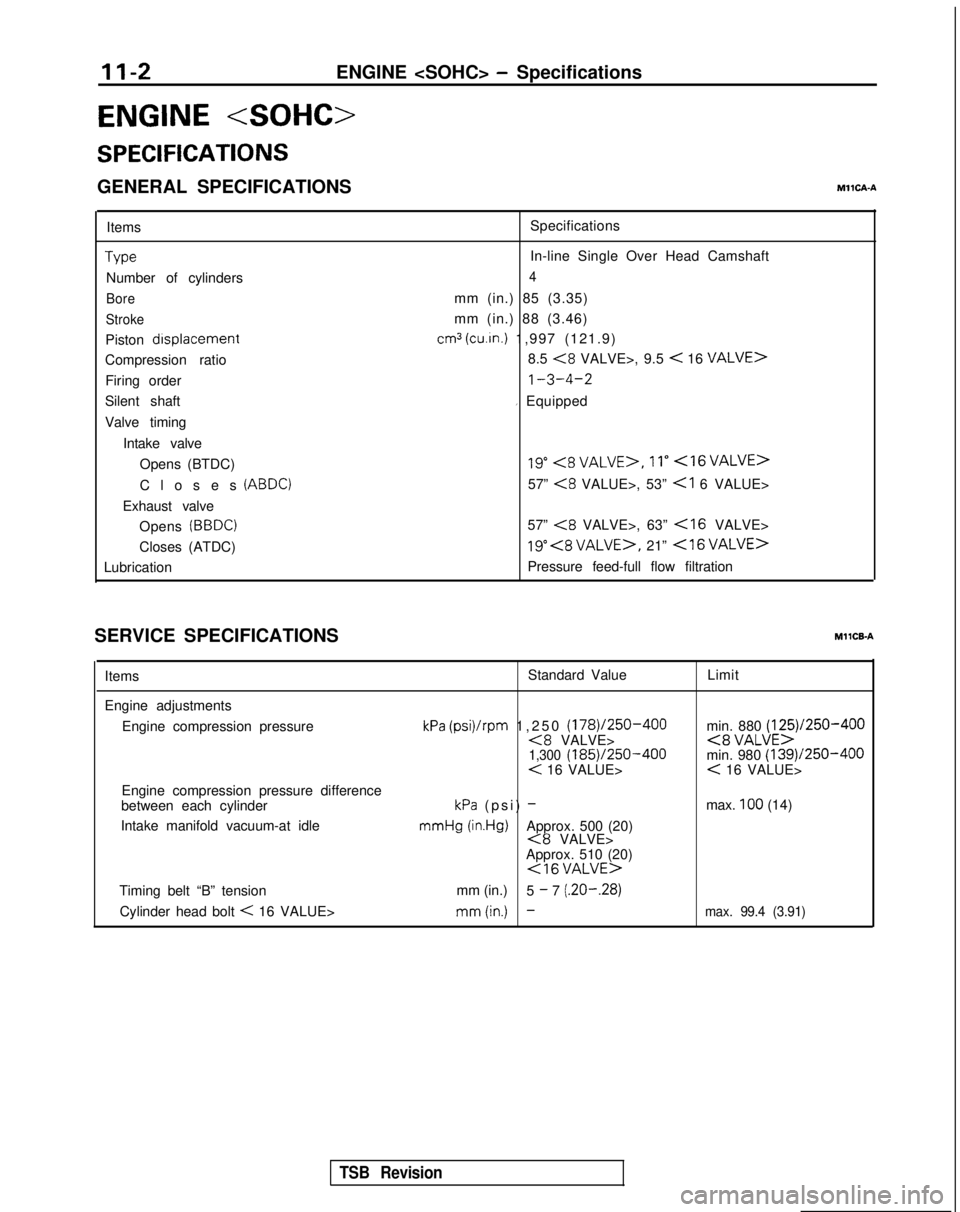

11-2ENGINE

ENGINE

SPECIFICATIONS

GENERAL SPECIFICATIONSMllCA-A

ItemsType

Number of cylinders

Bore

Stroke

Piston drsplacement

Compression ratio

Firing order

Silent shaft

Valve timing

Intake valveOpens (BTDC)

Closes

(ABDC)

Exhaust valveOpens

(BBDC)

Closes (ATDC)

Lubrication Specifications

In-line Single Over Head Camshaft

4

mm (in.) 85 (3.35)

mm (in.) 88 (3.46)

cm3 (cu.in.) 1,997 (121.9)

8.5

<8 VALVE>, 9.5 < 16 VALVE>

1-3-4-2

I Equipped

19”<8VALVE>,11”<16VALVE>

57” <8 VALUE>, 53”

57”

<8 VALVE>, 63”

19” , 21” <16VALVE>

Pressure feed-full flow filtration

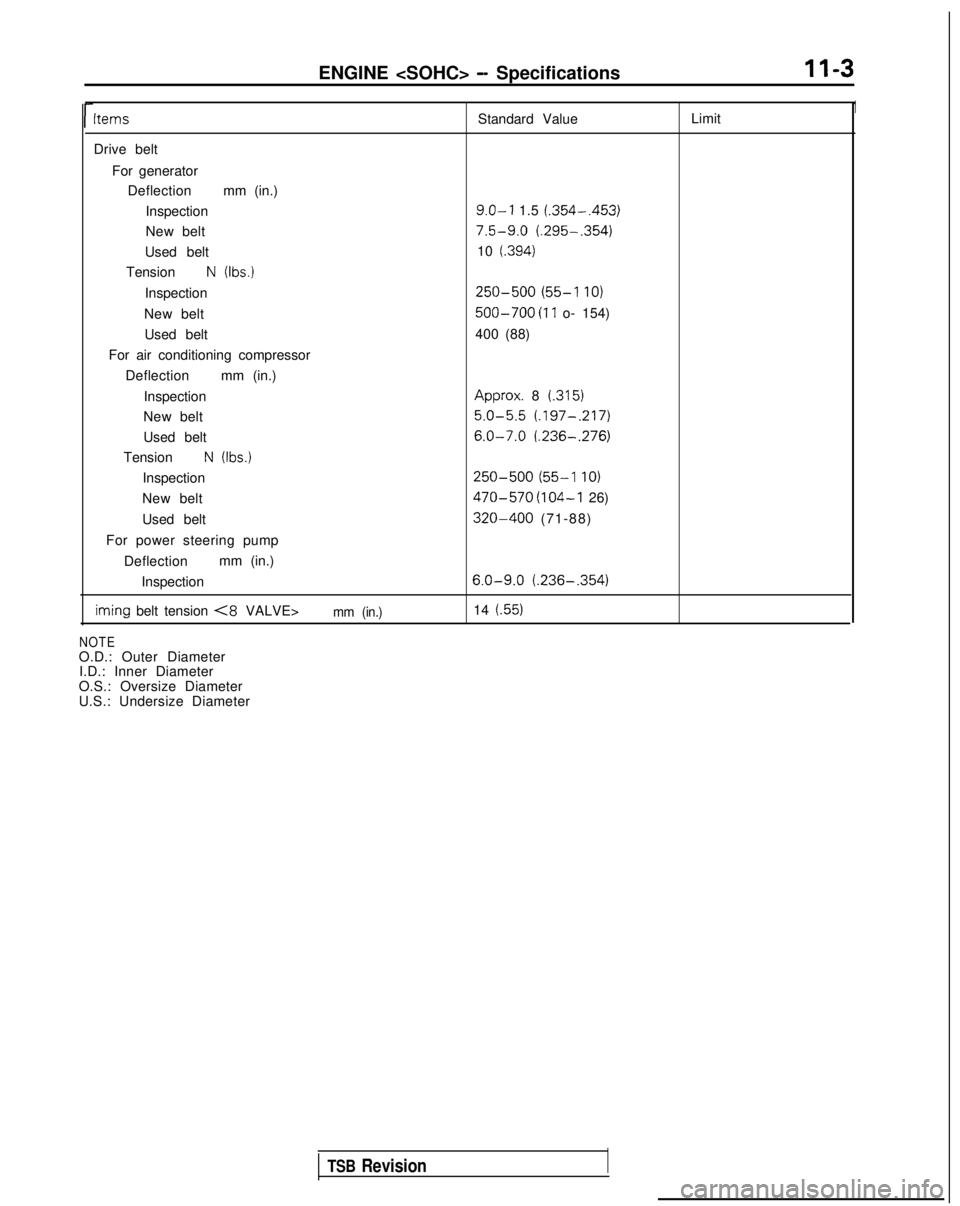

SERVICE SPECIFICATIONS

MllCB-A

Items Standard Value

Limit

Engine adjustments Engine compression pressure

Engine compression pressure difference

between each cylinder

Intake manifold vacuum-at idle

kPa (psi)/rpm 1,250 (178)/250-400<8 VALVE>1,300 (185)/250-400< 16 VALUE>

kPa (psi) - mmHg

(in.Hg)Approx. 500 (20)<8 VALVE>

Approx. 510 (20)

<16VALUE>

min. 880 (125)/250-400<8 VALUE>min. 980 (139)/250-400< 16 VALUE>

max.

100 (14)

Timing belt “B” tension mm (in.)

5

- 7 (.20-.28)

Cylinder head bolt

< 16 VALUE>mm(in.) -max. 99.4 (3.91)

TSB Revision

Page 53 of 1273

ENGINE

l-

Items

Standard ValueLimit1

Drive belt

For generatorDeflection mm (in.)

Inspection

9.0-l 1.5 (.354-,453)

New belt7.5-9.0 (.295-.354)

Used belt 10 (.394)

TensionN (Ibs.)

Inspection250-500 (55-l IO)

New belt500-700 (11 o- 154)

Used belt 400 (88)

For air conditioning compressor Deflection mm (in.)

Inspection Approx.

8

(.315)

New belt5.0-5.5 (.197-.217)

Used belt6.0-7.0 (.236-,276)

TensionN (Ibs.)

Inspection250-500 (55-l IO)

New belt470-570 (104-I 26)

Used belt

320-400 (71-88)

For power steering pump Deflection mm (in.)

Inspection

6.0-9.0 (.236-,354) iming

belt tension

<8 VALVE>mm (in.)14 (.55)

NOTE

O.D.: Outer Diameter I.D.: Inner Diameter

O.S.: Oversize Diameter

U.S.: Undersize Diameter

TSB Revision

Page 54 of 1273

II-4ENGINE

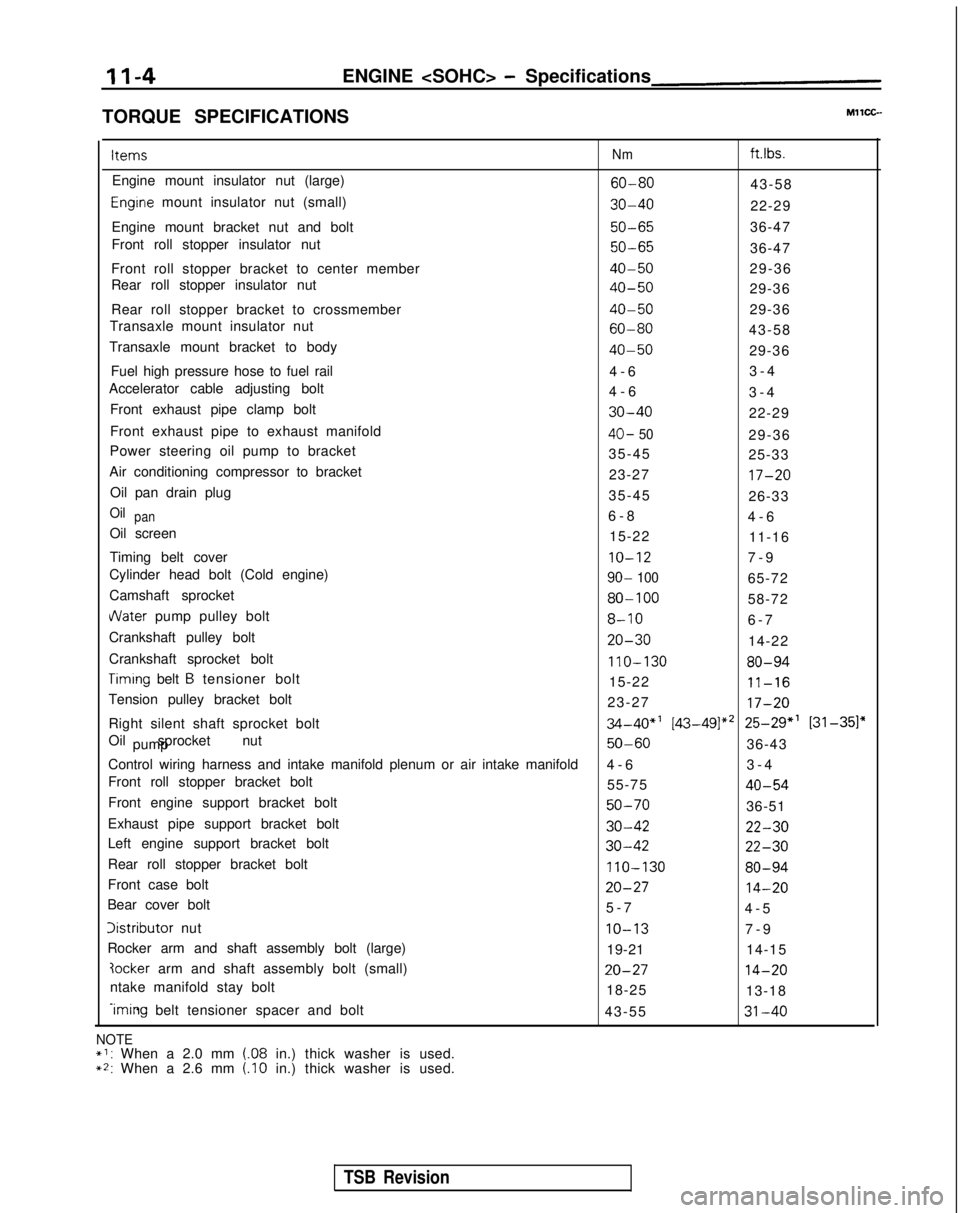

TORQUE SPECIFICATIONS Items

Nm ft.lbs.

Engine mount insulator nut (large)

60-8043-58

Engrne mount insulator nut (small)30-4022-29

Engine mount bracket nut and bolt

50-6536-47

Front roll stopper insulator nut

50-6536-47

Front roll stopper bracket to center member

40-5029-36

Rear roll stopper insulator nut

40-5029-36

Rear roll stopper bracket to crossmember

40-5029-36

Transaxle mount insulator nut

60-8043-58

Transaxle mount bracket to body

40-5029-36

Fuel high pressure hose to fuel rail 4-

6

3-4

Accelerator cable adjusting bolt 4-63-4

Front exhaust pipe clamp bolt

30-4022-29

Front exhaust pipe to exhaust manifold

40- 5029-36

Power steering oil pump to bracket 35-4525-33

Air conditioning compressor to bracket 23-27

17-20

Oil pan drain plug35-4526-33

Oilpan6-

8

4-6

Oil screen 15-2211-16

Timing belt cover

IO-127-

9

Cylinder head bolt (Cold engine)

90- 10065-72

Camshaft sprocket

80-10058-72

dater pump pulley bolt8-106-

7

Crankshaft pulley bolt

20-3014-22

Crankshaft sprocket bolt

110-13080-94

Timrng belt B tensioner bolt 15-2211-16

Tension pulley bracket bolt 23-2717-20

Right silent shaft sprocket bolt34-40”’ [43-49]*’ 25-29” [31-351”

Oil sprocket nut pump

50-6036-43

Control wiring harness and intake manifold plenum or air intake manifold\

4-

6

3-4

Front roll stopper bracket bolt 55-75

40-54

Front engine support bracket bolt50-7036-51

Exhaust pipe support bracket bolt

30-4222-30

Left engine support bracket bolt30-4222-30

Rear roll stopper bracket bolt110-13080-94

Front case bolt20-2714-20

Bear cover bolt 5-

7

4-5

Iistributor nutIO-137-

9

Rocker arm and shaft assembly bolt (large) 19-2114-15

?ocker arm and shaft assembly bolt (small)20-2714-20

ntake manifold stay bolt

18-2513-18

-iming belt tensioner spacer and bolt

43-5531-40

NOTE*I: When a 2.0 mm (.08 in.) thick washer is used.~2: When a 2.6 mm (.I0 in.) thick washer is used.

TSB Revision