torque MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 3 of 1273

00-l

GENERAL

CONTENTS

GENERAL DATA AND SPECIFICATIONS.....23

HOWTOUSETHISMANUAL......................

3

Definition of Terms ......................................3

ExplanationofCircuitDiagrams..................7

Explanation of

ManualContents .................4

Explanation of the Troubleshooting

Guide .............................................................

6

Model

Indications .........................................3

Scope of Maintenance, Repair and

Servicing Explanations

..................................

3

Troubleshooting .............................................3

LUBRICATIONANDMAINTENANCE............

34

MAINTENANCE SERVICE............................... 39

AirCleanerElement

.....................................39

Automatic

Transaxle

.....................................43

Ball Joint and Steering Linkage Seals ........45

Brake Hoses................................................. 45

Disc Brake Pads ........................................... 44

Drive Belt (For Water Pump and

Generator) .......................................................

41

Drive

Shaft Boots .........................................45

Engine Coolant

............................................. 44

Engine Oil .....................................................

41

Engine Oil Filter ...........................................41

Exhaust System

............................................ 45

FuelHoses

...................................................39

Fuel System

.................................................39

Manual Transaxle ..........................................42

RearAxle......................................................45

Rear Drum Brake Linings and

RearWheel Cylinders

..................................44

Spark

Plugs...................................................40

Timing Belt...................................................40

MASTER

TROUBLESHOOTING.....................28

PRECAUTIONS

BEFORESERVICE................15

RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIESTABLE..................35

SCHEDULED

MAINTENANCETABLE ...........38

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS

.......................................20

TABLE OF MAIN SEALANTS

AND

ADHESIVES ............................................46

TIGHTENING TORQUE

................................... 27

TOWING

ANDHOISTING ..............................17

VEHICLE

IDENTIFICATION .............................8

Chassis Number ...........................................

11

EngineModel

Stamping

...............................12

Theft Protection ............................................12

Vehicle Identification Code Chart Plate.......

8

Vehicle Identification Number List

..............8

Vehicle Identification Number Location .......

8

Vehicle Information

CodePlate...................1 1

Vehicle SafetyCertificationLabel................12

Page 6 of 1273

00-4GENERAL - How to Use This Manual

EXPLANATION OF MANUAL CONTENTSIndicates procedures to

be performed before the

work in that section is

started, and procedures

to be performed after

the work in that section

is finished.

Maintenance and Servicing Procedures

(1) A diagram of the component parts is provided near the front of each section in

order to give the reader a better under-

standing of the installed condition of

component parts.

(2) The numbers provided within the diagram indicate the sequence for maintenance

and servicing procedures; the symbol

mindicates a non-reusable part; the tighten-

ing torque is provided where applicable. l Removal steps:

The part designation number corres-

ponds to the number in the illustration

to indicate removal steps.

l Disassembly steps: The part designation number corres-

ponds to the number in the illustration

to indicate disassembly steps.

l Installation steps: Specified in case installation is impossi-

ble in reverse order of removal steps.

Omitted if installation is possible in

reverse order of removal steps.

8 Reassembly steps: Specified in case reassembly is im-

possible in reverse order of disassem-

bly steps.

Omitted if reassembly is possible in reverse order of disassembly steps.

Classificationsof Major Maintenance/

Service Points

When there are major points relative to mainte-

nance and servicing procedures (such as essential

maintenance and service points, maintenance and

service standard values, information regarding the

use of special tools, etc.), these are arranged

together as major maintenance and service points

and explained in detail.

*+ : Indicates that there are essential points for

removal or disassembly.

I)+ : Indicates that there are essential points forinstallation or reassembly. necessary. In this exam-

ple, sealant is applied

(where indicated) to the

I---

Symbols for Lubrication, Sealants and

Adhesives

4 . . . . .Grease

(multipurpose grease unless there is Information

concerning the locations for lubrica-

tion and for application of sealants and adhesives

is provided, by using symbols, in the diagram of

component parts or on the page following the

component parts page, and explarned.

a brand or type specified)

4 . . . . Sealant or adhesive

a. . . . .Brake fluid. automatic transmission

fluid or air conditioner compressor oil

a. . . . . Engine oil or gear oil

. . .Adhesive tape or butyl

rubber tape

Page 29 of 1273

GENERAL - Tightening Torque00-27

TIGHTENING TORQUE

Each torque value in the table is a standard value for tightening under \

the following conditions.

(1) Bolts, nuts and washers are all mode of steel and plated with zinc\

.

(2) The threads and bearing surface of bolts and nuts are all in dry c\

ondition.

The values in the table are not applicable:

(1) If toothed washers are inserted.

(2) If plastic parts are fastened.

(3) If bolts are tightened to plastic or die-cast inserted nuts.

(4) If self-tapping screws or self-locking nuts are used.

Standard bolt and nut tightening torque Bolt nominal

PitchTorque Nm (ft.lbs.1diameterb-m-dh-n)Head mark@Head mark@Head mark@

M50.8 2-3 (1.4-2.2) 4-6 (2.9-4.3)

5-7 (3.6-5.1)M6

1 .o4-6 (2.9-4.3)7-11 (5.1-8.0)8-12 (5.8-8.7)

M8

1.259-14 (6.5-10)17-26 (12-19)20-30 (14-22)

Ml01.2519-28(14-20)35-5

5

(25-40)45-60 (33-43)

Ml21.2534-50(25-36)70-95(51-69)85-110 (61-80)

Ml41.560-85 (43-61)120-160(87-116)130-180(94-130)

Ml61.595-130 (69-94)180-240(130-174)200-270(145-195)

Ml81.5140-190 (101-137)260-350(188-253)300-400(217-289)

Bolt nominal

Pitch Torque Nm (ft.lbs.1

diameterh-n)b-m-dHead mark@Head mark0Head mark@

M61 .o4-6 (2.9-4.3)8-12 (5.8-8.7)9-14 (6.5-10)

M81.25lo-15 (7.2-11)19-28 (14-20)22-33 (16-24)

Ml01.2521-31 (15-22)39-60 (28-43)50-65 (36-47)

Ml01.519-29 (14-21)

36-54 (26-39)45-65 (33-47)

Ml21.2538-55 (27-40)80-1'10 (58-80)90-120 (65-87)

Ml21.7534-52 (25-38)70-95 (51-69)85-110 (61-80)

.

TSB RevisionM20

1.5190-260(137-188)

M22

1.5260-350(188-253)M24

1.5340-460(246-333)630-860(456-622)

Flange bolt and nut tightening torque

Page 30 of 1273

00-28GENERAL - Tightening Torque/Master Troubleshooting

Taper thread tightening torque

Thread size

ITorque Nm (ftlbs.)I

r~Female thread material: Light alloy1-Female thread material: SteelI

NPTF II65-8 (3.6-5.8)

PT 1188- 12 (5.8-8.7)

PT 114, NPTF11420-30 (14-22)

PT

31840-55 (29-40)

NOTE: NPTF IS dry seat pope thread, while PT is pipe thread.

8- 12 (5.8-8.7)

16-20 (12-14)

35-45 (25-33)

60-75 (43-54)

MASTER TROUBLESHOOTING hlooKAAB

ENGINE OVERHEATS Symptom

Engine overheats Probable cause

Reference pageCoolrng system faulty14-5

Incorrect ignition timing

16-39, 40

ENGINE WILL NOT CRANK OR CRANKS SLOWLY Symptom Probable cause

Engine will not crank Starting system faulty

or cranks slowly Reference page

16-14

ENGINE WILL NOT START OR HARD TO START (CRANKS OK)

Symptom Probable cause Reference page

Engrne WIII not start or hard to

start (Cranks OK) No fuel supply to injector Injection

system problems

Ignition system problems

Vacuum leaks l Purge control valve hose

l Vacuum hoses

l intake manifold

l Intake manifold plenum

l Throttle body

l EGR valve13-90, 181, 295

13-90, 181, 295

16-32

17-3

Compression too low11-6

TSB Revision

Page 45 of 1273

GENERAL - Maintenance Service00-43

1

O.AUTOMATIC

TRANSAXLE

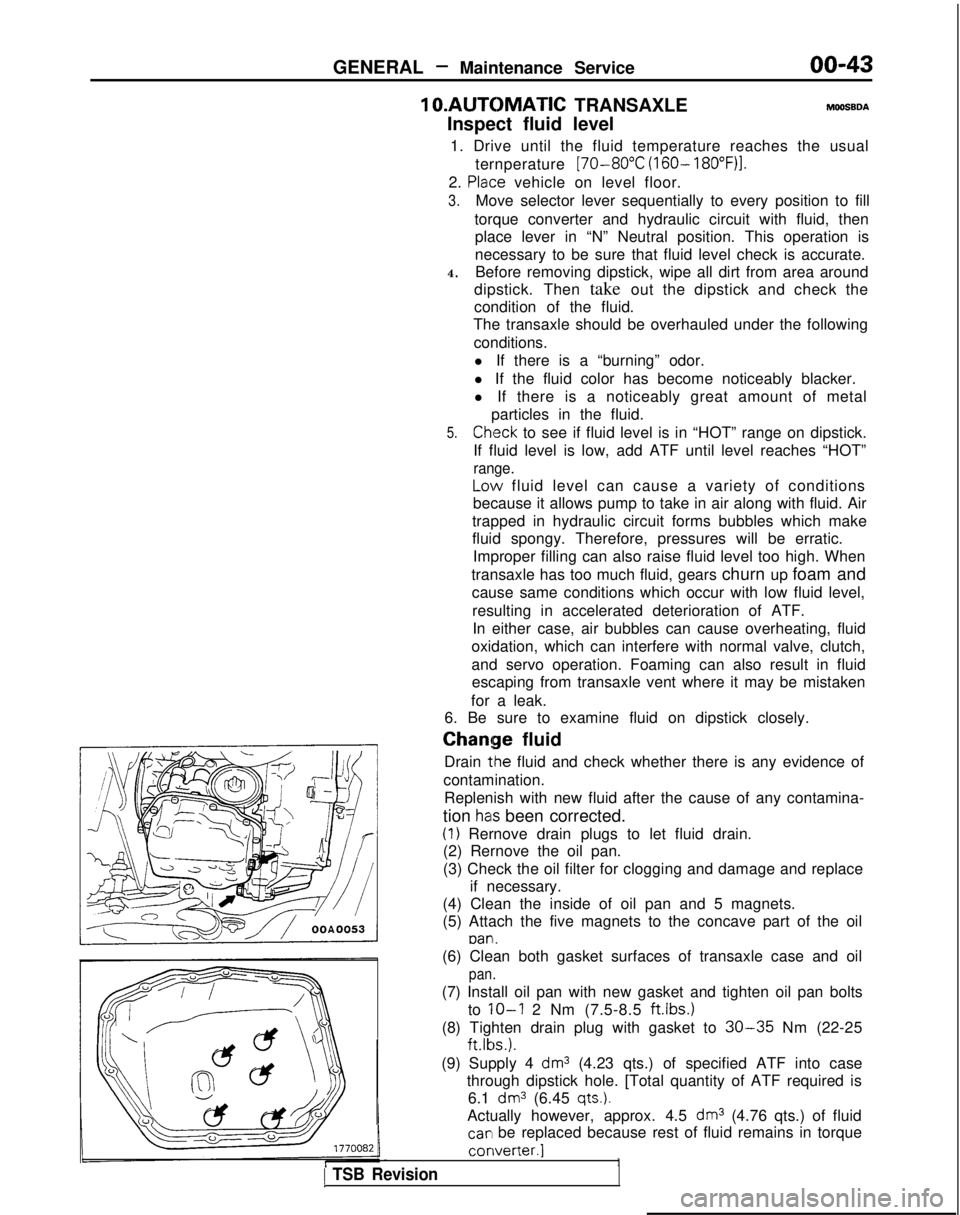

Inspect fluid levelMOOSSDA

1. Drive until the fluid temperature reaches the usual ternperature

[70-80°C (160- 18O”F)I.

2. Plaice vehicle on level floor.

3.Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place lever in “N” Neutral position. This operation is

necessary to be sure that fluid level check is accurate.

4. Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the

condition of the fluid.

The transaxle should be overhauled under the following

conditions.l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

l If there is a noticeably great amount of metal particles in the fluid.

5.Chleck to see if fluid level is in “HOT” range on dipstick.

If fluid level is low, add ATF until level reaches “HOT”

range.

LO\N fluid level can cause a variety of conditions

because it allows pump to take in air along with fluid. Air

trapped in hydraulic circuit forms bubbles which make

fluid spongy. Therefore, pressures will be erratic. Improper filling can also raise fluid level too high. When

transaxle has too much fluid, gears churn up foam and cause same conditions which occur with low fluid level,

resulting in accelerated deterioration of ATF.In either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch,

and servo operation. Foaming can also result in fluid escaping from transaxle vent where it may be mistaken

for a leak.

6. Be sure to examine fluid on dipstick closely. Chaqge

fluid

Drain

tlhe fluid and check whether there is any evidence of

contamination. Replenish with new fluid after the cause of any contamina-

tion

has been corrected.

(1) Rernove drain plugs to let fluid drain.

(2) Rernove the oil pan.

(3) Check the oil filter for clogging and damage and replace

if necessary.

(4) Clean the inside of oil pan and 5 magnets.

(5) Attach the five magnets to the concave part of the oil

pan.

1 TSB Revision

(6) Clean both gasket surfaces of transaxle case and oil

pan.

(7) Install oil pan with new gasket and tighten oil pan bolts

to

IO-I 2 Nm (7.5-8.5 ftlbs.)

(8) Tighten drain plug with gasket to 30-35 Nm (22-25 ft.lbs.).

(9) Supply 4

dm3 (4.23 qts.) of specified ATF into case

through dipstick hole. [Total quantity of ATF required is 6.1

dm3 (6.45 qts.).

Actually however, approx. 4.5 dm3 (4.76 qts.) of fluid

car1 be replaced because rest of fluid remains in torque converter.]

1

Page 51 of 1273

11-I

CONTENTSM11AA-

ENGINE

........................

53

CAMSHAFT AND CAMSHAFT OIL

SEALS..........................................68

CYLINDER HEAD GASKET

.................73

ENGINE ASSEMBLY

.........................63

OIL PAN AND OIL SCREEN ...............71

SERVICE ADJUSTMENT

PROCEDURES................................

57

Basic

Idle Speed Adjustment

...........................

.

Refer to GROUP 13

Compression Pressure Check ..............

59

Curb- Idle Speed Adjustment_.___..__._____....___._....Refer to GROUP 13

Dash Pot Inspection and Adjustment 58

Drive Belts Tension Adjustment . 6

1

Engine Oil Check . . .

_. _. . . _. . . . . . . 57

Ignition Timing Adjustment

__..._.__...................Refer to GROUP 16

Lash Adjusters Check ......................

.

57

Manifold Vacuum Inspection

..............

.

60

SPECIAL TOOLS.............................56

SPECIFICATIONS

............................53

General Specifications .....................

.

53

Sealants and Adhesives ....................

56

Service Specifications......................

.

53

Torque Specifications

......................

.

54

TIMINGBELT.................................80

TROUBLESHOOTING

........................56

E,NGINE

CAMSHAFT AND CAMSHAFT OIL

SEAL. . . . . . . . . . . . . . . . . . . ..*............ . . . . . . . . . .19

CYLINDER HEAD GASKET..................25

ENGINE ASSEMBLY.........................14

OIL PAN AND OIL SCREEN. . . . . . . . . . . . . . . .23

SERVICE ADJUSTMENT

PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . ..*.......7

Basic Idle Speed Adjustment

. . . . . . . .._......... . Refer to GROUP 13

Compression Pressure Check . .

.

8

Curb Idle Speed Adjustment

.__................ _. . . . Refer to GROUP 13

Drive Belts Tension Adjustment .........

.

12

Engine Oil Check

..........................

.

7

Ignition Timing Adjustment

_...___............... . . . . . Refer to GROUP 16

Lash Adjusters Check . . . . . . . . . . . .

7

Manifold Vacuum Inspection . . . . . . . . . .9

Timing Belt Tension Adjustment . . . .10

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

.5

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Specifications _. _.2

Sealants and Adhesives

._ _. . . . . . . .5

Service Specifications . . . .2

Torque Specifications . . . . . . . . . . . . . . . .4

TIMING BELT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . m.. .6

Compression Too Low

Connecting Rod Noise/Main Bearing Noise Excessive Engine Rolling and Vibration

Noisy Valves

Oil Pressure Drop

Oil Pressure Too High

Timing Belt Noise

Page 54 of 1273

II-4ENGINE

TORQUE SPECIFICATIONS Items

Nm ft.lbs.

Engine mount insulator nut (large)

60-8043-58

Engrne mount insulator nut (small)30-4022-29

Engine mount bracket nut and bolt

50-6536-47

Front roll stopper insulator nut

50-6536-47

Front roll stopper bracket to center member

40-5029-36

Rear roll stopper insulator nut

40-5029-36

Rear roll stopper bracket to crossmember

40-5029-36

Transaxle mount insulator nut

60-8043-58

Transaxle mount bracket to body

40-5029-36

Fuel high pressure hose to fuel rail 4-

6

3-4

Accelerator cable adjusting bolt 4-63-4

Front exhaust pipe clamp bolt

30-4022-29

Front exhaust pipe to exhaust manifold

40- 5029-36

Power steering oil pump to bracket 35-4525-33

Air conditioning compressor to bracket 23-27

17-20

Oil pan drain plug35-4526-33

Oilpan6-

8

4-6

Oil screen 15-2211-16

Timing belt cover

IO-127-

9

Cylinder head bolt (Cold engine)

90- 10065-72

Camshaft sprocket

80-10058-72

dater pump pulley bolt8-106-

7

Crankshaft pulley bolt

20-3014-22

Crankshaft sprocket bolt

110-13080-94

Timrng belt B tensioner bolt 15-2211-16

Tension pulley bracket bolt 23-2717-20

Right silent shaft sprocket bolt34-40”’ [43-49]*’ 25-29” [31-351”

Oil sprocket nut pump

50-6036-43

Control wiring harness and intake manifold plenum or air intake manifold\

4-

6

3-4

Front roll stopper bracket bolt 55-75

40-54

Front engine support bracket bolt50-7036-51

Exhaust pipe support bracket bolt

30-4222-30

Left engine support bracket bolt30-4222-30

Rear roll stopper bracket bolt110-13080-94

Front case bolt20-2714-20

Bear cover bolt 5-

7

4-5

Iistributor nutIO-137-

9

Rocker arm and shaft assembly bolt (large) 19-2114-15

?ocker arm and shaft assembly bolt (small)20-2714-20

ntake manifold stay bolt

18-2513-18

-iming belt tensioner spacer and bolt

43-5531-40

NOTE*I: When a 2.0 mm (.08 in.) thick washer is used.~2: When a 2.6 mm (.I0 in.) thick washer is used.

TSB Revision

Page 83 of 1273

ENGINE

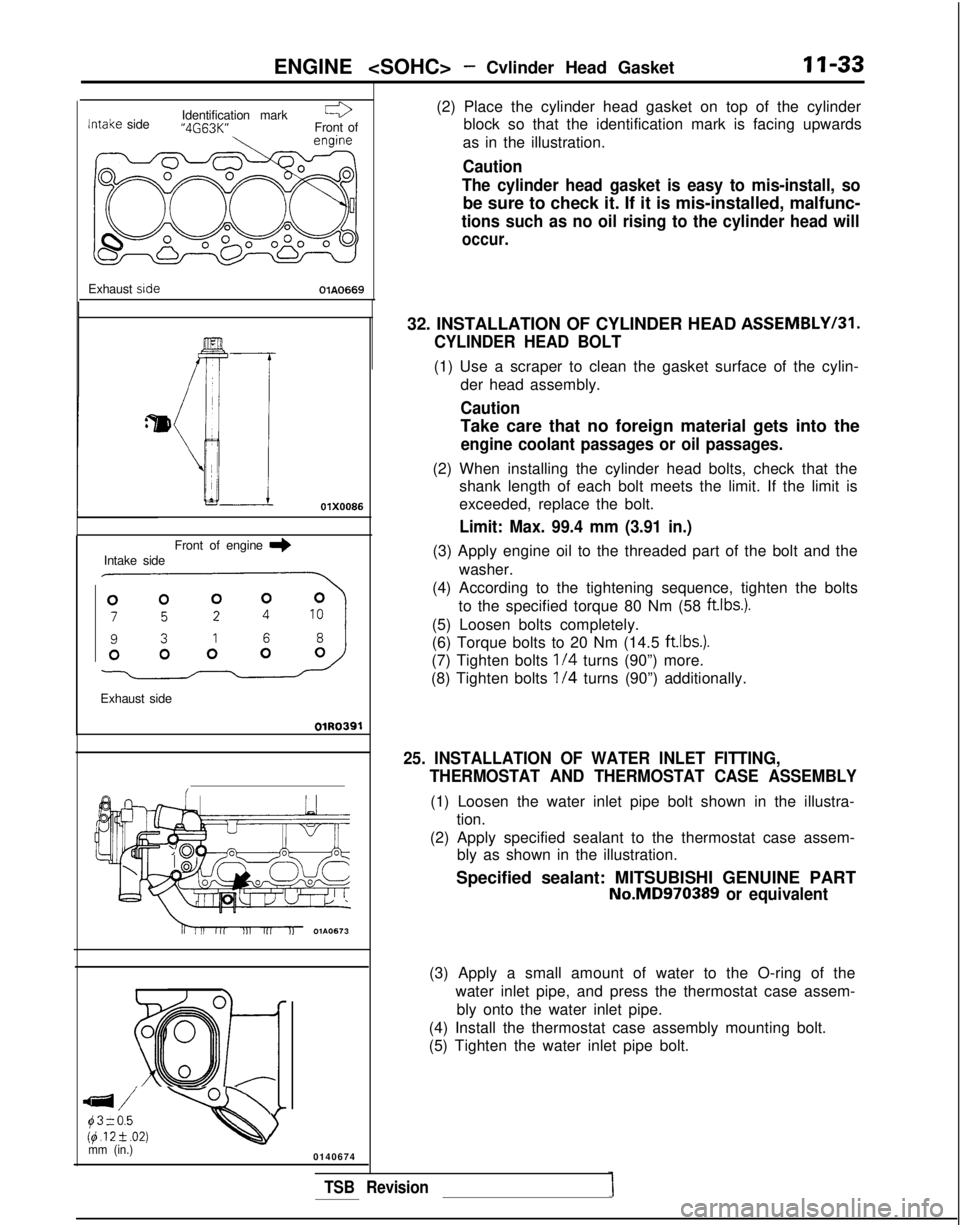

Identification markr3

Intake

side “4G63K”

Front of

Exhaust side

OlA0669

Front of engine

I)Intake side

Exhaust side

OlR0391

Ei;. -Qmm (in.)0140674 (2) Place the cylinder head gasket on top of the cylinder

block so that the identification mark is facing upwards

as in the illustration.

Caution

The cylinder head gasket is easy to mis-install, so

be sure to check it. If it is mis-installed, malfunc-

tions such as no oil rising to the cylinder head will

occur.

32. INSTALLATION OF CYLINDER HEAD ASSEMBLYI31.

CYLINDER HEAD BOLT

(1) Use a scraper to clean the gasket surface of the cylin-

der head assembly.

Caution

Take care that no foreign material gets into the

engine coolant passages or oil passages.

(2) When installing the cylinder head bolts, check that theshank length of each bolt meets the limit. If the limit is

exceeded, replace the bolt.

Limit: Max. 99.4 mm (3.91 in.)

(3) Apply engine oil to the threaded part of the bolt and the

washer.

(4) According to the tightening sequence, tighten the bolts to the specified torque 80 Nm (58 ftlbs.).

(5) Loosen bolts completely.

(6) Torque bolts to 20 Nm (14.5

ft.lbs.).

(7) Tighten bolts l/4 turns (90”) more.

(8) Tighten bolts

l/4 turns (90”) additionally.

25. INSTALLATION OF WATER INLET FITTING, THERMOSTAT AND THERMOSTAT CASE ASSEMBLY

(1) Loosen the water inlet pipe bolt shown in the illustra-tion.

(2) Apply specified sealant to the thermostat case assem- bly as shown in the illustration.

Specified sealant: MITSUBISHI GENUINE PART

No.MD970389 or equivalent

(3) Apply a small amount of water to the O-ring of the

water inlet pipe, and press the thermostat case assem-bly onto the water inlet pipe.

(4) Install the thermostat case assembly mounting bolt.

(5) Tighten the water inlet pipe bolt.

TSB Revision

Page 97 of 1273

ENGINE

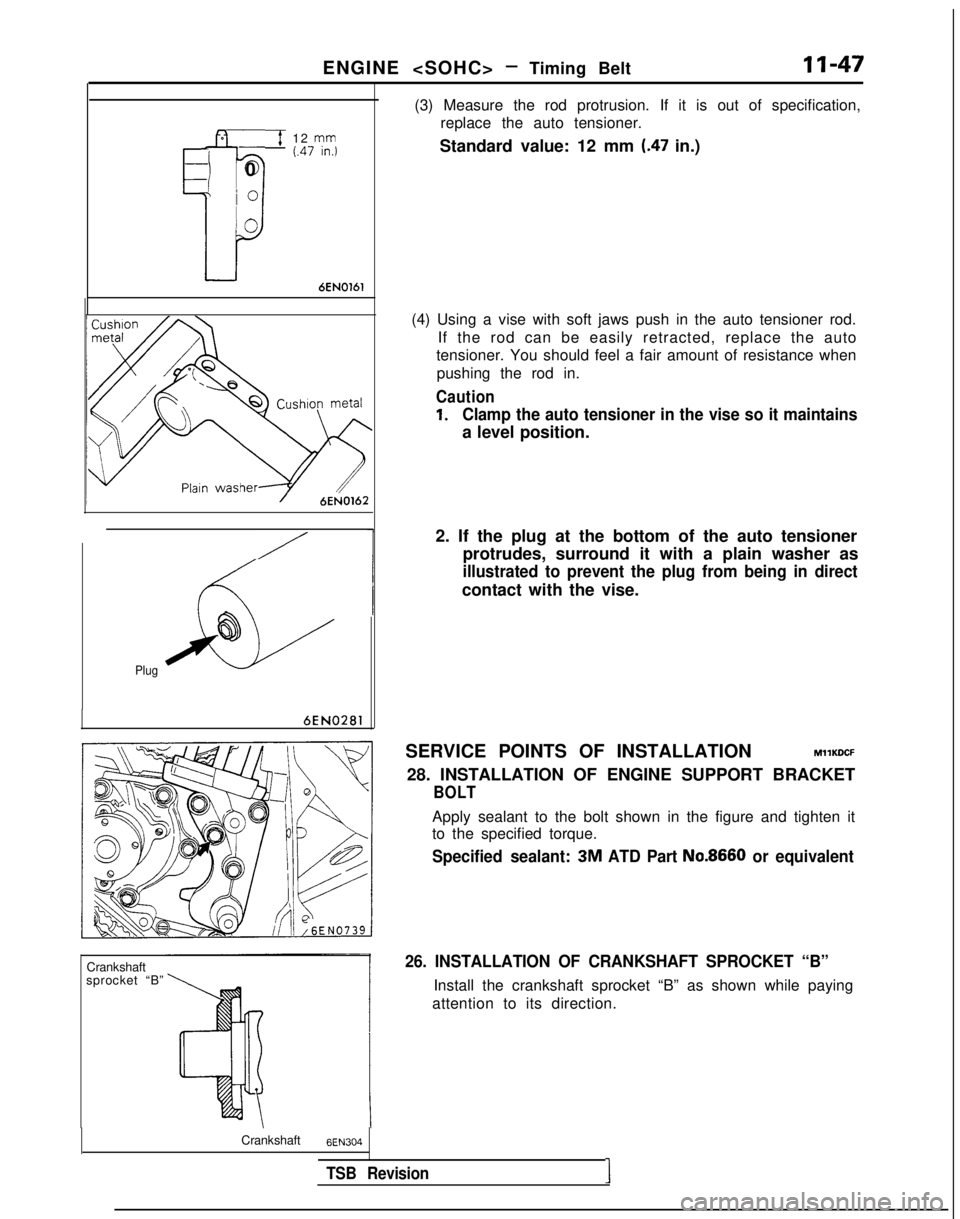

~7 12

rym

I

(.47 In.)-0

io

‘0

6EN0161

/

AL

@

Plug

6EN0281

Crankshaft

sprocket “B” (3) Measure the rod protrusion. If it is out of specification,

replace the auto tensioner.

Standard value: 12 mm

(.47 in.)

(4) Using a vise with soft jaws push in the auto tensioner rod. If the rod can be easily retracted, replace the auto

tensioner. You should feel a fair amount of resistance when

pushing the rod in.

Caution

1.Clamp the auto tensioner in the vise so it maintains

a level position.

2. If the plug at the bottom of the auto tensioner protrudes, surround it with a plain washer as

illustrated to prevent the plug from being in direct

contact with the vise.

SERVICE POINTS OF INSTALLATION

M1lKDCF

28. INSTALLATION OF ENGINE SUPPORT BRACKET

BOLT

Apply sealant to the bolt shown in the figure and tighten it

to the specified torque.

Specified sealant: 3M ATD Part No.8660

or equivalent

26. INSTALLATION OF CRANKSHAFT SPROCKET “B”

Install the crankshaft sprocket “B” as shown while paying

attention to its direction.

Crankshaft

6EN304

TSB RevisionI

Page 101 of 1273

ENGINE

r

L Camshaft sprocket

Idler

pulley

/Oil pumpOlA0668

sprocket

6EN0175

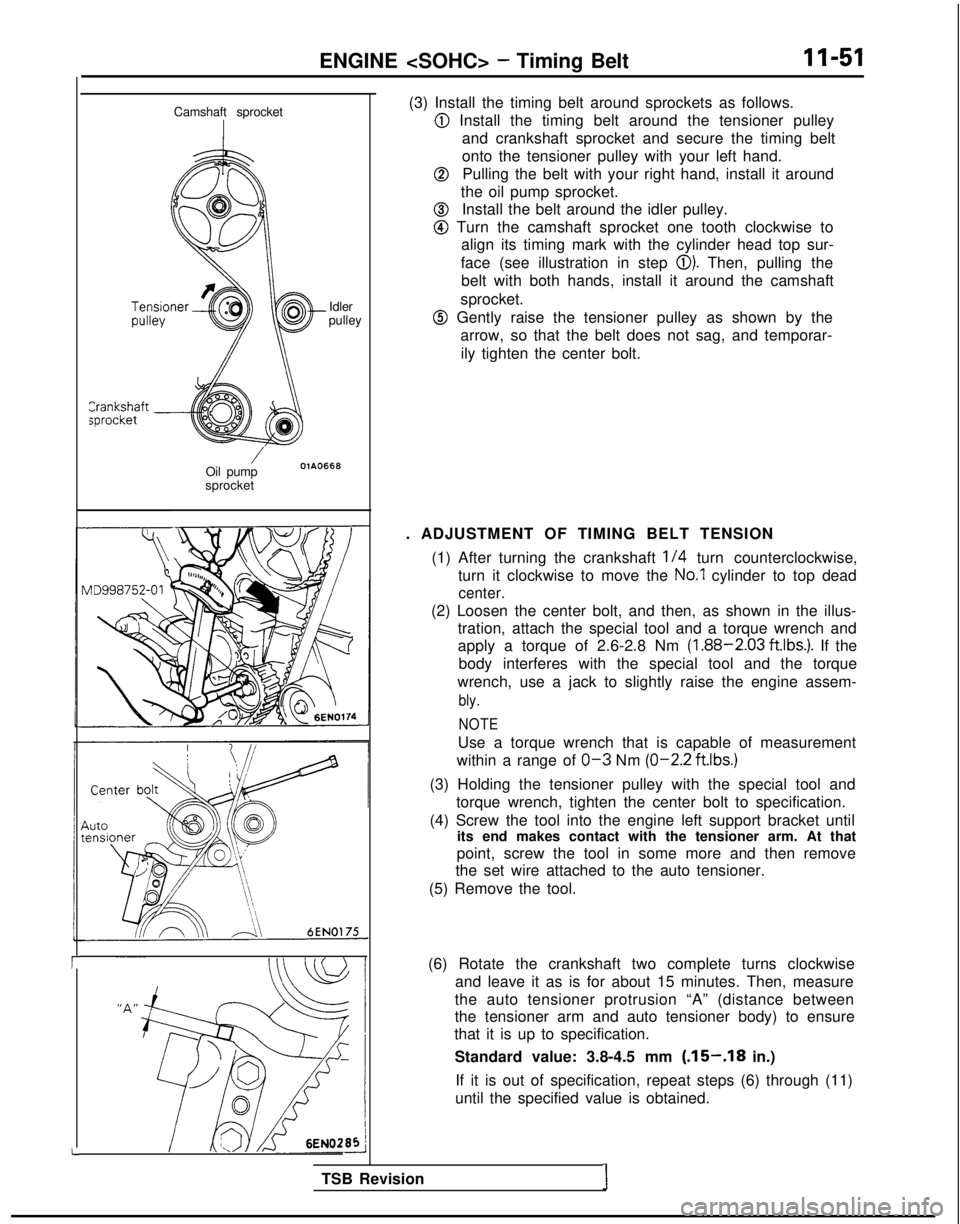

(3) Install the timing belt around sprockets as follows.

@ Install the timing belt around the tensioner pulley

and crankshaft sprocket and secure the timing belt

onto the tensioner pulley with your left hand.

@Pulling the belt with your right hand, install it around

the oil pump sprocket.

@Install the belt around the idler pulley.

@ Turn the camshaft sprocket one tooth clockwise to align its timing mark with the cylinder head top sur-

face (see illustration in step

0). Then, pulling the

belt with both hands, install it around the camshaft

sprocket.

@ Gently raise the tensioner pulley as shown by the arrow, so that the belt does not sag, and temporar-

ily tighten the center bolt.

. ADJUSTMENT OF TIMING BELT TENSION (1) After turning the crankshaft

l/4 turn counterclockwise,

turn it clockwise to move the

No.1 cylinder to top dead

center.

(2) Loosen the center bolt, and then, as shown in the illus- tration, attach the special tool and a torque wrench and

apply a torque of 2.6-2.8 Nm

(1.88-2.03 ft.lbs.). If the

body interferes with the special tool and the torque

wrench, use a jack to slightly raise the engine assem-

bly.

NOTE

Use a torque wrench that is capable of measurement

within a range of

O-3 Nm (O-2.2

ftlbs.)

(3) Holding the tensioner pulley with the special tool and

torque wrench, tighten the center bolt to specification.

(4) Screw the tool into the engine left support bracket until its end makes contact with the tensioner arm. At that

point, screw the tool in some more and then remove

the set wire attached to the auto tensioner.

(5) Remove the tool.

(6) Rotate the crankshaft two complete turns clockwise and leave it as is for about 15 minutes. Then, measure

the auto tensioner protrusion “A” (distance between

the tensioner arm and auto tensioner body) to ensure

that it is up to specification.

Standard value: 3.8-4.5 mm

(.15-.18 in.)

If it is out of specification, repeat steps (6) through (11)

until the specified value is obtained.

TSB Revision

I