height MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 24 of 1273

00-22GENERAL - Special Handling Instructions for AWD Models

REAR WHEEL MEASUREMENTS

After placing the rear wheels on the brake tester, follow thesame procedures as for the front wheel measurements.

WHEEL BALANCE

FRONT WHEEL MEASUREMENTS

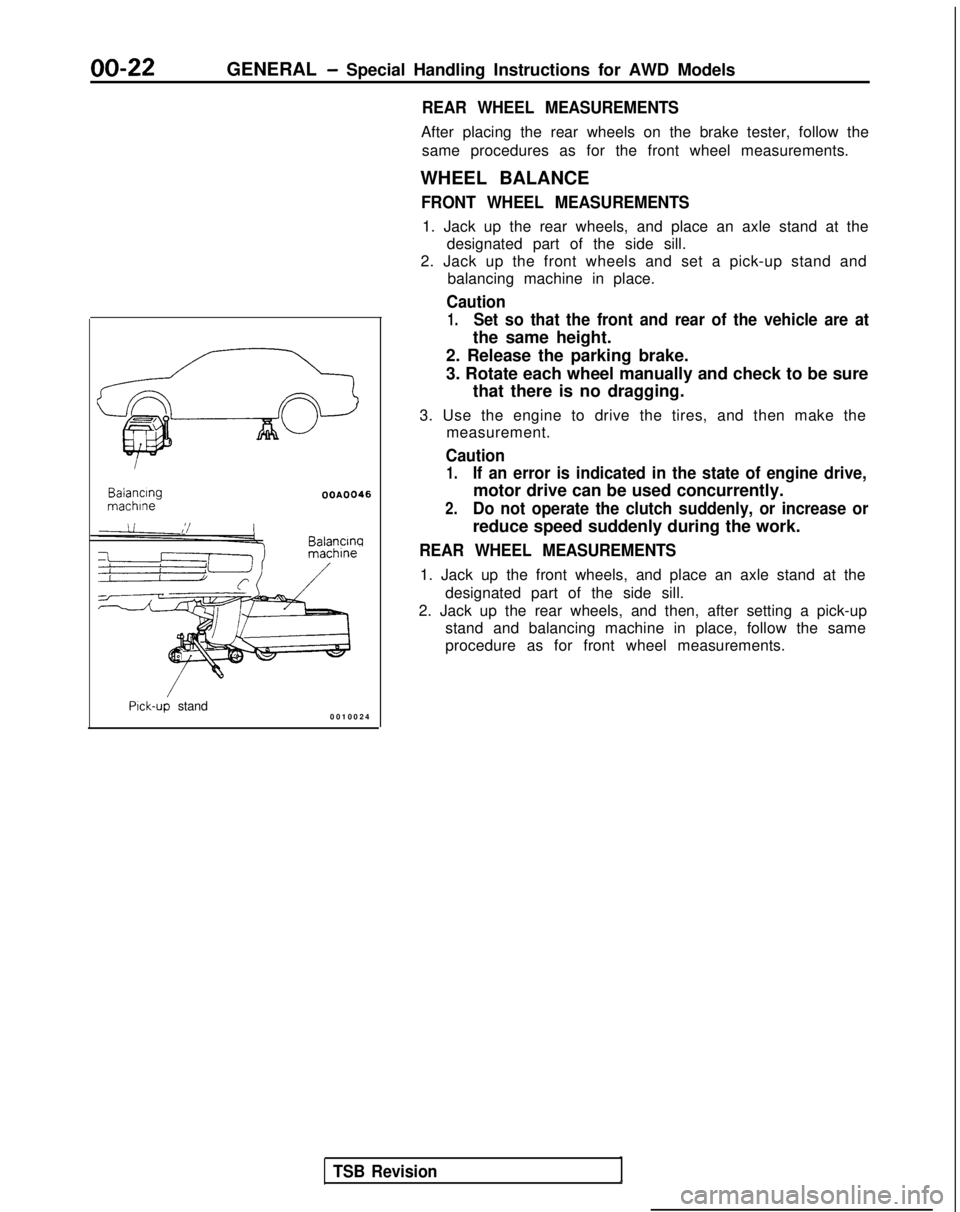

1. Jack up the rear wheels, and place an axle stand at the designated part of the side sill.

2. Jack up the front wheels and set a pick-up stand and balancing machine in place.

Caution

1.Set so that the front and rear of the vehicle are at

the same height. Balancing

machlne

OOA0046

Balancw

Pick-up stand

0010024

TSB Revision

2. Release the parking brake.

3. Rotate each wheel manually and check to be sure

that there is no dragging.

3. Use the engine to drive the tires, and then make the measurement.

Caution

1.If an error is indicated in the state of engine drive,

motor drive can be used concurrently.

2.Do not operate the clutch suddenly, or increase or

reduce speed suddenly during the work.

REAR WHEEL MEASUREMENTS

1. Jack up the front wheels, and place an axle stand at the

designated part of the side sill.

2. Jack up the rear wheels, and then, after setting a pick-up stand and balancing machine in place, follow the same

procedure as for front wheel measurements.

Page 25 of 1273

GENERAL - General Data and Specifications00-23

GENERAL DATA AND SPECIFICATIONSMOOHA-

3

I TT I

8

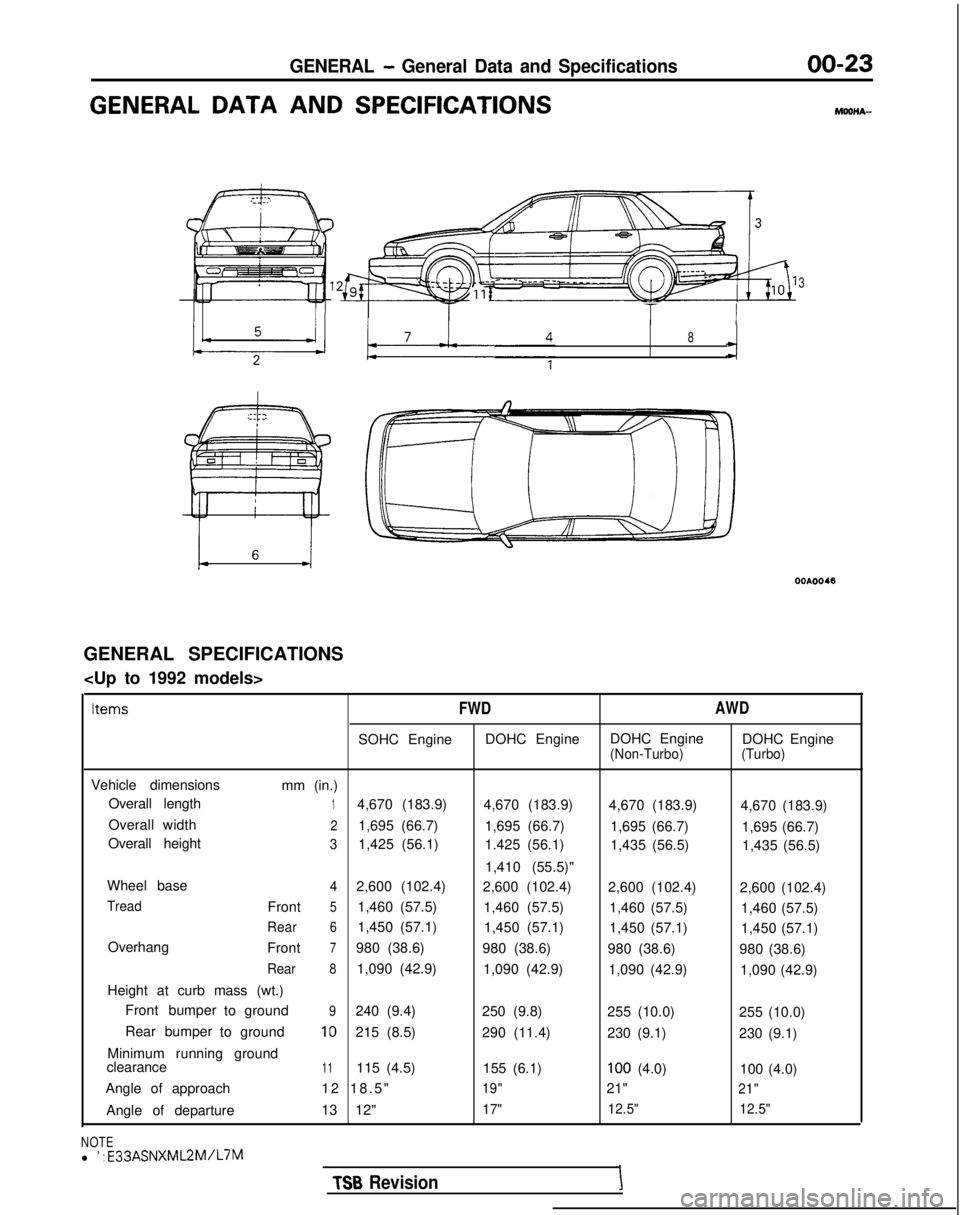

GENERAL SPECIFICATIONS

FWD

AWD

SOHC EngineDOHC EngineDOHC Engine

DOHC Engine(Non-Turbo) (Turbo)

Vehicle dimensions

mm (in.)

Overall length

14,670 (183.9) 4,670 (183.9)4,670 (183.9) 4,670 (183.9)

Overall width

21,695 (66.7) 1,695 (66.7)1,695 (66.7) 1,695 (66.7)

Overall height

31,425 (56.1) 1.425 (56.1)1,435 (56.5) 1,435 (56.5)

1,410 (55.5)"

Wheel base

42,600 (102.4) 2,600 (102.4)2,600 (102.4) 2,600 (102.4)

TreadFront51,460 (57.5)1,460 (57.5)1,460 (57.5) 1,460 (57.5)

Rear61,450 (57.1)1,450 (57.1)1,450 (57.1) 1,450 (57.1)

Overhang Front

7980 (38.6)980 (38.6)980 (38.6) 980 (38.6)

Rear81,090 (42.9)1,090 (42.9)1,090 (42.9) 1,090 (42.9)

Height at curb mass (wt.) Front bumper toground

9240 (9.4)

250 (9.8)255 (10.0) 255 (10.0)

Rear bumper toground

10215 (8.5)

290 (11.4)230 (9.1) 230 (9.1)

Minimum running ground

clearance

11115 (4.5) 155 (6.1)100 (4.0)100 (4.0)

Angle of approach 12 18.5

"

19"21"21"

Angle of departure

13 12"17"12.5"

12.5"

NOTEl ’ : E33ASNXML2M/L7M

TSB RevisionI

Page 27 of 1273

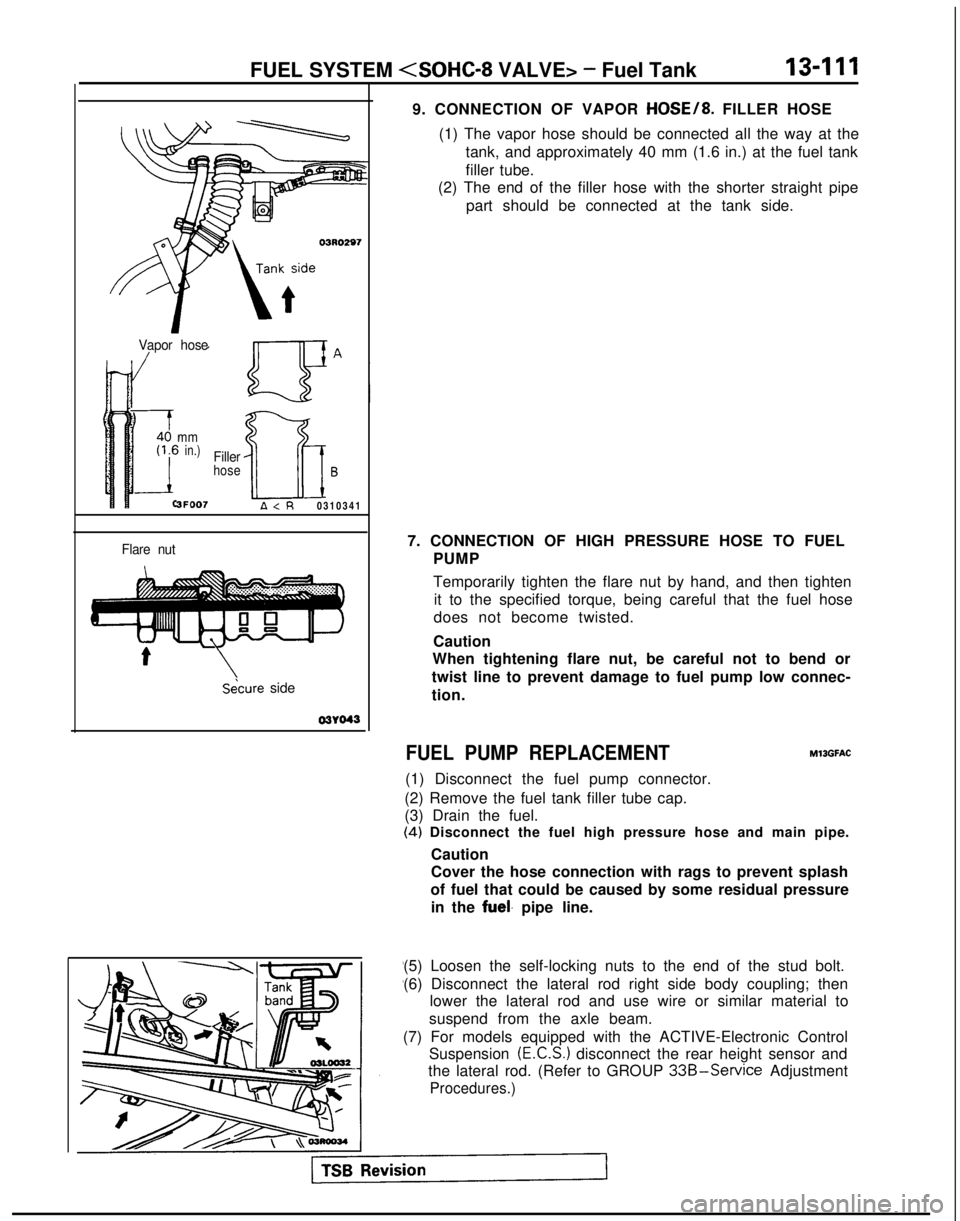

GENERAL - General Data and Specifications00-25

(1993 models

>

Items

FWD

SOHC Engine DOHC Engine

Vehicle dimensionsmm (in.)

Overall length14,670 (183.9)

4,670 (183.9)

Overall width21,695 (66.7)1,695 (66.7)

Overall height31,425 (56.1)1,425 (56.1) I,41

0

(55.5)*’

Wheel base4

2,600 (102.4)

2,600 (102.4)

Tread Front51,460 (57.5)1,460 (57.5)

Rear

61,450 (57.1) 1,450 (57.1)

Overhang Front7980 (38.6)980 (38.6)

Rear

81,090 (42.9) 1,090 (42.9)

Height at curb mass (wt.)

Front bumper to ground

9240 (9.4) 250 (9.8)

Rear bumper to ground10215 (8.5)290 (11.4)

Minimum running ground

clearance11115 (4.5)155 (6.1)

Angle of approach 12 18.5”19”

Angle of departure13 12”17”

lehicle weightkg (tbs.)

Curb weights

M/T

1,230 (2,712) or1,250 (2,755)*’I,31

0 (2,888)

A/T1,250 (2,755) or1,285(2,833)*3or1,270 (2,800)*4

Gross vehicle weight rating1,700 (3,747) 1,780 (3,923)

Gross axle weight rating Front900 (1,984)960 (2,116)

Rear 800 (1,763)

820 (1,807)

ieating capacity55lngine

Model No.

4G634G63 -ransaxle

Model No. Manual transaxle

F5M22 F5M22

Automatic transaxle

F4A22 lutch

Type

Dry-single disc & diaphragm spring

Dry-single disc &

diaphragm spring

d

TSB Revision

NOTE*l : E33ASNXML2MlL7M*2 : E33ASNGEL2MI7M*3 :

E33ASRXEL2M/7M*4 :

E33ASRGEL2M/7M

Page 253 of 1273

FUEL SYSTEM

03R0297

Vapor hose

mmin.)Fillerhose

i2.l

B

3FOO7

A

1

Flare nut

Skure side

03Yo43

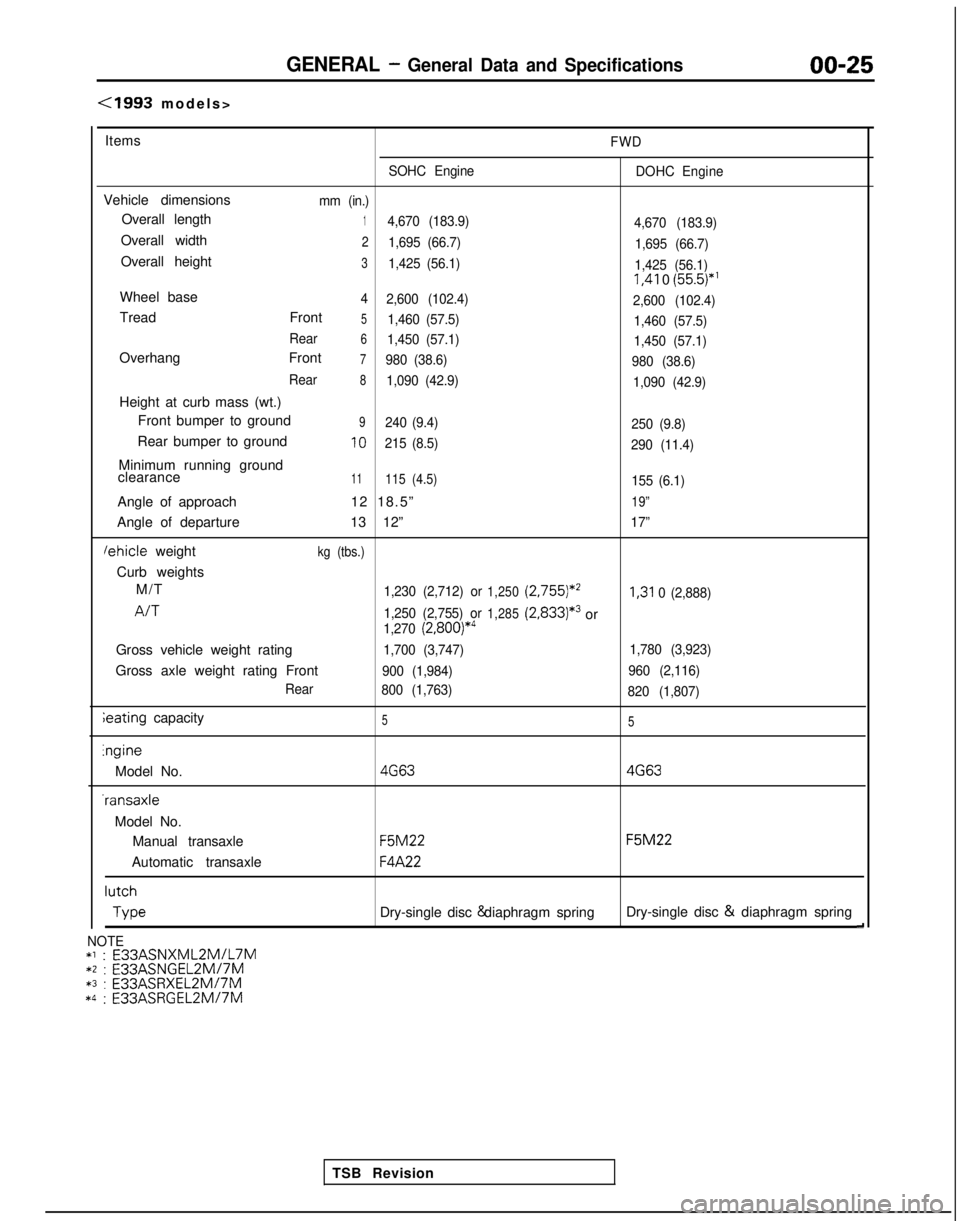

9. CONNECTION OF VAPOR HOSE/8. FILLER HOSE

(1) The vapor hose should be connected all the way at the tank, and approximately 40 mm (1.6 in.) at the fuel tank

filler tube.

(2) The end of the filler hose with the shorter straight pipe

part should be connected at the tank side.

7. CONNECTION OF HIGH PRESSURE HOSE TO FUEL PUMP

Temporarily tighten the flare nut by hand, and then tightenit to the specified torque, being careful that the fuel hose

does not become twisted.

Caution

When tightening flare nut, be careful not to bend or

twist line to prevent damage to fuel pump low connec-

tion.

FUEL PUMP REPLACEMENT

(1) Disconnect the fuel pump connector.

(2) Remove the fuel tank filler tube cap.

(3) Drain the fuel. MllGFAC

(4)

Disconnect the fuel high pressure hose and main pipe.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure in the

fuel. pipe line.

(5) Loosen the self-locking nuts to the end of the stud bolt.

(6) Disconnect the lateral rod right side body coupling; then lower the lateral rod and use wire or similar material to

suspend from the axle beam.

(7) For models equipped with the ACTIVE-Electronic Control Suspension

(E.C.S.) disconnect the rear height sensor and

the lateral rod. (Refer to GROUP

33B-Service Adjustment

Procedures.)

Page 254 of 1273

13-112FUEL SYSTEM

03L0018

QcD ua .

CFa

cc

0c aa0u0aa

Positioning projection

03L0009

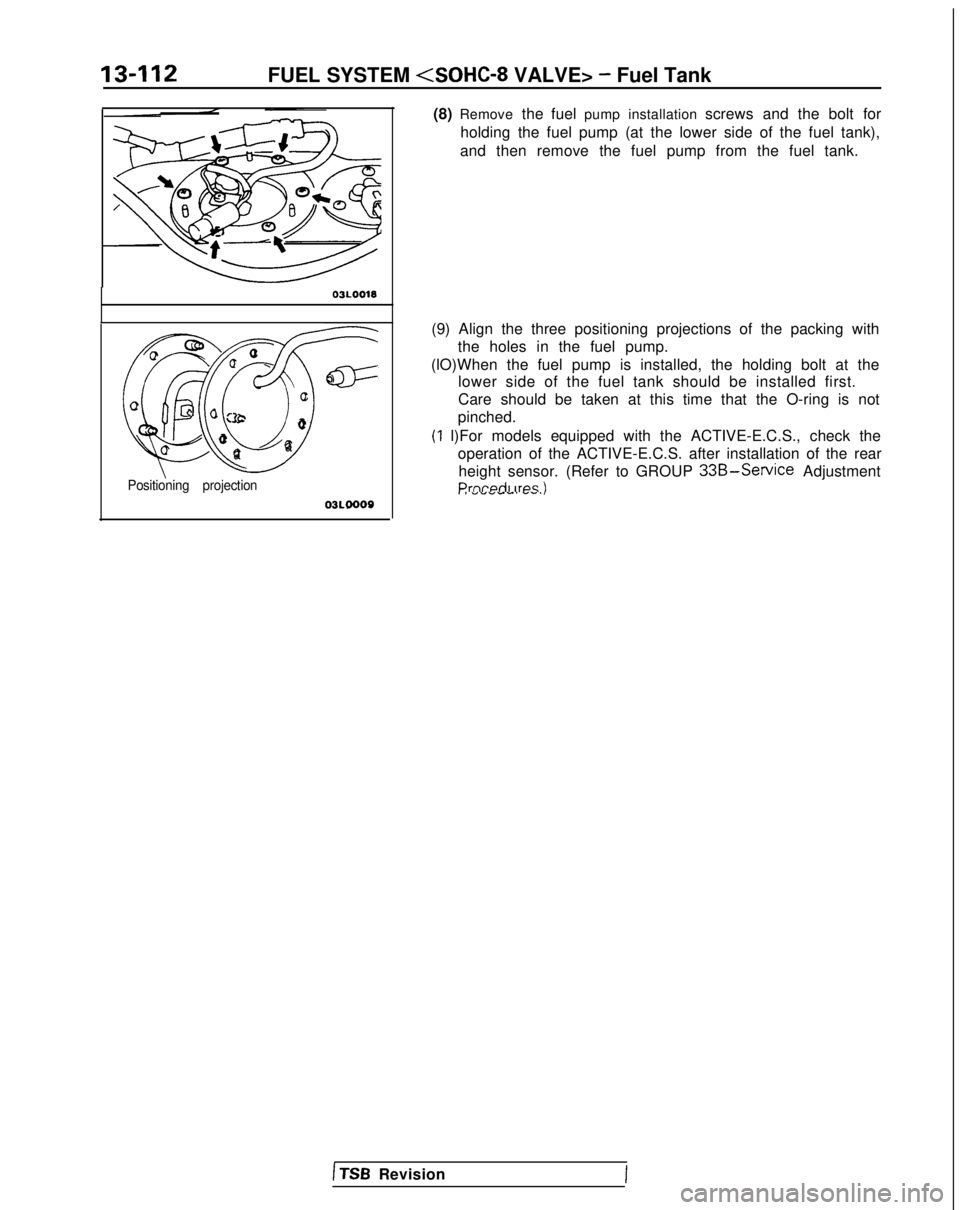

(8) Remove

the fuel pump installation screws and the bolt for

holding the fuel pump (at the lower side of the fuel tank),

and then remove the fuel pump from the fuel tank.

(9) Align the three positioning projections of the packing with the holes in the fuel pump.

(lO)When the fuel pump is installed, the holding bolt at the lower side of the fuel tank should be installed first.

Care should be taken at this time that the O-ring is not

pinched.

(1 l)For models equipped with the ACTIVE-E.C.S., check the operation of the ACTIVE-E.C.S. after installation of the rearheight sensor. (Refer to GROUP

33B-Service AdjustmentPrnrwiI irps II I ““VW-. W.S.,

1 TSB Revision

Page 462 of 1273

13-320FUEL SYSTEM

03RO297

V/apor hose

mmin.)

3FOO7

Filler

hoseB

A

\Secure side 03YO43

Ll

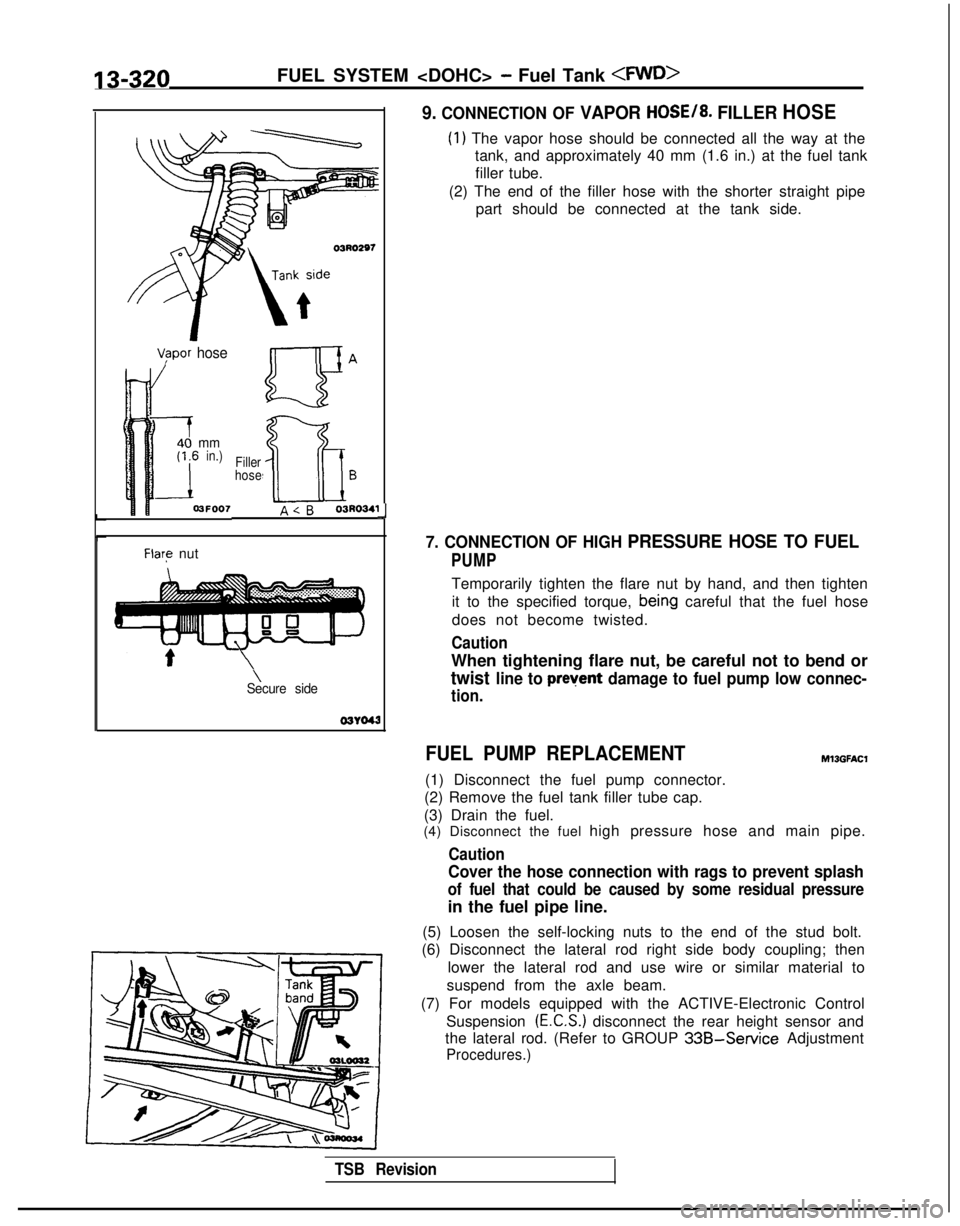

9. CONNECTION OF VAPOR HOSE/8. FILLER HOSE

(1) The vapor hose should be connected all the way at the

tank, and approximately 40 mm (1.6 in.) at the fuel tank

filler tube.

(2) The end of the filler hose with the shorter straight pipe part should be connected at the tank side.

7. CONNECTION OF HIGH PRESSURE HOSE TO FUEL

PUMP

Temporarily tighten the flare nut by hand, and then tighten

it to the specified torque,

bein,g careful that the fuel hose

does not become twisted.

Caution

When tightening flare nut, be careful not to bend or

twist line to prevent damage to fuel pump low connec-

tion.

FUEL PUMP REPLACEMENT

(1) Disconnect the fuel pump connector.

(2) Remove the fuel tank filler tube cap.

(3) Drain the fuel.

Ml3GFAt.X

(4) Disconnect the fuel high pressure hose and main pipe.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

(5) Loosen the self-locking nuts to the end of the stud bolt.

(6) Disconnect the lateral rod right side body coupling; then

lower the lateral rod and use wire or similar material to

suspend from the axle beam.

(7) For models equipped with the ACTIVE-Electronic Control Suspension

(E.C.S.) disconnect the rear height sensor and

the lateral rod. (Refer to GROUP

33B-Service Adjustment

Procedures.)

TSB Revision

Page 463 of 1273

FUEL SYSTEM

I03LOO18

-

QGB ua \

a=

C-CT

0a

c oc3i20’0Qaa

Positidning projection

03L0000

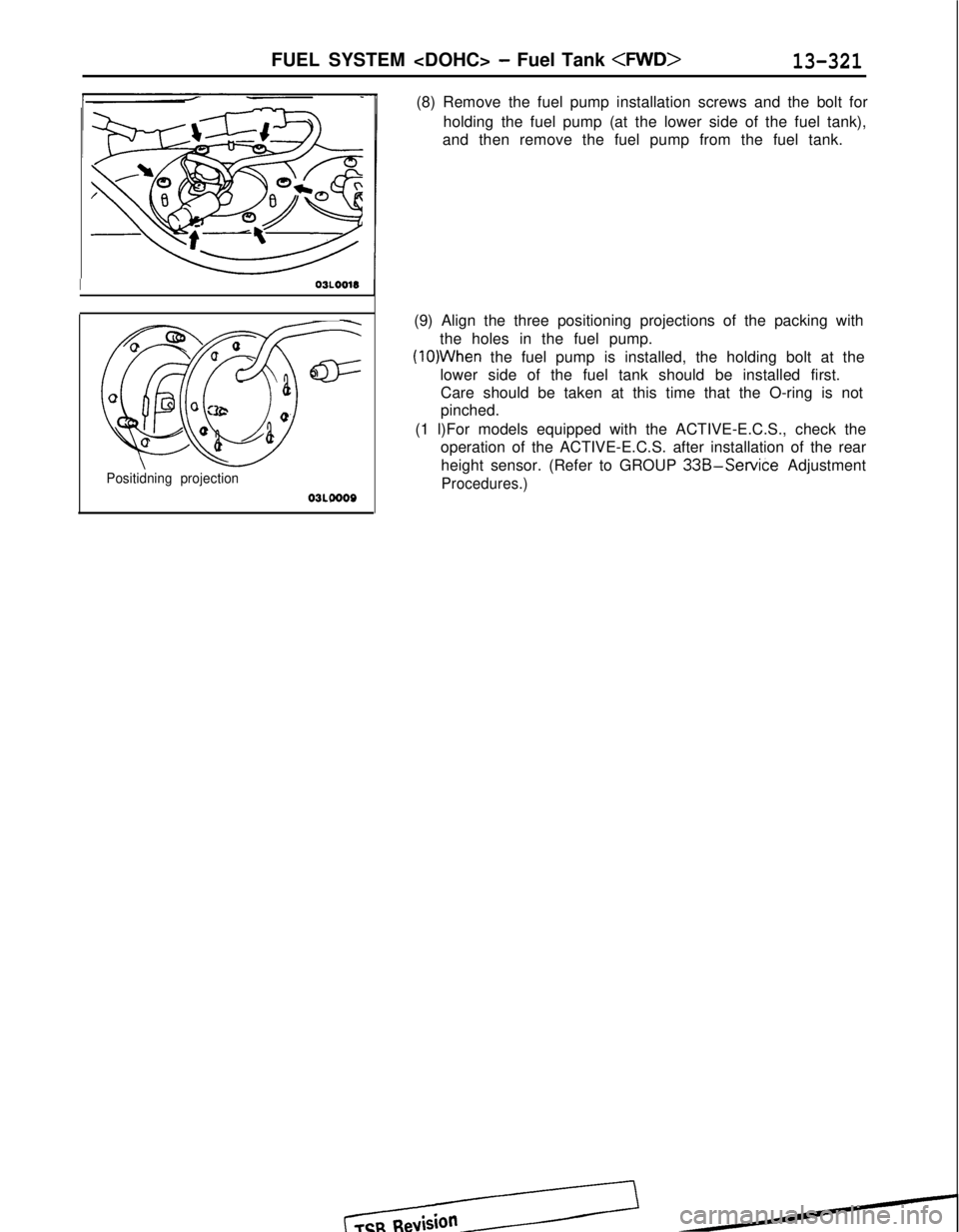

(8) Remove the fuel pump installation screws and the bolt for

holding the fuel pump (at the lower side of the fuel tank),

and then remove the fuel pump from the fuel tank.

(9) Align the three positioning projections of the packing with the holes in the fuel pump.

(lO)When the fuel pump is installed, the holding bolt at the

lower side of the fuel tank should be installed first. Care should be taken at this time that the O-ring is not

pinched.

(1 l)For models equipped with the ACTIVE-E.C.S., check the operation of the ACTIVE-E.C.S. after installation of the rear

height sensor. (Refer to GROUP

33B-Service Adjustment

Procedures.)

Page 566 of 1273

14-14COOLING - Thermostat

04UOO18

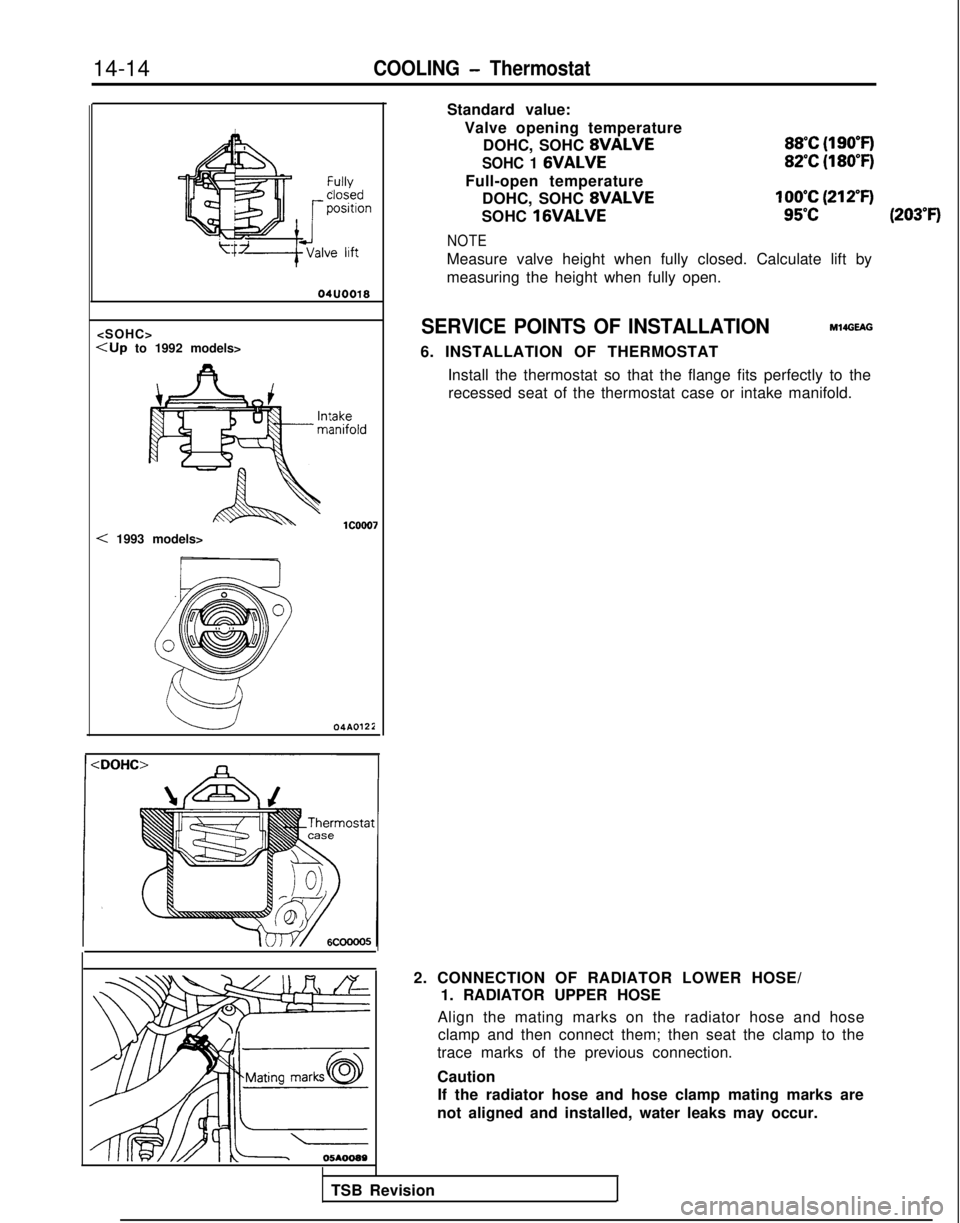

< 1993 models> 04AOlZIStandard value:

Valve opening temperature DOHC, SOHC

8VALVE

SOHC 1 GVALVE

Full-open temperatureDOHC, SOHC

8VALVE

SOHC 16VALVE

NOTE

88°C (19O’F)

82°C (180°F)

100°C (212°F)

95°C (203°F)

Measure valve height when fully closed. Calculate lift by

measuring the height when fully open.

SERVICE POINTS OF INSTALLATIONMWGEAG

6. INSTALLATION OF THERMOSTAT

Install the thermostat so that the flange fits perfectly to therecessed seat of the thermostat case or intake manifold.

2. CONNECTION OF RADIATOR LOWER HOSE/ 1. RADIATOR UPPER HOSE

Align the mating marks on the radiator hose and hose clamp and then connect them; then seat the clamp to the

trace marks of the previous connection.

Caution If the radiator hose and hose clamp mating marks are

not aligned and installed, water leaks may occur.

TSB Revision

Page 652 of 1273

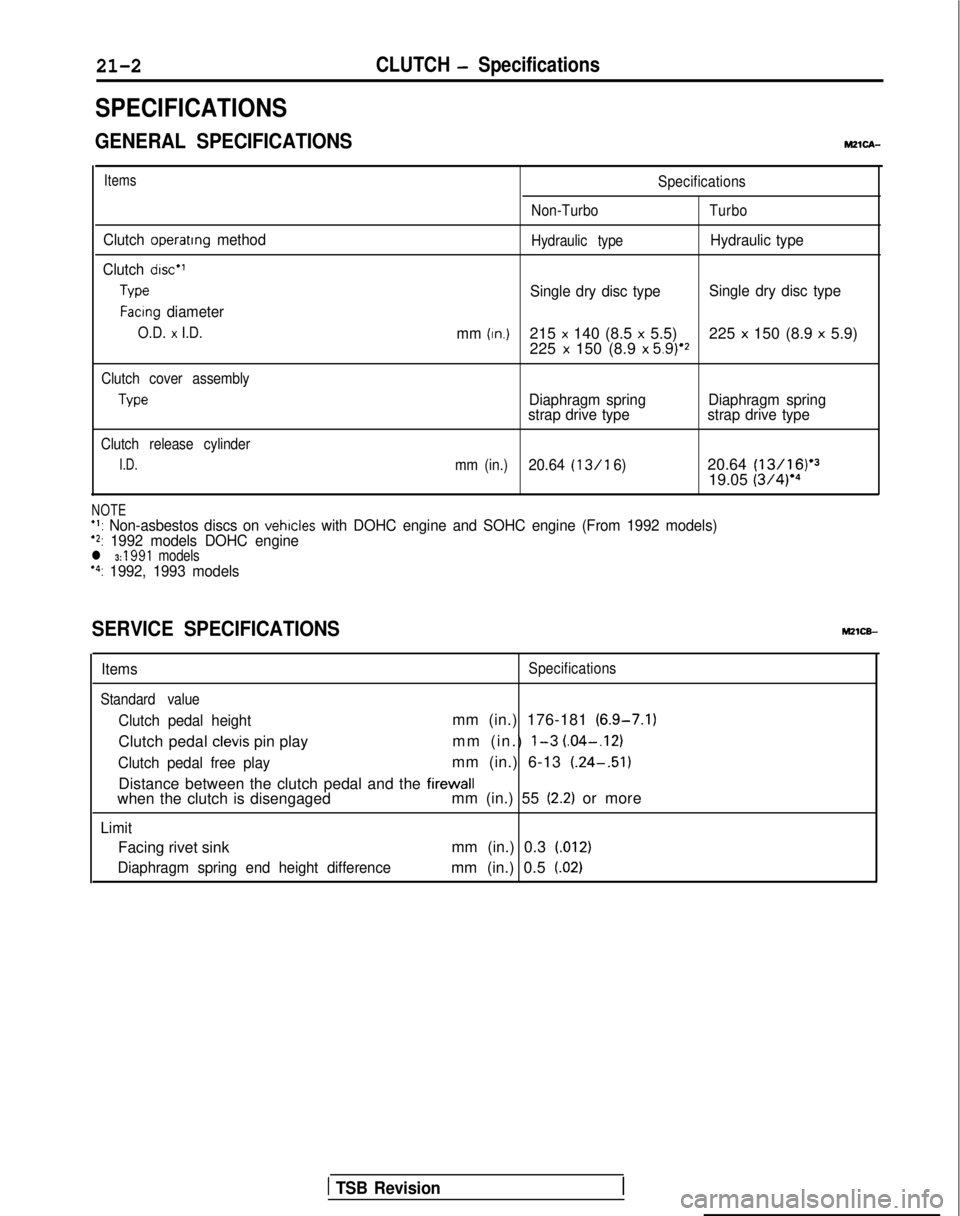

21-2CLUTCH - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSMZlCA-

Items

Clutch operattng method

Clutch disc”

Type

Facing diameter

O.D. x I.D.

Specifications

Non-Turbo Turbo

Hydraulic type

Hydraulic type

Single dry disc type Single dry disc type

mm

(In.)215 x 140 (8.5 x 5.5) 225 x 150 (8.9 x 5.9)

225 x 150 (8.9 x 5.9)‘2

Clutch cover assembly

Type

Clutch release cylinder

I.D.

Diaphragm spring Diaphragm spring

strap drive type strap drive type

mm (in.)20.64 (13/l 6)20.64 (13/16)‘3

19.05 (3/4)‘4

NOTE+l: Non-asbestos discs on vehicles with DOHC engine and SOHC engine (From 1992 models)‘2: 1992 models DOHC enginel 3: 1991 models“: 1992, 1993 models

SERVICE SPECIFICATIONS

ItemsSpecifications

Standard value

Clutch pedal heightmm (in.) 176-181 (6.9-7.1)

Clutch pedal

clevis pin play mm (in.) l-3 (.04-.I21

Clutch pedal free playmm (in.) 6-13

(.24-.51)

Distance between the clutch pedal and the

firewallwhen the clutch is disengaged mm (in.) 55 (2.2) or more

Limit

Facing rivet sinkmm (in.) 0.3 1.012)

Diaphragm spring end height differencemm (in.) 0.5 f.02)

1 TSB Revision

Page 654 of 1273

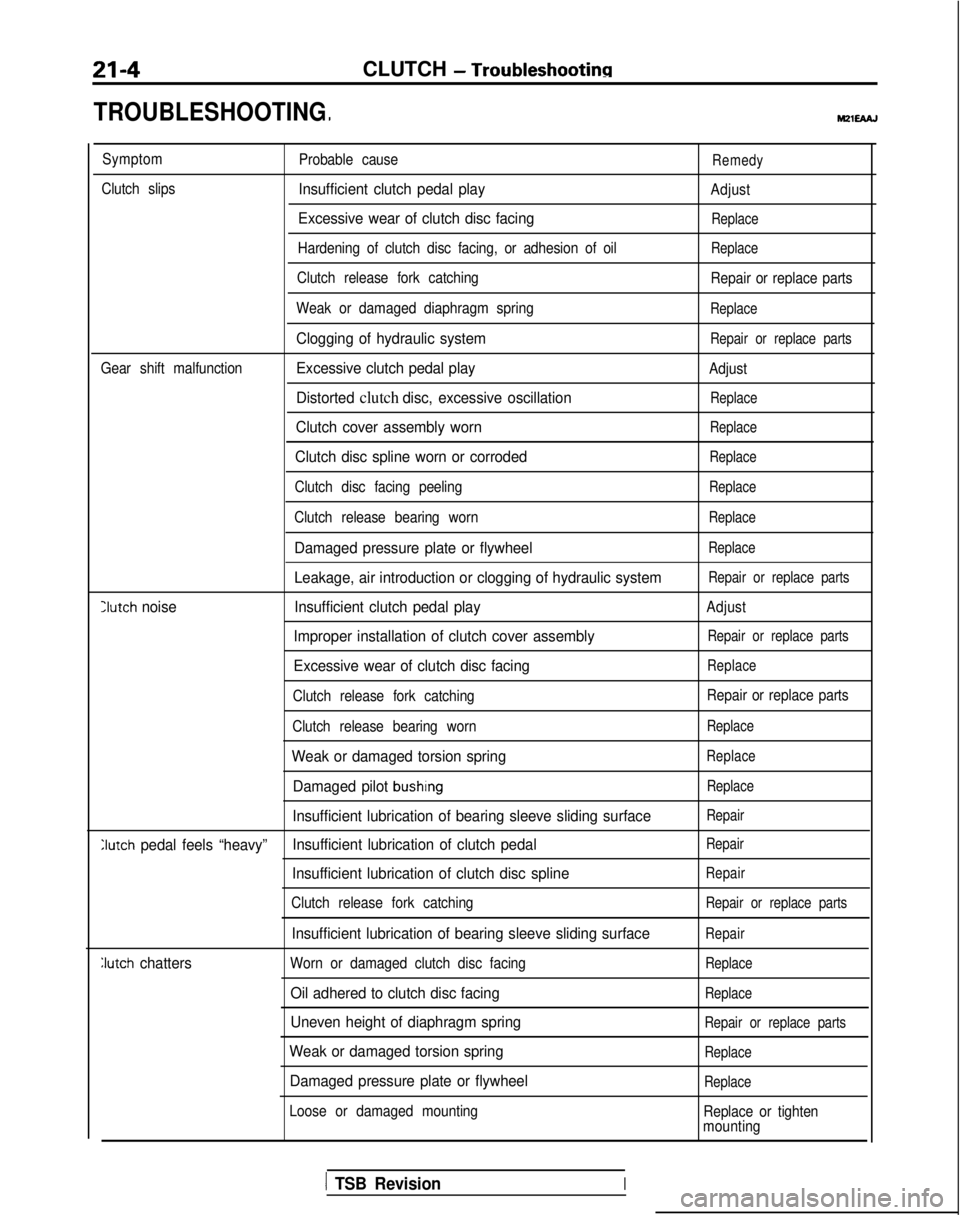

CLUTCH - Troubleshootinn

TROUBLESHOOTING

Symptom

Probable causeRemedy

Clutch slipsInsufficient clutch pedal playAdjust

Excessive wear of clutch disc facingReplace

Hardening of clutch disc facing, or adhesion of oilReplace

Clutch release fork catching Repair or replace parts

Weak or damaged diaphragm spring

Replace

Clogging of hydraulic systemRepair or replace parts

Gear shift malfunctionExcessive clutch pedal playAdjust

Distorted clutch disc, excessive oscillationReplace

Clutch cover assembly wornReplace

Clutch disc spline worn or corrodedReplace

Clutch disc facing peelingReplace

Clutch release bearing wornReplace

Damaged pressure plate or flywheelReplace

Leakage, air introduction or clogging of hydraulic systemRepair or replace parts

Iutch noise Insufficient clutch pedal playAdjust

Improper installation of clutch cover assemblyRepair or replace parts

Excessive wear of clutch disc facingReplace

Clutch release fork catching Repair or replace parts

Clutch release bearing worn

Replace

Weak or damaged torsion springReplace

Damaged pilot bushingReplace

Insufficient lubrication of bearing sleeve sliding surfaceRepair

Clutch pedal feels “heavy” Insufficient lubrication of clutch pedalRepair

Insufficient lubrication of clutch disc splineRepair

Clutch release fork catchingRepair or replace parts

Insufficient lubrication of bearing sleeve sliding surfaceRepair

Iutch

chattersWorn or damaged clutch disc facingReplace

Oil adhered to clutch disc facingReplace

Uneven height of diaphragm springRepair or replace parts

Weak or damaged torsion springReplace

Damaged pressure plate or flywheelReplace

Loose or damaged mounting

Replace or tighten

mounting

1 TSB RevisionI