fuel MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1 of 1273

BACKUP

Service Manual

GRLRNT

1989-1990-1991-1992-1993

Volume 1

Chassis & Mechanical

FOREWORD

This Service Manual has been prepared with thelatest service information available at the time of

publication. It is subdivided into various group cate-

gories and each section contains diagnostic, dis-

assembly, repair, and installation procedures along

with complete specifications and tightening ref-

erences. Use of this manual will aid in properly per-

forming any servicing necessary to maintain or res-

tore the high levels of performance and reliability

designed into these outstanding vehicles.

This BACKUP DSM manual is to be used DNLY as

a SACKUP. please DIJ NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed

DWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your

original

manual was lost or

destroyed.) Please

See

README.TXT

or

README.HTML

for additional

information.

1kyou.

- Gjmpiemym_ay&?h

@

A

.

.”

WE SUPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

Nallonal lnsrltule forAU~~~v3~;VPCT:VE

EXCELLENCE naiLcorn

MITSUBISHIMOTOR SALES OF AMERICA. Inc.

Mltsublshl Motors Corporat!on reserves the right to make changes indesign or to make additions to or Improvements In Its products

wlthout~mposng any obllgatlons upon Itself to install them on its productspreviously manufactured

0 1992 Mitsubishi Motors CorporationRcprintedinUSA

GROUP INDEXMOOAA-

General.........................................................

Engine...........................................................

Fuel................................................................

Cooling.........................................................

Intake and Exhaust..............................

Emission Control....................................

Clutch............................................................

Manual Transaxle..................................

Automatic Transaxle............................

Propeller Shaft........................................

Front Axle..................................................

Rear Axle....................................................

Wheel and Tire.......................................

Power Plant Mount..............................

Front Suspension...................................

Active-Electronic

Control Suspension..............................m

A

Rear Suspension....................................&

Service Brakes.........................................

Parking Brakes........................................

Alphabetical Index.................................

NOTE: Electrical system Information is contained in

Volume 2 “Electrical” of this paired Service Manual.

For overhaul procedures of engines or transmissions,

refer to the separately issued Engine

Service Manual

or Manual/Automatic Transmission Service Manual.

Page 3 of 1273

00-l

GENERAL

CONTENTS

GENERAL DATA AND SPECIFICATIONS.....23

HOWTOUSETHISMANUAL......................

3

Definition of Terms ......................................3

ExplanationofCircuitDiagrams..................7

Explanation of

ManualContents .................4

Explanation of the Troubleshooting

Guide .............................................................

6

Model

Indications .........................................3

Scope of Maintenance, Repair and

Servicing Explanations

..................................

3

Troubleshooting .............................................3

LUBRICATIONANDMAINTENANCE............

34

MAINTENANCE SERVICE............................... 39

AirCleanerElement

.....................................39

Automatic

Transaxle

.....................................43

Ball Joint and Steering Linkage Seals ........45

Brake Hoses................................................. 45

Disc Brake Pads ........................................... 44

Drive Belt (For Water Pump and

Generator) .......................................................

41

Drive

Shaft Boots .........................................45

Engine Coolant

............................................. 44

Engine Oil .....................................................

41

Engine Oil Filter ...........................................41

Exhaust System

............................................ 45

FuelHoses

...................................................39

Fuel System

.................................................39

Manual Transaxle ..........................................42

RearAxle......................................................45

Rear Drum Brake Linings and

RearWheel Cylinders

..................................44

Spark

Plugs...................................................40

Timing Belt...................................................40

MASTER

TROUBLESHOOTING.....................28

PRECAUTIONS

BEFORESERVICE................15

RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIESTABLE..................35

SCHEDULED

MAINTENANCETABLE ...........38

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS

.......................................20

TABLE OF MAIN SEALANTS

AND

ADHESIVES ............................................46

TIGHTENING TORQUE

................................... 27

TOWING

ANDHOISTING ..............................17

VEHICLE

IDENTIFICATION .............................8

Chassis Number ...........................................

11

EngineModel

Stamping

...............................12

Theft Protection ............................................12

Vehicle Identification Code Chart Plate.......

8

Vehicle Identification Number List

..............8

Vehicle Identification Number Location .......

8

Vehicle Information

CodePlate...................1 1

Vehicle SafetyCertificationLabel................12

Page 5 of 1273

GENERAL - How to Use This Manual00-3

HOW

TO USE THIS MANUALMOOBMTO

SCOPE OF MAINTENANCE, REPAIR AND

DEFINITION OF TERMS

SERVICING EXPLANATIONS STANDARD VALUE

This manual provides explanations, etc. concerning procedures for the inspection, maintenance, repair

and servicing of the subject model. Unless other-

wise specified, each service procedure covers all models. Procedures covering specific models are

identified by the model codes, or similar designation

(engine type, transaxle type, etc.). A description of

these designations is covered in this unit under “VEHICLE IDENTIFICATION”.

SERVICE ADJUSTMENT PROCEDURES

“Service Adjustment Procedures” are procedures

for performing inspections and adjustments of

particularly important locations with regard to the

construction and for maintenance and servicing, but

other inspections (for looseness, play, cracking,

damage, etc.) must also be performed.

SERVICE PROCEDURES

The service steps are arranged in numerical order and attentions to be paid in performing vehicleservice are described in detail in SERVICE POINTS.

TROUBLESHOOTING

Troubleshootinqs are classified into master trou-

bleshooting and group troubleshooting and located

as follows:

The master troubleshooting is prepared when the trouble symptom relates to two or more groups and

given in MASTER TROUBLESHOOTING.

The group troubleshooting guide is prepared for causes of problems related to that individual group

only; a troubleshooting guide is prepared for each

appropriate group. Indicates the value used as the standard for judging

the quality of a part or assembly on inspectian or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a part

or assembly on inspection and means the maximum

or minimum value within which the part or assembly must be kept functionally or in strength. It is a value

established outside the range of standard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and adjustment procedures, and so they can be

com- pleted

in a shorter time).

CAUTION

Indicates the presentation of information particularly

vital to the worker during the performance of maintenance and servicing procedures in order to

avoid the possibility of injury to the worker; or

damage to component parts, or a reduction of

component or vehicle function or performance, etc.

MODEL INDICATIONS

The following abbreviations are used in this manual for classification o\

f model types.

M/T . Indicates the manual transaxle, or models equipped with the manual\

transaxle.

A/T: indicates the automatic transaxle, or models equipped with the automati\

c transaxle.

MFI: Indicates the multiport

fuel injection, or engines equipped with the

multiport fuel injection.

SOHC: Indicates an engine with the single overhead camshaft, or a model \

equipped with such an engine.

DOHC: Indicates an engine with the double overhead camshaft, or a model \

equipped with such an engine.

Turbo: Indicates an engine with turbocharger, or a model equipped with s\

uch an engine. Non-Turbo: Indicates an engine without turbocharger, or a model equipped\

with such an engine.FWD: Indicates the front wheel drive vehicles.

AWD: Indicates the all wheel drive vehicles. ABS: Indicates the anti-lock braking system or models equipped with the \

anti-lock braking system.

Page 20 of 1273

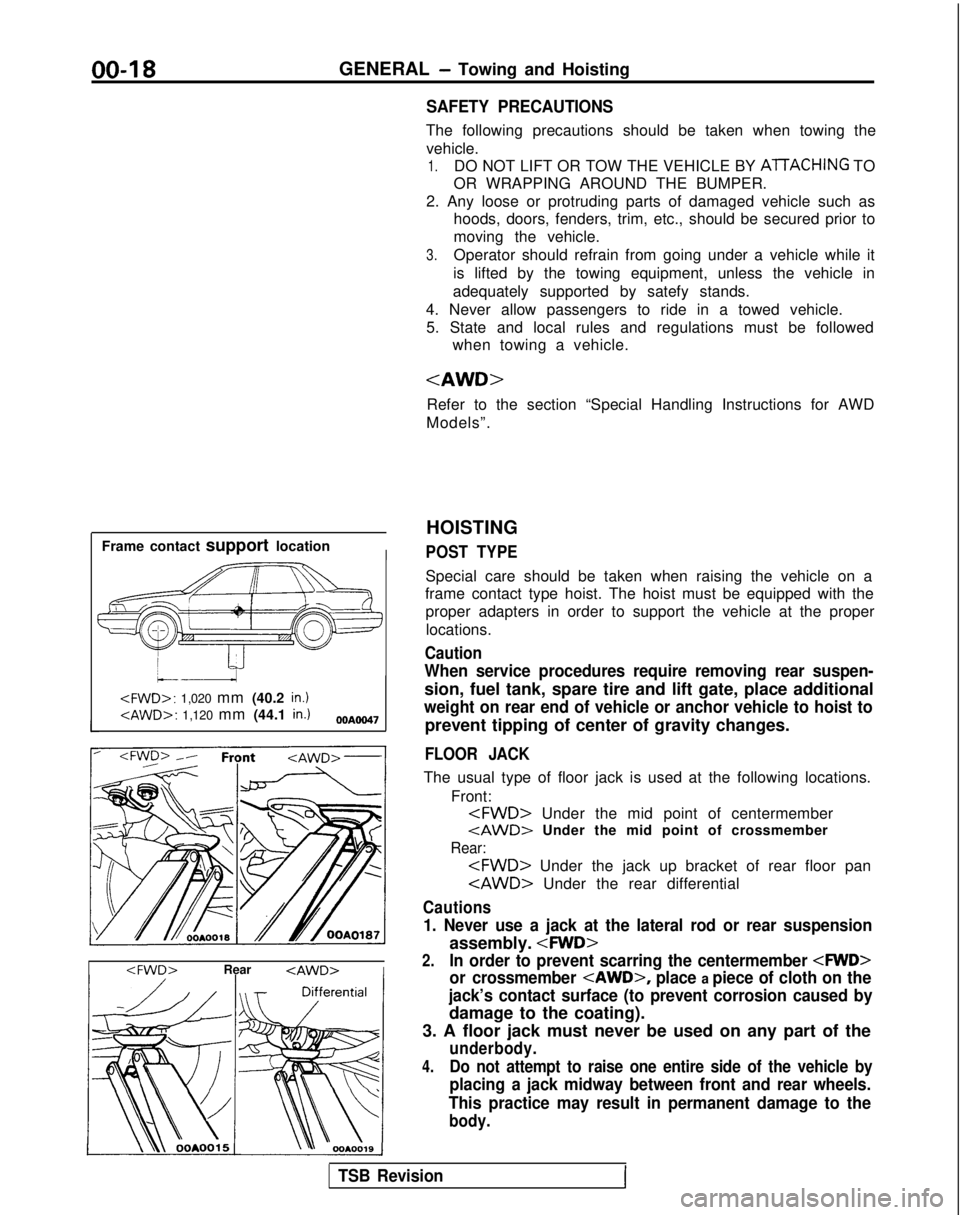

00-l 8GENERAL - Towing and Hoisting

SAFETY PRECAUTIONS

The following precautions should be taken when towing thevehicle.

1.DO NOT LIFT OR TOW THE VEHICLE BY ATTACHING TO

OR WRAPPING AROUND THE BUMPER.

2. Any loose or protruding parts of damaged vehicle such as hoods, doors, fenders, trim, etc., should be secured prior to

moving the vehicle.

3.Operator should refrain from going under a vehicle while it

is lifted by the towing equipment, unless the vehicle in

adequately supported by satefy stands.

4. Never allow passengers to ride in a towed vehicle. 5. State and local rules and regulations must be followed when towing a vehicle.

Refer to the section “Special Handling Instructions for AWD

Models”.

Frame contact support location

I

HOISTING

POST TYPE

Special care should be taken when raising the vehicle on a

frame contact type hoist. The hoist must be equipped with the

proper adapters in order to support the vehicle at the proper

locations.

Caution

When service procedures require removing rear suspen-

sion, fuel tank, spare tire and lift gate, place additional

weight on rear end of vehicle or anchor vehicle to hoist to

prevent tipping of center of gravity changes.

FLOOR JACK

The usual type of floor jack is used at the following locations.

Front:

tAWD> Under the mid point of crossmember

Rear:

Cautions

1. Never use a jack at the lateral rod or rear suspension

assembly.

2.In order to prevent scarring the centermember

or crossmember

place a piece of cloth on the

jack’s contact surface (to prevent corrosion caused by

damage to the coating).

3. A floor jack must never be used on any part of the

underbody.

4.Do not attempt to raise one entire side of the vehicle by

placing a jack midway between front and rear wheels.

This practice may result in permanent damage to the

body.

TSB RevisionI

Page 26 of 1273

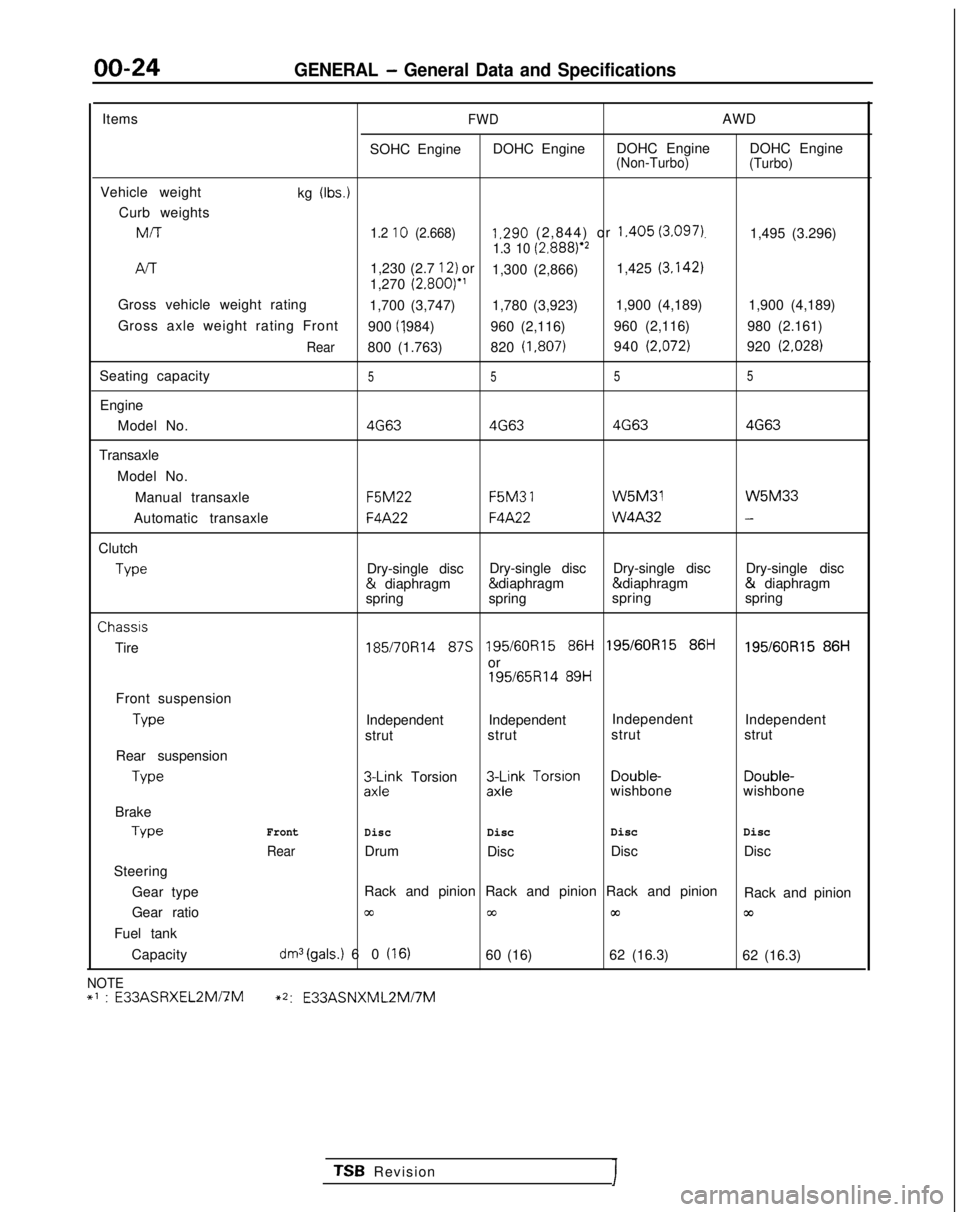

00-24GENERAL - General Data and Specifications

ItemsFWDAWD

SOHC Engine DOHC Engine DOHC Engine DOHC Engine

(Non-Turbo)

(Turbo)

Vehicle weight

kg (Ibs.)

Curb weightsMIT

1.2 10 (2.668)1.290 (2,844) or 1.405 (3.097).1,495 (3.296)1.3 10 (2.8881e2

/-v-r1,230 (2.7 12) or

1,300 (2,866) 1,425 (3.142)

1,270

(2.800)”

Gross vehicle weight rating 1,700 (3,747) 1,780 (3,923)1,900 (4,189)

1,900 (4,189)

Gross axle weight rating Front 900 (I ,984)

960 (2,116) 960 (2,116)

980 (2.161)

Rear800 (1.763)820 (1,807)940 (2.072)920 (2.028)

Seating capacity5 55 5

Engine

Model No.

4G634G63 4G634G63

Transaxle

Model No.Manual transaxle F5M22 F5M3

1 W5M31 W5M33

Automatic transaxle

F4A22F4A22 W4A32-

Clutch

Type

Dry-single disc

Dry-single disc

Dry-single disc Dry-single disc &

diaphragm & diaphragm & diaphragm &

diaphragm

spring spring spring

springChassis

Tire

185/7OR14 87s 195/60R15 86i-i 195/60R15 86ti195/60R15 86H

or

195/65R14 89H

Front suspension Type

Independent Independent

Independent

Independent

strut strut strut

strut

Rear suspension Type

3L$k Torsion3$k Torsion Double-

Double-

wishbone wishbone

Brake Type

Front

DiscDisc Disc

Disc

RearDrum

Disc Disc

Disc

Steering

Gear type Rack and pinion Rack and pinion Rack and pinion

Rack and pinion

Gear ratio

cc00m03

Fuel tank

Capacity

dm3(gals.) 60 (16)60 (16) 62 (16.3)

62 (16.3)

NOTE+’ : E33ASRXEL2Mi7M~2:

E33ASNXML2Mi7M

TSB RevisionI

Page 28 of 1273

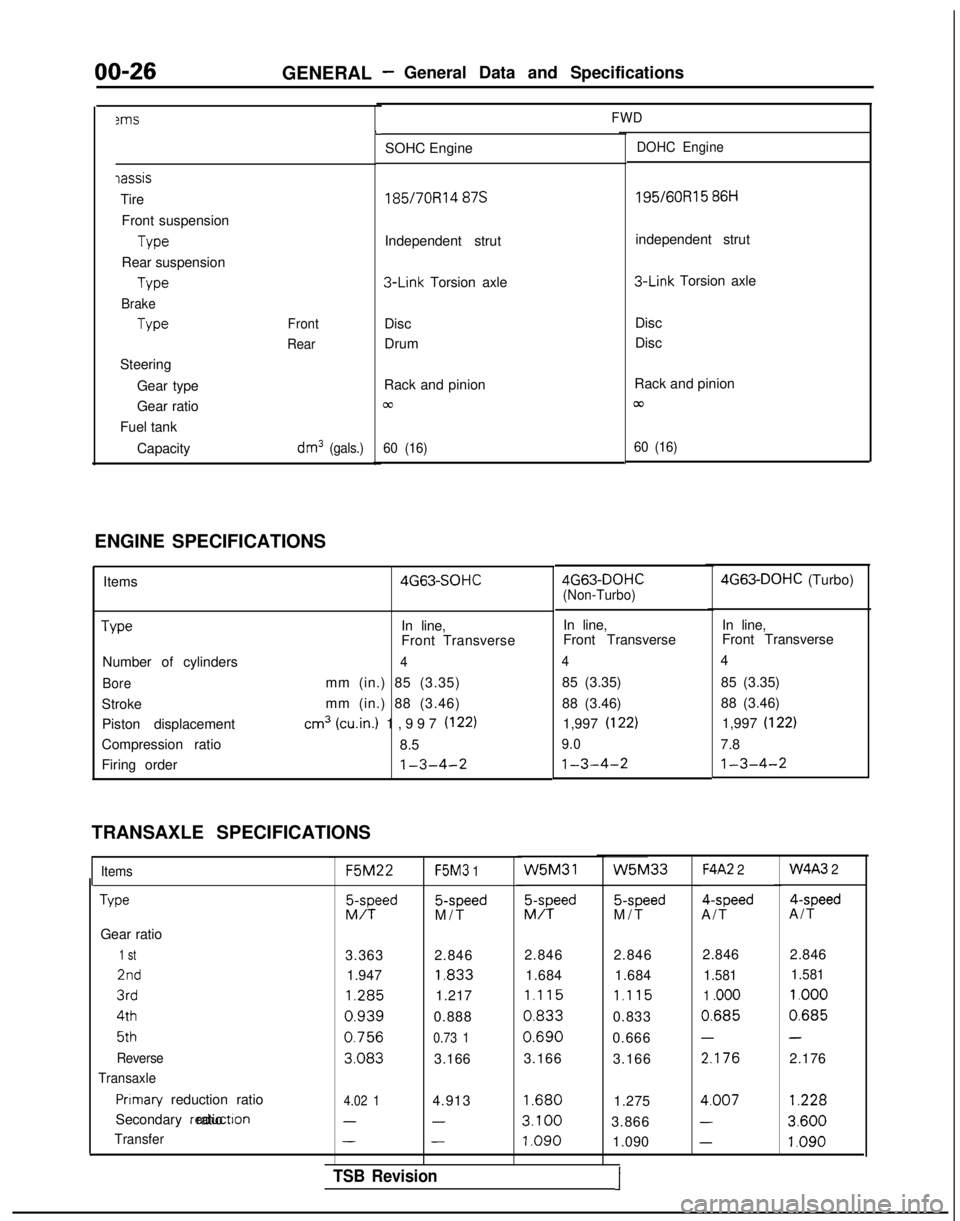

00-263ms

GENERAL -General Data and Specifications

FWD

iassis

Tire

Front suspension Type

Rear suspension Type

Brake

Type

Steering Gear type

Gear ratio

Fuel tank

Capacity

Front

Rear

dm3 (gals.)

L

SOHC EngineDOHC Engine

185/7ORl4 87s 195/60R15

86H

Independent strut independent strut 3-Link

Torsion axle 3-Link

Torsion axle

Disc

Drum Disc

Disc

Rack and pinion

cc

60 (16)

Rack and pinion

/cu

60 (16)

ENGINE SPECIFICATIONS Items Type

Number of cylinders

Bore

StrokePiston displacement

Compression ratio

Firing order 4G63-SOHC

In line,

Front Transverse

4

mm (in.) 85 (3.35)

mm (in.) 88 (3.46)

cm3 (win.) 1,997 (122)

8.5

1-3-4-2

TRANSAXLE SPECIFICATIONS

Items

Type

Gear ratio

1 st

2nd

3rd 4th

5th

Reverse

Transaxle

Pnmary reduction ratio

Secondary reductron ratio

Transfer F5M22

F5M3

1 5-speed

M/T W5M31

EFd

5-speed

M/T

F4A2 2 4-speed

A/T 4-speed

A/T

3.363 2.846 2.846 2.846

1.947 1.833

1.684 1.684 1.285

1.217

1.115 1.115

0.9390.8880.8330.833

0.7560.73 10.6900.666

3.0833.166

3.166

3.166 2.846 2.846

1.581

1.581

1 .ooo 1.000

0.6850.685

--

2.1762.176

4.02 14.9131.6801.2754.007

1.228

---3.1003.8663.600

---1.0901.090

1.0904G63-DOHC

(Non-Turbo) 4G63-DOHC

(Turbo)

In line, In line,

Front Transverse Front Transverse

44

85 (3.35) 85 (3.35)

88 (3.46) 88 (3.46)

1,997 (I

22)1,997 (I 22)

9.0

7.8

1-3-4-21-3-4-2

W5M33W4A3 2

TSB Revision1

Page 30 of 1273

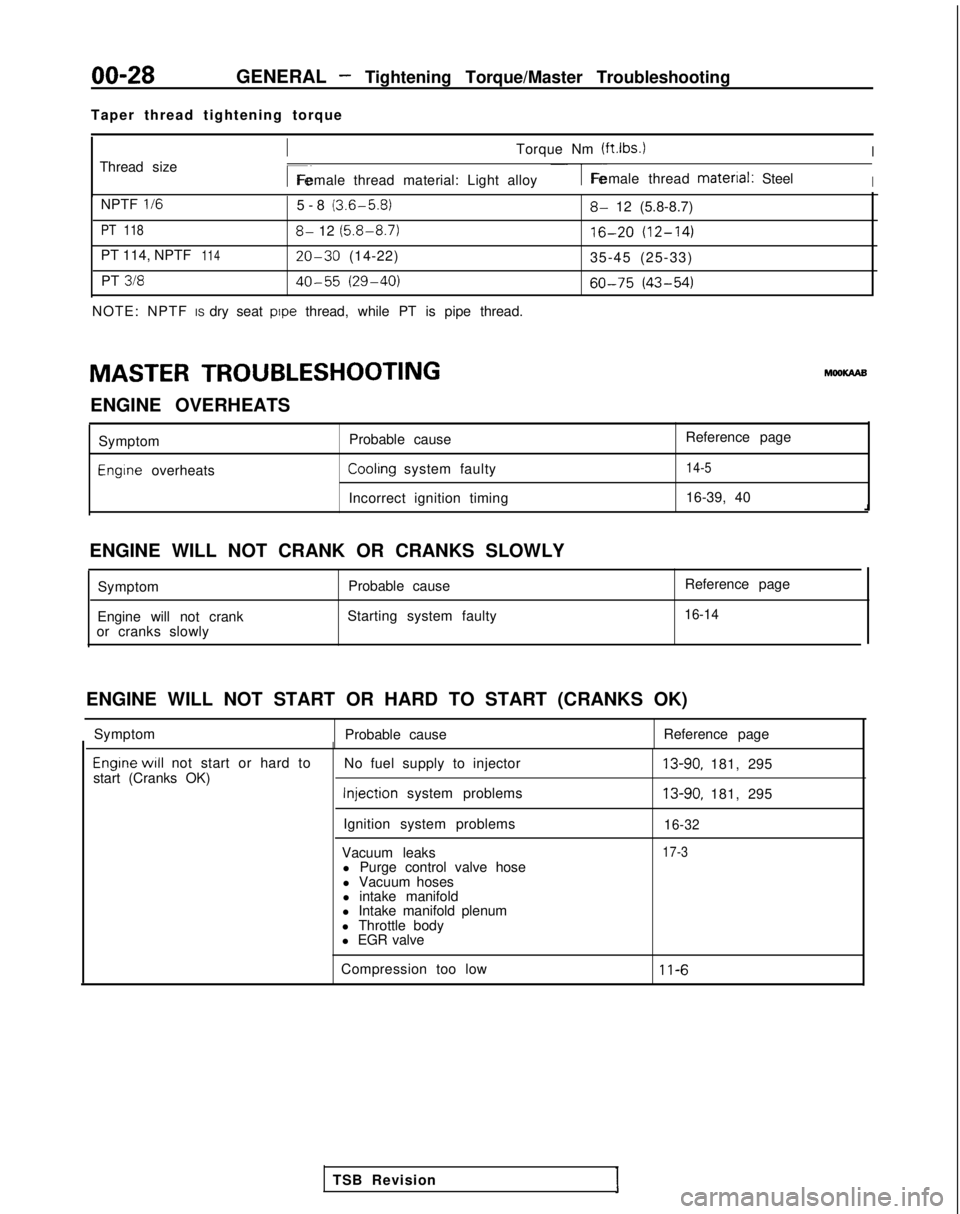

00-28GENERAL - Tightening Torque/Master Troubleshooting

Taper thread tightening torque

Thread size

ITorque Nm (ftlbs.)I

r~Female thread material: Light alloy1-Female thread material: SteelI

NPTF II65-8 (3.6-5.8)

PT 1188- 12 (5.8-8.7)

PT 114, NPTF11420-30 (14-22)

PT

31840-55 (29-40)

NOTE: NPTF IS dry seat pope thread, while PT is pipe thread.

8- 12 (5.8-8.7)

16-20 (12-14)

35-45 (25-33)

60-75 (43-54)

MASTER TROUBLESHOOTING hlooKAAB

ENGINE OVERHEATS Symptom

Engine overheats Probable cause

Reference pageCoolrng system faulty14-5

Incorrect ignition timing

16-39, 40

ENGINE WILL NOT CRANK OR CRANKS SLOWLY Symptom Probable cause

Engine will not crank Starting system faulty

or cranks slowly Reference page

16-14

ENGINE WILL NOT START OR HARD TO START (CRANKS OK)

Symptom Probable cause Reference page

Engrne WIII not start or hard to

start (Cranks OK) No fuel supply to injector Injection

system problems

Ignition system problems

Vacuum leaks l Purge control valve hose

l Vacuum hoses

l intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve13-90, 181, 295

13-90, 181, 295

16-32

17-3

Compression too low11-6

TSB Revision

Page 31 of 1273

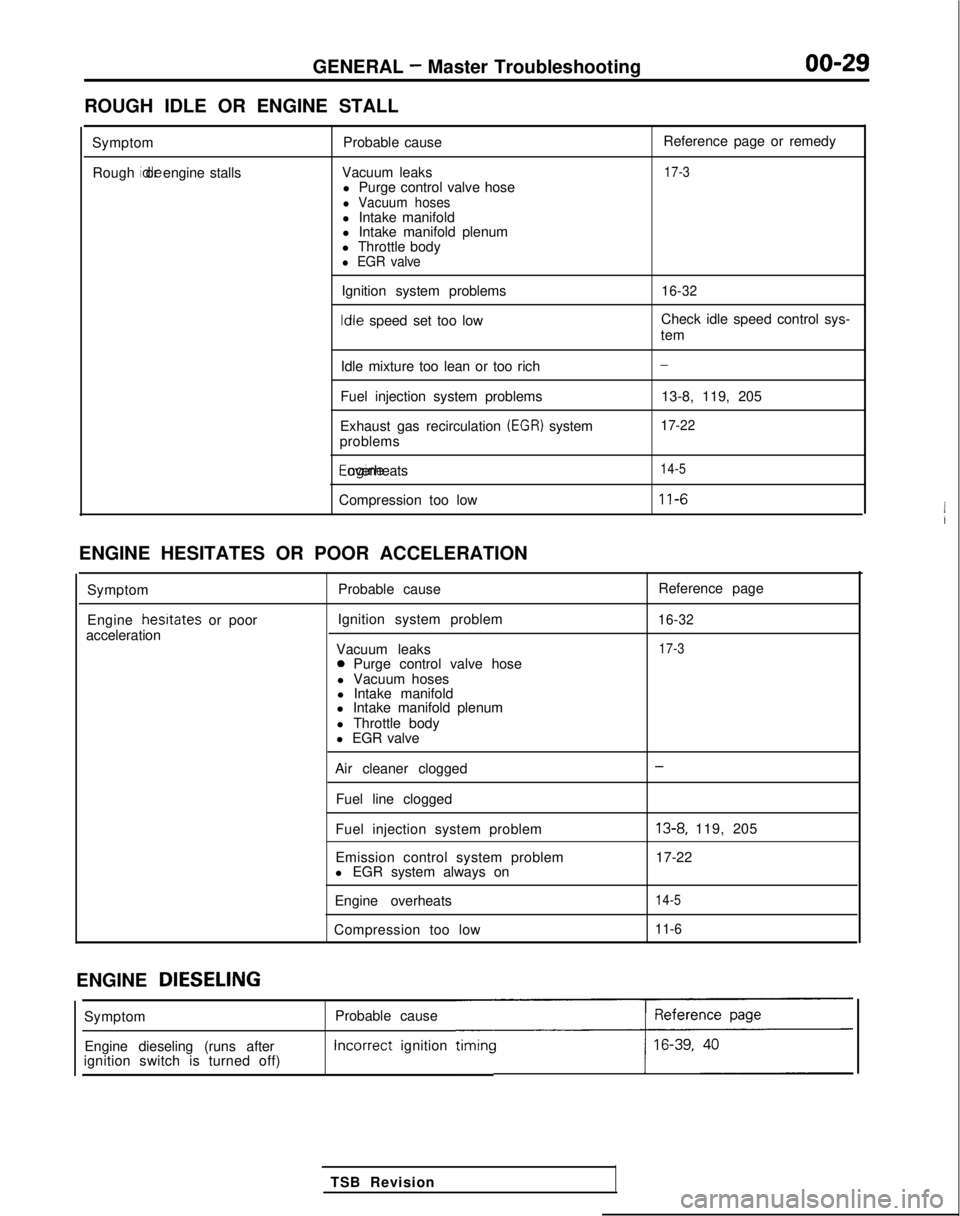

GENERAL - Master Troubleshooting00-29

ROUGH IDLE OR ENGINE STALL

SymptomRough idle or engine stalls

Probable cause

Vacuum leaks l Purge control valve hose

l Vacuum hosesl Intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve

Ignition system problems Idle

speed set too low Reference page or remedy

17-3

16-32

Check idle speed control sys-

tem

Idle mixture too lean or too rich

Fuel injection system problems

Exhaust gas recirculation

(EGR) system

problems Engine overheats

Compression too low

-

13-8, 119, 205

17-22

14-5

11-6

ENGINE HESITATES OR POOR ACCELERATION

Symptom

Engine hesrtates

or poor

acceleration Probable cause

Ignition system problem

Vacuum leaks

0 Purge control valve hose

l Vacuum hoses

l Intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve Reference page

16-32

17-3

Air cleaner clogged

Fuel line clogged

Fuel injection system problem

Emission control system problem

l EGR system always on

Engine overheats

Compression too low-

13-8, 119, 205

17-22

14-5

11-6

ENGINE DIESELING

Probable cause Incorrect

ignition

timincc

TSB Revision

Symptom

Engine dieseling (runs after

ignition switch is turned off)

Page 32 of 1273

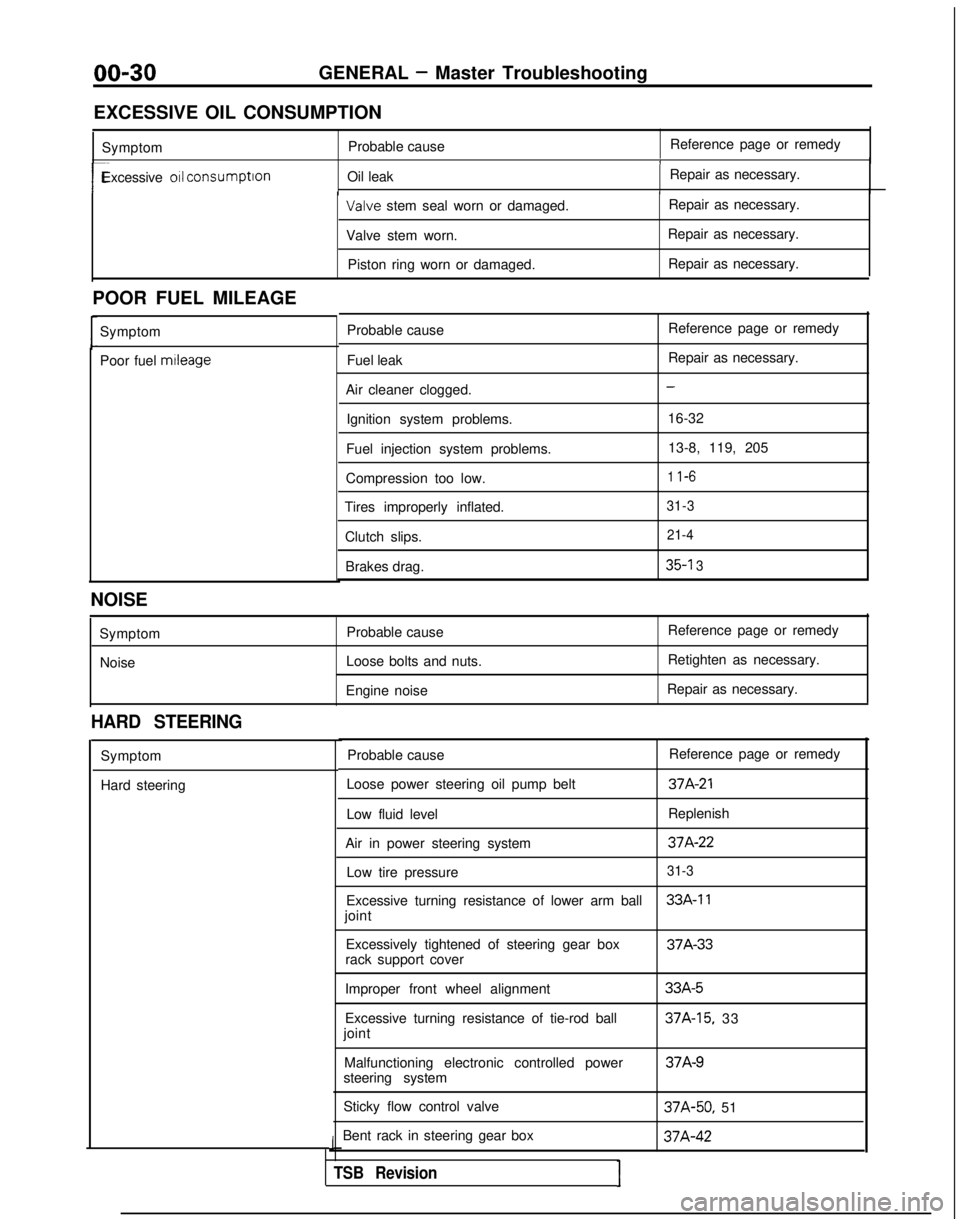

00-30GENERAL - Master Troubleshooting

EXCESSIVE OIL CONSUMPTION Symptom Probable cause Reference page or remedy

1

r-Excessive 011 consumption

Oil leak Repair as necessary.I Valve

stem seal worn or damaged. Repair as necessary.

Valve stem worn. Repair as necessary.

Piston ring worn or damaged. Repair as necessary.

POOR FUEL MILEAGE Symptom

Poor fuel mtleage

Probable cause

Fuel leak

Air cleaner clogged. Ignition system problems.

Fuel injection system problems.

Compression too low.

Tires improperly inflated.

Clutch slips.Brakes drag. Reference page or remedy

Repair as necessary.

-

16-32

13-8, 119, 205

1 l-6

31-3 21-4

35-l 3

NOISE

SymptomNoise Probable cause

Loose bolts and nuts.

Engine noise Reference page or remedy

Retighten as necessary.

Repair as necessary.

HARD STEERING

Symptom

Hard steering Probable cause

Reference page or remedy

Loose power steering oil pump belt

37A-21

Low fluid level Replenish

Air in power steering system

37A-22

Low tire pressure31-3

Excessive turning resistance of lower arm ball33A-11

joint Excessively tightened of steering gear box 37A-33

rack support cover

Improper front wheel alignment

Excessive turning resistance of tie-rod ball

joint

Malfunctioning electronic controlled power

steering system

Sticky flow control valve

Bent rack in steering gear box

J

TSB RevisionI

33A-5

37A-15, 33 37A-9

37A-50,

51 37A-42

Page 36 of 1273

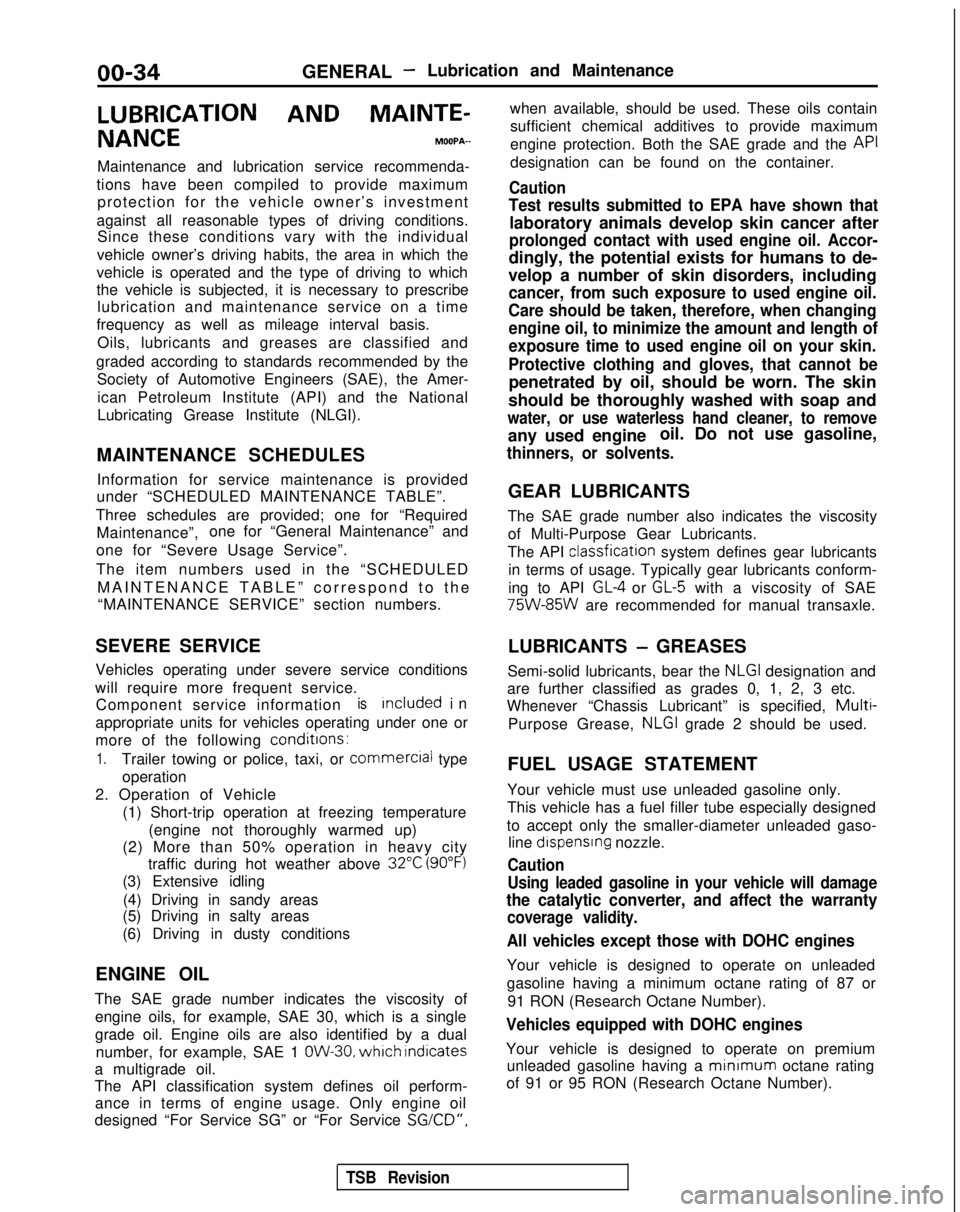

00-34GENERAL- Lubrication and Maintenance

LUBRICATION AND

MAINTE-

NANCEMOOPA-

Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum protection for the vehicle owner’s investment

against all reasonable types of driving conditions. Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by the Society of Automotive Engineers (SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute (NLGI).

MAINTENANCE SCHEDULES Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

The item numbers used in the “SCHEDULED MAINTENANCE TABLE” correspond to th

e

“MAINTENANCE SERVICE” section numbers.

SEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service. Component service information

isIncluded i

n

appropriate units for vehicles operating under one or

more of the following conditrons:

1.Trailer towing or police, taxi, or

commerciai

type

operation

2. Operation of Vehicle (1) Short-trip operation at freezing temperature(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city traffic during hot weather above

32°C (90°F)

(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual number, for example, SAE 1

OW-30, which Indicates

a multigrade oil.

The API classification system defines oil perform- ance in terms of engine usage. Only engine oil

designed “For Service SG” or “For Service

SGKD”,

when available, should be used. These oils contain

sufficient chemical additives to provide maximum

engine protection. Both the SAE grade and the API

designation can be found on the container.

Caution

Test results submitted to EPA have shown that

laboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-

dingly, the potential exists for humans to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be taken, therefore, when changing engine oil, to minimize the amount and length of

exposure time to used engine oil on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to remove

any used engine oil. Do not use gasoline,

thinners, or solvents.

GEAR LUBRICANTS

The SAE grade number also indicates the viscosity of Multi-Purpose Gear Lubricants.

The API classfication

system defines gear lubricants

in terms of usage. Typically gear lubricants conform-

ing to API

GL-4 or GL-5 with a viscosity of SAE 75W-85W

are recommended for manual transaxle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the

NLGI designation and

are further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified,

Multi-

Purpose Grease, NLGI grade 2 should be used.

FUEL USAGE STATEMENT

Your vehicle must use unleaded gasoline only.

This vehicle has a fuel filler tube especially designed

to accept only the smaller-diameter unleaded gaso- line

dispensrng nozzle.

Caution

Using leaded gasoline in your vehicle will damage

the catalytic converter, and affect the warranty

coverage validity.

All vehicles except those with DOHC engines

Your vehicle is designed to operate on unleaded

gasoline having a minimum octane rating of 87 or

91 RON (Research Octane Number).

Vehicles equipped with DOHC engines

Your vehicle is designed to operate on premiumunleaded gasoline having a minimum

octane rating

of 91 or 95 RON (Research Octane Number).

TSB Revision