gas type MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 36 of 1273

00-34GENERAL- Lubrication and Maintenance

LUBRICATION AND

MAINTE-

NANCEMOOPA-

Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum protection for the vehicle owner’s investment

against all reasonable types of driving conditions. Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by the Society of Automotive Engineers (SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute (NLGI).

MAINTENANCE SCHEDULES Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

The item numbers used in the “SCHEDULED MAINTENANCE TABLE” correspond to th

e

“MAINTENANCE SERVICE” section numbers.

SEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service. Component service information

isIncluded i

n

appropriate units for vehicles operating under one or

more of the following conditrons:

1.Trailer towing or police, taxi, or

commerciai

type

operation

2. Operation of Vehicle (1) Short-trip operation at freezing temperature(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city traffic during hot weather above

32°C (90°F)

(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual number, for example, SAE 1

OW-30, which Indicates

a multigrade oil.

The API classification system defines oil perform- ance in terms of engine usage. Only engine oil

designed “For Service SG” or “For Service

SGKD”,

when available, should be used. These oils contain

sufficient chemical additives to provide maximum

engine protection. Both the SAE grade and the API

designation can be found on the container.

Caution

Test results submitted to EPA have shown that

laboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-

dingly, the potential exists for humans to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be taken, therefore, when changing engine oil, to minimize the amount and length of

exposure time to used engine oil on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to remove

any used engine oil. Do not use gasoline,

thinners, or solvents.

GEAR LUBRICANTS

The SAE grade number also indicates the viscosity of Multi-Purpose Gear Lubricants.

The API classfication

system defines gear lubricants

in terms of usage. Typically gear lubricants conform-

ing to API

GL-4 or GL-5 with a viscosity of SAE 75W-85W

are recommended for manual transaxle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the

NLGI designation and

are further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified,

Multi-

Purpose Grease, NLGI grade 2 should be used.

FUEL USAGE STATEMENT

Your vehicle must use unleaded gasoline only.

This vehicle has a fuel filler tube especially designed

to accept only the smaller-diameter unleaded gaso- line

dispensrng nozzle.

Caution

Using leaded gasoline in your vehicle will damage

the catalytic converter, and affect the warranty

coverage validity.

All vehicles except those with DOHC engines

Your vehicle is designed to operate on unleaded

gasoline having a minimum octane rating of 87 or

91 RON (Research Octane Number).

Vehicles equipped with DOHC engines

Your vehicle is designed to operate on premiumunleaded gasoline having a minimum

octane rating

of 91 or 95 RON (Research Octane Number).

TSB Revision

Page 37 of 1273

GENERAL -Lubrication and Maintenance/Recommended Lubricants and Lubricant Capacities Table00-35

If premium unleaded gasoltne IS not available,

MATERIALS ADDED TO FUEL

unleaded gasoline having a octane rating of 87 or

91 RON (Research Octane Number) may be used. Indiscriminate use of fuel system cleaning agents

In this case, the performance and fuel consumption should be avoided. Many of these materials

in-

WIII suffer a little degradatron.tended for gum and varnish removal may contain

highly active

solvents or similar ingredients that can

be harmful to gasket and diaphragm materials used

in fuel system component parts.

Gasolines containing alcohol

Some gasolrnes sold at service stations contain

alcohol, although they may not be SC identified. Use

of fuels containing alcohol is not recommended

unless the nature of the blend can be

determrned

as being satisfactory.

Gasohol

- A mixture of 10% ethanol (grain alcohol)

and 90% unleaded gasoline may be used

In your

car. If

driveability problems are experienced as a

result of using gasohol, it IS recommended that the

car be operated on gasoline. Methanol

- Do not use gasolines containing

methanol (wood alcohol). Use of this type of

alcohol can result in vehicle performance deteriora-

tion and damage critical parts in the fuel system

components. Fuel system damage and performance

problems, resulting from the use of gasolines

containing methanol, may not be covered by the

new car warranty.

Gasolines containing MTBE (Methyl Tertiary Butyl

Ether)

Unleaded gasolrne containrng

15% or less MTBE

may be used in your car. (Fuel containing MTBE

over 15% vol. may cause reduced engine per-

formance and produce vapor lock or hard starting.) RECOMMENDED

LUBRICANTS AND

LUBRICANT CAPACITIES TAB,&-

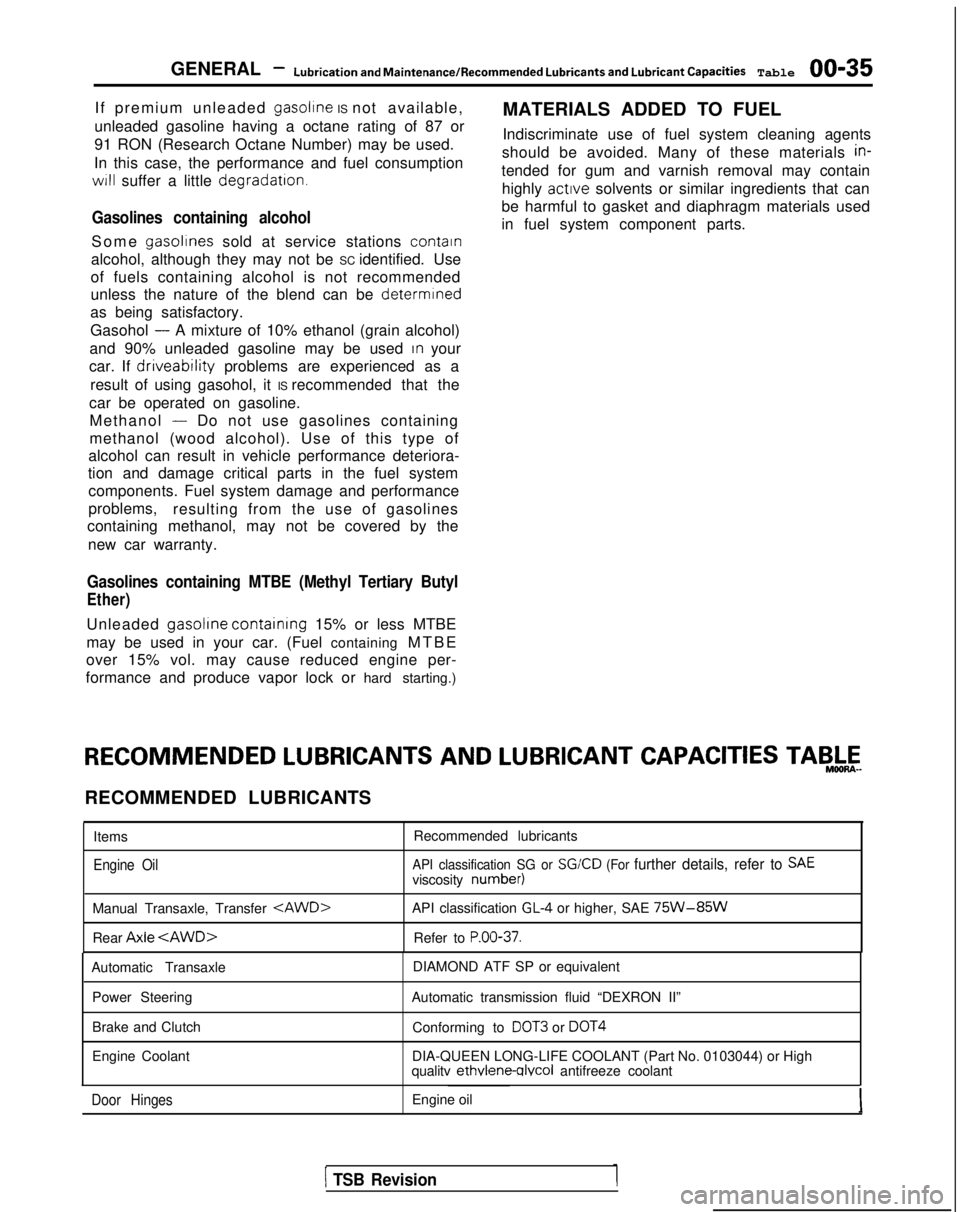

RECOMMENDED LUBRICANTS

Items

Engine Oil

Recommended lubricants

API classification SG or SGKD (For further details, refer to SAEviscosity number)

Manual Transaxle, Transfer

Rear Axle

API classification GL-4 or higher, SAE 75W-85W

Refer to P.OO-37.

Automatic Transaxle

Power Steering

Brake and Clutch

Engine Coolant DIAMOND ATF SP or equivalent

Automatic transmission fluid “DEXRON II” Conforming to

DOT3 or DOT4

DIA-QUEEN LONG-LIFE COOLANT (Part No. 0103044) or High

qualitv ethvlene-qlvcol

antifreeze coolant

Door HingesEngine oil

1 TSB Revision

Page 207 of 1273

FUEL SYSTEM

(1) Improper adjustment of the basic idling speed.

(2) Deposits adhering to the ttirottle valve.

(3) Air being taken into the intake manifold due to a gasket leak, etc.

OPERATION

ISC motor position sensor is a variable resistor type,

and is integrated in the

ISC motor system. The slid-

ing pin of

ISC motor position sensor is in contact

with the end of the plunger. Therefore, as the plun- ger moves, the internal resistance of

ISC motor pos-

ition sensor varies. This leads to the variation of the (4) Improper seating of the EGR valve seat.

(5) lmcomplete combustion within a cylinder. (Mal-

function of spark plugs, ignition coil, injectors,

compression pressure, etc.)

the plunger position of the

ISC motor system, and

sends the signal to ECM. ECM processes the

ISC

motor position sensor signal, idle signal, coolant

temperature signal, load signal (A/T &

A/C) and ve-

hicle speed signal to control the opening angle of

the throttle valve and revolution speed during

en-

output voltage. ISC motor position sensor detects gine idling.

TROUBLESHOOTING HINTS

Since idling is not controlled when ISC motor posi-

tion sensor is troubled, idling may not be evenly

maintained.

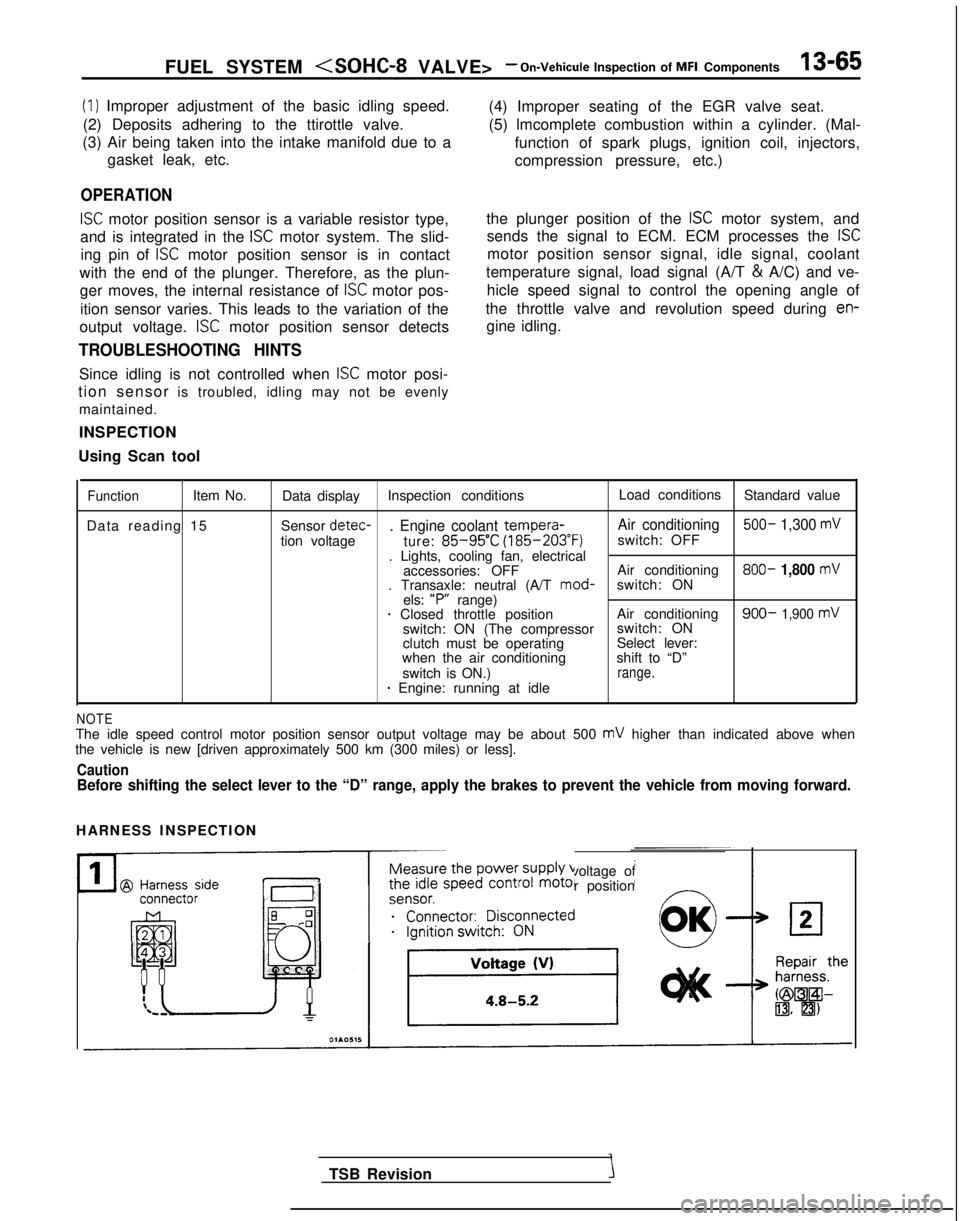

INSPECTION

Using Scan tool

FunctionItem No. Data display Inspection conditions Load conditions

Standard value

Data reading 15 Sensor detec-

. Engine coolant tempera-

Air conditioning 500- 1,300 mV

tion voltage

ture: 85-95’C (185-203°F)

switch: OFF

. Lights, cooling fan, electrical accessories: OFF Air conditioning 800-

1,800 mV. Transaxle: neutral (A/T

mod-

switch: ON

els: “P”

range)

1 Closed throttle position Air conditioning900- 1,900 mVswitch: ON (The compressorswitch: ON

clutch must be operating Select lever:

when the air conditioning shift to “D”

switch is ON.)

range.* Engine: running at idle

NOTEThe idle speed control motor position sensor output voltage may be about\

500 mV higher than indicated above when

the vehicle is new [driven approximately 500 km (300 miles) or less].

CautionBefore shifting the select lever to the “D” range, apply the brake\

s to prevent the vehicle from moving forward.

HARNESS INSPECTION

Measure the power supply voltage of

the idle speed control motor position

ei;;;it;;sco$ected

__...._ -.-

TSB Revision

Page 227 of 1273

FUEL SYSTEnrll (SOHC-8 VALVE> -On-Vehicule

Inspection of MFI Components13-85

EGR TEMPERATURE SENSOR

\+\+I connectorComponent side EGR temperaturn r-n~nrrHarness side@

connector 6FlJ1412

1

IwTemperaturelEzlooB

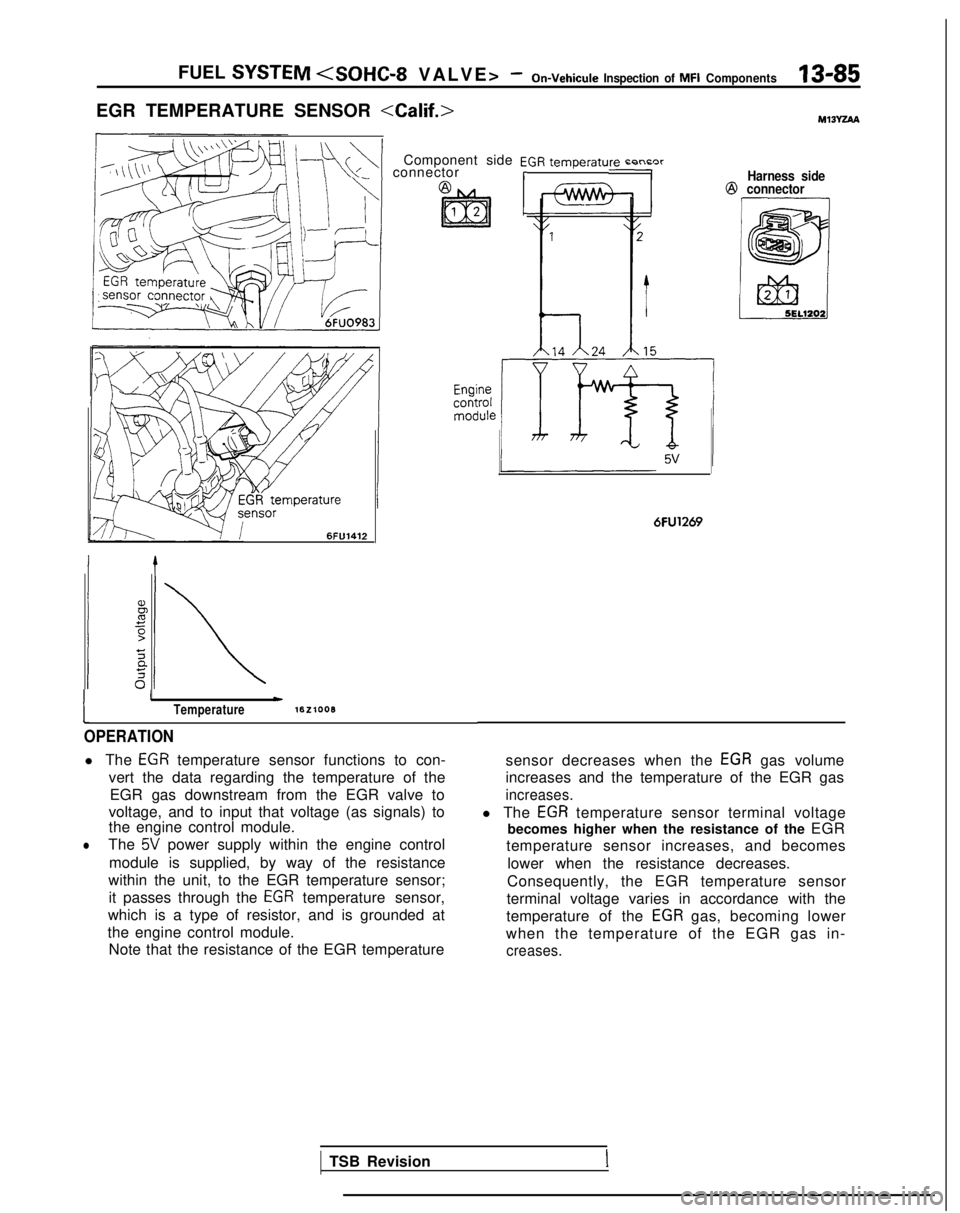

OPERATION

l The EGR temperature sensor functions to con-

vert the data regarding the temperature of the EGR gas downstream from the EGR valve to

voltage, and to input that voltage (as signals) to

the engine control module.

lThe 5V power supply within the engine control

module is supplied, by way of the resistance

within the unit, to the EGR temperature sensor; it passes through the

EGR temperature sensor,

which is a type of resistor, and is grounded at

the engine control module. Note that the resistance of the EGR temperature

6FU1269

sensor decreases when the EGR gas volume

increases and the temperature of the EGR gas

increases.

l The EGR temperature sensor terminal voltage

becomes higher when the resistance of the EGR

temperature sensor increases, and becomes

lower when the resistance decreases.

Consequently, the EGR temperature sensor

terminal voltage varies in accordance with the

temperature of the

EGR gas, becoming lower

when the temperature of the EGR gas in-

creases.

TSB RevisionI

Page 431 of 1273

FUEL SYSTEM

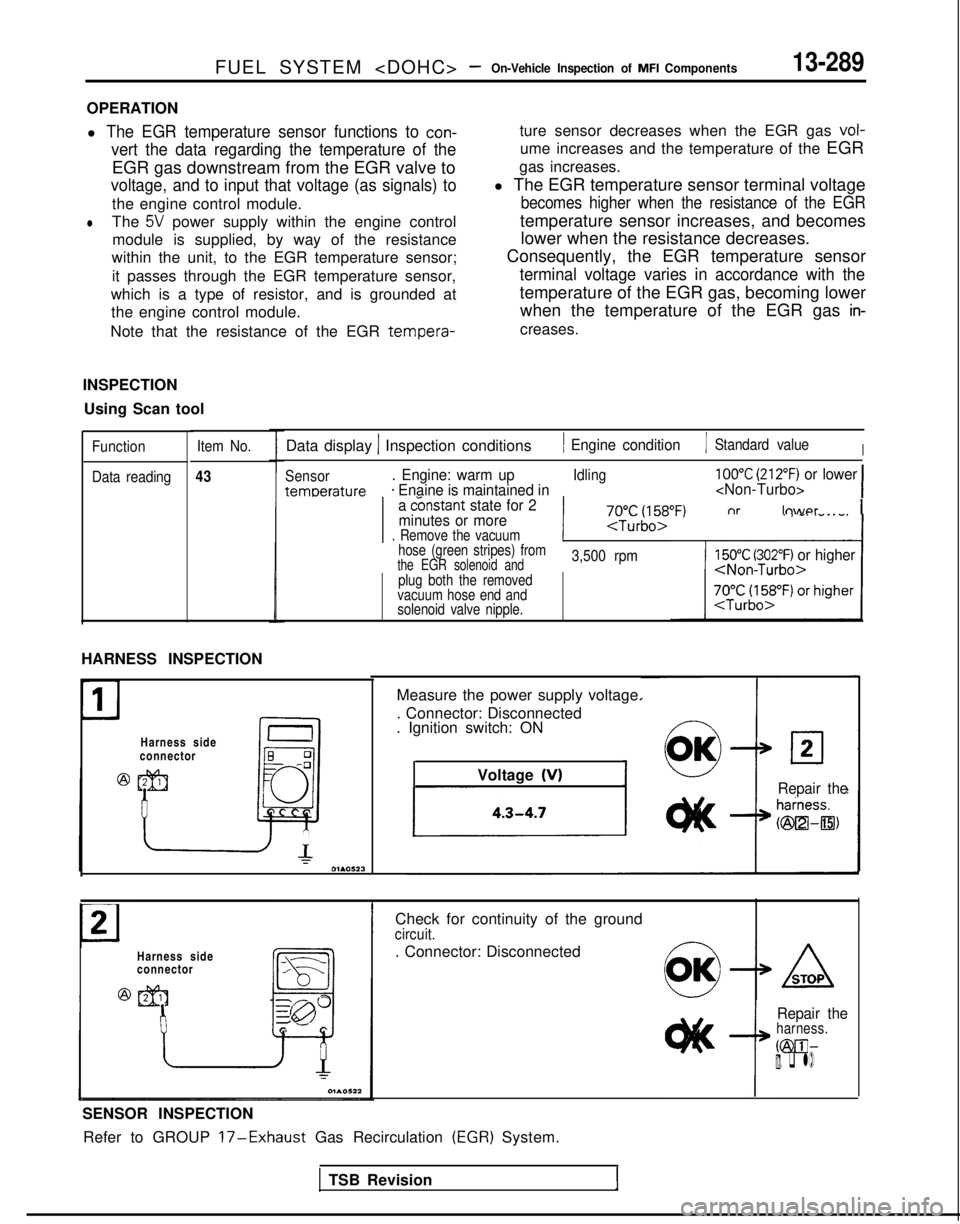

OPERATION

l The EGR temperature sensor functions to con-

vert the data regarding the temperature of the

EGR gas downstream from the EGR valve to

voltage, and to input that voltage (as signals) to

the engine control module.

lThe 5V power supply within the engine control

module is supplied, by way of the resistance

within the unit, to the EGR temperature sensor;

it passes through the EGR temperature sensor,

which is a type of resistor, and is grounded at the engine control module.

Note that the resistance of the EGR tempera-

ture sensor decreases when the EGR gas vol-

ume increases and the temperature of the EGR

gas increases.

l The EGR temperature sensor terminal voltage

becomes higher when the resistance of the EGR

temperature sensor increases, and becomes lower when the resistance decreases.

Consequently, the EGR temperature sensor

terminal voltage varies in accordance with the

temperature of the EGR gas, becoming lower when the temperature of the EGR gas

in-

creases.

INSPECTION Using Scan tool

Function Item No.

Data reading

43

Data display 1 Inspection conditions1 Engine condition1 Standard valueI

Sensor. Engine: warm upIdling100°C (212°F) or lower

temoerature* Enaine is maintained in

minutes or more

. Remove the vacuum

11 7J$lfifiF~ nr lower 1

hose (green stripes) fromthe EGR solenoid and3,500 rpm150°C (302°F) or higher/hlnn-Turbo>plug both the removed

vacuum hose end and

solenoid valve nipple.

HARNESS INSPECTION

Harness side

connector Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

Voltage

(V)Repair the

Harness side

connector Check for continuity of the ground

circuit.

. Connector: Disconnected

SENSOR INSPECTION Refer to GROUP

l7-Exhaust Gas Recirculation (EGR) System.

Repair theharness.

@El-IIll. q l)

TSB Revision

Page 452 of 1273

13-310FUEL SYSTEM

of MFI Components

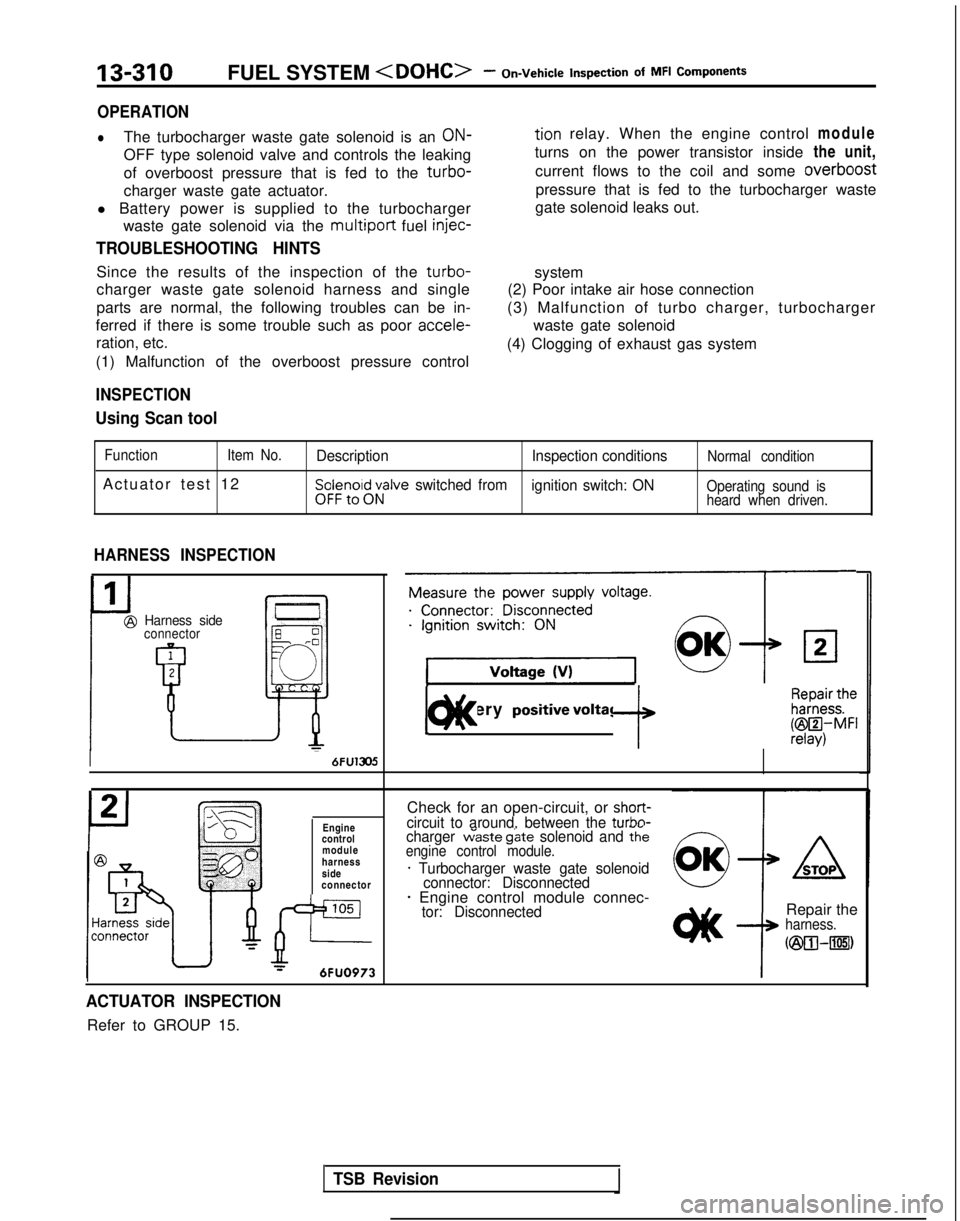

OPERATION

lThe turbocharger waste gate solenoid is an ON-tion relay. When the engine control

module

OFF type solenoid valve and controls the leaking turns on the power transistor inside

the unit,

of overboost pressure that is fed to the

turbo-current flows to the coil and some overboost

charger waste gate actuator. pressure that is fed to the turbocharger waste

l Battery power is supplied to the turbocharger gate solenoid leaks out.

waste gate solenoid via the

multiport fuel injec-

TROUBLESHOOTING HINTS

Since the results of the inspection of the turbo-

charger waste gate solenoid harness and single

parts are normal, the following troubles can be in-

ferred if there is some trouble such as poor accele-

ration, etc.

(1) Malfunction of the overboost pressure control system

(2) Poor intake air hose connection

(3) Malfunction of turbo charger, turbocharger waste gate solenoid

(4) Clogging of exhaust gas system

INSPECTION

Using Scan tool

Function Item No.

Actuator test 12

Description Inspection conditionsNormal condition

Sp:$r?,oi$;;alve switched from

ignition switch: ONOperating sound is

heard when driven.

HARNESS INSPECTION

Harness sideconnector

1

@

uI 6FU1305

Engine

control

module

harness

side

connector

105

JP--r6FUO973

Measure the power supply voltage.

9

1 Battery positivevoltage ]c)ll< f k&f$i

Check for an open-circuit, or short-circuit to around, between the turbn-charger w’aste g&e solenoid and thkengine control module.

* Turbocharger waste gate solenoid

connector: Disconnected

* Engine control module connec-tor: DisconnectedRepair theharness.

C@O--rn)

ACTUATOR INSPECTION

Refer to GROUP 15.

TSB Revision

Page 584 of 1273

14-32COOLING -Engine Coolant Temperature Gauge Unit, Engine Coolant

Temperature Sensor and Engine Coolant Temperature Switch

/

Sensor

J

046003

3

04GOO32

9FUO156

---

--I ‘Oi

l

QQQQQQ2cmn99

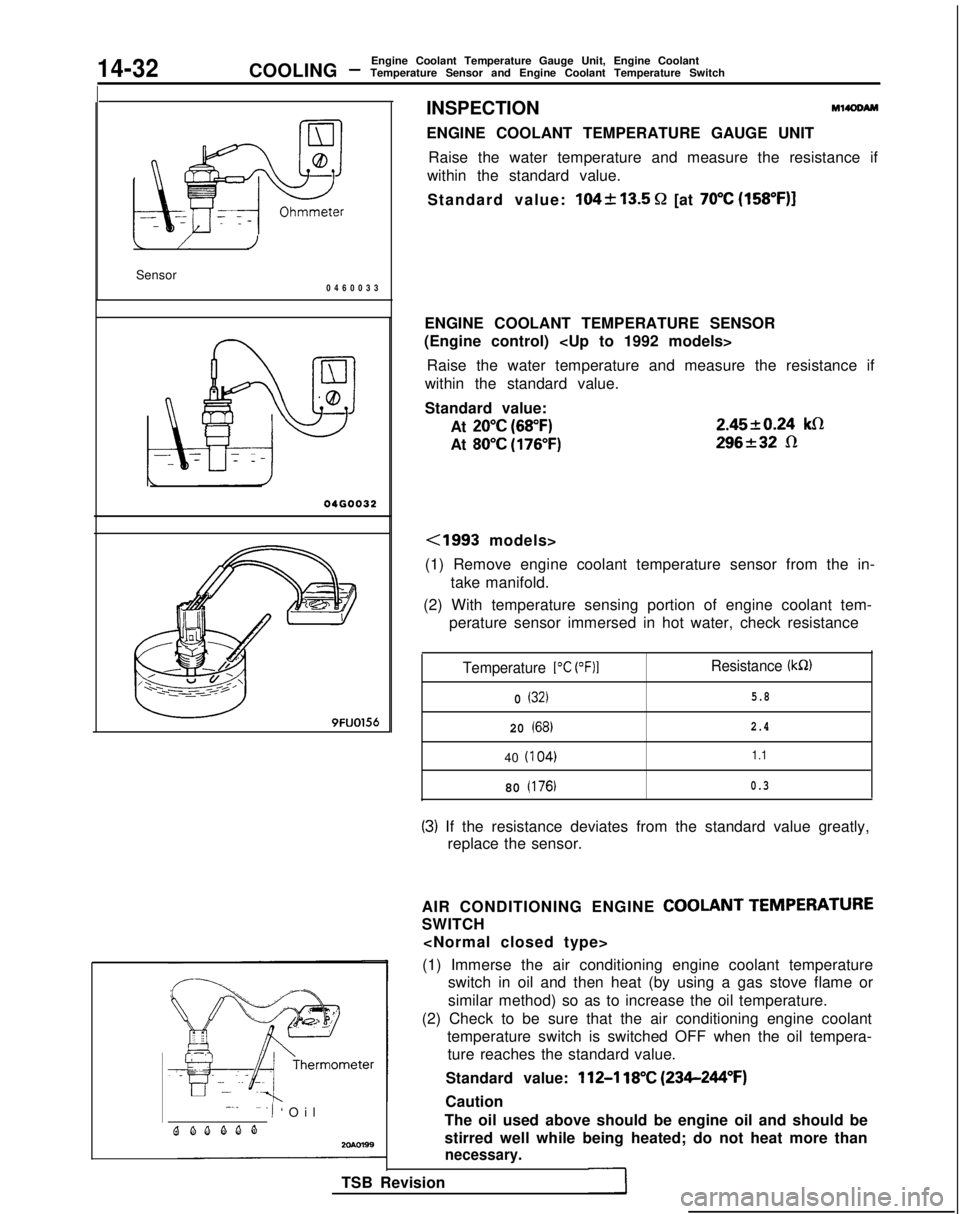

INSPECTIONM14OOAM

ENGINE COOLANT TEMPERATURE GAUGE UNIT

Raise the water temperature and measure the resistance if

within the standard value.

Standard value:

104k13.5 Q [at 70°C (158”F)]

ENGINE COOLANT TEMPERATURE SENSOR

(Engine control)

Raise the water temperature and measure the resistance if

within the standard value.

Standard value:

At

20°C (68°F)

At 80°C (176°F) 2.4520.24

klR

296232 R

<1993 models>

(1) Remove engine coolant temperature sensor from the in- take manifold.

(2) With temperature sensing portion of engine coolant tem- perature sensor immersed in hot water, check resistance

Temperature 1°C (OF)1Resistance (kR)

0 (32)5.8

20 (68)2.4

40

(I

04)1.1

80 (176)0.3

(3) If the resistance deviates from the standard value greatly,

replace the sensor.

AIR CONDITIONING ENGINE

COOLANT TEMPERATURE

SWITCH

(1) Immerse the air conditioning engine coolant temperature switch in oil and then heat (by using a gas stove flame or

similar method) so as to increase the oil temperature.

(2) Check to be sure that the air conditioning engine coolant temperature switch is switched OFF when the oil tempera-ture reaches the standard value.

Standard value:

112-l 18°C (234-244°F)

Caution

The oil used above should be engine oil and should be

stirred well while being heated; do not heat more than

necessary.

TSB Revision

Page 585 of 1273

COOLING -Engine Coolant Temperature Gauge Unit, Engine Coolant

Temperature Sensor and Engine Coolant Temperature Switch14-33

20R0586

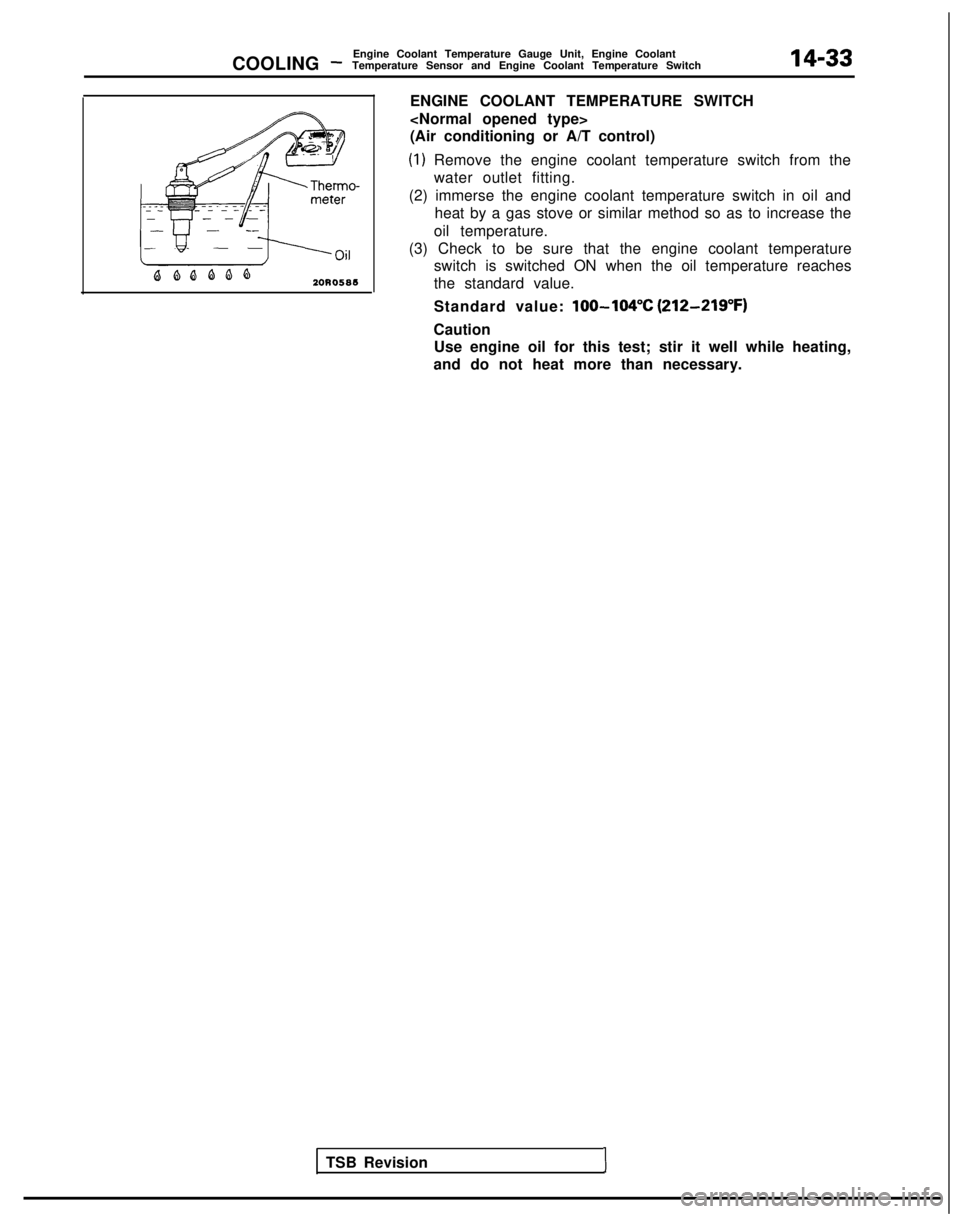

ENGINE COOLANT TEMPERATURE SWITCH

(Air conditioning or A/T control)

(1) Remove the engine coolant temperature switch from the

water outlet fitting.

(2) immerse the engine coolant temperature switch in oil and heat by a gas stove or similar method so as to increase the

oil temperature.

(3) Check to be sure that the engine coolant temperature switch is switched ON when the oil temperature reaches

the standard value.

Standard value:

lOO-104% (212-219°F)

CautionUse engine oil for this test; stir it well while heating,

and do not heat more than necessary.

TSB Revision

1

Page 588 of 1273

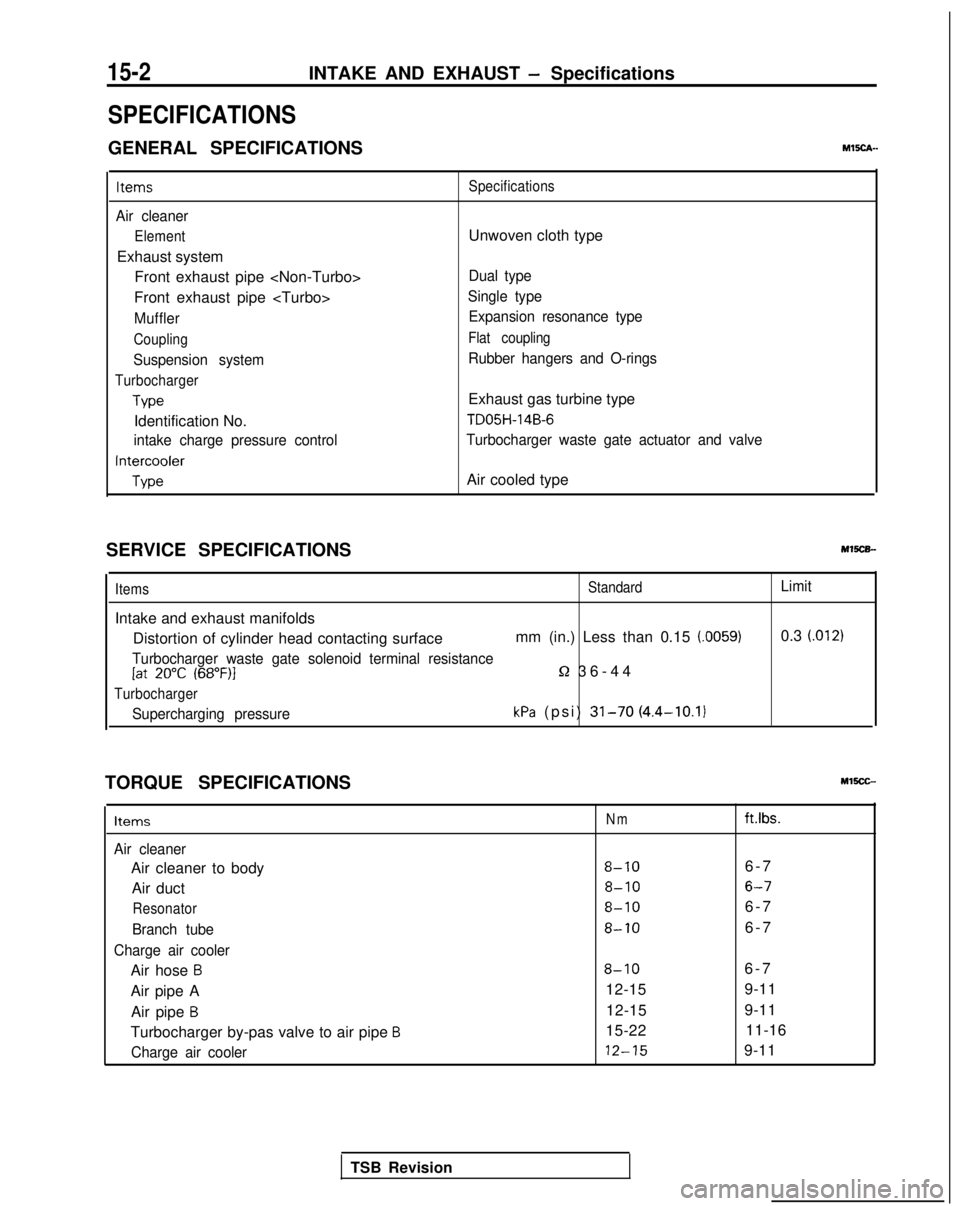

15-2INTAKE AND EXHAUST - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSMEch-

Items

Air cleaner

Element

Exhaust systemFront exhaust pipe

Front exhaust pipe

Muffler

Coupling

Suspension system

Turbocharger

Type

Identification No.

intake charge pressure control

Intercooler

Type Specifications

Unwoven cloth type

Dual type

Single type Expansion resonance type

Flat coupling

Rubber hangers and O-rings

Exhaust gas turbine type

TD05H-14B-6

Turbocharger waste gate actuator and valve

Air cooled type

SERVICE SPECIFICATIONS

Items

Intake and exhaust manifolds

StandardLimit

Distortion of cylinder head contacting surface mm (in.) Less than 0.15 (0059)0.3 (.012)

Turbocharger waste gate solenoid terminal resistance[at 20°C (68”F)l5-2 36-4

4

Turbocharger

Supercharging pressurekPa (psi) 31-70 (4.4-10.1)

TORQUE SPECIFICATIONS

Items

Air cleaner

Air cleaner to body

Air duct

Resonator

Branch tube

Charge air cooler

Air hose B

Air pipe A Air pipe

B

Turbocharger by-pas valve to air pipe B

Charge air cooler

Nmft.lbs.

8-106-

7

8-106-7

8-106-

7

8-106-

7

8-106-

7

12-15 9-11

12-15 9-11

15-22 11-16 12-15

9-11

TSB Revision

Page 622 of 1273

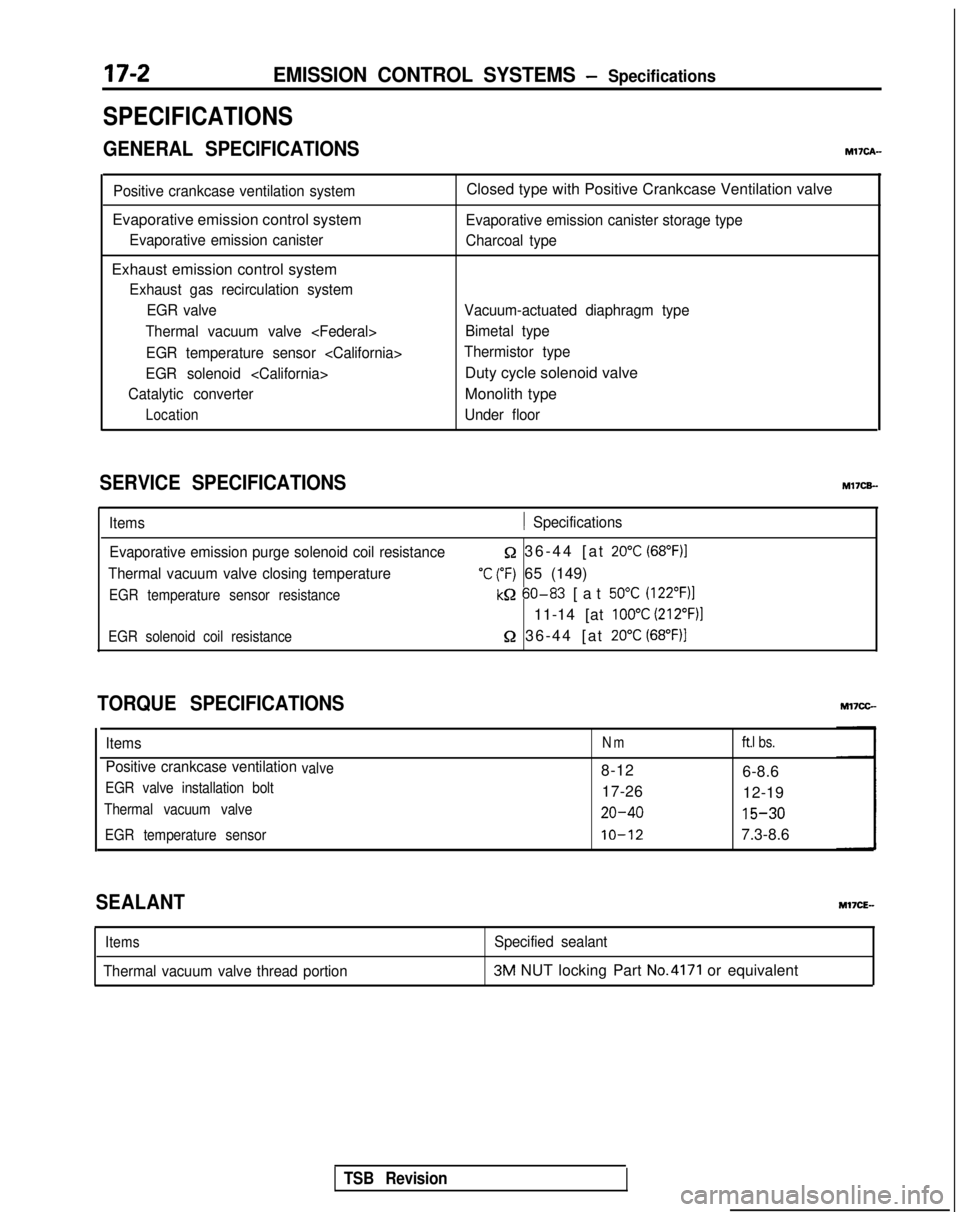

17-2EMISSION CONTROL SYSTEMS - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSMl’IcA-

Positive crankcase ventilation system

Evaporative emission control system

Evaporative emission canister

Exhaust emission control system

Exhaust gas recirculation systemEGR valve

Thermal vacuum valve

EGR temperature sensor

EGR solenoid

Catalytic converter

Location

Closed type with Positive Crankcase Ventilation valve

Evaporative emission canister storage type

Charcoal type

Vacuum-actuated diaphragm type Bimetal type

Thermistor type

Duty cycle solenoid valve

Monolith type

Under floor

SERVICE SPECIFICATIONS M17CB-

Items1 Specifications

Evaporative emission purge solenoid coil resistance

Thermal vacuum valve closing temperature

EGR temperature sensor resistance

Q 36-44 [at 20°C (68”F)I

‘C (“F) 65 (149)

kQ 60-83

[at 50°C (122”F)l

11-14 [at 100°C (212”F)l

EGR solenoid coil resistance52 36-44 [at 20°C (68°F))

TORQUE SPECIFICATIONS

ItemsNmft.1 bs.

Positive crankcase ventilationvalve8-12

6-8.6

EGR valve installation bolt17-2612-19

Thermal vacuum valve20-40 15-30

EGR temperature sensorIO-127.3-8.6

SEALANT

Items

Thermal vacuum valve thread portion

Specified sealant3M NUT locking Part No.4171 or equivalent

TSB Revision